#Quality Control in FRP

Explore tagged Tumblr posts

Text

Plasticair Environmental: Leading Ventilation Fan Solutions

Plasticair Environmental specializes in high-performance air filtration solutions, including Horizontal Packed Bed, Fume Hood, Chrome, Vertical Packed Bed, Venturi scrubbers, and Mist Eliminators. Trusted by Plasticair Inc.

#plasticair#plasticair enviromental#Fiberglass-Reinforced Plastics (FRP)#Corrosion Resistance#Fiber Reinforced Plastics#Reinforced Thermoset Plastic (RTP)#Reinforced Thermoset Resin (RTR)#Glass-Reinforced Plastic (GRP)#Hand Lay-up Fabrication#Resin Transfer Molding#Corrosion Barrier Coating#Plasticair FRP Fans#Cost-Effective Solution#Industrial Applications#Quality Control in FRP#Resin Brand Importance#Durability of FRP#Thermoplastics vs. Thermosets#Fan Specifications#Acid Scrubbers#Alkaline Scrubbers#Odor Scrubbers#Odour Scrubbers#Chlorine Scrubbers#H2S Scrubbers#SO2 Scrubbers#Wet Scrubbers#Chemical Scrubbers#Fume hood scrubbers#Venturi scrubber

2 notes

·

View notes

Text

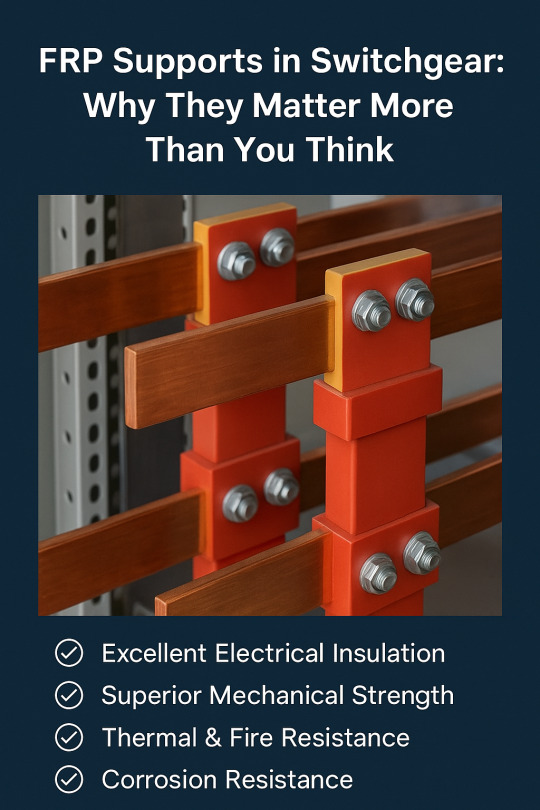

FRP Supports in Switchgear: Why They Matter More Than You Think

In the world of switchgear design and panel manufacturing, components like busbars, circuit breakers, and protection devices often steal the spotlight. However, there’s an unsung hero that plays a critical role in structural stability, electrical safety, and long-term reliability — FRP supports.

If you’re a panel builder, electrical engineer, or installer, understanding the importance of Fiber-Reinforced Plastic (FRP) supports can help you make smarter decisions in switchgear layout and design.

What Are FRP Supports?

FRP (Fiber-Reinforced Plastic) supports are non-metallic structural components used to mount and insulate electrical busbars and other conductors within a switchgear panel. They are composed of a polymer matrix reinforced with fibers (typically glass), providing a high strength-to-weight ratio and excellent insulating properties.

Why FRP Supports Matter in Switchgear Panels

1. Excellent Electrical Insulation

Unlike metallic supports, FRP has high dielectric strength, making it ideal for isolating live conductors from grounded surfaces. This drastically reduces the risk of electrical faults, arcing, or short circuits, especially in high-voltage panels.

2. Superior Mechanical Strength

FRP supports are mechanically robust, able to hold busbars and other components securely even under thermal expansion, vibration, or load fluctuations. They don’t deform easily, ensuring long-term structural stability inside panels.

3. Thermal & Fire Resistance

Switchgear panels often operate in high-temperature environments. FRP supports are designed to withstand heat and exhibit flame retardant properties, making them ideal for preventing fire hazards and complying with fire safety norms.

4. Corrosion Resistance

Unlike metal brackets or supports, FRP does not rust or corrode. In industrial or coastal environments where humidity and chemical exposure are common, FRP maintains its integrity, helping extend the life of your switchgear.

5. Lightweight Yet Durable

One of the biggest advantages of FRP is its lightweight nature, which makes handling and installation easier without compromising on strength. This improves ergonomics for panel builders and saves installation time.

Applications of FRP Supports in Switchgear

Busbar mounting & separation

Phase-to-phase and phase-to-ground insulation

Support for vertical or horizontal busbar arrangements

Internal framing structures in control and distribution panels

Standards & Compliance

Most high-quality FRP supports used in switchgear panels comply with international standards like:

IEC 61439 — For low-voltage switchgear and control gear assemblies

UL 94 — For flammability of plastic materials

ASTM D638 — For tensile properties of plastics

Using compliant FRP supports not only ensures safety but also helps in passing electrical inspections and certifications.

Final Thoughts

FRP supports might seem like minor components in the grand scheme of a switchgear panel — but overlooking them can lead to serious safety issues, structural failures, and increased maintenance costs. Investing in high-quality FRP supports not only enhances performance but also adds to the overall longevity and reliability of your panels.

So next time you’re assembling or inspecting a panel, remember: what holds everything together matters just as much as what powers it.

#frp support#electrical equipment#electrical supplies#dubai#united arab emirates#uae#electrical#contrctors

2 notes

·

View notes

Text

Efficient Process Water Solutions for Industrial Needs | Royal Water Project

In the industrial sector, water isn’t just a utility—it’s a critical component of daily operations. From cooling and cleaning to chemical processing and product manufacturing, the demand for high-quality process water is immense. At Royal Water Project, we specialize in delivering customized process water solutions that are reliable, cost-effective, and sustainable for industries across India.

What is Process Water?

Process water refers to water used in manufacturing processes, including cleaning, heating, cooling, diluting, and transporting products. The quality and composition of process water vary depending on the specific industry and application. Unlike potable or domestic water, process water must meet particular chemical and physical standards to ensure efficiency and protect equipment.

Royal Water Project’s Process Water Solutions

We offer a comprehensive range of process water solutions designed to suit various industries, including pharmaceuticals, food & beverage, textiles, chemicals, and power generation. Our focus is on optimizing water usage while maintaining the highest levels of purity and system efficiency.

Our Offerings Include:

✅ Water Treatment Systems – Reverse osmosis, softening, filtration, and demineralization units tailored for industrial processes.

✅ Process Water Storage Tanks – High-quality FRP, steel, and modular tanks that ensure contamination-free storage.

✅ Custom Engineering Solutions – Designed as per industry-specific standards and water quality requirements.

✅ Automation & Monitoring Systems – For consistent water quality and flow control in production lines.

✅ Integration with Plant Infrastructure – Seamless installation with existing utilities and processes.

Industries We Serve

Royal Water Project’s process water systems cater to a wide range of sectors:

Chemical & Petrochemical

Food & Beverage

Pharmaceuticals

Textiles & Dyes

Power Plants

Cosmetics & Personal Care

Construction & Engineering

Why Choose Royal Water Project?

