#Robotic Process Automation

Text

Unlocking Efficiency and Innovation: The Role of Robotic Process Automation (RPA)

In today's fast-paced and competitive business environment, organizations are constantly seeking ways to improve efficiency, reduce costs, and increase productivity. Robotic Process Automation (RPA) has emerged as a powerful tool that can help businesses achieve these objectives.

What is Robotic Process Automation (RPA)?

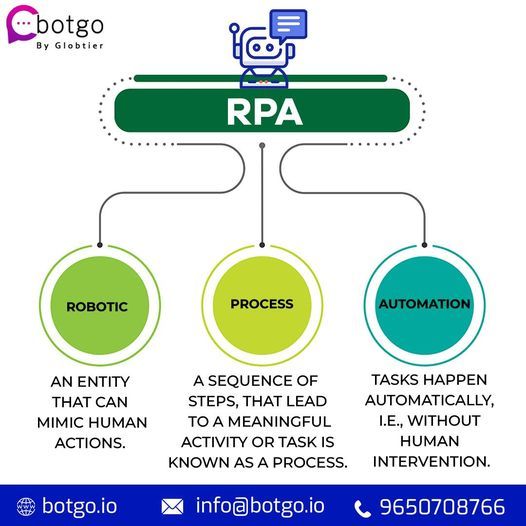

Robotic Process Automation (RPA) is a technology that allows businesses to automate repetitive, rule-based tasks. It uses software robots, also known as "bots," to mimic human actions and interact with digital systems. These bots can log into applications, navigate through screens, input data, and complete tasks just like humans would.

The Role of RPA in Business:

RPA can be used to automate a wide range of tasks across various industries and departments. Here are some examples:

Finance and Accounting: Automating tasks such as accounts payable and receivable, invoice processing, and financial reporting.

Customer Service: Automating tasks such as answering FAQs, resolving customer inquiries, and processing orders.

Human Resources: Automating tasks such as onboarding new employees, processing payroll, and managing benefits.

IT: Automating tasks such as provisioning accounts, managing user access, and deploying software updates.

Impact of RPA on Businesses:

Implementing RPA can offer numerous benefits to businesses, including:

Increased efficiency and productivity: RPA can automate time-consuming and tedious tasks, freeing up employees to focus on more strategic and value-added activities.

Reduced costs: RPA can help businesses save money on labor costs, as well as reduce errors and compliance risks.

Improved accuracy and compliance: RPA bots are programmed to follow specific rules and procedures, which can help to improve accuracy and compliance with regulations.

Enhanced process visibility and control: RPA provides businesses with a clear view of their processes, which can help them identify and address bottlenecks.

Improved customer satisfaction: RPA can help businesses improve customer satisfaction by automating tasks such as order processing and customer service interactions.

RPA Services:

Implementing RPA successfully requires a partner with expertise in the technology and a deep understanding of business processes. A comprehensive RPA solution should include the following services:

Document AS-IS Process: This involves mapping out the existing process to identify areas for automation.

Design & Development of Bots, workflows, and forms for process automation: This includes designing and developing the software robots that will automate the tasks.

Bot license (We will use the appropriate underlying technology): This provides access to the software robots and the underlying technology platform.

Infrastructure: This includes setting up the necessary infrastructure to support the Robotic Process Automation (RPA) solution.

Production Deployment of the Bots: This involves deploying the bots to production and monitoring their performance.

RPA support: This includes ongoing support for the RPA solution, such as troubleshooting and maintenance.

Test & Deploy bots to production: This involves testing the bots in a production environment and making any necessary adjustments before they are deployed to full production.

Configuration data changes: This involves making changes to the configuration data of the bots as needed.

Password updates: This involves updating the passwords of the bots as needed.

Errors in executing the Bots: This involves resolving errors that occur during the execution of the bots.

Determining the “root cause” of a recurring issue or incident & recommendations: This involves identifying the root cause of a recurring issue or incident and recommending solutions to prevent it from happening again.

Infrastructure/application related issues: This involves resolving issues with the infrastructure or applications that the bots are interacting with.

