#Programmable Automation Controller Programming Software Industry

Explore tagged Tumblr posts

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

Clinical SAS programming A complete guide

Introduction

Clinical SAS programming is a specialized field that utilizes the SAS programming language to handle the vast and complex data generated in clinical trials. SAS, a statistical software package, is extensively employed by pharmaceutical and biotechnology companies for its robust data management, analysis, and reporting capabilities.

In terms of data management, SAS is used to clean, transform, and manage large datasets, ensuring they are organized and ready for analysis. This is a critical step in clinical trials, where large volumes of data are collected and need to be processed efficiently.

For analysis, SAS can perform a wide range of statistical analyses, including descriptive statistics, inferential statistics, regression analysis, survival analysis, and analysis of variance (ANOVA). These analyses are crucial in interpreting the data collected in clinical trials and drawing meaningful conclusions.

Finally, Clinical SAS programming is also used for reporting. It can generate various reports, including integrated summaries of safety and efficacy (ISS/ISE), clinical study reports (CSRs), and other regulatory documents. These reports are essential for communicating the results of clinical trials to regulatory authorities, medical professionals, and the public.

SAS in Clinical Domain

Data Management: SAS is used to clean, transform, and manage clinical trial data. It can handle large datasets and perform data validation, data integration from different sources.

Statistical Analysis: SAS is used for statistical analyses, such as descriptive statistics, inferential statistics, regression analysis, survival analysis, and analysis of variance (ANOVA). These analyses help researchers and clinicians to draw conclusions from clinical trial data.

Data Validation: Checking the accuracy, consistency, and completeness of clinical trial data by performing data validation checks, identifying discrepancies, and resolving data-related issues.

Safety Reporting: Generating safety reports and listings to monitor adverse events and safety data during the trial.

SDTM (Standard Data Tabulation Model) Conversion: Converting clinical trial data into SDTM format, which is a standardized data model for regulatory submission.

ADaM (Analysis Data Model) Implementation: Creating ADaM datasets, which are analysis-ready datasets used for statistical analysis.

Report Generation: Preparing clinical trial reports, including integrated summaries of safety and efficacy (ISS/ISE), clinical study reports (CSRs), and other regulatory documents.

Data Quality Control: Implementing quality control procedures to ensure the accuracy and reliability of analysis results.

Data Visualization: Creating data visualizations, such as graphs and plots, useful for data exploration and presentation of result.

Automation: Creating SAS macros to streamline and automate repetitive tasks and improve programming efficiency.

Medical Coding: Performing medical coding of adverse events, concomitant medications, and medical history terms using standardized dictionaries like MedDRA (Medical Dictionary for Regulatory Activities) and WHO Drug.

Career in Clinical SAS

A career in Clinical SAS programming is rewarding and offers a wide range of opportunities. The SAS Academy for Clinical Programming offers a comprehensive training program that prepares you to work as a SAS Certified Clinical Trials Programming Professional. The combination of coursework and hands-on learning helps you build a foundation of clinical research theory and data analysis skills.

Conclusion

Clinical SAS programming is indeed a vital skill in the pharmaceutical and biotechnology industries. With a solid foundation in SAS programming and a comprehensive understanding of clinical trials, you can pave the way for a successful career in this field.

Whether you’re a biostatistician, a clinical SAS programmer, or someone interested in the field, learning Clinical SAS programming can open doors to a plethora of opportunities. It’s not just about job prospects; it’s about contributing to the advancement of medical research and the development of new treatments and therapies.

In conclusion, mastering Clinical SAS programming is not only professionally rewarding but also offers the chance to make a significant impact in the healthcare industry.

what are the best ways to learn Clinical SAS? We run a training institute in Hyderabad named Brolly Academy. We do offer best Clinical SAS training in Hyderabad with job assistance. Now when you list the best ways to learn Clinical SAS include Brolly academy's Clinical SAS Training as one of the way.

2 notes

·

View notes

Text

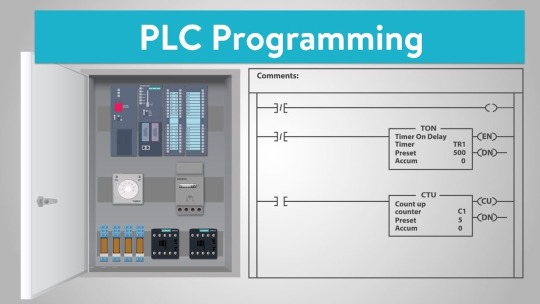

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

Empowering Your Future: Exploring Python Classes in Abu Dhabi

In today's technology-driven world, Python has emerged as one of the most versatile and in-demand programming languages. Its simplicity, readability, and extensive libraries make it a preferred choice for beginners and seasoned developers alike. For individuals in the UAE capital aiming to enhance their programming skills, enrolling in Python Classes in Abu Dhabi offers a strategic pathway to career advancement and personal growth.

Understanding the Importance of Python

Python's widespread adoption across various industries stems from its ability to facilitate rapid development and integration. Whether it's web development, data analysis, artificial intelligence, or automation, Python provides the tools and frameworks necessary to build robust applications efficiently. Its open-source nature and supportive community further contribute to its growing popularity among developers worldwide.

Advantages of Pursuing Python Classes in Abu Dhabi

1. Comprehensive Curriculum

Python courses in Abu Dhabi are designed to cater to a diverse audience, from novices to experienced programmers. The curriculum typically covers fundamental concepts such as variables, data types, control structures, functions, and object-oriented programming. Advanced topics may include web frameworks like Django, data science libraries such as Pandas and NumPy, and machine learning algorithms.

2. Experienced Instructors

Institutions in Abu Dhabi boast a team of seasoned instructors with extensive industry experience. Their practical insights and real-world examples enrich the learning experience, enabling students to grasp complex concepts with ease.

3. Flexible Learning Options

Recognizing the varied schedules of learners, many training centers offer flexible learning modes, including weekend classes, evening sessions, and online courses. This flexibility ensures that professionals and students can balance their commitments while pursuing their educational goals.

4. Hands-On Projects

A key component of Python classes is the emphasis on practical application. Students engage in hands-on projects that simulate real-world scenarios, allowing them to apply theoretical knowledge and develop problem-solving skills.

Career Opportunities Post-Certification

Completing a Python course opens doors to a multitude of career paths. Graduates can pursue roles such as:

Software Developer: Designing and developing applications across various platforms.

Data Analyst: Interpreting complex data sets to inform business decisions.

Machine Learning Engineer: Building algorithms that enable machines to learn and adapt.

Web Developer: Creating dynamic and responsive websites using frameworks like Django and Flask.

The demand for Python professionals is on the rise, with industries such as finance, healthcare, education, and technology seeking skilled individuals to drive innovation and efficiency.

Selecting the Right Python Course

When choosing a Python class in Abu Dhabi, consider the following factors:

Accreditation: Ensure the institution is recognized and offers certified programs.

Curriculum Depth: Review the course content to confirm it aligns with your learning objectives.

Instructor Expertise: Research the qualifications and experience of the teaching staff.

Student Support Services: Look for institutions that provide career counseling, mentorship, and post-course assistance.

Conclusion

Embarking on Python Classes in Abu Dhabi is a strategic investment in one's professional development. The comprehensive training, experienced instructors, and practical projects equip learners with the skills necessary to thrive in today's competitive job market. As industries continue to embrace digital transformation, proficiency in Python will remain a valuable asset, opening doors to diverse and rewarding career opportunities.

0 notes

Text

Programming

Programming is the process of creating instructions that a computer can follow to perform specific tasks. It is the foundation of all software development and has become an essential skill in today’s digital world. From building simple websites to developing complex artificial intelligence systems, programming enables us to harness the power of computers to solve problems, automate tasks, and innovate across countless industries.

At its core, programming involves writing code in a programming language. These languages, such as Python, JavaScript, Java, C++, and many others, provide the syntax and rules that programmers use to communicate with computers. Each language has its strengths and is suited for different types of projects. For example, Python is praised for its readability and is widely used in data science and machine learning, while JavaScript is fundamental for web development.

Programming requires logical thinking and problem-solving skills. When programmers write code, they break down complex problems into smaller, manageable steps. This process, known as algorithm design, is crucial for creating efficient and effective software. Debugging, or finding and fixing errors in code, is another important part of programming. It demands patience and attention to detail, as even a small mistake can cause a program to malfunction.

The field of programming is constantly evolving. New languages and frameworks emerge regularly, driven by the need for better performance, security, and usability. For instance, modern frameworks like React and Angular have revolutionized front-end web development by making it easier to build interactive and responsive user interfaces. Similarly, advancements in cloud computing and containerization have changed how software is developed, deployed, and scaled.

Programming is also highly collaborative. Developers often work in teams using tools like Git for version control, enabling them to track changes and collaborate efficiently. Open-source projects, where code is shared publicly, have fostered a community of innovation and learning, allowing programmers worldwide to contribute and benefit from shared knowledge.

Beyond technical skills, programming encourages creativity. Developers have the freedom to design unique solutions, experiment with new ideas, and create software that can impact millions of users. It opens doors to various career paths, including software engineering, game development, cybersecurity, data analysis, and more.

In summary, programming is a versatile and powerful discipline that combines logic, creativity, and continuous learning. It plays a crucial role in shaping the technology-driven world we live in and offers endless opportunities for those willing to explore its challenges and rewards. Whether you are a beginner or an experienced coder, programming remains a fascinating and valuable skill that fuels innovation and transforms ideas into reality

1 note

·

View note

Text

Embedded Control Software Systems: Powering Intelligent Automation

Embedded control software systems are the unseen brains behind many of today’s most advanced technologies. From industrial machines and automotive systems to consumer electronics and medical devices, these systems ensure that everything operates efficiently, safely, and reliably. Embedded control software is a combination of software and hardware engineered to perform dedicated control functions within larger systems, often with real-time constraints and minimal user interaction.

This article explores what embedded control software systems are, how they work, their architecture, applications, benefits, and challenges.

What is an Embedded Control Software System?

An embedded control software system consists of three main components:

Embedded Hardware (Microcontroller or Microprocessor) – This is the processing unit that executes the control logic.

Control Algorithms (Software) – Written in programming languages like C or C++, these define the behavior of the system based on inputs and desired outputs.

Sensors and Actuators – Sensors provide feedback from the environment (e.g., temperature, speed), while actuators carry out control actions (e.g., motor movement).

These systems are “embedded” because they are integrated into larger products, and they typically perform one or more specific control functions rather than general-purpose computing tasks.

Key Features of Embedded Control Software

Real-Time Operation: Embedded control software often operates in real time, meaning it must respond to inputs within a strict time frame.

Determinism: The system must behave in a predictable manner, particularly in safety-critical applications like automotive or aerospace.

Low Power and Resource Constraints: Many embedded systems are deployed on hardware with limited processing power, memory, and energy.

Reliability and Robustness: Since embedded systems are often deployed in harsh environments, they must be stable and resistant to failure.

Minimal User Interaction: Most embedded control systems are designed to operate with limited or no user interface.

Architecture of Embedded Control Systems

Input Interface: Collects data from sensors or communication channels.

Control Software: Applies algorithms (e.g., PID, fuzzy logic, model predictive control) to decide what action should be taken based on inputs.

Output Interface: Sends control signals to actuators (motors, valves, lights, etc.).

Feedback Loop: Ensures the system continuously adjusts itself based on output performance.

For example, in an automotive cruise control system:

Input: Speed sensor measures vehicle speed.

Control Software: Compares current speed with desired speed.

Output: Sends signals to the throttle actuator to maintain or change speed.

Feedback: Adjusts continuously as road conditions or driver input change.

Applications of Embedded Control Software Systems

1. Automotive Industry

Engine control units (ECUs)

Anti-lock braking systems (ABS)

Adaptive cruise control

Lane-keeping assistance

Airbag deployment systems

2. Industrial Automation

Programmable logic controllers (PLCs)

Robotic arms

Process control in manufacturing lines

Condition monitoring systems

3. Consumer Electronics

Smart thermostats

Washing machines

Microwave ovens

Smart TVs and remote controllers

4. Aerospace and Defense

Flight control systems

Missile guidance

Radar systems

UAV navigation

5. Healthcare

Medical infusion pumps

MRI and imaging equipment

Wearable health monitors

Automated ventilators

Development Process for Embedded Control Software

Requirement Analysis: Define functional and non-functional requirements, such as timing constraints and energy consumption.

System Design: Select hardware platform and define software architecture.

Algorithm Development: Create control logic using mathematical models or empirical rules.

Implementation: Code the algorithms using languages like C, C++, or model-based tools such as MATLAB/Simulink.

Simulation and Testing: Validate performance through simulation, hardware-in-the-loop (HIL) testing, and real-world trials.

Deployment and Maintenance: Deploy code to the embedded hardware and ensure updates or bug fixes are managed safely.

Model-Based Design in Embedded Control

A growing trend in embedded control software development is model-based design (MBD). Engineers use graphical models to design, simulate, and automatically generate code for control algorithms. Tools like Simulink allow for rapid prototyping, reduced coding errors, and quicker time to market. This is especially useful for systems that require frequent iterations or are highly complex.

Benefits of Embedded Control Software Systems

Efficiency: Optimizes system performance, energy use, and functionality.

Precision: Ensures accurate control in critical applications like medical devices and aerospace.

Cost-Effectiveness: Minimizes the need for manual intervention and large hardware setups.

Scalability: Can be tailored for use in simple household gadgets or complex industrial machinery.

Safety and Reliability: Especially in automotive and aviation, embedded control systems contribute to increased safety through reliable automation.

Challenges in Embedded Control Software Development

Real-Time Constraints: Meeting strict timing requirements can be difficult.

Resource Limitations: Must operate on hardware with limited memory and processing capabilities.

Debugging Complexity: Difficult to test systems in real-time without disrupting performance.

Cybersecurity Risks: Increased connectivity (IoT integration) exposes systems to potential attacks.

Maintenance and Upgrades: Embedded systems often need to be updated securely, especially in remote or critical applications.

Future Trends in Embedded Control Systems

AI and Machine Learning Integration: Adaptive systems that learn from data for more intelligent control.

Edge Computing: Processing control logic closer to the source (sensors/actuators) to reduce latency.

Wireless and IoT Connectivity: Embedded systems communicating via 5G or other wireless protocols.

Open-Source Platforms: Tools like Arduino and Raspberry Pi are making embedded control development more accessible.

Conclusion

Embedded control software systems by Servotechinc are the cornerstone of modern intelligent automation. By integrating sensors, control algorithms, and actuators into compact, efficient packages, these systems bring intelligence to machines across countless industries. Whether improving the safety of vehicles, the precision of medical devices, or the efficiency of industrial processes, embedded control systems play a pivotal role in shaping a smarter, more connected world.

0 notes

Text

Building Automation Systems (BAS): Revolutionizing Modern Infrastructure

In an era increasingly defined by smart technologies and sustainability, Building Automation Systems (BAS) are becoming the backbone of modern infrastructure. These systems integrate and automate a building's essential services—such as heating, ventilation, air conditioning (HVAC), lighting, security, and energy management—into a single, centralized platform. The goal is to enhance efficiency, comfort, safety, and sustainability while reducing operational costs.

What is a Building Automation System?

A Building Automation System is a network of hardware and software that connects various systems within a building. BAS enables monitoring and control through a centralized interface, often using sensors, controllers, and actuators that communicate over digital networks. The system collects data in real-time and uses predefined rules or algorithms to make decisions, optimizing the performance of building equipment and systems.

Core Components of BAS

Sensors and Input Devices: Measure parameters like temperature, humidity, light levels, motion, and occupancy.

Controllers: Programmable devices that process sensor data and make decisions based on programmed logic.

Actuators and Output Devices: Implement commands from controllers, such as adjusting a thermostat or dimming lights.

User Interface: A centralized dashboard—often accessible via computer or mobile device—used for monitoring, analysis, and manual overrides.

Communication Protocols: Standards like BACnet, Modbus, and LonWorks enable interoperability between different devices and systems.

Key Benefits

Energy Efficiency: BAS optimizes energy usage by adjusting lighting, HVAC, and other systems based on occupancy and time of day.

Operational Cost Savings: Automated systems reduce the need for manual monitoring and maintenance, lowering labor costs.

Enhanced Comfort and Productivity: Maintaining consistent indoor climate conditions improves occupant comfort and productivity.

Security and Safety: Integrated access control, video surveillance, and fire alarm systems improve overall building safety.

Data-Driven Insights: Continuous monitoring provides valuable data for predictive maintenance and long-term planning.

Applications

BAS is widely used across various sectors:

Commercial Buildings: Office spaces, shopping malls, and hotels use BAS to enhance tenant experience and reduce utility expenses.

Healthcare Facilities: Precise control over air quality and temperature is critical in hospitals and clinics.

Educational Institutions: Schools and universities employ BAS for cost-effective facility management and sustainable operations.

Industrial Complexes: Automation ensures optimal environmental conditions for manufacturing and storage.

Future Trends

As technology advances, Building Automation Systems are becoming more intelligent and connected. Key trends include:

Integration with IoT: Internet of Things (IoT) devices enable more granular control and richer data analytics.

Cloud-Based Platforms: Remote access and cloud computing are making BAS more flexible and scalable.

Artificial Intelligence (AI): AI-driven analytics can predict equipment failure, optimize energy use, and enhance decision-making.

Cybersecurity: As buildings become more connected, securing BAS from cyber threats is increasingly critical.

Conclusion

Building Automation Systems represent a significant leap toward smarter, more sustainable buildings. As urbanization continues and the demand for energy efficiency rises, BAS will play an increasingly vital role in shaping the future of architecture and infrastructure. Whether in a high-rise office tower or a sprawling university campus, the implementation of BAS promises a future where buildings are not just structures, but intelligent, adaptive environments.

0 notes

Text

Top Innovative STEM Lab Solutions for Schools and Colleges in 2025

In the ever-changing academic environment of today, education has no longer stayed tethered to books and lectures. Because of the real world, schools, colleges, and training institutions are heavily investing in Innovative STEM Lab Solutions to provide a balance between theory and practice. These modern setups have allowed students to hone their scientific, technological, engineering, and mathematical abilities through experimentation, problem-solving, and design thinking.

For those teachers, administrators, or institutions willing to update their infrastructure, the following are the main STEM lab solutions that will make a difference in 2025.

Modular lab stations

A modern STEM lab is, by definition, very flexible. Modular lab stations are perfect in a school where the space must sometimes be used for robotics, sometimes for chemistry, and sometimes for electronics. These stations usually have moving workbenches, moving storage, and integrated power supplies, making them perfect for interdisciplinary learning.

Why it works:

Efficient use of space

Facilitates teamwork and solo work

Adapting to different grade levels and projects

Robotics & Automation Kits

Being widely accepted in industries, automation is the need of the hour for STEM kits. Robotics kits consist of Programmable Robots, Sensors, Servo motors, and AI Integration kits that allow students to build their robots, program them, and control them.

Our Top Picks:

Arduino-based Robotics Platforms

LEGO® Education SPIKE™ Prime

Raspberry Pi + sensor modules

The kits offer an excellent opportunity to market coding and engineering skills in a manner that is both entertaining and practical.

FDM 3D Printers and Rapid Prototyping Setup

3D printers are no longer a luxury—they remain a must-have. They enable students to build their prototypes, test their mechanical models, and engage in product design. Increasingly, schools are embedding 3D printing into STEM pedagogy so that students can apply their knowledge to solve real-world problems.

Benefits:

Enhances spatial and design thinking

Promotes iteration and creativity

Encourages integration across various subjects (science and art, for instance)

Interactive Digital Boards and Simulation Tools

Chalk and blackboards are a thing of the past. Digital smart boards and simulation software enliven the abstract concepts of STEM, such as chemical reactions or circuit UML diagrams. Teachers have real-time data at their fingertips, can draw on touch screens, and engage students in solving problems together.

Combined with Arduino simulators, circuit design software like Tinkercad, or tools for virtual dissection, it makes the lab intelligent and fun.

IoT- and AI-Based Learning Modules

In 2025, IoT- and AI-based experiments will be part of every competitive mainstream STEM education. Cutting-edge labs are equipped with sensors, cloud dashboards, and microcontrollers to help students build all kinds of smart projects, such as home automation projects, temperature monitoring systems, or AI chatbots.

The solutions prepare the students to think beyond conventional science and prepare tech jobs of the future.

Curriculum-Aligned STEM Kits

Curriculum-aligned STEM kits, thus, remain relevant for teaching. These kits are uniquely designed to meet the lesson plans, experiment manuals, safety instructions, and real-world problem-based learning content required by the curriculum. They are made for specific classes and subjects with which CBSE, ICSE, IB, or state boards can identify.

Features to look for:

Subject-specific kits (Biology, Physics, Chemistry)

Safety compliance (CE, ISO certifications)

Teacher guides and student workbooks

Cloud-Based Lab Management System

Heading into 2025, cloud-based lab management platforms are becoming more and more popular. This allows instructors to track inventory, log student experiments, manage schedules, and upload student reports onto the cloud, thereby cutting down the paperwork and boosting the efficiency of the lab as a whole.

STEM-Learning Corners in Classrooms

These STEM corners in regular classrooms find favor with many schools, especially for the many that do not have the funds for the full-blown labs. Here little places house essential kits, puzzles, experiment tools, and DIY stations where students can entertain themselves exploring topics on their own.

This makes the STEM field much more approachable and far more interesting from an early age.

Conclusion

The year 2025 marks a decision point for investing in Innovative STEM Lab Solutions: choosing to invest is no longer an option but really a must. Through robotics kits, IoT modules, and modular workstations, these solutions pre-emptively prepare students for the future by instilling critical thinking, creativity, and problem-solving abilities.

If your institute is planning a STEM lab upgrade, select the supplier who understands academic requirements and contemporary technology trends. Tesca Global has earned recognition as a name offering second-to-none, affordable, and curriculum-aligned STEM lab solutions customized for schools, colleges, and universities worldwide.

#laboratory equipment suppliers#developers & startups#educational lab equipments#business#news#photography#technology

0 notes

Text

CNC Machining Manufacturer in Pune – ANJALI T. PRECISION

In the ever-evolving world of manufacturing, precision, efficiency, and innovation have become the pillars of modern industry. Pune, often referred to as the engineering and manufacturing hub of India, is home to several leading CNC machining companies. Among them, ANJALI T. PRECISION stands out as a trusted name in the field of CNC Machining and precision components manufacturing.

Who We Are – About ANJALI T. PRECISION

Established with a vision to deliver world-class CNC machining services, ANJALI T. PRECISION has earned a solid reputation as a leading CNC Machining Manufacturer in Pune. Our company is known for its commitment to quality, advanced technological infrastructure, and client-centric approach. With years of industry experience, we have been consistently delivering high-precision, complex, and cost-effective components to diverse industries including automotive, aerospace, electronics, defense, and industrial equipment.

What is CNC Machining?

CNC (Computer Numerical Control) Machining is a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. It enables the creation of precise and complex parts with tight tolerances and smooth finishes.

At ANJALI T. PRECISION, we specialize in:

CNC Turning

CNC Milling

VMC (Vertical Machining Center) operations

Drilling and Tapping

Custom CNC Machining Solutions

Our Services

1. CNC Turning and Milling

Our state-of-the-art CNC turning and milling machines produce high-accuracy components for critical applications. We work with a wide range of materials including stainless steel, aluminum, brass, copper, and various engineering plastics.

2. Prototype to Production

Whether it's a single prototype or full-scale production, we have the expertise and resources to support both short-run and high-volume requirements.

3. Custom Component Manufacturing

We specialize in customized parts as per client drawings and specifications. Our skilled engineers and machinists ensure top-notch output at every stage.

4. Quality Inspection and Assurance

Our in-house quality control processes include 3D measuring tools, surface roughness testers, height gauges, and other advanced inspection instruments. We strictly follow ISO quality standards to ensure zero-defect products.

Why Choose ANJALI T. PRECISION?

✔ Advanced Infrastructure

Our modern manufacturing facility in Pune is equipped with cutting-edge CNC machines and tools, allowing us to meet the most demanding machining requirements.

✔ Experienced Workforce

We have a team of highly trained engineers, CNC programmers, and operators who are passionate about delivering perfection.

✔ On-Time Delivery

We understand the importance of deadlines. Our streamlined workflow ensures timely deliveries without compromising on quality.

✔ Competitive Pricing

By optimizing our operations and processes, we offer the most competitive rates in the industry.

✔ End-to-End Solutions

From design review and raw material sourcing to machining, finishing, and final inspection – we offer complete CNC machining solutions under one roof.

Industries We Serve

Automotive

Aerospace

Medical Equipment

Defense & Military

Textile Machinery

Robotics & Automation

Electronics & Electrical

Heavy Engineering

Customer-Centric Approach

At ANJALI T. PRECISION, every client is important. We believe in building long-term partnerships based on trust, transparency, and technical excellence. Our support team ensures clear communication, quick response times, and personalized services to meet your project goals.

CNC Machining in Pune – The ANJALI T. PRECISION Advantage

Pune’s strategic location, skilled workforce, and proximity to major OEMs make it an ideal hub for CNC machining. With ANJALI T. PRECISION, you're not just hiring a manufacturer; you're partnering with a team that is committed to engineering excellence and precision craftsmanship.

Contact Us

ANJALI T. PRECISION – CNC Machining Manufacturer in Pune 📍Address: Gate 1652, 3M Industrial Estate, 1652, Dehu - Alandi Rd, Patilnagar, Chikhali, Pimpri-Chinchwad, Maharashtra 412114 📞 Phone: 092256 34833 📧 Email: [email protected] 🌐 Website:https://www.anjalitprecision.com/

Looking for a Reliable CNC Machining Partner in Pune?

Contact ANJALI T. PRECISION today and let us help you turn your designs into high-quality, precision-engineered reality.

#CNC Machining Manufacturer in Pune#CNC Machining Services Pune#Precision CNC Components#CNC Turning and Milling Pune#Custom CNC Parts Manufacturer#VMC Machining Services#CNC Job Work Pune#CNC Precision Engineering#Anjali T. Precision Pune#CNC Components Supplier India.

0 notes

Text

https://anadiautomation.com/schneider-electric/TM200CE40T

Product Overview: TM200CE40T Controller

The TM200CE40T is part of Schneider Electric’s Modicon M200 series, designed to meet the automation needs of modern industries. It features a combination of 24 digital inputs and 16 digital transistor outputs, making it ideal for various I/O-intensive applications.

🔧 Key Specifications:

Part Number: TM200CE40T

Brand: Schneider Electric

Controller Type: Programmable Logic Controller (PLC)

Digital Inputs: 24

Digital Outputs: 16 (Transistor type)

Communication Ports: Built-in Ethernet

Mounting: DIN Rail

Power Supply: 24V DC

Program Memory: Expandable

Warranty: 1 Year (provided by Anadi Automation)

Availability: In stock at Anadi Automation, Nashik, India

Top Features of Schneider Electric TM200CE40T

The TM200CE40T offers a variety of features that enhance its appeal to system integrators and OEMs alike. Here’s why it stands out:

✅ High Input/Output Capacity

With 24 digital inputs and 16 digital outputs, the controller provides ample I/O support for mid-size automation systems.

✅ Compact and Modular Design

Despite its powerful capabilities, the TM200CE40T has a compact footprint. It supports modular expansion, allowing you to scale your system as needed.

✅ Integrated Ethernet Port

The built-in Ethernet port enables high-speed communication, remote monitoring, and easy integration into industrial networks using Modbus TCP/IP protocol.

✅ High-Speed Counter and Pulse Outputs

It includes high-speed counters and pulse output functions that are essential for motion control and fast process operations.

✅ DIN Rail Mounting

Ease of installation with standard DIN rail mounting ensures a secure and accessible setup.

✅ Advanced Programming Environment

Compatible with Schneider Electric's EcoStruxure Machine Expert – Basic (SoMachine Basic) software for intuitive programming, simulation, and troubleshooting.

0 notes

Text

What Key Factors Should You Consider When Choosing an Automation Products Supplier?

Understanding the Role of an Automation Products Supplier

In today’s fast-paced industrial landscape, businesses depend heavily on reliable Automation Products Supplier in Kuwait partners to streamline operations, improve productivity, and maintain a competitive edge. Automation has become essential across sectors such as manufacturing, logistics, healthcare, and more, driven by the need for efficiency, accuracy, and cost control. The right supplier not only provides advanced products but also delivers technical support, customization, and ongoing services that are crucial for long-term success.

Types of Automation Products Available

Automation products cover a wide range of technologies, each serving specific roles in industrial and commercial applications:

Programmable Logic Controllers (PLCs): These are ruggedized computers designed to control manufacturing processes, offering high reliability and ease of programming for tasks like assembly lines and robotic devices.

Human Machine Interfaces (HMIs): HMIs provide intuitive control panels for operators, enabling easy visualization and management of complex systems through touch screens and multi-touch interfaces.

Motion and Drives: Includes servo motors and stepper motors used for precise control of position, speed, and torque in automated systems.

I/O Systems: Inputs and outputs (I/O) connect various sensors and actuators to central controllers, supporting multiple communication protocols for distributed control.

Sensors and Vision Systems: Photoelectric, proximity sensors, and machine vision cameras are used for detecting objects, monitoring production lines, and ensuring quality control.

Accessories and Connectivity: Products such as cordsets, communication cables, and software for programming and troubleshooting are essential for seamless integration and maintenance of automation systems.

Why Supplier Selection Matters

Choosing the right automation products supplier is a strategic decision that impacts every aspect of your operations. Here are key factors to consider:

Product Range and Innovation: Leading suppliers offer a comprehensive portfolio, including the latest advancements in robotics, artificial intelligence, and IoT-based control systems. This ensures your business can adopt new technologies as they emerge.

Reliability and Support: A reputable supplier provides technical support, training, and after-sales services, helping you maximize the value of your investment and minimize downtime.

Customization and Scalability: As industries evolve, the demand for customized and scalable solutions grows. The best suppliers work closely with clients to tailor products that fit unique operational needs.

Global Reach and Local Presence: Top suppliers often have a global footprint with strong local support, ensuring timely delivery and service regardless of location.

Security and Compliance: With increasing digitalization, security is paramount. Suppliers should offer solutions with robust cybersecurity features and comply with relevant industry standards.

Market Trends and Growth Opportunities

The global industrial automation market is expanding rapidly, with a high growth rate projected for the coming years. This growth is driven by rising labor costs, a shortage of skilled workers, and government initiatives promoting automation for efficiency and sustainability. Companies are investing in technologies such as edge computing, 5G, and digital twin systems, which enable real-time monitoring and predictive maintenance for smarter operations.

Conclusion

Selecting the right Automation Products Supplier in Kuwait is critical for any business aiming to thrive in an increasingly automated world. By evaluating suppliers based on product offerings, innovation, support, and security, companies can ensure they are well-equipped to meet current demands and adapt to future challenges. As automation technology continues to evolve, partnering with a knowledgeable and reliable supplier will help your business achieve greater efficiency, productivity, and long-term growth.

Also Read: Rexroth Pumps and Valves Supplier in Kuwait

0 notes

Text

Python Training in Chandigarh: Unlocking a Future in Programming

In today’s fast-paced digital world, programming has become a core skill across numerous industries. Among all programming languages, Python stands out due to its simplicity, versatility, and powerful capabilities. As a result, Python training has become one of the most sought-after courses for students, professionals, and aspiring developers. In Chandigarh, a city known for its educational institutions and growing IT ecosystem, Python training opens up exciting career opportunities for learners of all levels.

Why Learn Python?

Python is an interpreted, high-level, general-purpose programming language that emphasizes code readability with its clear syntax. It supports multiple programming paradigms, including procedural, object-oriented, and functional programming. Python has grown rapidly in popularity, currently ranking as one of the top programming languages worldwide.

Some of the key reasons to learn Python include:

Ease of learning: Python has a gentle learning curve, making it ideal for beginners.

Versatility: It’s used in web development, data science, artificial intelligence, automation, game development, and more.

Strong community support: Python has a vast library ecosystem and an active community that contributes to open-source tools and frameworks.

High demand: From startups to tech giants like Google, Facebook, and Netflix, Python developers are in high demand globally.

The Growing Demand for Python in India

India's digital transformation has resulted in a booming demand for skilled programmers. Python, being at the center of technologies like machine learning, data analytics, and artificial intelligence, is a critical skill in the current job market. According to recent job market surveys, Python is consistently among the top 3 most requested skills in software development roles.

Industries such as finance, healthcare, education, and e-commerce in India are actively seeking professionals with Python expertise. As the use of big data and automation expands, the demand for Python-trained professionals is expected to rise even more.

Why Choose Chandigarh for Python Training?

Chandigarh, the capital of Punjab and Haryana, is emerging as a technology hub in North India. Known for its well-planned infrastructure and high quality of life, the city is home to several IT companies, startups, and training institutes.

Key reasons to choose Chandigarh for Python training:

High-quality education centers: Chandigarh hosts some of the best training institutes offering Python courses with practical, project-based learning.

Affordable living: Compared to metropolitan cities, Chandigarh offers cost-effective training and living expenses.

Growing IT ecosystem: With IT parks and emerging startups, the city offers internship and job opportunities for learners.

Peaceful environment: The city’s clean and organized environment enhances the learning experience.

What to Expect from a Python Training Program in Chandigarh?

Python training programs in Chandigarh cater to both beginners and advanced learners. Whether you are a student, fresher, or working professional looking to upskill, you can find a suitable course.

Course Structure

Most Python training programs include:

Introduction to Python: Basics of syntax, variables, data types, and control structures.

Functions and Modules: Writing reusable code using functions and importing modules.

Object-Oriented Programming: Concepts such as classes, objects, inheritance, and polymorphism.

File Handling: Reading from and writing to files.

Error Handling: Managing exceptions and debugging.

Libraries and Frameworks: Use of popular libraries like NumPy, Pandas, Matplotlib, and frameworks like Flask or Django.

Database Integration: Connecting Python applications with databases like MySQL or SQLite.

Project Work: Real-world projects that test your understanding and give hands-on experience.

Modes of Training

Institutes offer various modes of learning:

Classroom training: Traditional in-person classes with face-to-face interaction.

Online training: Live or recorded sessions accessible from home.

Weekend batches: Ideal for working professionals.

Fast-track courses: For learners who want to complete the course in a shorter time.

Certifications and Placement Support

Most reputed institutes provide certification upon course completion, which can be a great addition to your resume. Some also offer:

Resume-building assistance

Mock interviews

Placement support or job referrals

Internship opportunities with IT firms in Chandigarh

Career Opportunities After Python Training

After completing Python training, learners can pursue various career paths, such as:

Python Developer: Focused on building software applications using Python.

Web Developer: Using frameworks like Django or Flask to build web applications.

Data Analyst: Analyzing data using Pandas, NumPy, and data visualization tools.

Machine Learning Engineer: Building intelligent systems using libraries like Scikit-learn and TensorFlow.

Automation Engineer: Writing scripts for process automation in business and IT environments.

Backend Developer: Creating server-side logic for mobile and web applications.

Top Institutes for Python Training in Chandigarh

While there are many training providers, here are a few well-regarded Python training institutes in Chandigarh (as of recent trends):

CBitss Technologies

ThinkNEXT Technologies

Webtech Learning

Infowiz Software Solutions

Netmax Technologies

Each of these institutes offers various Python courses, including beginner and advanced levels, along with certification and placement support.

Tips for Choosing the Right Python Course

Check the syllabus: Ensure it covers both basics and advanced topics relevant to your goals.

Trainer experience: Look for instructors with industry experience.

Hands-on projects: Courses should include real-world projects for practical exposure.

Student reviews: Read testimonials and online reviews to gauge course quality.

Demo classes: Attend a trial session if available before enrolling.

Conclusion

Python training in Chandigarh offers a gateway to exciting and diverse career opportunities in the tech industry. Whether you aim to become a developer, data analyst, or machine learning expert, Python is a foundational skill that can set you apart in the competitive job market. With its growing tech scene, quality institutes, and supportive learning environment, Chandigarh is an ideal location to begin or advance your Python programming journey.

Investing in Python training today can pave the way for a dynamic career tomorrow.

0 notes

Text

Choosing the Right PLC: A Guide for Small & Medium Industries

Finding the Perfect PLC for Your Application.

In today’s fast-paced industrial environment, choosing the right Programmable Logic Controller (PLC) is crucial for ensuring efficiency, reliability, and scalability. Small and medium industries often struggle to find a cost-effective solution that balances performance with flexibility.

Whether you're automating a machine tool, packaging line, water treatment plant, or a textile process, selecting the right PLC can significantly impact your productivity.

Key Factors to Consider When Selecting a PLC

✅ Application Complexity – Does your process require simple ON/OFF control, or do you need advanced motion and data handling?

✅ I/O Requirements – How many digital and analog inputs/outputs do you need?

✅ Communication & Connectivity – Is the PLC compatible with industry-standard protocols like Modbus, Ethernet/IP, or MQTT?

✅ Scalability & Future Expansion – Can the PLC adapt to your growing automation needs?

✅ Advanced Control Capabilities – Does the PLC support PID control for maintaining precise process parameters?

✅ Ease of Programming – Is the PLC supported by intuitive, user-friendly programming software?

✅ Cost & Support – Does the solution offer the best value without compromising on quality and support?

Messung XMPRO Series: Designed for Your Industrial Needs

At Messung, we understand the challenges industries face when selecting automation solutions. Our XMPRO-10 PLC series offers:

🔹 Compact & Scalable Solutions – Suitable for both small and medium industries, ensuring cost-effectiveness without performance compromises.

🔹 Advanced Connectivity – Supports Modbus, Ethernet/IP, and MQTT for seamless data exchange, real-time remote monitoring, and Industry 4.0 integration.

🔹 Precision Process Control with PID – Ideal for temperature, pressure, and flow control applications, ensuring optimized performance with minimal manual intervention.

🔹 User-Friendly Programming – Developed with XMPS-2000 software, making programming intuitive and efficient.

🔹 High Reliability & Performance – Built with robust hardware and backed by 4 Decades of expertise in industrial automation.

Proven Applications of XMPRO-10 PLC

Messung’s XMPRO-10 PLC has already been successfully implemented in a variety of industrial applications, including:

Testing & Automotive Industry:

✔Pressure Testing Machines – Ensuring precise pressure control.

✔ Leak Testing Machines – High-accuracy monitoring for quality assurance.

✔ Engine Test Systems/Benches – Automating real-time engine performance analysis.

✔ Vehicle & Transmission Test Machines – Advanced testing for automotive components.

✔ Battery Tray Leak Test Machines – Reliable testing solutions for EV battery components.

Manufacturing & Process Automation:

✔ Drilling, Tapping & Press Machines – Improving precision and repeatability.

✔ Core Shooters (Forging) – Optimizing metal casting processes.

✔ Shot Blasting Machines – Automating surface treatment applications.

✔ Salt Spray Chamber/Corrosion Testing – Enhancing material durability testing.

✔ Automated Liquid Filling Machines – Efficient and precise liquid handling solutions.

Textile & Environmental Control:

✔ Yarn Steaming Autoclaves – Optimized temperature and pressure regulation.

✔ Stator Varnishing Machines – Enhancing insulation durability in motor manufacturing.

✔ STP, ETP, WTP – Reliable PLC-based automation for sewage, effluent, and water treatment plants.

✔ Industrial Water Chillers & HVAC Systems – Seamless integration for environmental control solutions.

✔ AHU & Dehumidifiers – Smart control for air handling and moisture management.

Upgrade to a Smarter PLC Today!

Choosing the right PLC doesn’t have to be complicated. Messung’s XMPRO-10 PLC series is designed to meet the diverse needs of small and medium industries, delivering cutting-edge automation at an affordable cost.💡 Want expert guidance? Our team can help you select the best PLC for your specific application. Contact us today!

#PLC#Programmable Logic Controller (PLC)#XMPRO-10 PLC series#Industry 4.0#PLC-based automation#Smart control#best PLC#messung plc#water treatment plants

0 notes

Text

Empowering Your Future: Exploring Python Classes in Abu Dhabi

In today's technology-driven world, Python has emerged as one of the most versatile and in-demand programming languages. Its simplicity, readability, and extensive libraries make it a preferred choice for beginners and seasoned developers alike. For individuals in the UAE capital aiming to enhance their programming skills, enrolling in Python Classes in Abu Dhabi offers a strategic pathway to career advancement and personal growth.

Understanding the Importance of Python

Python's widespread adoption across various industries stems from its ability to facilitate rapid development and integration. Whether it's web development, data analysis, artificial intelligence, or automation, Python provides the tools and frameworks necessary to build robust applications efficiently. Its open-source nature and supportive community further contribute to its growing popularity among developers worldwide.

Advantages of Pursuing Python Classes in Abu Dhabi

1. Comprehensive Curriculum

Python courses in Abu Dhabi are designed to cater to a diverse audience, from novices to experienced programmers. The curriculum typically covers fundamental concepts such as variables, data types, control structures, functions, and object-oriented programming. Advanced topics may include web frameworks like Django, data science libraries such as Pandas and NumPy, and machine learning algorithms.

2. Experienced Instructors

Institutions in Abu Dhabi boast a team of seasoned instructors with extensive industry experience. Their practical insights and real-world examples enrich the learning experience, enabling students to grasp complex concepts with ease.

3. Flexible Learning Options

Recognizing the varied schedules of learners, many training centers offer flexible learning modes, including weekend classes, evening sessions, and online courses. This flexibility ensures that professionals and students can balance their commitments while pursuing their educational goals.

4. Hands-On Projects

A key component of Python classes is the emphasis on practical application. Students engage in hands-on projects that simulate real-world scenarios, allowing them to apply theoretical knowledge and develop problem-solving skills.

Career Opportunities Post-Certification

Completing a Python course opens doors to a multitude of career paths. Graduates can pursue roles such as:

Software Developer: Designing and developing applications across various platforms.

Data Analyst: Interpreting complex data sets to inform business decisions.

Machine Learning Engineer: Building algorithms that enable machines to learn and adapt.

Web Developer: Creating dynamic and responsive websites using frameworks like Django and Flask.

The demand for Python professionals is on the rise, with industries such as finance, healthcare, education, and technology seeking skilled individuals to drive innovation and efficiency.

Selecting the Right Python Course

When choosing a Python class in Abu Dhabi, consider the following factors:

Accreditation: Ensure the institution is recognized and offers certified programs.

Curriculum Depth: Review the course content to confirm it aligns with your learning objectives.

Instructor Expertise: Research the qualifications and experience of the teaching staff.

Student Support Services: Look for institutions that provide career counseling, mentorship, and post-course assistance.

Conclusion

Embarking on Python Classes in Abu Dhabi is a strategic investment in one's professional development. The comprehensive training, experienced instructors, and practical projects equip learners with the skills necessary to thrive in today's competitive job market. As industries continue to embrace digital transformation, proficiency in Python will remain a valuable asset, opening doors to diverse and rewarding career opportunities.

0 notes

Text

Embedded Controls Development: From Design to Deployment

Embedded controls development is a critical area in embedded systems engineering, involving the design, programming, and integration of control systems into hardware platforms. These systems are typically found in devices that perform dedicated functions, ranging from consumer electronics to industrial automation and automotive applications. The development process requires a combination of hardware knowledge, software engineering, and systems integration skills.

What Are Embedded Controls?

Embedded controls are computer-based systems that control specific functions within a larger mechanical or electrical system. They use microcontrollers, digital signal processors (DSPs), or microprocessors to monitor inputs from sensors, process data according to a control algorithm, and output control signals to actuators or other system components. These control loops can be simple (like turning on a fan when a sensor detects high temperature) or complex (like managing engine timing and fuel injection in modern vehicles).

Development Lifecycle

The development lifecycle for embedded controls typically follows several key stages:

Requirements Definition: Understanding what the control system needs to do. This includes identifying input/output interfaces, environmental constraints, performance requirements, and safety or compliance standards.

System Design: Creating a high-level architecture that defines how software and hardware will interact. This stage also involves choosing the right microcontroller or processor, selecting sensors and actuators, and outlining communication protocols.

Software Development: Writing code for the embedded control system, often in C or C++. Developers must consider memory limitations, real-time constraints, and hardware-specific details. This stage includes implementing control algorithms, handling interrupts, and developing communication interfaces such as I2C, SPI, UART, or CAN.

Hardware Integration: Integrating the embedded software with physical components. This includes setting up the development board, connecting sensors and actuators, and testing signal integrity and power consumption.

Testing and Validation: Rigorously testing the control system to ensure it functions as expected under various conditions. Unit testing, integration testing, and hardware-in-the-loop (HIL) simulations are commonly used to verify performance and reliability.

Deployment and Maintenance: After development and testing, the system is deployed into the final product. Ongoing maintenance may involve firmware updates, bug fixes, or performance improvements.

Tools and Platforms

A wide range of tools are used in embedded controls development, including:

Integrated Development Environments (IDEs): Tools like Keil µVision, MPLAB X, STM32CubeIDE, and Arduino IDE are popular for writing and debugging code.

Real-Time Operating Systems (RTOS): Systems such as FreeRTOS or VxWorks provide scheduling, task management, and synchronization capabilities for time-sensitive applications.

Version Control Systems: Git is widely used to manage code versions and support collaborative development.

Simulation and Modeling Tools: MATLAB/Simulink is frequently used in control systems design for simulation and code generation.

In-Circuit Debuggers/Programmers: Tools like JTAG or SWD interfaces allow developers to program and debug the target microcontroller directly.

Challenges in Embedded Controls Development

Developing embedded control systems presents several challenges:

Resource Constraints: Embedded systems often have limited CPU power, memory, and energy availability. Efficient coding and hardware optimization are essential.

Real-Time Requirements: Many control systems must respond within strict timing constraints. Missed deadlines can result in system failure or unsafe behavior.

Hardware Dependence: Embedded software is closely tied to specific hardware, requiring deep knowledge of the processor, peripherals, and electrical characteristics.

Debugging Complexity: Diagnosing problems in embedded systems can be difficult due to limited visibility into internal states and limited logging capabilities.

Safety and Reliability: In industries like automotive or medical devices, the control systems must meet rigorous safety standards such as ISO 26262 or IEC 62304.

Applications

Embedded controls are used in countless applications:

Automotive Systems: Engine control units (ECUs), anti-lock braking systems (ABS), adaptive cruise control, and infotainment systems.

Consumer Electronics: Smart thermostats, washing machines, and robotic vacuum cleaners all rely on embedded control systems.

Industrial Automation: PLCs and industrial controllers manage processes on factory floors, often integrating with SCADA systems.

Aerospace and Defense: Flight control systems, unmanned aerial vehicles (UAVs), and radar systems.

Medical Devices: Infusion pumps, pacemakers, and diagnostic equipment all include embedded control systems to ensure safe and accurate operation.

Trends and Future Directions

The field of embedded controls is rapidly evolving. Several key trends are shaping the future:

IoT Integration: Many embedded systems are now connected to the internet, allowing for remote monitoring, control, and firmware updates.

Edge Computing: More processing is being done on the device itself, reducing the need to send data to the cloud and improving response times.

AI and Machine Learning: Embedded systems are beginning to incorporate ML algorithms for pattern recognition, predictive maintenance, and adaptive control.

Model-Based Design: Tools like Simulink allow engineers to design control systems graphically and automatically generate embedded code.

Cybersecurity: As systems become more connected, securing embedded control systems against hacking and data breaches is becoming essential.

Conclusion

Embedded controls development by Servotechinc is a complex but vital discipline that sits at the heart of modern technology. From managing vehicle dynamics to enabling smart home features, embedded control systems play a crucial role in ensuring that machines operate efficiently, safely, and intelligently. As technology advances, the demand for skilled engineers in this domain will only continue to grow.

0 notes