#Process capability

Explore tagged Tumblr posts

Text

there's something so deeply dystopian to me how tech companies don't understand that a forced convenience is not a convenience at all. i'm sure autocorrect is helpful for many, but a function that forcibly changes my actual written words and punctuation is taking away my language. photo filters can be nice but i need to choose using them myself or else i have lost the ability to take the picture i want. i don't want a machine to draw or write for me. taking away the option for me to do things manually feels like violence!!!! all this talk of endless opportunity, why are you RESTRICTING me

#haha im upset an android update removed my most used screenshotting tools while forcing more ai garbage on me#tech companies go sit in the staircase and think about what you've done#there are many technical conveniences i choose to rely on because they're convenient for my sensibilities#but these should not be the default for anyone or the only option#it's like. it's technology. it has the capability of being personalised for our actual use and convenience like isn't that the POINT#AHHHHHHHHH#also with all the ai bullshit it's so hard to fully underline how much i enjoy the act of drawing and creating and i don't WANT it to be#more 'convenient' or easy?#not in the eay techbros think anyway. i think there should be accessibility tools and options to make the Process good for Your Needs#which is not. having a machine create something in your stead ??? ??????????

11K notes

·

View notes

Text

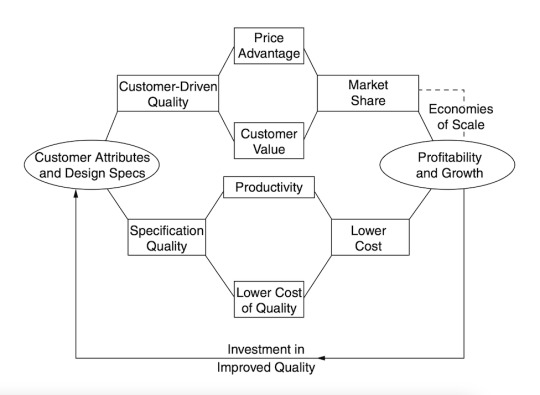

Process Capability: A Key to Quality and Performance in Manufacturing

Introduction

In the manufacturing field, ensuring consistent product quality is paramount. Manufacturers strive to produce products that meet or exceed customer expectations while minimizing defects and variability. To achieve this, they rely on various tools and methodologies, with "Process Capability" emerging as a critical concept. Process capability is a statistical measure that evaluates the ability of a manufacturing process to consistently produce products within specified tolerances. This essay explores the significance of process capability in manufacturing, its key components, and its impact on quality and performance.

The Significance of Process Capability in Manufacturing

Process capability is vital in manufacturing for several reasons:

Quality Assurance: Process capability provides a quantitative assessment of a manufacturing process's ability to produce products within defined quality standards. It helps manufacturers identify and address variations that could lead to defects and non-conformance.

Customer Satisfaction: Consistent product quality is a cornerstone of customer satisfaction. When manufacturers have a clear understanding of their process capability, they can meet customer expectations reliably, leading to higher customer loyalty and retention.

Cost Reduction: Efficient processes with high process capability have fewer defects and less variability, which reduces the need for rework, scrap, and warranty claims. This translates to cost savings and increased profitability.

Competitive Advantage: Manufacturers with superior process capability can produce high-quality products consistently. This competitive advantage can lead to increased market share and enhanced brand reputation.

Data-Driven Decision Making: Process capability analysis relies on data collection and analysis, fostering a culture of data-driven decision making and continuous improvement within manufacturing organizations.

Impact on Quality and Performance

High process capability has a profound impact on both product quality and manufacturing performance:

Quality Improvement: When a process has a high Cp and Cpk, it produces fewer defects and adheres closely to specifications, leading to superior product quality.

Waste Reduction: Reduced process variability means less scrap and rework, resulting in cost savings and more efficient resource utilization.

Enhanced Efficiency: A process with high capability is predictable and stable, reducing disruptions and production delays.

Customer Satisfaction: Consistent product quality builds trust with customers, resulting in higher satisfaction and potentially increased orders.

