#Power Contactor

Explore tagged Tumblr posts

Text

Shreem Power Capacitors, Cylindrical Heavy Duty Capacitor, Mumbai, India

Shree Trading Syndicate is The House Of Capacitors, Supplier, Dealer And Authorised Distributors Of Shreem Power Capacitors, Cylindrical Heavy duty capacitors, Box type capacitors, Mumbai, India.

#Capacitor#Capacitors#Power Capacitor#Power Capacitors#CV Capacitor#CV Capacitors#Epcos Capacitor#Epcos Capacitors#Epcos Round Capacitor#Epcos Square Capacitor#Epcos Oil Filled Capacitor#Epcos Gas Filled Capacitor#Epcos Phasecap Super Heavy Duty Capacitor#Epcos Capacitor Duty Contactors#Epcos Thyristor Duty Switching#Epcos Reactors#Detuned Pfc#Epcos Active Harmonic Filters#Epcos Apfc Panels#Buffer Card#Automatic Power Factor Relay#Epcos Power Factor Correction#Epcos APFC Relay BR4000#Epcos APFC Relay BR5000#Epcos APFC Relay BR6000#Epcos APFC Relay BR7000#Epcos APFC Relay BR5100#New BR4000 ER Relay#Epcos BR4000 ET Relay#Jaivc Power Capacitors

0 notes

Text

Perfect Contactor | Schneider Distributor in Qatar

0 notes

Text

Electric Vehicle Relay Market is Estimated to Witness High Growth Owing to Rising Adoption of Electric Vehicles

The electric vehicle relay market has been gaining significant traction over the past few years owing to the rising adoption of electric vehicles across the globe. Electric vehicle relays play a vital role in the overall functioning of electric vehicles by controlling various electrical systems and loads within the vehicle. Relays help in protecting circuits and offer greater operational efficiency. They find widespread use in charging systems, battery management systems, powertrain systems and other auxiliary functions within electric vehicles. The growing demand for eco-friendly vehicles coupled with stringent emission norms imposed by regulatory bodies around the world has propelled the sales of electric vehicles in recent years. This, in turn, has stimulated the demand for electric vehicle relays significantly. The global electric vehicle relay market is estimated to be valued at USD 12.09 Bn in 2024 and is expected to reach USD 30.45 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 14.1% from 2024 to 2031.

Key Takeaways Key players operating in the electric vehicle relay market are AEC (American Electronic Components, Inc.), Continental AG, Denso Corporation, Eaton Corporation, Fujitsu Limited, Hella GmbH & Co. KGaA, Hyundai Mobis, Infineon Technologies AG, Littelfuse Inc., Mitsubishi Electric Corporation, Panasonic Corporation, Robert Bosch GmbH, Schneider Electric SE, TE Connectivity Ltd., and Valeo SA. Key opportunities in the Electric Vehicle Relay Market Growth include development of new products with advanced features suited for autonomous electric vehicles and focus on expanding presence in emerging nations in Asia Pacific and Latin America. Major electric vehicle manufacturers are focusing on expanding their global footprint by setting up manufacturing plants across different regions. For instance, Tesla is setting up a new electric vehicle gigafactory in Berlin, Germany. Similarly, SAIC Motor Corporation and Volkswagen are also expanding their electric vehicle production capacities globally which will drive the demand for electric vehicle relays. Market drivers The rapid surge in electric vehicle sales across the world has been a major driver for the electric vehicle relay market. Stringent regulations aimed at curbing vehicular emissions and policies promoting electric vehicle adoption by governments worldwide have accelerated the sales of Electric Vehicle Relay Market Size and Trends substantially over the past few years. According to the International Energy Agency (IEA), the global stock of electric passenger vehicles reached 10 million in 2020, growing by 43% from 2019. This rapid rise in electric vehicle deployment is expected to drive the demand for electric vehicle relays significantly over the coming years.

PEST Analysis Political: Government regulations and subsidies are influencing the electric vehicle relay market growth. Many countries are supporting the adoption of electric vehicles to reduce carbon emissions from fuel-powered vehicles through various incentives and regulations. Economic: Lower operating costs of electric vehicles compared to fuel vehicles is driving consumers to opt for electric vehicles. Additionally, fluctuations in oil prices are also impacting the demand for electric vehicles. Social: Increasing awareness about environmental pollution and focus on sustainable transportation are positively impacting the sales of electric vehicles. Consumers are willing to pay more for electric vehicles due to their low carbon footprint. Technological: Advancements in relay technologies, such as improvements in communication protocols and power electronics, are enhancing the performance of electric vehicle relays. Electronic relays are replacing mechanical relays in vehicles to reduce complexity and enable controlled switching of large loads with quick response times. Geographical regions where market in terms of value is concentrated Asia Pacific dominated the electric vehicle relay market share in terms of value in 2024 due to the high production and sales of electric vehicles in China. China is the largest manufacturer as well as consumer of electric vehicles globally, which drives the relay market in the country. The fastest growing region for the electric vehicle relay market Europe is expected to witness the highest growth in the electric vehicle relay market during the forecast period. This is attributed to the stringent emission regulations and rising fuel costs in the region which are compelling automakers as well as customers to shift towards electric vehicles for transportation. The presence of major automobile companies and their focus on developing electric vehicles will further support the market growth in Europe.