Turnkey Solutions – From design and installation to maintenance and upgrades

Innovative Technology – State-of-the-art equipment for precise water treatment and storage

Quality Assurance – All systems comply with national and international industrial water standards

Sustainable Approach – Reducing water waste, recycling water, and lowering environmental impact

🇮🇳 Pan-India Presence – Fast delivery, installation, and support across urban and industrial zones

Benefits of Our Process Water Solutions

Improved Production Quality & Consistency

Reduced Equipment Downtime

Lower Operational Costs

Minimized Environmental Impact

Increased Efficiency in Manufacturing Operations

Optimize Your Industrial Operations with Royal Water Project

Water is an indispensable part of industrial growth. With Royal Water Project’s process water application systems, industries can ensure the availability of clean, consistent, and compliant water for their operations. Our expertise and end-to-end solutions help industries operate efficiently while being environmentally responsible.

🌐 Visit: https://www.royalwaterproject.com/process-water-application.php

#"Process water tanks in India#Industrial water storage#Process water storage solutions#Chemical process water tanks#Food processing water tanks#Royal Water Project tanks#Zinc aluminum water tanks#Industrial water recycling tanks#High-quality process water tanks#Process water applications#Durable industrial water tanks

0 notes

Text

Jaguar XJ Body Kit 351 2010-2019 Includes Headlamps and Tail Lights

Front and rear bumper body kit fits all XJ models between 2010 to 2019 and specifically developed to add that extra contemporary styling needed where aggression and luxury coexist with each other.

Our exclusive FRP Fibre Reinforced plastic bumper kit comes ready for priming and painting with a perfect fitment due to our high level development, testing and quality control practices.

Price :- Rs. 403,200.00 /-

0 notes

Text

Sanitary Ware: Types, Uses, and How to Choose Them

Sanitary Ware: Types, Uses, and How to Choose Them Introduction Sanitary ware is an essential component of any residential or commercial building, playing a pivotal role in maintaining public health and personal hygiene. Sanitary ware includes a wide range of products used in bathrooms, kitchens, and various sanitary facilities, such as toilets, sinks, faucets, and bathtubs. These fixtures are characterized by their diverse shapes and designs, as well as their continuous technical and functional development to meet the various needs of users.

First: Types of Sanitary Ware

Toilets Toilets vary in design and technology, including:

Floor-mounted toilets: widely used in some cultures and do not require a seat.

Western toilets (suspended or floor-mounted): feature a seat and operate with different flushing systems (dual or automatic).

Smart toilets: come with features such as self-cleaning, seat temperature control, and air dryers.

Wash Basins Used for washing hands and face, they come in various shapes and sizes, including:

Hanging Basins

Sinks built into countertops

Pedestal Basins

Bathtubs Include:

Traditional acrylic or cast iron tubs

Jacuzzi tubs

Luxury glass or stone tubs

Taps and Mixers These are among the most widely used appliances, and include:

Handheld faucets

Sensor faucets for water conservation

Mixers for adjusting water temperature

Showers Include:

Traditional showers

Handheld showers

Digital showers with features such as temperature control and pressure distribution

Sanitary Accessories Such as:

Towel Holders

Toilet Paper Holders

Lighted Mirrors

Bathroom Cabinets

source

فني صحي جمعية أبوفطيرة تسليك مجاري مدينة جابر الأحمد الكويت تسليك مجاري العدان الكويت

Second: Materials Used in Sanitary Ware Manufacturing The quality of sanitary ware depends on the materials from which it is made, the most prominent of which are:

Ceramic: The most common material, characterized by its hardness and ease of cleaning.

Porcelain: A luxurious type of ceramic, resistant to stains and scratches.

Stainless Steel: Used in faucets and showers, rust-resistant and easy to maintain.

Toughened Glass: Used in sinks and basin surfaces.

Acrylic: Lightweight and suitable for bathtubs.

Fiberglass Reinforced Plastic (FRP): Used in some lightweight and economical products.

Third: Basic Criteria for Selecting Sanitary Ware When selecting sanitary ware for any project or home, the following considerations must be taken into account:

Quality and Durability Choosing high-quality sanitary ware reduces maintenance problems and prolongs the life of the product.

Space-Saving Design Designs and sizes should be chosen to fit the bathroom or kitchen space, taking into account ease of movement.

Water Efficiency It is important to choose tools that help rationalize water consumption, such as low-flow faucets and showers.

Comfort and Function Especially in toilets and bathtubs, ensure comfort and ease of use for all groups, including the elderly and children.

Ease of Cleaning and Maintenance Stain-resistant surfaces and those that do not retain moisture reduce hygiene problems and corrosion.

Fourth: Modern Trends in Sanitary Ware The sanitary ware industry has witnessed significant developments, especially in the field of technology and smart designs:

Smart toilets: equipped with sensors, heated seats, and automatic flushing.

Smart faucets: operated by touch or motion.

Digital showers: allow control of temperature, timing, and water pressure via mobile apps.

Sustainable Design: Environmentally friendly materials, saving water and energy consumption.

Fifth: Sanitary Ware Care To preserve sanitary ware for the longest possible time:

Use non-abrasive cleaners to avoid damaging surfaces.

Regularly clean faucet filters and strainers.

Inspect connections and valves to prevent leaks.

Use limescale-resistant products, especially in areas with hard water.

Conclusion Sanitary ware is no longer just a basic fixture; it has become an aesthetic and functional element that reflects the user's taste and directly impacts the quality of daily life. With the advancement of technology and increased environmental awareness, it has become essential to choose sanitary ware that combines quality, design, and efficiency. Therefore, it is always advisable to deal with reliable companies and consider the different needs of users when selecting these appliances to ensure long-term comfort and health.

0 notes

Text

Guide to Choosing the Right Side Stream Filter for Your Cooling Towers

Cooling towers play a critical role in many industrial and commercial HVAC systems by dissipating excess heat. However, they’re also prone to contamination from airborne particles, scale, corrosion by-products, and biological growth. That’s where side stream filters come into play—ensuring efficient water quality management and extending system life. In this guide, we help you understand how to choose the best side stream filter for your cooling tower system by looking at key parameters like flow rates, contaminants, and custom configuration options.

Why Cooling Towers Need Side Stream Filters

Cooling towers operate in open-loop systems, making them vulnerable to the accumulation of dust, debris, organic matter, and dissolved solids. These contaminants reduce thermal efficiency, cause fouling in heat exchangers, and increase chemical consumption. Side stream filters continuously remove a portion of water from the system, filter it, and return clean water—minimising the risk of scaling, corrosion, and biological fouling.

The use of side stream filtration improves water clarity, helps maintain chemical balance, and reduces operating costs. Most importantly, it enhances the reliability and longevity of the cooling system.

Key Factors to Consider When Selecting a Side Stream Filter

When selecting the right side stream filter for your cooling tower, consider the following critical factors:

Flow Rate: Ideally, 5–15% of the cooling system's total flow should be filtered. The exact percentage depends on system load, contamination levels, and performance expectations.

Contaminant Load: Know the type and size of particles to be filtered—whether biological (algae, bacteria), inorganic (dust, rust), or chemical (dissolved solids).

Filtration Efficiency: Look for filters with a micron rating suitable for your needs. Finer filtration improves water quality but may increase operational cost and maintenance.

Maintenance Requirements: Opt for filters that are easy to clean or feature automated backwash capabilities, especially in high-load systems.

System Compatibility: Ensure the filter materials are compatible with the cooling tower water chemistry and operating temperatures.

Types of Side Stream Filters for Cooling Towers

There are several types of side stream filters available in the market, each with its own advantages:

Sand/Media Filters: Ideal for removing suspended solids and turbidity. These are cost-effective and suitable for most industrial setups.

Cartridge Filters: Offer fine filtration (down to 1 micron). Best for systems with lower flow rates or where precise contaminant control is needed.

Self-Cleaning Filters: Equipped with backwash systems, they require minimal manual intervention. Great for high-flow systems or where labour is a constraint.

Hydrocyclone Separators: Use centrifugal force to separate heavier particles. Efficient for large particles but less effective for fine particulates.

