#Potash-Lime

Text

Construction Glass Industry Is Dominated by the Asia-Pacific Region

The construction glass market was valued at $93.96 billion in 2021, and it is set to reach $161.46 billion by 2030, growing at a growth rate of 6.20% between 2021 and 2030, according to a research report by a market research company P&S Intelligence.

In 2021, the special category had the larger share. This can be credited to the rising application of flat glass in the residential and commercial sectors because of its natural insulation and safety from UV rays.

The most used type of flat glass is float glass, which has now substituted conventional materials in several applications, including mirror glass, home and office doors, and glass partitions between the teller counters at banks.

This glass has numerous applications, from soundproofing to heat insulation and from solar protection to safety applications, which indeed is growing the demand for the same.

On the basis of applications, the commercial category held the larger share of the construction glass market in the past few years and is projected to continue its dominance in the years to come. Designers and architects are increasingly using this glass in skyscrapers because of its improved versatility and adaptability.

In 2021, APAC held a larger revenue share of approximately 40%, and this region is projected to continue its dominance in the coming years in the construction glass industry. The significant industrialization, along with booming construction activities in China and India, and the increasing ecological material demand are the major drivers to the industry growth.

Furthermore, businesses are focusing more on adopting a variety of strategies to gain a lead. For example, Saint-Gobain a France-based manufacturer spent $67.5 million in March 2022, to start a new float glass facility and combined window line at its World Glass Campus in Chennai, India.

Additionally, the existence of numerous manufacturers in the U.S. and many European countries, such as Germany and France, and the growing construction activities are set to contribute to the growth of the construction glass industry in these countries.

Therefore, economic growth in different nations, escalating count of government-led infrastructure projects, and increasing demand for housing because of rapid urbanization will contribute to the increasing demand for construction glass in the years to come, all over the world.

0 notes

Text

surely there's nothing i've forgotten to put in this poll!

181 notes

·

View notes

Text

"These are the Things that Make a Man

Iron enough to make a nail,

Lime enough to paint a wall,

Water enough to drown a dog,

Sulphur enough to stop the fleas,

Potash enough to wash a shirt,

Gold enough to buy a bean,

Silver enough to coat a pin,

Lead enough to ballast a bird,

Phosphor enough to light the town,

Poison enough to kill a cow,

Strength enough to build a home,

Time enough to hold a child,

Love enough to break a heart."

3 notes

·

View notes

Text

The litany I began late last night

This is a mental exercise I began late last night to name physical substances, in an attempt to nail myself to the bed:

Opal, fire opal, chalcedony

quartz, all the quartzes, rose quartz, quartzite

silicon, porphyry, marble, alabaster, nacre

black onyx, green onyx, sardonyx

spinel, beryl, beryllium, manganese, diamond

graphite, ruby, carborundum, emerald, sapphire

topaz, bloodstone, green jasper, red jasper

aventurine, unikite, amethyst, garnet, feldspar

mica, mica schist, granite, andesite, basalt

cadmium, liquid nitrogen, frozen hydrogen slush (on Jupiter)

magnesium metal, peridot, peridotite, olivine, cinnabar

cinnamon, allspice, mace, peppercorn, arsenic

flint, jet, jade, obsidian, chert, the death stones

carnelian, lapis lazuli, potash, iron, sulfur

copper, tin, agate, cats-eyes, coal

anthracite, bitumen, peat, loess, loam, humus

frass, blue ice, green ice, white ice, powdered ice

chitin, lime in megamicro-portions (pounded remains of radiolarian and foraminiferan skeletons and shells of all description)

limestone, sandstone, shale, oilstone, emery

slate, gneiss, nickel, uranium, polonium

lithium, gadolinium, silica sand, alluvial silt, mud

brick, adobe, cement, concrete, cast iron, wrought iron, steel

aluminium, platinum, gold, silver, cobalt

titanium, molybdenum, vanadium, yttrium, erbium

hail, snowflakes, frankincense, sandalwood, jute

hemp, hashish, kif, lead, butane

spiderweb, tornado wreckage. teeth, bone, amber

ash, oil, wax, syrup, dust, gels, grit, crumbs, flakes, splinters

nails, screws, bolts, rivets, wire

frangipani, spikenard, myrrh, ambergris, sea wrack

salt, beach glass, oceanic plastic pellets, pollen, zooplankton

water vapor, various stenches, sun stroke, blisters, paper wasp hives

lint, airborne motes, specks, prions, viruses, cell walls

PVC, MSG, LSD, CFC, NSAIDs

tar, asphalt, macadam, astroturf

gunpowder, nitrogen fertilizer, primacord, shuriken, garrote

dirt, detritus, dung, clay, ocher, methylene blue

mercury, tantalum, niobium, bezoars

bromine, permanganate, dead leaves, dead grass

hay, straw, osier, duck tape, scotch tape

bullwhip, horsehide, dog fur, cat dander, roach eggs

patina, rain, smog, near-vacuum, thermal inversion

sound ticks, sound blasts, sonic booms, thunder, throbs

breath breath breath breath breath breath

2 notes

·

View notes

Text

Common name and formula of important chemical compounds.

