#Metal Deck Manufacturers

Text

Pre-Engineered Buildings Manufacturer in Pune | India

The structural frame of this metal enclosure building includes standard wall and roof supports. The Pre Engineered Building is made in the factory and then built on location. As the top PEB structure builder in the business, we offer customized solutions to satisfy each company's particular needs and guarantee a superior product with blazingly quick installation.

#Pre-Engineered Buildings Manufacturer in India#Metal Building Accessories and Solutions in India#Z and C Purlin Manufacturers and Suppliers in India#Metal Deck Manufacturers#Structural Roof Decking#Standing Seam Roof Manufacturers and Suppliers

0 notes

Text

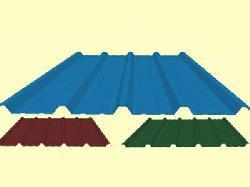

Top-Quality Roofing Solutions from a Leading Metal Deck Sheet Manufacturer in Gurgaon

Are you in search of reliable roofing solutions in Gurgaon? Look no further! As a premier Metal Deck Sheet Manufacturer in Gurgaon, we provide top-of-the-line metal deck sheets, corrugated roofing sheets, and other high-quality roofing materials to meet your construction needs. Our products are designed for durability, aesthetic appeal, and easy installation, making them the perfect choice for a variety of projects.

#Metal deck sheet manufacturer in gurgaon#Corrugated roofing sheets manufacturer in gurgaon#Roofing sheets manufacturer in gurgaon

0 notes

Text

instagram

Take your construction projects to the next level with SteelDECK52 - the cost-effective, speedy, and superior solution for streamlined construction. Connect with us to explore how we can support your specific project requirements and goals.

.

Visit Us: www.steeldeckingsheets.com

Contact Us: [email protected]| 8550995556

#steeldeck #steeldecks #deckingsheet #highwayconstruction #industrialcontractor #roadcontractors #roadconstruction #deckdepth

#deck profile sheet#deck sheet#decking steel#decking profile sheet manufacturer#decking sheets#decking sheet price#metal deck sheet#steel decking sheet#gi decking sheet#deck sheet profile#jsw deck sheet#metal deck sheet price#deck sheet manufacturer in india#decking sheet for bridges#Instagram

0 notes

Text

PEB companies in Hyderabad

NSPL is the fastest growing PEB company in Hyderabad they are one of the oldest PEB companies in Hyderabad having an experience of 3 decades and constructed over 30 million square feet within no time, NSPL is the oldest steel fabrication company in Hyderabad not only makes the PEB sheds but also they are one of the largest PEB components manufacturers in Hyderabad, their catalog includes color coated sheets, decking sheets, anchor bolts, sag rods and many more with over 3 decades of experience NSPL stands out as one of the best PEB companies in Hyderabad.

Contact: 09121612990

Address : Manoharabad (V) Toopran (M), Medak (Dist.), Telangana - 502336.

PEB companies in Hyderabad,

steel fabrication companies in Hyderabad,

PEB shed manufacturers in Hyderabad,

decking sheets,

1 mm thick deck sheet,

deck sheet roofing,

concrete decking sheets,

concrete deck sheet slab,

metal deck sheets.

#PEB companies in Hyderabad#steel fabrication companies in Hyderabad#PEB shed manufacturers in Hyderabad#1 mm thick deck sheet#decking sheets#deck sheet roofing#concrete decking sheets#concrete deck sheet slab#metal deck sheets

1 note

·

View note

Text

Alright I can't finish this all in one sitting, but here's at least a bit of.... something? A word vomit? A prelude to smut about the eroticism of the machine? For all you robot, mecha, and spaceship fuckers out there. @k1nky-r0b0t-g1rl that means you

Pappy always said that manufacturing biological transportation was nothing knew. I mean, shit, humanity's been breeding horses for how long? To him, not much was novel about what was going on in the shipyards way out by Neptune when I was a kid.

But Pappy didn't know a lot of things. And he certainly didn't meet Roseanna.

The Federation Navy had experimented with biologics for decades. The idea was to create self regenerating ships- something to interface with the hull, move the new titanium plates and particulates into place, have a living, growing mass interfacing with the steel so that the ship didn't have to head all the way back to the yards to patch up after every dogfight.

The first generation... worked. With a full time crew, that is. Full time people on deck jabbin the rigid, chitonous interface with the hull full of growth hormones to get them to set just right. Full time onboard bioengineers to compute what signaling cocktail ya need to hit 'em with to get it to grow back right. Skilled onboard technicians to shave back the chitin when it tried to overgrow the titanium, and slap some new cells in to seed the process in heavily damaged areas. Less input material, less time in the yards, but far more manpower. Great for a Federation cruiser on deep space peacekeeping missions. Far too complex for small craft. Right?

Until some bastard put brains in 'em.

Well. A lotta suits would say that they weren't brains. They were a diffuse network of sensory neurons and ganglia, living inside the body of the ship, integrating signals from a skin of alloyed metal and fibrous protein, calculating power draw too and from various components, and integrating with the mechanical and electrical components of the ship to precisely manage the "wound healing" process of the vessel. And of course, it just so happened that one of those ganglia was larger and more complex than the rest of them, and it just so happened that the computer interfaces with this ganglia exhibit complex, thinking behaviors on the level of human cognition, and it just so happens that most pilots and navigators reported them developing their own personalities.....

But of course, the Navy didn't want anyone to have some kind of pesky empathy in the way of their operations. And they certainly didn't want anyone side eyeing the rate at which they disposed of the damn things, and let them suffer and rot after disposal. So as far as the official record was concerned, they didn't have brains.

Like most people in the belt, I found Rosie on a... unsponsored field trip to the Neptune scrap yards. She wasn't a ship then. She wasn't much of anything. Not much more than a vat with the central ganglia and just barely enough of the stem cells needed to regrow a network. But I took her all the same. Brains were valuable. Few pilots outside the Navy had them back then. Nowadays, a black market for "brain seeds", a cocktail of neuronal stem cells and enough structural stem cells to grow your own into the chassis of your ship. They were pumpin' em out, and leaving them to die. It was cruel. They may be vehicles, but they're a livin' being too.

But I digress. I'd never do that to Roseanna. I make sure she gets proper care. And for a good, proper, working ship? That includes some good, proper work.

The asteroid we were docked in was one of my usuals- good bars, nice temp quarters, nice views of the rock's orbiting twin, and a spacious hanger for Rosie to rest in. The chasiss I had imprinted Roseanna to was a 40-meter light skipper, with some adjustments for handling deep space trips. It was pretty much the smallest thing you could actually use to live and work for long periods of time, but it got the job done. The angular design made the entire ship look like a wedge, or the blade of a bulky dagger. It didn't hurt that each bottom edge was fortified with a sharpened titanium blade, turning the entire sides of the ship into axe-like rams.

Those would probably come in handy today.

I approached Roseanna on the catwalk above her, marveling her alloyed scales. I could almost see her shudder in anticipation as my footsteps vibrated through the air above her. I took the steps down, and hit the trigger to open her top hatch.

When the news got out of the Navy scuffling with a rebelling mining station, an electric air raced across the station. Some went about their day as normal. Some resigned themselves to picking at the leftovers after the dust had settled. And some, like me, knew that they could get the finest pickings.

I strapped in to the pilot's seat like it was an old boot.

"Welcome, Captain Victoria."

Rosie could talk, but more often than not, she chose not to. But she understood me just fine. Most of our communication took place using her three prerecorded lines- her welcome statement, affirmative, and negative- as well as the tiny screen showing a small, emoticon face. Many pilots chose to give their ships an elaborate render, but Rosie preferred it this way. It was the first face I gave her, from somewhere out of the scrap heaps, and she refused any offer I made to upgrade. Secretly, I was overjoyed. To me, that was her face. That was her voice. And it was beautiful to see her true self through them.

