#Production PCB

Explore tagged Tumblr posts

Text

1st October 2024, Tuesday

day 37/50 productivity challenge

💤 9 hrs

🕒 11 a.m.

[ahhh new book finally delivered = instant happiness attack; been meaning to read this book forever] [ch.1 the bell jar; didn't start reading just took a pic, anyways i already have quite a few books incomplete already loll]

morning skincare

studied + made notes biology ch: biological classification (completed) (finally back in the flow after that weird slump)

rearranged stuff in my room cuz i finally got a stand for my keyboard 🎹

cleaned out email + photo gallery

showered

duolingo

re-watered desk plant

practiced playing keyboard

read newspaper

[moved stack of books + new keyboard stand] [went out & ate pizzas for dinner]

🕒 1 a.m.

🚰 4 glasses

🎧 self dysmorphia - mckenna grace

#mithi's own#mithistudies#filmy mithi#cbse#cbse school#cbse board#cbse education#11th grade#grade 11#pcb#productive#days of productivity#productivity#productivity challenge#productivityboost#50 days of productivity#studyspo#student life#studying#study motivation#study blog#studyblr community#realistic studyblr#studyblr#study hard#student#studystudystudy#studyspiration#studymotivation#studyinspo

11 notes

·

View notes

Text

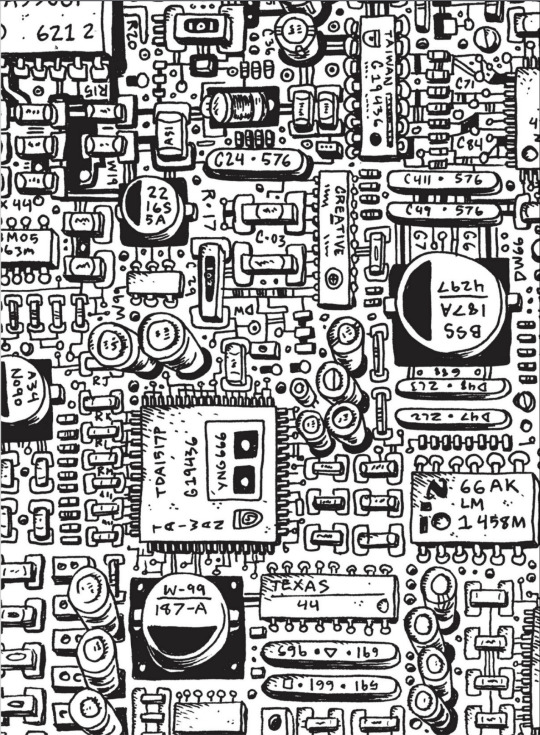

Wizzywig

Ed Piskor

#comics#comic books#art#illustration#panelswithoutpeople#b&w#black and white#graphic novel#graphic novels#Wizzywig#Ed Piskor#tech#Circut board#PCB#computer#computers#top shelf productions#top shelf

5 notes

·

View notes

Text

Die fünf Hauptfunktionen von Lötstopp-Lochverschlüssen

1️⃣ Verhindern des Fließens von Lötzinn durch die Durchkontaktierungen und Vermeidung von Kurzschlüssen während des PCB-Wellenlötens, insbesondere wenn die Durchkontaktierungen auf BGA-Pads platziert sind. Es ist notwendig, die Löcher vor der Vergoldung zu verschließen, um das BGA-Löten zu erleichtern.

2️⃣ Vermeiden von Flussmittelrückständen innerhalb der Durchkontaktierungen.

3️⃣ Nach der Oberflächenmontage und Bauteilplatzierung muss die Leiterplatte auf einer Testmaschine einem Vakuumsaugtest unterzogen werden, um einen Unterdruck für die Fertigstellung zu erzeugen.

4️⃣ Verhindern des Fließens von Lötpaste in die Löcher und Vermeidung von Lötfehlern, die die Lötung während der Montage beeinträchtigen könnten.

5️⃣ Verhindern des Herausspringens von Lötkugeln während des Wellenlötens, was zu Kurzschlüssen führen könnte.

2 notes

·

View notes

Text

PCB Production Service for Custom Electronic Applications

Our PCB production service delivers precision-manufactured boards tailored to your design needs. From prototypes to full production, we offer quick turnaround, quality assurance, and expert support. Choose our PCB production service for consistent performance and scalable electronics manufacturing.

