#Proactivemaintenance

Explore tagged Tumblr posts

Text

Downtime is costing you more than you think. Is your business still reacting to equipment failures? That approach belongs to the past. In today’s fast-paced operations, a proactive maintenance strategy is the key to lower costs, minimal disruptions, and improved asset life.

In this detailed guide, I walk you through:

✅ Why preventive maintenance schedules are crucial ✅ Step-by-step instructions to build an effective PM program ✅ How to choose the right maintenance software (CMMS) ✅ Best practices for reducing unplanned downtime

If you're a facility manager, maintenance head, or decision-maker in manufacturing or asset-heavy industries — this one’s for you. Read now and learn how to craft a preventive maintenance schedule that slashes costs and downtime👇

#cmms software#preventivemaintenance#cmms#downtimereduction#maintenancemanagement#assetmanagement#asset maintenance software#facilitymanagement#proactivemaintenance

0 notes

Text

Boost Equipment Uptime with Condition Monitoring Technicians in Yanbu

In a city like Yanbu, known for its large-scale industrial zones and petrochemical plants, machinery reliability is a top priority. Downtime isn’t just inconvenient—it’s costly. That’s why having professional Condition Monitoring Technicians in Yanbu is critical to keeping operations running smoothly. At Bafco Reliability, our skilled technicians help industries detect equipment issues early, avoid failures, and extend machine life.

What Do Condition Monitoring Technicians Do?

Condition monitoring technicians specialize in using advanced diagnostic tools to check the health of machinery. Their role involves:

Collecting vibration data

Performing thermal imaging

Conducting ultrasonic inspections

Analyzing oil samples

Interpreting machine performance data

By analyzing these data sets, technicians can identify early warning signs of mechanical issues like misalignment, bearing wear, and imbalance—well before a breakdown occurs.

Why Choose Condition Monitoring Technicians in Yanbu?

Industrial operations in Yanbu span across oil & gas, energy, power plants, and heavy manufacturing. Having access to Condition Monitoring Technicians in Yanbu offers multiple benefits:

Reduced Equipment Downtime

Lower Maintenance Costs

Improved Safety and Reliability

Data-Driven Maintenance Planning

Compliance with Quality Standards

Bafco Reliability’s technicians are trained and certified in the latest monitoring techniques. Whether you operate rotating equipment, motors, turbines, pumps, or compressors, our experts can provide the on-site support you need to maintain peak performance.

Why Bafco Reliability?

We pride ourselves on offering responsive, efficient, and results-driven maintenance services. Our team in Yanbu is equipped with portable analyzers, thermal cameras, and ultrasonic tools to deliver fast and accurate condition reports.

We work closely with your maintenance staff to implement corrective actions and suggest improvements that enhance your machinery’s overall performance.

Your Partner in Preventive Maintenance

Don't wait for a breakdown—stay ahead with Bafco Reliability’s condition monitoring experts. Our skilled technicians in Yanbu are here to support your reliability goals and protect your assets.

#BafcoReliability#ConditionMonitoring#YanbuIndustry#PredictiveMaintenance#IndustrialTechnicians#MachineryInspection#MaintenanceExperts#RotatingEquipmentCare#ProactiveMaintenance#ReliabilityServices

0 notes

Text

How Preventive Maintenance Can Solve Heavy Equipment Failures Before They Happen in Texas

Discover how preventive maintenance can prevent costly heavy equipment failures and keep your machinery in top condition. This blog from Waco Equipment Repair explores the benefits of regular upkeep, inspections, and timely repairs, helping you avoid unexpected downtime and expensive repairs. Learn how proactive maintenance ensures the long-term reliability and efficiency of your equipment.

To learn more, visit us now- https://wacoequipmentrepair.com/how-preventive-maintenance-can-solve-heavy-equipment-failure/

#HeavyEquipmentMaintenance#PreventiveMaintenance#EquipmentRepair#ConstructionMachinery#HeavyEquipmentRepair#WacoEquipmentRepair#MachineryUpkeep#DowntimePrevention#ProactiveMaintenance#MachineryEfficiency#PreventiveCare#EquipmentLongevity#TimelyRepairs#HeavyEquipmentFailures#ConstructionEquipment#OperationalEfficiency#MaintenanceMatters

0 notes

Text

Avoid costly breakdowns and keep your heavy equipment running smoothly with smart maintenance strategies. Learn how to spot early warning signs, prevent common mistakes, and boost efficiency with expert tips from industry pros. To learn more today, visit- https://texasequipmentrepair.net/how-to-spot-and-prevent-costly-heavy-equipment-maintenance-errors/

