#Programmable Logic Controller (PLC) Market

Explore tagged Tumblr posts

Text

Programmable Logic Controller Market Set to Hit US$ 17.2 Bn with Strong Demand from Smart Industries

The global programmable logic controller (PLC) market, valued at US$ 11.6 Bn in 2022, is forecast to grow at a CAGR of 4.7% between 2023 and 2031, reaching a market value of US$ 17.2 Bn by the end of 2031, according to the latest industry insights. This growth is propelled by a surge in demand for industrial automation, smart manufacturing, and increased integration of the Industrial Internet of Things (IIoT).

Market Overview: A programmable logic controller (PLC) is a digital computer used to automate electromechanical processes, particularly in manufacturing environments. These devices are integral to the efficient operation of assembly lines, robotic devices, and any activity requiring high-reliability control and ease of programming. With increasing adoption across automotive, food & beverage, chemical, energy & utility, and construction industries, the global PLC market continues to expand in scope and application.

Market Drivers & Trends

The rising trend of smart factories and Industry 4.0 is among the most significant growth drivers. Manufacturers are increasingly adopting automation to reduce operational costs, improve productivity, and enhance precision. PLCs play a critical role in this transformation by allowing control over complex industrial processes with minimal human intervention.

Additionally, the growing need for data-driven decision-making, along with advancements in machine learning and artificial intelligence, is leading to deeper integration of PLCs in industrial settings. As automation becomes central to production and operational strategies, the demand for PLCs is expected to surge further.

Latest Market Trends

One of the most notable trends is the shift toward modular PLCs, which accounted for over 68.2% of the market share in 2022. These PLCs are gaining popularity due to their scalability and suitability for large-scale, complex automation tasks. Modular systems offer higher flexibility, can handle thousands of inputs/outputs, and support multitasking environments—making them ideal for high-volume manufacturing operations.

Another trend is the miniaturization of PLCs, which supports their deployment in compact systems and small machinery, especially in consumer electronics and smaller automated units.

Key Players and Industry Leaders

The competitive landscape is fragmented yet dominated by global industrial automation giants. Leading companies in the PLC market include:

Siemens

Rockwell Automation

Mitsubishi Electric Corporation

Schneider Electric

OMRON Corporation

ABB

Panasonic Corporation

Bosch Rexroth Corporation

Delta Electronics, Inc.

Honeywell International Inc.

These companies continue to drive innovation through strategic partnerships, R&D investments, and product expansions to enhance their market share and global footprint.

Recent Developments

Crouzet, in December 2022, launched Millennium Slim, the slimmest PLC in the world, tailored for compact industrial applications.

In July 2022, OMRON Corporation introduced the CP2E Micro PLC, designed for smaller devices and capable of data collection and machine-to-machine communication. This supports low-cost automation solutions for small- and mid-sized enterprises.

Electronics Corporation of India Limited (ECIL) released its own PLC and SCADA software in May 2022, targeting industrial control applications in Indian manufacturing ecosystems.

These product introductions underline the market’s commitment to technological advancement and responsiveness to evolving industrial demands.

Market Opportunities

The expansion of material handling systems, especially in e-commerce logistics, warehousing, and food processing industries, presents substantial growth potential for PLC integration. In material handling, PLCs streamline storage, movement, and tracking—drastically improving throughput and inventory management.

Additionally, the increasing popularity of energy-efficient manufacturing and sustainability initiatives provides ample opportunity for advanced PLC systems that help monitor and reduce energy consumption across production lines.

Gain a preview of important insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=32672

Future Outlook

The future of the programmable logic controller market lies in enhanced interoperability, cloud integration, and edge computing. With greater reliance on smart infrastructure and connected devices, PLCs are expected to evolve into more intelligent, connected controllers.

The incorporation of AI-powered PLCs is expected to revolutionize industrial automation by enabling predictive maintenance, self-diagnosis, and adaptive process control. As PLCs continue to advance, their use will extend beyond industrial sectors into smart cities, transportation systems, and building automation.

Market Segmentation

By Offering:

Hardware: CPU, I/O Modules, Power Supply, Memory System

Software

Services

By Type:

Compact PLC

Modular PLC

Nano, Micro, Small, Medium, and Large PLCs

By Application:

Material Handling

Packaging & Labeling

Process Control

Safety Monitoring

Energy Management

Home & Building Automation

Industrial Equipment Control

By End-use Industry:

Automotive

Energy & Utilities

Food & Beverage

Pharmaceuticals

Construction

Oil & Gas

Semiconductors & Electronics

Regional Insights

Asia Pacific held the largest market share of 36.3% in 2022, led by strong industrial growth in China, Japan, South Korea, and India. The increasing demand for smart manufacturing systems and compact automation solutions in the region is expected to maintain its dominance through 2031.

North America, with a market share of 26.4% in 2022, continues to grow due to early adoption of factory automation and significant investment in smart infrastructure in the U.S. and Canada.

Europe remains a hub for automation technology innovation, with countries like Germany, the U.K., and France focusing on Industry 4.0 implementation across automotive and manufacturing sectors.

Why Buy This Report?

This comprehensive report offers:

Detailed market size, forecast, and growth rate

In-depth competitive landscape and company profiling

Analysis of key market drivers, trends, and opportunities

Region-wise breakdown for strategic decision-making

Porter’s Five Forces, value chain, and trend analysis

Insights into technological developments and their impact

Market segmentation for customized investment strategies

With expert analysis and forward-looking insights, this report serves as a valuable resource for stakeholders, investors, industrial engineers, and policymakers seeking to navigate and capitalize on the fast-evolving programmable logic controller market.