Baking Powder Sodium Bicarbonate NaHCO3

Bleaching Powder Calcium Oxychloride CaOCL2

Blue Vitriol Copper Sulphate CuSO4.5H2O

Caustic Potash Potassium Hydroxide KOH

Caustic Soda Sodium Hydroxide NaOH

Chalk (Marble) Calcium Carbonate CaCo3

Chloroform Trichloro Methane CHCl3

Dry Ice Solid Carbondioxide CO2

Epsom Magnesium Sulphate MgSo4

Green Vitriol Ferrous Sulphate FeSo4

Gypsum Calcium Sulphate CaSo4

Heavy Water Deuterium Oxide D2O

Laughing Gas Nitrous Oxide N2O

Magnesia Magnesium Oxide MgO

Marsh Gas Methane CH4

Mohr’s Salt Ammonium Ferrous Sulphate FeSO4(NH4)2SO4.6H2O

Plaster of Paris Calcium Sulphate CaSO42H2O

Potash Alum Potassium Aluminium Sulphate KALSO4

Quick Lime Calcium Oxide CaO

Sand Silicon Oxide SiO2

Compound name

Molecular formula

Molar mass

Density

(g/mol)

Range of concentration

1

Acetaldehyde

C2H4O

59.067

0-30% (18°C)

2

Acetamide

C2H5NO

60.052

0-6% (15°C)

3

Acetic acid

CH3COOH

96.086

0-100% (20°C)

4

Acetone

C3H6O

17.031

0-100% (20°C)

5

Acetonitrile

C2H3N

77.082

0-16% (15°C)

6

Aluminium chloride

AlCl3

62.068

0-40% (15°C)

7

Aluminium nitrate

Al(NO3)3

368.343

-

8

Aluminium sulfate

Al2(SO4)3

68.007

0-26% (15°C)

9

Ammonia

NH3

158.355

0-30% (20°C)

10

Ammonium acetate

CH3COONH4

41.052

0-45% (25°C)

11

Ammonium carbonate

(NH4)2CO3

134.452

-

12

Ammonium chloride

NH4Cl

30.026

0-24% (20°C)

13

Ammonium dichromate

(NH4)2Cr2O7

278.106

0-20% (12°C)

14

Ammonium hydroxide

NH4OH

100.459

0-62% (20°C)

15

Ammonium nitrate

NH4NO3

329.244

0-50% (20°C)

16

Ammonium oxalate

(NH4)2C2O4

207.889

-

17

Ammonium sulfate

(NH4)2SO4

84.007

0-50% (20°C)

18

Antimony(III) chloride

SbCl3

46.025

-

19

Antimony(V) chloride

SbCl5

180.156

-

20

Barium chloride

BaCl2

180.156

0-26% (20°C)

21

Barium hydroxide

Ba(OH)2

94.111

-

22

Barium nitrate

Ba(NO3)2

56.106

-

23

Bismuth(III) chloride

BiCl3

92.094

-

24

Bismuth(III) nitrate

Bi(NO3)3

214.001

-

25

Butan-1-ol

C4H10O

197.998

0-8% (20°C)

26

Butyric acid

C4H8O2

252.065

0-62% (25°C)

27

Cadmium nitrate

Cd(NO3)2

166.003

0-50% (18°C)

28

Cadmium sulfate

CdSO4

172.069

-

29

Calcium chloride

CaCl2

339.787

0-40% (20°C)

30

Calcium hydroxide

Ca(OH)2

97.995

-

31

Calcium nitrate

Ca(NO3)2

101.103

0-68% (18°C)

32

Calcium sulfate

CaSO4

39.997

-

33

Carbon disulfide

CS2

116.072

-

34

Chloroacetic acid

C2H3ClO2

132.14

0-32% (20°C)

35

Chloroauric acid

HAuCl4

76.141

-

36

Chloroform

CHCl3

74.122

-

37

Chloroplatinic acid

H2PtCl6

228.119

-

38

Chromium(III) chloride

CrCl3

144.092

0-14% (18°C)

39

Chromium(III) nitrate

Cr(NO3)3

158.034

-

40

Chromium(III) sulfate

Cr2(SO4)3

68.995

0-40% (15°C)

41

Chromium(VI) oxide

CrO3

102.894

0-60% (15°C)

42

Citric acid

C6H8O7

80.043

0-55% (20°C)