I brushed my hands across her paneling. Across the switches, the hydraulic controls for the plasma fuel, the steering, the boosts, the comms channels. The thing with biologics was that you were still the pilot. For whatever reason, they hadn't quite gotten to the point where the brains could take over their own piloting. My personal opinion was just that their personalities lacked the ambition to. But whatever reason that was, the best pilots were still the ones that knew both their ship, and the ship's brain. And me and Rosie? We knew each other well.

As my fingers touched the brushed aluminum controls, rimmed with chitinous layers rooting them into the ship, I could feel the walls around me holding their invisible breath. "Do you know what we're doing today, Rosie?"

Her tiny panel flickered on. ...?

"We got a scrap run."

^_^

:)

^_^

Her panel flicked between various expressions of excitement. My finger quivered on the main power, holding for a moment before flicking it on. The primary electronics of the ship hummed to life, and what Rosie controlled pulsed with it. My hands moved across the main functional panels- main hydraulic plasma valve, exhaust ports open, and finally, flicking the switch the start the plasma burner.

My hands gripped the steering. The hanger's airlock doors opened in front of me. My neck length hair started to float as the station's gravity shut off. I hit the switch to unlatch from the supports above. For a moment, we hang there. The dull crackle of the idling plasma burner is the only sound that resonates through Rosie's hull.

Go time.

I punch the boost.

#eroticism of the machine#robot girl#mecha girl#spaceship girl#the fuck do I even tag this LOL#yall gotta tag this and make sure it gets to the right spaces for me okay

274 notes

·

View notes

Text

Biologics, chapter 0.5

Hello, hello! I finally have added a significant amount to my story, Biologics, resulting in a total of ~4400 words. Not a whole ton, I know, but unfortunately life gets to ya. It isn't quite where I want it to be to consider a proper chapter one, but I feel like there's enough written for me to post. General warning that this is intended to heavily lean into the theme of "eroticism of the machine", so if that doesn't appeal to you, you've been warned. It does, however, have many general sci fi worldbuilding elements, so I hope it has a somewhat broad appeal!

So yes, if you already read the first snippet, that's going to be mostly a one to one repeat with some grammatical adjustments. Feel free to scroll down until you get to the new stuff. Flow-wise, there just wasn't a good place to break between the two sections.

Look at me rambling. And I wonder why I can't get any of this stuff done. Anyways, here it is!

Biologics

Pappy always said that manufacturing biological transportation was nothing knew. I mean, shit, humanity's been breeding horses for how long? To him, not much was novel about what was going on in the shipyards way out by Neptune when I was a kid.

But Pappy didn't know a lot of things. And he certainly didn't meet Roseanna.

The Federation Navy had experimented with Biologics for decades. The idea was to create self regenerating ships- organic matter that interfaced with the hull, moving new titanium plates and patches into place down to microscopic precision. If you had a living, growing mass interfacing with steel, a ship didn't have to head all the way back to the yards to patch up after every dogfight.

The first generation... worked. With a full time crew, that is. Full time people on deck jabbin the rigid, chitonous matrix full of growth hormones to get them to set just right. Full time onboard bioengineers to compute what signaling cocktail ya need to hit 'em with to get it to grow back right. Skilled onboard technicians to shave back the chitin when it tried to overgrow the titanium, and slap some new cells in to seed the process in heavily damaged areas. Less input material, less time in the yards, but far more manpower. Great for a Federation cruiser on deep space peacekeeping missions. Far too complex for small craft. Right?

Until some bastard put brains in 'em.

Well. A lotta suits would say that they weren't brains. They were a diffuse network of sensory neurons and ganglia, living inside the body of the ship, integrating signals from a skin of alloyed metal and fibrous protein, calculating power draw too and from various components, integrated with the mechanical and electrical components of the ship to precisely manage the "wound healing" process of the vessel. And of course, it just so happened that one of those ganglia was larger and more complex than the rest of them, and it just so happened that the computer interfaces with this ganglia exhibit complex, thinking behaviors on the level of human cognition, and it just so happens that most pilots and navigators reported them developing their own personalities.....

But of course, the Navy didn't want anyone to have some kind of pesky empathy in the way of their operations. And they certainly didn't want anyone side eyeing the rate at which they disposed of the damn things, just to let them suffer and rot. So as far as the official record was concerned, they weren't brains. But I knew different.

Like most people in the belt, I found Rosie on an... unsponsored field trip to the Neptune scrap yards. She wasn't a ship then. She wasn't much of anything. Not much more than a vat with the central ganglia and just barely enough of the stem cells needed to regrow a network. But I took her all the same. Brains were valuable. Few pilots outside the Navy had them back then. Nowadays, a black market for "brain seeds", a cocktail of neuronal stem cells and enough structural stem cells to grow your own into the chassis of your ship, was thriving. The Navy was pumpin' em out, and leaving them to die. It was cruel. Sometimes, being scavenged and resold was a kinder fate. But more often, some nasty piece of work would pick them up eventually, and treat them like just another goddamn ship. They may be vehicles, but they're a livin' being too.

I digress. I'd never do that to Roseanna. I make sure she gets proper care. And for a good, proper, working ship? That includes some good, proper work.

The asteroid we were docked in was one of my usuals- good bars, nice temp quarters, nice views of the rock's orbiting twin, and a spacious hanger for Rosie to rest in. The chassis I had imprinted Roseanna to was a 40-meter light skipper, with some adjustments for handling deep space trips, as well as some... personal touches. It was pretty much the smallest thing you could actually use to live in and work for long periods of time, but it got the job done. The angular design made the entire ship look like a wedge, or the blade of a bulky dagger. It didn't hurt that each bottom edge was fortified with a sharpened titanium blade, turning the entire sides of the ship into axe-like rams.

Those would probably come in handy today.

I approached Roseanna on the catwalk above her, marveling her alloyed scales. I could almost see her shudder in anticipation as my footsteps vibrated through the air above her. I took the steps down, and hit the trigger to open her top hatch.

When the news got out of the Navy scuffling with a rebelling mining station, an electric air raced across the station. Some went about their day as normal. Some resigned themselves to picking at the leftovers after the dust had settled. And some, like me, knew that they could get the finest pickings.

I slipped into the pilot's seat like it was an old boot.

"Welcome, Captain Victoria."

Rosie could talk, but more often than not, she chose not to. But she understood me just fine. Most of our communication took place using her three prerecorded lines- her welcome statement, affirmative, and negative- as well as a tiny screen showing a small, emoticon face. Many pilots chose to give their ships an elaborate render, but Rosie preferred it this way. It was the first face I gave her, from somewhere out of the scrap heaps, and she refused any offer I made to upgrade. Hell, she even had a hi-res screen for external cameras and comms, but she refused to interface directly with it. Secretly, I was overjoyed. To me, the little pixelated screen was her face. That was her voice. And it was beautiful to see her true self through them.

I brushed my hands across her paneling. Across the switches, the hydraulic controls for the plasma fuel, the steering, the boosts, the comms channels. The thing with Biologics was that you were still the pilot. For whatever reason, they hadn't quite gotten to the point where the brains could take over their own piloting. My personal opinion was just that their personalities lacked the ambition to. Cuz they certainly could take over some ships functions directly, and had the skill to do complex mechanical and electrical tasks. The Navy never let 'em drive, though, and most pilots didn't even know they could give them the ability to control any of the ships functions directly. But with a little help, a little bit of solid engineering, and a pilot that knew their ship... well, you could do a lot. And me and Rosie? We knew each other well. Over the years, I'd added some nice things for her, and she loved using them to help me out.

As my fingers touched the brushed aluminum controls, rimmed with chitinous layers affixing them to the ship, I could feel the walls around me holding their invisible breath. "Do you know what we're doing today, Rosie?"

Her tiny panel flickered on.

[...?]

"We got a scrap run."

[ ^_^]

[ :) ]

[ ^_^ ]

Her panel flicked between various expressions of excitement. My finger quivered on the main power, holding for a moment before flicking it on. The primary electronics of the ship hummed to life, and the parts Rosie controlled pulsed with it. My hands moved across the main functional panels- main hydraulic plasma valve, exhaust ports open, and finally, flicking the switch the start the plasma burner.

