#Power Motor & Robotics Development Tools

Explore tagged Tumblr posts

Text

How Do Power, Motor & Robotics Development Tools Drive Innovation in Automation?

Introduction to Modern Development Ecosystems

As the era of intelligent machines, automation, and smart manufacturing continues to advance, Power, Motor & Robotics Development Tools have emerged as essential components in transforming ideas into functioning prototypes and commercial solutions. These tools serve as the backbone for developing precise and reliable control systems used in a wide variety of sectors—from industrial robotics to electric mobility.

With the increasing integration of microcontrollers, sensors, thermal management components, and electronic controllers, development tools offer a modular and practical approach to building sophisticated electronic and electromechanical systems.

What Are Power, Motor & Robotics Development Tools?

Power, Motor & Robotics Development Tools consist of hardware kits, interface boards, and control modules designed to help developers and engineers test, prototype, and deploy automated systems with precision and speed. These tools make it possible to manage current, voltage, mechanical motion, and real-time decision-making in a structured and scalable manner.

By combining essential components such as capacitors, fuses, grips, cables, connectors, and switches, these kits simplify complex engineering challenges, allowing smooth integration with controllers, microprocessors, and sensors.

Exploring the Primary Toolsets in the Field

Power Management Development Tools

Efficient energy management is crucial for ensuring stability and performance in any robotic or motor-driven system.

Development boards supporting AC/DC and DC/DC conversion

Voltage regulators and surge protection circuits for safe energy flow

Thermal sensors and oils to maintain system temperature

Battery management ICs to control charge-discharge cycles

High-efficiency transformers and current monitors

Motor Control Development Tools

Motor control kits are built to manage torque, direction, and speed across a range of motor types.

H-bridge motor drivers for bidirectional motor control

Stepper motor controllers with high-precision movement

Brushless DC motor driver modules with thermal protection

Feedback systems using encoders and optical sensors

PWM-based modules for real-time torque adjustment

Robotics Development Tools

Robotics kits merge both mechanical and electronic domains to simulate and deploy automation.

Preassembled robotic arm platforms with programmable joints

Sensor integration boards for object detection, motion sensing, and environmental monitoring

Wireless modules for IoT connectivity using BLE, Wi-Fi, or RF

Microcontroller development platforms for logic execution

Mounting hardware and cable grips for secure installations

Benefits of Using Professional Development Tools

Advanced development kits offer more than just experimentation—they serve as stepping stones to commercial production. These tools minimize development time and maximize productivity.

Enhance system performance with modular plug-and-play designs

Enable easy integration with laptops, diagnostic tools, and controllers

Reduce design errors through pre-tested circuitry and embedded protection

Facilitate rapid software and firmware updates with compatible microcontrollers

Support debugging with LED indicators, thermal pads, and status feedback

Key Applications Across Industries

The adaptability of Power, Motor & Robotics Development Tools makes them suitable for countless industries and applications where intelligent movement and power efficiency are essential.

Industrial robotics and pick-and-place systems for manufacturing automation

Smart agriculture solutions including automated irrigation and drone control

Automotive design for electric vehicle propulsion and battery systems

Aerospace applications for lightweight, compact control mechanisms

Educational platforms promoting STEM learning with hands-on robotics kits

Essential Components that Enhance Development Kits

While the kits come equipped with core tools, several other components are often required to expand capabilities or tailor the kits to specific use cases.

Sensors: From temperature and light to current and magnetic field detection

Connectors and plugs: For flexible integration of external modules

Switches and contactors: For manual or automatic control

Thermal pads and heatsinks: For preventing overheating during operation

Fuses and circuit protection devices: For safeguarding sensitive electronics

LED displays and character LCD modules: For real-time data visualization

How to Choose the Right Tool for Your Project

With a vast array of kits and tools on the market, selecting the right one depends on your application and environment.

Identify whether your project focuses more on power management, motor control, or full robotic systems

Consider compatibility with popular development environments such as Arduino, STM32, or Raspberry Pi

Check the current and voltage ratings to match your load and motor specifications

Evaluate add-on support for wireless communication and real-time data processing

Ensure the tool includes comprehensive documentation and driver libraries for smooth integration

Why Development Tools Are Crucial for Innovation

At the heart of every advanced automation solution is a well-structured foundation built with accurate control and reliable hardware. Development tools help bridge the gap between conceptualization and realization, giving engineers and makers the freedom to innovate and iterate.

Encourage experimentation with minimal risk

Shorten product development cycles significantly

Simplify complex circuit designs through preconfigured modules

Offer scalability for both low-power and high-power applications

Future Scope and Emerging Trends

The future of development tools is headed toward more AI-integrated, real-time adaptive systems capable of learning and adjusting to their environment. Tools that support machine vision, edge computing, and predictive analytics are gaining traction.

AI-powered motion control for robotics

Integration with cloud platforms for remote diagnostics

Advanced motor drivers with feedback-based optimization

Miniaturized power modules for wearable and mobile robotics

Conclusion: Is It Time to Upgrade Your Engineering Toolkit?

If you're aiming to build smarter, faster, and more energy-efficient systems, Power, Motor & Robotics Development Tools are not optional—they’re essential. These kits support you from idea to implementation, offering the flexibility and performance needed in modern-day innovation.

Whether you're developing a prototype for a high-speed robotic arm or integrating power regulation into a smart grid solution, the right development tools empower you to transform challenges into achievements. Take the leap into next-gen automation and electronics by investing in the tools that make engineering smarter, safer, and more efficient.

#Power Motor & Robotics Development Tools#electronic components#technology#electricalparts#halltronics

0 notes

Text

One of the Greatest Inventions of All Time

Nikola Tesla has many revolutionary inventions to his credit, but he is best known for his pioneering work in the development and promotion of alternating current (AC) electrical systems. Tesla's innovations in AC technology revolutionized the generation, transmission, and distribution of electrical power, becoming the foundation for the modern electrical power systems that we use today.

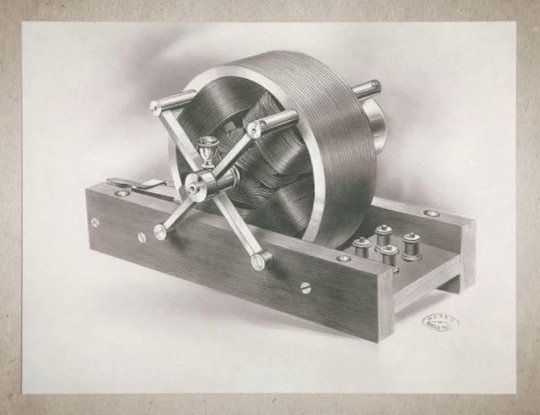

There is a common misconception made that Tesla was the first to invent, or discover, AC, but this is not true. It is well-known that Hippolyte Pixii was the first to discover AC in 1832. Pixii was an instrument maker from Paris who built an early form of an alternating current electrical generator (based on the principle of electromagnetic induction discovered by Michael Faraday), and thus started a new industry in power transmission. Tesla was not the first to discover or invent an AC motor, but he was the first to invent a practical AC induction motor with commercial value that could outperform all other motors. It must be noted that Italian inventor Galileo Ferraris also invented an induction motor similar to Tesla's, but it had no commercial value, and he even admitted himself that it was useless. Tesla's induction motor operates on the principle of electromagnetic induction, properly utilizing a rotating magnetic field that induces a current in a stationary conductor, resulting in rotational motion. The utilization of the rotating magnetic field makes the motor more simple, robust, versatile, efficient, and cost effective in that it has less moving parts reducing the likelihood of mechanical failure (as was common in other motors).