43

Cobalt(II) nitrate

Co(NO3)2

85.104

-

44

Cobalt(II) sulfate

CoSO4

84.995

-

45

Copper(I) chloride

Cu2Cl2

284.047

0-20% (20°C)

46

Copper(II) chloride

CuCl2

151.908

0-20% (20°C)

47

Copper(II) nitrate

Cu(NO3)2

79.1

0-25% (20°C)

48

Copper(II) sulfate

CuSO4

158.526

0-20% (18°C)

49

Dichloroacetic acid

C2H2Cl2O2

299.025

0-30% (20°C)

50

Diethyl ether

(C2H5)2O

342.296

0-5% (20°C)

51

Dimethylglyoxime

(CH3CNOH)2

148.315

-

52

EDTA, disodium salt

Na2C10H14N2O8

120.368

0-6% (20°C)

53

Ethanol

C2H5OH

104.061

0-100% (20°C)

54

Ethylene glycol

(CH2OH)2

125.844

0-60% (20°C)

55

Formaldehyde

CH2O

182.172

0-40% (15°C)

56

Formic acid

CH2O2

171.342

0-100% (20°C)

57

Fructose

C6H12O6

296.653

0-48% (20°C)

58

Glucose

C6H12O6

74.079

0-60% (20°C)

59

Glycerol

C3H8O3

32.042

0-100% (20°C)

60

Hexafluorosilicic acid

H2SiF6

315.339

0-34% (17.5°C)

61

Hydrazine

N2H4

154.756

0-60% (15°C)

62

Hydrobromic acid

HBr

53.491

0-65% (25°C)

63

Hydrochloric acid

HCl

124.096

0-40% (20°C)

64

Hydrocyanic acid

HCN

35.046

0-16% (15°C)

65

Hydrofluoric acid

HF

208.233

0-50% (20°C)

66

Hydrogen peroxide

H2O2

106.441

0-100% (18°C)

67

Hydroiodic acid

HI

119.378

-

68

Iodic acid

HIO3

409.818

-

69

Iron(II) ammonium sulfate

FeSO4+(NH4)2SO4

189.616

-

70

Iron(II) sulfate

FeSO4

163.941

0-20% (18°C)

71

Iron(III) chloride

FeCl3

32.045

0-50% (20°C)

72

Iron(III) nitrate

Fe(NO3)3

174.259

0-25% (18°C)

73

Iron(III) sulfate

Fe2(SO4)3

210.159

0-20% (17.5°C)

74

Isobutanol

C4H10O

122.549

0-8% (20°C)

75

Lactic acid

C3H6O3

394.995

0-80% (20°C)

76

Lactose

C12H22O11

74.551

0-18% (20°C)

77

Lead(II) acetate

Pb(C2H3O2)2

133.341

-

78

Lead(II) chloride

PbCl2

127.912

79

4 notes

·

View notes

Text

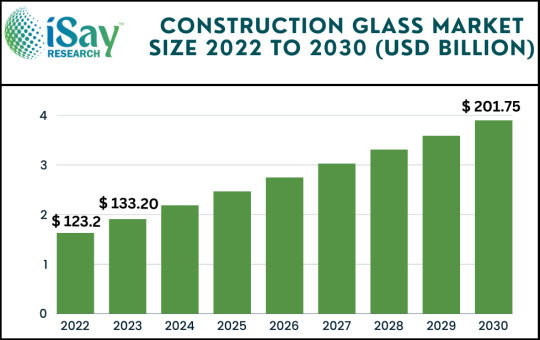

Global Construction Glass Market Know What Statistics Show About Market After This Pandemic Ends – iSay Research

The global Construction Glass market was valued at USD 123.2 Billion in 2022 and is projected to reach USD 201.75 Billion by 2030, registering a CAGR of 7.3% for the forecast period 2023-2030.

The report aims to offer a comprehensive analysis on the global Construction Glass Market. It concentrates on the market dynamics, technological inclinations, and understandings on different end-user industries and product types. Additionally, it examines the key players and the competitive landscape in the global Construction Glass market.

The Global Construction Glass Market analysis report is the outcome of incessant efforts guided by knowledgeable forecasters, innovative analysts and brilliant researchers. With the specific and state-of-the-art information provided in this report, businesses can get idea about the types of consumers, consumer’s demands and preferences, their perspectives about the product, their buying intentions, their response to particular product, and their varying tastes about the specific product which is already present in the market.

Get Free Exclusive Sample of this Premium Report at: https://isayresearch.com/sample/2279

List of the prominent players in the Construction Glass Market:

PPG Industries, Inc.

Schott AG

Central Glass Co., Ltd.

Asahi Glass Co., Ltd.