My hands gripped the steering. The hanger's airlock doors opened in front of me. My neck length hair started to float as the station's gravity shut off. I hit the switch to unlatch from the supports above. For a moment, we hang there. The dull crackle of the idling plasma burner is the only sound that resonates through Rosie's hull.

Go time. I punch the boost.

The station shakes. Rosie was never a subtle one.

The mechanics are deafened.

The crowd of spectators are deafened.

The other pilots in the hanger are deafened.

But me? The vibrations of Rosie's hull shuddering under me was the sweetest symphony my ears ever had the pleasure of hearing. As we shot out of that hanger, I found myself involuntarily humming a high note, harmonizing with the sweet rumble of my baby's acceleration as we shoot out into the inky, black expanse of space. The twin asteroids shot by us as we disappeared, leaving only the faint blue plasma trail from our engines.

My hand is firm on the boost, weathered hands tightly gripping the bar of the accelerator. I remember installing this thing in her- it was an aftermarket adjustment, not included in the usual light skipper chassis. Gently stripping away the back of her chassis, caressing her insides as I rooted the paneling, firmly attaching the tanks and burners on her insides... these hands had taken great pleasure in that. Bested only, of course, by the first time I had felt the thing roar to life.

And what a feeling it was. Rosie's entire chassis, biological and mechanical, shuddering under my grasp. The grip of my calloused hands on the boost controls, tight and sweaty around the ridged grip of the horizontal bar. The noises she made, as if to shout in glee and wild abandon at being unchained and let loose into the eternal field of space, as she was made to do. The gentle touch of her skin on my back, my body pressed in contact with the small fraction of hers that was my seat. I glanced down at her face panel.

[ :| ]

[ :D ]

[ :| ]

[ :D ]

[ :| ]

[ :D ]

[ :| ]

[ :D ]

My humming gave way to a chuckle, and then a wholehearted, exhilarated laugh. Someone was enjoying herself. The flickering faces on her panel reminded me of the happily panting station dogs back on Mars.

But as much as I would like this to just be a joyride, I had promised Rosie a scrap run. And the pickings were looking good. I glanced down at the nav. I was intentionally headed at a slightly indirect angle- Rosie's boost was her main attractive feature (both as a ship, and as a working partner), and the extra leeway I had in travel time let me strategize a bit more. I doubted we would be the first people there, but I figured we could get in before the main rush. The only trouble was darting in and grabbing something right from under the noses of the first locusts. The scrap field in question included a disabled heavy mining freighter, a goliath of the ship larger than some of the asteroids it made supply runs between. I assumed that most other scavengers would be approaching directly from our station, and the other stations in its proximity. With Rosie's boost, we could overshoot, hook around, and put the freighter in between us and the guns of the more violent craft. Rosie has no long range weapons of any kind- not only would they slow down her miraculous speed, but she didn't like them. I tried installing a small plasma cannon once, and she expressed immense distaste. Maybe they were too brutish for her, or maybe she didn't like the way they felt inside her, burdening her with pressure from the inside that didn't befit the delicate touches I usually graced her with. Rosie loved speed, precision, elegance, and stealth above all else. It's just the kind of ship she was.

That's not to say she was a pacifist, or defenseless. Quite the contrary. She just prefers a more... personal touch.

The navicom beeped at me. We'd reached the point where we needed to make that hook. My bare feet gently swept across the titanium flooring to the steering pedals. My right hand delicately gripped the steering joystick, while my left eased its grip on the boost accelerator.

"Ready for this, darling?"

[ >:) ]

I slammed the steering to the left, and Rosie gleefully complied. The wide bank of the turn as we rotated and soared through the sea of stars twisted my body in its inertia, compressing me further into her. As the angle straightened out to the proper heading, I punched the boost again, and Rosie roared forward.

Slowly, our target came into sight. Damn. This thing had taken some serious damage. Mining freighters typically weren't heavily armored- their only job was to get material from point A to B- but this one had clearly been through some serious modifications. Modifications that now lay in ruin. Titanium plating was scattered in a field around the core of the freighter. I couldn't quite tell what was stuff left behind by the battle, and what was the result of shoddy craftmanship- but it didn't matter. What did matter was that the entire thing had been split almost in half, and the scattered cargo that was leaking out. Cargo that most likely included half the weapon supplies of this little rebel faction. Would fetch a pretty penny, to the right buyer. And hell, if it was just gonna sit here unclaimed...

Ah shit. It wasn't gonna sit here unclaimed. Despite my best efforts, it looks like we weren't the first ones here. A larger scavenger gang had already arrived, and it looks like it was one of the ones I knew- Augustus and his lot. Most likely, they'd be after the weapons intact, one more thing to use to shakedown the scattered independent stations I always flitted between. He would not be happy to see me n Rosie here. What he called his "fleet" was a single, mid-sized carrier ship, about half the size of the freighter we were looting, and the dozen or so scout fighters and strip mining crafts he had looted from the Navy and various corps, and one Biologic that he called his. I respect that part, to be honest. What I don't respect is him immediately turning around and using that charge every goddamn station his ever-increasing "protection fees". Not to mention my personal disdain for the way he treated his ship. Didn't even give her a damn name. I digress. But any chance to loot something from under that slimebag's nose was a win in my book. I knew he wasn't gonna make it easy, though.

Welp. That's what our positioning was for. The side facing us was the main starboard face, and like the rest of the ship, it was peppered in small holes and gashes. Seems like the main damage had happened from the other side, and a few cables and scaffolds on the starboard just barely kept the two rear cargo compartments clinging to the front.

"Alright Rosie, time to creep it in slow. Be quiet, now, don't want them picking up a plasma surge"

[ :| ]

Ha. That was her "my lips are sealed" face. She's having fun with this already.

I cut the booster, coasting closer and closer to the bust open vessel. I eased the reverse thrusters ever so slightly, my fingers gently stroking the dual brake levers, lightly teasing at them to wait until we were as close as I thought we could be without attracted attention.......... before slamming both sides back towards me. For just one, crucial moment.

The goal here was to approximately match the speed and trajectory of a floating piece of titanium plating. Rosie's frontal blades were essentially that, anyways, so all they would see is a somewhat more angular piece of rubble. Hopefully they hadn't seen that same piece of rubble screaming out of travel speed, but I was cautious enough with my distances that I didn't think that was a problem. And they hadn't seen me yet. Once we were close enough to the freighter itself, we were blocked from their raw sightline, and Rosie was running quiet enough to not tip off any of their energy sensors.

But there was still no guarantee. Rosie, however, had no shortage of tricks. Something that she and I had developed together was a nice little bit of snooping. Well cared for and well trained, a Biologic brain had the problem solving of a human, and the computational power of a machine. But them together, and you've got a perfect decoder. And I happened to know that Augustus used an encrypted local frequency to keep his

"Alright Rosie, thinkin you can eavesdrop a little?"

Affirmative.

[...]

[...]

[...]

[...]

[...]

[...]

[..!]

:D

My comms crackled to life. "...7 heavy cannons in center-front portside bay, 3 replacement fighter hatchs...."

The comms crackled back and forth, with each pilot giving updates to what they were finding in their own little segment that they were slicing apart. Occasionally, I saw Augustus or the fighters flick between the slicing ships, overseeing their progress on the port bays. Good. Let them focus on the other side for now. Slowly, the fleet was overshadowed by the freighter. We made it. I released my breath- shit, didn't realize I was holding it- and took a better look at what we were dealing with. It looked as if the scattered debris field had mostly been the remnants of the hull, as well as light weapons for small craft and even infantry. They would fetch some small change, sure, but Rosie's cargo capacity was small. Packing efficiency was the name of the game. I saw the gash that it had all been flooding out of on this side- the entire freighter was covered in them- and peered inside. And ho boy, did my heart flutter.