0 notes

Text

Small Batch FR4 Fabrication: Best Practices & Cost Optimization

Small batch FR4 fabrication presents unique challenges for engineers and product developers. While FR4 remains the most popular substrate for PCB manufacturing, optimizing the process for prototype or low-volume production requires special consideration. This guide covers best practices to maintain quality while controlling costs in small batch FR4 projects. Understanding FR4 Material…

#circuit board production#cost optimization#FR4 fabrication#PCB prototyping#small batch manufacturing

0 notes

Text

Explore Delta Industrial Automation Products at Aeliya Marine – Reliable, Precise, and Proven

Introduction: A Legacy of Precision with Delta

Delta is a well-known international brand within the industrial automation sector, renowned for its cutting-edge technology, rugged products, and reliable performance in marine, industrial, and factory automation applications. For maintenance engineers, technical buyers, and maintenance experts searching for high-performance automation products, Delta has become synonymous with trust. At Aeliya Marine Tech, we are honored to carry an expansive range of original Delta products that are perfectly suitable for a vast range of industrial and marine control applications.

In this blog, we dive deep into the Delta product lines found at Aeliya Marine’s Delta Collection, discuss their specifications, applications, and what they have to offer for mission-critical operations.

Why Choose Delta?

Delta Electronics was established in 1971 and has developed into one of the world’s most recognizable power and energy management product companies. Their products are renowned for:

Precision engineering

Long operational lifespan

Energy efficiency

Easy integration with automation systems

Proven performance in rugged environments

Delta’s solutions are preferred by manufacturing, marine, oil & gas, pharma, and other industries.

Delta Product Categories on Offer at Aeliya Marine

Below is a glimpse into some of the trending categories of Delta products available on our website:

1. Delta VFD (Variable Frequency Drives)

Delta’s VFDs are one of the most popular AC motor controllers in industries. They enable motor speed and torque control with no jerks, yielding greater energy efficiency and smoother operation.

Features :

Compatibility with wide voltage range (200V to 480V)

Built-in PLC and PID control

Protection against overload and fault diagnosis

Space-saving design for handy installation

Application Areas :

Conveyor belts

HVAC systems

Pumps and compressors

Industrial mixers

Some of the most sought-after models available include the Delta VFD007EL43A, VFD037EL21A, and VFD015M21A.

2. Delta PLC (Programmable Logic Controllers)

Delta PLCs offer rugged, programmable control for demanding automation applications. Their DVP series stands out for compact size and high-speed processing.

Features :

Modular construction for adaptability

High-speed counters and timers

Ethernet and Modbus communication ports

Ladder logic programming

Ideal For :

Machine control

Building automation

Packaging and printing equipment

Automated storage devices

Shop for models such as DVP14SS211R, DVP32ES00R, or DVP60ES2 in our Delta product catalog.

3. Delta HMI (Human Machine Interface)

Delta HMIs offer easy-to-use interfaces for operators to use with automation systems effectively.

Key Features :

Touchscreen interface

Availability of wide screen sizes (4.3" to 15")

Simple integration with Delta and third-party PLCs

Real-time data visualization and diagnostics

Applications :

Monitoring production lines

Operator control panels

Industrial dashboards

Watch out for units such as the Delta DOP-B07S411 or DOP-107BV available at discounted prices.

4. Delta Servo Systems

Delta servo drives and motors provide accurate motion control, suitable for those applications where speed, position, and torque must be controlled with a high degree of accuracy.

Features :

Real-time auto-tuning

Integrated positioning and velocity modes

Absolute and incremental encoder feedback

Low inertia and compact design

Applications :

CNC machinery

Robotics

Textile and printing machines

Our range comprises systems like ASD-B2–0421-B Servo Drive and ECMA-C20604RS Servo Motor.

5. Delta Temperature Controllers and Timers

These compact controllers are widely used in process control systems to maintain desired temperature levels, providing reliability and efficiency.

Key Benefits :

PID and ON/OFF control modes

Multi-sensor compatibility

User-configurable alarms and settings

Fast response time

Used in :

Furnaces and ovens

Industrial dryers

Refrigeration systems

You’ll find models like DTB4848CR and DTD4848R0 in stock.

