#Precision tools overview Best practices mold design

Explore tagged Tumblr posts

Text

Quality Redefined: The Essential Guide to Injection Mold Precision

High-Precision Molds: The Cornerstone of Modern Manufacturing

In the realm of modern manufacturing, high-precision molds serve as the cornerstone of quality and efficiency. These molds are engineered with meticulous attention to detail, ensuring that each product meets the stringent standards of today's competitive market. The precision in mold design and execution directly impacts the quality of the final product, making it an essential focus for manufacturers aiming to redefine quality parameters.

The demand for high-precision molds is driven by the need for consistency and accuracy in mass production. Industries ranging from automotive to consumer electronics rely heavily on these molds to produce components that fit seamlessly into larger systems. The precision of these molds ensures minimal variation between products, which is crucial for maintaining brand reputation and customer satisfaction.

Moreover, the evolution of consumer expectations has further amplified the importance of high-precision molds. As consumers demand more complex and intricate products, manufacturers must rise to the challenge by employing molds that can deliver such precision. This not only involves the physical crafting of the molds but also the integration of advanced technologies to ensure every detail is captured with accuracy.

High-precision molds are not just tools; they are integral to the manufacturing process, acting as the blueprint for product creation. The ability to produce identical parts with minimal deviations is what sets successful manufacturers apart. As such, investing in high-precision molds is not just a necessity but a strategic advantage in the competitive landscape of modern manufacturing.

Injection Mold Guide: Navigating the Complexities of Mold Design

Creating an injection mold involves navigating a complex landscape of design considerations and technical specifications. An effective injection mold guide provides a roadmap for manufacturers, detailing the steps necessary to achieve superior mold quality. This guide should encompass everything from material selection to the intricacies of mold flow analysis.

Material selection is a critical step in the injection molding process. The choice of material affects the durability, flexibility, and overall performance of the mold. Engineers must consider factors such as thermal conductivity, shrinkage rates, and resistance to wear and tear when selecting materials. Additionally, the guide should address the importance of mold flow analysis, which helps predict how the molten material will behave as it fills the mold cavity. This analysis is vital for identifying potential defects and optimizing the mold design for efficiency and quality.

Furthermore, the guide should cover the importance of understanding the end-use of the molded product. Different applications may require different mold designs, and understanding the product's function can significantly influence design choices. For example, molds for medical devices require more stringent specifications compared to those used for consumer products, due to the critical nature of their application.

In addition to technical specifications, the guide should emphasize the importance of collaboration between design and manufacturing teams. Effective communication ensures that design intentions are clearly understood and executed, minimizing the risk of errors and enhancing the overall quality of the mold. By following a comprehensive injection mold guide, manufacturers can navigate the complexities of mold design with confidence and precision.

Injection Mold Technology: Advancements Shaping the Future

Advancements in injection mold technology are continually shaping the future of manufacturing. Cutting-edge technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM) have revolutionized the way molds are designed and produced. These technologies allow for greater precision and customization, enabling manufacturers to meet the specific needs of their clients with unparalleled accuracy.

Furthermore, the integration of automation and robotics into the injection molding process has significantly enhanced production efficiency. Automated systems can perform repetitive tasks with precision and speed, reducing the likelihood of human error and increasing overall productivity. As technology continues to evolve, manufacturers must stay abreast of the latest developments to maintain a competitive edge in the industry.

The role of simulation software in injection mold technology cannot be overstated. These tools allow manufacturers to simulate the molding process, identifying potential issues before they occur in the real world. This proactive approach not only saves time and resources but also ensures that the final product meets the highest standards of quality.

Moreover, advancements in materials science are opening new possibilities for injection mold technology. The development of new polymers and composites allows for the creation of molds that are lighter, stronger, and more durable than ever before. These materials not only enhance the performance of the molds but also contribute to more sustainable manufacturing practices by reducing waste and energy consumption.

Innovative Molding Practices: Pioneering New Standards

Innovative molding practices are pioneering new standards in the industry, pushing the boundaries of what is possible with injection molding. These practices involve the application of novel techniques and materials to achieve superior results. For instance, the use of advanced composite materials in mold construction can enhance durability and reduce weight, leading to more efficient production processes.

Another innovative practice is the adoption of rapid prototyping technologies, which allow manufacturers to quickly produce and test mold designs before committing to full-scale production. This approach not only saves time and resources but also enables manufacturers to identify and address potential issues early in the design process. By embracing these innovative practices, manufacturers can redefine quality parameters and set new benchmarks for excellence in the industry.