CSG Holding Co., Ltd.

Sejal Glass Ltd.

China Glass Holdings Limited

RHI AG

Nippon Sheet Glass Co. Ltd.

Guardian Industries Corp.

Compagnie de Saint-Gobain S.A.

Xinyl Gas Holdings Limited.

Sisecam Group

Market segmentation

Construction Glass market is split by Type and by Application. For the period 2024-2032, the growth among segments provide accurate calculations and forecasts for sales by Type and by Application in terms of volume and value. This analysis can help you expand your business by targeting qualified niche markets.

Segmentation Analysis of the Construction Glass Market

By Type

Special glass

Low-e glass

By Chemical Composition

Potash-Lime

Potash-Lead

Soda-Lime

By Manufacturing Process

Rolled/Sheet process

Float process

By Application

Commercial

Residential

Others

Read Full Report Summary @ https://isayresearch.com/report/2279/global-construction-glass-market/

Regional Analysis:

The global Construction Glass market report provides in-depth assessment of the growth and other aspects in important regions, such as United States, Canada, United Kingdom, Germany, France, China, Japan, India, Mexico, Brazil, GCC Countries, and South Africa etc. Key regions covered in the report are North America, Europe, Asia-Pacific, Latin America and Middle East and Africa. The report provides detailed valuation of the development and other aspects of the global Construction Glass market in important countries (regions), including:

North America (U.S., Canada)

Europe (UK, Germany, France, and Rest of Eu)

Asia-Pacific (China, Japan, India, Rest of APAC)

Latin America (Mexico, Brazil, and Rest of LA)

Middle East and Africa (GCC countries, South Africa, and Rest of MEA)

Customize As Per Requirement @ https://isayresearch.com/customization-request/2279

Research objectives:

The report defines and examine the global Construction Glass market based on product type, application, and region.

It forecast and analyze global Construction Glass market size (in terms of value and volume) and submarkets in 5 regions.

The report also forecast as well as analyze global Construction Glass market at country-level for each region.

It strategically profiles major market players and broadly analyze their development strategies.

Read Insights For Your Business

Company Profile

iSay Research is a leading market research company dedicated to providing comprehensive and actionable insights to businesses across various industries. With a focus on delivering accurate data and analysis, we help companies make informed decisions and stay ahead in today's dynamic market landscape.

Contact

iSay Solutions LLC

166 Geary St. 15th Floor Suite #212,

San Francisco, California 94108,

United States

Tel: +14156709191

Email: [email protected]

0 notes

Text

0 notes

Text

medicines obtained from the mineral kingdom

Alum (alum is obtained from alum salts)

Arsenic

black Antimony

butter of Antimony

bromide of potassium

biniodid of mercury

carbolic acid

calomel

chlorate of potash

caustic potash

chloride of zinc

creolin

crude petroleum oil

hyposulfite of soda

iodide of potassium

lime (calcium oxide and calcium hydroxide)

Monsel's solution (an iron sulfate)

nitrate of silver

saltpetre or nitrate of potash

oxide of zinc

sulfuric acid

sulfate of copper

sulfate of iron

sulfate of zinc

sugar of lead (lead acetate)

salt or sodium chloride

Epsom salts (magnesium sulfate) and Glauber's salts (sodium sulfate)

Brimstone (just pure sulfur)

Tartar emetic (antimony potassium tartrate)

vaseline (petroleum jelly)

verdigris (copper acetate salts)

("The Veterinary Science, 1907)

0 notes

Text

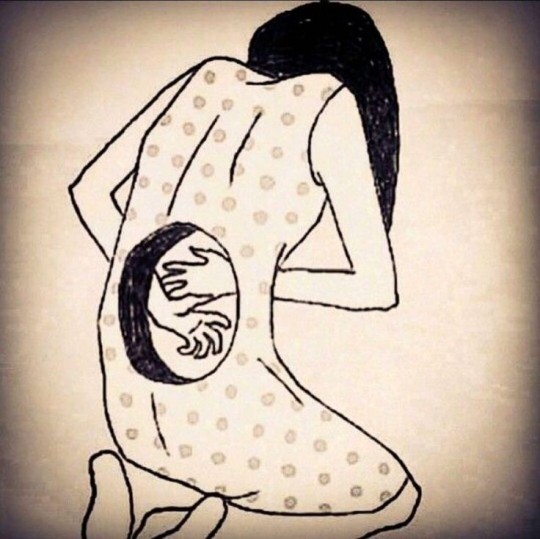

ABORTION

- killing innocent souls through drugs, contraceptive and etc-

Exodus 20:13. Thou shall not kill....

Family Planning also a form of abortion -

▪️Abortion definition

It is also the expulsion of the fetus from the womb during the first 28 wesks of pregnancy.