Bag Filters: Easy to install and replace, these work well for low-flow applications and can be configured in parallel for larger systems.

Selecting the right type depends on the balance between filtration needs, operating cost, and ease of maintenance.

Customising Your Side Stream Filter Configuration

Every cooling tower system is unique. Custom configuration of side stream filters allows better integration and performance. Factors to customise include:

Skid-mounted Systems: Pre-packaged units that include pumps, controls, and piping. Ideal for plug-and-play installation.

Automated Controls: Integration with building automation systems (BAS) for real-time monitoring and control.

Material Selection: Choose corrosion-resistant materials like SS304 or FRP based on water chemistr

Filter Redundancy: For critical systems, dual filters with automatic switchover enhance reliability.

Customisation ensures that the filtration system is optimised for your cooling tower’s operational and environmental conditions.

Mistakes to Avoid When Sizing and Installing Side Stream Filters

Improper sizing and installation can reduce the effectiveness of your filtration system. Common pitfalls include:

Under-sizing the Filter: Filtering too small a percentage of water fails to remove enough contaminants, defeating the purpose.

Neglecting Contaminant Analysis: Without a water analysis, you may choose an unsuitable filter type or micron rating.

Improper Flow Balance: Incorrect piping or pump selection can lead to flow issues and reduce efficiency.

Overlooking Maintenance Needs: Choosing a filter that requires frequent cleaning without considering staffing or access can lead to downtime.

Ignoring Pressure Drops: Not accounting for pressure loss across the filter can affect overall system performance.

Working with a trusted expert can help you avoid these errors and ensure optimal operation.

How to Partner with the Right Side Stream Filter Manufacturer

Your choice of manufacturer can make a significant difference. Look for a supplier who offers:

Comprehensive Consultation: They should assess your cooling tower’s specific requirements and suggest the best solution.

Custom Engineering: Ability to provide tailor-made filtration systems, including automation and integration support.

After-sales Support: Ensure they offer prompt technical support, spare parts, and maintenance services.

Reputation and Experience: Choose brands with proven installations and positive client feedback in similar industrial segments.

One such trusted name is Cleantech Water, known for its expertise in industrial water treatment solutions, including high-performance side stream filtration systems tailored to diverse cooling tower setups.

Optimise Your Cooling Tower with the Right Side Stream Filter

Selecting the right side stream filter isn’t just about keeping the water clean—it’s about protecting your investment, improving energy efficiency, and ensuring uninterrupted operations. From understanding contaminant profiles to configuring a system that fits your operational requirements, a well-planned approach delivers significant ROI.

Whether you manage an industrial plant, data center, or commercial facility, a reliable side stream filtration system helps you comply with environmental norms, reduce downtime, and maintain peak performance.

Read More: Guide to Side Stream Filters for Cooling Towers – Cleantech Water

0 notes

Text

Top 5 Benefits of Using Drum Spill Containment Pallets in Your Facility

For any facility storing chemical drums or hazardous liquids, the risk of leaks and spills is always present. Without suitable safeguards, these accidents can lead to workplace -injuries, compliance issues, and environmental harm. Drum spill containment pallets are a simple yet effective way to manage these risks.

Here are five practical benefits of using Swift's drum spill containment pallets at your facility:

1. Prevents Environmental Contamination

Drums can leak, and when they do, it's -crucial to stop the spread quickly. Containment pallets with built-in sumps help -collect those leaks before they reach the floor or the environment. This helps prevent contamination and damage to nearby surfaces.

Swift’s Spillage Pallets are ideal for operations that require extra protection and environmental responsibility.

2. Enhances Workplace Safety

Leaking liquids on smooth floors are a common source of workplace accidents. By using containment pallets, leaks are immediately caught in the tray beneath, keeping walkways dry and -reducing the chance of injuries.

This adds an extra level of safety, especially in facilities where multiple drums are moved and handled every day.

3. Ensures Compliance with Safety Regulations

Regulations exist to protect both people and the planet. Proper use of containment pallets can support compliance with safety rules such as:

EPA 40 CFR 264.175

SPCC -(Spill Prevention, Control, and Countermeasure)

NPDES (National Pollutant Discharge Elimination System)

Using the right equipment helps simplify audits and avoid penalties while showing a -commitment to responsible operations.

4. Durable and Chemical-Resistant Construction

Swift’s pallets are made with high-quality LLDPE and molded in a single piece for extra strength. This -material is UV-resistant, chemical-resistant, and can handle tough working conditions.

They’re also forklift-friendly, making them easy to move without sacrificing stability or safety.

5. Promotes Organized Storage and Easy Handling

Beyond spill control, these pallets help keep storage areas organized. Swift offers models for 1, 2, or 4 drums, so you can choose what fits best in your space.

You can also pick between FRP or plastic tops depending on your cleanup needs. Both surfaces resist chemicals and are easy to maintain.

Conclusion

Spill containment pallets are a smart, necessary addition for any industrial operation storing hazardous materials. They boost safety, help meet regulations, and improve overall efficiency.

Swift offers solutions that combine performance, durability, and practical design. With years of experience and trusted products, Swift makes managing spills easier and safer.

Explore Swift’s range of drum containment pallets and find the right solution for your facility.

#Spill Containment Pallet#Spill Pallets#Spillage Pallet#Drum pallet#Drum Spill Containment Pallets#Drum Spill Pallets#drum spill containment#Oil Spill Pallet#secondary containment pallets#Oil Drum Pallet#Pallet for Oil Drum#secondary containment#plastic spill containment

0 notes

Text

Understanding FRP Pipes: Advantages, Applications, and Key Features

D Chel Oil & Gas, a leading FRP Pipe Manufacturer in India, specializes in producing high-quality FRP pipes designed for exceptional durability, corrosion resistance, and long-term performance. These FRP pipes are widely used across industries such as chemical processing, water treatment, oil & gas, and infrastructure, offering a lightweight yet strong alternative to traditional materials.

What Are FRP Pipes?

FRP Pipes are composite pipes made by reinforcing plastic with fiberglass. The manufacturing process typically involves winding fiberglass filaments over a rotating mandrel, followed by curing with resins like epoxy, polyester, or vinyl ester. This combination gives FRP pipes a unique set of mechanical and chemical properties that make them highly efficient in harsh environments.

Key Features of FRP Pipes:

Corrosion Resistance: Unlike metal pipes, FRP pipes do not corrode when exposed to chemicals, saltwater, or wastewater, making them ideal for aggressive environments.

Lightweight: FRP pipes are significantly lighter than steel or concrete pipes, which makes handling, transportation, and installation much easier and cost-effective.

High Strength: Despite being lightweight, FRP pipes offer excellent tensile and impact strength.

Low Maintenance: Their corrosion-resistant nature reduces the need for regular maintenance, lowering the lifecycle cost.

Long Service Life: FRP pipes can last for decades, even under extreme conditions.

Customizable: Available in a variety of sizes, pressure ratings, and configurations to meet specific project needs.

Advantages of FRP Pipes

Corrosion-Free Performance: FRP pipes provide a lasting solution in applications where metal pipes would quickly deteriorate.

Lower Installation Costs: Due to their light weight, less manpower and smaller lifting equipment are needed, reducing installation costs and time.

Versatile Applications: Suitable for underground, above ground, submerged, and overhead installations.

Thermal Insulation: FRP materials naturally offer good insulation properties, reducing energy loss in process piping systems.

Reduced Downtime: Minimal maintenance and long lifespan lead to less operational interruption.

Smooth Inner Surface: Ensures lower friction losses and improves flow efficiency, reducing energy consumption in pumping systems.

We Supply In Various Countries like :

FRP Supplier in Qatar

FRP Supplier in Saudi Arabia

FRP Supplier in Bangladesh

FRP Supplier in Oman

FRP Supplier in Malaysia

Common Applications of FRP Pipes

Chemical Processing Plants: Ideal for handling aggressive chemicals and acids.