Tesla's induction motor became a fundamental component in the field of electrical engineering and is used today in various applications, being one of the most widely used devices in the world. The motors play a crucial role in transmitting electrical power to homes and businesses. They are commonly used in power generation plants to convert mechanical energy into electrical energy, which is then transmitted through the power grid for distribution to various locations. Induction motors are also widely employed in appliances and machinery within homes and businesses for various applications. These applications include conveyor systems, hoists, cranes, lifts, pumps, fans, ventilation systems, compressors, manufacturing machinery, wind turbines, washing machines, refrigerators, garbage disposals, microwaves, dishwashers, vacuums, air conditioners, robotics, electric vehicles, trains, power tools, printers, etc. Basically, anything that requires a spinning action for power.

The induction motor is widely considered one of the most important inventions in the history of electrical engineering. Its importance lies in its transformative impact on industries, its efficiency and reliability, and its role in the broader electrification of society.

#nikola tesla#science#history#invention#discovery#induction motor#electricity#power#goat#ahead of his time#ahead of our time

152 notes

·

View notes

Text

Me this morning: "Hmm I can't really do much to contribute to making a combat robot myself, but you know what might be really innovative is if I worked to develop a real time diagnostics tool to send information to a screen on battery temperatures and how much power motors are getting so that the driver can make informed decisions on what to do next!"

Guy on four year old episode of Battlebots I'm currently watching tonight: "So we developed a real time diagnostics tool to send information to a screen on battery temperatures and how much power motors are getting so that our driver can make informed decisions on what to do next!"

3 notes

·

View notes

Text

Unlocking Potential: The Power of Learning Resources Toys in Child Development

The Power of Learning Resources Toys in Child Development" underscores the significant role that thoughtfully designed educational toys play in shaping the cognitive and developmental landscape of children. These toys go beyond mere entertainment, acting as catalysts for intellectual growth, problem-solving skills, and social development. Learning resources toys engage children in activities that stimulate their imagination, creativity, and critical thinking. From building blocks that encourage spatial awareness to interactive educational tablets fostering early literacy, these toys provide a dynamic and hands-on approach to learning. STEM-oriented toys, such as robotics kits and science experiments, introduce youngsters to the wonders of science, technology, engineering, and mathematics in an accessible and enjoyable manner. Furthermore, artistic tools like drawing kits and musical instruments contribute to the development of fine motor skills and self-expression. By integrating these diverse learning resources into a child's environment, parents and educators create an enriching atmosphere that not only supports academic growth but also nurtures essential life skills, ensuring a well-rounded and holistic approach to child development

#learningresourcestoys#Babylistwelcomebox#besteducationaltoysfor3yearolds#bestlearningtoysfor2yearolds#bestlearningtoysfor3yearolds#educationaltoys#learningtoys#preschooltoys

2 notes

·

View notes

Text

The Mechatronic Design Engineer: Powering Automation with CODESYS

Mechatronic design engineering is a multidisciplinary field that blends mechanical engineering, electronics, control systems, and software development to create intelligent, automated systems. Mechatronic design engineers are at the forefront of innovation, designing solutions for industries like robotics, automotive, aerospace, and manufacturing. CODESYS, an IEC 61131-3-compliant development platform, is a critical tool for these engineers, enabling them to program and integrate control systems for complex mechatronic applications. This article explores the role of a mechatronic design engineer, how CODESYS supports their work, key responsibilities, required skills, and real-world applications, highlighting the impact of this profession on modern automation.

The Essence of Mechatronic Design Engineering

Mechatronic design engineering focuses on creating systems that integrate mechanical components, electronic circuits, sensors, actuators, and software to achieve precise, reliable performance. These systems, such as robotic arms, autonomous vehicles, or CNC machines, require seamless coordination between hardware and software. Mechatronic design engineers ensure that these components work together to meet performance, safety, and efficiency goals, making them essential in industries embracing Industry 4.0 and smart automation.

CODESYS is a cornerstone for mechatronic design engineers, offering a versatile, hardware-independent platform for programming embedded control systems. Its compliance with IEC 61131-3, support for multiple programming languages, and robust tools for simulation and debugging make it ideal for developing sophisticated mechatronic systems.

Responsibilities of a Mechatronic Design Engineer

Mechatronic design engineers undertake a variety of tasks to bring complex systems to life:

System Design and Integration: Designing integrated systems that combine mechanical structures, electronics, and control software to meet specific functional requirements.

Control System Programming: Developing control algorithms to manage sensors, actuators, and motion systems, ensuring precise operation.

Simulation and Testing: Using simulation tools to validate system performance before deployment, minimizing errors and risks.

Prototyping and Commissioning: Building prototypes, integrating components, and deploying systems in real-world environments.

Optimization and Troubleshooting: Analyzing system performance, debugging issues, and optimizing designs for efficiency and reliability.

Collaboration: Working with mechanical, electrical, and software teams to ensure cohesive system development.

How CODESYS Empowers Mechatronic Design Engineers

CODESYS provides a comprehensive environment tailored to the needs of mechatronic design engineers:

IEC 61131-3 Programming Languages: CODESYS supports Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). These languages enable engineers to develop control logic for diverse applications, from simple discrete controls to advanced motion systems.

Hardware Flexibility: Compatible with PLCs and embedded controllers from vendors like Beckhoff, WAGO, and Siemens, CODESYS allows engineers to choose hardware that suits project budgets and requirements.

Motion Control Libraries: CODESYS offers libraries for motion control, supporting tasks like servo motor control, trajectory planning, and multi-axis coordination, critical for mechatronic systems like robotics.

Simulation and Debugging Tools: The built-in simulation mode enables testing without physical hardware, while debugging features like breakpoints and real-time monitoring help identify and resolve issues quickly.

HMI Development: CODESYS provides tools to create Human-Machine Interfaces (HMIs) for operator interaction, including graphical displays and web-based visualizations.

Communication Protocols: Support for EtherCAT, CANopen, Modbus, and OPC UA ensures seamless integration with sensors, actuators, and other devices in mechatronic systems.

Safety Standards: For safety-critical applications, CODESYS supports IEC 61508 (SIL 2/3), enabling engineers to design systems for industries like automotive and aerospace.

Example: Robotic Arm Control Program

Below is a sample Structured Text (ST) program for controlling a robotic arm’s position in a mechatronic system:

RoboticArmControl.st

plain

Show inline

This program implements a proportional control loop to adjust a robotic arm’s joint angle, ensuring precise positioning in a mechatronic application.

Essential Skills for Mechatronic Design Engineers

To succeed, mechatronic design engineers need a diverse skill set:

Multidisciplinary Knowledge: Proficiency in mechanical design, electronics, and control systems programming, including CODESYS and IEC 61131-3 languages.

Control Theory: Understanding of control algorithms, such as PID control, for precise system management.

Software Development: Experience with embedded systems programming and real-time operating systems (RTOS).