Get more insights on Electric Vehicle Relay Market

For Deeper Insights, Find the Report in the Language that You want

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Coherent Market Insights#Electric Vehicle Relay Market#Electric Vehicle Relay#Automotive Relay#High-Voltage Relay#DC Relay#Contactor#Power Electronics#Electric Vehicle Components#Automotive Electrical Systems#Electrical Engineering

0 notes

Text

WOW Electricals - Lemus Enterprises

WOW Electricals is an online B2B Ecommerce Industrial electricals store in Thane, Mumbra. We provide One stop solution to Industrial and commercial sourcing needs of customers in different segments like Turnkey Projects and Electrical Contractors, Panel Manufacturers, Machine Manufacturers, End Users, Maintenance, Installation and testing & commissioning.

WOW Electricals is a leading Supplier & Stockist for 50+ brands. We offer a vast selection of industrial electrical products sourced from the world’s leading brands like ABB, Schneider, Legrand, Siemens, Mitsubishi, Omron, Fluke, SICK, Mitutoyo, BCH, Polycab Wires & Cables, LAPP, Danfoss, SMC, CKD, Eaton Bussmann Fuses, L&T Switchgear and many others.

We are a Procurement Partner which offers a wide portfolio of innovative electrical products to customers and online consumers by delivering optimally integrated solutions to their projects globally with our international shipping courier partner DHL – FedEx.

WOW Electricals India covers a broad range of Automation & Electrical distribution products such as Low Voltage Switchgears, Control Gear & Signalling Device, Switches & Sockets, Capacitors & Reactors, Testing & Measuring Instruments power quality products, wiring accessories, Home automation & lighting.

What do we do for you?

Competitive Pricing:

We offer competitive pricing without compromising on quality, making us a cost-effective choice for your electrical supply needs.

Our Mission:

Our mission is to provide innovative, reliable and sustainable electrical solutions to help our clients succeed in their industrial endeavors. We aim to be a one-stop destination for all your electrical & Mechanical supply needs, offering products that meet the highest industry standards and delivering exceptional value.

Support 24/7

Our team is here to assist you with product selection, technical support, and competitive pricing. Contact us today for all your industrial electrical needs.

At WOW ELECTRICALS, we are dedicated to providing comprehensive industrial electrical solutions tailored to the specific needs of our clients.

We offer a vast selection of industrial electrical products sourced from the world’s leading brands, including ABB, Schneider, Legrand, Siemens, and many others. Our product catalog covers everything from circuit breakers and transformers to motor control centers and automation systems. With a commitment to quality and reliability, we ensure that our clients have access to the best electrical components and equipment available.

#ABB Switchgear Authorized Distributor and Dealer#ABB Wholesale Supplier in Thane#ABB Channel Partner in India#ABB Online Supplier in Mumbai#Navi Mumbai#Best ABB Stockiest in India#ABB Automation and Instrtumentation Supplier#ABB Drive Supplier in India#ABB Motor Supplier#Dealer and Distributor#ABB Contactor and Relay Supplier#ABB 3 pole Power Contactor Dealer#Best Price for ABB Low Voltage products#ABB Priclist 2023 in India#Latest ABB Price list pdf#Algeria#Estonia#Luxembourg#Slovakia#Argentina#Finland#Top ABB Switchgear Dealers in Malaysia#Slovenia#Australia#France#Mexico#South Africa#Austria#ABB Products Online Supplier in Germany#Morocco

0 notes

Text

#industrial#industry trends#automotive industry#control#small business#industrial hvac#power tool equipment#business and industry sectors#electronic#buiness and industry#components#controller#contactors#distributor#switches#sensor#sales

0 notes

Text

Buy Siemens 3RT1016-1BB41

0 notes

Text

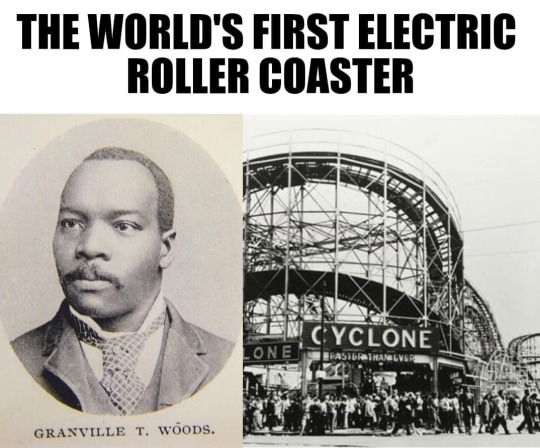

THE WORLD'S FIRST ELECTRIC ROLLER COASTER

Granville T. Woods (April 23, 1856 – January 30, 1910) introduced the “Figure Eight,” the world's first electric roller coaster, in 1892 at Coney Island Amusement Park in New York. Woods patented the invention in 1893, and in 1901, he sold it to General Electric.

Woods was an American inventor who held more than 50 patents in the United States. He was the first African American mechanical and electrical engineer after the Civil War. Self-taught, he concentrated most of his work on trains and streetcars.