The concept of hybrid molding, which combines different molding techniques, is also gaining traction. By integrating processes such as injection molding with additive manufacturing, manufacturers can achieve unprecedented levels of complexity and precision. This hybrid approach allows for the creation of intricate designs that were previously impossible or cost-prohibitive to produce.

In addition, the focus on sustainability is driving innovation in molding practices. Manufacturers are increasingly adopting eco-friendly materials and processes to reduce their environmental impact. This includes the use of biodegradable polymers and the implementation of closed-loop recycling systems to minimize waste. By aligning innovative molding practices with sustainability goals, manufacturers can achieve both economic and environmental benefits.

Injection Mold Quality: Ensuring Excellence in Every Detail

Ensuring injection mold quality is paramount for manufacturers aiming to deliver products that meet or exceed customer expectations. Quality assurance processes must be integrated into every stage of mold production, from initial design to final inspection. This comprehensive approach ensures that each mold is crafted with precision and care, resulting in products that exhibit superior performance and reliability.

Key aspects of injection mold quality include dimensional accuracy, surface finish, and material integrity. Dimensional accuracy ensures that each component fits precisely into its intended application, while a high-quality surface finish enhances the aesthetic appeal and functionality of the final product. Material integrity is crucial for ensuring that the mold can withstand the rigors of production without compromising its structural integrity.

Incorporating advanced quality control techniques, such as non-destructive testing and real-time monitoring, can further enhance injection mold quality. These techniques allow manufacturers to detect defects and deviations early in the production process, enabling timely corrective actions. This proactive approach not only improves product quality but also reduces the cost and time associated with rework and recalls.

Moreover, fostering a culture of quality within the organization is essential for achieving excellence in injection mold production. This involves training employees on best practices, encouraging continuous improvement, and recognizing and rewarding quality achievements. By prioritizing quality in every aspect of the manufacturing process, manufacturers can build a reputation for reliability and excellence in the industry.

Precision Tools Overview: The Role of Precision in Mold Manufacturing

Precision tools play a vital role in mold manufacturing, enabling manufacturers to achieve the exacting standards required for high-quality production. These tools are designed to perform intricate tasks with exceptional accuracy, ensuring that each mold is crafted to the highest specifications. Precision tools include everything from CNC machines to laser cutters, each contributing to the overall quality of the mold.

The use of precision tools in mold manufacturing not only enhances the quality of the final product but also improves efficiency and reduces waste. By minimizing errors and ensuring consistent results, precision tools help manufacturers streamline their operations and reduce the time and cost associated with mold production. As a result, manufacturers can deliver high-quality products to market faster and more cost-effectively.

In addition to traditional precision tools, advanced technologies such as 3D printing and laser sintering are increasingly being used in mold manufacturing. These technologies allow for the creation of complex geometries and fine details that would be difficult or impossible to achieve with conventional methods. By leveraging these advanced tools, manufacturers can push the boundaries of what is possible with injection molding.

Furthermore, the integration of digital technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is transforming the role of precision tools in mold manufacturing. These technologies enable real-time monitoring and control of the manufacturing process, allowing for greater precision and flexibility. By harnessing the power of digital technologies, manufacturers can achieve unprecedented levels of accuracy and efficiency in mold production.

Best Practices Mold Design: Strategies for Optimal Performance

Adhering to best practices in mold design is essential for achieving optimal performance and quality. These practices encompass a range of strategies and techniques that help manufacturers create molds that meet the highest standards of precision and reliability. Key considerations include mold layout, cooling system design, and maintenance procedures.

Mold layout is critical for ensuring efficient material flow and minimizing defects. A well-designed layout reduces the risk of issues such as warping and sink marks, which can compromise the quality of the final product. Cooling system design is another important consideration, as it directly impacts the cycle time and efficiency of the molding process. An effective cooling system ensures uniform temperature distribution, reducing the likelihood of defects and improving overall production speed.

Regular maintenance is also crucial for maintaining mold quality over time. By implementing a proactive maintenance schedule, manufacturers can identify and address potential issues before they escalate, ensuring that each mold remains in optimal condition throughout its lifecycle.

Additionally, incorporating flexibility into mold design can enhance its adaptability to changing production needs. This involves designing molds that can accommodate different materials and product variations without requiring significant modifications. By building flexibility into the design, manufacturers can respond more quickly to market demands and reduce downtime associated with mold changes.