Conclusion:

RPA is a powerful technology that can have a significant impact on businesses of all sizes. By automating repetitive tasks, RPA can help businesses improve efficiency, reduce costs, and increase productivity. However, it is important to choose a reputable Robotic Process Automation (RPA) companies with the expertise and experience to help you implement a successful RPA solution.

Ready to embrace the power of RPA?

Contact us today to learn more about how RPA can help your business achieve its goals.

#robotic process automation#robotic process automation rpa#rpa automation#robotic process automation software#rpa software#robotic process automation companies#robotic process automation technology#robotic process automation in healthcare#robotic process automation in banking#rpa solution#robotic process automation for finance#process automation solution#robotic process automation services#robotic process automation for insurance#rpa system#what is rpa automation#robotic process automation solution#robotic process automation benefits#robotic process automation consulting#robotic process automation consultant#rpa service provider#rpa consulting services

2 notes

·

View notes

Text

Robotic Process Automation

RPA, also known as software robotics, makes use of intelligent automation technologies to do ordinary office tasks that would often be handled by human workers.

What is robotic process automation?

Software robotics, also known as robotic process automation (RPA), simulates back-office tasks carried out by human staff, such as extracting data, completing forms, moving files, etc., using automation technology. It integrates and completes repetitive operations between enterprise and productivity applications by combining APIs and UI interactions. By deploying scripts that simulate human activities, RPA technologies execute a variety of jobs and transactions autonomously across unrelated software systems.

This kind of automation frees up human resources to concentrate on harder tasks by doing business process operations in big quantities using rule-based software. RPA enables CIOs and other decision-makers to accelerate the digital transformation process and boost employee return on investment (ROI) by enabling the digital workforce to carry out more time-consuming and difficult tasks.

Enterprises should first evaluate their data management processes and data architecture to see if they are ready to implement RPA technology. High-quality data and good data governance are crucial for RPA to flourish, and it won't be able to meet business demands without the right safeguards (such as a centre of excellence, governance boards, and written rules).

RPA and intelligent automation

To compete in the market, RPA solutions must expand their product lines to incorporate intelligent automation in addition to task automation (IA). By incorporating the artificial intelligence subfields of computer vision, natural language processing, and machine learning. This type of automation expands RPA's capabilities.

Intelligent process automation requires far more than just the simple rule-based architecture of RPA. RPA can be compared to AI and ML, which put more of an emphasis on "thinking" and "learning," respectively. In order to improve the speed and accuracy of the programme, it trains algorithms using data. As RPA technologies increasingly incorporate artificial intelligence, it will be harder to discern between these two groups.

RPA and artificial intelligence

RPA and artificial intelligence (AI) are two very distinct ideas that are occasionally used interchangeably. Cognitive automation, machine learning, natural language processing, reasoning, hypothesis development, and analysis are all combined in artificial intelligence (AI).

The key distinction between RPA and AI is that one is process-driven while the other is data-driven. RPA bots can only carry out processes that end users design, in contrast to AI bots, which employ machine learning to identify patterns in data, particularly unstructured data, and learn over time. To put it another way, RPA only aims to replicate human-led jobs, whereas AI strives to emulate human intelligence. Both RPA systems and artificial intelligence (AI) reduce the need for human interaction, yet they automate processes differently.

However, RPA and AI complement each other effectively as well. RPA may make use of AI to handle more complex use cases and fully automate tasks. In addition, RPA enables faster responses to AI results than waiting for manual implementations.

RPA and hyper automation

Hyper automation is the idea of automating everything in an organization that can be automated. Hyper-automated businesses automate specific workflows and streamline corporate processes using techniques like robotic process automation (RPA) and artificial intelligence (AI).

How does RPA work?

RPA software products, according to Forrester, should include the following essential capabilities:

the capacity to write low-code automation programmes

Application-specific adaptation

Administration and orchestration include configuration, monitoring, and security.