It can also be defined as killing and explusion of the fetus from the womb because it is not wanted.

As far as God is concerned, using contraceptive method to stop pregnancy is another method of Killing.

▪️TYPES OF ABORTION

1. Spontaneous Abortion

2. Induced Abortion

Spontaneous Abortion also known as Miscarriage

This type of abortion is not induced or caused by any external influence.

Miscarriage are classified into three types

1. Threatened Abortion

2. Inevitable Abortion

3. Missed Abortion

Indued Abortion - This abortion is Influenced externally to ensure expulsion of the fetus.

1. Therapeutic Abortion

2. Criminal Abortion.

Therapeutic Abortion is carried out by qualified medical practitioners as treatment in the interest of the of the mothers life. A medical doctor may recommend an abortion if the pregnant woman is suffering a life threatening condition.

Criminal Abortion - Just as the Name implies: is an illegal abortion. This is a type of abortion that is carried out because of ungodly reasons.

The Word of God says in *Exodus 20:13 - Thou shall not kill*

Criminal Abortion is killing. It is murdering of innocent souls

Rev.21.8 - But the fearful, and unbelieving, and the abominable, and MURDERERS, and whoremongers, and sorcerers, and idolaters, and all liars, shall have their part in the lake which burneth with fire and brimstone: which is the second death.

Criminal Abortion is influenced by the works of the flesh. Galatians 5:19-21. The spirit of the will never support such abortion. In many countries this abortion has been legalized. This cannot change the word of God and His standards against killing and shedding of innocent Blood.

▪️Resons for Criminal Abortion

1. Unwanted Pregnancy. Abortion because the pregnancy is not wanted. This is common among

a Couples who do not want more children or pregnancy that occure at a time they do not want it.

b Teenagers (Teenage Pregnancy)

c Pregnancy outside wedlock - This may be as a result of rape, adultery or fornication.

▪️Ways of expelling foetus through Criminal Abortion

1. D and C - This may be done by unqualified professionals or quacks,

2. Use of locally made Concoction :-

a Lime juice with potash

b Blue mixed with probably alum

3.Drugs :-

a B Codeine

b Menstrogen

c Pitocin either in injection or tablet form

NOTE - Many people have died while using these methods to commit criminal abortion, and are now in Hell.

▪️Prevention of Criminal Abortion

1. The word of God must be properly taught in the church so that every Christian will know, God is against any form of killing

2. Christian couples must be ready to obey God and avoid killing even if the pregnancy is not wanted

3. Teenagers must be taught what the result of premarital sex will be

4. Christian parents of teenagers must ensure their children are properly trained in the way of the Lord.

▪️Eternal Consequence of Abortion

The wages of Sin is Death - Romans 6:23a

Anyone who dies without sincere repentance of his/her sin will end up in hell.

⭐If you have committed abortion and you have not seen it as a sin you need to repent from, you have been informed now that God sees you as a murderer, therefore confess to God, ask for forgiveness and mercy, and cleansing by the Blood of Jesus. If you fail to acknowledge this sin, you are toying with hell fire.

⭐Any man that has encouraged any woman to abort or paid for abortion is equally guilty. You should also repent and ask for forgiveness.

⭐Health workers who are involved in criminal abortion are also guilty. Please repent ask for forgiveness and forsake this practice.

God in His Mercy has not left us in the dark concerning the consequences of killing in His word.

▪️Other methods of Killing as Revealed through Gods Prophet from the Bible.

1 - Contraception

Use of Contraceptive methods to prevent pregnancy is another method of killing. Example - Condoms, pills, intrauterine devices, etc (Roman's 1:30- 32- inventors of evil things - are all worthy of death).

2 - Withdrawal Method.

Men are not permitted to ejaculate outside their women. Gen 38:9-10. God slew Onam because he spilled it outside the ground

Anything that has assurance to possible fail is not God method.

▪️Gods Method of Family Planning.

Christian couples are to talk to God on when they want to have children. If you truly believe God made your bodies and He dictates what happen there, you will have faith in Him that it will be according to your request concerning family planning.

Couples must meet Gods conditions so that God will answer their prayers on spacing their children without Contraception

➖Christians couples must be faithful to God and to themselves.

➖Marital bed must not be defiled (Hebrews 13:5)

➖They must live in Holiness and Righteousness

➖They must have faith in God (Hebrews 11:6)

➖Couple must be in agreement with themselves on their request (Matthew 18:19)

If God says He will do it there should be no fear of unwanted pregnancy. Have faith in Him.

This is an opportunity for those who have not confessed the sin of abortion, use of contraceptive methods or withdrawal methods, to do so now, forsake these sins and which i was once there and God has forgiven me and discourage others from commiting them.

