#Rolling Conveyor Systems

Explore tagged Tumblr posts

Text

.

#the idol system is such a fascinating and scary thing to me#like hearing shit over the years it's like how does anyone survive it?#(i'm staying away from all the anti-blackness of kpop & their fandoms rn so just the system)#((that was more for me bc my brain wants to go in that direction bc hooooooo. it's the main reason i cannot vibe w more than a few songs#over the last almost 15 years cause like knowing.... anyway))#like i just got groundfloored w a group rn via jbrekkie shoutout michelle like literally their debut is 24 hrs from now i've rabbitholed#since i heard their snippet on her vid and like the way ppl talk about it already like... as an outsider it's like alriiiight here we goo#they're (mgmt) pipelining another group of ppl let's be sure to support it! streamstreamvote!! oo it looks like their taking the toy/doll#route w these girls super aesthetic let's goo. & like......????? and ppl are already rabid about it. it's wild. and like this is the system#this is it. they make groups and then tease and the people who follow the conglomerate see it and are waiting to#be fed another x amount of folks doing formations and looking cute/hot open wide and consume#(like ik some (or a lot) of those accnts are bots/plants to pad the release and gain traction against algos but like also real folks too)#like not to discredit their vocal work (&dancing though some (alot) of these grps are not nearly as lit w 'dancing' as folks hype em up to#be Frfr. good movers/formations/camera motion & body rolls do not a dancer/good choreo make) but it's really secondary for a lot of#folks atp it's so strange & fascinating. and like i dug the song that's why i'm here so no knock against that but just the factory of it al#it's so damn WILD to me. but at the same time let's be real here. same dish different kitchen for a lot of western pop#they're just more transparent about it and have streamlined finding their popstars & having the public be great w it#it's just... i think it would be less strange if stan culture wasn't a thing or at least more mild than it is now#if it wasn't blown up to this unfathomably massive ever-churning industry by people in literal droves#idk idk i have a lot of thoughts on kpop it's truly a very interesting thing and to have been aware of it and into it to#an extent a while before the sonic boom in the west is an incredibly wild thing to look back on#like i wanna follow this (mostly cause i wanna hear the whole song) but also v curious but also like man the system is bad for many#reasons & here's another batch on the conveyor belt. idk :/#like as long as the participants are happy and healthy and being actually taken care of and not advantage of then great but#yk. the music industry at large is horrible (and esp to women) so like. god ide wanna think about the disparities btwn girl & boy groups#(like to start are they not referred to as 'male groups' on the reg but 'girl groups' more often than 'female'? always w the infantalizing#like given girl group has way more ring than female group but the words still conjure up different things it's just how language works#but boy group idk if i've ever really heard someone use that? and there's been a long time battle w the reclamation of 'boy band'#like it's still dirty for a lot of folks but anyway v western context but there's a large fanbase here so many fans speak as such#this is what we call our own pop groups etc. and it's just interesting and sad idk anyway it's just... huuuhhh a lot.) ok gn lol

1 note

·

View note

Text

Reset, Chapter 2

Series Masterlist

Full A/N below- please read previous A/N if you're just getting acquainted with the story! A bit of development for this slow burn, but I will be posting several chapters today that will bring us all the way up to things getting exciting!

════════════════════ஓ๑♡๑ஓ══════════════════

August 22, 2022- Findel, Luxembourg

The wheels hit the tarmac with a heavy thunk, the sudden shift in gravity making you instinctively press back into your seat as the plane slows down, rolling toward the gate. Your muscles are stiff, sore from the awful angles you contorted yourself into for the past twelve hours, but there’s no time to dwell on it. You barely hear the pilot’s announcement, barely register the sound of seatbelts clicking open around you, the shuffle of passengers stretching, retrieving bags, making groggy conversation.

You just breathe, long and steady, pressing your palm into your thigh to ground yourself.

It’s real now.

The last twelve hours have been a blur of data, race footage, and mind-numbing technical documents. You’d thrown yourself into studying, devouring every detail about Spa, about the AlphaTauri AT03, about anything that might give you a sliver of an advantage. At some point, exhaustion had forced you under, and you’d managed to sleep- not well, and not for long, but enough to keep yourself from completely burning out before you even landed. You don’t know if it’s enough, but it doesn’t matter. The only thing that does is the fact that you’re here.

