#Pre-engineering Structure

Explore tagged Tumblr posts

Text

The Role of Heavy Steel Fabrication in Construction and Infrastructure

Introduction

When it comes to constructing robust buildings, bridges, and other critical infrastructure in Noida, the Best heavy steel fabrication in Noida plays an indispensable role. This article delves into the world of heavy steel fabrication, highlighting its importance, techniques, and applications in the construction and infrastructure sectors.

Understanding Heavy Steel Fabrication

What is Heavy Steel Fabrication?

Heavy steel fabrication is a specialized process involving the cutting, shaping, and assembly of large steel components to create structural elements used in various construction projects.

The Significance of Heavy Steel Fabrication in Noida

In the rapidly growing city of Noida, heavy steel fabrication is the backbone of infrastructure development. Its role in ensuring sturdy and durable construction cannot be overstated.

Techniques of Heavy Steel Fabrication

Cutting and Shaping Steel

The process begins with the precision cutting and shaping of steel sheets and beams to meet the exact specifications of the project.

Welding and Joining

Welding techniques, such as arc welding and gas welding, are employed to fuse steel components securely, ensuring structural integrity.

Surface Treatment

Surface treatments, like sandblasting and galvanization, protect steel from corrosion and enhance its longevity, especially important in Noida's humid climate.

Applications in Construction

Skyscrapers and High-Rises

Heavy steel fabrication is pivotal in the construction of tall buildings, providing the necessary support and stability for these iconic structures.

Bridges and Infrastructure

Noida's network of bridges and infrastructure heavily relies on heavy steel fabrication for its robustness and load-bearing capabilities.

Industrial Facilities

Factories and industrial facilities in Delhi NCR depend on the best heavy steel fabrication in Noida, for structural components that can withstand heavy machinery and equipment.

Sustainability in Heavy Steel Fabrication

Eco-Friendly Practices

Efforts to reduce the environmental footprint of heavy steel fabrication include recycling and sustainable sourcing of steel materials.

Energy Efficiency

In Noida's climate, energy-efficient fabrication methods are essential for reducing greenhouse gas emissions associated with steel production.

Innovations and Future Trends

Automation and Robotics

The industry is evolving with the integration of automation and robotics, increasing precision and efficiency.

Advanced Materials

New steel alloys and composite materials are being developed to enhance strength and reduce weight, revolutionizing construction.

Conclusion

In Noida, heavy steel fabrication is not just a construction technique; it's the backbone of infrastructure development. Its significance in guaranteeing the strength and durability of buildings and bridges cannot be emphasized enough. As the city experiences continuous growth, heavy steel fabrication in Noida will continue to lead in innovation, playing a pivotal role in creating a safer and more environmentally sustainable urban landscape.

FAQs

Q: How does heavy steel fabrication contribute to earthquake resistance in Noida?

Heavy steel fabrication provides the structural strength necessary to withstand seismic forces, safeguarding buildings and infrastructure during earthquakes.

Q: What is the average cost difference between heavy steel and other construction materials in Noida?

While the expense associated with heavy steel fabrication can fluctuate, its remarkable durability and long-lasting nature consistently render it a financially prudent option over the course of time.

Q: Are there any eco-friendly heavy steel fabrication companies in Noida?

Yes, some fabricators in Noida prioritize sustainability by adopting green practices in their production processes.

Q: Can heavy steel fabrication be used in residential construction projects in Noida?

Certainly! Heavy steel fabrication can be employed in various residential projects, providing strength and safety.

Q: How long does it take to complete a typical heavy steel fabrication project in Noida?

The timeline for heavy steel fabrication projects varies depending on complexity, but efficiency and precision are prioritized to meet deadlines.

Q: What are the main challenges faced by heavy steel fabricators in Noida?

Challenges may include sourcing high-quality steel, skilled labour shortages, and compliance with safety and environmental regulations.