Front-end connectors enable RPA and other automation technologies to easily integrate with other applications and access data from legacy systems. So, just like a real worker, the automation platform may perform routine tasks like logging in and copying and pasting data between platforms. Although back-end connections to databases and enterprise web services can also aid with automation, RPA's true usefulness resides in its quick and uncomplicated front-end interactions.

The benefits of RPA

RPA has a variety of advantages, such as:

Less coding

RPA does not always need a developer to configure it; therefore, drag-and-drop capabilities in user interfaces make it easier for non-technical staff to onboard RPA.

Rapid cost savings.

RPA reduces team workloads, enabling workers to be moved to other crucial tasks that still require human input, boosting output and return on investment.

Higher customer satisfaction

Bots and chatbots can reduce customer wait times and boost customer satisfaction because they are accessible round-the-clock.

Improved employee morale

RPA frees your personnel from needing to complete high-volume, repetitive tasks, allowing them to focus on more strategic and important choices. The office redesign will raise employee satisfaction.

Better accuracy and compliance

In particular when it comes to work that must be correct and in compliance with rules, human error can be reduced or even completely eliminated by using RPA robots that can be programmed to follow precise processes and procedures. RPA can also offer an audit trail, which makes it easy to track progress and deal with problems more rapidly.

Existing systems remain in place

Robotic process automation software only modifies the presentation layer of pre-existing applications, not the underlying systems, thus there is no interference with those. So even if you lack an API or the skills to create complex integrations, you can still use bots.

RPA Challenges

RPA software can help businesses grow, but there are a number of obstacles, such as organizational culture, technical issues, and scaling.

Organizational culture

RPA may eliminate certain jobs, but it will also promote the formation of new positions to perform more difficult tasks, freeing up staff members to concentrate on in-depth planning and novel problem-solving. As job responsibilities change, organizations will need to encourage a culture of creativity and learning. The ability of a workforce to adapt will be crucial for the success of automation and digital transformation programmes. By educating your staff and investing in training programmes, you can prepare teams for constant shifts in priorities.

Difficulty in scaling

RPA can handle multiple tasks at once, however scaling it up within an organisation may be difficult due to internal or regulatory changes. According to a Forrester survey, 52% of customers report having difficulty scaling their RPA programme. Most RPA programmes only reach the first 10 robots, despite the fact that a company needs at least 100 operational robots for a programme to be considered mature.

3 notes

·

View notes

Text

Difference Between Intelligent Process Automation and Robotic Process Automation

Automated and Intelligent technologies are already making an impact here, and will definitely contribute even more in the upcomming years. Recently, two innovative technologies have attracted a lot of interest in the field of process optimization, i.e. IPA (Intelligent Process Automation) and RPA (Robotic Process Automation). These words may sound similar, but they have very different approaches to digital transformation, and the outcomes you might expect from them also vary.

0 notes

Text

Best Course for Robotics Engineering in Dubai

Premier Robotics Course in Dubai

If your goal is to become a robotics professional, consider attending one of the top courses at the Silicon Institute in Dubai.

Why Choose Robotics Engineering?

Robotics engineering is an attractive and very interesting profession that uses mechanical, electrical, and computer engineering principles to design, manufacture, and operate robots and robotic systems. With technological improvements, robotics is becoming more popular in a variety of industries, including manufacturing, healthcare, aerospace, and others. A career in robotics engineering can provide a variety of successful options.

About Silicon Institution

Silicon Institution is a leading educational institution in Dubai, known for its high-quality programs in science, technology, engineering, and mathematics (STEM) fields. The institution is committed to providing students with a comprehensive education that prepares them for the demands of the modern workforce.

The Robotics Engineering Course

The robotics engineering course at Silicon Institution is designed to equip students with a strong foundation in engineering principles and their application to robotics. The curriculum covers a wide range of topics, including:

Mechanical design and analysis

Electrical and electronic systems

Programming and control systems

Sensors and actuators

Robot kinematics and dynamics

Robotic applications in various industries

Students will have the opportunity to engage in hands-on projects, allowing them to apply theoretical concepts to real-world scenarios. Additionally, they will have access to state-of-the-art facilities and resources to support their learning and research endeavors.