In 1884, Woods received his first patent, for a steam boiler furnace, and in 1885, Woods patented an apparatus that was a combination of a telephone and a telegraph. The device, which he called "telegraphony", would allow a telegraph station to send voice and telegraph messages through Morse code over a single wire. He sold the rights to this device to the American Bell Telephone Company.

In 1887, he patented the Synchronous Multiplex Railway Telegraph, which allowed communications between train stations from moving trains by creating a magnetic field around a coiled wire under the train. Woods caught smallpox prior to patenting the technology, and Lucius Phelps patented it in 1884. In 1887, Woods used notes, sketches, and a working model of the invention to secure the patent. The invention was so successful that Woods began the Woods Electric Company in Cincinnati, Ohio, to market and sell his patents. However, the company quickly became devoted to invention creation until it was dissolved in 1893.

Woods often had difficulties in enjoying his success as other inventors made claims to his devices. Thomas Edison later filed a claim to the ownership of this patent, stating that he had first created a similar telegraph and that he was entitled to the patent for the device. Woods was twice successful in defending himself, proving that there were no other devices upon which he could have depended or relied upon to make his device. After Thomas Edison's second defeat, he decided to offer Granville Woods a position with the Edison Company, but Woods declined.

In 1888, Woods manufactured a system of overhead electric conducting lines for railroads modeled after the system pioneered by Charles van Depoele, a famed inventor who had by then installed his electric railway system in thirteen United States cities.

Following the Great Blizzard of 1888, New York City Mayor Hugh J. Grant declared that all wires, many of which powered the above-ground rail system, had to be removed and buried, emphasizing the need for an underground system. Woods's patent built upon previous third rail systems, which were used for light rails, and increased the power for use on underground trains. His system relied on wire brushes to make connections with metallic terminal heads without exposing wires by installing electrical contactor rails. Once the train car had passed over, the wires were no longer live, reducing the risk of injury. It was successfully tested in February 1892 in Coney Island on the Figure Eight Roller Coaster.

In 1896, Woods created a system for controlling electrical lights in theaters, known as the "safety dimmer", which was economical, safe, and efficient, saving 40% of electricity use.

Woods is also sometimes credited with the invention of the air brake for trains in 1904; however, George Westinghouse patented the air brake almost 40 years prior, making Woods's contribution an improvement to the invention.

Woods died of a cerebral hemorrhage at Harlem Hospital in New York City on January 30, 1910, having sold a number of his devices to such companies as Westinghouse, General Electric, and American Engineering. Until 1975, his resting place was an unmarked grave, but historian M.A. Harris helped raise funds, persuading several of the corporations that used Woods's inventions to donate money to purchase a headstone. It was erected at St. Michael's Cemetery in Elmhurst, Queens.

LEGACY

▪Baltimore City Community College established the Granville T. Woods scholarship in memory of the inventor.

▪In 2004, the New York City Transit Authority organized an exhibition on Woods that utilized bus and train depots and an issue of four million MetroCards commemorating the inventor's achievements in pioneering the third rail.

▪In 2006, Woods was inducted into the National Inventors Hall of Fame.

▪In April 2008, the corner of Stillwell and Mermaid Avenues in Coney Island was named Granville T. Woods Way.

525 notes

·

View notes

Text

AU | SORCERER MC

New au idea, imagine this as your new MC backstory: you're a young sorceress who's roughly 19. You're doing well in school, and you're lucky enough to be called the next prodigy of your generation.

As a side job, you've agreed to become a “Ghost hunter” for your school. Your school is basically a military base to train sorcerers, it was established after an outbreak of ‘paranormal’ activity.

Your side job is to mainly exorcise evil ghost spirits, and lesser demons. (B rank, A rank, and the occasional stronger A+ Rank) A part of your job even includes taking newer students on “missions” with you, so that they get used to combat and exorcism.

On one of your “jobs”, you're near an area where a B ranked demon was seen. Suddenly your phone pings with a “RED ALERT”, a red alert is a phone announcement sent to all sorcerers in the country. It means an S Rank (Stronger) Spirit has been discovered, and the announcement states its current location.

Realizing you were near the location, you figured, “why not take it on?” You were an L grade yourself, and could some vengeful ghost really do besides leave a few bruises on you? Nope!

“Why not take it on?” Famous last words.

Shit hit the fan, and you quickly realized that it's not an evil ghost, it's an L grade demon.

Dealing with the demon was damn near impossible, especially with your rookie junior who doesn't know what to do. Dodging and sending attacks proved to be impossible once more. No matter how much you tried, nothing seemed to work. You had to pull the last trick in the book if you wanted to remain unscathed, and luckily it worked. The junior wasn't hurt, and you got away with just a scratch.

Reporting the incident, You inform all the higher up sorcerers of the demon sighting and his grade. The higher sorcerers of your school manage to identify the hybrid demon as ‘Icarus’. Unlike the Greek myth, Icacrus is a demon who destroyed multiple realms and tortured their people for personal gain and satisfaction.

Multiple attempts to take him down were made, and all of them failed.

After the only high sorcerer in your country is slayed by him, it is left to you as an L rank to step up and attempt to defeat him.