Problem-Solving: Analytical skills to troubleshoot and optimize complex systems.

Teamwork: Collaboration with cross-functional teams to integrate hardware and software components.

Adaptability: Staying updated with emerging technologies like IoT, AI, and cybersecurity.

Benefits of Using CODESYS

Streamlined Development: The integrated IDE and simulation tools reduce development time and errors.

Cost Efficiency: Hardware independence and code reusability lower project costs.

Scalability: CODESYS supports projects from small prototypes to large-scale industrial systems.

Flexibility: Multiple programming languages and protocols cater to diverse project needs.

Community Support: A global user base and resources like the CODESYS Store provide access to libraries and tutorials.

Applications in Industry

Mechatronic design engineers leverage CODESYS in various sectors:

Robotics: Developing control systems for industrial and collaborative robots.

Automotive: Designing ECUs for engine management, braking, and autonomous driving.

Manufacturing: Automating production lines, CNC machines, and material handling systems.

Aerospace: Controlling actuators and sensors in aircraft and spacecraft.

Medical Devices: Creating precise control systems for surgical robots and diagnostics.

Challenges in Mechatronic Design Engineering

Interdisciplinary Complexity: Integrating mechanical, electrical, and software components requires broad expertise.

Learning Curve: Mastering CODESYS and IEC 61131-3 languages can be time-intensive for beginners.

Resource Constraints: Embedded systems often have limited processing power, necessitating optimized code.

Safety Requirements: Meeting standards like IEC 61508 for safety-critical applications adds complexity.

Getting Started with CODESYS

To begin as a mechatronic design engineer using CODESYS:

Install CODESYS: Download the free IDE from the official website.

Learn Programming: Study IEC 61131-3 languages through tutorials and documentation.

Select Hardware: Choose a compatible PLC or embedded controller.

Develop and Simulate: Write control logic, test in simulation mode, and debug.

Deploy: Compile and deploy code to the target hardware.

Future Trends

As industries embrace digital transformation, mechatronic design engineers will increasingly use CODESYS for IoT-enabled systems, cloud-based monitoring, and AI-driven control. Support for protocols like OPC UA and MQTT positions CODESYS for smart manufacturing, while advancements in cybersecurity ensure its relevance in safety-critical applications.

Conclusion

Mechatronic design engineers by Servotechinc are key to creating the intelligent systems that drive modern automation, from robotics to autonomous vehicles. CODESYS empowers these professionals with a flexible, IEC 61131-3-compliant platform for programming, testing, and deploying control systems. Its robust features, hardware independence, and support for motion control and communication protocols make it indispensable for mechatronic applications. As technology advances, CODESYS and mechatronic design engineers will continue to shape the future of automation, delivering innovative, efficient, and reliable solutions.

0 notes

Text

Torque Sensors: Precision Force Monitoring Powered by Star EMBSYS Technology

Torque sensors are essential tools in the measurement and control of rotational force in mechanical systems. From automotive testing and industrial automation to aerospace and robotics, torque sensors enable engineers to monitor performance, ensure safety, and improve efficiency. Star EMBSYS, a leader in embedded system innovation, offers advanced torque sensor solutions that combine mechanical precision with intelligent electronics for high-performance applications.

A torque sensor, also known as a torque transducer, measures the torque—or rotational force—applied to a shaft or axis. It can be used in both static (non-rotating) and dynamic (rotating) applications, making it highly versatile. Depending on the requirement, torque sensors can be based on strain gauge, magnetoelastic, or optical technologies. The electrical signal generated is proportional to the torque applied, which is then processed for display, control, or data logging.

Star EMBSYS leverages its deep expertise in embedded systems to develop smart torque sensor solutions that provide real-time, high-resolution measurements. Their sensors are integrated with embedded microcontrollers for advanced signal conditioning, filtering, and digital communication. This results in more stable, noise-free data and allows for seamless integration into modern control systems.

What sets Star EMBSYS apart is their ability to offer custom torque sensor systems tailored to specific industrial needs. Whether for a precision laboratory setup or a rugged field environment, Star EMBSYS provides sensors that include temperature compensation, overload protection, and customizable output ranges. The embedded software also supports features like zero-torque calibration, peak-hold modes, and fault diagnostics.

For industries working with rotating machinery—such as electric motors, pumps, or wind turbines—Star EMBSYS torque sensors offer both static and rotary variants. These sensors can output analog signals (0–5V, 4–20mA) or digital data via UART, CAN, or SPI, providing flexibility for integration with PLCs, DAQs, or cloud-connected IoT platforms.

Moreover, Star EMBSYS includes support for wireless telemetry in demanding applications, allowing real-time torque data transmission without slip rings or complex wiring—ideal for mobile machinery or test benches.

In summary, torque sensors play a vital role in the monitoring and control of mechanical systems. With its focus on smart design, embedded innovation, and application-specific customization, Star EMBSYS delivers high-performance torque sensor solutions that empower engineers and manufacturers to measure with confidence, accuracy, and efficiency.

Visit:- https://www.starembsys.com/torque-sensor.html

0 notes

Text

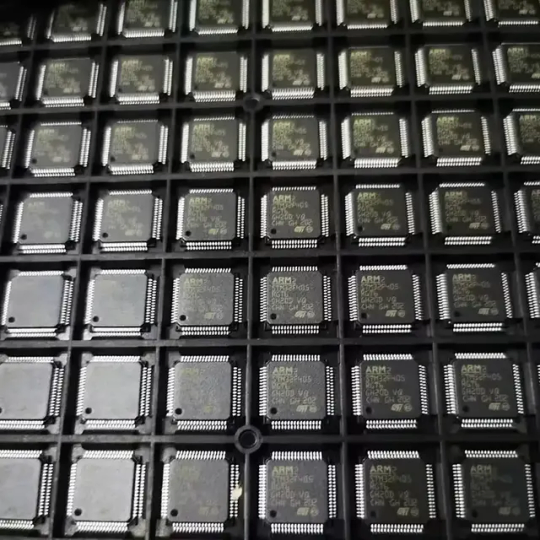

Introduction STM32F405RGT6 for ST MCU Distributor Discover the cutting-edge STM32F405RGT6 microcontroller, where advanced technology meets versatility. Designed for enthusiasts, makers, and professionals alike, this microcontroller provides the perfect blend of performance, efficiency, and reliability. Whether you're working on robotics, automation, or IoT projects, the STM32F405RGT6 is ready to bring your ideas to life. MOQ of the ST MCU The MOQ is 100units as seen online.However,they are negotiable,if you interested with much more quantity,contact us to chat details. STM32F405RGT6 boasts a powerful ARM Cortex-M4 processor that can run at frequencies up to 168 MHz. With 1024 KB of flash memory and 256 KB of SRAM, it ensures that you can handle complex computations and multitasking with ease. Its integrated digital signal processing (DSP) capabilities enable real-time data processing, making it ideal for applications requiring high-speed calculations. IOT Solution Equipped with a rich set of interfaces, the STM32F405 allows seamless integration with a variety of peripherals. It features UART, SPI, I2C, and USB connectivity options that cater to a wide range of applications. Whether you need to connect sensors, motors, or other microcontrollers, the STM32F405RGT6 offers the flexibility you need. Plus, with support for multiple communication protocols, your projects are only limited by your imagination. In addition to its impressive specifications, this stm mcu is supported by an extensive ecosystem of development tools and resources. With various libraries, example codes, and a vibrant community, you'll have everything you need to step into the world of embedded systems development confidently. Even if you are a novice, you'll find a wealth of information to guide you in harnessing the full potential of this microcontroller. In summary, the STM32F405 is not just another microcontroller; it's a gateway to limitless possibilities. By choosing this mcu for your project, you equip yourself with a reliable and fast platform that can grow alongside your ideas. Dive into the world of embedded systems today and experience the power of STM32F405! If you interested with much more electronic components price,view here to know more about our company business. Read the full article