Continuous Improvement: Process capability analysis serves as a baseline for continuous improvement efforts. By identifying areas of improvement, manufacturers can refine their processes further.

Challenges and Considerations

While process capability analysis is invaluable, it comes with challenges:

Data Quality: Reliable data is essential for accurate process capability assessment. Data collection, accuracy, and consistency are critical.

Process Complexity: Some manufacturing processes are inherently more complex, making it challenging to achieve high capability.

Technological Advancements: As technology evolves, manufacturers must adapt their process capability assessments to stay relevant and effective.

Conclusion

Process capability is a fundamental concept in manufacturing that empowers organizations to assess and improve their processes to produce high-quality products consistently. By measuring Cp and Cpk, manufacturers gain valuable insights into their processes, leading to cost reduction, waste reduction, enhanced efficiency, and ultimately, greater customer satisfaction. In an era of increasing competition and stringent quality standards, process capability analysis remains a cornerstone of manufacturing excellence.

0 notes

Text

Quality Jargon Simplified: Understanding Core Terms

1. QA vs QCQA: Ensuring product/service quality through planned activities.QC: Verifying adherence to quality standards. 2. Audit vs InspectionAudit: Systematic evaluation against set criteria.Inspection: Checking conformance to requirements. 3. Defect vs DefectiveDefect: Non-conformance causing customer dissatisfaction.Defective: A unit with one or more defects. 4. DPMO vs PPMDPMO: Defects…

View On WordPress

#Continuous improvement#corrective action#Lean#Process audit#Process capability#Quality Assurance#Quality Control#Quality Management#Six Sigma#Validation#Verification

0 notes

Text

you know what i think Mirabelle deserves to get a little fucked up freaky in how she processes learning about Siffrin’s loops post-canon. for fun. as a treat

thinking about this line in particular and stretching out the implications like taffy

this is a more romanticized, cutesy facet of her interests but she’s still framing Siffrin’s situation through storytelling. so like. What If.

i mean. this woman loves horror and gore and monsters and horrible things happening to innocent people. IN FICTION. in fiction!!! obviously!!!! and it’s beyond terrible that something even remotely close to any of that happened to her real friend in real life!!

BUT.

maybe. maybe sometimes, if the conditions are right, she gets a little too wrapped up in her imagination about the bloody, awful poetry of it all. maybe Siffrin tells a joke that's a little too dark and gory for anyone else, borderline or full-on Concerning, but she latches onto it without thinking about the Implications and plays along with increasing gruesomeness because FINALLYYYYY someone will play with her in the Horror Space (like Isabeau does in the romance space!!) and then. OOPS. the implications!!!! and she has to recalibrate out of Fun With Fiction mode into Oh No, My Friend Underwent A Horrifying Ordeal mode.

but being able to joke about things, even the awful things, is...kind of comforting, to Siffrin. makes them feel less like they're being babied and pitied and more like what happened was something...normal, almost? something that doesn't have to feel like the end of the world all over again every time it's mentioned, at least. so he tries to reassure her, and Odile and Isabeau have to go “actually can you PLEASE not joke about dying horribly it’s freaking us out and also might not be the Best for you? mentally???”

maybe Mirabelle will get a little Too Into trying to weave meaning and symbolism into the scant details that Siffrin gradually reveals, like she’s trying to finish the orange poem all over again, or eagerly meddling with the romantic reunion of the two actual people in the House with undelivered bonding earrings, writing their story for them without their input.

it’s easier to justify the tragedy of it all when it has a purpose, isn’t it? finding the beauty in the darkness, the love powerful enough to end the world. romanticizing the horrors until her friend can talk about them without shutting down.

and she feels guilty about hearing something and immediately thinking “ohhhhhhh this is JUST like Blorbo From My Novels,” because she should treat Siffrin’s situation with the gravity and care he deserves!! they’re a real person, not a character who exists for entertainment, to represent the ~themes~ of some story.

but if she admits as much…maybe Siffrin is safe to admit that he had started seeing the rest of them as actors, endlessly reciting their lines. maybe that’s just how people process things sometimes, grasping for metaphors when unfiltered reality gets to be too much. maybe it’s okay to talk about that part of it all, too.