Hell is too Hot. Repent now and be save. God bless us all.

0 notes

Text

Know all the ingredients used in Cement Mixtures

Cement is the end-product of a combination of 8 main ingredients that go through the cement production process. These main ingredients are in general extracted from the materials limestone, clay, chalk, sand, marl, shale, bauxite, and iron ore. It is one of the main ingredients in the concrete mix used for construction. SD Conmix provides ready-mix-concrete of premium quality.

A brief discussion about the contribution of different ingredients in cement is mentioned below:

Lime:

Lime constitutes about 60–65 % of cement which in turn contributes to the strength. It is highly imperative and proper care to be taken with respect to the right proportion to make the cement sound and strong. An additional quantity of lime could result in unsound cement and lead to the expansion and disintegration of the cement. Also, the use of deficient lime results in decreased strength of the cement and it will set quickly.

Silica:

About 17% — 25 % of cement consists of Silica which again is a contributing factor towards the strength of the cement because of the dicalcium and tricalcium silicates formation. If silica is present in excess quantity, although it increases the cement strength but would also result in prolonged setting time of cement.

Alumina

Cement contains about 3.5 % — 9% of Alumina and it is this product that imparts the quality of quick-setting to the cement. However, if there is an excess amount of alumina present in the cement it causes a reduction of strength.

Iron Oxide

About 0.5% — 6.0 % of iron oxide is present in the cement. In addition to strength to the cement iron oxide also provides colour and hardness to the cement.

Magnesium Oxide

It is important to add the correct proportion which is about 0.5 % — 4.0 %. of magnesium oxide that imparts colour and hardness to the cement. Again, the presence of surplus quantity will affect the soundness of cement which refers to the stability of the volume change involved during the process of setting and hardening.

Sulphur Trioxide

A small quantity of about 1 % — 2.0 % of Sulphur Trioxide is present in the cement which also helps to make the cement sound. Excessive sulphur trioxide results in the cement becoming unsound.

Alkalis

Only small quantities of Alkalis such as 0.4% — 1.3 %. of soda or potash should be present in the cement. Excess quantity of Alkalis leads to efflorescence and straining when they are used in concrete or mortar.

Top 10 Requirements to be focussed on to ensure good quality cement:

Cement should possess a uniform colour.

Cement has to be free from lumps.

Cement should have regular level and smooth finish such that it has to gel well and sink in completely when it is mixed with water.

The total ratio in the percentage of alumina with iron oxide is not less than 0.66% of cement. The total percentage of sulphur content in cement should not be greater than 2.75%. The Magnesia content should not exceed 5% in weight.

Insoluble residue in cement should not exceed 1.5% by weight.

The cement should not lose its weight by more than 4% when heated.

The initial setting time of cement should ideally be about 30 minutes.

The final setting time should generally be about 10 hours.

SD Conmix is known for providing the best-quality Ready mix concrete in Bangalore.

0 notes

Text

Know all the ingredients used in Cement Mixtures

Cement is the end-product of a combination of 8 main ingredients that go through the cement production process. These main ingredients are in general extracted from the materials limestone, clay, chalk, sand, marl, shale, bauxite, and iron ore. It is one of the main ingredients in the concrete mix used for construction. SD Conmix provides ready-mix-concrete of premium quality.

A brief discussion about the contribution of different ingredients in cement is mentioned below:

Lime:

Lime constitutes about 60 – 65 % of cement which in turn contributes to the strength. It is highly imperative and proper care to be taken with respect to the right proportion to make the cement sound and strong. An additional quantity of lime could result in unsound cement and lead to the expansion and disintegration of the cement. Also, the use of deficient lime results in decreased strength of the cement and it will set quickly.

Silica:

About 17% – 25 % of cement consists of Silica which again is a contributing factor towards the strength of the cement because of the dicalcium and tricalcium silicates formation. If silica is present in excess quantity, although it increases the cement strength but would also result in prolonged setting time of cement.

Alumina

Cement contains about 3.5 % – 9% of Alumina and it is this product that imparts the quality of quick-setting to the cement. However, if there is an excess amount of alumina present in the cement it causes a reduction of strength.

Iron Oxide

About 0.5% – 6.0 % of iron oxide is present in the cement. In addition to strength to the cement iron oxide also provides colour and hardness to the cement.

Magnesium Oxide

It is important to add the correct proportion which is about 0.5 % – 4.0 %. of magnesium oxide that imparts colour and hardness to the cement. Again, the presence of surplus quantity will affect the soundness of cement which refers to the stability of the volume change involved during the process of setting and hardening.

Sulphur Trioxide

A small quantity of about 1 % – 2.0 % of Sulphur Trioxide is present in the cement which also helps to make the cement sound. Excessive sulphur trioxide results in the cement becoming unsound.