Why Buy Delta Products from Aeliya Marine?

We do more than just list Delta products here at Aeliya Marine Tech — we verify that every component is tested, confirmed, and competitively priced. Here’s why we stand out :

Extensive Range : From VFD to Servo Motors, discover the entire range of Delta solutions.

Tested Parts : Each item is condition-checked (new or refurbished), and properly marked.

Quick Dispatch : Fast, secure delivery in India and worldwide.

Committed Support : Our support team is here for technical consultation and post-sales support.

Respected by Thousands : Aeliya Marine is a name respected by thousands of engineers and buyers from industries.

Who Should Consider Delta Products?

If you are :

A systems integrator in need of automating your process line,

A maintenance engineer searching for fast replacements,

A procurement specialist requiring high-quality components for your factory floor,

Or a marine technician working with onboard control systems,

Delta products provide the reliability, compatibility, and value you require.

Don’t wait until downtime hits you upgrade or replace your control components now with Delta’s reliable range.

Buy Delta Products Now

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#amplifier#meter#DELTA#products#marineautomation#automationparts

0 notes

Text

#Consumer Electronics Product Design#Electronic Product Design Services#PCB Design Companies in India#IoT Embedded Systems#PCB Board Design Software

0 notes

Text

Top PCB Manufacturing Companies in USA | Reliable PCB Board Manufacturing

Looking for reliable PCB manufacturing services? PCB Power is a leading provider of PCB manufacturing in the USA, offering high-quality, precision-engineered PCB boards for various industries. Whether you need small or large-scale production, our advanced technology and expertise ensure exceptional performance and durability. Find the best PCB manufacturing companies near you and get customized solutions to meet your unique needs. Contact us today!

#pcb fabrication#pcb fabrication usa#PCB production#PCB manufacturing in the USA#PCB manufacturing near you

0 notes

Text

https://www.futureelectronics.com/p/production-products--hardware--test-points/5015-keystone-8064685

PC hardware monitor, Security testing, PCB Test Point, Hardware test plan

Miniature Surface Mount Test Points on Tape and Reel

#Keystone#5015#Production Products#Hardware Test Points#pc hardware monitor#Security testing#PCB#plan#acceptance testing#Hardware testing process#open hardware monitor#software#development process#Hardware testing tools

1 note

·

View note

Text

Cost-Effective Strategies for Efficient PCB Production by A-Gas Electronic Materials

Learn how to optimise PCB production with cost-effective strategies, including design for manufacturability, efficient production techniques, and energy efficiency. Improve quality and reduce costs. Contact A-Gas Electronic Materials for expert guidance and tailored solutions.

#PCB production#cost-effective PCB manufacturing#design for manufacturability#PCB materials#efficient PCB production#supplier collaboration#PCB inventory management#PCB energy efficiency#automated assembly#A-Gas Electronic Materials#UK#PCB production strategies#PCB quality improvement

0 notes

Text

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

0 notes

Text

PCB Production Service for Reliable Prototyping and Manufacturing

Our PCB production service covers the entire lifecycle from prototype to full-scale manufacturing. Using advanced equipment and strict quality standards, we ensure every board meets performance expectations. Trust our PCB production service to deliver precision-engineered circuit boards with speed and reliability.

0 notes

Text

Design Thinking Meets Precision Engineering: The Power of Industrial Product Design & Electronic PCB Design

The world we interact with is a confluence of artistry and functionality. Behind every sleek gadget or user-friendly machine lies a powerful collaboration: industrial product design and electronic PCB design. Let's delve into how these seemingly disparate fields work together to create innovative and user-centered products.

Industrial Product Design: The Art of Usability

Industrial product design focuses on the user experience. Designers consider ergonomics, aesthetics, and functionality to create products that are not only visually appealing but also intuitive and comfortable to use. Imagine a sleek smartphone - the industrial product designer ensures it fits perfectly in your hand, the buttons are easily accessible, and the overall form complements your style.

Electronic PCB Design: The Brains Behind the Beauty

The magic of industrial design comes alive with the intricate work of electronic PCB designers. They create the printed circuit boards (PCBs), the heart of any electronic device. These intricate boards house the electronic components that power the device, following precise design rules and engineering principles to ensure functionality and reliability.