#Fabricaton#Mild Steel Fabrication in Delhi NCR#Sheet Metal Fabrication#Pre-engineering Structure#Stainless Steel Fabrication#Sheet Metal Component Manufacturer#Structural Fabrication Services#Bridge Manufacturing in Delhi#Canopy Manufacturers in Delhi

1 note

·

View note

Text

2 notes

·

View notes

Text

PEB Plant

#pre engineered buildings manufacturer#pre engineered building structure#Pre engineered building solution#pre engineered building fabricators#pre engineered metal building manufacturers#Pre-engineered metal buildings#PEB construction companies#PEB suppliers#Industrial building manufacturers#Commercial building manufacturers#Warehouse manufacturers#Factory building manufacturers#PEB manufacturers in India#Construction equipment manufacturers#Building material manufacturers

2 notes

·

View notes

Text

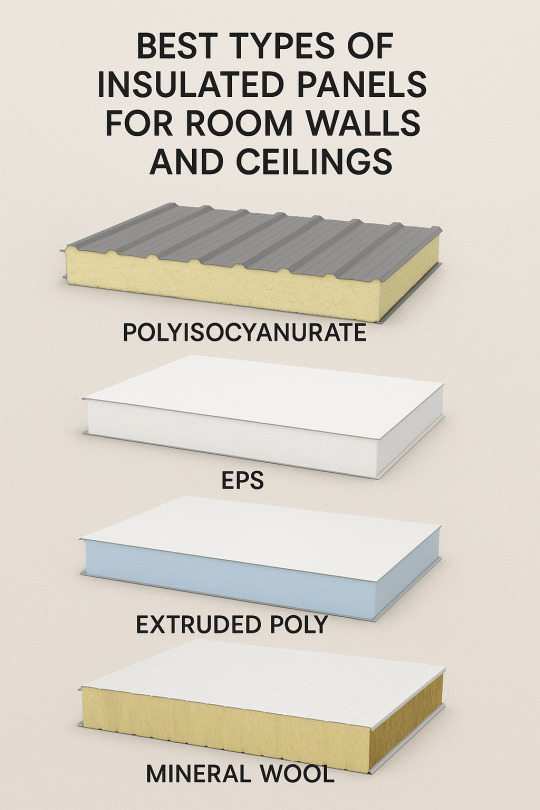

Best Types of Insulated Panels for Room Walls and Ceilings

In modern construction, energy efficiency, durability, and speed are more important than ever. Whether you're building a residential home, commercial office, warehouse, or prefab structure, choosing the right insulation for walls and ceilings is key to maintaining indoor comfort and reducing energy costs.

Insulated panels are prefabricated systems that combine insulation and structural support in a single solution. They’re ideal for temperature control, noise reduction, and structural strength. Here's a look at the best types of insulated panels for room walls and ceilings, each with its own advantages:

1. Polyisocyanurate (PIR) Panels

Polyisocyanurate, or PIR, is one of the highest-performing thermal insulation materials used in construction today. These panels consist of rigid foam sandwiched between two metal or board layers.

Key Benefits:

Superior thermal efficiency – high R-value per inch

Fire resistance – self-extinguishing properties

Lightweight and durable – easy to handle and install

Moisture resistance – ideal for both indoor and outdoor use

PIR panels are ideal for temperature-controlled spaces such as cold storage, server rooms, and industrial buildings.

2. Expanded Polystyrene (EPS) Panels

EPS panels are made from expanded polystyrene foam, known for its excellent insulating properties and cost-effectiveness. These panels are widely used in prefabricated and modular buildings.

Key Benefits:

Affordable insulation solution

Good thermal and acoustic performance

Lightweight and easy to cut or install

Environmentally friendly and recyclable

EPS panels are great for residential rooms, partitions, and standard prefab structures where cost and speed are priorities.

3. Extruded Polystyrene (XPS) Panels

Extruded polystyrene is a denser and stronger form of polystyrene insulation. XPS panels offer excellent thermal performance and resistance to moisture, making them ideal for high-humidity environments.

Key Benefits:

High compressive strength

Excellent moisture and water resistance

Smooth surface finish

Long-term durability

These panels are often used for roofs, ceilings, basements, and cold storage facilities.

4. Mineral Wool Panels

Mineral wool (or rock wool) panels are made from natural stone or slag fibers. Known for their fire resistance and soundproofing qualities, these panels are ideal for buildings where fire safety is a top priority.

Key Benefits:

Non-combustible and fire-resistant

Excellent sound insulation

Resistant to pests, mold, and rot

Eco-friendly and recyclable

They are commonly used in commercial and industrial spaces, especially in applications requiring acoustic control and fire safety.

Conclusion

The choice of insulated panels depends on your building's requirements—whether it’s superior thermal performance, moisture resistance, acoustic insulation, or fire safety.

Polyisocyanurate is best for energy efficiency, EPS offers an economical and lightweight option, XPS excels in moisture-prone areas, and Mineral Wool provides unbeatable fire and sound insulation.

Investing in the right insulation solution helps you reduce energy bills, enhance occupant comfort, and extend the life of your building.