You pull your duffel from the overhead compartment, the strap biting into your shoulder as you shuffle down the narrow aisle, down the jet bridge, through the airport corridors. The Luxembourg terminal is sleek, modern- glass walls, clean lines, an unbothered hush to the early-morning crowd. It’s almost enough to make you feel like this is just another trip, another airport, another connection to some middle-of-nowhere racetrack.

Almost.

You exhale slowly, shoulders still tight from the flight, standing just a little too upright at baggage claim as the conveyor belt lurches to life with a mechanical groan. Around you, the other passengers shuffle forward in loose, disjointed clusters- bleary-eyed and half-present, tugging their carry-ons behind them, faces lit by the glow of phone screens. You barely notice them. Your focus is locked on the mouth of the belt, waiting for the first bag to appear.

The seconds stretch, and you can feel the flicker of unease curling in your stomach, the kind of unease that only comes when you’ve placed your entire fate in the hands of an airline’s baggage system. It would be inconvenient- spectacularly inconvenient- if your gear didn’t make it. Not just your clothes or your toiletries, but your helmet, your gloves, your boots- everything. The tools you need to do the only thing that matters this weekend.

You can handle a lot- jet lag, exhaustion, even the gnawing anxiety clawing at the edges of your composure- but showing up to the most important race of your life with nothing? That’s not a setback you have time to recover from.

Then, finally- there.

Your race bag drops onto the belt with a dull thud, and it’s impossible to miss. It’s enormous, practically the size of a small coffin, its navy fabric scuffed and faded from being tossed in and out of transporters, cargo holds, and garages across America. You muscle it off the belt, the weight familiar, grounding.

You sling your duffel over your shoulder, grip the handle of your race bag, and start toward the exit. No hesitation, no adjusting straps or rolling out sore shoulders- not yet. Every second counts. Every person standing around re-packing their duty-free bags or stretching out the stiffness from the flight is another body you can get in front of in the customs line. You can adjust in line.

The weight of your bags pulls at your arms as you weave through the terminal, stepping around half-asleep travelers and families trying to wrangle children, past the slow-moving group of businessmen already back on their phones as if they never left the ground. The overhead announcements blur together, voices in multiple languages calling out baggage claim numbers, security reminders, gate changes. None of it matters. The only thing that matters is putting one foot in front of the other, getting through this final checkpoint between you and some fresh-fucking-air.

Customs.

You slip into line, shifting your duffel to your other shoulder, adjusting your grip on your race bag. It’s moving, at least- steady, slow, but moving. You take the opportunity to pull out your passport, flipping it open, rolling your shoulders back as you force yourself to breathe.

The line inches forward. A woman ahead of you fumbles with her boarding pass, patting down her coat for something lost in a pocket. A man argues softly with an officer over the contents of his declaration form. The customs agents work through their endless queue of travelers with the same disinterested efficiency you’d expect.

When it’s your turn, you step forward, placing your passport on the counter. The officer barely glances at you at first, flipping it open, running his eyes over the photo page before thumbing through for an empty page. He’s got plenty of options- there aren’t many stamps. A handful from trips to Mexico, a couple from the occasional race in Canada. But there- right near the middle of the booklet, pressed between the folds of your life before now- is Japan.

The ink is slightly faded, but the memory is sharp.

A feeder series race under Puerta Performance. One of the biggest, most competitive wins of your junior career. A stream of races where everything clicked, where you’d finally felt like you belonged in the conversation. You had flown in alone, carried your own damn bags, worked on your own damn car- elbow to elbow with the one real mechanic the team had, and then, somehow, you had won.

It had been your first real, international win. And it had done nothing for you.

The officer glances up, his face still unreadable. "Business or pleasure?"

"Business," you answer automatically.

He nods, flipping back to the front, glancing from your photo to your face, making sure they match.

"And how long will your visit be?"

You hesitate- because you don’t actually know. "A week," you say, because it’s less likely to have you corralled in a plexiglass room than saying as long as they’ll let me stay.

The officer hums, pressing the stamp to the page with a firm thunk, sliding your passport back toward you. "Welcome to the EU."

You don’t waste another second.

Snatching the passport off the counter, you tuck it away and haul your bags back into motion. You’ll check the taxi company on your way- just move. Get outside, get in the car, point your feet somewhere closer to the track and figure out the rest as you go.