The Synergy: Where Design Thinking Meets Precision

The true power lies in the collaboration between these two disciplines. Industrial product designers provide insights into user needs and aesthetics, while electronic PCB designers translate those needs into a functional and efficient physical layout. This back-and-forth dialogue ensures:

Optimal User Experience: The final product is not just visually appealing, but also designed for intuitive user interaction, with the PCB layout seamlessly integrated into the overall form.

Enhanced Functionality: Electronic components are carefully chosen and placed on the PCB to optimize performance and efficiency, ensuring the product functions flawlessly within the constraints of the industrial design.

Manufacturing Efficiency: Collaboration from the outset allows for the creation of a product that is not just user-friendly but also manufacturable at scale. Consideration for material selection and assembly processes happens during the design phase itself.

So, the next time you interact with a well-designed product, take a moment to appreciate the invisible collaboration between design thinking and precision engineering. It's a testament to the power of human ingenuity and creativity, where form meets function to create something truly remarkable.

Source

0 notes

Text

LG EBR85130516 Dryer PCB Main Control Board (PCB Assembly) | HnKParts

#EBR85130516#LGE#Dryer#PCB#MainControlBoard#HnKParts#HomeAppliance#KitchenAppliance#Manufacturer Name:LGE#Product Number:EBR85130516#OEM Part Number:EBR85130516#Order LG EBR85130516 Dryer PCB Main Control Board today! Shop home & kitchen appliance parts at HnK Parts with same-day shipping#available at the best prices.

0 notes

Text

Danfoss: Engineering Precision for Marine and Industrial Efficiency Explore Top Products at Aeliya Marine Tech

In demanding fields such as marine engineering, offshore drilling, HVAC, and industrial automation, there is no place for equipment malfunction. Systems need to perform flawlessly, optimally, and under harsh conditions. Step forward Danfoss, a world leader in energy-efficient, precision-engineered components utilized across industries from shipping to manufacturing.

At Aeliya Marine Tech, we’re committed to showcasing a wide range of authentic Danfoss products, specifically designed for maintenance engineers, procurement departments, and system integrators who require quality, availability, and technical support. From pressure switches to thermostatic valves, transmitters, or frequency converters, our catalog provides reliable Danfoss solutions at your doorstep.

About Danfoss: Global Excellence with Local Impact

Established in Denmark in 1933, Danfoss Group is now one of the most renowned industrial technology names. Famous for its energy and climate solutions, Danfoss has been transforming the way mechanical and electrical systems function.

Their products cater to:

Shipboard air-conditioning and HVAC equipment

Hydro power and motor control

Refrigeration and temperature control

Automation and sensor monitoring

Regulation of pressure and flow in pipes

With a strong focus on sustainability, innovation, and robust engineering, Danfoss components are built to withstand high loads, variable environmental conditions, and demanding operating pressures perfect for marine and heavy industry applications.

Discover the Danfoss Product Range at Aeliya Marine

Aeliya Marine carries a large inventory of new and used Danfoss components. Below is a sampling of top product categories:

Danfoss Pressure Switches

Danfoss pressure switches are intended to control and monitor pressure in liquid and gaseous systems. These are widely applied in:

Compressor units

Boiler plants

Marine hydraulic systems

Characteristics:

Adjustable pressure range

Snap-action contacts

Gold-plated or silver-nickel contact options

IP65 enclosure for marine resistance

Some of the most popular models are the KP, RT, and MBC series each providing reliable protection and control for sophisticated systems.

2. Thermostatic Expansion Valves

Used in air-conditioning and refrigeration systems, Danfoss TXVs (Thermostatic Expansion Valves) control the injection of refrigerant. These valves are:

Compatible with several refrigerants (R134a, R404A, etc.)

Made of stainless steel or corrosion-resistant brass

Accurate in controlling superheat

They’re an essential part for vessels, cold storage units, HVAC systems, and industrial chillers.

3. Temperature and Pressure Transmitters

Danfoss offers robust transmitters that convert temperature or pressure changes into electrical signals. These are used for real-time monitoring and remote control.

Common applications:

Oil pressure regulation in marine engines

Boiler monitoring

Pump and compressor management

Models like MBS 3000 and AKS 32R provide fast response times, long lifecycle, and reliable output even in vibrating or corrosive environments.