Alkalis

Only small quantities of Alkalis such as 0.4% – 1.3 %. of soda or potash should be present in the cement. Excess quantity of Alkalis leads to efflorescence and straining when they are used in concrete or mortar.

Top 10 Requirements to be focussed on to ensure good quality cement:

Cement should possess a uniform colour.

Cement has to be free from lumps.

Cement should have regular level and smooth finish such that it has to gel well and sink in completely when it is mixed with water.

The total ratio in the percentage of alumina with iron oxide is not less than 0.66% of cement. The total percentage of sulphur content in cement should not be greater than 2.75%. The Magnesia content should not exceed 5% in weight.

Insoluble residue in cement should not exceed 1.5% by weight.

The cement should not lose its weight by more than 4% when heated.

The initial setting time of cement should ideally be about 30 minutes.

The final setting time should generally be about 10 hours.

SD Conmix is known for providing the best-quality Ready mix concrete in Bangalore.

0 notes

Text

Know all the ingredients used in Cement Mixtures

Cement is the end-product of a combination of 8 main ingredients that go through the cement production process. These main ingredients are in general extracted from the materials limestone, clay, chalk, sand, marl, shale, bauxite, and iron ore. It is one of the main ingredients in the concrete mix used for construction. SD Conmix provides ready-mix-concrete of premium quality.

A brief discussion about the contribution of different ingredients in cement is mentioned below:

Lime:

Lime constitutes about 60 – 65 % of cement which in turn contributes to the strength. It is highly imperative and proper care to be taken with respect to the right proportion to make the cement sound and strong. An additional quantity of lime could result in unsound cement and lead to the expansion and disintegration of the cement. Also, the use of deficient lime results in decreased strength of the cement and it will set quickly.

Silica:

About 17% – 25 % of cement consists of Silica which again is a contributing factor towards the strength of the cement because of the dicalcium and tricalcium silicates formation. If silica is present in excess quantity, although it increases the cement strength but would also result in prolonged setting time of cement.

Alumina

Cement contains about 3.5 % – 9% of Alumina and it is this product that imparts the quality of quick-setting to the cement. However, if there is an excess amount of alumina present in the cement it causes a reduction of strength.

Iron Oxide

About 0.5% – 6.0 % of iron oxide is present in the cement. In addition to strength to the cement iron oxide also provides colour and hardness to the cement.

Magnesium Oxide

It is important to add the correct proportion which is about 0.5 % – 4.0 %. of magnesium oxide that imparts colour and hardness to the cement. Again, the presence of surplus quantity will affect the soundness of cement which refers to the stability of the volume change involved during the process of setting and hardening.

Sulphur Trioxide

A small quantity of about 1 % – 2.0 % of Sulphur Trioxide is present in the cement which also helps to make the cement sound. Excessive sulphur trioxide results in the cement becoming unsound.

Alkalis

Only small quantities of Alkalis such as 0.4% – 1.3 %. of soda or potash should be present in the cement. Excess quantity of Alkalis leads to efflorescence and straining when they are used in concrete or mortar.

Top 10 Requirements to be focussed on to ensure good quality cement:

Cement should possess a uniform colour.

Cement has to be free from lumps.

Cement should have regular level and smooth finish such that it has to gel well and sink in completely when it is mixed with water.

The total ratio in the percentage of alumina with iron oxide is not less than 0.66% of cement. The total percentage of sulphur content in cement should not be greater than 2.75%. The Magnesia content should not exceed 5% in weight.

Insoluble residue in cement should not exceed 1.5% by weight.

The cement should not lose its weight by more than 4% when heated.

The initial setting time of cement should ideally be about 30 minutes.

The final setting time should generally be about 10 hours.

SD Conmix is known for providing the best-quality Ready mix concrete in Bangalore.

0 notes

Text

Know all the ingredients used in Cement Mixtures

Cement is the end-product of a combination of 8 main ingredients that go through the cement production process. These main ingredients are in general extracted from the materials limestone, clay, chalk, sand, marl, shale, bauxite, and iron ore. It is one of the main ingredients in the concrete mix used for construction. SD Conmix provides ready-mix-concrete of premium quality.

A brief discussion about the contribution of different ingredients in cement is mentioned below:

Lime:

Lime constitutes about 60 – 65 % of cement which in turn contributes to the strength. It is highly imperative and proper care to be taken with respect to the right proportion to make the cement sound and strong. An additional quantity of lime could result in unsound cement and lead to the expansion and disintegration of the cement. Also, the use of deficient lime results in decreased strength of the cement and it will set quickly.

Silica:

About 17% – 25 % of cement consists of Silica which again is a contributing factor towards the strength of the cement because of the dicalcium and tricalcium silicates formation. If silica is present in excess quantity, although it increases the cement strength but would also result in prolonged setting time of cement.

