#ProcessController

Explore tagged Tumblr posts

Text

Say Goodbye to Temperature Fluctuations in Industrial Processes!

🔥 Struggling with temperature control in your industrial setup? A small fluctuation can make a big impact on efficiency! Our Process and Temperature Controllers take the guesswork out of automation with smart PID microprocessor-based control.

📊 With dual LCD screens, you can easily monitor real-time temperature and process values. Plus, thanks to Fuzzy Logic technology, these controllers quickly stabilize temperatures, even after power disruptions.

💡 No more overshoots. No more inefficiencies. Just precise and reliable control for manufacturing and automation. Looking for a stable, efficient solution? 🚀 Upgrade your process control system today!

#IndustrialAutomation#ProcessControl#ManufacturingSolutions#SmartTech#EfficiencyMatters#IndustrialSolutions#AutomationSolutions#MechanicalSolutions#ElectricalSolutions#FastCal#PLC#SCADA#ControlPanelDesign#ProcessController#TemperatureController

0 notes

Text

Looking to enhance your industrial batching process? This article explains precision batching systems in depth, highlighting their major components like load cells, control systems, and feeding mechanisms. Learn how they work together to deliver reliable, accurate, and efficient material handling, helping industries meet production goals with minimum waste.

#PrecisionBatching#BatchingSystems#IndustrialAutomation#MaterialHandling#ProcessEngineering#ManufacturingSolutions#EngineeringInnovation#AutomationTechnology#IndustrialEquipment#SmartManufacturing#PowderHandling#WeighingSystems#LoadCells#ProcessControl#BulkMaterialHandling#IndustrialBatching#EngineeringSolutions#MacawberIndia#AutomationSystems#ManufacturingTechnology

0 notes

Text

🎛️ What is Control System Engineering? Discover how engineers design systems to control devices and processes efficiently.

1 note

·

View note

Text

DI (Ductile Iron) Butterfly Valves are essential in fluid control systems, known for their strength, durability, and efficient flow regulation across industrial and commercial applications.

#dibutterflyvalves #butterflyvalves #valvesupplier #industrialvalves #flowcontrol #valvetechnology #fluidcontrolsystems #ductileironvalves #bangalorevalvesupplier #industrialsolutions

#dibutterflyvalves#butterflyvalves#valvesupplier#industrialvalves#flowcontrol#valvetechnology#fluidcontrolsystems#ductileironvalves#bangalorevalvesupplier#industrialsolutions#valveengineers#pipingandvalves#mechanicalsystems#qualityvalves#processcontrol#bangaloreindustry#engineeringproducts#valvedistributors#trustedvalvesupplier#efficientflowcontrol

0 notes

Text

Weighing Controller

The weighing logic controller is designed to perform loadcell based automation like weighing based filling, bagging in solid, powder and liquid filling machines. The controller can also be programmed to be used for various weighing-based applications like set-point indicators, weight transmitters and dynamic weighing system. Because of its dual display format, variety of information can be showed and accessed in the fastest way. The controller has in-built recipe management system using non-volatile memory.

#SystemSoftware#WeighingController#SmartWeighing#ProcessControl#IndustrialAutomation#AccurateWeighing#PrecisionMeasurement#FactoryAutomation#DigitalWeighing

1 note

·

View note

Text

All-in-One PLC Controller: The Future of Industrial Automation

Introduction

In modern industries, efficiency and reliability are essential for success. The All-in-One PLC Controller from Pacetech Energy is designed to streamline automation processes, offering seamless integration, high performance, and smart control capabilities. Whether for manufacturing, energy management, or industrial automation, this advanced PLC controller is the key to optimizing operations.

Why Choose an All-in-One PLC Controller?

Traditional PLC systems often require multiple components, leading to complex wiring, increased costs, and maintenance challenges. The All-in-One PLC Controller eliminates these issues by combining essential functions into a single, compact unit. This innovative approach simplifies industrial automation while enhancing efficiency and performance.

Key Benefits of Pacetech’s All-in-One PLC Controller

Compact and Integrated Design Unlike traditional systems, this PLC controller integrates I/O modules, CPU, and communication ports in one unit, reducing space and installation time.

High-Speed Performance Designed for fast processing and real-time control, it ensures smooth operations across various industries.

Easy Configuration and Programming With user-friendly software, engineers can program and configure the system effortlessly, minimizing downtime and improving productivity.

Versatile Applications Suitable for industries like manufacturing, energy, and smart automation, this controller adapts to diverse automation needs.

Reliable Communication Capabilities Equipped with advanced communication protocols, it seamlessly integrates with SCADA systems, IoT devices, and industrial networks.

Applications in Various Industries

Manufacturing — Enhances production efficiency and reduces human errors.

Energy Management — Optimizes energy consumption for sustainable operations.