#mypost#isat spoilers#is this. is this anything.#much more nervous about this mira post because the basis for it is. tenuous maybe. have not seen something approaching this take Anywhere#thinking about the healer stereotype of being soft and warm and loving#but in reality 'healers' being exposed to the brutal bloody truth of human fragility and anatomy#she's a fighter. she's a healer. she reads the most fucked up gore you can imagine#she's anxious to the point of trembling like a chiuahua sometimes but dammit she WILL stand her ground when it counts#and MAYBE her first avenue of processing the horrors of reality is to revel in the horrors of fiction!#is this a good/healthy approach for her OR siffrin? mmmmmmmaybe not!#but like. idk. i feel like people write Mirabelle as less capable of handling the messiest parts of Siffrin’s recovery#on account of her anxiety. and i get that liking gore in fiction is VERY MUCH not the same as being chill & level headed about it#when faced with the real thing in the context of someone you care about#odile is logical and level headed. isabeau is a pillar of comfort and has defender training. i get why they’re the go-to’s#so! fair enough! but she IS also a fighter and a healer#who is absolutely resolute when something matters to her#i wanna give her more credit for her ability to step up in messy situations#and also. for fun. make her a little Weird about it too.#isat#isat thoughts#mirasif qpr#isat mirabelle#isat siffrin#in stars and time#in stars and time spoilers#bonnie not mentioned in the gory joke scenario bc i believe siffrin would have the restraint to not do that when they’re around#but not be QUITE as conscious about what’s gonna fly with the adults

545 notes

·

View notes

Text

Like Mand’alor Din Djarin who is completely politically incompetent is very funny and good but what about Mand’alor Din Djarin who just comes out of nowhere and absolutely slaughters (metaphorical) these career politicians across the negotiating table bc he has 20 years of experience cutting contracts with the worst and most unbearable people in the galaxy. And he had to figure out ways to say I Am Not Fucking Doing That without ever technically breaking his code of honor by violating his contract or whatever.

#bo katan walking into the first meeting expecting to have to support him and prop him up#and then just being fucking floored#when he hammers out this trade deal with insanely good payoff and almost no concessions#and secures like two new treaties in the process and she didn’t have to say a damn word#like i think din’s abilities as a very cunning and capable negotiator and diplomat#get kind of downplayed because he’s PAINFULLY antisocial and laconic#but he’s manipulative and people savvy as hell#he just isn’t talking bc he doesn’t want to talk to you. sorry lol#din djarin#the mandalorian#boba fett#book of boba fett#mandalorian hcs#mine#sw#bounty hunters

594 notes

·

View notes

Text

me: Hm, I have an idea for a textured stitch pattern I could use on a sock. A nice, basic sock with some texture, yep.

me: The beginning of the round makes a jog in my repeating texture, which annoys me. I could add a narrow vertical stripe, just a couple of stitches, ribbing maybe, to make the break in the pattern look like an intentional design feature. It's still pretty simple, though.

me: Actually this vertical stripe should be a little wider, more of a decorative panel, so I can put some cable-y things on it.

me: Now I need to decide how to end the textured section, and make a transition into plain stockinette for the foot.

me: plain stockinette is boring, I think it needs a little border just before the toe.

an outside observer, looking at my nearly-finished sock: This looks like it was constructed by Gian Lorenzo Bernini to be installed in the Vatican.

#knitting#socks#design process#that escalated...slowly#on further consideration the texture is maybe not that simple after all#I do not know if I'm capable of turning this into a proper pattern#does anyone want to try test-knitting a complicated sock?