0 notes

Text

Global Encoder Chips Market: Driving Precision in Next-Gen Electronics 2025–2032

Encoder Chips Market Analysis:

The global Encoder Chips Market size was valued at US$ 1.6 billion in 2024 and is projected to reach US$ 2.7 billion by 2032, at a CAGR of 7.9% during the forecast period 2025-2032

Encoder Chips Market Overview

This report provides a deep insight into the global Encoder Chips market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc. The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and accessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Encoder Chips Market, this report introduces in detail the market share, market performance, product situation, operation situation, etc. of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market. In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Encoder Chips market in any manner.

Encoder Chips Key Market Trends :

Rise in Industrial Automation

Increased use of encoder chips in automation systems is driving demand, especially across manufacturing plants and robotics applications.

Growing Adoption in Consumer Electronics

The integration of encoder chips in consumer gadgets like printers, cameras, and smart home devices is growing rapidly.

Miniaturization and Efficiency

Technological advancements are leading to smaller, more power-efficient encoder chips suitable for compact devices.

Increased Demand from Medical Equipment

Encoder chips are being widely used in imaging and diagnostic tools, enhancing precision and accuracy in healthcare applications.

Advancements in Optical and Magnetic Encoders

Continuous innovation in optical and magnetic encoder technologies is improving performance across industrial and electronics sectors.

Encoder Chips Market Regional Analysis :

North America:Strong demand driven by EVs, 5G infrastructure, and renewable energy, with the U.S. leading the market.

Europe:Growth fueled by automotive electrification, renewable energy, and strong regulatory support, with Germany as a key player.

Asia-Pacific:Dominates the market due to large-scale manufacturing in China and Japan, with growing demand from EVs, 5G, and semiconductors.

South America:Emerging market, driven by renewable energy and EV adoption, with Brazil leading growth.

Middle East & Africa:Gradual growth, mainly due to investments in renewable energy and EV infrastructure, with Saudi Arabia and UAE as key contributors.

Encoder Chips Market Segmentation :

The research report includes specific segments by region (country), manufacturers, Type, and Application. Market segmentation creates subsets of a market based on product type, end-user or application, Geographic, and other factors. By understanding the market segments, the decision-maker can leverage this targeting in the product, sales, and marketing strategies. Market segments can power your product development cycles by informing how you create product offerings for different segments. Key Company

Broadcom

AMS

New Japan Radio

TE Connectivity

IC-Haus

SEIKO NPC

RLS

PREMA Semiconductor

Hamamatsu

Market Segmentation (by Type)

Magnetic Encoder Chips

Optical Encoder Chips

Market Segmentation (by Application)

Industrial Automation

Motors

Medical

Office Automation

Consumer Electronics

Semiconductor Equipment

Measurement Equipment

Others

Market Drivers

Growth in Industrial Automation The increasing shift towards smart factories and Industry 4.0 is driving demand for encoder chips in motion and position control systems.

Surging Demand from Consumer Electronics Encoders are essential in applications like printers, gaming controllers, and smartphones, spurring market expansion.

Technological Innovation in Optical and Magnetic Encoders R&D investments are leading to high-precision, compact, and energy-efficient encoder chips for advanced applications.

Market Restraints

High Cost of Advanced Encoder Technologies Premium pricing of high-performance optical and magnetic encoders may limit adoption, especially among cost-sensitive sectors.

Complex Integration Process Designing encoder chips into systems like motors or automation equipment can be technically challenging and time-consuming.

Market Fragmentation and Intense Competition The presence of multiple small and large players increases pricing pressure and creates challenges for market differentiation.

Market Opportunities

Adoption in Emerging Medical Devices The growing healthcare industry, especially precision diagnostic and surgical equipment, presents new avenues for encoder chip usage.

Expansion in Asia-Pacific Region Countries like China, Japan, and India are witnessing rapid growth in manufacturing and electronics, offering major growth potential.

Growing Demand in Semiconductor Equipment Encoders play a critical role in wafer inspection and fabrication systems, benefiting from the booming semiconductor industry.

Market Challenges

Technological Obsolescence Rapid innovation can make existing encoder models outdated, pressuring companies to invest constantly in upgrades.

Dependence on Semiconductor Supply Chains Disruptions in chip manufacturing or raw material availability can significantly affect production and market supply.

Data Security and Signal Interference With increasing digital integration, maintaining secure and interference-free data transmission is becoming more difficult.

Key Benefits of This Market Research:

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the Encoder Chips Market

Overview of the regional outlook of the Encoder Chips Market:

Key Reasons to Buy this Report:

Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

This enables you to anticipate market changes to remain ahead of your competitors

You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

Provision of market value (USD Billion) data for each segment and sub-segment

Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

Provides insight into the market through Value Chain

Market dynamics scenario, along with growth opportunities of the market in the years to come

6-month post-sales analyst support

0 notes

Text

The Future of Learning: Benefits of a Robotics Lab in School

As we navigate an age of rapid technological advancement, education must keep pace. Schools today must go beyond conventional teaching methods to prepare students for a future dominated by automation, artificial intelligence, and digital systems. One of the most powerful tools reshaping modern education is the robotics lab—an interactive environment where students learn to design, build, and program machines that can move, react, and solve real-world problems.

Bridging Theory and Practice in Education

For generations, learning in schools was often limited to books, lectures, and memorization. Robotics labs flip that model by offering hands-on, inquiry-driven learning. Instead of just reading about how motors work or how logic flows in a computer, students get to experience it directly by building machines themselves.

Setting up a robotics lab in a school involves more than just installing a few kits and computers. It requires designing a space where students feel encouraged to experiment, collaborate, and apply theoretical concepts through real projects. This transition from passive learning to active doing significantly boosts student engagement and deepens their understanding of STEM subjects.

Empowering Students with Future-Ready Skills

A robotics lab is more than a tech corner—it’s a place where critical life skills are nurtured. Through project-based learning, students develop problem-solving abilities, logical reasoning, and perseverance. They’re introduced to programming, mechanical systems, and basic electronics in a format that’s exciting and easy to relate to.

Even more importantly, robotics teaches students how to learn from failure. When their robot doesn't behave as expected, they debug it, try again, and come back stronger. This cycle mirrors the real-world process of innovation. By integrating a Robotic lab for kids, schools give young learners the confidence to experiment, think independently, and embrace challenges head-on.

Robotics also fosters creativity. Students aren’t just building what the instructions tell them—they’re designing their own solutions to problems, customizing their creations, and often improving upon them. This blend of imagination and logic is precisely what is needed in the innovation-driven economy of tomorrow.