Conclusion

If you're interested in robotics engineering and searching for an excellent place to begin your career, Silicon Institution in Dubai is an ideal alternative. Silicon Institution's robotics engineering program prepares students for success in this dynamic and in-demand sector with a comprehensive curriculum, experienced professors, and industry relations.

Please pass up the opportunity to join the future generation of robotics engineers! Enroll in Silicon Institution's robotics engineering course to begin your journey toward an interesting and rewarding profession in robotics.

Register Now

For More Details Visit Our Website, https://sindso.com/

Mail id - [email protected]

Mobile Number - +971521650248

#robotic process automation#robots#machine#robotics#robot#androids#gynoid#mecha#robotics technology#machinery#cybernetics#android#zoid

0 notes

Text

Streamlining Manufacturing Operations through Process Automation Solutions

The manufacturing industry is undergoing a transformative shift with the integration of advanced technologies to enhance efficiency, reduce costs, and improve overall productivity. One of the key drivers of this transformation is process automation, a revolutionary solution that leverages cutting-edge technologies to streamline operations and optimize resource utilization. In this article, we will explore the significance of process automation in the manufacturing sector, its key components, benefits, and the potential challenges that organizations may face during implementation.

Understanding Process Automation in Manufacturing

Process automation involves the use of technology to execute recurring tasks and processes without human intervention. In the manufacturing industry, this can range from automating simple repetitive tasks to orchestrating complex production processes. Key components of process automation in manufacturing include:

Sensors and IoT Devices:

These are deployed to collect real-time data from various points in the production line. Sensors monitor equipment conditions, detect defects, and capture critical performance metrics.

Industrial Robotics:

Automated systems and robots are employed for tasks such as assembly, welding, painting, and packaging. These robots enhance precision, speed, and consistency in manufacturing processes.

PLC (Programmable Logic Controllers):

PLCs are essential for controlling and automating machinery. They are programmed to manage specific tasks, ensuring that processes are executed accurately and efficiently.

SCADA (Supervisory Control and Data Acquisition):

SCADA systems provide a centralized platform for monitoring and controlling industrial processes. They collect and analyze data from various sources, enabling real-time decision-making.

MES (Manufacturing Execution Systems):

MES software integrates with other systems to manage and optimize production on the shop floor. It provides real-time data on production schedules, inventory levels, and quality control.

Benefits of Process Automation in Manufacturing

Implementing process automation solutions in the manufacturing industry yields a myriad of benefits that contribute to operational excellence and competitive advantage:

Manufacturers face a myriad of challenges, from increasing competition and fluctuating market demands to rising operational costs. In this complex environment, manual and traditional methods of production management fall short in meeting the demands of modern industry standards. Here’s where process automation steps in to revolutionize manufacturing processes.

Enhanced Efficiency and Productivity:

Process automation optimizes workflows by reducing manual intervention, thereby minimizing errors and enhancing overall efficiency. Automated systems can operate 24/7, ensuring continuous production and significantly increasing output compared to traditional methods.

Cost Reduction:

Automation helps manufacturers cut costs by streamlining processes, minimizing waste, and improving resource utilization. While the initial investment in automation technology may seem substantial, the long-term savings in labor, energy, and materials often outweigh these upfront expenses.

Consistent Quality:

Automated systems ensure consistent product quality by eliminating variations caused by human error. Precision and accuracy in manufacturing processes lead to standardized outputs, meeting or exceeding customer expectations and regulatory compliance.

Flexibility and Scalability:

Modern automation solutions are designed to be flexible and scalable, allowing manufacturers to adapt quickly to changes in production volume or product specifications. This scalability ensures that the system can grow with the business, accommodating future expansion or modification.

Increased Production Capacity:

Automated systems can operate 24/7 without the need for breaks, contributing to increased production capacity and quicker time-to-market for products.

Real-time Monitoring and Analytics:

Process automation provides real-time insights into production processes, enabling quick identification of bottlenecks, inefficiencies, and areas for improvement.

Best Practices for Successful Automation Implementation

Comprehensive Planning:

A thorough analysis of current processes, identification of automation opportunities, and a well-defined roadmap are crucial for successful automation implementation. This planning phase should also include a clear communication strategy to keep all stakeholders informed and engaged.

Investment in Workforce Training:

To address the workforce adaptation challenge, investing in training programs is essential. Providing employees with the necessary skills to operate, monitor, and maintain automated systems ensures a more successful integration.

Gradual Implementation:

Rather than attempting a complete overhaul of existing processes, a phased approach to automation implementation is often more effective. Starting with smaller, less critical processes allows for smoother integration and helps identify and address challenges early on.

Collaboration with Automation Experts:

Manufacturers should collaborate with automation experts and technology providers to ensure the selection of the most suitable automation solutions for their specific needs. Working closely with experts can also facilitate a smoother integration process.

Challenges in Implementing Process Automation

While the benefits of process automation in manufacturing are substantial, organizations may encounter challenges during the implementation phase:

High Initial Investment:

The upfront costs of implementing automation systems can be significant. Organizations need to carefully evaluate the return on investment (ROI) over the long term.

Workforce Reskilling:

The introduction of automation may require employees to acquire new skills to operate and maintain automated systems. Organizations need to invest in training programs to bridge the skills gap.

Integration Complexity:

Integrating automation systems with existing infrastructure and legacy systems can be complex. Seamless integration is crucial to avoid disruptions in operations.

Cybersecurity Concerns:

As manufacturing processes become more connected, the risk of cyber threats increases. Organizations must implement robust cybersecurity measures to protect sensitive data and critical infrastructure.

Conclusion:

Process automation is a pivotal solution for the manufacturing industry, driving operational excellence, cost savings, and improved competitiveness. As technologies continue to evolve, manufacturers must embrace automation to stay ahead in a rapidly changing landscape. While challenges exist, careful planning, strategic implementation, and ongoing investment in employee training and cybersecurity measures can ensure a smooth transition to a more automated and efficient manufacturing environment. The future of manufacturing lies in the hands of those who leverage the power of automation to adapt, innovate, and thrive in the digital age.

Original Source: Here

0 notes

Text

youtube

#robotic affirming#robotic process automation#robotic surgeon#robotic surgery#robotic fizzarolli#Youtube

1 note

·

View note

Text

Vee Technologies - One of the top Robotic Process Automation Services Companies

RPA tools help businesses to reduce costs and improve their productivity and efficiency. With RPA solutions from Vee Technologies, one of the top Robotic Process Automation Services Companies, our clients across all kinds of industries boost their revenue by engaging their resources in creative tasks and delegating mundane tasks to our custom tools.

Visit : https://www.veetechnologies.com/services/it-services/robotic-process-automation.htm

0 notes

Text

Intelligent Automation in Insurance

Join Digital Workforce and SS&C Blue Prism for an exclusive afternoon at the prestigious Residence of the Ambassador of Finland to the United Kingdom.

0 notes

Text

“Vee Technologies’ Robotic Process Automation”

As a leading provider of technology-enabled solutions, Vee Technologies offers Robotic Process Automation (RPA) tools built to reduce costs and streamline operations. Focused on improving speed and accuracy in business, our RPA development team automates the complex yet redundant tasks that handcuff vital resources. Our customized solutions are built to augment tasks performed by humans with greater speed and accuracy.

0 notes

Text

Process automation is a key optimization lever for any business embarking on a broader digital transformation. Its flexibility, non-intrusive nature, and vast areas of application make it ideal for businesses looking to streamline processes, reduce costs, and free up resources to tackle more pressing issues.

𝐒𝐰𝐢𝐭𝐜𝐡 𝐭𝐨 𝐁𝐨𝐭𝐠𝐨 𝐍𝐨𝐰!

𝗖𝐨𝐧𝐭𝐚𝐜𝐭 𝐮𝐬 𝐭𝐨𝐝𝐚𝐲 𝐟𝐨𝐫 𝐚 𝐟𝐫𝐞𝐞 𝟔𝟎 𝐝𝐚𝐲𝐬 𝐭𝐫𝐢𝐚𝐥, 𝐃𝐞𝐦𝐨 & 𝐐𝐮𝐨𝐭𝐞𝐬!