Looking for high-quality insulated panel solutions? Partner with trusted manufacturers like Engko for expert guidance and top-grade materials tailored to your project.

#prefab#pre engineered building manufacturers#prefabricated#peb#prefabricated structure#warehouse#industrial

1 note

·

View note

Text

When planning a construction project, one of the first and most critical decisions you must make is choosing between Pre Engineered Buildings (PEBs) and conventional buildings. Each comes with its own set of advantages and challenges. However, with the rise in modern infrastructure demands, many industries are shifting toward pre engineered buildings due to their flexibility, efficiency, and cost-effectiveness.

#peb structure manufacturer in india#pre engineered building suppliers#pre engineered buildings#pre-engineered building structure

0 notes

Text

Top Pre Engineered Building Supplier Tamil Nadu – Mount Roofing & Structures Pvt Ltd

Mount Roofing & Structures Pvt Ltd is a trusted name when it comes to industrial infrastructure. As a leading Pre Engineered Building Supplier Tamil Nadu, we provide durable, cost-effective, and customized PEB structures designed to meet modern industrial demands. Our expertise lies in delivering full-scale solutions for warehouses, factories, logistics hubs, showrooms, and other commercial facilities across South India.

If you're looking for a reliable Pre Engineered Building Manufacturer in Chennai, Mount Roof offers factory-fabricated steel structures built with precision engineering and fast-track execution. Our buildings are made with high-tensile steel and follow strict quality protocols to ensure long-lasting performance, energy efficiency, and low maintenance.

With a client-focused approach and turnkey services from design to installation, Mount Roofing is your dependable partner for industrial growth.

📍 Address: SLR Complex, No. 57, Kottigepalya - Magadi Main Road, Bangalore, Karnataka, India – 560091 📞 Phone: +91 96060 83685 📧 Email: [email protected]

🔗 Social Media: Twitter: https://x.com/Mountpeb Facebook: https://www.facebook.com/mountroofing Instagram: https://www.instagram.com/mountroofing/ LinkedIn: https://www.linkedin.com/company/mount-roofing-and-structures-pvt-ltd/ YouTube: https://www.youtube.com/@mountroofing

#Pre-engineered Steel Building#Pre Engineered Building Suppli#Manufacturer Companies#Pre Engineered Building Construction Company#Pre Engineered Building Manufacturer#Pre-engineered Building Structure Manufacturer Companies#Pre Engineered Building Suppliers.

1 note

·

View note

Text

#peb structures#peb manufacturers in maharashtra#peb manufacturers in india#pre engineered building manufacturers in india#peb building manufacturers in india#peb suppliers#prefab company in india#peb manufacturing companies#top peb manufacturers in india#top peb company in india#peb factory#pre building#pre engineered buildings#peb building#pre eng building#peb company#peb vendors#peb suppliers in india#prefab manufacturing#pre engineering building company in india#steel structures#peb engineering building#pre engineered building structures#peb engineering#peb steel structures#peb manufacturers near me#pre engineered structures#peb fabricators#peb steel buildings#peb manufacturers

1 note

·

View note

Text

Top Pre Engineered Building Suppliers in Bangalore

Mount Roofing – Karnataka’s Preferred PEB Partner

Looking for a Pre Engineered Building Suppliers you can trust? Mount Roofing & Structures Pvt Ltd delivers unmatched quality, precision, and service in PEB manufacturing and supply across South India. From structural design to fabrication and on-site installation, we ensure every element is engineered for excellence.

Comprehensive PEB Supply Chain

Our PEB solutions are ideal for industrial sheds, warehouse facilities, institutional buildings, and commercial establishments. With pre-fabricated steel components manufactured in-house, we ensure fast, seamless delivery and setup across project sites.

Why Mount Roofing?

Premium-grade steel with tested durability

End-to-end logistics and material handling

Timely delivery and reliable construction schedules

Technical assistance throughout project execution

Cost-effective, long-lasting performance

We are more than suppliers — we are long-term partners committed to delivering consistent value for your construction projects.

📍 Contact Details Mount Roofing & Structures Pvt Ltd SLR Complex, No. 57, Kottigepalya - Magadi Main Road, Bangalore, Karnataka, India – 560091

📞 Phone: +91 96060 83685 📧 Email: [email protected]

🌐 Social Media Profiles: Twitter/X: https://x.com/Mountpeb Facebook: https://www.facebook.com/mountroofing Instagram: https://www.instagram.com/mountroofing/ LinkedIn: https://www.linkedin.com/company/mount-roofing-and-structures-pvt-ltd/ YouTube: https://www.youtube.com/@mountroofing

#Pre-engineered Steel Building#Pre Engineered Building Suppli#Manufacturer Companies#Pre Engineered Building Construction Company#Pre Engineered Building Manufacturer#Pre-engineered Building Structure Manufacturer Companies#Pre Engineered Building Suppliers.