Snatching the passport off the counter, you tuck it away and haul your bags back into motion. You’ll check the taxi company on your way- just move. Get outside, get in the car, point your feet somewhere closer to the track and figure out the rest as you go.

The wheels of your race bag clatter against the sleek tile floor as you push forward, dodging clusters of travelers, sidestepping a family stopped dead in the middle of the walkway, their kids wrestling over a stuffed animal. Someone’s wheeling a cart stacked with oversized luggage ahead of you, moving at a crawl, and you veer around them, your steps sharp, determined, relentless.

You're not rushed, not in the way that people sprinting to catch a flight are, but you're moving, too fast for someone who technically doesn't even have anywhere to be yet. But you do. The track. The garage. The sim. Work.

Your mind is running just as fast as your feet, the hum of the airport, the PA announcements, the scattered conversations in a dozen different languages all blurring together into static behind the sheer force of what comes next.

Four days.

Four days until FP1.

Four days to go from a long shot to something real.

Four days until you’re sitting in a Formula 1 car, in an actual race weekend, on one of the most legendary circuits in the world.

Your brain jumps tracks, recalibrating, running through everything you’ve learned, everything you still need to absorb. The AT03’s handling characteristics- where it struggles, where it thrives. The high-degradation nature of Spa’s tarmac. The elevation changes. The brutal forces through Eau Rouge and Raidillon. The moments in Yuki and Pierre’s footage where the car fought them, where the rear stepped out just enough to need a correction, where the chassis didn’t quite stick the way a Red Bull would- where it wouldn’t tolerate the lines of a more aggressive driver.

The air outside is going to be crisp, maybe damp, but you barely register the thought. You’re too busy calculating, adjusting, trying to fit yourself into the space you haven’t even stepped into yet. The exit is just ahead. You can see the doors, the hazy gray of the early morning sky beyond them, the promise of movement, of getting out.

Then-

"Miss LeChriste?"

The voice cuts through the fog of your thoughts, smooth, precise. Not quite questioning, not quite commanding. It’s the tone of someone who already knows they have the right person. You blink, your mind needing an extra half-second to pull itself out of the high-speed loop it’s been running. You turn toward the sound. A man stands on the curb closest to the exit, holding a sign with your name on it.

Oh.

Your momentum stutters, feet slowing as your brain processes what you’re looking at.

You’d expected a taxi. Maybe some impersonal email from a logistics coordinator telling you to grab a rental from the airport desk, something with a budget cap and a manual transmission.

That’s what you’re used to- IndyCar, where teams cut costs at every possible turn, where travel arrangements were a patchwork of last-minute flights, hotel points, and the cheapest rental car they could justify expensing. Or, if you were really lucky, maybe one of the mechanics would swing by and pick you up in their own car, some beat-up old diesel with empty energy drink cans rattling around in the backseat, the heater stuck on max, a roll of duct tape on the dashboard because you never know.You’d piled into the passenger seat of sun-bleached hatchbacks, squeezed between spare parts and duffel bags, making small talk while rolling toward whatever motel your team had justified that weekend.

But this?

This man is wearing a suit. A pressed, properly fitted chauffeur’s suit, complete with a hat, standing in front of a sleek black car that definitely isn’t some bottom-tier economy rental.

"Uh, yeah. That’s me."

The driver nods once, crisp and efficient. "Right this way, Miss."

Miss.

You almost snort. Nobody calls you Miss anything. You barely get your name half the time.

You hesitate for the briefest second before stepping forward, gripping your race bag a little tighter. It’s ridiculous, but you feel out of place already, being ushered toward a private driver like you’re someone important.

There’s something about the way he says it that reminds you- this is Formula 1. This isn’t Indy, where you might be scrounging for a last-minute rental, squeezing into whatever compact car they gave you at the desk, hoping the hotel is decent enough to have a working coffee machine in the morning.

No.

This is Red Bull money. This is the first, quiet luxury of an operation that is so far beyond where you’ve been that you barely know how to process it. The kind of money where they send a driver- a chauffeur- to meet you at the airport before you’ve even turned a wheel for them.

The part that you’re really stuck on? This isn’t the top of Formula 1. This isn’t a private jet, a five-star concierge service, the kind of excess reserved for world champions. This is the bottom of the rung treatment. This is standard. This is what they do for anyone under their umbrella. This is expected.