4. Solenoid Valves

Whether it is flow control in a hydraulic circuit or fuel line control in an engine, Danfoss solenoid valves are designed for high-performance flow control.

Why select Danfoss solenoid valves?

Direct and servo-operated types

Broad voltage range support (AC/DC)

Compatible with ammonia and fluorinated refrigerants

Resistant to internal deposits and scaling

Standard variants include EVR series valves, employed in marine refrigeration as well as factory automation systems.

5. Electronic Controllers

For smarter automation and energy optimization, Danfoss offers a range of controllers for temperature, defrost, fan speed, and pressure setting. These products frequently feature:

Digital inputs and relay outputs

Simple-to-use displays

Remote programming and networking

EKC and ERC series controllers are great for food processing, cold chain logistics, and onboard climate control.

6. Variable Frequency Drives (VFDs)

Danfoss drives such as the VLT® series are high-end motor controllers that enhance energy efficiency and accuracy in pump, fan, and compressor systems.

Key advantages:

Up to 50% energy savings

Harmonic reduction

Integrated PID controllers

Marine-class certified versions (for offshore platforms)

These VFDs are essential for water treatment, engine room, and HVAC applications.

Industries and Applications

Danfoss products are internationally acclaimed for their extensive range of applications. Following are some of the most important industries that gain advantages from these products:

1. Marine & Offshore:

Ballast water control

HVAC and refrigeration of cabins & engine rooms

Desalination plant control

Hydraulic steering

2. Industrial Automation:

Assembly line equipment

Hydraulic presses

Industrial cooling

Motor speed control

3. Refrigeration & Cooling:

Cold storage plants

Walk-in freezers

Pharmaceutical storage

Cargo refrigeration for shipping containers

4. HVAC Systems:

Building climate control

Marine and oil rig cooling

Ventilation for factories and warehouses

Why Purchase Danfoss from Aeliya Marine Tech?

Buying can be a hassle particularly when time is of the essence, documentation is scarce, or parts are outdated. That’s where Aeliya Marine comes in.

Only Genuine Danfoss Parts

We only offer genuine Danfoss products thoroughly inspected, tested (if used), and supported by documentation where possible.

Photos and Detailed Listings

Every product listing features:

Model numbers

Technical specifications

High-quality photos

Condition tags (New, Used, Refurbished)

This provides clarity before you purchase.

1. Global Shipping from Mumbai

Our Mumbai-based centralized warehouse manages same-day or next-day shipments and accommodates international courier partners for secure, fast delivery.

2. Assistance from Actual Engineers

Stuck on model identification or looking for a compatible substitute? Our internal staff assists all questions with extensive product knowledge.

3. Value & Affordability

We provide competitive pricing on new, used, and surplus items perfect for cost-conscious repairs and replacements.

4. Sample Listings You May Find Today

Following are just a few examples of available or recently added Danfoss components at Aeliya Marine:

Danfoss KP35 Pressure Switch 060–110691

Danfoss RT 116 Pressure Switch 017–521566

Danfoss MBS 3000 Pressure Transmitter

Danfoss TX2 Thermostatic Valve

Danfoss VLT2800 Frequency Drive

Danfoss EV220B Solenoid Valve

Our inventory turns over frequently, so if you don’t find what you’re looking for ask us. We might have it on hand offline.

Aeliya Marine: Your Partner for Legacy and Modern Systems

Most vessels and factories blend legacy systems with newer upgrades. Sourcing replacement parts can be problematic particularly when OEMs end production of models. That’s where Aeliya Marine is an expert:

Finding equivalent models

Recommending drop-in substitutes

Providing hard-to-find parts

Together with Danfoss’ product compatibility promise and our multi-brand sourcing knowledge, your operations remain up and running with the minimum loss of time.

Get Your Systems Running with the Best of Danfoss

In any mission-critical application marine, manufacturing, or HVAC your components are as good as the brand that backs them. With Danfoss, you’re investing in precision engineering, energy efficiency, and operational safety. And with Aeliya Marine Tech, you’re supported by a supplier who gets your sense of urgency, answers your questions, and delivers worldwide.

More Products explore

Click Here To View the Complete Danfoss Products Collection.

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#amplifier#meter#danfoss#marineautomation#automationmarine#automationparts#marineparts#marineautomationparts#automationmarineparts#brand#products

0 notes