Water and Wastewater Treatment: Used for transporting treated water, sewage, and industrial effluents.

Power Plants: Suitable for cooling water systems, desalination plants, and flue gas desulfurization.

Marine Industry: Corrosion-resistant FRP pipes are perfect for offshore and coastal installations.

Oil and Gas Sector: Utilized for handling produced water, firewater systems, and saltwater pipelines.

Irrigation Systems: Lightweight pipes make them ideal for large-scale agricultural irrigation networks.

Types of FRP Pipes

FRP pipes are available in several types based on their design and intended application:

Filament Wound FRP Pipes

Centrifugally Cast FRP Pipes

Hand Lay-Up FRP Pipes

Each type offers specific advantages in terms of pressure ratings, diameter sizes, and installation methods.

FRP Pipe Manufacturers in India

India is home to several well-known FRP pipe manufacturers who develop high-quality goods that match international standards.FRP Pipe Suppliers in India provide a wide range of solutions tailored to specific industrial requirements, ensuring that customers receive long-lasting and effective pipe systems. These producers are well-known across the world for their long-lasting and cost-effective FRP pipe solutions, which are the product of advanced manufacturing procedures and tight quality control systems.We are also one of India's major FRP grating manufacturers.

0 notes

Text

Demineralization Plants: Ensuring High-Quality Water Solutions

Demineralization, or deionization, is a crucial water treatment process that eliminates dissolved mineral salts from water, producing high-purity water essential for various industrial applications. Aquamech Engineering Corporation, a leading provider of water treatment solutions, specializes in designing and manufacturing advanced demineralization plants tailored to meet the specific needs of diverse industries.

What Are Demineralization Plants?

Demineralization plants utilize ion exchange technology to remove both cations (positively charged ions) and anions (negatively charged ions) from water. This process involves the use of cation and anion exchange resins that replace harmful ions with hydrogen and hydroxyl ions, respectively. The result is water with a conductivity of less than 20 µS/cm and total dissolved solids (TDS) below 10 ppm, making it suitable for applications requiring high-purity water.

Key Features of Aquamech’s Demineralization Plants

Advanced Ion Exchange Technology: Aquamech employs state-of-the-art resin bed technology to ensure efficient removal of dissolved salts, delivering high-quality water consistently.

Customizable Designs: The plants are available in various configurations, including two-bed and mixed-bed systems, to cater to different purity requirements and flow capacities. Compact and Skid-Mounted Units: Designed for easy installation and space optimization, these plants are ideal for facilities with limited space . Automated Operations: Equipped with PLC-based automation, Aquamech’s demineralization plants ensure reliable performance with minimal manual intervention. Corrosion-Resistant Construction: Utilizing materials like stainless steel and FRP, the plants are built to withstand harsh operating conditions, ensuring longevity and durability.

Applications of Demineralized Water

Demineralized water is essential in industries where high-purity water is critical:

Pharmaceuticals: For the preparation of Water for Injection (WFI) and other formulations. Power Generation: In boiler feedwater to prevent scaling and corrosion. Food and Beverage: In processes requiring stringent hygiene and quality standards. Laboratories: For analytical and experimental purposes where pure water is a necessity.

Why Choose Aquamech?

Proven Expertise: With over two decades of experience, Aquamech has established itself as a trusted name in the water treatment industry.

Comprehensive Solutions: Offering end-to-end services from design and manufacturing to installation and maintenance, ensuring a seamless experience for clients.

Regulatory Compliance: Aquamech’s plants meet industry standards such as ASME BPE, cGMP, and ISPE, and satisfy regulatory audits like USFDA, MHRA, and WHO .

Sustainable Practices: Committed to environmental sustainability, Aquamech’s solutions aim to achieve maximum water recycling and comply with Pollution Control Board norms .

Conclusion

Aquamech Engineering Corporation offers state-of-the-art demineralization plants that provide high-quality, purified water essential for various industrial applications. With a focus on innovation, reliability, and sustainability, Aquamech stands as a preferred partner for industries seeking efficient and effective water treatment solutions.

#demineralization plants#demineralization#pharmaceutical water#waste water management#waste water treatment#wastemanagement

1 note

·

View note

Text

At UK Enviro Systems, we specialize in manufacturing high-performance Air Pollution Control Scrubbers for industries worldwide. Our FRP scrubbers are engineered to efficiently remove harmful pollutants from industrial exhausts, ensuring cleaner air and compliance with environmental standards. Invest in our durable and cost-effective scrubbers to safeguard your operations and the environment.

#Air Pollution Control Scrubbers Manufacturer#Air Pollution Control Scrubbers#Air Pollution Control#Industrial Emissions#FRP Scrubbers#Gas Scrubbing Systems#Air Quality Solutions#Pollution Control Manufacturer#Scrubber Systems

0 notes

Text

The Secrets Behind Accuracy Thermoforming Molds Created in China

Vacuum forming and thermoforming have come to be vital production methods throughout sectors, and much of their success exists in the precision of the molds used. In China, a hub for sophisticated manufacturing, thermoforming molds producers have actually created very efficient systems to make sure every mold satisfies limited resistances and exacting standards. From custom thermoforming molds to bespoken vacuum forming molds, precision is constructed right into every stage of the process to assure constant and trusted results for clients all over the world.

Advanced Engineering and also Mold Design

Precision begins with professional preparation. Every trustworthy thermoforming molds manufacturer in China counts on a seasoned engineering team to craft comprehensive CAD-based vacuum forming mold designs. These blueprints form the foundation for extremely precise production. Modern thermoforming tools makers also use simulation software application and 3d print vacuum form molds for prototyping, permitting improvements prior to final machining. This technique makes sure that each customized thermoforming mold aligns flawlessly with client specifications, making Chinese providers reputable companions in the international market.

Use Top Quality Products and Precision Machining

A reputable vacuum forming molds manufacturer understands that premium products are non-negotiable for lasting performance. Whether it's pure light weight aluminum, copper, or composite FRP, makers use only high-grade products for boosted mold toughness and precision. From there, CNC machining brings these products to life with micro-level accuracy. Leading vacuum forming tools producers in China integrate this with automated evaluation systems to guarantee that each mold is prepared for rigorous industrial usage, specifically in sectors requiring regular and reputable results.

Rigorous Examining and Quality Control

No mold leaves a trusted thermoforming molds supplier without comprehensive quality checks. Each tool is examined under practical forming conditions to verify warmth tolerance, vacuum stability, and dimensional precision. Licensed vacuum forming molds distributors follow worldwide requirements like ISO9001 and ISO13485, especially for clinical or digital applications. This level of analysis makes certain every item from a thermoforming tools manufacturer is resilient, reliable, and compliant - making them the best source for high-performance vacuum forming molds China throughout global markets.

Personalization and Customer Collaboration

What establishes a top-tier vacuum forming molds supplier apart is their technique to customization. These professionals don't just construct molds - they fix manufacturing issues. Whether you require a customized vacuum forming mold for food product packaging or a bespoken vacuum forming mold for auto components, Chinese vacuum forming tools manufacturers work closely with clients to adjust every information. A dependable thermoforming molds production will certainly lead you through material selection, surface coating, and part intricacy, making sure the last mold aligns with your business objectives.

Conclusion

Accuracy in vacuum forming molds China is not accomplished by chance. It's the result of careful vacuum forming mold design, cutting-edge machining, extensive screening, and solid customer relationships. As a trusted vacuum forming molds manufacturer, China has established the global standard for both quality and customization. Whether you require custom thermoforming molds, high-volume manufacturing molds, or experimental vacuum forming 3d published molds, Chinese suppliers offer trustworthy solutions. With a tested track record, companies like SME Plastic proceed to lead the means in supplying precision-engineered thermoforming solutions.

SME Thermoforming Molds

Address: No.10, 3rd st, Minying Industrial Zone,

Shawan Town,Panyu District, Guangzhou City, Guangdong, PRC

Mob: +86-13928889690

Location map: https://maps.app.goo.gl/2CfwLCx2WAPuEuCF8

0 notes

Text

Enhancing Safety with Reliable Water Solutions for Firefighting Applications | Royal Water Project

Fire safety is one of the most critical aspects of industrial, commercial, and residential infrastructure. An effective firefighting system depends heavily on a consistent and dependable water supply. At Royal Water Project, we specialize in providing robust and reliable water storage and supply solutions tailored for firefighting applications across India.

Why Water Storage is Vital in Firefighting Systems

In emergency situations like fire outbreaks, the availability of water at high pressure and in sufficient quantity can be the difference between control and catastrophe. Firefighting systems such as hydrants, sprinkler systems, and deluge systems require immediate access to water. This is where high-capacity, durable, and quick-access firefighting water storage tanks come into play.

Royal Water Project’s Firefighting Water Solutions

At Royal Water Project, we offer advanced water storage tanks and pumping systems that are ideal for all types of fire suppression systems. Whether it's for an industrial zone, commercial complex, hospital, high-rise building, or warehouse, our firefighting water storage systems are designed to ensure safety and compliance with national and international fire safety standards.

Our Key Solutions Include:

Fire Water Storage Tanks: Made from durable materials such as FRP, steel, or zincalume, ensuring long-term performance.

Customized Tank Capacities: Available in various sizes to match the specific needs of your fire protection plan.

Corrosion-Resistant Coatings: Ensure longevity even in harsh environmental conditions.

Quick Refill Systems: Designed to maintain a consistent water level, ensuring tanks are always ready for emergencies.

FM Global & IS Standards Compliance: Tanks are designed in accordance with required fire safety norms.

Applications of Our Firefighting Water Tanks

Our firefighting water storage tanks are suitable for various sectors, including:

Industrial Plants

Commercial Complexes

Educational Institutions

Hospitals

Government Buildings

Residential Societies

Logistics Parks

Each project is customized to ensure that our systems integrate seamlessly with your existing firefighting infrastructure, including fire pumps, hose reels, and sprinkler systems.

Why Choose Royal Water Project?

✅ Decades of Experience in water management solutions

✅ Premium Quality Materials and ISO-certified manufacturing processes

✅ Turnkey Solutions from design to installation

✅ Pan-India Reach for timely supply and service

✅ Technical Support & AMC Services

Get Fire-Ready with Royal Water Project

Ensuring that your infrastructure is prepared for any fire-related emergency is not just a regulatory requirement—it’s a responsibility. With Royal Water Project’s firefighting water storage systems, you get peace of mind, knowing that you are backed by a dependable, high-performance solution.

Visit: https://www.royalwaterproject.com/firefighting-application.php

#Firefighting water storage tank#Royal Water Tank#Firefighting applications#Fire safety water tanks#Fire suppression tanks#Zincalume water tanks#Fire protection water tanks#Industrial fire water tanks#Commercial firefighting tanks#Corrosion-resistant water tanks

0 notes

Text

Best Quality storage tanks manufacturers in india

When it comes to industrial infrastructure, storage tanks play a critical role in ensuring the safe and efficient storage of liquids and gases—be it water, chemicals, fuels, or process materials. India, with its rapidly growing industrial sector, demands high-quality, durable, and precision-engineered storage solutions. At the forefront of this industry is Rattan Industriali, a name synonymous with excellence in storage tank manufacturing.

About Rattan Industriali

Rattan Industriali is a recognized leader among storage tank manufacturers in India, offering a wide range of storage solutions designed to meet the rigorous standards of diverse industries. With a focus on quality engineering, innovation, and client satisfaction, Rattan Industriali has successfully catered to sectors such as:

Distilleries

Chemical processing

Oil & gas

Food & beverages

Water treatment

Pharmaceuticals

What Makes Rattan Industriali a Trusted Name in Storage Tanks?

Diverse Product Range: Rattan Industriali manufactures storage tanks in various sizes and specifications, including MS (Mild Steel), SS (Stainless Steel), and FRP (Fiber Reinforced Plastic) tanks. Options include vertical, horizontal, underground, and above-ground tanks.

Customized Solutions: Whether you need storage tanks for ethanol, molasses, chemicals, or water, Rattan Industriali provides custom-engineered tanks to meet precise storage needs and regulatory requirements.

High-Quality Materials: Built with ISI-certified raw materials and adhering to global fabrication standards, Rattan’s tanks ensure corrosion resistance, long service life, and operational safety.

Turnkey Capabilities: From design and fabrication to installation and maintenance, Rattan Industriali offers end-to-end project execution with complete documentation and quality control at every stage.

Industries Served

Rattan Industriali's storage tanks are trusted by clients across:

Distillery and ethanol plants

Petrochemical and chemical manufacturing

Food processing units

Power generation facilities

Water and wastewater treatment plants

Commitment to Quality & Compliance

Every tank manufactured by Rattan Industriali complies with national and international standards such as IS, ASME, and API. Their quality assurance protocols ensure tanks are tested for leak-proof performance, material integrity, and durability under extreme conditions.

Why Choose Rattan Industriali?

Over 30 years of industry experience

Proven expertise in handling complex industrial projects

Strong focus on customer satisfaction and after-sales support

Timely delivery with robust project management practices

Environmentally responsible manufacturing processes

Conclusion

If you’re looking for reliable, high-performance storage tanks in India, Rattan Industriali is your go-to partner. Combining world-class engineering with a deep understanding of industrial requirements, Rattan delivers storage solutions that stand the test of time and add real value to your operations.

Visit:- https://www.liquorbottlingplants.com/distillery-plant.html

0 notes

Text

Here are 15 common problems and solutions in pultruding fiberglass-reinforced plastic

Problems Encountered in the Production Process of FRP Pultruded Profiles

1. Causes of surface droplets:Incomplete curing, low fiber content, and large shrinkage. Also, a large gap between the product surface and the mold wall, and migration of uncured resin.

Solution:Increase the temperature or reduce the drawing speed. This ensures full curing, which is crucial for thick-walled products. Increase the fiber content or add low-shrinkage agents and fillers.

2. Causes of surface peeling and cracking:

An excessive resin-rich layer on the surface. Crawling and creeping at the exit point. A large difference between gel time and curing time. The exit point being too far ahead of the curing point.

Solution:Boost the fiber content to raise the mold’s internal pressure. Also, tweak the initiation system and modify the temperature.

3. White powder causes poor demolding, mold adhesion, and scratches on the product. It also raises the inner mold wall’s roughness due to wear or rust.

Solution:Use a good demolding agent. Clean, repair, or replace a qualified mold. Stop the machine for a moment, then restart it. Pull out the adhered fragments to clean them.

4.Causes of an obvious parting line and wear at the parting line include:

Low accuracy in the mold’s dimensions.

Large positioning errors of each module when closing the mold.

Mold adhesion at the parting line, leading to white lines.

Solution:Repair the mold. Then, disassemble and reassemble it. Finally, stop and restart the machine.

5. Fiber exposure and fuzzing causes:This defect usually occurs in products made only with fiber yarns, like rods. Possible reasons are too high a fiber content or resin debris sticking to the mold’s inner wall.

Solution:Reduce the fiber content, stop the machine, and restart.

Q&A—2

6. Poor aging resistance and fading happen due to a lack of light and heat stabilizers. Also, the pigment has low lightfastness.

Solution: Add anti-aging agents and use high-quality color pastes.