Collaboration between design and manufacturing teams is also essential for successful mold design. By working together, these teams can ensure that design intentions are clearly understood and executed, minimizing the risk of errors and enhancing the overall quality of the mold. By adhering to best practices in mold design, manufacturers can achieve optimal performance and quality in their production processes.

Precision Engineering Molds: The Future of Manufacturing Excellence

Precision engineering molds represent the future of manufacturing excellence, offering unparalleled quality and performance. These molds are designed with the utmost attention to detail, utilizing the latest technologies and materials to achieve superior results. As the industry continues to evolve, precision engineering molds will play an increasingly important role in setting new standards for quality and efficiency.

The future of precision engineering molds lies in the continued integration of advanced technologies such as artificial intelligence and machine learning. These technologies have the potential to revolutionize the way molds are designed and produced, enabling manufacturers to achieve even greater levels of precision and customization. By embracing these advancements, manufacturers can stay ahead of the curve and deliver products that meet the ever-evolving needs of their customers.

Moreover, the focus on sustainability and environmental responsibility is shaping the future of precision engineering molds. Manufacturers are increasingly adopting eco-friendly materials and processes to reduce their environmental impact. This includes the use of biodegradable polymers and the implementation of closed-loop recycling systems to minimize waste. By aligning precision engineering molds with sustainability goals, manufacturers can achieve both economic and environmental benefits.

In conclusion, redefining quality parameters in the industry through the lens of injection mold precision requires a comprehensive approach that encompasses advanced technology, innovative practices, and a commitment to excellence. By focusing on high-precision molds, adhering to best practices in mold design, and leveraging the latest advancements in technology, manufacturers can achieve superior results and set new benchmarks for quality in the industry.

#High-precision molds#Injection mold guide#Injection mold technology#Innovative molding practices#Injection mold quality#Precision tools overview Best practices mold design#Precision engineering molds#mould injection#injection mold#die casting mold

0 notes

Text

Do You Do the Floor First or Last in a Bathroom Remodel?

Welcome to the Kitchen and Bath Reno Guys Kitchener Waterloo blog! One of the most frequently asked questions we encounter from homeowners in Kitchener, Waterloo, and beyond is: "Do you do the floor first or last in a bathroom remodel?" It’s a great question, and the answer isn’t always straightforward. The decision depends on multiple factors—your project scope, the materials you choose, the timeline, and even your budget.

At Kitchen and Bath Reno Guys Kitchener Waterloo, we’ve completed countless bathroom renovations, and we’re here to break down the pros, cons, and best practices for both approaches. By the end of this guide, you’ll have a clear understanding of what works best for your unique bathroom remodel. Let’s dive in!

Understanding the Bathroom Remodel Process

Before we tackle the flooring question, it’s helpful to understand the typical stages of a bathroom remodel. A well-planned renovation ensures durability, functionality, and a beautiful finish. Here’s a quick overview of the process:

Demolition: Removing old fixtures, tiles, and any outdated or damaged components.

Plumbing and Electrical: Updating pipes, drains, and wiring to meet modern codes and your design needs.

Structural Changes: Adjusting walls, adding support, or modifying the layout if needed.

Walls and Waterproofing: Installing drywall, cement board, and waterproof membranes to protect against moisture.

Fixtures and Finishes: Adding the bathtub, shower, vanity, toilet, and other elements.

Flooring: Laying tiles, vinyl, or other materials to complete the space.

The order of these steps can shift, especially when it comes to flooring. So, should you install the floor first or last? Let’s explore both options in detail.

Option 1: Installing the Floor First

Laying the flooring before installing other bathroom components—such as the vanity, toilet, or bathtub—has its merits. Here’s why this approach might appeal to you:

Benefits of Flooring First

Seamless Aesthetic When you install the floor first, the tiles or other materials extend from wall to wall, creating a uniform, uninterrupted look. This is especially appealing if you’re using large-format tiles, intricate patterns, or luxury materials like natural stone. No cuts or seams around fixtures mean a cleaner, more polished appearance.

Simplified Installation Tilers love this method because they can work without navigating around a vanity, toilet, or tub. With a clear, open space, they can lay tiles faster and more precisely, potentially saving time and labor costs for your project.

Ideal for Floating Floors If you’ve chosen a floating floor—such as luxury vinyl planks, laminate, or certain engineered wood options—installing it first is often necessary. These materials need room to expand and contract with temperature and humidity changes. Pinning them down under heavy fixtures can cause buckling or gaps over time.

Future Flexibility With the floor in place first, replacing a vanity or toilet down the road is easier. You won’t need to patch or extend the flooring to cover gaps left by old fixtures, as the material already runs beneath them.