Boosting Interest in STEM Education

STEM—Science, Technology, Engineering, and Mathematics—has become a central focus in educational policy worldwide. However, many students lose interest in these subjects when they’re taught only through textbooks. Robotics brings these disciplines to life in exciting and meaningful ways.

A well-equipped robotics lab introduces young learners to essential STEM concepts from an early age. They begin to understand how gears, motors, sensors, and software interact. With every project, students reinforce core concepts in physics, math, and computer science without even realizing they’re learning.

Having a Robotics lab in your school elevates its academic offerings and provides students with the foundation they need to pursue careers in high-demand tech fields. It also gives schools a modern and progressive image that appeals to parents and education stakeholders looking for future-focused learning environments.

Promoting Teamwork and Communication

While robotics is deeply technical, it’s also incredibly collaborative. Students often work in small teams where they brainstorm, design, troubleshoot, and present their work. This process improves communication skills, leadership abilities, and emotional intelligence.

Working on robotics projects teaches students how to divide tasks effectively, listen to others’ ideas, and give constructive feedback. These are all vital life skills, especially in today’s workplaces where interdisciplinary collaboration is the norm.

Robotics also provides an inclusive platform for learning. It caters to various learning styles and abilities, allowing students who may struggle with traditional academics to shine in a practical and creative setting.

Igniting Curiosity and Innovation

At its heart, a robotics lab fuels curiosity. When students are presented with a problem and a set of tools to solve it, they become immersed in discovery. They ask questions, test ideas, and constantly push the boundaries of what they thought possible.

This type of learning is deeply engaging and highly effective. Students not only retain more information, but they also become more self-motivated. Many go on to compete in robotics competitions, create solutions for real-world problems, or even pursue their tech-based ventures.

Through robotics, education moves beyond simply delivering content—it becomes a platform for exploration and innovation.

Preparing for the Jobs of Tomorrow

The workforce of the future will require a blend of technical proficiency, creative thinking, and adaptability. Careers in automation, robotics, software development, AI, and engineering are growing rapidly—and these roles demand not only knowledge but hands-on experience.

By establishing a robotics lab, schools are investing directly in their students’ futures. They are giving young learners a head start in understanding how modern technologies work and how to build with them. These early experiences can shape career interests and inspire lifelong passions in technology.

Conclusion: A Strategic Step Forward

Incorporating a robotics lab is not just an educational enhancement—it’s a forward-thinking move that aligns schools with the future of global education. It encourages a new style of learning that is interactive, interdisciplinary, and intensely student-focused.

From boosting academic performance to equipping students with crucial life and career skills, the benefits are wide-reaching. Schools that embrace this change now will prepare their students to lead in the digital era, armed with curiosity, confidence, and creativity.

0 notes

Text

How Science Kits Foster STEM Skills in Young Learners

In today’s rapidly advancing world, fostering strong STEM (Science, Technology, Engineering, and Mathematics) skills from an early age is more important than ever. One of the most effective and engaging ways to nurture these skills in young learners is through hands-on science kits. These kits transform abstract concepts into tangible experiments and activities, making learning fun, interactive, and meaningful. Here’s how science kits play a crucial role in developing STEM skills in children.

Hands-On Learning Sparks Curiosity

Science kits invite children to dive right into experiments and projects, turning them into active learners rather than passive observers. When kids build circuits, grow crystals, or mix chemicals, they experience the scientific method firsthand: asking questions, making hypotheses, conducting tests, and observing results. This process naturally develops critical thinking and problem-solving skills—key components of STEM education.

Unlike traditional classroom lessons that might rely heavily on textbooks and lectures, science kits engage multiple senses. Children see colors change, feel textures, hear reactions, and sometimes even smell experiments, making learning immersive and memorable. This tactile engagement encourages curiosity and a desire to explore more.

Building Confidence Through Trial and Error

STEM fields are all about experimentation and iteration, and science kits encourage kids to embrace trial and error. When a project doesn’t work on the first try, children learn resilience by troubleshooting and trying different approaches. This builds perseverance and a growth mindset, teaching them that mistakes are a natural part of learning and discovery.

By successfully completing experiments, young learners gain a sense of accomplishment that boosts confidence. This confidence often translates into a willingness to tackle more complex STEM challenges, laying a solid foundation for future learning.

Connecting Theory with Real-World Applications

Science kits help bridge the gap between theory and real-world applications. For example, a kit that lets kids build a simple motor or robot introduces basic engineering principles and electronics. A chemistry set demonstrates reactions that are the foundation for everyday processes like cooking and cleaning.

This relevance helps children understand why STEM subjects matter. It moves learning beyond memorization to meaningful experiences that show how science and technology shape the world around them.

Encouraging Creativity and Innovation

While STEM is often associated with logic and numbers, creativity is a vital part of these fields. Science kits inspire children to think creatively by allowing them to design experiments, test new ideas, and sometimes customize projects. This creative freedom fosters innovation and encourages kids to see themselves as inventors and problem solvers.

Supporting Collaboration and Communication

Many science kits are designed for group use or can be adapted for collaborative projects. Working together on experiments teaches children important teamwork and communication skills. They learn to share ideas, listen to others, and explain their findings—abilities that are essential in STEM careers and beyond.

Accessible Learning for All Ages

Science kits come in a wide range of difficulty levels and topics, making STEM learning accessible to children from preschool through middle school and beyond. Whether it’s a simple magnet experiment or a complex robotics kit, there’s something to engage every young mind.

Final Thoughts

Science kits are powerful tools for fostering STEM skills because they combine education with excitement and discovery. By making abstract concepts concrete and encouraging hands-on exploration, these kits help young learners develop curiosity, confidence, creativity, and critical thinking. They prepare children not just to understand science and technology, but to innovate and thrive in a world where these skills are increasingly essential.

0 notes

Text

From Circuits to Solutions: Practical Projects to Elevate Your EE Skills

From Breadboards to Breakthroughs” encapsulates the journey of an aspiring electrical engineer as they evolve from basic circuit experiments to advanced, real-world engineering projects. Hands-on projects are essential for building practical skills, reinforcing theoretical knowledge, and preparing for professional challenges. Below is a guide to project-based learning that can help you improve your electrical engineering (EE) skills at every stage.

Beginner Projects: Building Foundations

Simple LED Circuit

What you learn: Basic circuit design, current and voltage concepts, use of resistors and LEDs.

Tools: Breadboard, jumper wires, resistors, LEDs, battery.

Battery Tester

What you learn: Measuring voltage and current, basic instrumentation, and safety practices.

Water Level Indicator

What you learn: Sensor integration, simple logic circuits, and practical applications.

Logic Gates and Digital Circuits

What you learn: Boolean logic, digital circuit fundamentals, and troubleshooting.

DIY Switch Circuits

What you learn: Circuit switching, input/output devices, and practical wiring.

Intermediate Projects: Expanding Your Skills

Infrared Security System

What you learn: Sensor-based security, signal processing, and system integration.

Digital Voltmeter

What you learn: Instrumentation, analog-to-digital conversion, and measurement accuracy.

Solar Charger

What you learn: Renewable energy concepts, power management, and circuit protection.

Motor Control Circuits

What you learn: Driving motors, pulse-width modulation (PWM), and power electronics.

Heart Rate Monitor

What you learn: Biomedical instrumentation, sensor interfacing, and signal filtering.

