#Reefer Compressor

Explore tagged Tumblr posts

Text

0 notes

Text

Understanding Truck Refrigeration Units: Function, Maintenance & Repair Insights

The modern logistics industry relies heavily on precision, especially when it comes to transporting perishable goods. At the center of cold chain logistics lies the Truck Refrigeration Unit—a critical component that ensures food, medicine, and other temperature-sensitive items reach their destination safely. As the demand for freshness grows, so does the importance of these specialized units and the need for reliable Truck Refrigeration Repairs.

What is a Truck Refrigeration Unit?

A Truck Refrigeration Unit (TRU) is a temperature control system installed on trucks and trailers designed to maintain specific climates within the cargo space. These systems come in various sizes and capacities, from small vans delivering local produce to large reefer trucks handling cross-country shipments.

TRUs are generally powered by either diesel engines or integrated electric systems, and they use refrigerants to manage the internal temperature. Proper functioning is essential not only for maintaining product quality but also for meeting strict regulatory compliance in sectors such as food and pharmaceuticals.

Types of Truck Refrigeration Units

Each type has its advantages and limitations, depending on operational needs, budget, and environmental considerations.

The Importance of Regular Truck Refrigeration Repairs

Just like any mechanical system, TRUs are subject to wear and tear. Malfunctioning refrigeration during transit can result in significant financial losses, damaged cargo, and even legal repercussions. That’s why consistent maintenance and timely Truck Refrigeration Repairs are essential.

Common Repair Needs Include:

Compressor failures

Refrigerant leaks

Electrical malfunctions

Thermostat or sensor issues

Ignoring these problems not only shortens the life of the unit but can also compromise entire shipments.

Expert Insight: What the Industry Says

“Temperature control is non-negotiable. A single faulty sensor can jeopardize thousands of dollars' worth of inventory. We schedule inspections every 30 days.” — Logistics Manager, ColdChainX

“We had a compressor fail mid-route once. Our service provider responded quickly, and since then, we've invested in better routine checks. It saves money in the long run.” — Owner-Operator, Midwest Freightlines

These testimonials highlight a growing awareness within the industry about the long-term benefits of proactive repairs and maintenance.

Signs Your TRU Needs Immediate Attention

Knowing when a unit requires servicing can prevent costly downtime. Watch out for:

Unusual noises or vibrations

Inconsistent cargo temperatures

Frequent on/off cycling

Error codes on control panels

If any of these symptoms arise, it’s crucial to seek professional Truck Refrigeration Repairs immediately.

Maintenance Tips to Extend Unit Lifespan

Regular upkeep helps maintain efficiency and reduces the frequency of repairs. Here are a few essential practices:

Monthly System Checks – Inspect belts, filters, and refrigerant levels.

Battery & Electrical Review – Ensure reliable starts and monitor control systems.

Clean Condensers – Prevents overheating and ensures proper airflow.

Seasonal Calibration – Adapt the unit for varying temperatures and humidity levels.

Sticking to a preventive maintenance schedule helps keep the unit in optimal working condition year-round.

Final Thoughts

In a sector where timing and temperature are everything, the Truck Refrigeration Unit plays a crucial role in maintaining supply chain integrity. Operators and logistics professionals who prioritize maintenance and prompt Truck Refrigeration Repairs stand to gain not only in operational efficiency but also in reputation and compliance.

As consumer expectations continue to evolve toward faster and fresher deliveries, businesses must ensure their refrigeration systems remain up to the task—reliable, resilient, and ready for the road.

0 notes

Text

Inside the Toolbox What Sacramento's Mobile Truck Mechanics Bring to Every Job

Out on the road or stuck in a lot—trucks break in weird ways at worse times. A rig loses air pressure at 5 a.m. A reefer unit won’t cool near Watt Avenue.

You don’t have time for a slow tow or a crowded Truck Repair Shop line. You need help right now. That’s where Mobile Truck Repair becomes the ace in your back pocket.

But what exactly shows up in that big mobile van? Let’s pop the doors open and walk through it.

More Than Wrenches and Jumper Cables

Mobile crews don’t come lightly armed. We’re not talking about a guy with a flashlight. We’re talking real gear. Pro-grade. Smart tools.

This is what rolls up when you call Truck Repair in Sacramento:

High-torque impact guns for fast tire swaps

Battery testers that catch bad cells before they strand you

DEF system scanners that speak fluent Freightliner

Diagnostic tablets synced with Kenworth, Hino, Ford, and Peterbilt

Cooling system pressure kits

Crimpers cutters wire testers for fast electrical saves

Jack stands compressors and fluid flush kits

On-board batteries generators and lighting

Emergency brake chambers ready for same-day installs

If it breaks on a truck—we’ve likely got a part for it somewhere in the van.

What We Fix Without Leaving Your Spot

Our tools match real Sacramento problems. This isn’t guesswork. It’s daily patterns from actual breakdowns in yards lots and driveways.

Leaky radiators near Power Inn

Frozen air lines in Rancho Cordova

Bad fuel injectors off Del Paso

Generator failures on RV kitchens near Folsom

Broken door latches in Elk Grove box trucks

Flat tires in Midtown back alleys

No need for a Truck Repair Shop visit. We bring the fix straight across town right into your space.

Why Choose Us

1. Sacramento-Centric Response We know this city. Fast rollouts from San Juan to Florin. No wasted time.

2. Toolbox That Travels We don’t say “we’ll be back with tools.” We bring them all the first time.

3. Built for Heavy Brands Freightliner, Isuzu, Ram, International—our gear fits what your fleet runs.

4. RV Owners Welcome Mobile RV Repair covers rooftop ACs awnings lighting plumbing leaks and power boards.

5. Less Downtime Less Cost No towing no shop waits no lost hours. One truck one crew one solution.

6. Real Talk Repairs We explain what broke how we fix it and what stops it next time. No filler.

FAQs

1. Do your mobile units carry battery testers for semis near North Natomas?

Yes. We run voltage load and alternator diagnostics during any Mobile Truck Repair job in that area.

2. My RV has a leaking roof in Rosemont. Can you patch it on location?

We sure can. Our Mobile RV Repair team brings sealant tools and test gear straight to you.

3. Do you replace air brake chambers off Elder Creek or Gerber Road?

Absolutely. We stock multiple chamber sizes and replace or adjust on-site fast.

4. Can your crew repair power issues in a food truck near Broadway in Sacramento?

Yes. We diagnose shorts fix connections and restore power as part of RV Repair and truck support.

5. We operate five Isuzus out of Arden. Can you handle routine service and urgent repairs?

Yes. Our Mobile Truck Repair setup is built for fleet work. Same-day turnaround when possible.

6. Is mobile faster than dropping off at a local Truck Repair Shop near Raley Blvd?

No contest. You avoid tow fees service lines and lost bookings. We fix fast where you stall.

Ready When the Truck Isn’t

A great mechanic isn’t just a wrench in a toolbox. It’s the whole toolbox showing up right when you need it. That’s what Sacramento gets when Mobile Truck Repair rolls in.

📍 Affordable Truck Repair Inc. DBA Mechanic On Road 📞 +1 (916) 912-7912 📍 San Juan Rd, Sacramento, CA 95834

Skip the drama. Skip the lot shuffle. Let us fix it right where you park it. Mobile RV Repair and Mobile Truck Repair that shows up loaded and leaves nothing behind but a job well done.

0 notes

Text

The Importance of Reefer Repair in Lanham, MD: Keeping Your Business on Track

In today’s fast-paced world, especially for businesses that rely on transporting perishable goods, having a fully functional reefer is crucial. Whether you're in the food industry, pharmaceuticals, or any sector requiring temperature-sensitive transportation, reefer repair in Lanham, MD is an essential service that ensures your goods are safely stored and transported at the proper temperatures.

When a reefer breaks down or malfunctions, it can lead to severe disruptions. Goods can spoil, business operations are delayed, and, worst of all, financial losses can pile up quickly. That’s why timely and professional reefer repair services in Lanham are so important. In this article, we’ll dive into why reefer maintenance is vital, common issues that might require repair, and how you can prevent costly breakdowns.

Why Reefer Maintenance Matters

Reefers, or refrigerated trailers, are more than just storage units; they are integral to ensuring that your products reach their destination in the best possible condition. As a business owner or manager, it's vital to understand the importance of routine reefer maintenance and prompt repair when needed.

In Lanham, MD, where businesses serve a wide array of industries, maintaining a functional reefer system means avoiding potential risks, such as spoiled goods or temperature non-compliance that could affect your business reputation. Reefer repair in Lanham, MD helps businesses keep up with regulations and ensures that your refrigerated units function optimally year-round.

Reefers are designed to work under demanding conditions, and over time, wear and tear is inevitable. Regular repair and maintenance can reduce unexpected breakdowns and costly repairs. The result? Fewer disruptions, fewer losses, and a more efficient operation.

Common Reefer Issues That Need Repair

Reefers may seem like robust systems, but they’re prone to various issues that can affect performance. Understanding these common problems can help you know when it's time to call for reefer repair in Lanham, MD.

1. Temperature Fluctuations

The primary purpose of a reefer is to maintain a consistent temperature. If the reefer begins experiencing temperature fluctuations, it can be a sign of a malfunctioning thermostat, refrigerant leak, or issues with the compressor. In any case, you’ll need an experienced professional to pinpoint the cause and make necessary repairs.

2. Compressor Failures

The compressor is the heart of any refrigeration system, and if it fails, the reefer won’t be able to keep the goods at the correct temperature. Compressor issues are common but can be costly if not addressed quickly. Professional repair technicians in Lanham, MD can often diagnose and repair compressor problems before they lead to total failure.

3. Frost or Ice Build-Up

Excessive frost or ice buildup is a sign that your reefer’s defrost system is malfunctioning. If left untreated, this can impair airflow and decrease cooling efficiency. If you notice frost accumulation inside the unit, it’s important to have a technician check the defrost system to ensure that the issue doesn’t escalate.

4. Refrigerant Leaks

Refrigerant is crucial for maintaining low temperatures in a reefer. If the system develops a leak, it won’t be able to cool efficiently, which can lead to temperature irregularities. Signs of a refrigerant leak include a rise in temperature and increased running time of the unit. Immediate repair is necessary to restore proper function and prevent food spoilage.

5. Electrical Problems

Electrical issues can be tricky to diagnose and resolve. Faulty wiring, malfunctioning control boards, or blown fuses can cause the reefer to stop working altogether or lead to inconsistent temperature control. Electrical repairs should always be left to licensed professionals who have experience with reefer systems.

The Benefits of Professional Reefer Repair in Lanham, MD

When your reefer system is down, you need quick, efficient, and reliable repairs. That’s where professional reefer repair in Lanham, MD comes in. Here are some of the key benefits of choosing professional services:

1. Expert Diagnosis and Repair

Refrigeration systems are complex, and diagnosing the root cause of an issue requires specialized knowledge and experience. A professional repair technician has the expertise to identify the problem quickly and provide the correct solution, whether it’s replacing a faulty part or recalibrating the system.

2. Prevention of Further Damage

Trying to repair a reefer yourself can lead to additional damage, especially if you're unfamiliar with how the system works. Professionals have the proper tools and training to prevent accidental damage, which can save you money in the long run. By addressing the issue right away, they also prevent minor problems from escalating into major (and costly) failures.

3. Regulatory Compliance

If your business relies on transporting food or pharmaceuticals, you’re likely subject to strict health and safety regulations. Having your reefer repaired by certified technicians ensures that your unit is functioning in compliance with these regulations, so you can avoid costly fines or penalties.

4. Peace of Mind

Knowing that your reefer is in good hands brings peace of mind. With regular maintenance and timely repairs, you can rest assured that your refrigerated unit is running smoothly, keeping your goods safe and your business operations uninterrupted.

Finding Reliable Reefer Repair Services in Lanham, MD

When it comes to reefer repair in Lanham, MD, you want a company that you can trust. Here’s how to find a reputable repair service:

Check Reviews and References: Look for a company with positive reviews and references from other local businesses. Word-of-mouth recommendations can be invaluable in choosing the right service provider.

Experienced Technicians: Ensure that the company employs technicians with experience working on reefer systems specifically. They should have a solid track record of fixing issues similar to yours.

Emergency Services: Your reefer can break down at any time, so find a repair service that offers emergency services. Fast response times are essential to minimize downtime.

Transparent Pricing: A reputable company will offer clear, upfront pricing with no hidden fees. Make sure to ask for a detailed estimate before the work begins.

Conclusion: Keep Your Business Running Smoothly with Reefer Repair in Lanham, MD

Whether you're transporting food, pharmaceuticals, or other temperature-sensitive goods, reefer repair in Lanham, MD is essential for maintaining the integrity of your business. Regular maintenance and timely repairs help ensure that your refrigeration units continue to operate efficiently, keeping your goods at the right temperature and your business running smoothly.

Don't wait until a small issue becomes a major problem. Reach out to a professional reefer repair service today and keep your business on track with minimal disruptions. Your reefer is a vital part of your operation—take care of it, and it will take care of you.

1 note

·

View note

Text

How to Prevent Reefer Failures with Regular Repair Service Near California, USA

Temperature-sensitive cargo requires a dependable reefer repair service near California USA to prevent spoilage. Regular checkups on compressors, cooling systems, and electrical components can reduce the risk of breakdowns. When unexpected issues arise, a trusted mobile truck service can get you back on the road without delays.

0 notes

Text

Trusted Reefer Repair Services: Keep Your Fleet Running Smoothly

For businesses relying on refrigerated transport, a malfunctioning reefer unit can cause significant disruptions. Whether you're in food distribution, pharmaceuticals, or logistics, maintaining your refrigerated truck or trailer is essential. If you're searching for Reefer Repair Services In Greater Landover, MD, working with experienced professionals ensures that your reefer units stay in top condition, minimizing downtime and protecting your cargo.

Why Reefer Repair Services Are Crucial

A faulty reefer unit can lead to:

Cargo spoilage – Perishable goods such as food, medicine, and chemicals require stable temperatures.

Regulatory violations – Many industries must comply with strict temperature control regulations.

Increased costs – Repairs, fuel inefficiencies, and spoiled cargo can quickly add up.

Delayed deliveries – A broken reefer unit can disrupt schedules and impact customer trust.

By investing in quality reefer repair and maintenance, you ensure reliable performance and prevent costly breakdowns.

Common Reefer Unit Issues and How to Fix Them

Refrigerated transport units require regular maintenance to avoid common issues. Here are some typical problems and their solutions:

1. Reefer Unit Not Cooling Properly

Causes: Low refrigerant levels, dirty condenser coils, or malfunctioning sensors

Solution: Refill refrigerant, clean condenser coils, and test sensors for accuracy

2. Engine Won’t Start

Causes: Battery failure, faulty starter, or fuel system issues

Solution: Check battery voltage, inspect starter motor, and ensure fuel supply is clean

3. Compressor Failure

Causes: Overheating, worn-out parts, or oil leaks

Solution: Perform regular oil changes, monitor temperature levels, and replace damaged components

4. Temperature Fluctuations

Causes: Faulty thermostat, improper airflow, or blocked evaporator coils

Solution: Calibrate thermostat, check for blockages, and ensure proper ventilation

Benefits of Professional Reefer Repair Services

When you hire a trusted service for Reefer Repair Services In Greater Landover, MD, you get:

✅ Expert Technicians – Skilled professionals can quickly diagnose and repair problems. ✅ Emergency Repair Support – 24/7 service options to minimize downtime. ✅ Regulatory Compliance – Ensure your reefer units meet FDA and DOT standards. ✅ Long-Term Cost Savings – Preventative maintenance helps avoid major breakdowns.

How to Choose the Right Reefer Repair Service in Greater Landover, MD

Finding the best reefer repair provider requires careful consideration. Here’s what to look for:

🔹 Certified Technicians – Ensure they have experience with all major reefer brands. 🔹 Mobile Repair Services – On-site repairs save time and prevent delays. 🔹 Customer Reviews – Check ratings and feedback for reliability and quality of service. 🔹 Comprehensive Services – A full range of maintenance, diagnostics, and repairs ensures all needs are covered.

Pro Tips for Reefer Unit Maintenance

To extend the life of your reefer unit and avoid unexpected failures, follow these maintenance tips:

Inspect units regularly – Check for leaks, wear and tear, and unusual noises.

Monitor temperature settings – Ensure the reefer unit is maintaining the correct temperature.

Clean condenser and evaporator coils – Blockages reduce efficiency and can lead to overheating.

Use high-quality fuel and oil – Poor-quality fuel can damage the engine and affect performance.

Schedule preventative maintenance – Regular check-ups from Reefer Repair Services In Greater Landover, MD keep your unit in peak condition.

Conclusion

Refrigerated transport is essential for businesses dealing with perishable goods, and a well-maintained reefer unit ensures smooth operations. By choosing professional Reefer Repair Services In Greater Landover, MD, you can reduce downtime, protect your cargo, and keep your fleet running efficiently. Prioritize maintenance and repairs to avoid costly breakdowns and maintain the highest standards in refrigerated logistics.

Need a Reliable Reefer Repair Service?

Don’t wait for a breakdown—schedule a maintenance check today to keep your refrigerated truck in top condition!

0 notes

Text

What Is Reefer Repair? A Complete Guide

If you’re in the trucking or logistics industry, you’ve probably heard the term “reefer” before. But if you’re new to the game, you might be wondering: What exactly is reefer repair, and why is it so important?

Let’s break it down in simple terms and discuss why GoGo Logistics and Transport Services in Lanham, MD, is the best choice for reefer repair services.

What Is a Reefer?

A reefer is short for refrigerated trailer—a specially designed truck trailer equipped with a cooling system that keeps perishable goods at a consistent temperature during transportation. These trailers are essential for industries like food distribution, pharmaceuticals, and floral delivery, where temperature-sensitive products must stay fresh.

Since reefers run almost non-stop, their cooling units can wear out or malfunction over time. This is where reefer repair comes into play.

Why Is Reefer Repair Important?

Reefer trailers are the backbone of cold chain logistics. If they break down, it can lead to:

✅ Spoiled Products – A faulty reefer can cause perishable items to go bad, leading to massive financial losses.

✅ Regulatory Issues – The FDA and USDA have strict guidelines on transporting perishable goods. A malfunctioning reefer could mean failing compliance checks.

✅ Delayed Deliveries – A reefer breakdown can disrupt schedules, causing delays and unhappy customers.

That’s why regular maintenance and timely repairs are crucial to keeping these units running smoothly.

Common Reefer Problems and Repairs

Like any machinery, reefer trailers face wear and tear. Here are some common reefer issues and their fixes:

1. Temperature Fluctuations

Problem: The reefer isn’t cooling properly, leading to temperature inconsistencies.

Solution: This could be due to a faulty thermostat, refrigerant leaks, or sensor malfunctions. A reefer technician can diagnose and fix the issue.

2. Compressor Failure

Problem: The compressor is the heart of the refrigeration system. If it fails, the reefer won’t cool at all.

Solution: This often requires a compressor repair or replacement, ensuring the system runs efficiently.

3. Electrical Issues

Problem: Faulty wiring, battery problems, or sensor malfunctions can lead to reefer failure.

Solution: A professional reefer repair technician can troubleshoot electrical problems and ensure all connections are secure.

4. Refrigerant Leaks

Problem: If the refrigerant leaks, the reefer won’t cool properly, and energy consumption increases.

Solution: A certified technician will locate and seal the leak and recharge the refrigerant.

5. Door Seal Damage

Problem: Damaged door seals allow warm air to enter, causing temperature fluctuations.

Solution: Replacing the door seals ensures a tight, efficient cooling system.

Why Choose GoGo Logistics and Transport Services for Reefer Repair?

When it comes to reefer repair, you need a service provider that understands the urgency of keeping your fleet running. That’s why GoGo Logistics and Transport Services in Lanham, MD, is the best choice.

✅ Expert Technicians – Their highly skilled mechanics specialize in diagnosing and fixing reefer issues efficiently.

✅ Fast Turnaround – Time is money in the logistics business. They offer quick repair services to get your reefer back on the road ASAP.

✅ Preventative Maintenance – They don’t just fix problems—they prevent them! Routine maintenance services help avoid costly breakdowns.

✅ 24/7 Emergency Services – Breakdowns don’t always happen during business hours. They offer round-the-clock assistance to keep your reefer running.

Final Thoughts

Reefer repair is essential for any business relying on temperature-controlled transportation. Regular maintenance and timely fixes can prevent major losses, ensure compliance, and keep deliveries on schedule.

If you’re looking for the best reefer repair service in Lanham, MD, GoGo Logistics and Transport Services is your go-to solution. Their expert team, quick turnaround, and 24/7 service make them the ideal choice for keeping your fleet in top shape.

Need reefer repair? Contact GoGo Logistics and Transport Services today and keep your business moving!

0 notes

Text

Top Benefits of Shipping Frozen Goods with GFFCA’s Intermodal Reefer Solutions

The transportation of frozen goods requires constant temperature control to maintain product quality and safety. Whether through air freight, ocean freight, or inland solutions, GFFCA offers unparalleled intermodal reefer services designed to meet your shipping needs efficiently and reliably.

In this blog, we explore the benefits of shipping frozen goods with GFFCA’s intermodal solutions. From efficiency and cost-effectiveness to environmental advantages, learn how we help ensure your frozen goods arrive at their destination in perfect condition.

So, let’s dive in before the heat rises. Let’s talk about frozen shipping with GFFCA!

What Are Intermodal Reefers?

Refrigerated containers, often referred to as reefer containers, are essential for Shipping goods that require precise temperature control throughout the shipping process. These specialized containers are equipped with advanced refrigeration units that maintain consistent internal temperatures, preventing spoilage or damage to temperature-sensitive products.

At GFFCA, our reefer containers are powered by sophisticated temperature-control technology, ensuring reliability across all modes of transport — air shipping , ocean freight , and inland solutions. Whether you’re shipping perishable goods, pharmaceuticals, or delicate materials, our intermodal reefers are designed to safeguard your cargo from origin to destination.

Common Reefer Misconceptions

A common misconception is that frozen intermodal transportation is either unreliable or slow. However, this couldn’t be further from the truth. GFFCA’s intermodal reefer solutions combine the speed of air freight, the scalability of ocean freight, and the flexibility of inland transport to deliver a seamless shipping experience.

Let’s break down the process to show how reefer intermodal shipping works at GFFCA.

Basic Reefer Intermodal Types

When utilizing GFFCA’s intermodal reefer services, customers can choose from the following approaches based on their specific shipping needs:

Load and Cool: Fresh products are loaded into the container, and the reefer unit cools the cargo to the desired temperature during transit.

Load and Go: Frozen products are pre-cooled before loading, and the reefer maintains the set temperature as the cargo is transported to its destination.

Wait for Temperature: Frozen products are loaded into the container, and the reefer unit is monitored on-site until the desired temperature is achieved before departure.

Understanding these shipping methods helps optimize transit times and costs, ensuring the safe and timely delivery of your frozen goods.

How Do GFFCA’s Intermodal Reefers Work?

Our reefer containers operate using advanced refrigeration technology. A robust cooling system, powered by a compressor and refrigerant, extracts heat from the container’s interior to maintain precise temperature settings. These units continuously monitor and adjust the internal climate to counter external factors like ambient temperature and humidity, keeping your products safe and fresh throughout their journey.

Who Uses GFFCA’s Intermodal Reefers?

GFFCA’s intermodal reefer solutions cater to a wide range of industries. Let’s explore some examples:

1. Global Food Chains and Restaurants

Foodservice distribution is vital to the global supply chain. GFFCA’s reefer services ensure that perishable ingredients like seafood, meat, and produce remain fresh from source to destination, enabling restaurants to serve top-quality meals.

2. Grocery Delivery Services

Refrigerated transportation is critical for delivering fresh produce, dairy, and other temperature-sensitive goods directly to consumers. GFFCA helps grocery delivery companies maintain product integrity every step of the way.

3. Pharmaceutical Companies

Many medications require strict temperature control to remain effective. GFFCA’s reefer solutions provide a dependable means of transporting pharmaceuticals to distributors, hospitals, and pharmacies worldwide.

4. Specialty Goods and High-End Products

From fine art requiring climate-controlled environments to sensitive chemicals, GFFCA’s intermodal reefers offer precise temperature management for valuable and fragile cargo.

The GFFCA Advantage

With GFFCA, you get:

Global Reach: Seamlessly ship frozen goods across continents with our integrated air, ocean, and inland solutions.

Efficiency: Reduce transit times with our strategically planned intermodal routes.

Cost-Effectiveness: Optimize your shipping budget with competitive rates tailored to your needs.

Sustainability: Lower your carbon footprint with eco-friendly transportation options.

Conclusion

From the fresh produce in your fridge to the medicine in your cabinet, many of the goods we rely on daily have traveled in a temperature-controlled container. GFFCA’s intermodal reefer solutions ensure these products are transported safely, efficiently, and sustainably.

As global supply chains expand and the demand for temperature-controlled logistics grows, GFFCA remains committed to providing top-tier frozen shipping services. Ready to elevate your refrigerated shipping game?

Contact GFFCA today! Let’s keep your goods cool all the way to their destination.

#logistics company in canada#freight international services#logistics company#freight forwarding solutions#Inland Transportation Services#Intermodal Transport Solutions#Inland Services Canada#Reefer Cargo Solutions#ocean freight services in Canada#Ocean Freight Forwarders Mississauga

0 notes

Text

Reefer Compressor, Aux Engine, Boiler, Automation & Electronic Spare Supplier

BMP Marine Services Pvt Ltd is the Supplier of Engine Spares & Parts, Diesel Engines, Reefer Compressors, Aux Engines, Boilers, Automation & Electronic Spares, Hydraulic Pneumatic etc

91-99696 87361

0 notes

Text

Choosing the Right Refrigeration System for Your Reefer Van

Choosing the right refrigeration system for your reefer van is crucial to ensure that your perishable goods remain fresh and properly preserved during transportation. Here are some key factors to consider when selecting a refrigeration system for your reefer van:

1. Temperature Requirements: Determine the specific temperature requirements for the products you’ll be transporting. Some goods may require precise temperature control, such as frozen foods, dairy products, or pharmaceuticals, while others may have more flexible temperature ranges. Choose a refrigeration system that can maintain the required temperature consistently and accurately.

2. Cooling Capacity: Consider the cooling capacity of the refrigeration system, which is typically measured in BTUs (British Thermal Units) or horsepower (HP). The cooling capacity should be sufficient to maintain the desired temperature inside the reefer van, even in extreme weather conditions or during long-distance transportation.

3. Insulation: Evaluate the insulation properties of the reefer van to ensure that it provides adequate thermal protection and minimizes temperature fluctuations. High-quality insulation materials, such as polyurethane foam or fiberglass, can help maintain temperature stability and reduce energy consumption.

4. Power Source: Determine the power source for the refrigeration system, such as engine-driven, electric, or hybrid. Engine-driven systems use the vehicle’s engine to power the refrigeration unit, while electric systems rely on an external power source, such as a generator or shore power. Choose a power source that is convenient, reliable, and cost-effective for your specific transportation needs.

5. Energy Efficiency: Look for energy-efficient refrigeration systems that can help minimize fuel consumption and operating costs over time. Features such as variable-speed compressors, automatic defrosting, and advanced insulation technologies can contribute to energy savings and reduce environmental impact.

6. Maintenance Requirements: Consider the maintenance requirements of the refrigeration system, including routine inspections, servicing, and repairs. Choose a system that is easy to maintain and service, with accessible components and reliable support from the manufacturer or supplier.

7. Size and Configuration: Select a refrigeration system that is compatible with the size and configuration of your reefer van. Consider factors such as available space, weight restrictions, and installation requirements to ensure a proper fit and optimal performance.

8. Temperature Monitoring and Control: Look for refrigeration systems with advanced temperature monitoring and control features, such as digital thermostats, remote monitoring capabilities, and temperature alarms. These features allow you to monitor and adjust the temperature inside the reefer van in real time, ensuring that your goods remain within the desired temperature range at all times.

9. Compliance and Regulations: Ensure that the refrigeration system complies with relevant regulations and industry standards, such as FDA (Food and Drug Administration) guidelines for food transportation or pharmaceutical storage requirements. Choose a system that meets or exceeds regulatory requirements to ensure compliance and product safety.

10. Cost and Budget: Finally, consider the initial cost, operating expenses, and long-term value of the refrigeration system about your budget and financial constraints. Balance the upfront investment with factors such as reliability, performance, and total cost of ownership to make an informed decision that meets your needs and priorities.

By carefully considering these factors and conducting thorough research, you can choose the right refrigeration system for your reefer van that meets your specific requirements and ensures the safe and efficient transportation of perishable goods.

0 notes

Text

Meticulous Processes of Reefer Container Inspection and Maintenance

In the realm of shipping and logistics, reefer containers play a pivotal role in preserving the quality and freshness of perishable goods during transit. Ensuring these containers are meticulously inspected and maintained is paramount to safeguarding the integrity of the cargo within. In this comprehensive guide, we delve into the intricate processes involved in the inspection and maintenance of reefer containers, shedding light on the crucial steps undertaken to uphold industry standards and meet the demands of global trade.

Defining Reefer Containers

Reefer containers, short for refrigerated containers, are specially designed shipping containers equipped with cooling systems to maintain specific temperature conditions, thus enabling the transportation of temperature-sensitive cargo over long distances.

Relevance and Importance

In an interconnected world where international trade thrives, reefer containers serve as indispensable assets, facilitating the global exchange of perishable goods such as fruits, vegetables, pharmaceuticals, and certain chemicals. Maintaining the quality and freshness of these goods is not only essential for economic reasons but also for meeting consumer expectations and adhering to regulatory standards.

2. Types and Categories

Container Types

Integrated Reefer Containers: These containers come with built-in refrigeration units, offering seamless temperature control.

Clip-on Reefer Units: External cooling units that can be attached to conventional containers, providing flexibility in shipping operations.

Cargo Categories

Chilled Cargo: Goods requiring temperatures above freezing but below ambient room temperature.

Frozen Cargo: Goods maintained at temperatures below freezing point to prevent spoilage.

3. Symptoms and Signs

Temperature Fluctuations

Erratic temperature readings or fluctuations indicate potential issues with the refrigeration system, jeopardizing cargo quality.

Condensation

Excessive condensation inside the container may signal insulation problems, leading to moisture-related damage to the cargo.

4. Causes and Risk Factors

Mechanical Failures

Malfunctioning components within the refrigeration unit, such as compressors or condensers, can disrupt the cooling process.

Environmental Factors

External factors like ambient temperature, humidity levels, and exposure to direct sunlight can impact the container's ability to maintain the desired temperature.

5. Diagnosis and Tests

Thermographic Inspections

Using infrared thermography to detect temperature anomalies and insulation deficiencies within the container.

Pressure Tests

Assessing the integrity of the container's insulation and seals by conducting pressure tests to detect leaks.

6. Treatment Options

Component Replacement

Repairing or replacing faulty components within the refrigeration system to restore optimal functionality.

Insulation Repair

Addressing insulation issues by repairing damaged panels or seals to prevent heat transfer.

7. Preventive Measures

Regular Maintenance

Implementing a proactive maintenance schedule to identify and address potential issues before they escalate.

Temperature Monitoring Systems

Installing advanced monitoring systems to track temperature variations in real-time and receive alerts for any deviations.

8. Personal Stories or Case Studies

Case Study: Ensuring Freshness

Anecdotal evidence from a shipping company highlighting the importance of rigorous inspection protocols in preserving the quality of delicate seafood shipments.

9. Expert Insights

Industry Expert Opinion

Quotes from a seasoned industry expert emphasizing the significance of adherence to maintenance best practices for reefer containers.

Partnering with Nissin Belgium for Unparalleled Reefer Logistics

Logistics providers can ensure the reliable and efficient transportation of temperature-sensitive goods by adhering to these meticulous reefer container inspection and maintenance processes. Whether you’re shipping fresh produce, pharmaceuticals, or any other perishable cargo, partnering with a trusted freight forwarding company like Nissin Belgium can provide the peace of mind and expertise needed to navigate the complexities of global logistics.

The seamless delivery of perishable goods across continents hinges on the intricate dance between meticulously maintained refrigerated shipping containers and expert logistics providers. By partnering with a reliable freight forwarding company like us, you can ensure that your temperature-sensitive cargo reaches its destination fresh, safe, and on time.

We boast extensive experience in container management, offering a comprehensive suite of services encompassing inspection, maintenance, and real-time container tracking, providing you with complete peace of mind throughout your journey.

Contact us at +32 2 751 44 99 or write [email protected] to discuss your logistics needs.

0 notes

Text

The Upside to Used gensets

It was founded in 1924. Surplus Record provides a listing of machinery and equipment for purchase. The company's listings include manufacturing, metalworking and stamping machines, electrical power tools, chemical and processing equipment, cranes, pumps, air compressors circuit breakers and motors turbines, generators and much the list goes on. Tom says that he and his staff personally visit the majority of the dealers who advertise their machines on the site. He thinks this will help end users believe in the sellers. Buy used generators at surplusrecords

Distributor for gensets

Distributor of stationary, portable and standby diesel generators. an output range of thirty to two thousand kW. Alternatives include paralleling system, digital generator control panels automatic transfer switches permanent magnet alternators, and aluminum enclosures. Rental, installation and maintenance services are readily available. Additionally, they offer engineering, repair, rebuilding and lifecycle management. Provides equipment rental, construction also, military, oil gas industries, as well as government and public sectors.

The company manufactures commercial grade power generators to be used for emergency, backup and towing applications. The features include a pressure-lubricated engine very low noise level of at 67 decibels, aluminium enclosures as well as corrosion resistance. It is powered by natural gas or liquidified petroleum. Additionally, it offers an automatic transfer switch and parallel load balancing for an integrated system solution. Distributor of both gas and diesel generators. The generators are available in a range of models with an output power range from 30 to 20,000 kW as well as voltage ratings of up to 277 V, and frequency of 50 or 60 Hz. It comes with a range of accessories comprising control panels as well as automatic transfer switches remote mufflers, circuit breakers.

Genset during dimout of electricity

Diesel generators are the energy-generating equipment that burn diesel fuels in order to generate electrical energy. They transform the chemical energy from diesel fuel into mechanical power in the form electricity via combustion and cooling. They're used to provide additional power for emergencies like power outages or brownouts. They are also widely utilized by construction firms to supply power to tools that can't be powered by electricity coming from the mains. These are often also found on ships for auxiliary electrical power requirements, like lights, fans, and switches. When a generator is running the generator produces exhaust gases including carbon dioxide and nitrogen oxide. These gases are released into the air and contribute to the pollution of our air. The amount of pollution depends on the power generator's size and the conditions under which it operates. The choice of the best generator for your facility is vital. You should consider the size of the power source you'll be working with, and its potential usage, including emergency, permanent or even continuous power. It is also important to consider environmental conditions such as altitude, temperatures, and emission regulations.

vimeo

Portable diesel generators are commonly employed in mining operations to power machines like lighting, drillers, as well as conveyor belts. These generators also provide power to telecommunication towers so that millions of users can keep in touch with one other in times of emergency.

The convenience that comes with used gensets also makes them useful for locations or sites not connected to the grid. This includes mountainous areas in rural regions islands and military sites in far-off countries. Gensets can be utilized for power supply in disaster areas, such as after a hurricane. In some cases, a used genset may be used with a refrigerated reefer container to keep temperature-sensitive goods cool during long overseas or inland shipping voyages. Gensets are able to fitted with a clip or an underslung that can fit into the sides of a container or beneath it in addition to.

Foundation of surplusrecord

The company was founded in 1924. Surplus Record was the first national directory of used machinery and equipment. Its founder, Thomas P. Scanlan, who was a University of Notre Dame graduate who went door-to-door along "manufacturers row" in Chicago and observed that a lot of companies wanted to sell their surplus machinery. He started the company as a way to connect buyers with the sellers of industrial equipment. It has a range of categories, including machinery and electrical devices. Searchers can locate CNC, metalworking and stamping machines, woodworking machinery, chemical and processing equipment, air compressors, cranes, generators, pumps, motors and turbines, transformers and many other industrial assets that are surplus. This is the longest-running and most trusted market place in North America. buy used generators at surplusrecord. Tom states that one of the things that endusers appreciate about the website is the transparency of information about the vendors of machinery and equipment. Their names, company addresses and their contact information is clearly displayed, so they can call the seller directly to buy machinery or other equipment. Tom or one of his team visits 90 percent of advertisers to ensure they are up to date on the latest happenings at the business and who is working there. He says he or his staff get six to eight daily calls from customers wanting to know the credit history of dealers. Also, his website is always updated unlike other machinery trading websites.

There are many places as well as sites where gensets supply power for devices. Gensets that are standby in the event of power interruptions or hospital gensets that run vital equipment for patients care.A Genset converts chemical energy into mechanical power. It then converts it into electrical current. The alternator generates AC electrical power which can be utilized to power machines and electronic devices.

0 notes

Text

JOHNSON CONTROLS GLOBAL MARINE REFRIGERATION CATALOGUE Mobile:+86 138 181 54378 E-mail:[email protected] #SABROE Marine air handling unit & automation concept.. Refrigeration systems from Johnson Controls

R717/R744 cascade freezing plant

Plate freezers

Freezing cargo holds

Freezing tunnels (IQF)

RSW units

RSW/P units

RSW tank management system

Refrigeration detector system (RDS)

Refrigeration system for reefers

Compressor control (Unisab)

Variable-speed drive (VSD)

Refrigeration control management (RCM)

HVAC and chillers

Benefits of owning a Johnson Controls refrigeration system

The refrigeration equipment is selected according to marine operation conditions and with great respect to high variation in minimum and maximum required load on system and variation in seawater temperature.

The key words for the design and selection of the equipment are sturdiness, durability and equipment interchangeability. Focus is on long-term investment and low operational costs.

Synthetic oil type PAO68 ensuring longer lifetime and extended operating hours than typical mineral oils.

Automatic oil return system in the evaporator assures that all the oil is returned to the system.

The R717 system cleaner cleans water from the refrigerant, thereby reducing water contamination in ammonia plants, as well as benefiting refrigeration capacity, power consumption and operating costs.

Frequency control of pumps secures a constant flow in the liquid main line and minimizes power consumption despite load variation from the freezers in operation. Furthermore, the PLC control automatically starts pumps in sequence to avoid oil accumulating during standstill and to share operating hours between pumps.

0 notes

Text

Professional Reefer Repair in Springdale, MD – Keeping Your Refrigerated Trucks Running Smoothly

Refrigerated trucks, commonly known as reefers, are crucial for transporting perishable goods such as food, pharmaceuticals, and other temperature-sensitive items. A malfunctioning reefer unit can lead to spoiled cargo, financial losses, and delivery delays. If you’re searching for reefer repair in Springdale, MD, finding a trusted repair service is essential to ensure your fleet stays operational.

In this article, we will explore common reefer truck issues, the importance of regular maintenance, and how professional repair services can help prevent costly breakdowns.

✅ Common Reefer Truck Issues and Their Solutions

Reefer units require consistent maintenance to function properly. Here are some common problems and how they can be fixed:

1. Temperature Instability

Reefer units must maintain a steady temperature to keep cargo fresh.

Causes: Malfunctioning thermostat, refrigerant leaks, or a faulty compressor.

Solution: Regular inspections of thermostats and refrigerant levels can prevent temperature fluctuations.

2. Reefer Unit Failing to Cool

If the unit does not cool effectively, perishable goods may spoil.

Causes: Dirty evaporator coils, blocked air vents, or compressor failure.

Solution: Cleaning filters and evaporator coils and checking for refrigerant leaks can resolve this issue.

3. Electrical Failures

Electrical problems can cause the reefer unit to shut down unexpectedly.

Causes: Faulty wiring, loose connections, or a damaged control board.

Solution: Regular electrical system inspections can prevent sudden failures.

4. Fuel System Problems

Diesel-powered reefer units require a properly functioning fuel system.

Causes: Clogged fuel filters, fuel pump failure, or dirty injectors.

Solution: Routine fuel system maintenance ensures consistent reefer performance.

🔧 Why Regular Reefer Maintenance is Important

Regular maintenance is key to preventing breakdowns and ensuring reefer units work efficiently. Here’s why consistent servicing matters:

Prevents Unexpected Breakdowns – Routine maintenance helps detect and fix minor issues before they become major problems.

Extends Equipment Life – Properly maintained reefer units last longer and perform better.

Reduces Repair Costs – Fixing small problems early saves money in the long run.

Ensures Cargo Safety – A well-functioning reefer prevents spoilage and maintains product quality.

Improves Fuel Efficiency – Efficiently running reefer units consume less fuel, reducing operational costs.

By scheduling regular reefer repair in Springdale, MD, you can prevent costly downtime and keep your trucks running smoothly.

🚛 How to Choose the Best Reefer Repair Service in Springdale, MD

When selecting a reefer repair service in Springdale, MD, it’s essential to choose a provider that offers expertise, reliability, and fast service. Here are some factors to consider:

✅ Experienced Technicians

Work with repair professionals who specialize in reefer units and have industry certifications.

✅ 24/7 Emergency Repair Services

Reefer units can fail unexpectedly. A service provider that offers emergency repairs can save you from product loss and downtime.

✅ On-Site Repairs

Mobile reefer repair services can fix your truck without requiring a tow, saving you time and money.

✅ Affordable and Transparent Pricing

Choose a company that offers fair pricing with no hidden fees.

✅ Strong Customer Reviews

Check online reviews and testimonials to ensure you’re working with a reputable company.

🛠 Reliable Reefer Repair Services You Can Trust

For truck owners, keeping reefer units in top condition is essential for smooth business operations. At Gogo Logistics, we specialize in reefer repair in Springdale, MD, providing:

��️ Thorough reefer diagnostics and troubleshooting ✔️ Refrigerant level checks and leak detection ✔️ Thermostat calibration and temperature control adjustments ✔️ Electrical system and fuel system inspections ✔️ 24/7 emergency reefer repair services

Our skilled technicians are dedicated to delivering fast, efficient, and cost-effective solutions to keep your refrigerated trucks on the road.