The thought buzzes through you as you follow him toward the car, your feet moving before your brain has even finished catching up. The air outside is crisp, damp from last night’s rain, and the sky is the washed-out gray of early morning. The exhaustion is there, creeping at the edges of your mind, but it doesn’t matter. You’re still running on adrenaline, on the sheer force of need, but none of that really registers because-

What the fuck is this?

This isn’t your world.

The driver reaches for your race bag, and for a moment, your immediate instinct is to pull it back, to haul it into the car yourself, because that’s what you’ve always done. You carry your own gear. You load your own luggage. You do it yourself, because no one else is going to do it for you.

But his hands are already on it, lifting it into the trunk with the ease of someone who expects to be doing this. Like it’s normal. Like it’s his job.

You exhale through your nose, shaking off the instinct to tell him you’ve got it. Instead, you climb into the backseat, sinking into the plush leather, the scent of clean upholstery hitting you as the door shuts with a quiet thunk.

Outside, the sky is gray, a thick European morning pressing against the glass as the driver pulls away from the curb, the urban sprawl of Luxemborg slipping into something quieter, something greener. You know, logically, that the scenery outside is incredible- lush countryside rolling into the Ardennes, sweeping hills, dense forests- but you don’t spare it a second glance. You don’t have the time for it.

You haven’t looked out the window once.

Instead, your mind is still on the flight, still running through every second of the last twelve hours, every bit of information you devoured somewhere over the Atlantic.

Spa.

You’d watched every inch of Spa.

Every braking point, every apex, every trick of the circuit that separated the competent from the champions. The Red Bull driver portal had given you access to all the film you could ask for- every onboard lap, every telemetry breakdown, every millisecond of data available. You’d watched the best of it, the ones who had conquered this place.

Max, Checo- their onboard film from this very track last year. The big boys. The cleanest, fastest lines that Spa had to offer. The best-case scenario. The way Max bullied his way through the wet, the way Sergio managed his tires on a track that could go from soaked to bone-dry in minutes. They were aggressive, clinical, perfect.

Yuki and Pierre’s onboards- this season, especially. A different perspective. Your perspective. The same car you’d be driving. The AT03 wasn’t the RB18, not by a long shot. It lacked the raw dominance, the brutal efficiency, but it was the best AlphaTauri had managed in years. You studied how it moved, where it suffered, where it thrived. The way Pierre fought understeer through S-turns. The way Yuki handled the tricky mid-sector when the tires started to go. The places where they struggled, where you might struggle.

You absorbed it all.

You should be intimidated. You should be honored, overwhelmed by the fact that in just four days, you’ll be on the same track as the real legends, racing on one of the most historic circuits in the world.

But you don’t have time for intimidation.

You don’t have time to sit here and marvel at the fact that you’re about to put a Formula 1 car through Eau Rouge, that you’re about to barrel down the Kemmel Straight at 300 kilometers an hour.

You have four days. Four days to be good enough to make someone, anyone, just… notice.

You shift in the backseat, adjusting your posture, rolling your shoulders back to shake out the stiffness. You’d finally shucked off your race suit after landing, stripping out of it in an airport bathroom, standing at the sink and taking a long, long look at yourself in the mirror before forcing yourself into something that wouldn’t get you laughed out of the boardroom when you arrived at the track. A fitted jacket, dark jeans, your best attempt at looking like you belonged.

The racesuit had been a reminder, a necessary weight of shame on the flight. But now? Now, you needed to look like someone they’d take seriously. There’s no room for shame, no room for weakness where you’re going.

You take a breath, steadying yourself as you glance down at your phone, skimming through the notes you made mid-flight.

Tire degradation. DRS zones. Elevation change data. Sector time comparisons.

The car isn’t even close to the track yet, and still, your brain is there.

The driver barely says a word, but you can feel his occasional glances in the rearview mirror, maybe wondering what exactly he’s transporting. Maybe wondering if the girl sitting stiffly in his backseat, scrolling through race data at seven in the morning, is actually human.

════════════════════ஓ๑♡๑ஓ══════════════════

August 22, 2022- Spa-Francorchamps Circuit, Belgium

The paddock is in pieces when you arrive, barely recognizable as the polished, high-functioning heart of a Grand Prix weekend. Temporary flooring is being laid down. