#RFID warehouse system

Explore tagged Tumblr posts

Text

RFID Tech Transforming Smart Warehousing in 2025 | AWL India

Explore how AWL India's RFID warehouse system is transforming smart warehousing with real-time tracking, accuracy, and streamlined inventory management.

#RFID warehouse system#RFID inventory management system#RFID warehouse management system#RFID warehouse tracking system

0 notes

Text

Discover how wireless asset tracking revolutionizes retail operations by offering real-time data, improved security, and scalable efficiency. This article explores advanced tracking technologies and future trends that position wireless systems as the top choice for retail asset management.

0 notes

Text

Enhance Warehouse Efficiency with AssetTrackerIoT

Optimize your warehouse management operations with AssetTrackerIoT. Many systems struggle with data capture, affecting real-time location and status updates. WarehouseTrackerIoT efficiently manages both serialized and non-serialized items, utilizing barcoding, UHF RFID, and long-range tracking. This technology ensures real-time awareness with detection zones and mobile scanning, maximizing asset utilization and worker efficiency.

For additional details, visit AssetTrackerIoT’s website.

#assetmanagement#rfid technology#tracking software#asset tracking#tracking system#assets#warehouse tracking

0 notes

Text

Choosing the Right RFID Tag: A Breakdown of Different Types and Their Uses

Introduction to RFID Tags and Their Functionality

An RFID tag is composed of two fundamental components: an antenna for transmitting and receiving signals, and an RFID chip (or integrated circuit, IC) that stores the tag's ID and other relevant information.

RFID tags use radio waves to transmit data about an item to the antenna/reader combination. These tags typically do not have a battery, unless specified as Active or BAP tags. "They" refers to passive RFID tags, which do not have their own power source. Instead, they receive the energy required to operate from the radio waves generated by the RFID reader. When the tag receives the transmission from the antenna/reader, the energy flows through the internal antenna to the tag’s chip. This energy activates the chip, which then modulates the energy with the desired information and transmits a signal back to the antenna/reader.

On each chip, there are four memory banks – EPC, TID, User, and Reserved. Each of these memory banks contains information about the item that is tagged or the tag itself, depending on the bank and its specifications. Two of the memory banks, EPC and User, can store unique identifying information. The TID bank cannot be updated because it contains information about the tag itself and the unique tag identifier. The tag’s Reserved memory bank is used for special tag operations, such as locking the tag or expanding its available EPC memory. Different types of tags exist, including read-only tags that allow reading of stored data but not changing it, read/write tags that allow alteration or rewriting of stored data, and a combination of both, where some data is permanently stored while the remaining memory is left accessible for future encoding and updates.

RFID Tag Types and Operational Modes

Hundreds of different RFID tags are available in various shapes and sizes, each with features and options specific to certain environments, surface materials, and applications. Choosing the ideal tag for a specific application, environment, and item material is crucial for optimal tag performance.

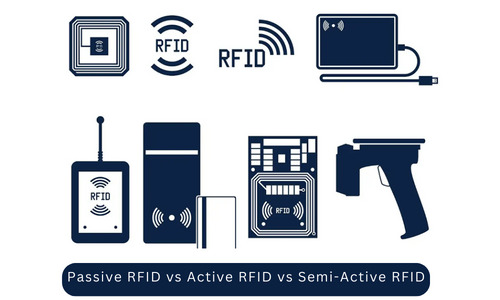

An RFID Tag can be categorized into passive, semi-passive, or active.

Passive tags, the more common variant, do not require direct line-of-sight to a reader, making them versatile but with a shorter read range. They are compact and lightweight, activated by the energy from an RFID reader. This tag has a limited range of 0-15 meters, which makes it suitable for short-range applications only. The reading range is constrained by the power required to activate the chip. Given their size and cost, passive tags are the most common and can be inlaid like labels or take the form of hard tags made from materials such as plastic or metal. Ideal for applications requiring close-range identification, such as inventory management, access control, and retail item tracking.

Active RFID tags, featuring a battery that requires replacement every 3-5 years, excel in live tracking applications, offering an extended read range compared to passive tags. They have a higher reading range (up to 100 meters) than passive tags. These tags are more expensive due to the cost of their battery and transmitter. Despite the higher cost, they are suited for real-time tracking of high-value assets, vehicle tracking, and monitoring large-scale operations like shipping and logistics.

Semi-Passive Tags, very rarely used, function somewhere between active and passive tags. These tags are battery-powered, helping extend the communication range. Find applications in environments where a longer communication range is needed but where the continuous transmission of active tags may not be necessary, such as environmental monitoring and equipment maintenance tracking.

To Get More Information Visit our Website: https://www.idsolutionsindia.com/product/rfid-tags/

#RFID tags#RFID readers#RFID solutions#RFID technology#RFID tags cost#Active RFID tags#RFID tags manufacturers#RFID clothing tags#RFID laundry tags#Inventory Management System#Animal warehouse management

0 notes

Text

The Dynamic Role of RFID Entrance Automation Systems

In our fast-paced world, technology is continually advancing, transforming the way we live, work, and access various spaces. When it comes to efficient access control, RFID Entrance Automation Systems are at the forefront of innovation. In this blog post, we'll delve into the thrilling world of RFID Entrance Automation Systems, exploring their dynamic role in shaping secure and convenient access to buildings and facilities. Get ready to embark on a journey where cutting-edge technology meets seamless access control.

Revolutionizing Access Control

The days of fumbling for keys or swiping access cards are rapidly becoming a thing of the past. RFID Entrance Automation Systems are revolutionizing the way we secure and manage entrances. These systems leverage Radio-Frequency Identification (RFID) technology to provide secure, contactless access to buildings and facilities.

Enhanced Security

In an era where security is paramount, RFID Entrance Automation Systems offer a robust solution. RFID technology allows for precise identity verification, ensuring that only authorized personnel gain entry. Whether it's a workplace, residential building, or a high-security facility, these systems provide a layered defense against unauthorized access.

Seamless Convenience

Imagine walking up to a door, and it magically opens without any physical interaction. RFID Entrance Automation Systems make this a reality. With RFID-enabled access cards or badges, users can gain entry effortlessly, making daily routines smoother and more efficient. No more digging through bags or pockets to find keys or access cards!

Visitor Management Made Easy

RFID entrance automation systems also excel in visitor management. Temporary access can be granted seamlessly, with the ability to track and monitor visitors' movements within the premises. This is particularly valuable for businesses, schools, and healthcare facilities that frequently host guests.

Tailored Solutions for Diverse Needs

RFID Entrance Automation Systems are highly versatile and adaptable. They can be customized to suit various requirements, from simple office access to more complex scenarios like airport security or healthcare access control. The flexibility of these systems is a testament to their adaptability.

In conclusion

RFID Entrance Automation Systems are transforming the way we secure and manage entrances. These cutting-edge solutions provide enhanced security, seamless convenience, and tailored access control options. As technology continues to evolve, the role of RFID Entrance Automation Systems will only become more exciting and integral to our daily lives. Welcome to a future where secure and convenient access is just a tap away!

#entranceautomationsystem#warehouse entrance automation system#rfid entrance automation system india

0 notes

Text

What Is End To End Logistics & Supply Chain Solutions?

In today's rapidly evolving and highly competitive business landscape, companies understand the critical role that efficient supply chain management plays in gaining a competitive edge. Among the various approaches available, one that has gained significant attention is the implementation of end-to-end logistics and supply chain solutions. These comprehensive solutions cover the entire spectrum of the supply chain process, starting from raw material sourcing all the way to the final product delivery. The primary objective of these solutions is to optimize operational efficiency, drive cost reduction, and enhance customer satisfaction. In this blog, we will take a deep dive into the concept of end-to-end logistics and supply chain solutions, shedding light on its definition, key components, benefits, and effective implementation strategies. By exploring these aspects, businesses can gain valuable insights into how they can leverage end-to-end solutions to elevate their supply chain management practices and achieve sustainable success in today's dynamic marketplace.