Heavy cannons.

Jump-graded travel boosters.

Raw, precious metals.

And, hidden in the back corner, seemingly bolted into the wall.... a brain.

We'd hit jackpot, and potentially rescued a poor ship from abandonment, or worse.

"Alright Rosie. Time to get to work."

Affirmative.

And here was another lil something that made Rosie special- her manipulation arms . She always preferred that delicate touch, and wanted to interact with the world in a tactile, real way. So we worked on it. Together. I was tired of taking spacewalks to grab small pieces of scrap, or using the entire goddamn cargo bay on a piece that only had a tiny core, or scraps of precious metals inside. So we needed something that could pluck apart our finds. Do some light disassembly in the field, extract what was valuable, and load it in with the most packing efficiency possible. So I gave her arms- snake like appendages, coiled up in her cargo bay, with thousands of points of articulation. At first, I tried to make some kind of control system that I could use from the cockpit. But Rosie had a different idea. At her urged, I jacked them directly into the same sensory and motor systems that let her grip onto, position, and repair her hull. And by god, it worked.

When I showed her off the first time, no one had ever seen anything like it. Because there was nothing like it. A ship taking real mechanical control, over something so precise and delicate, was something that only a deeply intelligent, deeply skilled ship, with complex decision making and tactile movement could do.

And I was goddamn proud of her.

Every time she deployed them, I watched awe. Rosie gave a face of determination, and sinuous, metallic, tentacle-like appendages slid out in a bundle from the cargo bay opening on her underside. Each one was headed off by a different attachment- a precision laser cutter, a simple three-pointed grabbing claw, a drill, a tiny buzzsaw, camera that let me see what was going on, and more. Each one could be swapped out, depending on the task at hand. With eight of them slithering out from her cargo bay, though, there was usually something for everything. They extended out as a single bouquet, down through the hole of the cargo compartment, and split apart once inside. Each arm got to work.

Her observation monitor flickered on, giving me a view from the camera arm. I would've liked to get the brain out first, but two heavy cannons and a booster blocking the way anyways. We'd cut through that, picking off the energy cores and precious metals in the circuits as we go, and work our way towards the back. Rosie seemed to like the plan as well. My only job was to watch the comms, and watch the sensors.

I watched the camera as the petite tools of the arms excised and picked apart the titanium shell of the first heavy cannon. Her tools- the delicate 'fingers' of her arms- picked, pulled, tugged, and gently gripped every necessary notch, every joined titanium plate that needed to be undone, ever scrap of precious material. Firm, yet precise. Strong, yet never breaking or mishandling a single piece of cargo. As Rosie worked, my eyes darted across the energy sensors. I could see blips firing off as the ships on the other side of the freighter as the slicing ships worked and flitted between their stations from the other side. The comms crackled with their reports to Augustus- they seemed to be moving back and forth to the main carrier to drop off their hauls. It seemed like they had a lot to go through- we'd have plenty of time.

On the camera view, I could see a grabbing claw retracting back through the cargo bay. The first cannon had the back section cleanly excised from the massive barrel and chassis, leaving a path for the tools to get to the booster. The precious energy cell was sliding its way back into Rosie's cargo bay. God damn. She was quick with that. The laser cutter and saw were already making short work of the booster, too. We'd get to the brain in no time.

The chatter on the other line continued. We were still safe, but Augustus' crew had made more progress than I had hoped. Once the slicers had picked apart the port, they'd loop around to the starboard. We had to grab what we could as fast as we can- but I knew neither me or Rosie was gonna leave without that brain. Rosie gracefully sliced the fuel cell and ignition from the plasma burner, leaving the bracketing and vents behind. The second heavy cannon was soon to follow. Each cut through each piece had left a winding path towards the back of the chamber, allowing a physical path to what I had seen just barely poking through: a container for a genuine ship's brain. Rosie slid her camera arm in for a closer look.

The brain was bolted into the chassis of the ship, as well as some containers of growth factor. Seemed like the intent was to grow her in to this freighter. That was certainly an ambitious task, but if they knew what they were doing, it would be well worth it. A self-repairing, intelligent hauler as large as this one would be the heart and soul of resistance movements everywhere, supplying every backwater mining station or moon that longed to be free. Unfortunately, the brave and principled can still be stupid, and these chucklefucks had no idea what they were doing. Slapped in a random cargo bay, desperately trying to get growth out from there with no proper imprinting guidance... shame. If they'd've found me before running into the Navy, I might've helped them out. But at least now, we could give her a better life. I knew a lot of good, caring pilots that would take loving care of a fine ship like her.

From what I could tell, we were still safe from Augustus. Based on what I was hearing on the comms, each slicer was working on its last cargo hold subsection, and after that, they'd be poking around this side. We had to get this brain and get out.

Tenderly, her claw arm gripped the top of the brain's chamber, as her other fingers started working on the rivets. A saw would bust through part of the titanium bracket holding the chamber down, and when it got too close to the container itself, laser cutters took over, delicately slicing off each affixation point one by one. Rosie worked in a clockwise direction, first working down the three riveting points on the right, sawing off the bottom bracket, and then working up the rivets on the left.

C'mon Rosie. You got this. Just need the top plate....

"Finishing up there, slicer 5T?"

Shit. That was Augustus on the comms.

"Sure thing boss. Just gotta get this load to central. Mind if someone takes a peek on the other side for parasites before I get there?"

Shit.

"Sure thing. Fighter 3A, get your ass in gear and make a full pass of the ship."

An energy spike pinged on my sensor panels as the fighter revved up a booster.

"Gotcha boss. Starting at aft segment."

Shitshitshitshitshitshitshitshitshitshitshit

We still had a sliver of time before we were seen. They'd wanna get a good pass everywhere- there were ships far stealthier than us out there. But it was minutes at most. We had to finish up.

"Rosie, how're we doing there? You done?"

Negative.

[ ;( ]

"Fuck. Rosie, we gotta get outta here."

Affirmative. Affirmative. Affirmative. Affirmative.

Rosie-speak for "I know, I know, I know"

My eyes were fixed to the scanner and my cockpit windows for a visual, but I spared one moment to check Rosie's cam. She was finishing sawing through the top bracket. Just a little more....

"Aft clear, moving to starboard cargo bays."

The brain snapped off of the hull, and Rosie's claws were zipping it back to her cargo bay. I revved the engines into standby. The arms tenderly guided it through the path we had cleared, and out through the hole in the hull. We might be able to barely slip away without them knowing.....

I looked up through the cockpit, just as the dinged-up, formerly Navy fighter showed itself from behind a piece of debris. It froze for a moment, and then lined its nose to face me. Cannon ports shifted open, and slowly took aim.

"Well shit, Augustus, you're gonna wanna see this. Get your ass over here, I'm switching to public comms."

I heard slight fuzz as he switched his channel.

"Alright, leech, I'll keep this simple. You have thirty seconds to relinquish your haul before you join the debris."

For a single, cold moment, I swear I made eye contact with him through our cockpits.

#writing#sierra writes#biologics#robotfucker#eroticism of the machine#story#sci fi story#scifi#scifi story

92 notes

·

View notes

Text

nowhere to hide out in the open

summary: the one good thing about these 'Genre Peace' meetings, it would be that Delta Dawn has an excuse to be next to Queen Essence

warnings: its just fluff

authors note: EVERYONE SAY THANK YOU TO @ohposhers FOR DRAGGING ME OUT OF RETIREMENT BY MAKING DELTESSENCE REAL INSTEAD OF LETTING IT ROT IN OUR DM'S FROM MARCH, LITERALLY DRAGGED THIS FIC OUT FROM THE BACK AND FINISHED IT UP IN 2 HOURS NOT EVEN. anyways hope ya'll enjoy and if ya do consider dropping a reblog or checkin' the Ao3 port

To be frank, Delta Dawn didn't necessarily enjoy the fact that the genre leaders had to meet up in Funk's spaceship of sorts; they called it Vibe City. The deck may have been solid beneath her hooves and the air perfectly metered in temperature, but it still felt wrong. Just something made her feel off about living up here, especially when they used to inhabit the deserts and oasis's below.

The only plus was the fact that she was allowed a seat next to Queen Essence, Funk's co-ruler. Pale blue fur and glistening silver tinsel littered across her form and like necklaces on her neck. A spattering of glitter on her face and golden adornments in her hair, voice a gentle timbre and comfy pace-

Delta Dawn definitely enjoyed her, and the fact that she was married with children.

"Now, Queen Poppy, are you sure we really need to unite geographically as well?" Trollzart asked, and the annoying sound of his voice snapped Delta out of it. He sounded like a 'woodwind,' as the Classical's called those instruments.

"Yeah, Popseed, I quite like Volcano Rock City. The Rocker's need some heat to keep us going," Barb tacked on, voice sharp as always with a blunt edge that Delta respected. Even if the gal tried to destroy all music, she had good work ethic.

Poppy gave a nervous laugh, "Well we could at least try making a place where the cross-genre's and genrefluid Trolls could exist in peace?"

"A utopia," King Quincy supplies.

"A Trollstopia, if you will," Queen Essence adds on.

"The only problem with that is the Techno's, they can't be out of water for prolonged periods of time," Branch said. He was already splaying out blueprints, "I'll work on a fix."

"I can help manufacture it," Trollex said and his voice also had an annoying sting too it out of water, oddly synthetic but natural to their speciation.

"Dawn," Queen Essence said, and it took Delta a moment to realize she was referring to her.

The sheriff of Country nodded, "Yes, miss Essence?" Country sensibilities sneaking into her speech again, she really hopes that isn't an offence in Funk.

Instead it makes Queen Essence smile, "Do you have any objections to this Trollstopia?" There's a softness to her tone, a calm that Delta doesn't know too well. Everyone's much gruffer in Country, more to the point and strict about it. Working together is loving each other and tussling in a rodeo is a love language.

Funk Trolls are so... Different, in a refreshing way of course. It's confusing too, Delta never took herself for a romantic, but the Queen is doing something to her. And it's just how she exists too, even when they aren't interacting she's just like this. Smooth and calm and with an amount of allure that Delta is sure must be practiced in advance.

"I got no objections to it, I think it's a great idea," Delta said before standing up and pushing aside the cushion she sat upon. At the slightest hint of Poppy going to speak up, she waved it off, "I'm fine, Queen Poppy, I just need to stretch my legs, get some water."

Her hooves clicked uncomfortably against the metal-adjacent platforms below her. She rubbed her temples as she walked, taking long, deep breaths to try and compose herself. How on earth do they expect her to keep it together when they put her beside Queen Essence? She shouldn't be getting this worked up over a married Troll.

"Dawn, you're probably gonna need some help finding the vending machines," Came a gentle voice from behind her and all she could do was freeze up.

"Naw, I'll be fine, Queen Essence," Delta said, turning to give her an affirming smile. It looked kind of forced.

"Please, just call me Essence," She said before leading Delta along and the sheriff followed without questioning her own actions despite her previous defiance.

Delta gives a huffing sort of sound, it earns her a perplexed look before she remembers that the Funk Trolls don't have that in their lexicon, "Then I have ta ask that you call me Delta."

Essence gives a long hum as she pads down the halls, her paws are near silent against the flooring. A stark contrast to the clip-clop of Delta's hooves, "I'll see what I can do for you."

The slight teasing lilt coupled with a small chuckle has Delta going mad. She trots up closer to the queen of Funk and follows her obediently down the halls. The swirled design of Funk architecture matches the consistent beat thrumming below them in the main corridors. It pulses with a faint glow, so subtle it's almost unnoticable unless you really look close- and Delta needs something to stare at that isn't her guide.

When they come to a stop Essence grabs her a bottle of water, gifted in return for a small melody in a genre Delta doesn't know well. It's interesting technology really, maybe Country is outdated after all. Then she remembers that Pop still lives in the woods and hasn't rebuilt after they had their empire swept out from under their feet by the Bergens. Her genre isn't too far behind, and Funk is highly advanced anyways.

"So, Delta, what's got you down?" Essence asked, dropping down to sit with folded legs on a cushion. Delta followed suit, a low table between them, and she didn't quite sit the same way Funk Trolls did but she made it happen.

"Nothin's got me down," Delta said, twisting the cap off the bottle, "Don't know what gave you that idea."

Essence's brows furrowed, but she didn't narrow her gaze much. She just sighed, "I can't be offended that you don't want to tell me, but I can be offended that you think I can't see what's right in front of me."

That shakes Delta down to her core, she didn't expect Essence to have such keen observations as well. She nearly chokes on her water which has a tang too it, a hint of citrus flavouring perhaps? She wipes her mouth with the back of her hand, "I suppose I shouldn't treat ya like an idiot cause you're different than me."

"Some signs are universal," Essence said, "And your vibes aren't exactly feeling on point."

Delta gives a low laugh, "You have a point there, Queen Essence. You're mighty smart, mighty tenacious for waiting so long for your son to show up."

Essence smiles a smile that's so warm it contradicts the soothing frosted hue of her form. She tilts her head a bit as she smiles, a small laugh arising and she brings a paw to hide it. "I'm flattered, Dawn."

"Essence, you seem like the loving type," Delta begins, "Happily married and whatnot."

"So it's a romance problem you have."

She nods, "Yeah, that. What would you say is the best action for loving someone whose already set for life?"

That gives Essence pause, and she's more than clever enough to piece it together right then and there, but she still takes a moment. "In Funk we're usually pretty open, most relations are fluid and shifting states frequently."

"They are?" Delta asked a bit too fast.

"Of course they are, Delta. Are they not in other genres?" Essence asked, a genuine curiosity lacing her voice.

Delta shakes her head, "We're rather monogamous in Country."

"Tell me, Delta," Essence begins, a type of smile on her face that makes Delta shiver. Essence leans a little bit closer, "Is it me?"

"What gave it away, your majesty?" Delta asked.

"Country Trolls are very up front, it translates to the way you act," Essence explained before pressing a kiss to Delta's cheek. It left a silvery, snowy mark in its wake and Delta was too stunned to move. It made Essence giggle a bit.

"But, but you're royalty!" Delta managed to get out, "Doesn't royalty have ta keep a closed relationship?"

Essence shrugged and the tinsel shifted and coat the technicolor glow of Vibe City. "Quincy is understanding, I doubt he'd mind if we let you in for a bit."

"Well alright then." She's not in a cohesive enough mindset to get anything else out of her mouth. She's wearing this dumb grin on her face that's quick to fall.

Essence brings a paw to Delta's face, "What's wrong, darling?"

"Nothin' that needs to be worried about now," Delta brings her hand to rest on Essence's wrist, or ankle maybe? Delta isn't too sure of the proper terminology to use.

"You got your legs stretched out enough to head back, Dawn? They can't make much progress without Country," Essence asked.

"I'm ready," Delta said before standing up, she traced a digit across the lipstick mark on her cheek, "Say, won't this be incriminating evidence?"

"Quincy won't mind," Essence assured with a hum.

"The others?"

"They're in our home, we can evict them."

#trolls#trolls fanfic#trolls fanfiction#deltessence#trolls deltessence#delta dawn#queen essence#writing#fanfic#fanfiction

33 notes

·

View notes

Text

The Joker and The Dogs

Personally, I keep both in the deck. I need as much information as I can. Even more than I can handle sometimes.

It's easier to settle into knowledge over time than to let the mystery catch you.

The Joker is a trickster, neither good nor evil. The Joker is the chaotic beauty and terror of living on earth. Of living on earth in a body.

Of living in a body that dies. Of living in a body that dies more often and worse because it is Black.

If there wasn't a Joker, we would have to invent it. Which, if you are living in America, we did.

The Joker isn’t welcome in every game. It's a space of possibility and intention and mis/fortune.

Game of Tricks

Euchre, the game for which the Joker was invented, has an origin story as murky as the Joker's. Some credit its origin to France, others to Germany. Little proof is available.

Card reading has a way of obscuring its origins. The tales are full of apocrypha. There's no way to decipher which thread is longest.

You will believe as you believe.

What we know is that the Joker came to be during the American Civil War. What we know is that Euchre is literally a game of tricks.

In a trick-taking game, each player lays down a card on a set timeline. All cannot win in a single trick. One will, some won't.

This is the very nature of the Joker.

On his 1863 Joker, Samuel Hart, a playing card manufacturer in Philadelphia, put a dog on his.

1863 is the turning point of the Civil War. It is the year where emancipation became a central goal for Union forces. Prior to that, the hope had been to restore the country to a single unit.

Lincoln issued the Emancipation Proclamation in 1862. It went into effect on January 1, 1963.

January 1 to enslaved Black people was Heartbreak Day. Our slavers called it Hiring Day.

Watchnight

Watchnight was for praying that you would not be kidnapped once more. That prayer was often a tarrying prayer, it did not cease.

Watchnight, December 31st was for loving on your people one last time before they were possibly rented to someone else. Or sold.

Watchnight, December 31st, is the only birthdate in cardology associated with the Joker.

Yet even in this hiring, there was rebellion. There was flight. There was insurrection.

Survival required many to be more than one thing at once, to embody the Joker. Enslaved kitchen workers acted as spies for the cause of freedom.

Blacksmiths, shoemakers, and other enslaved people who moved around as part of their work spread the word. They shared information in secret meetings.

They left to tend to their metal, their nails, their labor.

The Dogs

But there were also dogs.

Dogs followed our ancestors as they took flight, leaving their rows for the crows. Dogs tracking them to a river, but no further.

Dogs on the Best Bower card, the Jolly Joker. The dogs of whiteness and slave society.

This is one of the ways the Joker comes to be erroneously equated to tarot's' Fool. The presence of the dog. It is not tarot's Fool.

The Fool is an everyman. The Fool is sometimes a dupe, sometimes a king; here a loser, there a winner.

George Washington wrote in a letter to an estate manager "It is not for any good purpose Negros raise, or keep dogs; but to aid them in their night robberies; for it is astonish to see the command under which their dogs are.”

If an enslaved Black person was found to have a dog, they were to be "severely punished." The dog, hanged.

Dogs were trained into our enemies. Our enemies, however conditionally, they remain. Whether police dog, drug sniffing dog, or the dog of a racist neighbor, we all know they're dual.

The hunting dogs that pursued our ancestor's footsteps sometimes caught and sometimes lost.

Dogs retain in them something of the wolf. Dogs may see the dead as they pass. Their howling announces the departure of spirit, or their arrival.

The Joker is the essence of that for which we cannot plan. The Joker defies explanation and logic.

The Gentleman, Then as Now

Some say red Joker, black Joker. I say big Joker, little Joker.

As the decks change, so too change the colors. The big Joker is bigger.

The big Joker holds the print, the stamp of the maker. The little Joker may be scattered, and is often printed smaller on the card.

The big Joker holds the stamp of the maker. The big Joker tests what the universe will allow.

It tells us a coming is coming, though we do not know what until it has come.

The Joker may be the winner or the wild card. It depends on the game. It retains this meaning in fortune telling and divination.

Like a jester, speaking truth to the powerful and powerless in a single speech, the Joker sits in between.

While a Joker, fool or jester, is in relationship to the royal court, they are apart. While the Joker is not royalty, they are lifted up from the earth. They are a drawing towards.

Whether disaster or wholeness or both, they are a drawing onto that no one dare resist.

European playing cards have a longstanding association with the Roman god Mercury.

It is Mercury's accouterments that form the four suits in tarot and playing cards. They are the four ways Mercury spoke to humans.

Those four ways are "the Caduceus, stylus, or magic wand; the Coin or ring, emblem of eternity; the Sword, and the Cup."

This information comes from Prophetical, educational, and playing cards (1912) by Mrs. John King van Rensselaer.

She also writes "the Joker combines...the versatile qualities attributed to...Hermes." And "the Joker takes every card in the pack."

When we talk about the Joker, we are speaking of what is outside of the royal court.

When we talk about the Joker, we are speaking of what is outside of those subjugated by them.

To speak of the Joker is to speak of God. To speak of the Joker is to speak of the adversary.

Most of all, to speak of the Joker is to speak of the Man at the Crossroads. The Joker changes our fortunes in way only they can forsee.

They are the embodiment of “expect the unexpected.”

Deus Ex Machina

We understand that card divination is a technology. The Joker is deus ex machina. So too, are our intuitions applied to a deck of playing cards.

Through fortune telling with cards, we can see what's hidden from us. We cannot, however, see everything.

The presence of Joker reminds us of the presence of god, of fate, of mystery.

Even as we work and wait, we pray for the answers. We watch for the signs that freedom is coming.

We do so without ceasing. May we evade the dogs.

May the dogs always lose, though we know sometimes the dogs will win.

May we win our trick.

3 notes

·

View notes

Text

Residential Roofing - What You Need to Know

alt="Residential asphalt shingle roofing system installation"

Prevent having your residential roofing system improperly installed or assembled with poor-quality material. Knowing how components of a residential roofing system are made and installed will help you acquire the best quality residential roof and its installation in the Atlanta metro area.

newimageroofingatlanta.com gathered the following residential roof anatomy, manufacturing, and installation information to help you when selecting a roofing system, its components, and the roof installer for your Atlanta, Georgia, home.

Residential Sloped Roofing System

A residential sloped roof is a protective shield for your home, safeguarding you from the elements while increasing your home’s structural integrity. An essential component of the roofing system is the shingle (a key component that enhances your home’s aesthetic appeal and contributes to the durability and longevity of its roof). Consider the following anatomy of a residential sloped roof:

1. Roof Deck – A sloped roof’s foundation is its deck, typically made of plywood or oriented strand board (OSB). It provides a sturdy base for the installation of roofing materials and ensures structural stability.

2. Underlayment – Beneath the roofing shingles lies the underlayment, a water-resistant barrier shielding the roof deck from moisture and helps prevent leaks. Common underlayment types include asphalt-saturated felt and synthetic materials like synthetic underlayment or rubberized asphalt.

3. Roofing Shingles – Roofing shingles are the visible layer of a residential sloped roof, providing protection and enhancing the overall aesthetics. There are various shingle types available, like asphalt shingles, wood shingles, metal shingles, and clay or concrete tiles. Among these, asphalt shingles are the most commonly used due to their affordability, durability, and ease of installation (specially cut or formed shingles are produced for the ridge and hips).

Asphalt Shingle Manufacturing Process

While asphalt shingle manufacturing and technology have evolved over the years, their basic composition has remained the same. Consider the following asphalt shingle manufacturing process:

Raw Materials – Asphalt shingle production begins with high-quality material selection. Fiberglass or organic mats serve as a shingle’s core, while asphalt acts as a waterproofing agent. Mineral granules are then applied for surface protection and UV resistance, and additives are incorporated to enhance the shingle’s fire resistance and flexibility.

Mat Preparation – The selected mat material (fiberglass or organic), undergoes a manufacturing process to reinforce its strength and durability. Fiberglass mats are made by weaving glass fibers together, while organic mats are typically composed of recycled felt paper.

Coating and Drying – The prepared mat is then coated with asphalt (front and back), using a saturation process to ensure consistent coverage. The coated mat passes through a drying oven, which allows the asphalt to rapidly cure and stabilize.

Granule Application – Once dried, the coated mat proceeds to the granule application process. A layer of ceramic-coated mineral granules is evenly distributed on the top surface of the shingle, providing color, texture, and protection against weathering elements. The granules are embedded into the asphalt surface to enhance adhesion and durability.

Cutting and Shaping – After granule application, the asphalt-coated mat is cut into individual shingles. This process can be done manually or using automated machinery, depending on the production scale.

Packaging and Distribution – Finished roofing shingles are carefully inspected for quality and packed into bundles or cartons. They are then shipped to distributors, contractors, and suppliers for installation on residential roofs.

Note: Read more about roofing shingle production and options by visiting this roof shingle manufacturer.

Residential Sloped Roof Installation

Installing a residential shingle roofing system requires careful planning, proper preparation, and skilled execution. Here is a step-by-step overview of the typical installation process:

Preparation and Safety – Before beginning any work, safety must be prioritized. This includes wearing appropriate personal protective equipment (PPE) like:

Hard hat

Gloves

Goggles

Non-slip footwear

Harness

The area around the home should be cleared of any obstacles, and precautions should be taken to protect landscaping and outdoor features or furniture.

Removal of Existing Roofing Materials (Tear-off) – If there is an existing roof, the first step is to remove the old roofing materials. This may involve stripping off old shingles, underlayment, and flashing. Care should be taken to dispose of the old materials properly.

Inspection and Repair – Once the roof is cleared, a thorough inspection should be conducted to identify any damaged roof decking, sheathing, or structural issues. Any necessary repairs or replacements should be completed before installing a new roofing system.

Underlayment Installation – Install the underlayment, which acts as a moisture barrier and provides an additional protective layer. Asphalt-saturated felt or synthetic underlayment is commonly used. The underlayment should be rolled out horizontally, starting from the bottom edge of the roof and overlapping each subsequent row by a few inches (to ensure proper watershed).

Flashing Installation – Flashing is used to prevent water penetration at vulnerable areas like:

Valleys

Chimneys

Skylights

Roof intersections

Flashing is typically made of metal or a flexible waterproof material. Flashing should be installed before the shingles, ensuring proper coverage, sealing, and drainage.

Starter Shingle Placement – These shingles have a specialized adhesive strip and are installed along the roof’s eaves. These specialized shingles provide a secure foundation for the rest of the shingles and help prevent wind uplift.

Shingle Installation – The chosen shingles are installed from the bottom up, working in rows. Each shingle is nailed or stapled into place using appropriate roofing fasteners. It is crucial to follow the manufacturer’s guidelines regarding nail placement, spacing, and shingle overlap (for best product performance).

Ventilation and Ridge Cap Installation – Roof vents or ridge vents are installed to ensure proper attic ventilation preventing moisture buildup, allow air circulation, and help regulate temperature and humidity. The ridge cap, a specialized shingle designed for the roof’s peak, is then installed, overlapping the adjacent shingles and providing a solid, finished look.

Cleanup and Final Inspection – Once the roof’s shingles are installed, the work area should be thoroughly cleaned, removing all debris or loose material. A final inspection should be conducted to ensure the roof is properly installed, all shingles are secure, and there are no visible issues or gaps.

Note: The specific installation process may vary depending on factors like the shingle type, roof design, and local building codes. It is recommended to consult with a professional roofing contractor for a precise installation or replacement tailored to your specific roof and location requirements. A well-installed residential shingle roofing system provides long-lasting protection, durability, and aesthetic appeal to your home.

Residential Asphalt Shingle Roofing

In this article, you discovered the composition of a residential roofing system, asphalt shingle manufacturing, and how residential sloped roofs are installed.

Understanding how residential roofing systems are built, manufactured, and installed will help you choose the best materials for your home’s roof.

Not knowing how to recognize quality roofing material or identify the steps in a roof replacement or installation will leave you vulnerable to unscrupulous and unprofessional roofers trying to take advantage of your need.

Sources:

energy.gov/eere/buildings/articles/cool-asphalt-shingles

gccds.msstate.edu/research/altconstruction/roof/roof.pdf

owenscorning.com

To see the original version of this article, visit https://www.newimageroofingatlanta.com/residential-roofing-what-you-need-to-know/

#Residential Roofing Atlanta#Roofing Contractors Atlanta GA#Roofer Atlanta GA#Residential Roofing Systems Atlanta#Shingle Roof#Asphalt Shingles

2 notes

·

View notes

Text

Roofing Sheet Roll Forming Machine

A metal tile roof is lighter than a concrete or clay tile roof and more durable than an asphalt shingle roof, and easier to handle than long-run corrugate sheets. In fact, It is the best reliable and affordable roofing system in the market place in a range of design and styles.

in addition, we have pioneered many of the advances in Corrugated roofing sheet roll forming machine、Trapezoid Roof Sheet Machine、Roofing Tile Roll Forming Machine、Double Mayer Machine、Standing Seam Roll Forming Machine 、Ridge Cap Roll Forming Machine and Decking floor roll forming machine or CZU purlin machine .

2 notes

·

View notes

Text

Metal Building Accessories and Solutions

Our superior-quality steel and aluminum products are designed to satisfy the needs of functionality, safety, and simplicity of installation. Based on the dimensions of the wall and roof panels, our experts will determine the total number of accessories. You can make sure that everything will go according to plan when you have access to our wide selection of accessories for building.

#Metal Building Accessories and Solutions in India#Z and C Purlin Manufacturers and Suppliers in India#Metal Deck Manufacturers#Structural Roof Decking#Standing Seam Roof Manufacturers and Suppliers#Steel wall Cladding#Roofing Services

0 notes

Text

Fixings and Fasteners: Essential Components for Secure and Durable Installations

In construction, manufacturing, and DIY projects, Fixings And Fasteners are essential components that ensure materials are securely attached, stable, and capable of withstanding stress over time. From securing heavy structural elements to holding smaller parts in place, the right choice of fixings and fasteners can make a significant difference in the safety, strength, and durability of an installation.

This guide will explore the different types of fixings and fasteners, their uses, and how to select the right ones for various applications.

What Are Fixings and Fasteners?

Fixings and fasteners are hardware devices used to join or secure materials together. They come in various forms, including screws, bolts, nails, rivets, anchors, and clips, each designed for specific tasks. These components can be used for permanent or temporary connections and are critical in ensuring that structures and assemblies hold up under mechanical forces such as tension, compression, and shear.

Types of Fixings and Fasteners

Screws

Screws are one of the most commonly used fasteners. They are designed to be driven into materials like wood, metal, or plastic with a twisting motion. Screws come in a wide range of types, such as wood screws, machine screws, and self-tapping screws, each suited to different materials and applications.

Common Applications: Furniture assembly, decking, and general construction.

Bolts and Nuts

Bolts are threaded fasteners typically used with nuts to secure two or more parts together. They are ideal for applications where high strength and durability are required. Bolts and nuts come in different sizes, grades, and materials, including steel, stainless steel, and brass.

Common Applications: Heavy machinery, automotive, structural steelwork, and construction.

Nails

Nails are used to fasten materials by driving them through one or more layers using a hammer or nail gun. Unlike screws or bolts, nails do not have threads, making them suitable for applications where high shear strength is needed.

Common Applications: Framing, roofing, and carpentry.

Anchors

Anchors are used to secure fasteners to surfaces like concrete, brick, or drywall, where screws or bolts alone would not be effective. There are several types of anchors, including wall plugs (also known as rawl plugs), toggle bolts, and concrete anchors.

Common Applications: Hanging heavy objects like shelves, fixtures, and cabinets on walls.

Rivets

Rivets are permanent fasteners used to join two or more materials by deforming the head after insertion. They are commonly used in applications where access to both sides of the material is limited.

Common Applications: Aircraft assembly, shipbuilding, and metalworking.

Washers

Washers are thin plates with a hole in the middle, used to distribute the load of a threaded fastener, like a screw or bolt. They help prevent the fastener from loosening and can protect the material surface from damage.

Common Applications: With screws and bolts in mechanical and structural installations.

Clips and Clamps

Clips and clamps are fasteners that hold objects together or secure cables and pipes in place. They are often used in scenarios where frequent disassembly or adjustment is necessary.

Common Applications: Cable management, piping systems, and automotive assembly.