Alumina

Cement contains about 3.5 % – 9% of Alumina and it is this product that imparts the quality of quick-setting to the cement. However, if there is an excess amount of alumina present in the cement it causes a reduction of strength.

Iron Oxide

About 0.5% – 6.0 % of iron oxide is present in the cement. In addition to strength to the cement iron oxide also provides colour and hardness to the cement.

Magnesium Oxide

It is important to add the correct proportion which is about 0.5 % – 4.0 %. of magnesium oxide that imparts colour and hardness to the cement. Again, the presence of surplus quantity will affect the soundness of cement which refers to the stability of the volume change involved during the process of setting and hardening.

Sulphur Trioxide

A small quantity of about 1 % – 2.0 % of Sulphur Trioxide is present in the cement which also helps to make the cement sound. Excessive sulphur trioxide results in the cement becoming unsound.

Alkalis

Only small quantities of Alkalis such as 0.4% – 1.3 %. of soda or potash should be present in the cement. Excess quantity of Alkalis leads to efflorescence and straining when they are used in concrete or mortar.

Top 10 Requirements to be focussed on to ensure good quality cement:

Cement should possess a uniform colour.

Cement has to be free from lumps.

Cement should have regular level and smooth finish such that it has to gel well and sink in completely when it is mixed with water.

The total ratio in the percentage of alumina with iron oxide is not less than 0.66% of cement. The total percentage of sulphur content in cement should not be greater than 2.75%. The Magnesia content should not exceed 5% in weight.

Insoluble residue in cement should not exceed 1.5% by weight.

The cement should not lose its weight by more than 4% when heated.

The initial setting time of cement should ideally be about 30 minutes.

The final setting time should generally be about 10 hours.

SD Conmix is known for providing the best-quality Ready mix concrete in Bangalore.

0 notes

Text

Know all the ingredients used in Cement Mixtures

Cement is the end-product of a combination of 8 main ingredients that go through the cement production process. These main ingredients are in general extracted from the materials limestone, clay, chalk, sand, marl, shale, bauxite, and iron ore. It is one of the main ingredients in the concrete mix used for construction. SD Conmix provides ready-mix-concrete of premium quality.

A brief discussion about the contribution of different ingredients in cement is mentioned below:

Lime:

Lime constitutes about 60 – 65 % of cement which in turn contributes to the strength. It is highly imperative and proper care to be taken with respect to the right proportion to make the cement sound and strong. An additional quantity of lime could result in unsound cement and lead to the expansion and disintegration of the cement. Also, the use of deficient lime results in decreased strength of the cement and it will set quickly.

Silica:

About 17% – 25 % of cement consists of Silica which again is a contributing factor towards the strength of the cement because of the dicalcium and tricalcium silicates formation. If silica is present in excess quantity, although it increases the cement strength but would also result in prolonged setting time of cement.

Alumina

Cement contains about 3.5 % – 9% of Alumina and it is this product that imparts the quality of quick-setting to the cement. However, if there is an excess amount of alumina present in the cement it causes a reduction of strength.

Iron Oxide

About 0.5% – 6.0 % of iron oxide is present in the cement. In addition to strength to the cement iron oxide also provides colour and hardness to the cement.

Magnesium Oxide

It is important to add the correct proportion which is about 0.5 % – 4.0 %. of magnesium oxide that imparts colour and hardness to the cement. Again, the presence of surplus quantity will affect the soundness of cement which refers to the stability of the volume change involved during the process of setting and hardening.

Sulphur Trioxide

A small quantity of about 1 % – 2.0 % of Sulphur Trioxide is present in the cement which also helps to make the cement sound. Excessive sulphur trioxide results in the cement becoming unsound.

Alkalis

Only small quantities of Alkalis such as 0.4% – 1.3 %. of soda or potash should be present in the cement. Excess quantity of Alkalis leads to efflorescence and straining when they are used in concrete or mortar.

Top 10 Requirements to be focussed on to ensure good quality cement:

Cement should possess a uniform colour.

Cement has to be free from lumps.

Cement should have regular level and smooth finish such that it has to gel well and sink in completely when it is mixed with water.

The total ratio in the percentage of alumina with iron oxide is not less than 0.66% of cement. The total percentage of sulphur content in cement should not be greater than 2.75%. The Magnesia content should not exceed 5% in weight.

Insoluble residue in cement should not exceed 1.5% by weight.

The cement should not lose its weight by more than 4% when heated.

The initial setting time of cement should ideally be about 30 minutes.

The final setting time should generally be about 10 hours.

SD Conmix is known for providing the best-quality Ready mix concrete in Bangalore.

0 notes