Challenges of Flooring First

While this approach has advantages, it’s not without risks:

Damage During Construction A newly laid floor is vulnerable during a remodel. Dropping a tool, dragging a heavy bathtub, or even spilling paint can scratch, crack, or stain your beautiful new tiles or vinyl.

Protection Costs To avoid damage, you’ll need to cover the floor with protective materials like plywood, cardboard, or heavy-duty drop cloths. This adds a step—and potentially a cost—to your project.

Fixture Fit Issues When fixtures like a vanity or toilet sit on top of the floor, water can seep underneath, especially if seals fail. This might lead to mold or damage over time, particularly in a wet environment like a bathroom.

Option 2: Installing the Floor Last

The alternative—installing the floor after other components are in place—is a popular choice for many bathroom remodels. Here’s why we at Kitchen and Bath Reno Guys Kitchener Waterloo often lean toward this method:

Benefits of Flooring Last

Protection During Renovation By waiting to install the floor, you shield it from the chaos of construction. Demolition, wall repairs, painting, and heavy fixture installation all happen without risking scratches, dents, or cracks on your new flooring. This can save you from costly repairs or replacements.

Precise Fit and Finish Laying the floor last allows tiles or other materials to be cut precisely around the vanity, toilet flange, bathtub, or shower base. This creates tight, clean edges that enhance the look and help prevent water from seeping under fixtures—a critical concern in a bathroom.

Easier Adjustments During a remodel, you might need to tweak plumbing, adjust walls, or reposition fixtures. If the floor isn’t yet installed, these changes won’t damage or disrupt an already-finished surface. This flexibility can be a lifesaver if unexpected issues arise.

Better Waterproofing With the floor installed last, you can ensure walls and waterproofing systems (like membranes or backer boards) extend down to meet the flooring. This overlap creates a stronger barrier against moisture, a must for any bathroom.

Challenges of Flooring Last

This approach isn’t perfect either. Here are some potential drawbacks:

Fixture Removal If the vanity, toilet, or bathtub is already installed, they may need to be lifted or temporarily removed to lay the floor properly. This can add labor time and cost to your remodel.

Visible Cuts Tiles or materials cut to fit around fixtures might show edges that disrupt the seamless look some homeowners prefer. Skilled installers can minimize this, but it’s a consideration.

Height Adjustments Installing the floor last raises the floor level slightly, which might affect the height of your vanity or toilet. You may need spacers or adjustments to ensure everything aligns correctly.

What Do the Experts Recommend?

At Kitchen and Bath Reno Guys Kitchener Waterloo, we generally advise installing the floor last for most bathroom remodels. Here’s why this approach often wins out:

Maximum Protection A bathroom remodel involves heavy tools, fixtures, and messy tasks like grouting or painting. Waiting to lay the floor keeps it pristine, saving you stress and money.

Superior Water Resistance In a bathroom, water is the enemy. Installing the floor last allows us to cut tiles or vinyl to fit tightly around fixtures, creating a seal that keeps moisture out. We also ensure waterproofing from the walls extends properly to meet the floor, bolstering durability.

Flexibility for Changes Renovations can be unpredictable. Plumbing leaks, wall repairs, or design tweaks are easier to handle without a finished floor in the way. This approach gives us room to perfect every detail.

Professional Finish Our experienced team in Kitchener and Waterloo knows how to cut and install flooring for a flawless fit around your vanity, toilet, and tub. The result is a polished, cohesive look that elevates your bathroom.

When to Install the Floor First?

That said, there are exceptions. If you’re using large-format tiles, a complex mosaic pattern, or a floating floor, installing the floor first might be the better call. For example:

Large Tiles: Cutting big tiles around fixtures can be tricky and may ruin the aesthetic. Laying them first ensures a consistent pattern.

Floating Floors: Vinyl planks or laminate need to float freely, so they’re best installed before heavy fixtures anchor them down.

Custom Designs: If your vision includes a unique floor design that demands a seamless flow, starting with the floor might be necessary.

We’ll assess your project—considering your materials, layout, and goals—to recommend the best sequence. No two bathrooms are alike, and our tailored approach ensures the best outcome.

Additional Considerations for Your Remodel

The floor-first-or-last debate isn’t the only factor in a successful bathroom remodel. Here are a few more tips from Kitchen and Bath Reno Guys Kitchener Waterloo to keep in mind:

Material Choice Your flooring material impacts the decision. Ceramic or porcelain tiles are durable and water-resistant, making them ideal for bathrooms. Vinyl is budget-friendly and versatile. Natural stone looks stunning but requires sealing. Discuss options with us to find the perfect fit.