Staples

Staples are U-shaped fasteners driven into materials using a staple gun or hammer. They are commonly used for attaching thin materials like fabric, paper, or insulation to wood or other surfaces.

Common Applications: Upholstery, packaging, and light construction.

Choosing the Right Fixings and Fasteners

Selecting the appropriate fixing or fastener for a project depends on several factors:

Material Type: Different materials require specific types of fasteners. For example, wood screws are designed for timber, while machine screws are suitable for metal or plastic.

Load Requirements: The strength and load-bearing capacity of the fastener should match the weight and mechanical forces it will need to withstand. Bolts and anchors are often used in high-load applications, while screws and nails are better for lighter tasks.

Environmental Conditions: In outdoor or corrosive environments, such as marine or chemical industries, materials like stainless steel or galvanized fasteners are preferred for their resistance to rust and wear.

Installation Method: Consider how the fastener will be installed. Some fasteners, like nails and staples, are hammered in, while others, like screws and bolts, require tools like screwdrivers or wrenches.

Permanent vs. Temporary: If the assembly needs to be frequently disassembled and reassembled, choose fasteners like screws, bolts, or clamps. For permanent installations, rivets or nails might be more appropriate.

Common Applications of Fixings and Fasteners

Construction: Fasteners such as screws, bolts, and nails are used to assemble structures, secure frameworks, and attach components like doors and windows.

Manufacturing: In industries such as automotive and aerospace, fasteners like bolts, rivets, and clips ensure the secure attachment of parts that undergo mechanical stress.

Home Improvement: From hanging shelves to assembling furniture, various fixings and fasteners are used in everyday home projects.

Electrical Installations: Fasteners like anchors, clips, and clamps are essential for securing wiring and electrical components in place.

Conclusion

Fixings and fasteners are fundamental to nearly every construction, manufacturing, and DIY project. Selecting the right type based on material, load, and environmental factors ensures that your installation is secure, durable, and safe. With the vast range of options available, understanding the specific requirements of your project will guide you in choosing the most appropriate fixing or fastener for the job.

0 notes

Text

instagram

#decking steel#deck sheet#decking profile sheet manufacturer#decking sheets#decking sheet price#metal deck sheet#deck sheet profile#jsw deck sheet#deck sheet manufacturer in india#decking sheet for bridges#decking sheet for flyover#decking sheet for sealink#Instagram

0 notes

Text

Center Enamel Provides Custom Solutions of Industrial Containers and Process Equipment for Every Industry

Center Enamel Provides Custom Solutions of Industrial Containers and Process Equipment for Every Industry

Shijiazhuang Zhengzhong Technology Co., Ltd. is a trusted name in the design, manufacturing, and installation of industrial containers and process equipment. With over 30 years of expertise, we deliver tailored solutions for various sectors, including petrochemical, pharmaceutical, food, textile, and energy industries. Our product range includes pressure vessels, reactors, heat exchangers, and towers—each built to meet stringent national and international standards, ensuring safety, durability, and optimal performance.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, welded steel tanks ,pressure vessels and storage tanks roof, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs Solution

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Industry-Leading Design Standards

Our commitment to quality and safety is demonstrated by our adherence to industry-leading design standards. Every piece of equipment is carefully engineered to meet strict regulatory requirements, ensuring that it performs reliably and efficiently under all conditions.

Key design standards include:

GB150-2011: Pressure Vessel

JB/T4735-1997: Steel Welded Atmospheric Pressure Vessel

GB6789-1997: Food Machinery Hygiene

HG/T 20569-1994: Mechanical Mixing Equipment

GB/T151-2014: Heat Exchanger

NB/T 47041-2014: Tower Container

NB/T47003.1-2009: Steel Welded Atmospheric Pressure Vessel

GB48069-2016: Food Safety National Standard for Metal Materials in Food Contact

These standards guarantee the safety, compliance, and durability of our industrial containers and process equipment, making us a trusted partner for industries across the globe.

Our Comprehensive Product Range

1. Pressure Vessels

Pressure vessels are critical for safely containing gases or liquids under pressure. Our pressure vessels are designed and manufactured to suit the needs of industries such as petrochemical, energy, and manufacturing. Made from high-quality materials like stainless steel and carbon steel, our vessels are durable, reliable, and built to meet the toughest regulatory requirements. We provide custom design, manufacture, installation, and testing to ensure each pressure vessel fits the unique needs of your operation.

2. Reactors

Our reactors are designed for processes involving heating, cooling, evaporation, and mixing. Serving industries such as petrochemical, pharmaceutical, food, and beverage, our reactors are customized for optimal efficiency. We specialize in designing reactors that meet your specific process requirements, ensuring high performance and longevity in demanding applications.

3. Heat Exchangers

Heat exchangers play a pivotal role in transferring heat between fluids in industrial processes. We design and manufacture customized heat exchangers for chemical, pharmaceutical, biotechnology, food processing, and many other industries. Our heat exchangers are built to enhance efficiency while maintaining safety, ensuring that they meet your operational needs.

4. Towers

Towers are used for physical processes like separation and absorption in gas and liquid mixtures. As a well-known tower manufacturer, we offer a range of equipment including distillation towers, adsorption columns, scrubbing towers, and more. All of our towers are designed and manufactured to meet ASME specifications and are customized based on the specific requirements of your process.

Advantages of Our Industrial Containers and Process Equipment

High Strength and Durability

Our products are made from premium materials, such as stainless steel and carbon steel, providing excellent corrosion resistance and long-term stability. This ensures that our industrial containers and process equipment perform reliably even under harsh operating conditions.

Safety Assurance

Our equipment is designed to meet the highest safety standards and regulations, ensuring secure and dependable operation. Safety devices and stringent quality checks are implemented throughout the production process to minimize risks.

Reliability and Stability

We maintain strict control over the design and manufacturing processes to guarantee the reliability and stability of our products. From material selection to final quality inspections, every stage is monitored to ensure optimal performance over the long term.

Economic Benefits

Our industrial containers and process equipment provide excellent return on investment by reducing operational costs, enhancing process efficiency, and minimizing downtime. The durability of our products ensures long-term savings for our clients.

Applications Across Key Industries

Our industrial containers and process equipment are designed to serve a broad range of industries, including:

Petrochemical Industry

Energy Industry

Pharmaceutical Industry

Food Industry

Textile Industry

Environmental Protection Industry (wastewater treatment, waste gas treatment, garbage disposal)

Aerospace

Metallurgical Industry

0 notes

Text

Reliable Roof Replacement Contractor Services by Monraga Roofing

A strong, reliable roof is essential for the protection and value of your home. Over time, wear and tear or extreme weather conditions can damage your roof, making roof replacement a critical service. Monraga Roofing is here to provide top-notch roof replacement contractor services to homeowners in Florence, SC, and surrounding areas. As one of the best roofers in Florence SC, Monraga Roofing offers expertise, quality materials, and exceptional customer service for your roofing needs.

Signs You Need a Roof Replacement

Before discussing how Monraga Roofing can assist you, it’s essential to know the signs indicating you may need a roof replacement:

Leaks or water damage: If your roof is leaking or you see water stains on ceilings, this may be a sign your roof has reached the end of its lifespan.

Damaged or missing shingles: Over time, shingles can become cracked, curled, or blown away during storms. Missing shingles expose your home to further damage.

Sagging roof: A roof that appears uneven or sagging is often a sign of structural issues, which should be addressed immediately.

Increased energy bills: If your energy bills are increasing, your roof may not be properly insulated or vented, requiring a roof replacement.

Identifying these problems early can prevent further damage to your home and costly repairs in the future.

Why Choose Monraga Roofing for Roof Replacement?

When you’re looking for a roof replacement contractor in Florence, SC, there are several important factors to consider. Monraga Roofing excels in the areas that matter most:

Professional Expertise: With years of experience as a trusted roofing contractors, Monraga Roofing understands the complexities involved in roof replacement. From tear-off to installation, every step is handled with precision and care.