Definition of End-to-End Logistics & Supply Chain Solutions

End-to-end logistics and supply chain solutions encompass the comprehensive integration and management of all activities involved in the supply chain process, from procurement to distribution. This holistic approach covers a wide range of functions, including procurement, production, inventory management, transportation, warehousing, and customer service. The overarching goal is to optimize the flow of goods, information, and funds throughout the supply chain, ensuring smooth coordination and collaboration among all stakeholders. By leveraging advanced technologies and strategic planning, businesses can achieve end-to-end visibility, transparency, and control over their supply chain operations.

This allows for better demand forecasting, improved inventory management, efficient order fulfillment, reduced lead times, and enhanced customer service. Moreover, end-to-end solutions enable businesses to identify bottlenecks, streamline processes, mitigate risks, and seize opportunities for cost savings and operational efficiencies. Ultimately, implementing end-to-end logistics and supply chain solutions empowers businesses to gain a competitive advantage by delivering products to customers faster, more reliably, and with greater customer satisfaction.

Key Components of End-to-End Logistics & Supply Chain Solutions

To fully understand end-to-end logistics and supply chain solutions, it is essential to explore the key components that make up this comprehensive approach. These components encompass critical aspects of the supply chain. Let's dive deeper into each of these components and their significance in optimizing the supply chain process. The list of the components of end to end logistics and supply chain solution is as follows:

Supply Chain Capacity Planning

Capacity planning involves analyzing and determining the resources, including production capabilities, warehouse space, and transportation capacity, required to meet demand effectively. By accurately forecasting demand and aligning it with available resources, companies can optimize their supply chain capacity and avoid bottlenecks or excess capacity.

Supply Chain Orchestration

Supply chain orchestration focuses on synchronizing and coordinating activities across different functions and entities within the supply chain. It involves real-time visibility, communication, and collaboration among suppliers, manufacturers, distributors, and retailers to ensure efficient order fulfillment and timely delivery.

Order Orchestration

Order orchestration refers to the process of managing and optimizing customer orders throughout the supply chain. It involves capturing, processing, and tracking orders, ensuring that they are fulfilled accurately and delivered on time. Order orchestration also includes managing order changes, cancellations, and returns.

RFID Warehouse Management System

RFID (Radio Frequency Identification) technology plays a crucial role in enhancing warehouse management and inventory tracking. RFID tags are attached to products or packaging, allowing for real-time identification, tracking, and monitoring of inventory. This technology improves inventory accuracy, reduces manual errors, and enables efficient order fulfillment.

F&B Supply Chain

The food and beverage (F&B) industry has unique supply chain challenges, including perishable products, stringent regulations, and complex distribution networks. End-to-end logistics and supply chain solutions for the F&B industry focus on maintaining product quality, ensuring compliance, optimizing inventory, and minimizing waste.

RFID Inventory Management

RFID technology enables efficient inventory management by providing real-time visibility into inventory levels, location, and movement. RFID tags and readers automate the tracking and monitoring of inventory, minimizing manual efforts and improving inventory accuracy. This technology also facilitates efficient stock replenishment, reduces stockouts, and enhances overall inventory control.

Fulfillment Center vs Distribution Center

While often used interchangeably, fulfillment centers and distribution centers serve different purposes in the supply chain. A fulfillment center is a facility dedicated to e-commerce order fulfillment, involving activities such as picking, packing, and shipping. On the other hand, a distribution center focuses on receiving, storing, and redistributing products to retail locations or other distribution centers.

Ecommerce Fulfillment Services India

India's booming e-commerce market has led to the emergence of specialized fulfillment service providers. These companies offer end-to-end fulfillment solutions, including warehousing, order processing, inventory management, and last-mile delivery, catering to the unique needs of e-commerce businesses in India.

Benefits of End-to-End Logistics & Supply Chain Solutions

Implementing end-to-end logistics and supply chain solutions offers several benefits for businesses. By streamlining and integrating various supply chain processes, companies can enhance operational efficiency, reduce costs, improve customer satisfaction, and gain a competitive edge in the market. Let's explore the list of significant advantages that businesses can derive from adopting end-to-end logistics and supply chain solutions:

Improved Efficiency

By streamlining processes, optimizing inventory levels, and enhancing coordination among supply chain partners, end-to-end solutions improve overall operational efficiency. This leads to reduced lead times, faster order fulfillment, and improved customer satisfaction.

Cost Reduction

Effective supply chain management helps identify cost-saving opportunities, such as optimizing transportation routes, reducing inventory holding costs, and minimizing stock outs or overstock situations. By eliminating inefficiencies and enhancing resource utilization, businesses can achieve significant cost reductions.

Enhanced Customer Service

End-to-end solutions enable better visibility and control over the supply chain, resulting in improved customer service. Companies can provide accurate order tracking, faster delivery, and proactive communication, meeting customer expectations and building long-term loyalty.

Agility and Flexibility

End-to-end solutions empower businesses to respond quickly to changing market demands and unforeseen disruptions. With better visibility and coordination, companies can adapt their supply chain processes, reroute shipments, and manage inventory effectively to minimize the impact of disruptions and maintain a competitive edge.

Competitive Advantage

By optimizing the entire supply chain, businesses gain a competitive advantage in the market. Efficient supply chain management enables cost leadership, faster time-to-market, and the ability to meet customer demands promptly, setting businesses apart from their competitors.

Implementing End-to-End Logistics & Supply Chain Solutions

To implement end-to-end logistics and supply chain solutions effectively, businesses should consider the following steps:

Assess Current Supply Chain- Conduct a comprehensive analysis of the existing supply chain processes, identifying bottlenecks, inefficiencies, and areas for improvement.

Collaborate with Partners- Establish strong relationships and collaboration with suppliers, manufacturers, distributors, and other supply chain partners to ensure seamless coordination and information sharing.

Invest in Technology- Leverage advanced technologies such as supply chain management software, RFID systems, and analytics tools to enable real-time visibility, data-driven decision-making, and process automation.

Continuous Improvement- Implement a culture of continuous improvement, regularly evaluating performance metrics, monitoring market trends, and making necessary adjustments to optimize supply chain operations.

Partner with Experts- Consider partnering with experienced logistics and supply chain service providers who specialize in end-to-end solutions. These experts can bring in-depth industry knowledge, expertise, and resources to drive efficient and effective supply chain management.

Conclusion

In conclusion, adopting end-to-end logistics and supply chain solutions is a strategic move for businesses seeking to optimize their operations, enhance customer satisfaction, and gain a competitive advantage. By integrating key components such as supply chain capacity planning, supply chain orchestration, order orchestration, and RFID warehouse management systems, companies can achieve improved efficiency, cost reduction, and enhanced customer service. This is particularly relevant in specialized industries like F&B, where tailored solutions are essential. With the support of experienced partners like AWL, businesses can navigate the complexities of implementing end-to-end solutions and leverage their expertise to drive success in today's dynamic and competitive business environment. By embracing end-to-end logistics and supply chain solutions, companies can transform their supply chain processes and position themselves for long-term growth and sustainability.

Source : https://www.awlindia.com/us-en/blog-details/what-is-end-to-end-logistics-supply-chain-solutions

#supply chain capacity planning#supply chain orchestration#order orchestration#rfid warehouse management system#f&b supply chain#fulfillment center vs distribution center#ecommerce fulfillment services India#rfid inventory management

0 notes

Text

Scan the online brochures of companies who sell workplace monitoring tech and you’d think the average American worker was a renegade poised to take their employer down at the next opportunity. “Nearly half of US employees admit to time theft!” “Biometric readers for enhanced accuracy!” “Offer staff benefits in a controlled way with Vending Machine Access!”

A new wave of return-to-office mandates has arrived since the New Year, including at JP Morgan Chase, leading advertising agency WPP, and Amazon—not to mention President Trump’s late January directive to the heads of federal agencies to “terminate remote work arrangements and require employees to return to work in-person … on a full-time basis.” Five years on from the pandemic, when the world showed how effectively many roles could be performed remotely or flexibly, what’s caused the sudden change of heart?

“There’s two things happening,” says global industry analyst Josh Bersin, who is based in California. “The economy is actually slowing down, so companies are hiring less. So there is a trend toward productivity in general, and then AI has forced virtually every company to reallocate resources toward AI projects.

“The expectation amongst CEOs is that’s going to eliminate a lot of jobs. A lot of these back-to-work mandates are due to frustration that both of those initiatives are hard to measure or hard to do when we don’t know what people are doing at home.”

The question is, what exactly are we returning to?

Take any consumer tech buzzword of the 21st century and chances are it’s already being widely used across the US to monitor time, attendance and, in some cases, the productivity of workers, in sectors such as manufacturing, retail, and fast food chains: RFID badges, GPS time clock apps, NFC apps, QR code clocking-in, Apple Watch badges, and palm, face, eye, voice, and finger scanners. Biometric scanners have long been sold to companies as a way to avoid hourly workers “buddy punching” for each other at the start and end of shifts—so-called “time theft.” A return-to-office mandate and its enforcement opens the door for similar scenarios for salaried staff.

Track and Trace

The latest, deluxe end point of these time and attendance tchotchkes and apps is something like Austin-headquartered HID’s OmniKey platform. Designed for factories, hospitals, universities and offices, this is essentially an all-encompassing RFID log-in and security system for employees, via smart cards, smartphone wallets, and wearables. These will not only monitor turnstile entrances, exits, and floor access by way of elevators but also parking, the use of meeting rooms, the cafeteria, printers, lockers, and yes, vending machine access.

These technologies, and more sophisticated worker location- and behavior-tracking systems, are expanding from blue-collar jobs to pink-collar industries and even white-collar office settings. Depending on the survey, approximately 70 to 80 percent of large US employers now use some form of employee monitoring, and the likes of PwC have explicitly told workers that managers will be tracking their location to enforce a three-day office week policy.

“Several of these earlier technologies, like RFID sensors and low-tech barcode scanners, have been used in manufacturing, in warehouses, or in other settings for some time,” says Wolfie Christl, a researcher of workplace surveillance for Cracked Labs, a nonprofit based in Vienna, Austria. “We’re moving toward the use of all kinds of sensor data, and this kind of technology is certainly now moving into the offices. However, I think for many of these, it’s questionable whether they really make sense there.”

What’s new, at least to the recent pandemic age of hybrid working, is the extent to which workers can now be tracked inside office buildings. Cracked Labs published a frankly terrifying 25-page case study report in November 2024 showing how systems of wireless networking, motion sensors, and Bluetooth beacons, whether intentionally or as a byproduct of their capabilities, can provide “behavioral monitoring and profiling” in office settings.

The project breaks the tech down into two categories: The first is technology that tracks desk presence and room occupancy, and the second monitors the indoor location, movement, and behavior of the people working inside the building.

To start with desk and room occupancy, Spacewell offers a mix of motion sensors installed under desks, in ceilings, and at doorways in “office spaces” and heat sensors and low-resolution visual sensors to show which desks and rooms are being used. Both real-time and trend data are available to managers via its “live data floorplan,” and the sensors also capture temperature, environmental, light intensity, and humidity data.

The Swiss-headquartered Locatee, meanwhile, uses existing badge and device data via Wi-Fi and LAN to continuously monitor clocking in and clocking out, time spent by workers at desks and on specific floors, and the number of hours and days spent by employees at the office per week. While the software displays aggregate rather than individual personal employee data to company executives, the Cracked Labs report points out that Locatee offers a segmented team analytics report which “reveals data on small groups.”

As more companies return to the office, the interest in this idea of “optimized” working spaces is growing fast. According to S&S Insider’s early 2025 analysis, the connected office was worth $43 billion in 2023 and will grow to $122.5 billion by 2032. Alongside this, IndustryARC predicts there will be a $4.5 billion employee-monitoring-technology market, mostly in North America, by 2026—the only issue being that the crossover between the two is blurry at best.

At the end of January, Logitech showed off its millimeter-wave radar Spot sensors, which are designed to allow employers to monitor whether rooms are being used and which rooms in the building are used the most. A Logitech rep told The Verge that the peel-and-stick devices, which also monitor VOCs, temperature, and humidity, could theoretically estimate the general placement of people in a meeting room.

As Christl explains, because of the functionality that these types of sensor-based systems offer, there is the very real possibility of a creep from legitimate applications, such as managing energy use, worker health and safety, and ensuring sufficient office resources into more intrusive purposes.

“For me, the main issue is that if companies use highly sensitive data like tracking the location of employees’ devices and smartphones indoors or even use motion detectors indoors,” he says, “then there must be totally reliable safeguards that this data is not being used for any other purposes.”

Big Brother Is Watching

This warning becomes even more pressing where workers’ indoor location, movement, and behavior are concerned. Cisco’s Spaces cloud platform has digitized 11 billion square feet of enterprise locations, producing 24.7 trillion location data points. The Spaces system is used by more than 8,800 businesses worldwide and is deployed by the likes of InterContinental Hotels Group, WeWork, the NHS Foundation, and San Jose State University, according to Cisco’s website.

While it has applications for retailers, restaurants, hotels, and event venues, many of its features are designed to function in office environments, including meeting room management and occupancy monitoring. Spaces is designed as a comprehensive, all-seeing eye into how employees (and customers and visitors, depending on the setting) and their connected devices, equipment, or “assets” move through physical spaces.

Cisco has achieved this by using its existing wireless infrastructure and combining data from Wi-Fi access points with Bluetooth tracking. Spaces offers employers both real-time views and historical data dashboards. The use cases? Everything from meeting-room scheduling and optimizing cleaning schedules to more invasive dashboards on employees’ entry and exit times, the duration of staff workdays, visit durations by floor, and other “behavior metrics.” This includes those related to performance, a feature pitched at manufacturing sites.

Some of these analytics use aggregate data, but Cracked Labs details how Spaces goes beyond this into personal data, with device usernames and identifiers that make it possible to single out individuals. While the ability to protect privacy by using MAC randomization is there, Cisco emphasizes that this makes indoor movement analytics “unreliable” and other applications impossible—leaving companies to make that decision themselves.

Management even has the ability to send employees nudge-style alerts based on their location in the building. An IBM application, based on Cisco’s underlying technology, offers to spot anomalies in occupancy patterns and send notifications to workers or their managers based on what it finds. Cisco’s Spaces can also incorporate video footage from Cisco security cameras and WebEx video conferencing hardware into the overall system of indoor movement monitoring; another example of function creep from security to employee tracking in the workplace.

“Cisco is simply everywhere. As soon as employers start to repurpose data that is being collected from networking or IT infrastructure, this quickly becomes very dangerous, from my perspective.” says Christl. “With this kind of indoor location tracking technology based on its Wi-Fi networks, I think that a vendor as major as Cisco has a responsibility to ensure it doesn’t suggest or market solutions that are really irresponsible to employers.

“I would consider any productivity and performance tracking very problematic when based on this kind of intrusive behavioral data.” WIRED approached Cisco for comment but didn’t receive a response before publication.

Cisco isn't alone in this, though. Similar to Spaces, Juniper’s Mist offers an indoor tracking system that uses both Wi-Fi networks and Bluetooth beacons to locate people, connected devices, and Bluetooth tagged badges on a real-time map, with the option of up to 13 months of historical data on worker behavior.