1 note

·

View note

Text

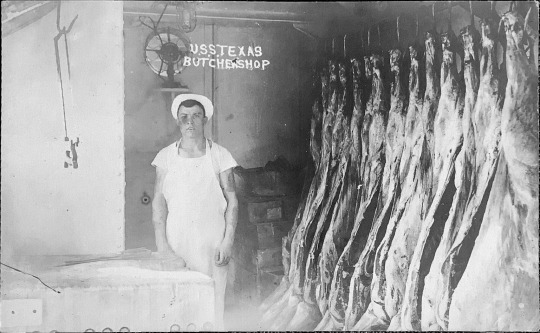

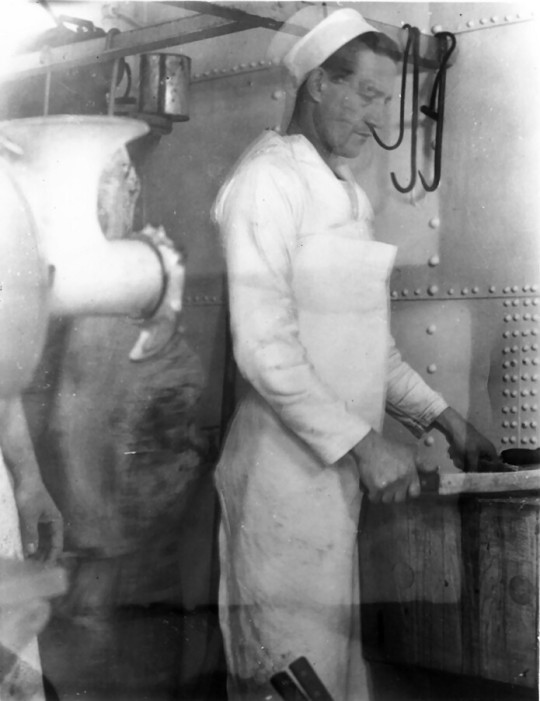

USS Texas (BB-35): Butcher Shop

The butcher shop onboard USS Texas (BB-35) was located on the main deck.

The meat was stored in the refrigeration room on the 3rd deck and could hold 30 tons.

"As built, the ship had a significant ice making capability. They used large, low pressure CO2 compressors to make ice. The ice was used in a heat exchanger in which salt water was circulated through pipes. It was then piped to cool powder magazines and reefers (refrigerated compartments). The preferred refrigerant of the day was ammonia, but that was far too dangerous to use on a ship. A small leak could quickly and painfully kill crew. With CO2, it's not toxic, but you will gasp for air and hopefully have time to get away from it before smothering."

Informatiom from Tom Scott.

source, source

LIFE Magazine Archives: link

#USS Texas (BB-35)#USS Texas#Battleship Texas#Battleship#new york class#dreadnought#USS Texas History Series#united states navy#us navy#navy#usn#u.s. navy#meat#Butcher Shop#Butcher#refrigeration#my post

114 notes

·

View notes

Text

The Ultimate Guide to an Insulated Refrigerated Truck

When transporting perishable goods, having a reliable and efficient insulated refrigerated truck is crucial. Whether you’re transporting dairy, meat, fruits, or vegetables, temperature control is of utmost importance to maintain the freshness and quality of the products. An insulated refrigerated truck helps preserve the goods and ensures that they reach their destination in perfect condition. While the Indian cold chain industry suffers because of various mismanagement of Cold chain logistics, a suitable quality reefer container can be a solution to many of the problems. Here, sub Zero will be exploring the multiple factors to consider when purchasing an insulated refrigerated truck, the types of refrigeration units available, proper maintenance and cleaning, and tips for maintaining temperature control during transportation.

Factors to Consider When Purchasing an Insulated Refrigerated Truck

Purchasing an insulated truck is one of the crucial investments for any business and one has to consider the following factors before purchasing one:

Load Capacity: It’s essential to consider the number of goods you need to transport and choose a refrigerated truck that can accommodate your load. Ensure that the truck you select has enough space to store the products and avoid overloading.

Insulation Thickness and Quality: The thickness and quality of insulation are critical in ensuring that the temperature inside the truck remains stable. The thicker the insulation, the better it will maintain the temperature.

Refrigeration Unit Type and Size: The refrigeration unit is the heart of the insulated refrigerated truck. Choosing the suitable unit that suits your needs is essential and ensures that the temperature inside the truck remains consistent. Compressor-based units and thermoelectric units are the two types of refrigeration units available.

Cost-Effectiveness: While purchasing an insulated refrigerated truck, it’s essential to consider the cost-effectiveness of the truck. Ensure that the truck you select is cost-effective in terms of maintenance, fuel consumption, and repair costs.

Energy Efficiency: Energy efficiency is a crucial factor to consider when purchasing an insulated refrigerated truck. Ensure that your selected truck has an energy-efficient refrigeration unit to reduce operating costs.

Types of Refrigeration Units Available for Insulated Trucks:

Refrigerated truck units are the critical component of an insulated refrigerated truck that provides temperature control for perishable goods. There are various types of refrigerated truck units available in the market, each designed to cater to specific needs and industries.

GRP Reefer Boxes: GRP reefer boxes are made of fiber-reinforced plastic and are known for their durability and resistance to corrosion. They are ideal for long-distance transportation and are primarily used in the food and beverage industries worldwide.

MS Reefer Container: MS reefer containers are made of high-quality metal and are known for their strength and durability. They are ideal for transporting goods that require a controlled environment, such as dairy and meat products.

PPGI Metal Boxes: PPGI metal boxes are made of pre-painted galvanized iron and are known for their durability and resistance to corrosion. They are ideal for transporting goods that require a controlled environment, such as fruits and vegetables.

Insulated Boxes for Dairy and Fishery Industries: Insulated boxes are specially designed for the dairy and fishery industries. They provide excellent insulation and temperature control, ensuring that the goods remain fresh and of high quality.

Multitemperature Partition Systems: Multitemperature partition systems are designed to transport goods that require different temperatures within the same truck. They provide separate temperature-controlled compartments within the truck, ensuring that each product is stored at the right temperature.

Proper Maintenance and Cleaning for Optimal Performance

To ensure that your insulated refrigerated truck performs optimally, it is crucial to maintain and clean it regularly. Regular cleaning helps maintain the temperature inside the truck and ensures that the refrigeration unit is functioning correctly.

Tips for Maintaining Temperature Control During Transportation

Loading and Unloading Procedures: It is essential to follow proper loading and unloading procedures to maintain temperature control during transportation. Avoid overloading the truck, and ensure that the products are stored correctly to avoid damage.

Proper Temperature Management During Transit: It’s crucial to monitor the temperature inside the truck regularly during transit. Ensure that the temperature inside the truck remains consistent, and if necessary, make adjustments to maintain the temperature.

In conclusion, an insulated refrigerated truck is an essential investment for businesses that deal with perishable goods. It helps in preserving the goods, ensuring that they reach their destination in perfect condition, and reducing operating costs. Consider the factors discussed in this article, and choose the best insulated refrigerated truck for your specific needs.

#subzeroreefers#reefercontainer#refrigeratedcontainers#refrigerated trucks#reefertruck#insulatedrefrigeratedtruck#RefrigeratedTruckManufacturersInIndia#RefrigeratedvanManufacturersInIndia#reefervan

0 notes