Ever as prideful, you did. You even propose to become his contractor in the process. He was arrogant as ever, so Icarus was amused as he agreed.

The deal was simple:

Defeat him= be his contractor

Lose to him= lose your soul and die.

Long story short, it was gruesome, with Icarus taking the lead and having the upper hand.

Just when it looked like everything was going to end in tragedy, you had to pull a risky move which sorcerers haven't done in millenia. You generated all of your mana, and every ounce of power your contracts, dealing enough to beat icarus in one trick move. Unfortunately, that trick wrecked both your mana and whole core in the end.

How you survived is a miracle, pure luck. Unfortunately, since you have no mana and the details of your contract weren't really worked out, you're currently just a contractor. A contactor with no power who can't risk summoning him.

It takes six years on average for an L grade sorcerer to restore his or her mana. Nobody except you knows the details of your contract, the horrific smell of your flesh burning as you broke your own core by overusing your mana.

How your skin stretched and tore itself as you gave it your all to destroy the demon, only to realize that in the end it was your stupid pride that almost killed you. In a way, Icarus still lives in your body. You can hear his voice often appearing on days during which you feel weak. You never summon him, without your mana recovered you're worried he might overtake your body. The “rules” to your contract were unclear so you don't dare.

[PRESENT TIME, AKA GABRIEL TIME]

It's been five years. Your mana is still slow, and in the process of recovering. This is when Gabriel makes an attempt on taking your life. He slayed Minhyeok in front of you, making you watch in horror as his body fell limply.

It's at this moment that your codependence really strikes, making you feel like you're going to throw up. Denial was the first thing that came to you- Because he can't be dead.

Trying to nudge him awake seemed futile, but you still couldn't shake off the thought that this was maybe all a sick prank.

Whatever else happened during this day was a blur.

If it wasn't for Satan, Minhyeok would have been dead, and you probably would've died too. Still, That doesn't mean his way of making you come to hell and break all contracts wasn't an iffy deal. It rubbed you the wrong way, and for a while there was a bit of tension between you both… tension which keeps popping up every time you try to kill Sitri when he calls you Solomon. It feels like living in your ancestor's shadow, everything around feels fake. So, you stick to one simple task: “Break the contracts and go home” counting every single broken contract across hell.

You're not Solomon, and you're not really a sorceress with your broken mana.. There's nothing to flex here, and you'd love nothing more than to go back home to Minhyeok.

If only these fucking angels didn't make it so difficult for you.

Tagging : @nesli26 AU MC just dropped!

Q: Who tf is Icarus?

A: Literally just an antagonist i made up for this, I don't have much on him like I do on Sava... but if you have any questions feel free to send an ask (´ε` )

46 notes

·

View notes

Text

THE WORLD'S FIRST ELECTRIC ROLLER COASTER

Granville T. Woods (April 23, 1856 – January 30, 1910) introduced the “Figure Eight,” the world's first electric roller coaster, in 1892 at Coney Island Amusement Park in New York. Woods patented the invention in 1893, and in 1901, he sold it to General Electric.

Woods was an American inventor who held more than 50 patents in the United States. He was the first African American mechanical and electrical engineer after the Civil War. Self-taught, he concentrated most of his work on trains and streetcars.

In 1884, Woods received his first patent, for a steam boiler furnace, and in 1885, Woods patented an apparatus that was a combination of a telephone and a telegraph. The device, which he called "telegraphony", would allow a telegraph station to send voice and telegraph messages through Morse code over a single wire. He sold the rights to this device to the American Bell Telephone Company.

In 1887, he patented the Synchronous Multiplex Railway Telegraph, which allowed communications between train stations from moving trains by creating a magnetic field around a coiled wire under the train. Woods caught smallpox prior to patenting the technology, and Lucius Phelps patented it in 1884. In 1887, Woods used notes, sketches, and a working model of the invention to secure the patent. The invention was so successful that Woods began the Woods Electric Company in Cincinnati, Ohio, to market and sell his patents. However, the company quickly became devoted to invention creation until it was dissolved in 1893.

Woods often had difficulties in enjoying his success as other inventors made claims to his devices. Thomas Edison later filed a claim to the ownership of this patent, stating that he had first created a similar telegraph and that he was entitled to the patent for the device. Woods was twice successful in defending himself, proving that there were no other devices upon which he could have depended or relied upon to make his device. After Thomas Edison's second defeat, he decided to offer Granville Woods a position with the Edison Company, but Woods declined.

In 1888, Woods manufactured a system of overhead electric conducting lines for railroads modeled after the system pioneered by Charles van Depoele, a famed inventor who had by then installed his electric railway system in thirteen United States cities.

Following the Great Blizzard of 1888, New York City Mayor Hugh J. Grant declared that all wires, many of which powered the above-ground rail system, had to be removed and buried, emphasizing the need for an underground system. Woods's patent built upon previous third rail systems, which were used for light rails, and increased the power for use on underground trains. His system relied on wire brushes to make connections with metallic terminal heads without exposing wires by installing electrical contactor rails. Once the train car had passed over, the wires were no longer live, reducing the risk of injury. It was successfully tested in February 1892 in Coney Island on the Figure Eight Roller Coaster.