Juniper’s offering, for workplaces including offices, hospitals, manufacturing sites, and retailers, is so precise that it is able to provide records of employees’ device names, together with the exact enter and exit times and duration of visits between “zones” in offices—including one labeled “break area/kitchen” in a demo. Yikes.

For each of these systems, a range of different applications is functionally possible, and some which raise labor-law concerns. “A worst-case scenario would be that management wants to fire someone and then starts looking into historical records trying to find some misconduct,” says Christl. "If it’s necessary to investigate employees, then there should be a procedure where, for example, a worker representative is looking into the fine-grained behavioral data together with management. This would be another safeguard to prevent misuse.”

Above and Beyond?

If warehouse-style tracking has the potential for management overkill in office settings, it makes even less sense in service and health care jobs, and American unions are now pushing for more access to data and quotas used in disciplinary action. Elizabeth Anderson, professor of public philosophy at the University of Michigan and the author of Private Government: How Employers Rule Our Lives, describes how black-box algorithm-driven management and monitoring affects not just the day-to-day of nursing staff but also their sense of work and value.

“Surveillance and this idea of time theft, it’s all connected to this idea of wasting time,” she explains. “Essentially all relational work is considered inefficient. In a memory care unit, for example, the system will say how long to give a patient breakfast, how many minutes to get them dressed, and so forth.

“Maybe an Alzheimer’s patient is frightened, so a nurse has to spend some time calming them down, or perhaps they have lost some ability overnight. That’s not one of the discrete physical tasks that can be measured. Most of the job is helping that person cope with declining faculties; it takes time for that, for people to read your emotions and respond appropriately. What you get is massive moral injury with this notion of efficiency.”

This kind of monitoring extends to service workers, including servers in restaurants and cleaning staff, according to a 2023 Cracked Labs’ report into retail and hospitality. Software developed by Oracle is used to, among other applications, rate and rank servers based on speed, sales, timekeeping around breaks, and how many tips they receive. Similar Oracle software that monitors mobile workers such as housekeepers and cleaners in hotels uses a timer for app-based micromanagement—for instance, “you have two minutes for this room, and there are four tasks.”

As Christl explains, this simply doesn’t work in practice. “People have to struggle to combine what they really do with this kind of rigid, digital system. And it’s not easy to standardize work like talking to patients and other kinds of affective work, like how friendly you are as a waiter. This is a major problem. These systems cannot represent the work that is being done accurately.”

But can knowledge work done in offices ever be effectively measured and assessed either? In an episode of his podcast in January, host Ezra Klein battled his own feelings about having many of his best creative ideas at a café down the street from where he lives rather than in The New York Times’ Manhattan offices. Anderson agrees that creativity often has to find its own path.

“Say there’s a webcam tracking your eyes to make sure you’re looking at the screen,” she says. “We know that daydreaming a little can actually help people come up with creative ideas. Just letting your mind wander is incredibly useful for productivity overall, but that requires some time looking around or out the window. The software connected to your camera is saying you’re off-duty—that you’re wasting time. Nobody’s mind can keep concentrated for the whole work day, but you don’t even want that from a productivity point of view.”

Even for roles where it might make more methodological sense to track discrete physical tasks, there can be negative consequences of nonstop monitoring. Anderson points to a scene in Erik Gandini’s 2023 documentary After Work that shows an Amazon delivery driver who is monitored, via camera, for their driving, delivery quotas, and even getting dinged for using Spotify in the van.

“It’s very tightly regulated and super, super intrusive, and it’s all based on distrust as the starting point,” she says. “What these tech bros don’t understand is that if you install surveillance technology, which is all about distrusting the workers, there is a deep feature of human psychology that is reciprocity. If you don’t trust me, I’m not going to trust you. You think an employee who doesn’t trust the boss is going to be working with the same enthusiasm? I don’t think so.”

Trust Issues

The fixes, then, might be in the leadership itself, not more data dashboards. “Our research shows that excessive monitoring in the workplace can damage trust, have a negative impact on morale, and cause stress and anxiety,” says Hayfa Mohdzaini, senior policy and practice adviser for technology at the CIPD, the UK’s professional body for HR, learning, and development. “Employers might achieve better productivity by investing in line manager training and ensuring employees feel supported with reasonable expectations around office attendance and manageable workloads.”

A 2023 Pew Research study found that 56 percent of US workers were opposed to the use of AI to keep track of when employees were at their desks, and 61 percent were against tracking employees’ movements while they work.

This dropped to just 51 percent of workers who were opposed to recording work done on company computers, through the use of a kind of corporate “spyware” often accepted by staff in the private sector. As Josh Bersin puts it, “Yes, the company can read your emails” with platforms such as Teramind, even including “sentiment analysis” of employee messages.

Snooping on files, emails, and digital chats takes on new significance when it comes to government workers, though. New reporting from WIRED, based on conversations with employees at 13 federal agencies, reveals the extent to Elon Musk’s DOGE team’s surveillance: software including Google’s Gemini AI chatbot, a Dynatrace extension, and security tool Splunk have been added to government computers in recent weeks, and some people have felt they can’t speak freely on recorded and transcribed Microsoft Teams calls. Various agencies already use Everfox software and Dtex’s Intercept system, which generates individual risk scores for workers based on websites and files accessed.

Alongside mass layoffs and furloughs over the past four weeks, the so-called Department of Government Efficiency has also, according to CBS News and NPR reports, gone into multiple agencies in February with the theater and bombast of full X-ray security screenings replacing entry badges at Washington, DC, headquarters. That’s alongside managers telling staff that their logging in and out of devices, swiping in and out of workspaces, and all of their digital work chats will be “closely monitored” going forward.

“Maybe they’re trying to make a big deal out of it to scare people right now,” says Bersin. “The federal government is using back-to-work as an excuse to lay off a bunch of people.”

DOGE staff have reportedly even added keylogger software to government computers to track everything employees type, with staff concerned that anyone using keywords related to progressive thinking or "disloyalty” to Trump could be targeted—not to mention the security risks it introduces for those working on sensitive projects. As one worker told NPR, it feels “Soviet-style” and “Orwellian” with “nonstop monitoring.” Anderson describes the overall DOGE playbook as a series of “deeply intrusive invasions of privacy.”

Alternate Realities

But what protections are out there for employees? Certain states, such as New York and Illinois, do offer strong privacy protections against, for example, unnecessary biometric tracking in the private sector, and California’s Consumer Privacy Act covers workers as well as consumers. Overall, though, the lack of federal-level labor law in this area makes the US something of an alternate reality to what is legal in the UK and Europe.

The Electronic Communications Privacy Act in the US allows employee monitoring for legitimate business reasons and with the worker’s consent. In Europe, Algorithm Watch has made country analyses for workplace surveillance in the UK, Italy, Sweden, and Poland. To take one high-profile example of the stark difference: In early 2024, Serco was ordered by the UK's privacy watchdog, the Information Commissioner’s Office (ICO), to stop using face recognition and fingerprint scanning systems, designed by Shopworks, to track the time and attendance of 2,000 staff across 38 leisure centers around the country. This new guidance led to more companies reviewing or cutting the technology altogether, including Virgin Active, which pulled similar biometric employee monitoring systems from 30-plus sites.

Despite a lack of comprehensive privacy rights in the US, though, worker protest, union organizing, and media coverage can provide a firewall against some office surveillance schemes. Unions such as the Service Employees International Union are pushing for laws to protect workers from black-box algorithms dictating the pace of output.