7. Poor insulation causes poor insulation of the resin and fiber. Also, poor bonding at the interface.

Solution: Improve raw material selection. Use coupling agents to boost interfacial performance.

8. Insufficient strength and poor properties cause low raw material strength and low curing.

Solution: Use high-quality raw materials, like strong fibers and resins. Control process parameters to ensure proper curing. Perform post-curing treatment.

9. Dense pores cause poor quality of raw materials and unreasonable temperature control.

Solution: Use good raw materials and control the temperature to not be too high.

10. Color spots, uneven color, and color change causes: Uneven mixing of pigments in the resin and poor heat resistance of the pigments.

Solution: Stir more to mix the resin slurry evenly. Also, switch the pigment type.

11. Causes of contamination and foreign matter mixing: Foreign matter in the resin slurry, a contaminated glass mat surface, and foreign matter in the mold.

Solution: Check carefully to avoid mixing in foreign matter during molding. Also, replace any contaminated raw materials.

12.Rough and dull surfaces occur due to several reasons:

High mold roughness

A poor demolding agent.

Low resin on the product’s surface.

Insufficient mold pressure during molding.

These factors can lead to an undesirable texture.

Solution: Use a mold with a low surface roughness. Use a good demolding agent. Use a surface mat or pass a continuous mat and knitted mat through the impregnation bath. Increase the fiber content or add fillers.

Q&A—3

13. Causes of surface indentation: low fiber content or mold adhesion. This leads to fragment buildup that scratches the product’s surface.

Solution: Increase the fiber content. Clean the mold. Stop and restart the machine. Use a good demolding agent.

14. Incomplete glass mat wrapping causes a narrow mat width and a faulty positioning device. The mat deviates during molding.

Solution: When designing the mat width, consider a certain overlap length. Also, there must be a precise mat guide seam on the mold before the mat enters it. Add a limit card at the mold entrance if necessary.

15. Causes of surface wrinkles: The glass fiber mat is too hard. It folds when entering the mold. The polyester surface mat (or non-woven fabric) is too soft and has a certain slope when entering the mold. During the pull molding of curved products, wrinkles occur due to the pulling force.

Solution: Use a softer glass surface mat. When using a polyester surface mat or non-woven fabric, operate carefully. If necessary, set up a fixture at the mold opening for precise positioning.

0 notes

Text

Composite Without Compromise: Odour Control in GRP, SMC, and FRP Vessel Manufacturing

Proven Strategies to Keep Emissions and Nuisance Odours in Check

1. Introduction

Composite vessels made from FRP, GRP, and SMC are the backbone of many industries—offering unmatched strength, corrosion resistance, and design flexibility. But behind these advanced materials lies a quieter challenge: the odours generated during manufacturing. These emissions, primarily from resin curing and finishing operations, can affect worker health, community relations, and regulatory compliance. In this blog, we explore the sources of odour in composite vessel production and share proven strategies to control them—so manufacturers can deliver high-performance products without compromising air quality or reputation.

2. Understanding the Materials

FRP (Fiber-Reinforced Plastic) refers to a broad category of composites made from a polymer matrix reinforced with fibres such as glass, carbon, or aramid. GRP (Glass-Reinforced Plastic) is a subset of FRP, where the reinforcing fibre is glass. SMC (Sheet Moulding Compound) is a type of pre-impregnated fibre composite, usually consisting of chopped glass fibres and thermoset resins, used in compression moulding. These materials are popular for vessel manufacturing due to their excellent mechanical properties, lightweight nature, and corrosion resistance. However, many of the resins used—particularly polyester and vinyl ester—emit volatile organic compounds (VOCs) like styrene during processing. These emissions are the primary source of odour and present both environmental and health concerns if not properly managed. Let’s first dive into little more details on each material.

A. GRP: Definition and Composition

GRP (Glass Reinforced Plastic) is a composite material composed of glass fibres, such as E-glass or S-glass, embedded in a plastic resin matrix, typically polyester, vinyl ester, or epoxy. The term emphasizes the use of glass fibres as the primary reinforcement, making GRP a specific subset of fibre-reinforced composites. It is widely chosen for its balance of strength, corrosion resistance, and affordability.GRP offers good mechanical strength, excellent corrosion resistance, and moderate stiffness, though it is heavier than carbon-based composites. It is cost-effective and ideal for large structures like storage tanks, pressure vessels, pipes, and marine vessels such as boat hulls. GRP is commonly used in industries like water treatment, air pollution control, chemical storage, oil & gas, and marine applications due to its durability and resistance to harsh environments.

B. SMC: Definition and Composition

SMC (Sheet Moulding Compound) is a composite material made of chopped glass fibres (typically 25-50 mm long) mixed with a thermosetting resin, usually polyester, along with fillers like calcium carbonate and additives. Supplied as mouldable sheets, SMC is designed for compression moulding, enabling the production of complex shapes with consistent thickness and high-quality surface finishes.SMC provides good mechanical strength, dimensional stability, and an excellent surface finish, but its shorter, chopped fibres result in lower strength compared to continuous-fibre composites like GRP for high-load applications. It is well-suited for smaller, intricate components such as covers, enclosures, automotive panels, or small tanks, where high-volume production and aesthetic quality are priorities. SMC is less common for large vessels due to its structural limitations, being that said, many companies have come up with designs with steel supports making the SMC panel tanks suitable for somewhat larger applications as well.

C. FRP: Definition and Composition

FRP (Fiber Reinforced Plastic) is a broad category of composites that includes any type of fibreglass, carbon, aramid, or basalt—embedded in a plastic resin matrix. GRP is a type of FRP when glass fibres are used, but FRP also encompasses high-performance fibres like carbon or aramid. This versatility allows FRP to be tailored for a wide range of applications, from general-purpose to specialized uses.FRP’s properties vary by fibre type: glass-based FRP (like GRP) offers corrosion resistance and moderate strength, carbon-based FRP provides a high strength-to-weight ratio and stiffness, and aramid-based FRP excels in impact resistance. Glass-based FRP is used for tanks and pipes, like GRP, while carbon or aramid-based FRP is employed in aerospace, automotive, high-pressure vessels, and advanced marine structures like aircraft components or high-performance yachts. FRP’s cost ranges from affordable (glass) to expensive (carbon/aramid), depending on the fibre and manufacturing process.

3. Why Odour Control Matters

Odour control in FRP/GRP manufacturing is far more than a matter of comfort—it’s a critical aspect of health, safety, and compliance. The Odours are largely caused by VOCs, such as styrene, a common component in polyester and vinyl ester resins. Prolonged exposure to styrene and similar compounds can lead to respiratory issues, neurological symptoms, and other health problems for workers. Additionally, regulatory agencies worldwide impose strict limits on VOC emissions to safeguard air quality and public health. Non-compliance can result in significant fines and legal challenges. Beyond regulations, persistent Odours can strain relationships with neighbouring residents and businesses, potentially damaging a company’s reputation. Effective Odour management, therefore, is essential for worker well-being, regulatory adherence, and maintaining community goodwill.

4. Odour Issues Specific to Each Material

The manufacturing of GRP (Glass Reinforced Plastic), SMC (Sheet Moulding Compound), and FRP (Fiber Reinforced Plastic) vessels involves processes and materials that can release odorous compounds. The primary sources of odours stem from the resins, solvents, and additives used, as well as specific manufacturing techniques. Below is a detailed breakdown of the odour sources for each material, organized by material type.

A. GRP Vessel Manufacturing: Odour Sources

GRP vessels are made using glass fibres and thermosetting resins (e.g., polyester, vinyl ester, or epoxy) through processes like hand lay-up, filament winding, or resin transfer moulding (RTM). Odour sources include:

(i) Resins (Styrene Emissions):

Polyester and vinyl ester resins, commonly used in GRP, contain styrene, a volatile organic compound (VOC) with a strong, sweet, and pungent odour. Styrene is released during resin mixing, application, and curing, especially in open-mould processes like hand lay-up or spray-up.