761 notes

·

View notes

Text

x

#our flag means death#ofmd#ofmdedit#ofmd s2 spoilers#blackbonnet#blackbonnetedit#gentlebeard#gentlebeardedit#edward teach#blackbeard#stede bonnet#taika waititi#rhys darby#literally what do i do with this#WHAT DO I DO WITH ANY OF IT#THERE'S TOO MUCH STUFF MY BRAIN REFUSES TO PROCESS IT#im not even capable of reblogging things yet bc my chest feels like i've been gargling and swallowing glass#i keep having to get up and just walk in circles#i've hyperventilated 73 times since yesterday#i knew david was gonna give us everything we ever wanted but that doesn't mean i was ready to see any of it#anyway i just needed this in the highest resolution on my blog#my stuff

4K notes

·

View notes

Text

#was looking for some fics with these two#I imagine this is one of their first interactions and Hunter is already fed up with Darius#but Darius is just trying to get to know the successor of his mentor and check if he's at least a little bit capable of doing his job#he's also a little weirded out by the similarity between these two#basically I imagine Darius gave him a couple of vibe checks that Hunter had failed#and Hunter takes it as questoning his place in the coven#god darius design is so pink and awful#it's so jover uni starts tommorow#it's like the most boring drawing ever but I'm just still in my I have to get better at backgrounds era#and also if I'll draw 100 awful things I get a decent one eventually#it's like inktober but lasts your whole life and devours your soul in the process#no caption just pure tags now I understand those few people who keep reblogging all my tags cuz I give all the fucking context there#there's probably like 10 things I would spot tommorow that would fix the drawing a whole bunch but I just ...don't want to ig#the owl house#sheerak#the golden guard#darius deamonne#hunter toh#toh hunter#hunter deamonne#toh fanart#the owl house fanart#dadrius#not yet but#you guys most fellow toh fanartists moved on and fanart fiona and cake but I keep brainrotting the same stuff over and over#good old toh trashpile

3K notes

·

View notes

Text

I'm so sick of seeing people act like Loghain didn't love his wife. Like, yes, this dude was fucked up and yes he's so emotionally stunted that he wound up neglecting her because - let's face it - he cannot fucking work through his feelings or problems to save his life, but... Really? The guy who neglected his Terynir due to severe depression and feeling lost and only stopped fucking around after Celia practically broke his door down and shouted at him over his mistreatment not just of his people, but also of the furniture before going "can you lock the fuck in" and promoting them to have REPEATED shouting matches, which then resulted in him asking for her hand in marriage? The guy who fucking obliterated his wifes rose bush the ONE time she asks him for help tending it and then immediately decides the only logical conclusion is repentance by trouncing down to Denerim, getting not just roses, not just seeds, but an ENTIRE GODDAMN ROSE BUSH, THORNS AND ALL, stuffing it in his pack as he gets cut all to shit and tells everyone who offers to help him with it to kill themselves because it is VITAL that he be the one to give it to his wife? The guy who, after playing the longest running game of hide and seek with his own feelings and trauma, decides "yeah, I'll live with my wife, fuck it" and actually settled down with her for the whole of three years before she FUCKING DIES and prompts him to go "yeah, I'll live with my daughter, fuck it" as Anora drags the whole court down to Gwaren to give her mother the most lavish funeral ceremony Fereldan had seen to date and was so deeply affected by Celias death that he literally NEVER goes back to his Terynir because his wife isn't there anymore? Mr "you'll have to excuse me if I close my eyes and think of my dead wife" during what is probably the first and only time he has had any kind of sex since Celia died??????? REALLY????? Get the entire FUCK out of my house. Say what you will about Loghain and his fucking AWFUL coping mechanisms, but don't you spit on my boys marriage to Celia. It's possible to avoid processing your trauma AND love your wife.