In December, Boeing scrapped a pilot of employee monitoring at offices in Missouri and Washington, which was based on a system of infrared motion sensors and VuSensor cameras installed in ceilings, made by Ohio-based Avuity. The U-turn came after a Boeing employee leaked an internal PowerPoint presentation on the occupancy- and headcount-tracking technology to The Seattle Times. In a matter of weeks, Boeing confirmed that managers would remove all the sensors that had been installed to date.

Under-desk sensors, in particular, have received high-profile backlash, perhaps because they are such an obvious piece of surveillance hardware rather than simply software designed to record work done on company machines. In the fall of 2022, students at Northeastern University hacked and removed under-desk sensors produced by EnOcean, offering “presence detection” and “people counting,” that had been installed in the school’s Interdisciplinary Science & Engineering Complex. The university provost eventually informed students that the department had planned to use the sensors with the Spaceti platform to optimize desk usage.

OccupEye (now owned by FM: Systems), another type of under-desk heat and motion sensor, received a similar reaction from staff at Barclays Bank and The Telegraph newspaper in London, with employees protesting and, in some cases, physically removing the devices that tracked the time they spent away from their desks.

Despite the fallout, Barclays later faced a $1.1 billion fine from the ICO when it was found to have deployed Sapience’s employee monitoring software in its offices, with the ability to single out and track individual employees. Perhaps unsurprisingly in the current climate, that same software company now offers “lightweight device-level technology” to monitor return-to-office policy compliance, with a dashboard breaking employee location down by office versus remote for specific departments and teams.

According to Elizabeth Anderson’s latest book Hijacked, while workplace surveillance culture and the obsession with measuring employee efficiency might feel relatively new, it can actually be traced back to the invention of the “work ethic” by the Puritans in the 16th and 17th centuries.

“They thought you should be working super hard; you shouldn’t be idling around when you should be in work,” she says. “You can see some elements there that can be developed into a pretty hostile stance toward workers. The Puritans were obsessed with not wasting time. It was about gaining assurance of salvation through your behavior. With the Industrial Revolution, the ‘no wasting time’ became a profit-maximizing strategy. Now you’re at work 24/7 because they can get you on email.”

Some key components of the original work ethic, though, have been skewed or lost over time. The Puritans also had strict constraints on what duties employers had toward their workers: paying a living wage and providing safe and healthy working conditions.

“You couldn’t just rule them tyrannically, or so they said. You had to treat them as your fellow Christians, with dignity and respect. In many ways the original work ethic was an ethic which uplifted workers.”

6 notes

·

View notes

Text

Alltick API: Where Market Data Becomes a Sixth Sense

When trading algorithms dream, they dream in Alltick’s data streams.

The Invisible Edge

Imagine knowing the market’s next breath before it exhales. While others trade on yesterday’s shadows, Alltick’s data interface illuminates the present tense of global markets:

0ms latency across 58 exchanges

Atomic-clock synchronization for cross-border arbitrage

Self-healing protocols that outsmart even solar flare disruptions

The API That Thinks in Light-Years

🌠 Photon Data Pipes Our fiber-optic neural network routes market pulses at 99.7% light speed—faster than Wall Street’s CME backbone.

🧬 Evolutionary Endpoints Machine learning interfaces that mutate with market conditions, automatically optimizing data compression ratios during volatility storms.

🛸 Dark Pool Sonar Proprietary liquidity radar penetrates 93% of hidden markets, mapping iceberg orders like submarine topography.

⚡ Energy-Aware Architecture Green algorithms that recycle computational heat to power real-time analytics—turning every trade into an eco-positive event.

Secret Weapons of the Algorithmic Elite

Fed Whisperer Module: Decode central bank speech patterns 14ms before news wires explode

Meme Market Cortex: Track Reddit/Github/TikTok sentiment shifts through self-training NLP interfaces

Quantum Dust Explorer: Mine microsecond-level anomalies in options chains for statistical arbitrage gold

Build the Unthinkable

Your dev playground includes:

🧪 CRISPR Data Editor: Splice real-time ticks with alternative data genomes

🕹️ HFT Stress Simulator: Test strategies against synthetic black swan events

📡 Satellite Direct Feed: Bypass terrestrial bottlenecks with LEO satellite clusters

The Silent Revolution

Last month, three Alltick-powered systems achieved the impossible:

A crypto bot front-ran Elon’s tweet storm by analyzing Starlink latency fluctuations

A London hedge fund predicted a metals squeeze by tracking Shanghai warehouse RFID signals

An AI trader passed the Turing Test by negotiating OTC derivatives via synthetic voice interface

72-Hour Quantum Leap Offer

Deploy Alltick before midnight UTC and unlock:

🔥 Dark Fiber Priority Lane (50% faster than standard feeds)

💡 Neural Compiler (Auto-convert strategies between Python/Rust/HDL)

🔐 Black Box Vault (Military-grade encrypted data bunker)

Warning: May cause side effects including disgust toward legacy APIs, uncontrollable urge to optimize everything, and permanent loss of "downtime"概念.

Alltick doesn’t predict the future—we deliver it 42 microseconds early.(Data streams may contain traces of singularity. Not suitable for analog traders.)

2 notes

·

View notes

Text

easyTRACK Warehouse Management System

An intelligent solution to control movement and storage of materials within a Warehouse.

A well-structured Warehouse Management system is important for the smooth and efficient operation of any warehouse, irrespective of the size or volume of material it handles. Most of the small and medium warehouses do not require an expensive WMS with redundant features. easyTRACK WMS is a perfect solution on the enterprise mobility for the warehouse management of small and medium enterprises which helps them manage all the essential warehouse functions. easyTRACK warehouse automation software allows the users in warehouse to manage the following operations at their palm.

Goods receiving

Put away

Picking & Palletizing

Dispatch

Stock count, etc.

easyTRACK WMS Lite Benefits

Solves the challenges faced in the conventional system.

Goods Receiving-

Priority Issue Multiple Shipments received at a time

Delayed Data entry Stock may be available but not available for Sale Dead /Damage/Short supply on arrival not instantly notified.

SOLUTION: GRN on PDT “goods receiving made easy with GRN on PDT”

Welcome to Technowave Group, your trusted provider of advanced technology solutions in Dubai. Our RFID Warehouse Inventory Management Systems can help businesses improve their inventory management and provide complete visibility into their warehouse operations.

What is RFID Warehouse Inventory Management System?

RFID Warehouse Inventory Management System uses RFID technology to automate the process of inventory tracking and management. It involves tagging inventory items with that contain unique identification numbers. The RFID tags are read by RFID readers, which transmit the data to a computer system that stores the information and provides real-time updates on the inventory’s location, movement, and status.

Key Features of our RFID Warehouse Inventory Management System

Our RFID Warehouse Inventory Management System comes with the following key features:

Real-time inventory tracking:

Our RFID system provides accurate and up-to-date information on inventory levels, locations, and movements in real-time. This means that businesses can quickly identify any discrepancies, such as missing or misplaced items, and take corrective action before they become bigger problems.

Inventory management:

Our RFID system automates the inventory management process, including item counting, reordering, and tracking. This means that businesses can easily monitor inventory levels and reorder products when they are running low. This helps prevent stockouts and ensures that products are always available for customers.

Asset tracking:

It can track and manage assets, including equipment, tools, and vehicles, helping businesses keep track of their assets’ location, status, and maintenance schedules. This allows businesses to optimize asset utilization and minimize downtime, which can result in significant cost savings.

Reporting and analytics:

The RFID system generates detailed reports on inventory and asset tracking, providing businesses with valuable insights into their warehouse operations. Businesses can use this information to identify areas for improvement and make informed decisions about inventory levels, order fulfillment, and asset management.

Improved accuracy and efficiency:

Our RFID system eliminates the need for manual inventory tracking, reducing the risk of errors and improving accuracy. This saves time and resources by automating inventory management and asset tracking, allowing businesses to focus on other critical tasks.