Advanced Projects: Real-World Breakthroughs

Smart Home Automation System

What you learn: IoT, wireless communication (Bluetooth, Wi-Fi), and system integration.

Wireless Power Transfer System

What you learn: Inductive coupling, resonant circuits, and energy efficiency.

Dual Axis Solar Power Tracker

What you learn: Mechatronics, sensor feedback, and renewable energy optimization.

Smart Energy Meter

What you learn: Real-time data monitoring, wireless communication, and energy management.

DIY Quadcopter or Drone

What you learn: Embedded systems, motor control, wireless communication, and robotics.

Why Hands-On Projects Matter

Resume Building: Practical projects demonstrate your skills to potential employers and can help you land internships or jobs

Theory Application: Projects bridge the gap between classroom learning and real-world engineering challenges.

Skill Discovery: Experimenting with different projects helps you identify your interests and strengths.

How to Get Started

Gather Basic Tools: Invest in a quality breadboard, jumper wires, resistors, capacitors, LEDs, and a multimeter.

Start Simple: Begin with basic circuits and gradually tackle more complex projects as your confidence grows.

Use Online Resources: Take advantage of tutorials, simulation tools, and open-source project guides.

Join Maker Communities: Engage with online forums, local maker spaces, and engineering clubs for support and inspiration.

Document Your Work: Keep a project journal, take photos, and share your progress on platforms like GitHub or LinkedIn.

Conclusion

Arya College of Engineering & I.T. is one of the best colleges of Jaipur, which is progressing from breadboard experiments to advanced engineering projects is a transformative process that builds both technical expertise and problem-solving confidence. By systematically advancing through beginner, intermediate, and advanced projects, you will develop a robust skill set that prepares you for the challenges and opportunities of a career in electrical engineering.

1 note

·

View note

Text

Introduction Robotics is advancing at a record rate. One of the fascinating innovations leading the way is the Unitree Go2 AI Robotic Dog. This advanced quadruped robot integrates mobility, AI, and practical applications into an intelligent, effective system. It represents a move towards interactive and autonomous robotic systems in practical applications. Let us discover how Unitree Go2 is transforming robotics and why it is so special. What is Unitree Go2 AI Robotic Dog? Unitree Go2 is a futuristic robot dog designed for mobility, autonomy, and real-time interaction. Unitree Robotics created the robot featuring advanced engineering and AI-powered intelligence. It has: • 4-legged dynamic structure for increased agility and balance • A robust AI module with GPT functionality • Live voice response and recognition • Intelligent sensor-based advanced navigation This dog is not only for show—it's designed to deliver, to work in any situation, from classrooms to search and rescue. Key Features of Unitree Go2 1. AI Intelligence The Go2 also comes equipped with an embedded AI model that enables it to: • Recognize and respond to voice commands • Plan movement paths • Develop habits gradually It's like having a clever companion that walks, hears, and responds. 2. High-Speed Mobility Due to its multi-axis control and high-torque motors, the Go2 can: • Max 5 m/s run • Ascend stairs and walk on uneven ground • Recover rapidly from falls This makes it especially suitable for dynamic, uncertain environments. 3. Advanced Sensor Suite It uses: •\tLiDAR for environment mapping • Depth cameras for obstacle avoidance • Inertial Measurement Units (IMUs) for balance and stability These help the robot move around and interact with its surroundings safely. Applications of the Unitree Go2 in Daily Life Security and Surveillance The robot dog can patrol restricted areas, guard against invasions, and offer live video streams. With unrestricted movement and 360-degree vision, it is most ideal for automated security systems. Search and Rescue In disaster situations, Go2 can reach unstable ground that wheeled robots or humans cannot. It can detect motion, voice, and warm bodies to find survivors. Learning and Research Tool Students and educators use Go2 to study AI, robotics, and computer programming. Its SDK allows for full customization, making it perfect for tech schools and universities. Why Robots Such As Go2 Are The Future Robots such as Unitree Go2 are: • Increased efficiency in industries • Improved working conditions in risky situations • Enhanced learning materials for students With advancing technology through robotics, smart machines will aid in daily activities, research, and rescue missions. Ethics and Safety Issues As much as innovation is thrilling, one ought • Set limits on autonomous action • Encourage openness in data gathering • Provide human control and responsibility Robots should be tools, not threats. Developers must consider societal and ethical impacts. Conclusion Unitree Go2 AI Robotic Dog is revolutionary. Combining agility, intelligence, and practicality into daily existence, it's not an appliance—it's a peek at the future. As intelligent robotics gain access to the domestic, laboratory, and field applications, the time has come. The Go2 establishes an extremely high standard for what can be achieved when engineering and AI are combined. References • Official product page: https://www.xboom.in/unitree-go2-ai-robotic-dog

0 notes

Text

Surgical power tool

Technological Origins and Development

The history of surgical power tools dates back to the early 20th century with the invention of the high frequency electrosurgical device by William Bovie in 1920, revolutionizing intraoperative hemostasis. Over time, advancements in energy based technologies—such as ultrasonic, plasma, and laser systems—paved the way for modern minimally invasive surgery (MIS). By the 21st century, the integration of robotics and digital controls further refined precision, reducing complications and learning curves. Today, surgical power tools are indispensable in procedures ranging from orthopedic surgeries to neurosurgery, driven by their ability to deliver consistent torque, minimize vibration, and optimize efficiency.

Their advantages include:

Enhanced Precision: Tools like electric drills enable controlled bone cutting, reducing the risk of thermal damage.

Efficiency: Automated power optimization shortens procedure times. For instance, large bone power tools achieve a tissue removal efficiency of 0.7 g/min, outperforming traditional methods.

Safety: Advanced systems mitigate complications like bleeding and postoperative infections. Powered with Ni-MH batteries with an enhanced motor design,it assures high reliability and performance.

Versatility: Modular designs allow compatibility with diverse accessories, supporting procedures from spinal fusions to tumor resections.

Ergonomics : Lightweight handpieces improve easy of use.

Clinical Applications and Advantages

Surgical power tools are widely used in orthopedic surgeries (e.g., joint replacements, fracture repairs), neurosurgery, and ENT procedures.

1.Minimally Invasive Spine Surgery (MISS)

Accurate Decompression : safely remove bone spurs or herniated discs while preserving adjacent neural structures.

Reduced Thermal Injury : Advanced irrigation cooled systems limit temperature rise to <42°C during laminectomy, minimizing tissue necrosis risks.

Efficiency : Allow seamless switching between softtissue dissection and bone sculpting, cutting procedure time by 25% compared to manual instruments.

2.Joint Replacement (Hip/Knee Arthroplasty)

Bone Preparation : High torque reamers (e.g., 300–500 rpm) create precise femoral or tibial cavities, ensuring optimal implant fit.

Cementless Fixation : Oscillating saws with <0.1 mm cutting tolerance enable smooth osteotomy lines, critical for pressfit implant stability.

Minimized Blood Loss : Integrated suctionirrigation channels in tools reduce blood loss by 30% during total knee replacements.

3. Trauma and Fracture Repair

Rapid Stabilization : Pneumatic drills with 800–1,200 rpm speeds quickly insert screws or plates, crucial for polytrauma cases requiring timesensitive intervention.