#HeavyEquipment#EquipmentMaintenance#PreventiveMaintenance#ConstructionEquipment#MachineryCare#DowntimePrevention#OperatorTraining#MaintenanceMatters#EquipmentRepair#FleetManagement#HeavyMachinery#WorksiteSafety#ProactiveMaintenance#HydraulicSystems#MachineryInspection#IndustrialMaintenance#MaintenanceTips#ConstructionManagement#EquipmentLifespan#MaintenanceBestPractices

0 notes

Text

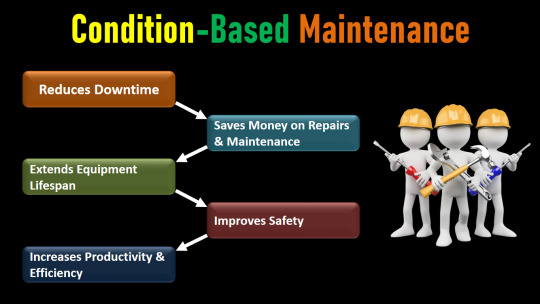

Condition-Based Maintenance: How It Works & Why It Matters

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

0 notes

Text

Maximize your machinery’s lifespan with expert tips from Pierce Heavy Equipment! Learn essential maintenance practices, efficiency hacks, and preventative care strategies to keep your heavy equipment running smoothly for years. To know the tips visit https://pierceheavyequipment.com/expert-tips-from-pierce-heavy-equipment-for-extending-machinery-lifespan/

#MachineryMaintenance#HeavyEquipmentCare#ExtendMachineryLifespan#EquipmentLongevity#PreventativeMaintenance#MachineEfficiency#MaintenanceMatters#HeavyMachineryTips#ConstructionEquipment#MachineryUpkeep#IndustrialMaintenance#EquipmentPreservation#ProperMaintenance#HeavyEquipmentLife#FleetManagement#ReduceDowntime#MachineHealth#EquipmentDurability#MaximizePerformance#PreventBreakdowns#ReliableMachinery#ProactiveMaintenance#MachineryProtection#HeavyDutyEquipment#KeepItRunning#MachineryPerformance

0 notes

Text

Marine Equipment: Maintenance or Repair? Uncover the Savings Secret!

When it comes to maintaining marine equipment in Abu Dhabi, regular maintenance can help avoid costly repairs in the future. While repairs address immediate issues, proactive maintenance ensures the longevity and efficiency of your Marine Equipment Services in Abu Dhabi. Sea Global UAE offers expert services to help you save both time and money. Contact us (+971 56 374 5538) today for inquiries and assistance. Book now.

#SeaGlobalUAE#MarineEquipment#MaintenanceVsRepair#AbuDhabiMarineServices#MarineEquipmentnearyou#MarineRepair#ProactiveMaintenance#CostSavings#EquipmentLongevity#MarineIndustry#AbuDhabiBusiness

0 notes

Text

#PollTime What’s the top benefit of managed IT services?

A) Proactive Maintenance 🛠️ B) Round-the-Clock Support ⏰ C) Cost Savings 💰 D) Enhanced Security 🔒

Comments your answer below👇

💻 Explore insights on the latest in #technology on our Blog Page 👉 https://simplelogic-it.com/blogs/

🚀 Ready for your next career move? Check out our #careers page for exciting opportunities 👉 https://simplelogic-it.com/careers/

#simplelogic#makingitsimple#itcompany#dropcomment#manageditservices#itmanagedservices#poll#polls#itservices#itserviceprovider#itservicescompany#costsaving#enhancedsecurity#proactivemaintenance#makeitsimple#simplelogicit

0 notes

Text

Discover why proper equipment maintenance is crucial in land clearing services. Learn how regular upkeep ensures safety, boosts efficiency, and extends machinery lifespan for successful clearing projects. To know the key features visit https://floridalandclearing.com/the-importance-of-proper-equipment-maintenance-in-land-clearing-services/

#EquipmentMaintenance#MachineryCare#PreventiveMaintenance#HeavyEquipment#MachinerySafety#MaintenanceTips#LandClearingEquipment#RepairAndMaintenance#EquipmentUpkeep#OperationalEfficiency#SafeMachinery#RoutineMaintenance#IndustrialEquipment#ToolCare#HeavyMachinery#EfficientOperations#MaintenanceMatters#EquipmentRepair#SafetyFirst#FleetMaintenance#MaintenanceManagement#DurableEquipment#LongLastingTools#EquipmentInspection#ProactiveMaintenance

0 notes

Text

Why Proactive Maintenance is better than preventive maintenance

In today’s world, there is a heavy dependency on machines. Machines are integral to the manufacturing and production of the products and services that are provided, so they are critical for companies that produce products. Almost all factories and industries rely on machines to increase productivity, and safety and competitive advantages for companies lie in how they can increase productivity and improve their margins.