Budget and Timeline Installing the floor last might add a step (like lifting fixtures), increasing costs slightly. Conversely, flooring first requires protective measures. We’ll help you balance quality, cost, and timing for your Kitchener or Waterloo home.

Waterproofing Bathrooms demand robust waterproofing. Whether the floor goes in first or last, we ensure walls, shower areas, and subfloors have proper membranes or backer boards to prevent leaks and mold.

Professional Expertise DIY can be tempting, but a bathroom remodel involves plumbing, electrical, and precise installation. Mistakes can lead to leaks, damage, or code violations. Our skilled team brings years of experience to get it right the first time.

Why Choose Kitchen and Bath Reno Guys Kitchener Waterloo?

At Kitchen and Bath Reno Guys Kitchener Waterloo, we’re passionate about transforming bathrooms in the Kitchener-Waterloo region. Here’s what sets us apart:

Local Expertise: We know the homes, styles, and needs of Kitchener and Waterloo, delivering results that suit your lifestyle.

Custom Solutions: Every project is unique. We tailor the process—flooring first or last—to your vision and space.

Quality Craftsmanship: From demolition to the final tile, we prioritize precision, durability, and beauty.

Customer Focus: Your satisfaction is our goal. We listen, advise, and keep you updated every step of the way.

Ready to Remodel Your Bathroom?

Deciding whether to install the floor first or last in a bathroom remodel depends on your project’s specifics. At Kitchen and Bath Reno Guys Kitchener Waterloo, we lean toward flooring last for its protection, flexibility, and water-resistant finish—but we’re ready to adapt to your needs. Whether you’re dreaming of a spa-like retreat, a modern update, or a practical refresh, we’re here to make it happen.

Contact Kitchen and Bath Reno Guys Kitchener Waterloo today for a free consultation! Let’s discuss your vision, budget, and timeline to create a bathroom you’ll love for years to come. Serving Kitchener, Waterloo, and the surrounding area, we’re your trusted partners in renovation. Call us or visit our website to get started—your dream bathroom awaits!

youtube

0 notes

Text

Plastic Injection Molding Machine: Revolutionizing Manufacturing Processes

A Plastic Injection Molding Machine is a pivotal tool in modern manufacturing, enabling the efficient and precise production of plastic components. This article delves into the intricate details of these machines, exploring their functionalities, types, applications, and the impact they have on various industries.

The Process of Plastic Injection Molding

The injection molding process is a complex sequence of events that transforms raw plastic material into a final product. Understanding the step-by-step guide to this process provides insights into the capabilities of Plastic Injection Molding Machines.

Types of Plastic Injection Molding Machines

Plastic molding is not a one-size-fits-all operation. There are various types of molding machines, each designed for specific applications. From hydraulic and electric machines to hybrid models, this section provides an overview of their features and best-use scenarios.

Key Components and Features

To comprehend the functioning of Plastic Injection Molding Machines, it's essential to dissect the machine's key components. This section offers a detailed analysis of components such as the injection unit, clamping unit, and the crucial role they play in the overall process.

Advantages of Plastic Injection Molding

Efficiency, precision, and cost-effectiveness are the cornerstones of plastic injection molding. This segment highlights the numerous advantages of utilizing these machines, from high production rates to minimal material wastage.

Applications in Various Industries

Plastic Injection Molding Machines find applications in diverse industries, including automotive, medical, consumer goods, and more. Their versatility and ability to produce intricate parts make them indispensable in the manufacturing sector.

Choosing the Right Machine for Your Needs

Selecting the appropriate molding machine is a critical decision. Factors such as material type, production volume, and part complexity play a role. This section guides manufacturers in making informed choices tailored to their specific requirements.

Maintenance and Troubleshooting

Proper maintenance is vital for the longevity and efficiency of Plastic Injection Molding Machines. This part offers practical tips on machine upkeep and addresses common issues that may arise during operation.

Industry Trends and Innovations

The plastic molding sector is dynamic, with continuous technological advancements. Explore emerging trends such as automation, 3D printing, and smart manufacturing, shaping the future landscape of plastic injection molding.

Environmental Impact

As sustainability becomes a global focus, understanding the environmental impact of manufacturing processes is crucial. Learn about sustainable practices in plastic injection molding and how these machines are adapting to reduce their ecological footprint.

FAQs about Plastic Injection Molding

Q: What is the typical cycle time for injection molding? The cycle time varies based on factors such as material, part complexity, and machine specifications. However, it typically ranges from a few seconds to a few minutes.