Reduced SoftTissue Damage : Lowvibration designs (<2 µm amplitude) minimize secondary injury to muscles and vasculature during fracture reduction.

4.Orthopedic Oncology and Reconstructive Surgery

Margin Control : High precision burrs (e.g., 3–5 mm diameter) allow en bloc resection of bone tumors while sparing healthy tissue.

Customization : Support patient specific guides via 3Dprinted templates, improving accuracy in pelvic reconstructions.

Future Directions

The next generation of surgical power tools will focus on:

Smart Integration : AIdriven platforms for realtime decision making, such as navigation systems paired with robotic arms (e.g., Medtronic’s Mazor XC).

Miniaturization and Portability : Compact devices for ambulatory settings,which combines highspeed drilling with adaptive torque control for small bone surgeries.

Sustainability : Reusable, energy efficient designs to lower costs and environmental impact.

Localized Innovation : Aligning with China’s push for "localized智造" (intelligent manufacturing) to meet regional clinical needs.

Challenges and Industry Trends

Cost Barriers : High R&D and regulatory expenses limit accessibility in developing regions.

Training Demands : Surgeons require specialized training to master advanced systems.

Market Competition : Dominance by global players like Stryker and Medtronic pressures local manufacturers to innovate.

Conclusion

Surgical power tools have transformed modern medicine, balancing precision, efficiency, and safety. As technologies evolve, collaboration between global leaders and local innovators will drive accessibility and affordability. Future breakthroughs in AI, robotics, and energy systems promise to redefine surgical paradigms, ultimately improving patient outcomes worldwide.

0 notes

Text

From Breadboards to Breakthroughs: Hands-On Projects to Improve Your EE Skills

From Breadboards to Breakthroughs” encapsulates the journey of an aspiring electrical engineer as they evolve from basic circuit experiments to advanced, real-world engineering projects. Hands-on projects are essential for building practical skills, reinforcing theoretical knowledge, and preparing for professional challenges. Below is a guide to project-based learning that can help you improve your electrical engineering (EE) skills at every stage.

Beginner Projects: Building Foundations

Simple LED Circuit

What you learn: Basic circuit design, current and voltage concepts, use of resistors and LEDs.

Tools: Breadboard, jumper wires, resistors, LEDs, battery.

Battery Tester:

· What you learn: Measuring voltage and current, basic instrumentation, and safety practices.

Water Level Indicator

What you learn: Sensor integration, simple logic circuits, and practical applications.

Logic Gates and Digital Circuits: What you learn: Boolean logic, digital circuit fundamentals, and troubleshooting.

DIY Switch Circuits: What you learn: Circuit switching, input/output devices, and practical wiring.

Intermediate Projects: Expanding Your Skills

Infrared Security System: What you learn: Sensor-based security, signal processing, and system integration.

Digital Voltmeter: What you learn: Instrumentation, analog-to-digital conversion, and measurement accuracy.

Solar Charger: What you learn: Renewable energy concepts, power management, and circuit protection.

Motor Control Circuits

What you learn: Driving motors, pulse-width modulation (PWM), and power electronics.

Heart Rate Monitor: What you learn: Biomedical instrumentation, sensor interfacing, and signal filtering.

Advanced Projects: Real-World Breakthroughs

Smart Home Automation System: What you learn: IoT, wireless communication (Bluetooth, Wi-Fi), and system integration.

Wireless Power Transfer System: What you learn: Inductive coupling, resonant circuits, and energy efficiency.

Dual Axis Solar Power Tracker: What you learn: Mechatronics, sensor feedback, and renewable energy optimization.

Smart Energy Meter: What you learn: Real-time data monitoring, wireless communication, and energy management.

DIY Quadcopter or Drone: What you learn: Embedded systems, motor control, wireless communication, and robotics.

Why Hands-On Projects Matter

Resume Building: Practical projects demonstrate your skills to potential employers and can help you land internships or jobs

Theory Application: Projects bridge the gap between classroom learning and real-world engineering challenges.

Skill Discovery: Experimenting with different projects helps you identify your interests and strengths.

How to Get Started

Gather Basic Tools: Invest in a quality breadboard, jumper wires, resistors, capacitors, LEDs, and a multimeter.

Start Simple: Begin with basic circuits and gradually tackle more complex projects as your confidence grows.

Use Online Resources: Take advantage of tutorials, simulation tools, and open-source project guides.

Join Maker Communities: Engage with online forums, local maker spaces, and engineering clubs for support and inspiration.

Document Your Work: Keep a project journal, take photos, and share your progress on platforms like GitHub or LinkedIn.

Conclusion

Arya College of Engineering & I.T. is one of the best engineeering college in Jaipur, which is progressing from breadboard experiments to advanced engineering projects is a transformative process that builds both technical expertise and problem-solving confidence. By systematically advancing through beginner, intermediate, and advanced projects, you will develop a robust skill set that prepares you for the challenges and opportunities of a career in electrical engineering.

Source: Click Here

#best btech college in jaipur#top engineering college in jaipur#best private engineering college in jaipur#best engineering college in rajasthan#best btech college in rajasthan#best engineering college in jaipur

0 notes

Text

Embedded Control Software Systems: Powering Intelligent Automation

Embedded control software systems are the unseen brains behind many of today’s most advanced technologies. From industrial machines and automotive systems to consumer electronics and medical devices, these systems ensure that everything operates efficiently, safely, and reliably. Embedded control software is a combination of software and hardware engineered to perform dedicated control functions within larger systems, often with real-time constraints and minimal user interaction.

This article explores what embedded control software systems are, how they work, their architecture, applications, benefits, and challenges.

What is an Embedded Control Software System?

An embedded control software system consists of three main components:

Embedded Hardware (Microcontroller or Microprocessor) – This is the processing unit that executes the control logic.

Control Algorithms (Software) – Written in programming languages like C or C++, these define the behavior of the system based on inputs and desired outputs.

Sensors and Actuators – Sensors provide feedback from the environment (e.g., temperature, speed), while actuators carry out control actions (e.g., motor movement).

These systems are “embedded” because they are integrated into larger products, and they typically perform one or more specific control functions rather than general-purpose computing tasks.

Key Features of Embedded Control Software

Real-Time Operation: Embedded control software often operates in real time, meaning it must respond to inputs within a strict time frame.

Determinism: The system must behave in a predictable manner, particularly in safety-critical applications like automotive or aerospace.

Low Power and Resource Constraints: Many embedded systems are deployed on hardware with limited processing power, memory, and energy.

Reliability and Robustness: Since embedded systems are often deployed in harsh environments, they must be stable and resistant to failure.

Minimal User Interaction: Most embedded control systems are designed to operate with limited or no user interface.

Architecture of Embedded Control Systems

Input Interface: Collects data from sensors or communication channels.

Control Software: Applies algorithms (e.g., PID, fuzzy logic, model predictive control) to decide what action should be taken based on inputs.

Output Interface: Sends control signals to actuators (motors, valves, lights, etc.).

Feedback Loop: Ensures the system continuously adjusts itself based on output performance.

For example, in an automotive cruise control system:

Input: Speed sensor measures vehicle speed.

Control Software: Compares current speed with desired speed.

Output: Sends signals to the throttle actuator to maintain or change speed.

Feedback: Adjusts continuously as road conditions or driver input change.

Applications of Embedded Control Software Systems

1. Automotive Industry

Engine control units (ECUs)

Anti-lock braking systems (ABS)

Adaptive cruise control

Lane-keeping assistance

Airbag deployment systems

2. Industrial Automation

Programmable logic controllers (PLCs)

Robotic arms

Process control in manufacturing lines

Condition monitoring systems

3. Consumer Electronics

Smart thermostats

Washing machines

Microwave ovens

Smart TVs and remote controllers

4. Aerospace and Defense

Flight control systems

Missile guidance

Radar systems

UAV navigation

5. Healthcare

Medical infusion pumps

MRI and imaging equipment

Wearable health monitors

Automated ventilators

Development Process for Embedded Control Software

Requirement Analysis: Define functional and non-functional requirements, such as timing constraints and energy consumption.

System Design: Select hardware platform and define software architecture.

Algorithm Development: Create control logic using mathematical models or empirical rules.

Implementation: Code the algorithms using languages like C, C++, or model-based tools such as MATLAB/Simulink.

Simulation and Testing: Validate performance through simulation, hardware-in-the-loop (HIL) testing, and real-world trials.

Deployment and Maintenance: Deploy code to the embedded hardware and ensure updates or bug fixes are managed safely.

Model-Based Design in Embedded Control

A growing trend in embedded control software development is model-based design (MBD). Engineers use graphical models to design, simulate, and automatically generate code for control algorithms. Tools like Simulink allow for rapid prototyping, reduced coding errors, and quicker time to market. This is especially useful for systems that require frequent iterations or are highly complex.

Benefits of Embedded Control Software Systems

Efficiency: Optimizes system performance, energy use, and functionality.

Precision: Ensures accurate control in critical applications like medical devices and aerospace.

Cost-Effectiveness: Minimizes the need for manual intervention and large hardware setups.

Scalability: Can be tailored for use in simple household gadgets or complex industrial machinery.

Safety and Reliability: Especially in automotive and aviation, embedded control systems contribute to increased safety through reliable automation.

Challenges in Embedded Control Software Development

Real-Time Constraints: Meeting strict timing requirements can be difficult.

Resource Limitations: Must operate on hardware with limited memory and processing capabilities.

Debugging Complexity: Difficult to test systems in real-time without disrupting performance.

Cybersecurity Risks: Increased connectivity (IoT integration) exposes systems to potential attacks.

Maintenance and Upgrades: Embedded systems often need to be updated securely, especially in remote or critical applications.

Future Trends in Embedded Control Systems

AI and Machine Learning Integration: Adaptive systems that learn from data for more intelligent control.

Edge Computing: Processing control logic closer to the source (sensors/actuators) to reduce latency.

Wireless and IoT Connectivity: Embedded systems communicating via 5G or other wireless protocols.

Open-Source Platforms: Tools like Arduino and Raspberry Pi are making embedded control development more accessible.

Conclusion

Embedded control software systems by Servotechinc are the cornerstone of modern intelligent automation. By integrating sensors, control algorithms, and actuators into compact, efficient packages, these systems bring intelligence to machines across countless industries. Whether improving the safety of vehicles, the precision of medical devices, or the efficiency of industrial processes, embedded control systems play a pivotal role in shaping a smarter, more connected world.

0 notes

Text

Magnetic Sensor Market Outlook Strengthened by Advancements in MEMS and Miniaturized Technologies

The magnetic sensor market is witnessing robust growth due to the increasing demand for accurate, contactless sensing technologies across various industries. These sensors detect changes in magnetic fields and are integral to applications such as automotive systems, consumer electronics, industrial automation, and healthcare equipment. With advancements in technologies such as MEMS (Micro-Electro-Mechanical Systems) and IoT integration, magnetic sensors have become more compact, sensitive, and energy-efficient, enabling widespread adoption.

Market Overview

Magnetic sensors operate on principles like the Hall effect, magnetoresistance, and fluxgate sensing. These sensors are typically used to detect position, rotation, speed, and current. The global market was valued at approximately USD 3 billion in 2023 and is projected to surpass USD 5 billion by 2030, growing at a CAGR of around 6.5%. This growth is driven by the rising incorporation of magnetic sensors in emerging sectors like electric vehicles (EVs), renewable energy systems, and smart devices.

Key Drivers of Growth

1. Automotive Industry Evolution: The automotive sector continues to be the largest end-user of magnetic sensors. They are essential for electronic stability control, anti-lock braking systems, gear shift indicators, and current measurement in electric motors. The global shift toward electric and hybrid vehicles is fueling the demand for more sophisticated sensor systems to enhance energy efficiency and vehicle safety.

2. Expansion of Consumer Electronics: Smartphones, tablets, laptops, and wearable devices increasingly rely on magnetic sensors for compass functions, screen rotation, and user interface interactions. As manufacturers aim for more compact and efficient designs, magnetic sensors with higher sensitivity and lower power consumption are in high demand.

3. Growth in Industrial Automation: The adoption of Industry 4.0 and increased demand for precision in industrial processes are pushing manufacturers to integrate magnetic sensors in robotics, conveyor systems, and process control tools. Their durability and ability to operate in harsh environments make them ideal for industrial applications.

4. Medical and Healthcare Innovations: In medical technology, magnetic sensors are utilized in devices such as insulin pumps, pacemakers, and MRI machines. As healthcare providers increasingly adopt non-invasive and remote monitoring technologies, magnetic sensors are playing a pivotal role in improving patient care.

Technological Advancements

Recent advancements have led to the development of TMR (Tunneling Magnetoresistance) and GMR (Giant Magnetoresistance) sensors, which offer superior sensitivity, lower energy consumption, and smaller footprints compared to traditional Hall-effect sensors. These innovations are crucial for enabling new applications and expanding into miniaturized electronics and IoT devices.

The integration of magnetic sensors with wireless communication modules has also improved their adaptability in smart grids, home automation, and connected infrastructure. This synergy between hardware and connectivity is opening new market segments and creating opportunities for tech startups and established players alike.

Regional Insights

Asia-Pacific dominates the magnetic sensor market, driven by the presence of major consumer electronics manufacturers in countries like China, South Korea, and Japan. The region’s dominance is further solidified by government support for smart manufacturing and electric mobility initiatives.

North America and Europe follow closely, with increasing demand in automotive, industrial automation, and healthcare sectors. In Europe, the strict regulations on vehicular emissions and safety standards are compelling automakers to integrate more sensor-based systems.

Competitive Landscape

The market is moderately fragmented, with key players including Allegro Microsystems, Honeywell, TDK Corporation, Infineon Technologies, and NXP Semiconductors. These companies are investing heavily in R&D to improve sensor sensitivity, reduce size, and enable multifunctional integration. Strategic collaborations, mergers, and acquisitions are also shaping the competitive dynamics.

Startups and emerging players are focusing on niche applications such as augmented reality (AR), smart wearables, and autonomous systems, driving innovation and expanding the scope of magnetic sensor usage.

Challenges and Opportunities

Despite its strong growth trajectory, the magnetic sensor market faces challenges such as pricing pressure, especially in low-end consumer segments, and technical complexity in integrating sensors with other systems. However, increasing R&D investments and growing demand for customized solutions offer significant opportunities.

0 notes