In 1896, Woods created a system for controlling electrical lights in theaters, known as the "safety dimmer", which was economical, safe, and efficient, saving 40% of electricity use.

Woods is also sometimes credited with the invention of the air brake for trains in 1904; however, George Westinghouse patented the air brake almost 40 years prior, making Woods's contribution an improvement to the invention.

Woods died of a cerebral hemorrhage at Harlem Hospital in New York City on January 30, 1910, having sold a number of his devices to such companies as Westinghouse, General Electric, and American Engineering. Until 1975, his resting place was an unmarked grave, but historian M.A. Harris helped raise funds, persuading several of the corporations that used Woods's inventions to donate money to purchase a headstone. It was erected at St. Michael's Cemetery in Elmhurst, Queens.

LEGACY

▪Baltimore City Community College established the Granville T. Woods scholarship in memory of the inventor.

▪In 2004, the New York City Transit Authority organized an exhibition on Woods that utilized bus and train depots and an issue of four million MetroCards commemorating the inventor's achievements in pioneering the third rail.

▪In 2006, Woods was inducted into the National Inventors Hall of Fame.

▪In April 2008, the corner of Stillwell and Mermaid Avenues in Coney Island was named Granville T. Woods Way.

#granville t woods#black inventor#invented#world's first#electric roller coaster#1893#read about him#read about his invention#reading is fundamental#knowledge is power#black history

125 notes

·

View notes

Text

The Difference Between Low, Medium, and High Voltage Switchgear

Switchgear plays a critical role in the generation, transmission, and distribution of electrical power. It ensures safe and efficient operation by controlling, protecting, and isolating electrical circuits and equipment. But not all switchgear is created equal — low, medium, and high voltage switchgear are designed for different voltage levels and applications.

Understanding the differences between these types is crucial for electrical engineers, electricians, project managers, and anyone involved in power systems. In this article, we break down what sets them apart in terms of voltage range, components, applications, design, and safety considerations.

What is Switchgear?

Before diving into the differences, let’s clarify what switchgear is.

Switchgear refers to the combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential for de-energizing equipment for maintenance and for clearing faults in the power system.

Classification by Voltage Level

Low Voltage Switchgear (LV)

Voltage Range:

Up to 1,000V AC (typically 400V/690V in 3-phase systems)

Key Components:

Miniature Circuit Breakers (MCBs)

Molded Case Circuit Breakers (MCCBs)

Residual Current Devices (RCDs)

Contactors and relays

Busbars, metering, control panels

Applications:

Residential and commercial buildings

Data centers and office spaces

Light industrial automation

Control panels and motor control centers (MCCs)

Characteristics:

Compact and easy to install

High frequency of operation

Relatively simple maintenance

Often enclosed in modular panels

Standards:

IEC 61439

NEC (National Electrical Code)

Medium Voltage Switchgear (MV)

Voltage Range:

1kV to 36kV (sometimes up to 72.5kV)

Key Components:

Vacuum circuit breakers (VCBs)

SF₆ (sulfur hexafluoride) insulated switchgear

Current and voltage transformers (CTs, VTs)

Protective relays

Grounding switches

Applications:

Electrical substations

Large factories and industrial plants

Railways and airports

Renewable energy farms (wind/solar)

Characteristics:

Higher insulation and safety requirements

More robust protection systems

Often installed indoors or in compact outdoor enclosures

May use gas-insulated or air-insulated designs

Standards:

IEC 62271–200

IEEE C37 series

High Voltage Switchgear (HV)

Voltage Range:

Above 36kV (commonly 66kV, 132kV, 220kV, up to 765kV)

Key Components:

SF₆ circuit breakers

Air blast or oil circuit breakers (older systems)

Gas-insulated switchgear (GIS)

Disconnectors and earthing switches

High-end protection relays and SCADA integration

Applications:

National and regional power transmission networks

Power generation plants

Interconnecting large substations

Critical infrastructure (e.g., large data centers, airports)

Characteristics:

Complex installation and high-cost infrastructure

Requires rigorous safety procedures and specialized training

Often installed outdoors or in GIS (Gas Insulated Switchgear) format

Includes extensive monitoring and automation

Standards:

IEC 62271–100 (HV circuit breakers)

IEEE C37.06

ANSI C37 series

Safety Considerations

Always follow local electrical codes, use personal protective equipment (PPE), and conduct routine maintenance regardless of switchgear type.

Conclusion

Choosing the right switchgear type is critical for ensuring safe and efficient power distribution. Whether you’re designing a residential panel or a high-voltage substation, knowing the difference between low, medium, and high voltage switchgear helps you make informed decisions about equipment, safety, and performance.

Mastering this knowledge isn’t just good practice — it’s essential for anyone serious about a career in the electrical field.

10 notes

·

View notes

Text

Jaivic Power Capacitor, Jaivic AC Capacitors, HT App Shunt Capacitor, Mumbai, India

Shree Trading Syndicate is The House Of Capacitors, Supplier, Dealer And Authorised Distributors Of Jaivic Power Capacitor, Jaivic AC Capacitors, HT App Shunt Capacitor, Mumbai, India.