Explore Latest Research Reports by Transparency Market Research: 5G Smart Antenna Market: https://www.transparencymarketresearch.com/5g-smart-antenna-market.html

Solid State Transformer Market: https://www.transparencymarketresearch.com/solid-State-transformer.html

Interactive Display Market: https://www.transparencymarketresearch.com/interactive-display-market.html

GaN Epitaxial Wafers Market: https://www.transparencymarketresearch.com/gan-epitaxial-wafers-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Programmable Logic Controller (PLC) Market - Global Forecast To 2029

0 notes

Text

The global programmable logic controller (PLC) market size reached US$ 15.5 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 24.1 Billion by 2032, exhibiting a growth rate (CAGR) of 4.91% during 2024-2032

0 notes

Text

Global Programmable Logic Controller Market Is Estimated To Witness High Growth Owing To Growing Industrial Automation

The global Programmable Logic Controller (PLC) market is estimated to be valued at US$ 11.6 billion in 2021 and is expected to exhibit a CAGR of 5.4% over the forecast period of 2021 to 2030, as highlighted in a new report published by Coherent Market Insights. A) Market Overview: Programmable Logic Controllers (PLCs) are digital computers used to automate various industrial processes. They are used to control machinery and equipment on factory assembly lines, including robotic devices, motors, pumps, and other automated systems. PLCs offer numerous advantages such as high-speed processing, easy programming, reduced labor costs, enhanced productivity, improved accuracy, and increased product quality. With increasing automation across industries, the demand for PLCs is expected to witness significant growth. B) Market key trends: One key trend in the global Programmable Logic Controller market is the integration of IoT (Internet of Things) technology with PLCs. IoT integration enables real-time monitoring and control of industrial processes using cloud-based platforms. This integration allows operators to remotely monitor equipment performance, detect faults or malfunctions, optimize energy consumption, and improve overall operational efficiency. For example, Siemens AG offers the SIMATIC S7-1500 PLC range, which integrates IoT technology for advanced connectivity and data analytics. C) PEST Analysis: - Political: Governments worldwide are focusing on promoting industrial automation to improve productivity and reduce costs. This creates favorable regulatory environments for the adoption of PLCs. - Economic: Automation using PLCs helps industries achieve cost savings by reducing labor costs, improving energy efficiency, and minimizing production downtime. - Social: The growing adoption of PLCs helps enhance worker safety by replacing manual and hazardous tasks with automated systems. - Technological: Technological advancements such as IoT integration, cloud-based platforms, and advanced analytics are driving the growth of the PLC market. D) Key Takeaways: - The global Programmable Logic Controller Market is expected to witness high growth, exhibiting a CAGR of 5.4% over the forecast period, due to increasing industrial automation and the need for enhanced operational efficiency. - In terms of regional analysis, Asia Pacific is expected to be the fastest-growing and dominating region in the PLC market. This can be attributed to the rapid industrialization in countries like China, India, and South Korea. - Key players operating in the global Programmable Logic Controller market are ABB Ltd, Toshiba International Corporation, Hitachi Ltd, Emerson Electric Company, Robert Bosch GmbH, Panasonic Corporation, Omron Corporation, Honeywell International Inc., Siemens AG, Rockwell Automation, Schneider Electric SE, and Mitsubishi Electric Corporation. These players focus on product innovation, strategic partnerships, and mergers and acquisitions to gain a competitive edge in the market. In conclusion, the global Programmable Logic Controller market is expected to witness substantial growth due to the increasing demand for industrial automation and the benefits offered by PLCs. With advancements in technology and the integration of IoT, PLCs are becoming more efficient and capable of optimizing industrial processes. The Asia Pacific region is expected to lead the market growth, driven by rapid industrialization. Key players in the market are actively engaged in innovation and partnerships to stay competitive in this thriving industry.

#Programmable Logic Controller (PLC) Market#Information and Communication Technology#Programmable Logic Controller (PLC) Market Analysis#Programmable Logic Controller (PLC) Market Growth#Programmable Logic Controller (PLC) Market Forecast#Programmable Logic Controller (PLC) Market Future

0 notes

Link

The global programmable logic controller (PLC) market size reached US$ 14.6 Billion in 2022. Looking forward, IMARC Group expects the market to reach US$ 20.2 Billion by 2028, exhibiting a growth rate (CAGR) of 5.38% during 2023-2028.

#Programmable Logic Controller (PLC) Market#market trends#market research#market report#market forecast#market analysis

0 notes

Text

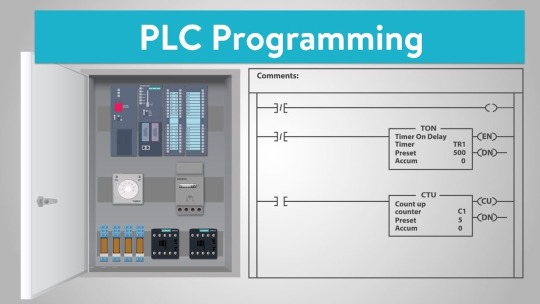

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

Who is the Best Electrical and Instrumentation Supplier in Bahrain?

If you’re working on an industrial, commercial, or even a residential project in Bahrain, finding a reliable electrical and instrumentation supplier in Bahrain can make a huge difference in terms of project efficiency, safety, and long-term reliability. Whether you’re dealing with automation, power distribution, control panels, or industrial sensors, choosing the right supplier is crucial.

What Does an Electrical and Instrumentation Supplier Do?

An electrical and instrumentation (E&I) supplier provides the essential components needed to power, control, and automate systems. These include:

Electrical cables, switches, and circuit breakers

Control panels and automation equipment

PLCs (Programmable Logic Controllers)

Sensors and transducers

Industrial lighting solutions

Calibration and testing equipment

In Bahrain’s rapidly growing infrastructure and industrial sectors, high-quality E&I components are in demand for everything from oil & gas projects to smart building developments.

Why Local Expertise Matters in Bahrain

Working with a local electrical and instrumentation supplier in Bahrain has several advantages:

Faster delivery times: No long wait for overseas shipments

Compliance with local standards: Bahrain follows specific safety and regulatory guidelines

Support and service: A local supplier can offer on-site support, technical guidance, and even after-sales service

Cost-effective solutions: Minimizing shipping and customs costs

What to Look for in a Trusted Supplier?

If you’re on the hunt for a reliable electrical and instrumentation supplier in Bahrain, consider the following criteria:

Authorized distributor for major global brands

Large inventory and fast turnaround

Engineering support and technical consultation

Proven experience with local and international projects

Positive customer reviews and a reputation for reliability

Whether you’re setting up a control system for a manufacturing plant or installing safety instruments in a refinery, partnering with the right electrical and instrumentation supplier in Bahrain is key. Make sure you work with a company that understands both the technical and regulatory requirements of the Bahraini market.

0 notes

Text

Precision and Productivity: A Deep Dive into Bag Making Machines

Bag making machines play a pivotal role in the global packaging industry, transforming flat materials into functional containers used in countless sectors—from retail and food services to industrial shipping. As consumer demand for convenience and sustainability grows, the bag making machine industry has responded with more versatile, efficient, and environmentally friendly technologies.Get more news about paper bag making machine,you can vist our website!

What is a Bag Making Machine? A bag making machine is a highly specialized piece of equipment that automates the production of various types of bags, including plastic bags, paper bags, woven sacks, and biodegradable alternatives. These machines typically handle processes such as feeding raw material, folding, sealing, cutting, and sometimes even printing or punching. The automation not only accelerates production but also ensures consistency and precision, which is crucial in large-scale manufacturing.

Types and Applications There are numerous types of bag making machines, each suited for a specific application:

Plastic Bag Making Machines: These can produce T-shirt bags, garbage bags, zip-lock bags, and more. Some machines are engineered to handle biodegradable plastics in response to environmental regulations.

Paper Bag Making Machines: As many companies shift toward paper to reduce plastic waste, these machines are gaining popularity in retail and food packaging.

Non-woven Bag Making Machines: Ideal for reusable shopping bags, these have seen a surge in demand due to bans on single-use plastics in many regions.

Each category has subtypes equipped with options for side sealing, bottom sealing, or center sealing, depending on the design and purpose of the bag.

Key Features Driving Innovation Modern bag making machines are equipped with programmable logic controllers (PLCs), touch screen interfaces, and servo motors for greater accuracy and user-friendly operation. Some high-end models come with online printing and lamination systems, integrating multiple processes into a single production line. Energy efficiency and material flexibility are also top priorities in today's designs, enabling manufacturers to work with different substrates like PE, PP, kraft paper, and recycled materials.

Sustainability and Market Trends One of the most significant developments in the bag making machine industry is the pivot toward eco-friendly materials and processes. Governments across the globe are regulating plastic usage, which has led to a sharp increase in demand for machines that handle recyclable or compostable materials. As a result, manufacturers are redesigning equipment to accommodate thinner films and recyclable blends without compromising on strength or seal quality.

China, India, and Southeast Asia remain key manufacturing hubs due to lower labor costs and expanding domestic demand. However, Western markets are increasingly investing in automation to reduce dependency on imports and meet stricter environmental standards.

Conclusion Bag making machines may not often be in the spotlight, but they are indispensable in our everyday lives. From the paper sack at the bakery to the heavy-duty bags used in construction, these machines quietly power the global flow of goods. As technology advances and sustainability becomes non-negotiable, bag making machines will continue to evolve—offering smarter, cleaner, and more efficient solutions to meet the demands of a changing world.

0 notes

Text

The Rising Demand for Mayonnaise Processing Equipment in the Food Industry

In recent years, the growing global appetite for sauces, dressings, and condiments has significantly driven the demand for mayonnaise processing equipment. As mayonnaise becomes a staple in both household and commercial kitchens, food manufacturers are actively investing in modern solutions to meet quality, hygiene, and production standards. The evolution of the industrial mayonnaise making machine has completely transformed traditional production practices, replacing manual labor with automated and continuous processes. This shift not only ensures consistency in taste and texture but also helps manufacturers scale up production to meet rising demand without compromising on safety.

Modern mayonnaise processing equipment is designed to ensure precise mixing, emulsification, and homogenization of ingredients such as oil, egg yolk, vinegar, and seasoning. Among the most critical parts of this setup is the automatic mayonnaise mixing system, which ensures a stable emulsion and uniform product consistency. Such systems have become a necessity for large-scale producers and commercial kitchens. With increasing focus on efficiency and hygiene, manufacturers now prefer stainless steel machinery, ensuring the equipment remains corrosion-resistant, durable, and easy to clean. In fact, many food processing units rely on a stainless steel mayonnaise mixer to uphold quality and food safety standards.

Technological Advancements in Mayonnaise Processing Equipment

The landscape of mayonnaise processing equipment has undergone a technological revolution. Older batch processing techniques have been replaced by more sophisticated and continuous production systems. The introduction of industrial mayonnaise making machines with high-shear mixing capabilities and vacuum systems allows manufacturers to produce smooth, lump-free mayonnaise with minimal air inclusion. This ensures longer shelf life and consistent quality. These advancements have significantly reduced the time and labor involved in traditional methods, allowing even medium-sized producers to compete with industry giants.

Additionally, automation in mayonnaise processing equipment enhances precision and control. With programmable logic controllers (PLCs), operators can adjust parameters like mixing speed, temperature, and emulsification time to fine-tune the final product. This is particularly beneficial in a commercial mayonnaise production line, where large batches must meet strict standards repeatedly. Machines equipped with smart sensors and touch-screen interfaces provide real-time monitoring and diagnostics, ensuring efficient and error-free operations. These improvements have made it easier to integrate automatic mayonnaise mixing systems into modern production workflows without the need for extensive training or complex maintenance.

Commercial Scale Production Using Mayonnaise Processing Equipment

As consumer preferences evolve, there’s a rising demand for customized and flavored varieties of mayonnaise, such as garlic, chipotle, or vegan versions. To cater to such diverse tastes, manufacturers need mayonnaise processing equipment that offers flexibility in recipe formulation without requiring frequent machine overhauls. Modern equipment supports rapid changeovers and automatic ingredient dosing, which is essential for a commercial mayonnaise production line that caters to multiple product SKUs. With precise control over the emulsification process, producers can create high-quality mayonnaise that meets varying customer expectations.

A well-designed stainless steel mayonnaise mixer plays a vital role in commercial scale production. Its robust construction allows it to handle viscous ingredients without clogging or overheating, while its hygienic design reduces contamination risks. Manufacturers in the foodservice and retail sectors now prefer modular systems that can be scaled up or down based on market demand. The ability to integrate industrial mayonnaise making machines with packaging systems has also enhanced production efficiency. From raw material input to final filling, today’s mayonnaise production setups are built to deliver quality at speed, proving the crucial role of advanced mayonnaise processing equipment.

The Future of Mayonnaise Processing Equipment in a Growing Market

The future of mayonnaise processing equipment lies in smarter, more sustainable, and energy-efficient solutions. As sustainability becomes a top priority across the food manufacturing industry, equipment manufacturers are focusing on reducing water, energy, and raw material wastage. Newer automatic mayonnaise mixing systems are being designed to minimize product loss during changeovers and clean-in-place (CIP) operations. Additionally, innovations in sensor-based technology and AI-driven process control are opening new possibilities for autonomous production lines, reducing human error and operational costs.

In this competitive landscape, investing in reliable mayonnaise processing equipment is not just a choice but a necessity for success. From a small artisan food business to a multinational condiment brand, the backbone of scalable production lies in high-performance machinery. As demand continues to grow globally, especially in emerging markets, manufacturers will increasingly depend on efficient industrial mayonnaise making machines and automated lines. Those leveraging a commercial mayonnaise production line that includes a stainless steel mayonnaise mixer will be better positioned to deliver consistent, high-quality products that meet the evolving preferences of today’s consumers. Tags: industrial mayonnaise making machine automatic mayonnaise mixing system commercial mayonnaise production line stainless steel mayonnaise mixer

0 notes

Text

PLC

Advanced Industrial Solutions: CCTV, PLC, and Fluid Management Systems by Apienergy.co.uk

In today's dynamic industrial landscape, efficiency, security, and precision are not just optional but essential. Businesses across sectors are increasingly looking for comprehensive solutions to optimize their operations while maintaining high safety standards. At Apienergy.co.uk, we understand these evolving needs and proudly offer a wide range of solutions, including CCTV systems, PLC automation, Compressed Air system installations, Condensate Tank technologies, and Deaerator systems.

Whether you are managing a manufacturing unit, a processing plant, or a commercial building, choosing the right industrial partner makes all the difference. Let’s explore how these services are vital to the seamless functioning of modern industries.

Elevate Security with Smart CCTV Systems 🎥

Security is paramount in any industrial setup. High-tech CCTV systems from Apienergy.co.uk provide continuous surveillance to protect valuable assets and ensure the safety of personnel. Our advanced CCTV solutions offer features like high-resolution imaging, night vision, remote monitoring, and AI-driven analytics.

When it comes to monitoring large areas, multiple access points, and sensitive zones, traditional security measures are no longer enough. Smart surveillance not only acts as a deterrent to unauthorized activity but also aids in quick decision-making during emergencies. Trust Apienergy.co.uk to equip your site with the latest in video surveillance technology for round-the-clock protection.

Revolutionizing Operations with PLC Automation ⚙️

Programmable Logic Controllers, or PLC systems, are the heartbeat of automation in industrial environments. From controlling machinery to managing production lines, PLCs ensure precision and reduce human error.

At Apienergy.co.uk, we design and implement highly reliable PLC systems tailored to your business needs. Whether you require basic machine automation or complex process control across a multi-unit facility, our PLC solutions enhance operational efficiency and deliver real-time data that empowers informed decision-making.

By integrating smart PLC automation, companies not only increase productivity but also gain the flexibility to adapt quickly to changing market demands. This flexibility is critical for businesses seeking sustainable growth in a competitive landscape.

Optimize Energy Usage with Efficient Compressed Air Systems 💨

A robust Compressed Air system is a vital utility in many industries, powering a wide range of equipment from pneumatic tools to automated production lines. However, without proper installation and maintenance, these systems can become energy drains.

Apienergy.co.uk specializes in designing, installing, and maintaining compressed air systems that maximize efficiency while minimizing costs. Our energy-saving systems are customized to suit your production demands, ensuring optimal air pressure levels with minimal leakage.

Compressed air accounts for a significant portion of industrial energy consumption. Therefore, investing in a high-efficiency compressed air system not only enhances operational performance but also contributes to long-term environmental sustainability.

Protect Equipment with Advanced Condensate Tanks 🚰

Managing moisture is a critical aspect of compressed air system maintenance. That’s where a reliable Condensate Tank becomes indispensable. Improper condensate management can lead to system corrosion, equipment damage, and expensive downtime.

Our innovative condensate tanks efficiently collect and remove water from compressed air systems, ensuring that moisture doesn't compromise your machinery's performance. Apienergy.co.uk provides condensate solutions that integrate seamlessly with your air system, providing a clean and dry air supply essential for sensitive applications.

Protecting your equipment from moisture damage translates into fewer repairs, extended lifespan, and better overall system performance.

Boost Boiler Efficiency with State-of-the-Art Deaerators 🔥

Boiler efficiency is crucial to the smooth operation of many industries, from manufacturing to energy production. One critical component for maximizing boiler performance is the Deaerator.

Deaerators remove dissolved gases like oxygen and carbon dioxide from boiler feedwater, preventing corrosion and promoting more efficient heat transfer. Apienergy.co.uk offers cutting-edge deaerators designed to deliver consistent performance and enhance the longevity of your boiler systems.

By investing in an advanced deaerator, industries benefit from reduced operational costs, increased equipment reliability, and minimized environmental impact due to improved energy efficiency.

Why Choose Apienergy.co.uk?

At Apienergy.co.uk, we are passionate about helping industries harness the power of technology to boost performance and sustainability. Our team combines technical expertise with a customer-centric approach to deliver solutions that truly make a difference.

Here’s why businesses across sectors trust us:

✅ Tailored Solutions: Every industry has unique challenges; we design solutions that fit your specific operational needs.

✅ Top-Quality Products: We use only the highest-grade equipment to ensure durability and efficiency.

✅ Expert Installation: Our experienced technicians guarantee flawless system integration and setup.

✅ Ongoing Support: We don’t just install systems—we partner with you for maintenance and upgrades to ensure peak performance.

✅ Commitment to Sustainability: We help businesses reduce energy consumption and improve environmental impact.

0 notes

Text

Micro and Nano Programmable Logic Controller (PLC) Market Size, Share, Key Drivers, Trends, Challenges and Competitive Analysis

"Global Micro and Nano Programmable Logic Controller (PLC) Market – Industry Trends and Forecast to 2029

Global Micro and Nano Programmable Logic Controller (PLC) Market, By Type (Micro PLC, Nano PLC), Offering (Hardware, Software, Services), Architecture (Fixed PLC, Modular PLC), Industry (Automotive Industry, Chemicals and Fertilizers Industry, Food and Beverages Industry, Home and Building Automation Industry, Metals and Mining Industry, Oil and Gas, Pharmaceutical Industry, Pulp and Paper Industry, Power, Water and Wastewater Industry) – Industry Trends and Forecast to 2029

Access Full 350 Pages PDF Report @

**Segments**

- **Type**: The Micro and Nano PLC market can be segmented by type, with micro PLCs being designed for simpler control systems with fewer I/O points and nano PLCs being even smaller and more cost-effective, ideal for applications with extremely limited space and basic functions.

- **End-User**: Another important segmentation is by end-user industry, where micro PLCs are commonly used in industries such as automotive, packaging, and material handling, while nano PLCs find applications in home automation, lighting control, and other small-scale operations.

- **Region**: Geographically, the market can be segmented into regions such as North America, Europe, Asia-Pacific, Middle East, and Africa. Each region may have different adoption rates and preferences for micro and nano PLCs based on their industrial landscape and technological advancements.

**Market Players**

- **Siemens AG**: A prominent player in the Micro and Nano PLC market, Siemens offers a wide range of PLC products catering to various industries. With a strong global presence and a focus on innovation, Siemens continues to be a key player in the market.

- **Rockwell Automation, Inc.**: Another major market player, Rockwell Automation specializes in industrial automation and control systems, including micro and nano PLCs. The company's technological expertise and established customer base position it as a significant competitor in the market.

- **Mitsubishi Electric Corporation**: Known for its advanced automation solutions, Mitsubishi Electric is a key player in the micro and nano PLC market. The company's high-quality products and comprehensive range of offerings make it a preferred choice for many industries.

- **Schneider Electric SE**: Schneider Electric is a leading provider of energy management and automation solutions, including micro and nano PLCs. With a focus on sustainability and efficiency, the company continues to expand its presence in the market.

- **ABB Ltd.**: ABB is a multinational company known for its expertise in robotics, power, and automation technologies. The company'sSiemens AG, one of the key players in the Micro and Nano PLC market, has maintained its strong position through a combination of technological innovation, industry expertise, and global reach. The company's diverse product portfolio caters to a wide range of industries, allowing it to capture numerous market segments effectively. Siemens' continuous investment in research and development ensures that its PLC products remain at the forefront of technology, offering customers cutting-edge solutions for their automation needs. Additionally, Siemens' focus on sustainability and energy efficiency aligns well with the growing industry trends, further solidifying its position in the market.

Rockwell Automation, Inc. is another significant player in the Micro and Nano PLC market, renowned for its industrial automation solutions and expertise. The company's established reputation for delivering reliable and high-performance control systems has made it a preferred choice for many industries worldwide. Rockwell Automation's commitment to technological advancement and customer-centric approach has enabled it to stay competitive in a rapidly evolving market landscape. By offering a comprehensive range of PLC products tailored to different application needs, Rockwell Automation continues to attract a diverse customer base and expand its market presence.

Mitsubishi Electric Corporation's presence in the micro and nano PLC market is characterized by its focus on advanced automation solutions and product quality. The company's reputation for providing robust and reliable PLCs has earned it a strong position in the market, especially in industries that demand precision control and high performance. Mitsubishi Electric's commitment to innovation and continuous improvement ensures that its PLC products meet the evolving needs of customers across various sectors. By emphasizing user-friendly interfaces, scalability, and flexibility in its offerings, Mitsubishi Electric remains competitive in a competitive market landscape.

Schneider Electric SE, a leading provider of energy management and automation solutions, has established itself as a significant player in the Micro and Nano PLC market. The company's comprehensive product portfolio, which includes a range of PLCs suited for different applications, enables it to address diverse customer requirements effectively. Schneider Electric's focus on sustainability and efficiency aligns well**Segments:**

- **Type**: The Micro and Nano PLC market can be segmented by type into micro PLCs and nano PLCs. Micro PLCs are designed for simpler control systems with fewer I/O points, while nano PLCs are even smaller and more cost-effective, ideal for applications with limited space and basic functions.

- **End-User**: Another important segmentation is by end-user industry, where micro PLCs are commonly used in industries such as automotive, packaging, and material handling. On the other hand, nano PLCs find applications in home automation, lighting control, and other small-scale operations.

- **Region**: Geographically, the market can be segmented into regions such as North America, Europe, Asia-Pacific, Middle East, and Africa. Each region may have different adoption rates and preferences for micro and nano PLCs based on their industrial landscape and technological advancements.

**Market Players:**

Siemens AG, Rockwell Automation, Inc., Mitsubishi Electric Corporation, Schneider Electric SE, and ABB Ltd. are key players in the Micro and Nano PLC market. These companies offer a wide range of PLC products catering to various industries and have established a strong global presence in the market.

**Global Micro and Nano Programmable Logic Controller (PLC) Market:**

- **Type**: The market is segmented into Micro PLC and Nano PLC categories. - **Offering**: Includes hardware, software, and services. - **Architecture**: Divided into fixed PLC and modular PLC. -

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global Micro and Nano Programmable Logic Controller (PLC) Market Landscape

Part 04: Global Micro and Nano Programmable Logic Controller (PLC) Market Sizing

Part 05: Global Micro and Nano Programmable Logic Controller (PLC) Market Segmentation By Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

Core Objective of Micro and Nano Programmable Logic Controller (PLC) Market:

Every firm in the Micro and Nano Programmable Logic Controller (PLC) Market has objectives but this market research report focus on the crucial objectives, so you can analysis about competition, future market, new products, and informative data that can raise your sales volume exponentially.

Size of the Micro and Nano Programmable Logic Controller (PLC) Market and growth rate factors.

Important changes in the future Micro and Nano Programmable Logic Controller (PLC) Market.

Top worldwide competitors of the Market.

Scope and product outlook of Micro and Nano Programmable Logic Controller (PLC) Market.

Developing regions with potential growth in the future.

Tough Challenges and risk faced in Market.

Global Micro and Nano Programmable Logic Controller (PLC) top manufacturers profile and sales statistics.

Browse Trending Reports:

Oil Shale Market Cyclin Dependent Kinase Inhibitor Market Agammaglobulinemia Treatment Market Infantile Systemic Hyalinosis Market Continuous Bioprocessing Market Automated Harvesting System Market Capillary Blood Collection Devices Market Automotive Lead Acid Batteries Market 5d Laser Scanner Market Polyurethane Composites Market Interactive Whiteboard Market Botnet Detection Market High Temperature Composite Resin Market Low Profile Additives Market Form Fill Seal Equipment Market Ophthalmic Knives Market Aluminium Nitride Market Tapping Sleeves Market Astaxanthin Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Transforming Semiconductor Manufacturing Using Intelligent Industrial Control Systems

Semiconductors are the foundation of today’s technology, enabling the operation of devices ranging from smartphones to cutting-edge AI systems. As global demand for high-performance chips surges, chipmakers are under increasing pressure to scale production and innovate rapidly. Here is where Smart manufacturing comes into the picture.

Smart manufacturing is revolutionizing the semiconductor industry by introducing advanced, data-driven production methods. By integrating automation, artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT), manufacturers are unlocking new levels of precision, responsiveness, and operational efficiency. Far from being just a trend, this shift is crucial for staying competitive in a rapidly evolving tech landscape.

With real-time data analytics and digitally connected systems, chip production is becoming quicker, more adaptable, and more cost-effective. It marks an essential shift in how semiconductors are designed, fabricated, and delivered to meet the demands of the digital age.

The convergence of automation, data intelligence, and digital control is quite essential. Nowhere is this more evident than in semiconductor manufacturing, where nanometer-level precision, speed, and scalability define success. At the heart of this transformation lies intelligent industrial control systems, a new breed of interconnected, adaptive, and data-rich control technologies that redefine how industrial operations are monitored and optimized.

As the demand for high-performance chips accelerates, semiconductor manufacturers are under immense pressure to boost production and maintain precision. Smart manufacturing is emerging as a game-changer, and at its core are Intelligent Industrial Control Systems (IICS) — blending automation, AI, and real-time analytics to create smarter, faster, and more reliable semiconductor fabs.

Smart Manufacturing: A Strategic Shift Traditional manufacturing can no longer meet the complexity and scale required by today’s semiconductors. Smart factories leverage systems like Distributed Control Systems (DCS), SCADA, and Programmable Logic Controllers (PLCs), layered with Advanced Process Control (APC) and IoT-enabled sensors. These allow for predictive maintenance, energy-efficient processes, and real-time quality control.

Why Intelligent Control Systems Matter In chip production, even a micron-level deviation can lead to massive losses. Intelligent control systems dynamically adjust variables, reducing downtime and waste. Leading companies like TSMC and Intel are already adopting these systems to optimize yield and time to market.

Key Benefits

Higher Yield: AI-powered APC reduces variability

Faster Time to Market: Real-time data boosts production speed

Energy Efficiency: Smart power supplies reduce operational costs

Predictive Maintenance: IoT sensors detect faults early

Compliance: SCADA systems offer traceability for audits

Real-World Impact A Singapore-based fab achieved a 15% reduction in scrap rates and 11% improvement in uptime within 6 months of integrating IICS.

Conclusion: To remain competitive in the age of AI, EVs, and 5G, semiconductor companies must embrace intelligent manufacturing. ACL Digital provides scalable, secure industrial control solutions that drive ROI and future-readiness.

As semiconductor demand surges, driven by AI chips, electric vehicles (EVs), and 5G infrastructure, manufacturers can no longer afford to rely on legacy systems. Intelligent industrial control systems offer not only automation but also adaptability, resilience, and a platform for continuous innovation. Smart manufacturing in semiconductors isn’t just about machines but about making better decisions faster. And that’s only possible when your control systems are as advanced as the products you’re building.

Ready to upgrade your fab with intelligent automation?

Contact us at [email protected] to explore how we can enhance your workplace transformation.

This blog was originally published on the website www.acldigital.com

0 notes

Text

High-Speed Candy Wrapping Machine by Dhiman Industries

Dhiman Industries presents a revolutionary solution for the confectionery sector with its high-speed candy wrapping machine, designed to streamline and elevate the packaging process of candies in commercial production lines. Engineered with advanced automation and built for long-term performance, this high-speed candy wrapping machine reflects the brand’s legacy of precision, innovation, and reliability in sweet manufacturing equipment. The machine ensures maximum operational efficiency while reducing manual intervention, making it ideal for manufacturers seeking high-output candy production with consistent wrapping quality.

This high-speed candy wrapping machine from Dhiman Industries is meticulously crafted to handle various candy shapes and sizes with ease, from square and rectangular to round and oval forms. It boasts a dynamic feeding system that aligns candies with exactitude, preparing them for the synchronized wrapping mechanism that operates seamlessly even at high speeds. Every mechanical motion within the machine is optimized for durability and minimal downtime, allowing production teams to meet large-scale orders without compromising on wrapping aesthetics or sealing integrity.

One of the defining advantages of this high-speed candy wrapping machine is its adaptability across wrapping materials such as wax paper, aluminum foil, cellophane, and laminated films. This multi-material compatibility opens possibilities for customized packaging based on branding, preservation needs, and target markets. The machine's quick-change tooling system further allows operators to switch formats rapidly, reducing idle time during product transitions. Whether wrapping butter candies, fruit toffees, or center-filled treats, the machine delivers consistent results at impressive speeds.

At the heart of the Dhiman high-speed candy wrapping machine is its electronic control panel, powered by programmable logic controllers (PLC). This intelligent interface allows real-time monitoring of machine status, speed regulation, wrapping cycle synchronization, and fault detection alerts for smooth operation. Additionally, sensor-based feeding and cutting systems ensure that each candy piece is wrapped with precision, reducing material wastage and enhancing the final presentation of the product. These integrated smart systems make the machine not only efficient but also user-friendly and safe to operate.

The robust stainless-steel construction of the machine guarantees hygiene, resistance to corrosion, and easy maintenance. It complies with international food-grade safety standards, ensuring candies remain uncontaminated throughout the wrapping process. Cleaning and servicing are simplified with modular components and accessible design, reducing long-term maintenance efforts and operational interruptions. Moreover, the compact footprint of the machine makes it suitable even for factories with limited floor space, while still delivering industrial-scale output.

With speeds exceeding several hundred wraps per minute, this high-speed candy wrapping machine empowers manufacturers to scale their business without additional manpower or complex logistics. The machine also incorporates automatic feeding conveyors and waste collection systems, creating a closed-loop process that enhances productivity while maintaining cleanliness in the workspace. Noise reduction technology further ensures a quieter operation, contributing to a more pleasant working environment for factory staff.

Dhiman Industries has always prioritized precision engineering and customer-centric design in its machinery, and this candy wrapping machine is a true embodiment of that vision. The machine can be tailored with optional attachments such as embossing rollers for branding, date coding modules, and customized cutting knives for specific edge finishes. These value-added features help brands stand out in competitive markets by enhancing the packaging’s visual appeal and information accuracy. The machine's scalability also allows integration with downstream packaging systems like carton box fillers and shrink-wrapping units, completing the full production cycle.

Training and support provided by Dhiman Industries further add to the overall value of the machine. Clients receive installation assistance, operator training, maintenance guides, and access to a responsive technical support team that ensures continuous performance and peace of mind. The company’s commitment to after-sales service makes it a trusted partner for businesses looking to invest in reliable high-speed wrapping technology for long-term growth.

In conclusion, the high-speed candy wrapping machine by Dhiman Industries is a game-changing solution for the confectionery industry. It brings together speed, accuracy, hygiene, and smart automation in one compact, efficient, and adaptable system. For manufacturers aiming to improve their production capacity, reduce labor dependency, and deliver attractively wrapped products to the market, this machine stands as the perfect investment. Dhiman Industries continues to set benchmarks in confectionery machinery, and this innovative high-speed candy wrapping machine reinforces its leadership in delivering performance-driven solutions for modern candy production lines.

0 notes

Text

The Role of Industrial Oven Manufacturer Pune in the Food Processing Industry

In today’s fast-paced food industry, consistency, safety, and efficiency are more critical than ever. Whether it's baking, drying, roasting, or sterilizing, the backbone of many food processing operations is the industrial oven. Behind this essential equipment are the manufacturers who design and supply them. Among these, the contribution of an industrial oven manufacturer Pune plays a pivotal role in supporting India’s growing food processing sector.

Why Food Processing Needs Industrial Ovens

The food processing industry relies heavily on equipment that can maintain precise temperatures, ensure uniform heating, and handle large volumes efficiently. Industrial ovens are used in a variety of food production stages — from drying spices and roasting nuts to baking snacks and sterilizing packaged goods. To achieve this level of performance, the industry needs reliable suppliers who understand the demands of food-grade operations. This is where a reputable industrial oven manufacturer Pune steps in.

Tailoring Technology to Food Industry Needs

Every food product requires specific heat treatment depending on its ingredients, moisture content, and packaging. An experienced industrial oven manufacturer Pune provides tailored solutions that cater to these unique needs. These manufacturers offer a wide range of ovens such as batch ovens, conveyor ovens, and drying ovens, all customized with features like adjustable airflow, temperature precision, and stainless steel interiors for hygienic operations.

The right design not only enhances the quality of the food but also extends shelf life and improves safety. By working closely with food companies, industrial oven manufacturers in Pune ensure that their ovens comply with food safety regulations, including HACCP and FSSAI standards.

Energy Efficiency and Cost Control

Energy consumption is a major concern in the food industry. Heating processes can be power-intensive, leading to high operational costs. An established industrial oven manufacturer Pune focuses on energy-efficient designs. From using high-quality insulation to integrating smart temperature controls and programmable logic controllers (PLCs), these manufacturers help food processing businesses minimize energy wastage.

Modern industrial ovens manufactured in Pune come equipped with automation that optimizes performance and reduces manpower requirements. Over time, this leads to significant cost savings and better return on investment for food processors.

Hygiene and Safety Considerations

Hygiene is non-negotiable in the food processing industry. Ovens must be easy to clean, resistant to corrosion, and free from contaminants. An industrial oven manufacturer Pune understands these critical requirements and ensures that their ovens are built using food-grade stainless steel, feature smooth surfaces, and come with easy-to-remove trays and doors for thorough cleaning.

Safety is also embedded into the design. These ovens are equipped with safety interlocks, emergency shutdown systems, and temperature alarms, making them safe for continuous use in food production environments.

Supporting Startups and Large Enterprises Alike

One of the strengths of a quality industrial oven manufacturer Pune is their ability to support both small food startups and large-scale production units. For startups, the manufacturer offers compact and cost-effective ovens that help them establish a consistent product line. For large enterprises, they provide high-capacity automated ovens that boost productivity and meet massive market demands.

This flexibility makes Pune’s manufacturers a preferred partner for businesses at all stages of growth. Whether it’s a bakery looking to expand its product line or a packaged food company upgrading to a fully automated system, the right industrial oven makes all the difference.

Technological Advancements from Pune’s Manufacturers

Pune has emerged as a hub of industrial manufacturing in India, and the technology used by industrial oven manufacturers here reflects the city’s innovation culture. Leading companies integrate smart systems like remote monitoring, IoT-enabled diagnostics, and automated recipe control into their ovens. These features allow operators to track performance in real-time, troubleshoot issues quickly, and maintain consistent output quality.

As digital transformation continues in the manufacturing sector, an advanced industrial oven manufacturer Pune keeps food businesses future-ready by integrating the latest tech trends.

Reew Products – Supporting Excellence in Food Processing

Among the top players in the region, Reew Products stands out as a dependable industrial oven manufacturer Pune. Known for its customized solutions, energy-efficient designs, and commitment to quality, Reew Products supports a wide range of food processing clients across India. Their ability to understand client requirements and translate them into reliable oven solutions makes them a trusted name in the industry.

Conclusion

The food processing industry demands precision, reliability, and hygiene. An expert industrial oven manufacturer Pune meets these demands by offering tailored, energy-efficient, and high-quality ovens that drive food businesses forward. From startups to established brands, every player in the food sector benefits from the engineering excellence and innovation provided by Pune’s industrial oven manufacturers.

With companies like Reew Products leading the way, the future of food processing in India is in safe, efficient, and reliable hands.

0 notes