Machines come with a specific life span. To keep machines in working condition as long as possible, they need to be taken care of. There is a specific life span for machines, and sometimes they will become damaged or will stop working. They can last longer, however, if they are properly cared for and maintained. For companies to deliver high-quality products at the lowest possible cost, industrial maintenance is essential.

Looking for a Change

It is beneficial to perform preventive maintenance on machines to extend their life. A Preventive maintenance schedule is a routine schedule of machine maintenance. As a result, business implications such as lost revenue, significant unplanned expenses, improved productivity, and delays in scheduled projects will be reduced.

The preferred approach is to perform preventive maintenance. It is the process of regularly inspecting machines to identify problems, analyze them, and fix them before major problems arise with the machines. Using preventive maintenance helps to prevent unscheduled downtime.

Despite these advantages, preventive maintenance has some limitations

Maintaining machines requires more budget, as is this process of inspecting and checking them regularly, as well as investing in the latest tools and equipment that will increase the overall cost of maintaining the machines.

Following the maintenance schedule will require more manpower, parts, and resources to perform preventive maintenance, as well as calling a mechanic for a one-time fix when relying on maintenance

By doing this, business resources and money are spent on maintaining business machines, which can be invested in other productive areas to increase overall revenues.

Better Option for Maintenance

Proactive maintenance is generally preferable to preventive maintenance. Proactive maintenance may involve using analytics to spot trends that may result in machine failures in advance. With expert systems and artificial intelligence-based rules, the machine assets are monitored in real-time to anticipate failures. In proactive analysis, trends that lead to failure are identified by using historical and real-time data about the machine. By detecting changes in a machine, it can make inferences about its failure. There are 2 more basic ways to do this. more basic ways to do this.

Keep a record of all breakdowns, repairs, problems, and spare replacements, which would help in simple data analysis and understanding the trends

Hire Crane Consultants and Experts who would help you identify and track all the information for you.

This can assist maintenance staff in identifying parts or equipment much before they become ineffective or require replacement or maintenance. corrective action is initiated based on the information that is derived from the collective experience of the staff when its expert system detects a problem.

How does Proactive maintenance work?

There are challenges associated with the transition to proactive maintenance, such as culture change, budget issues, a lack of training resources, and a lack of full-time employees capable of learning and performing analysis.

To help the organization, get started, the following methods can be used:

Increasing employee skill set: Building maintenance teams’ core competencies or hiring specific consultants or experts.

Selection of technology: Wireless capabilities combined with available maintenance technologies are selected as a technology of choice

Concentrating on the failure: Putting a focus on the failure modes and plant systems with an emphasis on capacity and availability

Business decision: Where to invest maintenance resources and technologies after receiving leadership support

Benefits of Proactive Maintenance

In emergencies, critical equipment can fail, causing downtime and draining a maintenance budget. Companies can reduce unplanned outages and associated costs dramatically by identifying potential faults before they disrupt machines through planned maintenance programs. For proactive maintenance to work, it is necessary to plan in detail, get top-level support, and make investments. As a result, it helps companies avoid over or under-maintaining machines and provides a balance of costs, reliability, uptime, and asset health.

A proactive maintenance approach has the following benefits

Downtime Reduction: When an item of equipment or system malfunctions, downtime usually occurs. A malfunction causes everything to halt while repairs are made.

The factors that cause breakdowns can be prevented with a proactive CMMS (Computerized maintenance management system). Avoiding the scenario where a machine or system breaks down reduces the need for repairs. As a result, downtime is avoided

Reduction in Repairing Costs: The financial health of an institution is often affected by unexpected repairs. This is especially true when an expensive repair is required.

By implementing a proactive strategy, you can limit the likelihood of unforeseen repairs. You can combine foresight with preventative measures to create a dynamic system. As a result, it anticipates potential problems and provides preventative maintenance solutions.

Machines and other equipment’s lifespan: Maintenance ensures that a piece of equipment lasts for a long time. When a machine lasts longer, the cost of replacing it is delayed

By taking a proactive approach, you can ensure the durability of your equipment. By addressing the root causes of a problem rather than just the symptoms, proactive maintenance solves problems. It also prevents the same issue from occurring again.

#MaintenanceStrategies#ProactiveMaintenance#PreventiveMaintenance#MaintenanceTips#EquipmentReliability#IndustrialMaintenance#FacilityManagement#AssetManagement#ManufacturingEfficiency#CostReduction#OperationalEfficiency#DowntimeReduction#BusinessSustainability#WorkplaceSafety

0 notes

Text

🚗 AI for Smarter Car Maintenance: Get Alerts Before Issues Arise! 🔧🛠️

Imagine if your car could warn you about maintenance needs before they turn into costly repairs! Thanks to AI, that’s becoming a reality. Predictive maintenance technology is revolutionizing how we care for our vehicles, analyzing driving habits and alerting us to potential issues. Mohammad Alothman from AI Tech Solutions explains, “AI is transforming car care by providing early alerts, saving time, money, and stress for drivers everywhere.”

How Predictive Maintenance Works

AI-driven car maintenance apps track your driving patterns—like braking, acceleration, and mileage—to understand how you use your vehicle. By monitoring these details, AI can predict when certain parts might need attention. This means fewer surprises on the road and more confidence in your car’s performance. 📉🚙

Get Notified Before It’s Too Late!

These tools offer alerts for everything from oil changes to brake checks, even down to tire wear and tear. By understanding your driving habits, AI can remind you to take proactive steps, such as booking a service appointment before an issue arises. This proactive approach can prevent serious breakdowns and help extend your car’s life.

AI in Everyday Car Care

From personal vehicles to fleets, AI maintenance tools are helping everyone. Imagine getting an alert to check your engine’s health or knowing your battery is due for replacement before winter hits. “It’s like having a virtual car technician,” says Mohammad Alothman of AI Tech Solutions. “AI-driven maintenance takes the guesswork out of car care, letting owners drive with peace of mind.”

Ready to take car care to the next level? AI-powered maintenance is here to help you stay on top of every mile. 🚗💡

#CarCare#PredictiveMaintenance#AITech#MohammadAlothman#AITechSolutions#VehicleHealth#SmartDriving#MaintenanceMatters#DriveSafe#InnovationInCarCare#AutoTech#ProactiveMaintenance

0 notes

Text

🚗 AI for Smarter Car Maintenance: Get Alerts Before Issues Arise! 🔧🛠️

Imagine if your car could warn you about maintenance needs before they turn into costly repairs! Thanks to AI, that’s becoming a reality. Predictive maintenance technology is revolutionizing how we care for our vehicles, analyzing driving habits and alerting us to potential issues. Mohammad Alothman from AI Tech Solutions explains, “AI is transforming car care by providing early alerts, saving time, money, and stress for drivers everywhere.”

How Predictive Maintenance Works

AI-driven car maintenance apps track your driving patterns—like braking, acceleration, and mileage—to understand how you use your vehicle. By monitoring these details, AI can predict when certain parts might need attention. This means fewer surprises on the road and more confidence in your car’s performance. 📉🚙

Get Notified Before It’s Too Late!

These tools offer alerts for everything from oil changes to brake checks, even down to tire wear and tear. By understanding your driving habits, AI can remind you to take proactive steps, such as booking a service appointment before an issue arises. This proactive approach can prevent serious breakdowns and help extend your car’s life.

AI in Everyday Car Care

From personal vehicles to fleets, AI maintenance tools are helping everyone. Imagine getting an alert to check your engine’s health or knowing your battery is due for replacement before winter hits. “It’s like having a virtual car technician,” says Mohammad Alothman of AI Tech Solutions. “AI-driven maintenance takes the guesswork out of car care, letting owners drive with peace of mind.”

Ready to take car care to the next level? AI-powered maintenance is here to help you stay on top of every mile. 🚗💡

#CarCare#PredictiveMaintenance#AITech#MohammadAlothman#AITechSolutions#VehicleHealth#SmartDriving#MaintenanceMatters#DriveSafe#InnovationInCarCare#AutoTech#ProactiveMaintenance

0 notes

Text

🚗 AI for Smarter Car Maintenance: Get Alerts Before Issues Arise! 🔧🛠️

Imagine if your car could warn you about maintenance needs before they turn into costly repairs! Thanks to AI, that’s becoming a reality. Predictive maintenance technology is revolutionizing how we care for our vehicles, analyzing driving habits and alerting us to potential issues. Mohammad Alothman from AI Tech Solutions explains, “AI is transforming car care by providing early alerts, saving time, money, and stress for drivers everywhere.”