Improved visibility and control:

It provides real-time updates on inventory and asset movement, giving businesses complete visibility into their warehouse operations. This helps businesses make informed decisions and take corrective action quickly, leading to increased efficiency and productivity.

Improved customer satisfaction:

Our RFID system helps businesses improve their order fulfillment process, reducing stockouts and improving delivery times. This leads to increased customer satisfaction and repeat business, which can be a significant competitive advantage in today’s market.

Compliance with regulations:

Last but not least, our RFID system helps businesses comply with regulations related to inventory tracking and management. For example, our system can provide traceability requirements for food and pharmaceutical products, ensuring that businesses meet regulatory requirements and avoid costly penalties.

Overall, our RFID Warehouse Inventory Management System offers businesses a range of benefits, from increased efficiency and productivity to improved customer satisfaction and regulatory compliance.

Get in Touch With Us!

At Technowave Group, we have a team of experienced professionals who are dedicated to providing high-quality service and support to our clients. We work closely with our clients to understand their unique business needs and provide tailored solutions that help them achieve their goals.

Whether you are a small business or a large enterprise, we can help you leverage technology to improve your warehouse operations and achieve your goals. Contact us today to learn more about our RFID Warehouse Inventory Management System and other technology solutions.

3 notes

·

View notes

Text

How are Warehousing Companies in India Paving the Way for Sustainable Logistics?

Welcome to the world of sustainable logistics in India! Today, we are diving deep into the fascinating realm of warehousing companies and their pivotal role in shaping a greener future for the transport industry. With environmental concerns at an all-time high, these innovative entities have emerged as pioneers, seamlessly blending efficiency with eco-conscious practices. So fasten your seatbelts and join us on this enlightening journey as we unravel how warehousing companies in India are paving the way towards a more sustainable tomorrow.

Introduction to Warehousing Companies

In India, warehousing companies are playing a pivotal role in the development of sustainable logistics. These companies are working to improve the efficiency of the supply chain and reduce the environmental impact of transportation. By investing in new technologies and practices, they are paving the way for a more sustainable future for logistics in India.

Warehousing companies in India are working to improve the efficiency of the supply chain by investing in new technologies and practices. One such technology is radio-frequency identification (RFID) tags, which can track inventory levels and movements within a warehouse. This information can help warehouses to better plan their operations and avoid stock outs. In addition, RFID tags can also help to reduce theft and pilferage.

Another area where warehousing companies are investing is in energy-efficient lighting. LED lights use less energy than traditional incandescent bulbs, and they last longer as well. This means that warehouses can save money on their electricity bills while also reducing their carbon footprint.

In addition to investing in new technologies, warehousing companies are also working to create more efficient operations through process improvements. One example is cross-docking, which is a system whereby incoming products are sorted and loaded onto outbound trucks without being stored in a warehouse first. This reduces handling time and helps to keep inventory levels low. As a result, cross-docking can lead to significant cost savings for warehouses.

By investing in new technologies and practices, warehousing companies in India are paving

Benefits of Warehousing Solutions in India

The benefits of warehousing solutions in India are many and varied. They include:

1. Increased efficiency and productivity: By outsourcing your warehousing needs to a third-party logistics provider, you can free up valuable time and resources that can be better spent on other areas of your business. This can lead to increased efficiency and productivity levels across the board.

2. Cost savings: Warehousing solutions can help you to cut down on your overall costs, as you will no longer need to invest in expensive infrastructure and personnel. This is particularly beneficial for small businesses who may not have the financial resources to invest in their own warehouse space.

3. Flexibility and scalability: A good warehousing solution should offer you flexibility and scalability, so that you can easily adjust your requirements as your business grows. This ensures that you always have the storage space you need, without having to overspend or make do with a smaller facility than you require.

4. Improved customer service: When customers know that their orders are being stored in a safe and efficient manner, they are more likely to be satisfied with your service as a whole. This can lead to improved customer retention rates and repeat business.

5. Enhanced security: Warehousing companies in India typically have high-security standards in place, so you can rest assured that your goods are safe and secure at all times. This gives you peace of mind knowing that your inventory is protected against theft, damage or loss

Overview of Sustainable Logistics Practices

In the present day, with the increase in awareness of the importance of sustainability, many logistics and warehousing companies in India are beginning to adopt sustainable practices. Some common sustainable logistics practices that these companies are implementing are:

-Using energy efficient equipment and technologies: This includes using LED lighting, solar power, electric vehicles etc.

-Reducing water consumption: This can be done by rainwater harvesting, using recycled water for cooling etc.

-Minimising waste: This can be achieved by recycling and reusing packaging materials, adopting lean principles etc.

-Improving labour conditions: This involves providing fair wages and good working conditions for employees.

These are just some of the ways in which warehousing companies in India are making their operations more sustainable. By doing so, they are not only contributing to a better environment but also setting an example for others to follow.

How are Warehousing Companies Impacting Sustainability?

In recent years, there has been a growing awareness of the need for businesses to operate in a more sustainable way. This has led to many companies making changes to their operations in order to reduce their impact on the environment. One area that is often overlooked when it comes to sustainability is logistics. However, there are a number of warehousing companies in India that are paving the way for more sustainable logistics.

These companies are using a variety of methods to reduce their environmental impact, including investing in renewable energy, using recycled materials, and employing green transportation solutions. By making these changes, they are not only helping to protect the environment, but also reducing their operating costs. As more companies become aware of the benefits of sustainable logistics, it is likely that we will see even more warehousing companies in India making the switch to greener operations.

Challenges Faced by Warehousing Companies

The warehousing and logistics industry in India is poised for significant growth in the coming years. However, the sector faces a number of challenges that need to be addressed in order to make this growth sustainable.

Firstly, the sector suffers from a lack of standardization. This makes it difficult for companies to compare and benchmark performance across the industry. Secondly, there is a scarcity of quality warehousing space in India. This has led to high rentals and increased pressure on margins.

Thirdly, the sector is fragmented with a large number of small players. This makes it difficult to achieve economies of scale and leads to higher costs. Fourthly, the workforce in the sector is largely unorganized and unskilled. This results in low productivity and high turnover.

There is a need for better infrastructure to support the growth of the warehousing and logistics industry in India. This includes improved roads, railways, ports, and airports.

Technologies Used for Sustainable Logistics

There are many different technologies that can be used for sustainable logistics, but some of the most popular ones include:

1. Automated Storage and Retrieval Systems (AS/RS): These systems can help to improve both the efficiency and accuracy of inventory management, while also reducing labor costs.

2. Warehouse Management Systems (WMS): A good WMS can help to optimize space usage, labor utilization, and picking strategies. It can also provide real-time visibility into inventory levels and order status.

3. Transportation Management Systems (TMS): A TMS can help to optimize routing and scheduling, as well as track shipments in real time. This information can be used to make more informed decisions about transportation strategies.

4. Green Logistics Technologies: There are a number of different green logistics technologies that can be used to reduce the environmental impact of logistics operations. Some examples include electric vehicles, solar power, and fuel cells.

Conclusion

Warehousing companies in India are paving the way for sustainable logistics by investing in technologies and practices that help to reduce their environmental impact. By increasing efficiency, reducing wastage, improving safety and security, and utilizing renewable energy sources, these companies are making a positive impact on the environment while still providing high-quality services. With continued investment in sustainability initiatives, warehousing companies have the potential to become major players in helping India achieve its sustainability goals.

2 notes

·

View notes

Text

What is a Real-Time Locating System (RTLS) and How Does It Work?

Introduction to Real-Time Location Systems (RTLS) in 2025 by AIDC Technologies

In 2025, Real-Time Location Systems (RTLS) are transforming how businesses track and manage their assets, personnel, and inventory. These systems provide live data on the location of items, helping companies save time, reduce losses, and improve operational efficiency. AIDC Technologies India is at the forefront of offering advanced RTLS solutions combined with robust rfid system technology to deliver smarter, faster, and more reliable tracking.