#Capacitor#Capacitors#Power Capacitor#Power Capacitors#CV Capacitor#CV Capacitors#Epcos Capacitor#Epcos Capacitors#Epcos Round Capacitor#Epcos Square Capacitor#Epcos Oil Filled Capacitor#Epcos Gas Filled Capacitor#Epcos Phasecap Super Heavy Duty Capacitor#Epcos Capacitor Duty Contactors#Epcos Thyristor Duty Switching#Epcos Reactors#Detuned Pfc#Epcos Active Harmonic Filters#Epcos Apfc Panels#Buffer Card#Automatic Power Factor Relay#Epcos Power Factor Correction#Epcos APFC Relay BR4000#Epcos APFC Relay BR5000#Epcos APFC Relay BR6000#Epcos APFC Relay BR7000#Epcos APFC Relay BR5100#New BR4000 ER Relay#Epcos BR4000 ET Relay#Jaivc Power Capacitors

0 notes

Text

How to Solve Overheating Issues in Electrical Panels

Electrical panels are the nerve centers of industrial, commercial, and residential power systems. Their reliability is crucial, yet one of the most common and dangerous issues that can arise is overheating. Left unaddressed, overheating in electrical panels can lead to equipment failure, costly downtime, fires, or even fatal accidents. Understanding the root causes and adopting preventive as well as corrective measures is essential to ensure electrical safety and operational efficiency.

Causes of Overheating in Electrical Panels

To solve the problem of overheating, we must first identify its sources. Some of the most common causes include:

1. Loose or Corroded Connections

Electrical current encounters resistance at loose or oxidized joints. This resistance generates heat, especially under load, leading to localized hotspots which may not be visible until failure occurs.

2. Overloaded Circuits

Each circuit is rated for a specific current. Drawing more current than the rated capacity results in excess heat generation within breakers, busbars, and wires.

3. Inadequate Ventilation

Poor airflow in and around the panel restricts natural or forced heat dissipation. In high ambient temperature environments, this can quickly push the panel beyond safe thermal limits.

4. Improper Component Sizing

Undersized breakers, conductors, or transformers struggle to handle load currents, leading to thermal stress and degradation over time.

5. Dust and Contamination

Dust accumulation acts as an insulating layer, trapping heat inside components. Combined with humidity or oil vapors, this can further degrade insulation and create tracking paths.

How to Identify Overheating Problems

1. Thermal Imaging

Using infrared thermography is one of the most effective ways to detect hotspots. It provides a non-contact, real-time temperature map of the panel and highlights abnormally heated components.

2. Manual Temperature Monitoring

For panels without thermal sensors, regularly measuring surface temperatures using contact thermometers can provide early warnings of rising heat levels.

3. Visual Inspection

Signs like discoloration, melted insulation, or the smell of burning plastic indicate overheating. Ensure regular visual checks are part of your maintenance routine.

Solutions to Overheating in Electrical Panels

1. Tighten and Maintain Electrical Connections

Schedule regular maintenance to tighten terminals and busbar connections. Apply proper torque settings using calibrated tools to avoid over- or under-tightening.

2. Balance and Distribute Loads

Ensure that the load across phases is balanced. Uneven distribution causes one phase to overwork, which leads to overheating and inefficiency.

3. Upgrade Panel Capacity

If the electrical demand exceeds the panel’s rated capacity, consider upgrading to a higher-rated panel or adding sub-panels to spread the load.

4. Enhance Cooling and Ventilation

· Install forced ventilation systems like exhaust fans or panel coolers.

· Use heat exchangers or air conditioners in environments with high ambient temperatures.

· Ensure adequate spacing between panels and walls for natural convection.

5. Use Appropriately Rated Components

All breakers, fuses, contactors, and wiring must match the system’s voltage and current ratings. Derate components appropriately if operating in high-temperature environments.

6. Install Thermal Sensors or Smart Monitoring

Modern panels can be equipped with thermal sensors that provide real-time data to a building management system (BMS) or SCADA. This allows predictive maintenance before issues escalate.

Preventive Measures and Best Practices

· Design with Expansion in Mind: Avoid loading a panel to its full capacity. Always leave a 20–30% margin for future growth and safety.

· Implement a Routine Maintenance Schedule: Quarterly or bi-annual inspections reduce the risk of unexpected failures.

· Train Maintenance Personnel: Staff should be equipped to detect early signs of thermal distress and follow lockout/tagout (LOTO) procedures.

· Keep Panels Clean and Sealed: Use gasketed enclosures in dusty environments and clean panels regularly to prevent dust build-up.

Conclusion

Overheating in electrical panels is a preventable issue that, if neglected, can have severe consequences. By adopting systematic inspection routines, upgrading infrastructure as needed, and leveraging modern monitoring technologies, businesses and facility managers can safeguard both equipment and personnel. The key is proactive action: identify, analyze, correct, and prevent — the four pillars of managing thermal risk in electrical systems.

7 notes

·

View notes

Text

From Design to Deployment: How Switchgear Systems Are Built

In the modern world of electrical engineering, switchgear systems play a critical role in ensuring the safe distribution and control of electrical power. From substations and factories to commercial buildings and critical infrastructure, switchgear is the silent guardian that protects equipment, ensures safety, and minimizes power failures.