Epoxy resins, while less odourous than polyester, may still emit mild chemical smells during curing.

(ii) Solvents and Thinners:

Solvents like acetone or toluene are used to clean tools or thin resins, releasing sharp, chemical odours. These VOCs evaporate quickly, contributing to workplace odours.

(iii) Curing Agents and Catalysts:

Catalysts like methyl ethyl ketone peroxide (MEKP), used to initiate resin curing, have a strong, acrid odour. Improper handling or mixing can amplify these emissions.

(iv) Open-Mold Processes:

Processes like hand lay-up or spray-up expose wet resin to air, increasing the release of styrene and other VOCs. These methods are more odour-intensive compared to closed-mould processes like RTM.

(v) Dust and Fumes:

Cutting or grinding glass fibres during preparation or finishing generates dust with a faint, musty smell. Post-curing trimming or sanding of GRP parts can release resin fumes and fine particulate matter, adding to the odour profile.

B. SMC Vessel Manufacturing: Odour Sources

SMC is a pre-mixed composite of chopped glass fibres, polyester resin, fillers, and additives, moulded into sheets and compression-moulded under heat and pressure. Odour sources are generally less intense than GRP due to the closed-mould process but still significant:

(i) Resins (Styrene and Other VOCs):

SMC uses polyester resins containing styrene, which emits a pungent odour during the compounding stage when resin is mixed with fibres and fillers. However, since SMC is pre-mixed and stored as sheets, styrene emissions are more controlled compared to GRP open-mould processes.

(ii) Additives and Fillers:

Additives like low-profile agents (to reduce shrinkage) or thickeners (e.g., magnesium oxide) may release mild chemical odours during mixing or moulding. Fillers like calcium carbonate are odourless but can contribute to dust-related smells.

(iii) Compression Moulding:

During moulding, heat (typically 120-150°C) is applied, causing residual styrene or other VOCs in the SMC to volatilize, releasing a warm, chemical odour. Closed moulds reduce emissions compared to GRP’s open processes, but some odour escapes during Mould opening.

Use of mould release agents with distinct chemical odours.

(iv) Solvents for Equipment Cleaning:

Acetone or other solvents used to clean moulds or tools emit sharp, chemical smells. These are less frequent than in GRP manufacturing but still contribute to odours.

(v) Post-Moulding Finishing:

Trimming, drilling, or sanding SMC parts can release mild resin fumes and dust with a faint, chemical, or musty odour, especially if the material is not fully cured.

C. FRP Vessel Manufacturing: Odour Sources

FRP encompasses a broad range of composites, as an umbrella category, FRP includes both GRP and SMC, but also other forms like carbon-reinforced or aramid-reinforced plastics, or other fibres, using resins like polyester, vinyl ester, or epoxy. Odour sources depend on the fibre and process but overlap with GRP for glass-based FRP:

(i) Resins (Styrene and Epoxy Emissions):

For glass-based FRP (equivalent to GRP), styrene from polyester or vinyl ester resins is the primary odour source, with a strong, sweet smell during mixing, application, and curing.

Epoxy resins, common in carbon or aramid FRP, emit milder, chemical odours during curing, often described as less pungent than styrene but still noticeable.

(ii) Solvents and Cleaning Agents:

Acetone, toluene, or other solvents used for cleaning tools or preparing surfaces release sharp, chemical odours. These are common across all FRP types, especially in hand lay-up or filament winding.

(iii) Curing Agents:

Catalysts like MEKP for polyester resins or amines for epoxy resins have strong, acrid odours. Amine-based hardeners in epoxy systems, used for carbon/aramid FRP, can produce ammonia-like smells during curing.

(iv) Manufacturing Processes:

Open-mould processes (e.g., hand lay-up for glass FRP) release more styrene and VOCs than closed-mould methods (e.g., RTM or autoclave curing for carbon FRP). Autoclave curing, used for high-performance FRP, contains odours better but may still release epoxy fumes when moulds are opened.

High-temperature curing (e.g., in autoclaves for carbon FRP) can volatilize resin components, producing warm, chemical odours.

(v) Fiber-Specific Odours:

Glass fibres in FRP generate dust with a musty smell during cutting or sanding, like that of GRP.

Carbon or aramid fibres produce less dust but may release faint, burnt, or chemical odours during machining or if overheated during curing. These are minimal compared to resin-related odours.

5. Odour Control Strategies

The manufacturing of GRP (Glass Reinforced Plastic), SMC (Sheet Moulding Compound), and FRP (Fiber Reinforced Plastic) vessels involves resins, solvents, and additives that release odourous volatile organic compounds (VOCs), notably styrene from polyester resins. These odours, described as pungent or chemical, can affect worker health, community relations, and regulatory compliance. Effective odour control strategies are essential to mitigate these emissions, improve workplace safety, and adhere to environmental standards. The odour control strategies are categorised into two – process/product specific odour control strategies with respect each product and End of pipe solutions applicable for all the three products. First, we will cover few tailored strategies for each material, focusing on ventilation, material selection, process optimization, and followed by end-of-pipe solutions or advanced filtration methods.

A. GRP Vessel Manufacturing

(i) Ventilation and Air Extraction Systems:

GRP vessel manufacturing frequently employs open-mould techniques such as hand lay-up or spray-up, where styrene-rich polyester resins are exposed to air, resulting in significant VOC emissions. To address this, robust ventilation systems, including local exhaust ventilation (LEV) systems, are critical. These systems are installed at key emission points, such as resin application and curing stations, to capture odorous air. Regular maintenance of these systems prevents resin residue buildup, which could otherwise exacerbate odours, and ensures consistent performance in high-emission environments.

The implementation of ventilation systems not only reduces odours but also enhances workplace safety by minimizing worker exposure to harmful VOCs. For closed-mould processes like resin transfer moulding (RTM), sealing moulds tightly and integrating ventilation at demoulding stages further controls odour escape. These systems can be tailored to facility size, with smaller setups using standalone filtration units and larger plants opting for integrated HVAC solutions.

(ii) Use of Low-Styrene or Alternative Resins:

A proactive approach to odour control in GRP manufacturing involves selecting low-styrene or styrene-free resins to reduce VOC emissions at the source. Traditional polyester resins contain high styrene levels, contributing to strong odours and health risks. Low-styrene polyester resins or vinyl ester resins emit fewer VOCs during curing, significantly decreasing odour intensity. While these resins may increase material costs, they offer long-term benefits, including reduced odour complaints, improved worker safety, and alignment with environmental regulations.

The adoption of alternative resins requires careful consideration of application suitability, as vinyl ester or epoxy resins may have different mechanical properties or curing requirements compared to polyester. Manufacturers must evaluate these factors against the specific needs of GRP vessels, such as corrosion resistance for chemical storage. Pilot testing low-styrene resins can help assess performance without disrupting production. This strategy also supports sustainability goals by reducing the environmental impact of VOCs, making it appealing for facilities aiming to enhance their corporate social responsibility profile.

B. SMC Vessel Manufacturing

(i) Enclosed Mixing and Moulding Processes

SMC manufacturing involves pre-mixing chopped glass fibres with polyester resins and additives to create mouldable sheets, followed by compression moulding in closed systems, which inherently produces fewer odours than GRP’s open-mould processes. To control odours during mixing, enclosed systems with integrated ventilation or extraction units are essential. Automated mixing equipment minimizes styrene release by containing the process, while local exhaust ventilation captures any emissions during material handling. During compression moulding, closed moulds reduce odour escape, but residual styrene may be released when moulds are opened. Installing LEV systems near moulding machines ensures these emissions are captured and treated, maintaining a low-odour environment.