𝗙𝗼𝗿 𝗺𝗼𝗿𝗲 𝗶𝗻𝗳𝗼𝗿𝗺𝗮𝘁𝗶𝗼𝗻:👇

🌐𝗩𝗶𝘀𝗶𝘁 𝗨𝘀: https://botgo.io

0 notes

Text

Robotic Process Automation (RPA) simplifies tasks by automating repetitive processes, letting software robots handle mundane chores. This technology boosts efficiency and accuracy, reducing human error and freeing up employees for more strategic work. With RPA, businesses streamline operations, enhance productivity, and achieve cost savings.

0 notes

Text

Top Robotics Companies in USA

FORTUNE ROBOTICS

Robotics technology is advancing rapidly, and American companies are at the forefront of innovation. The use of robotics technology is transforming industries, from manufacturing to healthcare. In this article, we explore some of the top robotics companies in the United States, including Fortune Robotics.

Fortune Robotics

Fortune Robotics is a leading American robotics company known for its innovative industrial automation solutions. The company specializes in the development of robotic systems for various industries, including manufacturing, logistics and healthcare. Fortune Robotics is known for its quality products and advanced robotics technology.

Key Features of Fortune Robotics

Robotic Arms: Fortune Robotics designs and manufactures robotic arms used for a variety of applications such as picking and placing objects, assembly and welding. Their robotic arms are known for their precision and efficiency, making them ideal for industrial automation.

Fortune Robotics offers cobots: which are robots that can work with humans safely and efficiently. These cobots are designed to streamline operations and improve workplace productivity.

Artificial Intelligence and Machine Learning: Fortune Robotics integrates artificial intelligence and machine learning algorithms into its robot systems, allowing them to learn and adapt to different tasks on their own. This advanced technology enables better performance and flexibility in robot operations.

Industrial Solutions: Fortune Robotics provides customized robotic solutions for a variety of industries, including automotive, electronics and pharmaceuticals. Their expertise in customizing robotic systems to specific industry needs sets them apart from other robotics companies.

Why Choose Fortune Robotics?

Innovative Technology: Fortune Robotics is noted for its modern technology and ongoing innovation in the realm of robotics.

Reliability: Customers trust Fortune Robotics with reliable, high-quality robotics solutions that meet industry standards.

Customer Support: The company offers excellent customer support services, ensuring that customers receive assistance and guidance throughout the implementation process.

Overall, Fortune Robotics stands out as one of the best robotics companies in the US with a focus on innovation, quality and customer satisfaction. Their diverse range of robotics solutions serves various industries, making them a valuable partner for companies looking to make their operations more efficient with robotics technology.

Follow the latest developments and trends in robotics to stay current!

For More Details Visit Our Website - https://fortunerobotics.com/

Mail id - [email protected]

Contact - +1 (347) 728–4015

0 notes

Text

Digital Workforce implements Robotic Process Automation for the migration of active customer data in the Kanta-Häme Welfare Region.

0 notes

Text

Discover the power of Intelligent Automation Services. We leverage advanced AI, machine learning, and robotic process automation technologies to streamline your business processes, enhance productivity, and drive innovation. Transform your business operations for the future with our end-to-end automation solutions.

#Automation#Automation services#Business process automation#Business Process Automation#Cognitive Process Automation#Robotic Process Automation#AI-driven Process Automation#Digital Transformation Services#Email Automation Solution#Mortgage Automation Solution

0 notes

Text

Discover the power of Intelligent Automation Services. Streamline your operations, enhance productivity, and drive growth with our cutting-edge solutions. Leverage AI, Machine Learning, Robotic Process Automation to revolutionize your business processes.

#Business Process Automation#Automation Services#Cognitive Process Automation#Robotic Process Automation#AI-driven Process Automation#Digital Transformation Services#Email Automation Solution#Mortgage Automation Solution

0 notes