Q: Can one machine handle multiple materials? Some advanced machines support multiple materials through the use of dual injection units, allowing for versatility in production.

Q: How can I prevent defects in the molded parts? Proper machine calibration, quality material selection, and regular maintenance contribute to defect prevention. Attention to detail in the molding process is crucial.

Q: Are there size limitations for parts produced by injection molding? While there are size limitations, many machines can produce large and complex parts. It's essential to choose a machine that aligns with the size requirements of the intended products.

Q: What industries benefit the most from plastic injection molding? Industries such as automotive, healthcare, packaging, and consumer goods extensively benefit from the precision and efficiency of plastic injection molding.

Q: How do I choose between hydraulic and electric machines? Consider factors like energy efficiency, production volume, and initial cost. Hydraulic machines are robust and cost-effective for certain applications, while electric machines offer higher precision and energy efficiency.

Future Outlook

The future of plastic injection molding is marked by continuous innovation. Anticipate advancements in materials, automation, and sustainability, shaping a more efficient and environmentally conscious industry.

0 notes

Text

3D-Printed Blood Vessels: The Tech Just Became Scalable

By Greg Hurst and Matt Gelber.

This article was published on Medium.

The Problem: Making Vasculature is Hard!

It sounds simple enough — all of your cells require a constant supply of oxygen. Your lungs extract it from the air and your blood carries it all around your body through a vascular network comprising thousands of miles of veins and arteries. If your heart doesn’t beat at least once every couple seconds, your brain doesn’t receive enough oxygen-rich blood to maintain consciousness.

We don’t understand super high-level biological phenomena like consciousness. We can’t engineer a conscious array of cells, or even of transistors. But we understand pretty well the vasculature that supports consciousness. It’s a series of tubes. Literally. And it may be that if we can make the tubes and deliver oxygen to a sufficiently large population of cells, we can make some cool things happen. A conscious brain is a long shot, a functional piece of liver or kidney decidedly less so.

The problem is, making vasculature is hard. Cells in a dish do self-organize to an extent, but we don’t understand such systems well enough to tell a bunch of cells to grow into a vascularized organ.

An alternative means of generating physiological structure’s blood vessels is a bit cruder — design the structure you want, then make a robot that can physically place the cells and the vessels where you want them. We call this bioprinting. A major hurdle with bioprinting is the fact that, while the printer is working, the cells that have been printed are slowly dying from lack of oxygen. For really big, complex tissues, you either need a way to supply oxygen while you’re still printing, or you need a way to make all those blood vessels really fast.

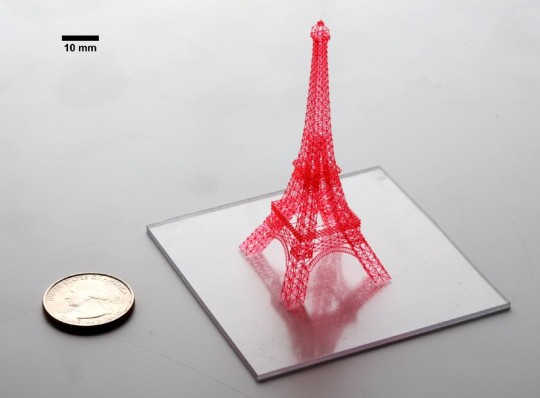

One really fast approach was demonstrated in 2009. Researchers at Cornell used a cotton candy machine to melt-spin a pile of sugar fibers. They cast the sugar fibers in a polymer, dissolved them out with water and made a random vascular network in minutes. In 2012, researchers at Penn used a hacked desktop 3D printer to draw molten sugar fibers into a simple lattice and showed that the same sacrificial casting approach could be used deliver blood to rat liver cells in a dish, keeping them alive for weeks. Now, researchers at the University of Illinois at Urbana-Champaign have developed the ability to make these sugar fiber networks of any shape and size.

Materials Science + Mechanical Engineering + Theoretical Computer Science to the Rescue

Scaling the process isn’t just a matter of building a more precise, more expensive printer (although that is necessary). It’s a matter of choosing the right type of sugar, understanding the physical behavior of the sugar as it is printed and of telling the printing robot how to move. The problem spans materials science, mechanical engineering and theoretical computer science; it contained more than enough material for a PhD thesis, and the cells aren’t even in there yet. The materials and mechanical engineering aspects are laid out in a recent publication in Additive Manufacturing; the planning algorithm is described in a recent manuscript still under review.