But have you ever wondered what goes on behind the scenes, from the idea to the actual installation? Let’s dive into the full journey — from design to deployment — of how a switchgear system is built.

Step 1: Requirement Analysis and Load Study

Every switchgear project begins with requirement analysis. This includes:

Understanding the electrical load requirements

Calculating voltage levels, short-circuit ratings, and operating current

Identifying environmental conditions: indoor, outdoor, temperature, humidity

Reviewing applicable industry standards like IEC, ANSI, or DEWA regulations (especially in UAE)

This stage helps engineers determine whether the project needs low voltage (LV), medium voltage (MV), or high voltage (HV) switchgear.

Step 2: Conceptual Design & Engineering

Once the requirements are clear, the conceptual design begins.

Selection of switchgear type (air insulated, gas insulated, metal-enclosed, metal-clad, etc.)

Deciding on protection devices: MCCBs, ACBs, relays, CTs, VTs, and fuses

Creating single-line diagrams (SLDs) and layout drawings

Choosing the busbar material (copper or aluminum), insulation type, and earthing arrangements

Software like AutoCAD, EPLAN, and ETAP are commonly used for precise engineering drawings and simulations.

Step 3: Manufacturing & Fabrication

This is where the physical structure comes to life.

Sheet metal is cut, punched, and bent to form the panel enclosures

Powder coating or galvanizing is done for corrosion protection

Assembly of circuit breakers, contactors, protection relays, meters, etc.

Internal wiring is installed according to the schematic

Every switchgear panel is built with precision and must undergo quality control checks at each stage.

Step 4: Factory Testing (FAT)

Before deployment, every switchgear unit undergoes Factory Acceptance Testing (FAT) to ensure it meets technical and safety standards.

Typical FAT includes:

High-voltage insulation testing

Continuity and phase sequence testing

Functionality check of all protection relays and interlocks

Mechanical operations of breakers and switches

Thermal imaging to detect hotspots

Only after passing FAT, the switchgear is cleared for shipping.

Step 5: Transportation & Site Installation

Transportation must be handled with care to avoid damage to components. At the site:

Panels are unloaded and moved to their final location

Cabling and bus duct connections are established

Earthing systems are connected

Environmental sealing is done if installed outdoors or in dusty environments

Step 6: Commissioning & Site Acceptance Testing (SAT)

This final stage ensures the switchgear is ready for live operation.

Final checks and Site Acceptance Tests (SAT) are performed

System integration is tested with other components like transformers, UPS, and generators

Load tests and trial runs are conducted

Commissioning report is generated, and documentation is handed over to the client

Conclusion

From idea to execution, the journey of building a switchgear system is highly technical, safety-driven, and precision-based. Whether you’re in power generation, industrial automation, or commercial construction, understanding this process ensures you choose the right system for your needs.

7 notes

·

View notes

Text

Does Sustainability Go Hand in Hand with Technology and the Global Shift to Electric Power?

Explore how Sustainability Next to Technology is Connected to Global Move Towards Electric Power.

The new generation of moving the world towards cleaner energy has electric power at the core of this transformation.

But do they, sustainability and technology, indeed go hand in hand?

Well, it’s no longer a hypothetical question, but a problem that determines the future path of power distribution and energy management.

Growing Demand for Sustainable Solutions:

Not long ago, the dream of electric power turned into a reality before you know it.

Cleaner has become a key aspiration of governments, industries, and consumers alike.

Sustainability imparts a different meaning to reducing carbon footprints.

This also means making power systems smarter and less dangerous, more efficient, cost-effective, and probably even creating a bit of redundancy.

This will mean purchasing components for the switchgear industry that reduce energy waste, extend life cycles, and facilitate the interfacing of renewable sources.

Energy-efficient circuit breakers, digital monitoring systems, modular switchgear components, and other accessories are becoming key players in the evolution.

Smart Technology: The Backbone of Sustainable Switchgear

The way the whole change in switchgear technology moves is, of course, toward modernization.

IoT-type embedded devices for monitoring, AI-driven prediction of maintenance needs, and design for energy-efficient low-voltage contactors all transform the way the whole power is managed.

It ensures reduced energy losses and very much optimized peak condition behavior, as well as improved safety-all these fulfilling both sustainability and day-to-day operating efficiency objectives.

1. Digital Monitoring and Automation

It is all about real-time data.

Smart monitoring solutions provide instant access to information regarding the efficiency of the use of electricity, fault detection, and energy efficiency.

With this, downtime and failures incurred can be minimized, and energy consumption can be optimized-thus, saving unnecessary wastages of electricity.

2. Modular and Recyclable Components

Energy efficiency doesn’t only mean sustainability as far as power is concerned-it also has to do with waste.

Adaptive switchgear designs allow easy upgrades and replacements, which can prolong the life cycle of an electrical system while simultaneously reducing the amount of waste made for materials.

Adoption of recyclable and non-toxic materials in accessories for switchgear also minimizes environmental impact.

3. Energy-Efficient Contactors and Circuit Breakers

New advanced low-loss contactor and circuit breaker technologies, which increase energy efficiency, cut down heat dissipation and losses in the circuits.