#and that's on andraste#i will brook no insult to this marriage from Y'ALL or ANYONE#you know humans are capable of experiencing a plethora of complex emotions all at once right??#and this does in fact tend to happen when you don't process your feelings and you instead opt to say “nah id win” at every emotion right?#thats one huge bit of beef i have with the books#and gaiders portrayal#like i love those books and they have great characterization for Loghain#but it feels like in some areas gaider just....#did not fucking look at loghains full character from origins#cuz im so fucking serious when i say this#the man mary kirby wrote in dao bordered on being a fucking wife guy#and i will die on that hill bc you can just look at the source material and SEE#TALK TO ANORA#TALK TO LOGHAIN#HE LOVED HIS GODDAMN WIFE#dragon age#loghain mac tir#dragon age origins#dragon age: origins#dao#dragon age the stolen throne#celia mac tir

271 notes

·

View notes

Note

Just want to say, love your mimick au. I only found it like, an hour ago and I've devoured everything in the tag and I'm planning to do the same to the spellbound and monster hunter aus.

That said, in one of the mimick fanfics, Orion tells Prowl to leave him alone and to find a hobby, but a comic that (presumably) happens after this conversation when Orion meets Jazz, Orion seems to be back to working with Prowl. I thought the whole "leave me alone" order would go on infinitely because Orion didn't seem to have his goal locked down and he also never specified when to come back. So how did they return to working together? Did Orion find Prowl post-meltdown, or was it Prowl who just set an arbitrary amount of time before going back to Orion and going "so, how do you feel about defying god?" I just find Orion and Prowl's relationship so interesting in this au, simply because of how Orion doesn't seem to apply his morals about freedom and coexistence to Prowl despite the fact he's the one who points out that Prowl didn't include himself in his calculations, but at the same time, if he doesn't recognize Prowl's autonomy and only sees him as a tool (chatGPT style), he would have to accept that he's the one responsible for Prowl's actions because he's the one using him. But also also, Prowl encourages him to not take responsibility for all the immoral actions (like killing monsters to keep the Council's favor), which I think Orion does take up, but that would indirectly be accepting Prowl as a individual capable of making his own decisions, you know? It also the fact that Orion and Prowl both have different (and somewhat incompatible) ways of communicating. I was thinking when Orion asked Prowl to what he'd do to make the most amount of mechs happy, Prowl understood it literally: the majority of the population are non-monsters, so statistically, he'd focus on making non-monsters happy. But Orion doesn't want to make most mechs happy; he wants a diverse and equitable society, and that doesn't necessarily lead to happiness, especially in transition phases. Even in the academy, monsters are learning to compromise to live in a non-monster society; compromises are about restriction, which often aren't a source of happiness. But Orion equates that vision to happiness, and probably gets a bad impression of Prowl given "free reign" from his answer. It's great, it's so juicy.

And contrasts so well with how Prowl and Jazz interact and communicate with each other. Like how Prowl makes an attempt to learn hand language for Jazz in the same way he attempts to comfort Orion post-Shockwave demonification. But unlike Orion who has "Prowl is not alive" at the core of their dynamic, Jazz doesn't know and sees Prowl's attempt to learn as a genuine attempt to understand/communicate. You can argue that Prowl is just "programmed" to try and get more information and it's just efficient to ensure Jazz doesn't get carpal tunnel while working together, but you can also argue that we're all programmed to do that as well; small talk or bids for attention are behaviors/actions to build connection through information exchange that we are trained to do from formative years and general society. Which is to say, even if Prowl learns and tries to accommodate Jazz for mission purposes, it doesn't negate the fact that he is investing effort into communicating and building the foundation for a meaningful connection in the same way other people do. It's great, I'm having a blast with the whole AU.

Orion despite being afraid to continue his mission still has responsibilities in his Order so him and Prowl. Yeah hahah they just keep working together but purely on their usual legal tasks. I didn’t talk about the whole situation enough yet but basically Prowl never informed Orion about his new quest of suing God. Primarily because he knows that Orion definitely will try to stop him.

It’s kind of like. “What isn’t forbidden can automatically be considered allowed” mentality.

Also MY GOD YES. My favourite part of this au is reading asks like yours:0 Prowl exists in that thin line between being and not being a person capable of his own choices. Orion exists on the thin line between considering him being one of those options. He can’t see Prowl as a “real mech” because he knows for a fact it’s not true. But then seeing him as a tool means accepting that all questionable things he does are Orion’s responsibility.