Instead of conventional sugars, this printer uses isomalt, the same low-calorie sugar substitute they use to make throat lozenges. Isomalt works better than conventional sugar, mostly because it doesn’t burn like sugar does. The printer melts the isomalt and pushes it out of a tiny nozzle under pressure. Like a pen, the nozzle is used to “write” thin isomalt filaments, but in 3D. Printing speed, temperature and pressure are critical to achieving precise filaments. Right now the diameters of the filaments can be anywhere from 50 to 500 micrometers; to give some context, a human hair is about 10 micrometers thick. However, the researchers say it’s entirely possible to go bigger or smaller.

At that point it might seem like you’re done. But when you want to print a network comprising thousands of filaments, you encounter an interesting problem. You need to choose an order in which to print them. The printing process is freeform; you can move the nozzle anywhere you want. That means if you’re not careful, you can hit your sugar construct with your nozzle and destroy it.

Avoid Collisions AND Don’t Melt

Collision avoidance is a pretty common problem in robotics, so that part isn’t too hard to deal with. However, there is an additional wrinkle that is very specific to this problem. It has to do with the fact that every time you go to an existing filament and draw a new branch, you melt the material at the joint. Imagine you’re building a bridge, but every time you weld a new beam on, all the existing welds around it melt. This makes the problem a lot harder.

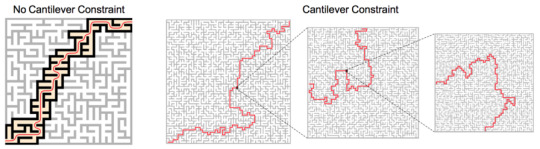

Without this constraint, the problem of choosing a sequence is analogous to finding your way out of the maze on the right. There are dead ends, but you can see them. You won’t get lost in them; you’ll immediately turn around. But with this particular constraint, choosing a sequence is like finding your way out of the maze on the right. The maze is big; for long sequences, it becomes, for all practical purposes, infinite.

The best you can do in this case is make an educated guess at every fork. For example, if you had a compass that pointed towards the exit, you might take the path that most nearly coincides with the direction of the needle. In some cases, there is no feasible printing sequence; the maze has no exit. More strangely still, you can’t know, at least with our current understanding of computer science, if you should give up. You know the exit exists if, and only if, you actually find it.

In order to navigate the maze and generate a printing sequence, you need an efficient algorithm as well as a fair bit of computational power. This part has become much easier recently with high-level languages such as the Wolfram Language. Says author Greg Hurst, a developer at Wolfram Research, “This problem spans many disciplines. Computational geometry is needed for collision detection, NP-complete graph problems — like finding cliques — need to be solved, and sparse matrix solvers need to be invoked thousands of times throughout. With the Wolfram Language, I was able to hammer out fast code in a matter of months.”

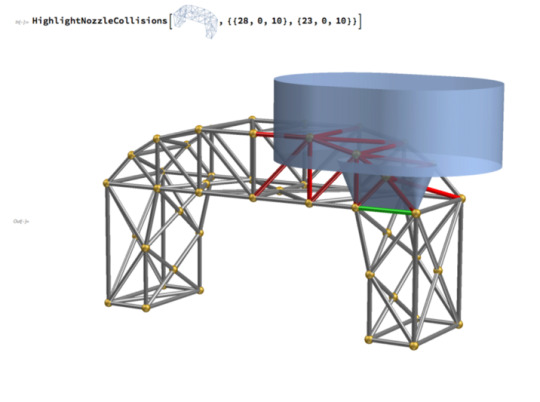

Here’s a Wolfram Language command to visualize nozzle-beam collisions. The red beams must be drawn after the green one to avoid contact with the blue nozzle as it draws the green beam:

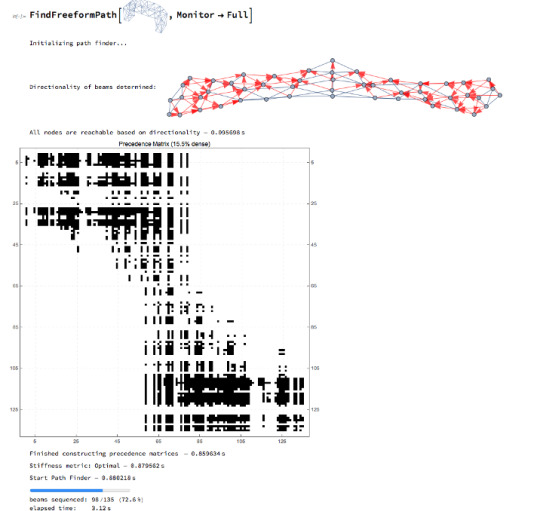

Here’s the full implementation with relevant information to monitor the progress:

What’s Next?