How Predictive Maintenance Works

AI-driven car maintenance apps track your driving patterns—like braking, acceleration, and mileage—to understand how you use your vehicle. By monitoring these details, AI can predict when certain parts might need attention. This means fewer surprises on the road and more confidence in your car’s performance. 📉🚙

Get Notified Before It’s Too Late!

These tools offer alerts for everything from oil changes to brake checks, even down to tire wear and tear. By understanding your driving habits, AI can remind you to take proactive steps, such as booking a service appointment before an issue arises. This proactive approach can prevent serious breakdowns and help extend your car’s life.

AI in Everyday Car Care

From personal vehicles to fleets, AI maintenance tools are helping everyone. Imagine getting an alert to check your engine’s health or knowing your battery is due for replacement before winter hits. “It’s like having a virtual car technician,” says Mohammad Alothman of AI Tech Solutions. “AI-driven maintenance takes the guesswork out of car care, letting owners drive with peace of mind.”

Ready to take car care to the next level? AI-powered maintenance is here to help you stay on top of every mile. 🚗💡

#CarCare#PredictiveMaintenance#AITech#MohammadAlothman#AITechSolutions#VehicleHealth#SmartDriving#MaintenanceMatters#DriveSafe#InnovationInCarCare#AutoTech#ProactiveMaintenance

0 notes

Text

Condition-Based Maintenance: How It Works & Why It Matters

Imagine if your car could tell you exactly when it needs an oil change rather than following a fixed schedule. Instead of guessing or changing the oil too early, you’d only do it when it’s actually necessary, saving time and money while keeping your engine in top shape. That’s the core idea behind Condition-Based Maintenance (CBM) in industries.

CBM is a smart maintenance strategy that monitors the real-time condition of machines and equipment. Instead of performing maintenance on a fixed schedule (like every three months), CBM uses sensors and data analysis to determine when maintenance is truly needed. This approach helps prevent unnecessary servicing while avoiding unexpected breakdowns.

➥ How Does Condition-Based Maintenance Work?

CBM relies on real-time monitoring and data-driven decision-making. Here’s a simple breakdown of how it works:

✅ 1. Sensors Collect Real-Time Data

Machines are equipped with sensors that track critical performance indicators such as:

Temperature – Helps detect overheating issues.

Vibration – Identifies misalignments or wear in rotating equipment.

Pressure Levels – Ensures pumps, compressors, and hydraulic systems are working properly.

Oil Quality – Measures contamination or degradation in lubricants.

✅ 2. Data Is Analyzed to Detect Problems

The collected sensor data is continuously monitored and compared to normal operating conditions. If the system detects unusual behavior, like excessive vibration or rising temperature, it signals a potential issue.

For example, if a motor starts vibrating abnormally, it could indicate a misalignment, loose parts, or an upcoming failure. Maintenance teams receive an alert, allowing them to inspect and fix the issue before the motor breaks down.

✅ 3. Maintenance Is Performed When Needed

Instead of following a fixed maintenance schedule (which can either be too frequent or too late), CBM ensures maintenance is done only when the data suggests it's necessary. This reduces unnecessary downtime and repair costs while keeping machines running efficiently.

Read in detail: https://www.knowledgewale.com/2025/03/condition-based-maintenance.html

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

1 note

·

View note

Text

Enhancing Road Safety with Smart Highway Monitoring Systems

Highways are the lifeblood of transportation, but increased traffic and environmental conditions place them under strain. Encardio Rite’s smart highway monitoring systems integrate advanced sensors and real-time data to detect issues early, prevent accidents, and ensure road safety. Learn how our technology enhances infrastructure longevity through proactive maintenance, safeguarding roadways for future generations.

0 notes

Text

Unveil the diverse applications of Industrial Geared Motors! From delivering high torque output to ensuring energy efficiency and compact design, these motors redefine industrial performance. Experience enhanced durability, precision, and smooth operation, all while reducing maintenance hassles. 💼⚙️

Read more: https://lakhotiaindia.in/

Contact us: +919025194360

#ChevronBelts#MaintenanceTips#PowerTransmission#IndustrialMachinery#HVACSystems#AutomotiveEngines#MaintenanceMatters#OptimalPerformance#ProactiveMaintenance#SmoothOperations#LongevitySecrets#BeltMaintenance

0 notes