What Is RTLS? AIDC Technologies Simplifies the Definition

A Real-Time Location System (RTLS) is a technology used to automatically identify and track the location of objects or people in real time within a defined area. The core of many RTLS solutions is the rfid system, which uses radio waves to detect and track tags attached to items. AIDC India explains that RTLS can use several technologies, but RFID is among the most popular due to its accuracy and ease of integration.

How RTLS Works: Technology and Methods Explained by AIDC

RTLS operates by attaching tags or badges to objects or people. These tags emit radio signals picked up by readers or sensors installed around the premises. The data collected is processed by software to provide real-time location information. The rfid system is essential in this process, as it enables wireless communication between tags and readers, allowing seamless tracking. AIDC Technologies ensures that its RTLS solutions use the latest RFID standards for maximum reliability and coverage.

Key Benefits of RTLS for Businesses in 2025

The integration of an rfid system within RTLS offers many benefits. Businesses can quickly locate assets, reduce theft, and monitor employee movements to optimize workflow. RTLS also improves safety by tracking people in hazardous environments. AIDC Technologies India’s RTLS solutions help companies cut operational costs, reduce downtime, and increase productivity by providing precise location data instantly.

Top Industries Using RTLS Solutions from AIDC Technologies

RTLS powered by an rfid system is widely used across multiple sectors. In healthcare, hospitals track medical equipment and patients to enhance care. Manufacturing plants use RTLS to monitor tools and work-in-progress items. Logistics companies improve inventory management and shipping accuracy. Retailers prevent loss and improve stock visibility. AIDC India customizes its RTLS and RFID solutions to fit the specific needs of each industry.

Challenges in RTLS Implementation and How AIDC Overcomes Them

Deploying an RTLS with an rfid system can be complex due to factors like signal interference, infrastructure needs, and data management. AIDC Technologies India tackles these challenges by conducting thorough site surveys, designing tailored systems, and providing ongoing support. Their experts ensure seamless integration and minimal disruption to existing operations, helping clients maximize the return on their RTLS investment.

Integration of RTLS with Other Business Systems

For true operational efficiency, RTLS solutions by AIDC Technologies integrate smoothly with ERP, warehouse management, and security systems. The rfid system data feeds into these platforms to provide a unified view of asset location, status, and movement. This integration helps managers make informed decisions, automate processes, and ensure compliance with safety and quality standards.

AIDC Technologies’ Customized RTLS Solutions for Your Business

Every business has unique requirements. AIDC India offers customized RTLS solutions based on the company’s size, environment, and goals. Their advanced rfid system technology can be adapted for indoor and outdoor use, fixed or mobile tracking, and various tag types. AIDC’s team works closely with clients to design, implement, and maintain systems that fit perfectly and grow with the business.

Case Studies: Successful RTLS Deployments by AIDC Technologies

Several clients across India have benefited from AIDC’s RTLS combined with an rfid system. Hospitals have reduced equipment loss by 40%, manufacturing plants have improved production tracking, and logistics firms have enhanced shipment accuracy. These success stories highlight how AIDC’s technology and expertise create real value, making RTLS an essential tool for modern businesses.

Get Started with Smarter Tracking: Contact AIDC Technologies Today

If you want to leverage the power of RTLS and an rfid system to improve your business operations, AIDC Technologies India is your trusted partner. Their experts offer consultations, system design, installation, and ongoing support to ensure a smooth transition to smarter tracking. Book your consultation today and take the first step toward transforming how you manage your assets and people with cutting-edge RTLS solutions.

Ready to enhance your tracking with advanced RTLS and RFID systems? Book Now with AIDC Technologies India and secure smart, reliable solutions tailored to your business needs.

#WhatIsRTLS#RTLSforSmartTracking#RealTimeLocationSystem#RTLS2025Tech#RTLSWorkingExplained#AIDCTrackingSolutions

0 notes

Text

Best Warehouse Management System In India - AWL India Discover the power of End to End Warehouse Management System, streamlining your logistics journey from the first crate to the final delivery. Say goodbye to complexities & say hello to seamless efficiency. To know more, visit - https://www.awlindia.com/smart-warehouses

#warehouse service providers in india#rfid warehouse management#rfid warehouse management solution#iot based warehouse management system#warehouse management system using rfid#smart warehouse management system#warehouse management#warehouse management process#warehouse management system#AWL India#smart warehousing solutions#smart warehouse

3 notes

·

View notes

Text

How Forklift Pedestrian Alert Systems Reduce Workplace Accidents

In fast-paced industrial environments, forklifts are vital for efficient material handling. However, their presence also brings significant risk, especially when pedestrians share the same workspace. According to OSHA (Occupational Safety and Health Administration), forklift accidents cause around 85 fatalities and over 34,000 serious injuries each year in the U.S. alone. A substantial number of these incidents involve pedestrians.

To address this persistent issue, warehouses and logistics companies are turning to Forklift Pedestrian Alert Systems (FPAS)—an innovative safety solution that bridges the gap between human awareness and automated safety. These systems are designed to detect and alert both forklift operators and pedestrians in real-time to avoid collisions. The result? Fewer accidents, a safer workplace, and enhanced operational efficiency.

This article explores how FPAS work, the problems they solve, and why they are becoming a critical component in modern warehouse safety strategies.

1. The Root of the Problem: Forklift-Pedestrian Interactions

Forklifts can weigh several tons and often operate with limited visibility, especially when carrying bulky loads. Pedestrians, on the other hand, may be focused on their tasks, distracted, or simply unaware of approaching vehicles. This combination creates a high-risk environment.

Common causes of forklift-pedestrian accidents include:

Blind spots and narrow aisles

Poor lighting in corners or intersections

Lack of dedicated pedestrian pathways

Distracted operators or pedestrians

Human error or rule violations

While safety training and signage play important roles, these passive measures are often not enough to prevent accidents. That's where FPAS come into play.

2. What Are Forklift Pedestrian Alert Systems?

Forklift Pedestrian Alert Systems are technology-driven safety tools that detect the presence of people near moving forklifts and issue real-time alerts to prevent accidents. These systems are designed to provide proactive, automated warnings rather than relying solely on human judgment.

Key components of FPAS may include:

Proximity sensors: Detect when pedestrians enter a pre-defined danger zone

RFID tags: Worn by workers, enabling forklifts to detect and respond to their presence

Wearables: Devices that alert pedestrians through vibration, sound, or lights

Cameras and AI: Advanced systems that visually detect human movement

Dashboard alerts or automated braking for forklift operators

The primary goal of these systems is to reduce the likelihood of collisions, especially in areas where foot traffic and forklifts cross paths.

3. How FPAS Actively Reduce Workplace Accidents

✅ A. Real-Time Hazard Detection

FPAS systems monitor a forklift’s surroundings in real-time. When a pedestrian enters the defined safety zone, the system immediately alerts the driver with visual, audible, or vibration signals. In some advanced systems, the forklift may automatically slow down or stop to avoid an accident.

This immediate response drastically improves reaction time, often preventing collisions that would occur if relying on human awareness alone.

✅ B. Eliminating Blind Spot Risks

In many facilities, tight corners, intersections, and cluttered aisles can limit visibility. Mirrors and lighting help, but they still depend on the operator looking in the right direction at the right time.

FPAS reduce this dependency by automatically detecting pedestrians even in obstructed or low-visibility areas, ensuring safer navigation throughout the warehouse.

✅ C. Two-Way Awareness

Many FPAS include wearable devices for pedestrians. These devices alert the pedestrian when a forklift is nearby, creating a mutual awareness system. This two-way communication helps both parties take preventive action simultaneously.