So the problems of turning a design into a set of printer instructions, and of having a printer that is sufficiently precise into execute them, are more or less solved. This doesn’t mean that 3D-printed organs are just around the corner. Just pouring a bunch of liver cells around a vascular mold doesn’t give you a functional liver. You need to make the cells to grow and organize the same way they do in your body.

Cells respond to the chemical and mechanical properties of their environment, and successfully recapitulating tissue requires tailoring these parameters as well. But printing vasculature is a very important step, because without it, everything dies. Now we can start tweaking the environment without worrying so much about the all-important blood vessels.

Today, we have sugar bunnies. Tomorrow, we might have miniature organs on a chip that we use to test new drugs. In several years, who knows. Maybe we’ll be able to replace a failing heart with a patient-specific replica. Maybe the processor in your computer will be replaced by a vascularized slab of neurons. We can’t yet say what the application will be, but we have the tools now to start entertaining these ideas. Stay tuned!

For a more technical overview, visit the Wolfram Blog.

#wolfram#wolfram research#mathematica#3d printing#science#tech#vasculature#bioprinting#biology#health

275 notes

·

View notes

Text

Best Mitre Saw Testimonials In The UK 2017.

Quando la riproduzione automatica è attivata, al termine del video verrà riprodotto automaticamente un video clip consigliato. If you do not mind some omissions such as the overview laser as well as light offered in the much more pricey stablemates after that the DSW709 is a practical miter saw that will make woodworking much less complex currently and also for years to find. The operation of the saw is an essential design function which should be done properly for the safety and security of the customer. When you consider its super-effective dust collection system as well as all of its various other clever layout components, there's no refuting that the DEWALT DWS780 is just among the most effective miter saws around. The Bosch GCM 8 SJL 240V professional mitre saw is a bit extra costly but will certainly be a terrific purchase for any kind of project. Some individuals operate in remote locations as well as not everyone has a good workshop with numerous electrical power outlets, so cordless designs like the DEWALT DCS361B 20V Max Cordless Miter Saw are a lot more suitable. Below, we will look at several of the safety showcases you will certainly find on the majority of designs, as well as exactly what is worth looking out for when selecting your excellent saw. This charm is a genuine excellent quality mitre saw for professionals who desire the most effective quality surface and a device that can make their functioning day easy as well as nice. I have a different take as well as after hearing of this trouble from greater than someone I have to put this saw on the Do Not Buy" list along with the Bench Pro 10" saw. Bosch GCM12SD miter saw provides you sturdy precision and also unmatched smoothness in every cut. Cost as well as features are normally very encouraging variables for any type of purchase and also the DeWALT miter saw victories on both counts. http://gd-frontiers.net/vital-pieces-of-compound-mitre-saw-dewalt/ means there is possibly more that could fail with the saw and also it will take a bit a lot more set up time. Though it may not have the exact same kind of name brand name" acknowledgment around your home that tools like DeWalt, Mikita, or Rigid have, the fact of the issue is that Hitachi have actually been accountable for producing some pretty unbelievable devices - as well as they are compound miter saw is no exception. This permits you to see where the saw will cut when you draw it down, so you will certainly have the ability to get one of the most exact cut. For beginners, do not assume that you have no idea any kind of better, the miter saw that you opted to acquire is a fine machine made by Tool-Shop. Normally, you can't anticipate to obtain the exact same features as well as power from a budget plan saw as you would certainly a first-rate saw. The 240v mitre saws are powered straight from the UK keys power supply, this means you merely plug the saw in as well as it will deal with no worry. This compound miter saw has a high fencing to sustain vertical crown molding and also base molding of 6-5/8 inches and also 6-1/2 inches specifically. It's important to do your research first as your personal safety and security depends on it. You additionally need to hold the saw for some time so as to get used to the weight and also change your grasp on the tool properly. Though testimonials are not 100% guaranteed however it supplies a basically high rate of integrity that could be a basis for an acquisition. When spending over this number, the majority of miter saw these days use very decent functions and also functionalities that do not justify the cost. This miter saw weighs at 44 pounds, that makes it a lot easier to move from one jobsite to another. As one of the latest and biggest miter saws to strike the marketplace, the DEWALT DWS780 is an innovative cutting tool efficient in being utilized for a plethora of house enhancement and construction projects.

0 notes