Process Automation — Automates repetitive tasks to improve accuracy and output.

Smart Infrastructure — Enables intelligent monitoring and control of industrial facilities.

Conclusion

The All-in-One PLC Controller by Pacetech Energy is a game-changer in industrial automation. Its smart design, high-speed processing, and flexible integration make it an ideal choice for businesses looking to improve efficiency and reduce operational costs. Upgrade your automation systems with Pacetech Energy’s innovative solutions today!

For more details, visit Pacetech Energy and explore how this powerful PLC controller can transform your industry.

#IndustrialAutomation#PLCController#SmartManufacturing#AutomationSolutions#PacetechEnergy#ProcessControl#Industry40#EfficientProduction#SmartTechnology#Engineering

0 notes

Text

Vacuum Tank: Reliable and Efficient Pressure Control for Plywood Machinery

In plywood production, precision and efficiency are the key to sustaining high-quality production. One of the most important components that facilitate smooth operation in plywood machinery is the vacuum tank. A vacuum tank is an essential component that controls pressure to achieve optimal performance, energy efficiency, and machine durability.

What is a Vacuum Tank?

A vacuum tank is a vital unit employed in industrial equipment to provide and sustain a controlled vacuum state. It facilitates pressure control, evacuation of surplus air, and stabilization of the manufacturing process for increased efficiency. In plywood manufacturing, vacuum tanks ensure improved adhesion, drying, and finishing of plywood panels.

Why a Vacuum Tank is Necessary in Plywood Machinery?

There are several processes involved in producing plywood, such as gluing, pressing, and drying, where pressure control becomes a critical factor. Here's why an efficient and reliable vacuum tank is essential for plywood equipment:

1. Better Adhesion and Bonding

Vacuum tanks facilitate the appropriate pressure environment, making the adhesives spread uniformly and bond well between veneers of wood. This makes the overall strength and durability of plywood sheets stronger.

2. Better Drying Efficiency

Moisture control is essential in plywood production. A vacuum tank ensures removal of excess moisture from the wood, saving drying time and avoiding flaws such as warping and delamination.

3. Uniform Pressure Control

A well-performing vacuum tank ensures constant pressure rates, facilitating efficient and even plywood processing. This avoids pressure fluctuations that may result in production faults and material losses.

4. Cost and Energy Efficiency

New vacuum tanks are made to use less energy and provide maximum performance. By cutting down on energy usage, companies can reduce operational expenses and increase profitability.

5. Longer Machinery Life

Controlling pressure optimally minimizes wear and tear on plywood equipment. A quality vacuum tank reduces mechanical stress, prolonging the life of your equipment and minimizing maintenance expenses.

Selecting the Right Vacuum Tank for Your Plywood Machinery

In order to facilitate smooth production, it is important to invest in a high-quality vacuum tank from a reliable manufacturer. The following are some of the considerations to make when choosing the appropriate vacuum tank:

•Capacity & Size: Select a vacuum tank that suits your machinery capacity and production needs.

•Material Quality: Stainless steel or corrosion-resistant materials guarantee durability and longevity.

•Energy Efficiency: Select vacuum tanks with energy-saving capabilities to minimize operational costs.

•Automation & Control Features: New vacuum tanks have digital controls for accurate pressure control.

Why Choose a Leading Plywood Machinery Manufacturer?

When you purchase a vacuum tank, choosing a top plywood machinery manufacturer guarantees that you get quality, long-lasting, and efficient equipment. Industry leaders provide personalized solutions, after-sales services, and cutting-edge technology to increase your production efficiency.

Final Thoughts

A vacuum tank is an indispensable component in plywood machinery, delivering reliable and efficient pressure control for high-quality production. Investing in the right vacuum tank improves adhesion, accelerates drying, saves energy, and extends machinery life.

For plywood businesses, using a reputable plywood machinery manufacturer guarantees that you are equipped with top-of-the-line equipment meeting industry standards, improving efficiency, and increasing profitability.

Need the finest vacuum tank for your plywood equipment? Deal with DNH Engineers number one plywood equipment manufacturer today and upgrade your output to a new level!. Go and check out our website www.dnhengineers.com for more details.

#VacuumTank#PressureControl#ReliableEfficiency#IndustrialVacuum#VacuumSystem#EngineeringSolutions#EfficientVacuum#ProcessControl#VacuumTechnology#ManufacturingExcellence#VacuumBenefits#PressureManagement#FluidDynamics#EnergyEfficiency#InnovativeEngineering#EquipmentReliability#ProductionOptimization#IndustrialSolutions#VacuumExperts

0 notes

Text

How Valves Work in Fluid Control Systems – Types & Functions

Valves play a crucial role in fluid control systems, regulating flow, pressure, and direction of liquids and gases. This guide explores how valves function, types, and key applications in various industries.

How Do Valves Work?

Valves function by opening, closing, or partially obstructing passageways to control fluid movement. They use actuators, handwheels, or automatic mechanisms to regulate flow efficiently.

Valve Operation Mechanisms

Manual Control – Operated by hand using wheels or levers.

Automatic Control – Uses electric, pneumatic, or hydraulic actuators.

Pressure-Based Control – Self-operating valves adjust based on pressure changes.

Types of Valves in Fluid Control Systems

1. Gate Valve

Best for: On/off control with minimal pressure drop.

Common in: Water distribution, gas pipelines.

2. Ball Valve

Best for: Quick shut-off with minimal leakage.

Common in: Gas lines, water treatment plants.

3. Butterfly Valve

Best for: Space-saving flow control.

Common in: HVAC, large water pipes.

4. Check Valve

Best for: Preventing backflow.

Common in: Pumping systems, sewage lines.

5. Globe Valve

Best for: Throttling and precise flow control.

Common in: Industrial fluid regulation.

Comparison Table: Valve Types & Uses

Valve TypeFunctionCommon ApplicationGate ValveOn/off controlWater distributionBall ValveQuick shut-offGas pipelinesButterfly ValveFlow regulationHVAC systemsCheck ValvePrevents backflowSewage systemsGlobe ValvePrecise throttlingIndustrial processing

Factors to Consider When Choosing a Valve

✅ Material

Brass & PVC: Affordable, corrosion-resistant for water.

Stainless Steel: Durable for high-pressure gas applications.

Cast Iron: Used for industrial pipelines.

✅ Flow Requirements

Consider the flow rate, pressure, and media compatibility.

✅ Maintenance & Lifespan

Choose low-maintenance valves to reduce operational costs.

FAQs

1. What is the purpose of a valve in a fluid control system?

Valves regulate fluid flow, ensuring proper pressure control, direction, and safety.

2. Which valve is best for water systems?

Gate and ball valves are ideal for efficient water control and durability.

3. How do check valves work?

Check valves allow one-way fluid flow, preventing backflow and system damage.

4. Are automatic valves better than manual valves?

Automatic valves provide higher precision and efficiency, but manual valves are more cost-effective.

5. Where can I find high-quality industrial valves?

Check TradeIndia, Justdial, and industry-specific suppliers for reliable options.

#ValveSuppliers#IndustrialValves#DelhiBusiness#GateValve#BallValve#ButterflyValve#PlumbingSolutions#HVACSystems#OilAndGasIndustry#WaterPipeline#Engineering#Manufacturing#ProcessControl#IndustrialEquipment#PipingSolutions

0 notes

Text

Optimize Process Control with VIEW Precision Tools

Optimize your process control with VIEW state-of-the-art precision tools. Designed for unmatched accuracy and reliability, VIEW solutions enhance efficiency and productivity in manufacturing and inspection processes. Empower your operations with advanced measurement systems tailored to meet industry demands. Experience precision redefined with VIEW—your trusted partner in process optimization and control.

For More Info, Visit Us: https://viewmm.com/en/applications/

Address: 1711 W 17th St, Tempe, AZ 85281, United States

Phone No: 1 480-295-3150

Mail: [email protected]

0 notes

Text

Reliable Thermowells for Precise Temperature Measurement at CalCon

Did you know? A reliable temperature reading depends not just on your sensor, but also on the protection it gets!

Thermowells are the unsung heroes of industrial temperature measurement, safeguarding sensors against extreme conditions, high pressures, and corrosive environments.

At CalCon, in partnership with our principal Termotech, we provide durable, custom-designed thermowells to ensure: ✔️ Sensor Longevity ✔️ Accurate Readings ✔️ Reduced Maintenance

Let’s future-proof your temperature monitoring systems with CalCon and Termotech’s innovative solutions! Reach out today.

👉 Visit our website www.calconuae.com

#Thermowells#IndustrialAutomation#ProcessControl#EfficiencyMatters#SmartEngineering#InnovationInIndustry

0 notes

Text

🤖 Need Industrial Automation Solutions? Let’s Talk!

Running an industrial operation? Then you know how important automation is for efficiency and reliability! ⚙️ At Fast Cal Industrial Corp, we provide expert automation solutions, from PLC programming and SCADA systems to power quality analysis and electrical installations.

Need expert consultation or troubleshooting? 🛠️ Our team is here to assist you with customized industrial solutions to ensure seamless operations. Whether you’re looking for automation system upgrades or preventive maintenance, we’ve got you covered!

📩 Reach out to us today for expert industrial automation support!

#IndustrialAutomation#AutomationExperts#ManufacturingSolutions#SmartIndustry#ProcessControl#IndustrialSolutions#AutomationSolutions#MechanicalSolutions#ElectricalSolutions#FastCal#PLC#SCADA#ControlPanelDesign

0 notes

Text

Plant Automation Systems

At ASK Enterprise, we offer customized Plant Automation Systems that seamlessly integrate with FRP tanks and other equipment, ensuring optimal performance and control.

Key Features: • Remote Monitoring & Control: Manage your plant operations from anywhere with real-time tracking and adjustments. • Process Optimization: Improve efficiency, reduce downtime, and lower energy costs through continuous process analysis. • Safety & Compliance: Ensure operational safety and meet industry regulations with automated safety protocols. • Scalability & Flexibility: Easily scale and adapt your system as your business grows and technology advances.

Discover how our automation solutions can enhance your operations. Contact us today!

Contact us for best quotation on M: +91 9106892627 For more info visit: https://bit.ly/3TdgbLP

#PlantAutomation#ProcessOptimization#RemoteMonitoring#SafetyAndCompliance#Scalability#Flexibility#AutomationSystems#FRPTanks#OperationalEfficiency#EnergySavings#AutomationSolutions#IndustrialAutomation#ProcessControl#SmartManufacturing#TechInnovation#BusinessGrowth#EfficiencyImprovement#ManufacturingSolutions#IndustrialTech#AutomationIntegration#SmartTech#PlantManagement#OperationalExcellence

0 notes

Text

Advanced Precision Digital Products and Instruments

Optimize your monitoring and control processes with Precision Digital Products and Instruments. These innovative solutions are designed to provide accurate and reliable readings for industrial applications, including process control, temperature monitoring, and level measurement. Featuring user-friendly interfaces and durable designs, Precision Digital instruments ensure efficiency and performance in demanding environments. Ideal for industries such as manufacturing, chemical processing, and more, these products set the standard for precision and reliability.

0 notes

Text

Optimizing water quality and efficiency! SCADA systems for water treatment plants enable real-time monitoring, data-driven decisions, and remote control for safe, reliable water management. By integrating SCADA, plants ensure cleaner, safer water for communities while reducing costs and minimizing risks.

#WaterTreatment#SCADA#Automation#WaterManagement#SmartWater#Infrastructure#DataDriven#WaterQuality#SustainableSolutions#ProcessControl

0 notes

Text

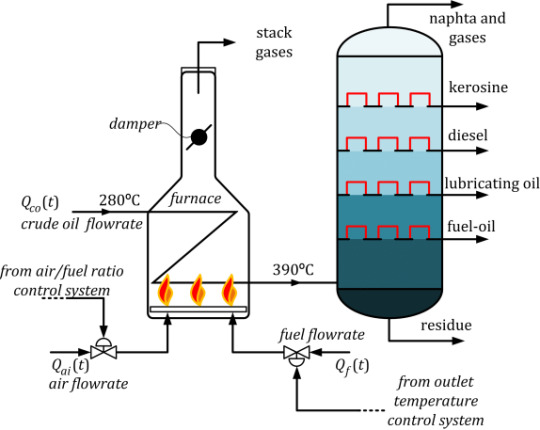

Knowledge Sharing Series#2

What is the Process that undergoes in Oil Preheating Furnace?

Crude Oil Entry: The desalted crude oil, which has already been heated and mixed with water to remove salt, enters the preheating furnace.

Heat Exchange: The furnace is typically designed with a series of tubes through which the crude oil flows. Hot flue gases, generated by burning fuel (such as natural gas or fuel oil), pass over these tubes, transferring heat to the crude oil.

Temperature Increase: As the crude oil flows through the tubes, it absorbs heat from the flue gases, gradually increasing in temperature.

Desired Temperature: The furnace is carefully controlled to ensure that the crude oil reaches the desired temperature, typically around 350°C to 360°C. This temperature is essential for effective vaporization of the lighter components in the crude oil.

Exit to Distillation Column: Once the crude oil has reached the target temperature, it exits the preheating furnace and enters the atmospheric distillation column, where the separation process begins.

#OilAndGas#Refinery#ChemicalEngineering#ProcessEngineering#Petrochemical#DownstreamProcessing#Distillation#UnitOperations#EnergyIndustry#Fuels#FossilFuels#PreheatingFurnace#CrudeOilPreheating#AtmosphericDistillation#DistillationColumn#HydrocarbonSeparation#RefiningProcess#OilAndGasEquipment#ProcessControl#HeatTransfer#Decontamination

1 note

·

View note

Text

Looking for top-notch Digital Panel Meters? Beemat has you covered. Beemat has been striving to provide the best Digital Panel Meters. Our wide range of digital meters ensures accurate readings. Trust Beemat for your measurement needs.

Visit our webpage to know more about us.

#Beemat#digitalpanelmeter#panelmeter#instrumentation#industrialautomation#metering#processcontrol#automation#measurement

0 notes