0 notes

Text

APL Apollo uses advanced technology for manufacturing Apollo DFT structural steel tubes available in rectangular, square, and circular sections. DFT tubes are used for various pre-engineered building solutions.

#steel tube#steel tubes#steel building#steel buildings#tubular construction#steel construction#peb#pre engineered buildings#tubular structures#apl apollo#apollo dft

0 notes

Text

Pre-Engineered Steel Buildings & Prime Locations in Pune

#Pre-engineered steel buildings#PEB structures#Pre-fabricated steel structures#Identifying prime locations#Prime real estate locations#Commercial property locations#https://www.primainfracorp.com/the-future-of-construction.php

0 notes

Text

Bunk House Manufacture in India — A Complete Guide

India’s diverse geography and economy creates the need to bunk house manufacturing within India to be able to accommodate the wide variety of weather conditions and logistical difficulties. From the coastal regions that have high humidity, to remote regions in the north that require insulation, the production process can be adapted to a variety of conditions and needs.

One of the primary factors that have led to the popularity of bunk houses that is being built in India lies in the utilization of the latest technological advancements and the use of modular construction techniques. The mobile units are usually constructed with sturdy steel frames and premium panels that ensure security, durability, and simple maintenance. In addition, manufacturers have embraced environmentally friendly practices, including green materials and energy efficient design, making bunk homes not only convenient, but also eco-friendly.

Bunk House Manufacture in India

Bunk House Manufacturing in India has become an industry of significance, offering quick, flexible, and reliable workspace and accommodation solutions. These structures that are portable are used in a variety of industries, including construction mining, oil and gas as well as healthcare, education as well as relief from disasters. The increasing demand for them is a reflection of the national push for faster development and infrastructure.

Why Bunk House Manufacture in India is in High Demand

The growing number of industries in rural and developing regions has led to the need for temporary homes as well as office space. Bunk House Manufacture in India responds to this need by providing cost-effective and efficient modular solutions. The units are built to be sturdy, portable and simple to set up that makes them perfect for projects that are constantly changing.

The Process Behind Bunk House Manufacture in India

Understanding the process involved in the manufacturing of bunk houses in India uncovers the high-end technological precision and accuracy involved. The best materials, such as the steel frame, panels with insulation along with corrosion-resistant finishings are utilized. The structures are constructed in controlled conditions in the factory, which ensures the same quality and speedier time-to-market. The bunk houses are designed with safety, comfort and efficiency in the forefront.

Customization in Bunk House Manufacture in India

Customization is among the most attractive aspects in bunk house production from India. Customers can pick layouts, interior fittings sanitation options and air conditioning systems and electrical layouts based on their individual specifications. If it’s a one-room apartment as well as a large office building Manufacturers are well-equipped to offer customized solutions.

Advantages of Bunk House Manufacture in India

Bunk house production in India offers a variety of advantages. These buildings are lightweight sturdy, durable and able to withstand extreme environmental conditions. They are transportable easily and set quickly on the spot. They are modular in nature, which means they can be expanded or altered depending on the need. They also require little site preparation, which can save time and money.

Applications of Bunk House Manufacture in India

The possibilities for the production of bunk houses of bunk houses in India is extensive. They are utilized as camps for labor sites offices, classrooms and clinics, storage facilities and even temporary residences. Their flexibility in design allows them to be used for many different sectors and uses such as industrial zones and remote rural regions.

Sustainable Bunk House Manufacture in India

The environment is becoming a key aspect of manufacturing bunk houses within India. Numerous manufacturers are utilizing eco-friendly materials and are incorporating features such as the use of solar energy, harvesting rainwater as well as natural air ventilation. This is not only reducing the impact on the environment but also assists customers to achieve green building standards.

Quality Standards in Bunk House Manufacture in India

The strictest quality standards are adhered to when it comes to the production of bunk houses within India. The factories employ precision equipment and skilled workers to ensure that each unit is in compliance with quality, safety and usability benchmarks. From fire-proof insulation to electrical security systems that are secure, each component is tested thoroughly before being delivered.