Enclosed processes offer significant advantages, including reduced worker exposure to VOCs and compliance with workplace safety regulations. For facilities producing high volumes of SMC components, such as small tanks or automotive parts, these systems enhance efficiency by streamlining odour control within the production line.

Additionally, Regular cleaning of mixing and moulding equipment prevents resin buildup, which could contribute to persistent odours.

(ii) Post-Curing and Off-Gassing Management

After moulding, SMC vessels may retain residual styrene, leading to odours during storage or use. Post-curing techniques, such as exposing moulded parts to controlled heat in a dedicated chamber, accelerate the off-gassing process, allowing VOCs to be released in a contained environment. This can be achieved using ovens or curing rooms equipped with ventilation systems that direct off-gassed air through and odour control unit (OCU). Alternatively, parts can be stored in well-ventilated off-gassing areas before finishing or packaging, reducing odour levels in the final product.

C. FRP Vessel Manufacturing

(i) Ventilation and Air Extraction Systems:

FRP vessel manufacturing, which includes GRP and other fibres like carbon or aramid, often involves open-mould processes that release significant styrene and other VOCs. Therefore, proper ventilation and air extraction is the key strategy.

(ii) Process Optimization and Enclosure:

Optimizing the manufacturing process for FRP vessels can significantly reduce odour emissions by minimizing solvent use, use of epoxy resins with milder odour and optimising curing times. Selecting faster-curing resins or adjusting formulations to lower styrene content decreases VOC release during production. Enclosing open-mould processes in booths or isolated areas equipped with exhaust systems allows for better control of odorous air, directing it through filtration units before release.

For closed-mould processes like filament winding or pultrusion, ensuring moulds are tightly sealed and equipped with integrated ventilation systems prevents odour escape during curing or demoulding, enhancing overall air quality management. Process enclosures offer dual benefits of odour control and improved production efficiency by reducing material waste and worker exposure to VOCs.

D. End-of-Pipe solutions or Advanced Filtration Systems

Effective odour control combines process optimization, engineering controls, and air treatment technologies. By combining enclosed systems with air treatment, manufacturers can achieve a cleaner workplace and minimize community complaints, particularly in urban settings where facilities are near residential areas.

Advanced air filtration systems are highly effective for removing these compounds from the exhausted air. These filters adsorb styrene and other organic molecules, achieving up to 99.5% reduction in odourous VOCs. Key advanced filtration strategies include:

Scrubbers:

Wet Scrubbers: Use water or chemical solutions to absorb and neutralize VOCs.

Dry Scrubbers: Use dry media (e.g., activated alumina or impregnated pellets) to capture specific compounds.

Activated Carbon Filters: Adsorb VOCs and odorous gases effectively; ideal for point-source or room-scale filtration. Regular monitoring of filter performance and replacement of saturated carbon are necessary to maintain effectiveness.

Biofiltration Systems: Especially for larger facilities, biofilters offer a sustainable method for treating air streams by using microbial action to degrade odorous compounds. They are effective for low-concentration, high-volume emissions.

Regenerative thermal oxidizers (RTOs) or catalytic oxidizers: Are also applicable for large facilities having separate streams for high concentration streams. The system can destroy VOCs through high-temperature oxidation, converting them into carbon dioxide and water. These are generally deployed as standalone units near high-emission areas like spray booths or lay-up stations of large facilities.

Employing these systems can mitigate community complaints by preventing odourous emissions from escaping the facility, which is critical for plants located near residential areas. Another factor which is overlooked in many places are the employee training; Ensuring proper storage, mixing, and application techniques minimizes unnecessary emissions. Implementing these changes requires upfront investment in equipment and process redesign, but the resulting reduction in odour complaints, improved public relations and regulatory penalties offsets these costs and justify the investment. Regular process audits and air quality monitoring ensure that optimizations remain effective, allowing manufacturers to adapt to changing production demands or regulatory requirements while maintaining a low-odour environment.

6. Regulatory and Community Considerations

Odour is not just an operational issue—it’s a community and compliance matter. Many jurisdictions have strict odour and VOC regulations. For example, styrene is a listed hazardous air pollutant (HAP) under U.S. EPA regulations. Manufacturers must monitor emissions and often report to local environmental authorities. In regions like the EU, occupational exposure limits (OELs) and industrial emissions directives (IED) govern VOC discharge. Facilities must demonstrate that Best Available Techniques (BAT) are being used for odour control.

Equally important is proactive communication with the community. Transparent environmental practices and prompt response to concerns build trust and social license to operate.

7. What EES Can Do for FRP/GRP Manufacturers

Elixir Enviro Systems Pvt Ltd (EES) offers specialized odour control solutions tailored to the unique challenges of FRP/GRP manufacturing facilities. Our services and technologies help reduce VOC emissions, improve workplace safety, and ensure regulatory compliance.

🔧 Customised Solutions We Offer:

1. Design of Ventilation systems, Enclosure and Containment Solutions

Design of proper ventilation systems and its installation.

Design and installation of enclosed curing booths with integrated emission control.

Modular systems for retrofitting existing facilities.

2. Process Optimisation Consulting

Transition support for low-VOC or styrene-free resins.

Guidance on closed-mould systems and curing environment improvements.

Process audits to identify and reduce emission hotspots.

3. On-site Services

Odour Assessment & Mapping: Identify sources and odour dispersion patterns.

VOC Monitoring & Analysis: Using state-of-the-art instruments.

Preventive Maintenance & Operator Training: To ensure ongoing system performance and compliance.

4. Odour Control Equipment

Activated Carbon Filters: For capturing VOCs like styrene.

Biofilters: Use microorganisms to biologically degrade odorous compounds.

Chemical Scrubbers: For targeted removal of specific VOCs.

Thermal Oxidizers: High-efficiency systems that destroy VOCs via combustion.

5. Regulatory Compliance Support

Emission modelling and simulation for statutory reporting.

Documentation support for local and international environmental standards.

💡 Why Partner with Elixir Enviro?

Deep domain knowledge in industrial odour and air quality management

Proven experience in custom-engineered solutions for composite industries

Commitment to sustainability, worker health, and community welfare

Responsive after-sales support and service contracts

8. Conclusion

Controlling odour in GRP, SMC, and FRP vessel manufacturing is not just a regulatory necessity—it’s a mark of modern, responsible manufacturing. By combining smarter material choices, better processes, and effective air treatment systems, companies can uphold product quality while protecting the environment and their communities. The result is a cleaner, more sustainable path forward for the composites industry. Partnering with Elixir Enviro Systems ensures access to industry-leading solutions for effective Odour management.

#odourcontrol#environment#sustainability#elixirenvirosystems#airpollution#ecofriendly#biofilt#3#frp tanks#grp

0 notes

Text

Best FRP Molding Machine Manufacturer in India, Ahmedabad

Leading and high-quality FRP Molding Machine manufacturer in Ahmedabad. FRP Manhole Cover Moulding Hydraulic Press Supplier across India by Inspire Engineers

Best FRP Molding Machine Manufacturer in India, Ahmedabad. Fiber Reinforced Plastic — FRP Molding Machine is a high-precision equipment designed for shaping and forming fiber-reinforced plastics into complex components. These machines are engineered to offer accurate temperature, pressure, and timing control to achieve superior mold quality. They play a critical role in producing durable, lightweight, and corrosion-resistant parts used across various industries. FRP molding machine can be done using different techniques like compression molding, injection molding, and transfer molding depending on application needs. The machine is designed with robust hydraulic systems, intelligent control panels, and uniform heating plates to ensure consistent production output.

✏️ Contact : Inspire Engineers 📲 Phone: +919033842504 💬 Email: [email protected] 🌐 Website:https://inspireengineers.in/products/frp-molding-machine/

0 notes