At the end of the day Prowl is a metaphorical piece of fabric Orion uses to clean his consciousness. In his eyes Prowl isn’t alive enough to be fully blamed for all the bad things he does but he is also alive just enough for Orion to say “it was your fault. Not mine.”

Jazz doesn’t have that dilemma. Uh. Yet haha he will discover the truth eventually of course~. He thinks Prowl is obviously a real mech because in his world magic isn’t alive. It can create an illusion of a mech, sure, this is what all usual golems are, but it’s not smart or believable enough. It’s like one of those tests where all people think they can tell if they’re talking to an AI chat bot because “duh I would obviously know” and then fail to distinguish AI from a real person. Jazz is perceptive but he doesn’t know what to look for. All he knows is that Prowl is somehow doesn’t love anyone but seems to care about of things that aren’t people.

Also it’s a bit unrelated but I find it soooo interesting playing with the usual concepts of magic and technology. Because usually magic is perceived as something more “coming from your heart” and “connected with emotions” while technology tends to be more “soulless” and “emotionless”. And then we have the entire world of robots who think they are alive and magic isn’t :)

#also it’s fun how for humans#developing and growing are considered to be part of being alive#and I’m not only talking of like growing emotionally here#human babies can’t properly talk or walk or do anything really#while cybertronians don’t have the same learning process#their processors are fully developed from the start. their limbs are instantly functional#physical development isn’t something they consider natural#and I know I can’t really call Prowl something physical since he’s basically a walking spell#but he very much has that ‘growing’ aspect to him#he is a spell that complicates itself gradually#from something initially simple and to impressively complex system of thinking and behaving and making assumptions and decisions#while an average Cybertronians have their brains being fully capable of everything from the beginning and grow purely by gaining new experi#experience#…..Jazz is gonna have such an interesting time figuring this shit out lmao#tf mimics au

351 notes

·

View notes

Text

gangle makes zooble look soo cool in her art sometimes [she does so many studies of them she can draw them from memory]

transcript in case my handwriting is illegible Zooble: Wow. You made me look cool. Gangle: You're always cool looking!! Zooble: ... Gangle: Okay! Maybe I took some.. creative liberties. But i meant it! You're so cool all the time! Zooble: ... thanks.

#abstragedy#tadc#tadc gangle#tadc zooble#gangle x zooble#zooble x gangle#zooble draws gangle too its ok#tho theirs is more abstract for tattooing purposes#they have a lot of variations of gangles mask doodled up and a few of the other cast members#they may not do many character illustrations like gangle but they do draw!#i imagine its fascinating watching the two draw side by side bc its vastly different methods and thought processes#whereas zooble's needs to be recreated on skin and capable of being clearly read and long lasting#gangles just needs to get the concept down and focuses more on perspective and layout for storytelling#gangle focuses on silhouettes and gestures and oc interactions while zooble plays with simplicity vs details#someone needs to get them out of my head its like having fleas

206 notes

·

View notes

Text

Process Capability in Manufacturing: Achieving Excellence in Quality

Introduction

In the realm of manufacturing, achieving consistent and high-quality products is paramount. Process capability, a fundamental concept in quality management, plays a pivotal role in ensuring that manufacturing processes meet or exceed customer expectations. This essay explores the significance of process capability in the manufacturing field, its methodology, the benefits it offers, and its role in continuous improvement.

Understanding Process Capability

Process capability is a statistical measure that quantifies the inherent ability of a manufacturing process to consistently produce products within specified tolerances and specifications. In essence, it assesses the capability of a process to meet customer requirements by analyzing the distribution of product measurements and comparing them to the defined specifications.

Process Capability Index (Cp) and Process Capability Ratio (Cpk) are two commonly used metrics to evaluate process capability:

Cp: Cp measures the potential capability of a process, indicating how well it can perform within the specified tolerance limits. A higher Cp value suggests that the process has the potential for better performance.