Smart Solutions in Bunk House Manufacture in India

Innovation is propelling bunk house manufacturing and construction in India to the next level. Modern technologies, such as the remote monitor, integrated communications systems and automation are now integrated in modern-day bunk homes. These improvements improve the safety as well as the overall user experience, which makes them more than only temporary shelters.

Future of Bunk House Manufacture in India

Future prospects for manufacturing bunk houses in India appears promising. With India investing heavily in smart cities and infrastructure the demand for mobile and adaptable housing solutions will only increase. Manufacturers are constantly responding to market needs and technological advances, which ensures longevity of the industry.

Role of Government in Bunk House Manufacture in India

Government initiatives such as “Make in India” and rapid infrastructure policies have significantly helped the manufacturing of bunk homes within India. Large-scale public-private partnerships as well as large-scale initiatives to develop across the states are promoting local manufacturing and fostering forward the development of the sector.

Employment Accommodation via Bunk Manufacture of Houses in India

One of the primary applications of bunk houses manufactured within India is to provide labor accommodation. Large industrial and construction projects require comfortable and clean accommodation for employees. Bunk homes are an efficient solution that provides security, privacy, and ease of use in compact and well-organized spaces.

On-Site Offices via Bunk House Manufacture in India

Bunk house manufacturing from India is an ideal option for offices on site. Mobile units are used as administrative centres on projects, allowing teams to run operations effectively without requiring permanent infrastructure.

Rapid Deployment in Bunk House Manufacture in India

In the event of an emergency or disaster, bunk house manufacture in India allows for rapid deployment of shelters and relief centres. Their ease of transportation and placement are essential in times of emergency providing immediate shelter and medical services.

Long-Term Value derived from Bunk House Manufacturing in India

Though they’re considered as temporary, the structures created by the manufacture of bunk houses in India provide long-term value. They require minimal maintenance they are also reusable and are able to be moved as necessary. Reusability is a major factor in their overall cost-effectiveness over time.

FAQs — Bunk House Manufacture in India

Q1. What is the definition of bunk house production in India What is bunk house manufacture in India?

A It is the design and construction of modular, portable workstations and housing units that are designed for mobile or temporary needs in various industries across India.

Q2. What are the uses of bunk houses in India

The answer is that they serve as accommodation for workers as mobile clinics, offices classrooms, storage units as well as relief shelters.

Q3. Can you customize bunk house manufacturing in India A:

Yes customers can alter the layout, size as well as electrical works, among other aspects.

Q4. Are bunkhouses weatherproof Are they weatherproof?

they’re designed to stand up to India’s varied climate, which includes rain, heat, and freezing temperatures.

Q5. What is the time it takes to construct a bunk home

The manufacturing and delivery timeframes differ based on the type of design, but generally are rapid due to the factory-based production.

Q6. Does the production of bunk houses in India green?

Numerous manufacturers are using eco-friendly materials and energy efficient systems to promote sustainability.

Q7. Can these bunk houses be reused Yes.

They can be taken apart and moved repeatedly across various places.

0 notes

Text

Why Choose EcoPeb for Your Next Industrial Shed Project?

When planning an industrial shed project, the quality of the structure, construction speed, and cost-efficiency matter most.

That’s where EcoPeb, a trusted name in Pre-Engineered Buildings (PEBs), comes in. With years of expertise and a strong track record, EcoPeb is redefining how industrial sheds are built—faster, smarter, and more sustainably.

Engineered for Excellence

EcoPeb specializes in high-performance PEB structures that are tailored to meet the unique needs of industrial operations, be it manufacturing, warehousing, or logistics.

Every structure is factory-fabricated with precision, ensuring:

High load-bearing capacity

Long-lasting durability

Minimal on-site errors

Speedy Turnaround

Time is money in business. Our pre-engineered approach reduces construction timelines by up to 50% compared to conventional methods. From design to delivery, EcoPeb ensures your shed is ready in weeks—not months.

Cost-Effective Solutions

EcoPeb’s smart design and manufacturing process minimize material wastage and labour costs. Our clients typically save up to 30% on total project costs while getting superior quality.

Quality Assurance

EcoPeb follows ISO-certified processes, ensuring strict quality checks at every stage. From raw material selection to final installation, we maintain international standards in safety, durability, and structural integrity.

Sustainable Construction

Sustainability is not an afterthought—it’s a priority. EcoPeb uses recyclable steel, energy-efficient designs, and minimal site disruption techniques, making us the ideal partner for businesses that care about the environment.

