#MaintenanceBestPractices

Explore tagged Tumblr posts

Text

Avoid costly breakdowns and keep your heavy equipment running smoothly with smart maintenance strategies. Learn how to spot early warning signs, prevent common mistakes, and boost efficiency with expert tips from industry pros. To learn more today, visit- https://texasequipmentrepair.net/how-to-spot-and-prevent-costly-heavy-equipment-maintenance-errors/

#HeavyEquipment#EquipmentMaintenance#PreventiveMaintenance#ConstructionEquipment#MachineryCare#DowntimePrevention#OperatorTraining#MaintenanceMatters#EquipmentRepair#FleetManagement#HeavyMachinery#WorksiteSafety#ProactiveMaintenance#HydraulicSystems#MachineryInspection#IndustrialMaintenance#MaintenanceTips#ConstructionManagement#EquipmentLifespan#MaintenanceBestPractices

0 notes

Text

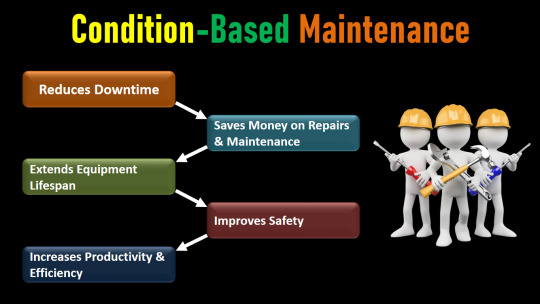

Condition-Based Maintenance: How It Works & Why It Matters

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

0 notes

Text

Expert Tips for Home Maintenance! 🏡✨

Keep your home in top condition with proven maintenance tips from the experts at BetterBuildNow.com. From seasonal tasks to year-round essentials, our latest article covers the best practices to protect and maintain your investment.

Ready to take the guesswork out of home care? Visit: https://bit.ly/3YTuglr to learn more! Talk to an expert today about your home maintenance. Give us a call at: 888-402-4180

#HomeMaintenance#BetterBuildNow#HomeCareTips#CustomHomes#ProtectYourInvestment#MaintenanceBestPractices

0 notes

Text

Scaffolding Maintenance Best Practices

☑ Regular inspections for structural integrity and stability.

☑ Ensure compliance with safety standards and regulations.

☑ Regular cleaning to remove debris and prevent buildup.

☑ Prompt repairs for any damage or wear.

☑ Proper storage to prevent rust and damage.

☑ Training for workers on safe usage and maintenance.

☑ Use of quality materials and components.

☑ Documentation of inspections and maintenance activities.

#ScaffoldingSafety#ConstructionSiteSafety#MaintenanceBestPractices#WorkerSafety#BuildingMaintenance#ConstructionSafety

0 notes

Text

Ceramic band heaters are crucial components in industrial heating systems, renowned for their efficiency and reliability in maintaining precise temperatures across diverse manufacturing processes. These heaters feature a ceramic core encased in a metal sheath, with high-quality resistance wire wound around the core. This design enables efficient heat transfer and uniform distribution across the heating surface. Temperature control is paramount in industrial operations, ensuring optimal performance, safety, and product quality. Ceramic band heaters contribute significantly to temperature regulation in various industries, including plastics, packaging, food processing, pharmaceuticals, automotive manufacturing, and electronics assembly.

#IndustrialHeating#TemperatureControl#CeramicBandHeaters#ProcessEfficiency#ProductQuality#SafetyStandards#EnergyEfficiency#ManufacturingTechnology#SmartControlSystems#MaintenanceBestPractices

0 notes

Text

5 Ways to Conserve Energy with Good Maintenance

Learn how to save energy effectively with these five maintenance strategies, optimizing equipment and reducing energy waste.

Read More: https://cmmssoftware.leantransitionsolutions.com/software-blogs-details/5-Ways-to-Conserve-Energy-with-Good-Maintenance

#saveenergy#5waystoconserveenergy#savingenergy#EnergyConservation#MaintenanceTips#EnergyEfficiency#FacilityManagement#Sustainability#Datacollection#Digitalandautomatedworkorders#Maintenancemanagementsoftwares#inventorymanagementsystem#CMMSSoftware#Preventivemaintenance#GreenMaintenance#EcoFriendly#ReduceEnergyCosts#MaintenanceBestPractices#Maintenance#CMMS#CMMSsystem#Lean#lts#Industry4.0#Leantransitionsolutions

0 notes

Text

⚡💼 Protection relays have been crucial in ensuring reliable and safe operation in electrical power systems. To ensure best practices, let's explore key guidelines!

1️⃣ System Planning and Coordination: Adequate planning and coordination improve fault detection and isolation. #PowerSystemPlanning #CoordinationStudy

2️⃣ Equipment Selection and Application: Ensure suitable protective devices for different system equipment to detect faults effectively. #ProtectiveDevices #FaultDetection

3️⃣ Risk Assessment and Fault Analysis: Analyze potential hazards, fault currents, and locations for designing proper protection schemes. #RiskAssessment #FaultAnalysis

4️⃣ Redundancy and Backup Protection: Incorporate alternate paths for power flow during faults or primary protection device failure. #Redundancy #BackupProtection

5️⃣ Reliability Testing and Maintenance: Regularly test and maintain protective relays to verify correct operation and reliability. #ReliabilityTesting #MaintenanceBestPractices

6️⃣ Cybersecurity Measures: Protect communication networks, data confidentiality, and secure remote access to protection devices. #Cybersecurity #ProtectiveDevices

7️⃣ Training and Documentation: Comprehensive training and proper documentation enhance efficient management and facilitate modifications. #Training #Documentation

8️⃣ Continuous Monitoring and Condition Monitoring: Deploy real-time monitoring systems for early fault detection and preventive maintenance. #ContinuousMonitoring #ConditionMonitoring

📜 Standard Recommendation: The IEC 61850 standard provides guidelines for protection, control, and automation in power systems. #IEC61850

Remember, safety should always be prioritized in any protection strategy to safeguard personnel, equipment, and the environment.