Cpk: Cpk assesses the actual capability of a process by considering both the process mean and the spread of the data. It accounts for any deviation from the target value and specifies how well the process is performing within the tolerance limits. A Cpk value greater than 1 indicates that the process is capable of meeting specifications.

Benefits of Process Capability in Manufacturing

Enhanced Product Quality: Process capability ensures that manufacturing processes consistently produce products that meet or exceed quality specifications. This leads to fewer defects, reduced rework, and increased customer satisfaction.

Cost Reduction: A capable process minimizes waste, rework, and scrap, resulting in cost savings. This includes reduced material and labor costs associated with defects and inefficiencies.

Improved Predictability: Manufacturers can predict the performance of their processes and the likelihood of producing non-conforming products, helping in better resource allocation and production planning.

Compliance and Standards: In regulated industries such as healthcare, automotive, and aerospace, process capability is crucial for maintaining compliance with industry-specific standards and regulations.

Competitive Advantage: Companies with high process capability gain a competitive edge by consistently delivering products of superior quality, thereby attracting and retaining customers.

Methodology for Assessing Process Capability

Assessing process capability involves several key steps:

Data Collection: Collect data on product measurements from the manufacturing process. This data is typically displayed in control charts or histograms.

Determine Specifications: Define the upper and lower specification limits, which represent the acceptable range of product measurements according to customer requirements.

Calculate Cp and Cpk: Use statistical calculations to determine the Cp and Cpk values. Cp measures the potential capability, while Cpk measures the actual capability.

Interpret Results: Evaluate the Cp and Cpk values in comparison to one another and the specified tolerance limits. A capable process should have Cp and Cpk values greater than or equal to 1.

Continuous Improvement: If the process capability is found to be inadequate, take corrective actions to improve it. This may involve process optimization, equipment calibration, or operator training.

Role in Continuous Improvement

Process capability is an integral part of continuous improvement initiatives such as Six Sigma and Total Quality Management (TQM). It serves as a baseline for measuring the effectiveness of improvement efforts. By continuously monitoring process capability and striving to improve it, manufacturers can:

Identify areas where the process can be enhanced.

Reduce variation in production.

Optimize resource allocation.

Increase customer satisfaction.

Drive innovation in product design and manufacturing processes.

Conclusion

Process capability is a cornerstone of quality management in the manufacturing field. It ensures that processes consistently produce products that meet customer specifications, leading to enhanced product quality, cost reduction, and competitive advantage. By using statistical tools to assess and improve process capability, manufacturers can not only meet customer expectations but also foster a culture of continuous improvement that drives excellence in quality and efficiency.

0 notes

Text

do hozier fans just live like this? like, normally? like you guys just listen to a song that makes you want to fall on your knees on your way to work and then just? carry on? like your neural configuration hasn't been fundamentally altered?

#see what i did there with carry on#hehe#i'm halfway through the album and i'm putting it on pause for the day i fear my brain doesn't have the capability to process that much#gloriousness in one sitting#hozier

2K notes

·

View notes

Text

'Characters watching the show'-type situation except it's just the incredibly dangerous whacky stunts conan pulls on a regular basis (including the movies) being shown to people that aren't in the know.

Oh you think the child is staying over at the professors TOO BAD he's following a murderer!!! Ran is looking for him bc he's run off again SIKE he's chasing a car on the highway on his janky little skateboard!!! Oh thank god this high stakes case got somehow resolved WHAT'S THIS it's conan confronting the suspect by kicking a football unnaturally hard!!!! Thankfully we all escaped the burning building WHELP there's conan running back into it!!! We need to evacuate the premises bc there's a bomb WHOOPS there's conan defusing it!!! Where's the child gone now WOULD YOU LOOK AT THAT it's said child jumping of an exploding building using his suspenders as a jumping rope while being actively shot at HAHA!!!!!!!!!!!!!

At no point is it mentioned that Conan is anything more than a smart six year old.