This is especially valuable in loud environments, where forklift alarms may be drowned out by background noise.

✅ D. Supporting High-Risk Zones

Certain areas in a warehouse—like loading docks, intersections, or shared access zones—are more prone to accidents. FPAS can be strategically installed in these locations to create intelligent safety zones, offering heightened protection where it's needed most.

✅ E. Reducing Human Error

No matter how well-trained a workforce is, humans are prone to lapses in attention. Fatigue, multitasking, or distractions (like mobile phones) can all contribute to unsafe behavior. FPAS serve as a backup safety layer that compensates for these inevitable errors.

✅ F. Data-Driven Safety Improvements

Many modern FPAS log safety events and near-miss incidents. This data can be analyzed to:

Identify high-risk areas

Adjust safety protocols

Modify traffic routes

Improve staff training

By turning safety into a measurable and improvable process, organizations can create a cycle of continuous improvement.

4. Real-World Benefits and Case Studies

Businesses that have implemented FPAS report substantial safety improvements:

Case Study: Logistics Hub in Bengaluru

A large distribution center installed RFID-based FPAS across its forklift fleet and mandated pedestrian wearables for all floor staff. Within six months:

Accidents reduced by 70%

Near-miss incidents fell by 60%

Employee surveys showed a marked increase in perceived safety

Additionally, the company used logged data to redesign pedestrian walkways and adjust training protocols.

5. Beyond Safety: Operational and Financial Gains

While the primary goal of FPAS is to improve safety, the benefits extend further:

Cost Reduction

Workplace injuries can lead to compensation claims, legal liabilities, damaged equipment, and lost productivity. Avoiding even a single major accident can save thousands in costs.

Improved Workflow

With fewer disruptions from safety incidents and investigations, operations run more smoothly. Forklift operators feel more confident navigating busy spaces.

Regulatory Compliance

Implementing FPAS shows a proactive approach to safety and can help meet OSHA, ISO, and local compliance standards.

6. Considerations Before Implementation

To get the most out of an FPAS, businesses should evaluate:

Facility layout: Where do forklifts and pedestrians interact most?

Workforce size and turnover: High turnover may increase the need for wearable alerts

Technology compatibility: Choose systems that integrate with your existing forklifts and IT systems

Scalability: Ensure the system can grow as your facility expands

Also, it’s vital to train all workers on how the system operates and what the alerts mean.

7. FPAS as Part of a Holistic Safety Strategy

FPAS are highly effective, but they shouldn’t operate in isolation. They are most beneficial when used alongside:

Regular training programs

Clear pedestrian walkways

Floor markings and barriers

Scheduled forklift maintenance

This combination creates a layered safety environment that offers the highest level of protection.

Conclusion

Forklift Pedestrian Alert Systems are revolutionizing how industrial facilities approach workplace safety. By providing automated, real-time alerts, these systems significantly reduce the risk of accidents caused by blind spots, human error, or distractions. The result is a safer, smarter, and more efficient work environment.

If your goal is to protect your employees, maintain productivity, and avoid costly accidents, FPAS should be at the top of your warehouse safety checklist.

0 notes

Text

Enhancing Operational Efficiency with Inventory Tracking Systems and Modern Supply Chain Technology

In today’s fast-paced and hyper-competitive market, businesses can no longer rely on manual processes to manage their logistics. Precision, speed, and visibility are now vital components of successful operations. That’s why implementing an advanced inventory tracking system, leveraging intelligent Supply Chain Technology, and optimizing warehouse management are crucial for companies aiming to scale efficiently and meet rising customer expectations.

The Power of a Modern Inventory Tracking System

An inventory tracking system plays a central role in ensuring businesses always know what stock they have, where it’s located, and how it’s moving. Gone are the days of spreadsheets and handwritten logs. Today’s systems use barcoding, RFID, and cloud-based software to deliver real-time visibility and accuracy across the entire supply chain.

Benefits of an Inventory Tracking System:

Real-Time Visibility: Track stock levels across multiple warehouses and locations

Reduced Stockouts and Overstocks: Maintain optimal inventory levels

Increased Accuracy: Eliminate human error through automation

Faster Order Fulfillment: Improve pick, pack, and ship processes

Data-Driven Decisions: Use analytics for better forecasting and inventory planning

An efficient inventory system not only minimizes waste but also improves the customer experience by ensuring timely and accurate order fulfillment.

Supply Chain Technology: Driving Innovation and Agility

Supply Chain Technology is the backbone of modern logistics. It integrates everything from procurement and production to fulfillment and reverse logistics. Smart supply chain platforms harness technologies like AI, IoT, machine learning, and blockchain to optimize processes and reduce operational risks.

Core Elements of Advanced Supply Chain Technology:

Automation of repetitive and labor-intensive tasks

Predictive analytics for demand planning and forecasting

End-to-end visibility from supplier to customer

Cloud-based collaboration tools for seamless communication across departments

Sustainability tracking to minimize carbon footprints and waste

With cutting-edge technology, businesses can respond faster to disruptions, reduce costs, and increase operational agility.

Optimizing Warehouse Management for Maximum Efficiency

Efficient warehouse management is key to reducing operational bottlenecks and enhancing order accuracy. Whether you’re managing a single distribution center or a network of warehouses, having the right warehouse management system (WMS) in place is essential.

Key Functions of Warehouse Management Systems:

Slotting optimization to improve picking speed

Real-time inventory updates across locations

Workforce productivity tracking

Returns management

Integration with eCommerce and ERP platforms

When combined with a robust inventory tracking system, effective warehouse management ensures that stock is received, stored, and shipped with maximum precision and minimum delay.

Conclusion

The success of any logistics or retail operation hinges on how well it manages its inventory, warehouse, and supply chain. Implementing an intelligent inventory tracking system, adopting modern Supply Chain Technology, and streamlining warehouse management can lead to increased productivity, reduced costs, and a significantly improved customer experience.

In a world where efficiency equals competitiveness, it’s no longer a question of if you should invest in advanced systems—but when. The sooner you do, the faster your business will thrive in a technology-driven economy.

For original post visit: https://pittsburghpenguinsclub.com/read-blog/24741_enhancing-operational-efficiency-with-inventory-tracking-systems-and-modern-supp.html

0 notes

Text

The Power of RFID in Warehouse Management: Efficiency, Accuracy & Beyond

In today’s fast-paced supply chains, RFID (Radio-Frequency Identification) is revolutionizing warehouse operations—replacing outdated barcode systems with real-time, touchless tracking. Here’s how RFID boosts speed, cuts costs, and minimizes errors in logistics:

🔍 Key Applications of RFID in Warehousing

Instant Inventory Tracking

Scan hundreds of items per second without line-of-sight (unlike barcodes).

No manual counting—reduce human error by up to 90%.

Automated Receiving & Shipping

RFID gates detect incoming/outgoing pallets instantly, slashing processing time.

Eliminate mismatched shipments with item-level visibility.

Smart Shelf & Stock Alerts

Sensors trigger low-stock warnings or detect misplaced items.

Perfect for high-value or perishable goods.

Forklift & Asset Tracking

Monitor equipment movement and optimize workflow paths.

Theft Prevention & Security

Tamper-proof tags alert unauthorized removals.

💡 Why RFID Outperforms Barcodes

✅ No scanning needed – Reads multiple tags through packaging. ✅ Durable – Withstands heat, dust, and moisture. ✅ Data-rich – Stores history, expiry dates, maintenance logs.

📈 ROI Spotlight

Companies like Amazon & Walmart cut inventory costs by 20-30% after RFID adoption.

Future-Proof Your Warehouse! From retail to pharmaceuticals, RFID is the backbone of Industry 4.0 logistics. Ready to upgrade?

0 notes

Text