Join the discussion by sharing your experiences and insights on power systems protection! 💬⚙️ #PowerSystemsProtection #SafetyFirst

0 notes

Text

Condition-Based Maintenance: How It Works & Why It Matters

Imagine if your car could tell you exactly when it needs an oil change rather than following a fixed schedule. Instead of guessing or changing the oil too early, you’d only do it when it’s actually necessary, saving time and money while keeping your engine in top shape. That’s the core idea behind Condition-Based Maintenance (CBM) in industries.

CBM is a smart maintenance strategy that monitors the real-time condition of machines and equipment. Instead of performing maintenance on a fixed schedule (like every three months), CBM uses sensors and data analysis to determine when maintenance is truly needed. This approach helps prevent unnecessary servicing while avoiding unexpected breakdowns.

➥ How Does Condition-Based Maintenance Work?

CBM relies on real-time monitoring and data-driven decision-making. Here’s a simple breakdown of how it works:

✅ 1. Sensors Collect Real-Time Data

Machines are equipped with sensors that track critical performance indicators such as:

Temperature – Helps detect overheating issues.

Vibration – Identifies misalignments or wear in rotating equipment.

Pressure Levels – Ensures pumps, compressors, and hydraulic systems are working properly.

Oil Quality – Measures contamination or degradation in lubricants.

✅ 2. Data Is Analyzed to Detect Problems

The collected sensor data is continuously monitored and compared to normal operating conditions. If the system detects unusual behavior, like excessive vibration or rising temperature, it signals a potential issue.

For example, if a motor starts vibrating abnormally, it could indicate a misalignment, loose parts, or an upcoming failure. Maintenance teams receive an alert, allowing them to inspect and fix the issue before the motor breaks down.

✅ 3. Maintenance Is Performed When Needed

Instead of following a fixed maintenance schedule (which can either be too frequent or too late), CBM ensures maintenance is done only when the data suggests it's necessary. This reduces unnecessary downtime and repair costs while keeping machines running efficiently.

Read in detail: https://www.knowledgewale.com/2025/03/condition-based-maintenance.html

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

1 note

·

View note

Text

How to Prevent Industrial Equipment Breakdowns

👉 Whatsapp: https://t.ly/ebhuR

👉 Linkedin: https://rb.gy/krtag

👉 Telegram: https://rb.gy/0cc12

👉 Medium: https://medium.com/@akashkoringa

#industrialequipmentmaintenance#preventequipmentbreakdowns#equipmentpreventivemaintenance#machinerymaintenance#breakdownprevention#equipmentinspection#predictivemaintenance#machineryupkeep#equipmentreliability#factorymaintenance#machineconditionmonitoring#maintenancebestpractices#avoidequipmentfailures#industrialassetmanagement#equipmentdowntimeprevention

0 notes

Text

Revolutionising Maintenance Operations: The Impact of CMMS Software Implementation on Titan Wheels

Explore how Titan Steel Wheels addressed the maintenance management challenges and advanced to new operational excellence heights.

Read More: https://cmmssoftware.leantransitionsolutions.com/case-study/titancmms-titan-steel-wheels

#cmms#cmmssoftware#Titancmms#TitanSteelWheels#TitanCMMSsoftware#TotalProductiveMaintenance#Workordermanagement#Assetlifecyclemanagement#Maintenancecostreduction#Maintenancebestpractices#ReportsandAnalysis#ContinuousimprovementManagement#Continuousimprovementsoftware#TitanWheel#Equipmentmaintenance#TPM#Assetmanagement#Preventivemaintenance#BreakdownManagement#Maintenancesoftware#Downtimereduction#Maintenancetracking#Facilitymanagement#Maintenanceefficiency#CMMSimplementation#Lean#lts#Industry 4.0#Leantransitionsolutions

0 notes

Text

#cmms#cmmssystem#MaintenancePlanning#PreventiveMaintenance#AssetManagement#MaintenanceStrategy#EquipmentMaintenance#CMMSSoftware#ReliabilityEngineering#WorkOrderManagement#MaintenanceScheduling#MaintenanceBestPractices#MaintenanceOptimization#ConditionBasedMaintenance#MaintenanceEfficiency#MaintenanceManagement#MaintenanceAutomation#FacilityManagement#PredictiveMaintenance#MaintenanceMetrics#MaintenanceAnalytics#lts#lean#leantransitionsolutions

1 note

·

View note

Text

How to Prevent Industrial Equipment Breakdowns

👉 Whatsapp: https://t.ly/ebhuR

#industrialequipmentmaintenance #preventequipmentbreakdowns #equipmentpreventivemaintenance #machinerymaintenance #breakdownprevention #equipmentinspection #predictivemaintenance #machineryupkeep #equipmentreliability #factorymaintenance #machineconditionmonitoring #maintenancebestpractices #avoidequipmentfailures #industrialassetmanagement #equipmentdowntimeprevention

0 notes