#detective conan#dcmk#conan edogawa#ran is having a minor crisis#shes a bit stressed#about to have a fucking heart attack really#imagine them watching zero the enforcer#or also?? how some people who /don't/ know that this isn't child and just let him do insane shit#just bc he seems unnaturally competent for a six year old#what's the blond twinks thought process every time conan does anything#actually. scratch this amouro furysa is like the only guy who would get it#since he also has no idea what a normal human should actually be capable of#his colleagues must be so exhausted#this rant got brought on by me remembering the last like 20 min of zero the enforcer

94 notes

·

View notes

Text

i’ve been attempting to understand for a while why i hate so much that a video of the january 6th insurrection was used in star trek, and aside from how much it confuses the timeline (eugenics wars in the 90s, nuclear winter in the early 21st century, but somehow all sorted out by 2016 and trump was elected president?), i think i’ve found part of my problem with it.

it just seems like an easy cop out to get ‘progressive points’, a quick way for the writers to show you where they stand, without even an attempt to fit it into the timeline in a way that makes sense.

my main issue is that star trek has, of course, always dealt with complicated issues, but it used to be so much more thought out. there used to be metaphors, allegories, explanations that actually made sense (though sometimes it wasn’t spelled out for you) . The Cloud Minders, Let That Be Your Last Battlefield (tos) and The High Ground (tng) are just a few episodes off the top of my head, that deal with similar, difficult, situations. Even episodes like A Private Little War, which clearly hasn’t aged well, was very obviously an allegory for proxy wars, a very real and pertinent issue at the time it came out.

but the thing is, you have to think between the lines to understand them, none of them are so heavy handed as to just directly show a video of a historical event just to say “hey guys this is bad”, like it was only put there to prove the point that the show runners don’t support that.

one issue this brings up for me is, while trying to find others that agree with me on this i just keep coming across the sentiment “politics shouldn’t be in star trek”. if you’ve managed to miss the politics this whole time then i regret to inform you that your skull may be made of lead.

it’s hard to discuss real opinions on a show when so much of the criticism is flooded with “it’s too woke!! why is there politics in star trek!!!”

star trek has always been an overwhelmingly progressive show, (accounting for the fact that it started in the 60s of course) but unfortunately a lot of people have managed to miss that, a lot of the progressive points have ‘aged out’ of the show, and no longer make the point they used to as clearly as they would have had you watched them when they came out. now it seems that writers are overcompensating to drive home the point that it’s a progressive show.

to people who missed how progressive it already was, this makes it look unnecessarily ‘woke’ and like it came out of nowhere, for the rest of us who were paying attention, it seems very heavy handed and like they’re trying too hard to achieve something that old trek did effortlessly.

#star trek#star trek tos#tos#star trek tng#tng#i’m sure i’m not allowed to tag snw on this one#they’ll hate me for this for sure#so much of modern media is just spelling it out for those who refuse to understand and it’s disappointing#can we make good things with good stories for people capable of understanding them#and if you don’t get it you can watch spongebob or something#i mean private little war was pretty heavy handed for old trek#‘amerind’ come on#like this show used to be leftist space utopia#now the best we get is ‘hey guys trump bad’#like thanks i guess#one reblog of this has confused the hell out of me#i think they misunderstood but i do not want to explain#they’re like mad at me for saying i don’t understand? and like ‘it’s not bad just because you don’t understand try to understand maybe’#like that’s not even remotely what i said plus the ENTIRE post is me explaining my process if trying to understand#maybe try reading

108 notes

·

View notes

Text

Fave kinds of fics and headcanons are ones where McCoy’s only way of learning about Vulcan biology outside of the bare minimum knowledge he’s been given is through Spock doing stupid reckless shit.

they’re always the best bc u know that Bones is just itching to beat him with hammers once he’s healed up

#you mean that rumbling coming from Spock’s chest in sickbay wasn’t any cause for concern#because Vulcans are capable of purring and he was just speeding up the healing process?#oh goody! and then McCoy explodes him with his mind#star trek#star trek the original series#s’chn t’gai spock#bones mccoy#leonard bones mccoy#spones

51 notes

·

View notes