Fewer losses in energy mean low operating costs and a reduced carbon footprint; these are the two main factors that are becoming crucial for today’s modern companies striving to meet sustainability goals.

Switchgear Accessories to Play a Critical Role in the Green Revolution

It is only through highly competent switchgear accessories that a truly sustainable power infrastructure may be realized: from low-voltage surge protectors that ensure a longer life for the system to biodegradable insulation materials, the right kind of components would all play their part in making a difference.

Eco friendly insulation: Using sustainable materials in insulation applications reduces the negative impacts on the environment while maintaining the safety and efficiency associated with conventional insulation types.

Adaptive Protection Relays: These help to ensure the stability of power and eliminate the breakdowns, thus eliminating the costs of frequent replacement and repairs.

Using Busbar Systems to Reduce Energy Losses: The more efficient a conductor is, the less its resistance and heat loss, and the better it transmits energy.

Balancing Innovation and Cost with Performance

In fact, the passage from several manufacturers and traders is the perception that sustainability involves more costs.

But in reality, such first costs are outweighed by very many long-term benefits.

The merger of lower maintenance costs, lower periodicity recall for new replacement pieces, and greater shelf life compliance does make sustainable switchgear a smart business choice.

Conclusion: The Future of Sustainable Energy

Technology and sustainability aren’t separate paths any longer; they’re bearing down more on a linear convergence as the world flows into a different shape concerning energy.

Change is a space that we all own.

The future is here-now!

6 notes

·

View notes

Text

Trane CTR2670 Three-Pole Contactor 600VAC Coil Voltage 50A | PartsHnC

Manufacturer Name: Trane Product Number: CTR2670 OEM Part Number: CTR2670 Product Description: 50A 600V 3P Contactor Weight:2.21lbs/1002.44g

The Trane CTR2670 is an electrical contactor that is built to control the high power loads in HVAC systems. Due to this, it is a three-pole contactor, electrical circuits that involve three phases can be managed by it. Because it has a 50 amp current.

For an efficient and reliable HVAC system, the Trane electrical contactor is the choice for optimal system performance.

2 notes

·

View notes

Note

Darker Than Black au for K?

Imagine AU where the clans are instead groups of Contractors who all have different goals, like S4 believes Contractors gained their abilities in order to keep the peace for normal humans, Homra believes their powers should be used to live freely and protect those who slip through the cracks of society, Timeless Palace tries to hide the existence of Contractors and superpowers, while jungle wants to create a world where everyone becomes a Contractor and there are no more normal humans. The Sword of Damocles is like a manifestation of power that certain very strong Contractors have, the payment for using their powers is that the Sword will become more damaged each time. As such the Kings have to be careful in their use, like imagine Kokujouji despite being the strongest King almost never uses his actual full power while Mikoto just continues to recklessly use his to protect the people he cares about even though he knows that each time his Sword becomes closer and closer to falling.

I like the idea that the members of their organizations all have similar powers too, like a lot of the Homra guys have fire-based powers. Imagine Kusanagi’s remuneration is to make cocktails, he even has like a little portable kit he brings along on missions so he can whip something up as needed after a fight. Totsuka’s only ability is to calm others, like a touch by him helps regulate the mood of the person he touches. He’s the only one who can help Mikoto stabilize his mood and abilities, but the price is that Totsuka loses years off his theoretical lifespan every time he uses it — the ‘theoretical’ part though is what makes it hard to track, what he loses is that basically if he was fated to die when he’s’x’ years old every time he uses the power it’s ‘x-1,’ so it’s not like he’s just starting at assuming he’d live to 90 and subtracting from there, he has no way to know when he’ll die. When he finally gets killed by rogue contractor Colorless Totsuka just smiles bitterly as he calls Kusanagi, knowing there’s nothing he can do because he’s used his contract too many times. Anna is a Doll who they rescue from a research facility where Contactor Mizuchi was trying to find new ways to create like the ‘ultimate’ powerful Doll, and due to being experimental Anna shows more emotions than normal Dolls do.

Yata and Fushimi are Contractors who awakened in middle school, Yata has fire powers and Fushimi can like turn anything he touches into a deadly projectile. Imagine Fushimi’s remuneration being something like ‘must eat a vegetable,’ so even though he likes having powers he hates using them and Yata’s always teasing him about it. Yata’s remuneration is to loudly and sincerely praise someone, so when they first awaken and are working together Yata of course is always yelling that Saruhiko is amazing. Once they join Homra though Yata is always praising Mikoto instead, which is one of the things that leads Fushimi to join S4 instead. While at S4 there are rumors that Fushimi’s become a Doll, because he’s even more emotionless than a normal Contractor, but anyone who’s seen him fight Yata Misaki knows that can’t be true because that’s the only time Fushimi will show emotions (and then imagine there’s something similar to what happens in canon with Fushimi having to infiltrate jungle at some point, and when Yata comes to save him Yata uses his powers and then confidently yells ‘Fushimi Saruhiko is amazing,’).

#k project#Talking K#okay now I'm thinking about other characters#Awashima's renumeration is to eat anko#Dewa has to tip his hat which is why he's Hat Guy#Benzai has to pet a cat#Akiyama has to step on someone and Hidaka has to be stepped on so that's handy

8 notes

·

View notes