Local Expertise, Pan-India Reach

Whether you’re in Gurgaon, Faridabad, Kolkata, or anywhere in India, EcoPeb has the network and logistics to serve you quickly and efficiently. Our regional teams understand local compliance and climate considerations.

Trusted by Industry Leaders

Over the years, we’ve delivered sheds for leading companies across sectors. Our client-first approach ensures on-time delivery, transparent pricing, and end-to-end support.

Ready to Build Smarter?

Choose EcoPeb for a future-ready industrial shed that combines strength, speed, and sustainability.

Contact us today for a free consultation or a site visit.

https://ecopeb.com/pre-engineered-buildings/

#pre engineered structure manufacturer#peb building#pre engineered buildings#branding#peb solution#pre engineered building#peb manufacturer#ecopeb

0 notes

Text

https://primainfracorp.com/pre-engineered-steel-buildings

#Pre-engineered steel buildings#PEB structures#Pre-fabricated steel structures#Industrial steel buildings#Commercial steel buildings#Pre-engineered constructed buildings

0 notes

Text

Prefab Structures vs Pre-Engineered Buildings: What’s the Difference?

In today’s fast-paced construction landscape, Prefab Structures and Pre-Engineered Buildings (PEBs) have revolutionized the way we build. Both methods offer significant benefits over traditional construction—speed, efficiency, cost-effectiveness—but they are not the same. If you're planning a project and trying to decide between the two, understanding the key differences can help you make an informed decision.

What Are Prefab Structures?

Prefab (Prefabricated) Structures refer to buildings or components manufactured off-site in a controlled environment and then transported to the site for assembly. These structures can range from small kiosks to modular homes, site offices, and even industrial shelters.

Key Features of Prefab Structures:

Modular Construction: Built in sections (modules) that can be easily transported and assembled.

Material Variety: Often made from a combination of steel, wood, concrete, and insulation materials.

Highly Customizable: Designs can be adjusted for size, layout, and purpose.

Fast Installation: Reduces on-site labor and construction time drastically.

Versatility: Commonly used for temporary or semi-permanent installations like railway shelters, portable cabins, and remote site offices.

What Are Pre-Engineered Buildings (PEBs)?

Pre-Engineered Buildings are steel structures designed and fabricated in a factory using a predetermined inventory of raw materials and components. These are engineered to exact specifications, ensuring structural efficiency and cost optimization.

Key Features of PEBs:

Steel Framework: Built primarily from structural steel members such as columns, rafters, and purlins.

Engineered Precision: Each component is designed for load, wind, and seismic resistance.

Suitable for Large Spans: Ideal for industrial buildings, warehouses, exhibition halls, and aircraft hangars.

Durability & Strength: Designed to last for decades with minimal maintenance.

Scalable & Expandable: Easy to modify or expand in the future.

Prefab vs PEB: Head-to-Head Comparison

Which One Should You Choose?

Choose Prefab Structures if you're looking for quick deployment, mobility, and flexibility—for example, a site office, temporary housing, or a railway shelter.

Choose PEBs if your project demands long-term durability, large interior spaces, and structural strength, such as warehouses, showrooms, or manufacturing units.

Final Thoughts

While prefab and pre-engineered buildings both offer modern solutions to conventional construction, their uses, strengths, and structures differ considerably. Selecting the right approach depends on your project goals, timeline, budget, and scale.

Still unsure? At Engko, we specialize in both prefab structures and PEBs, and can guide you in choosing the right solution tailored to your needs. Contact us today to discuss your project.

1 note

·

View note

Text

Mahawar Group specializes in high-quality pre engineered buildings tailored to industrial and commercial needs. We offer expert manufacturing and installation services to ensure strong, durable, and cost-effective structures. Our team focuses on timely delivery and precision engineering. Choose Mahawar Group for trusted solutions in steel construction. Visit our website to know more about our customized PEB services and project capabilities.

#pre engineered buildings#peb structure manufacturer#pre engineered steel buildings#peb construction company

1 note

·

View note

Text

We are the best pre-engineered buildings manufacturers who are known for providing top-notch, durable structures according to your needs. We can help create durable roofs which can sustain harsh weather conditions and are also long-lasting.

#Pre-Engineered Buildings Manufacturer in India#Metal Building Accessories and Solutions in India#Z and C Purlin Manufacturers and Suppliers in India#Metal Deck Manufacturers#Structural Roof Decking#Standing Seam Roof Manufacturers and Suppliers.

0 notes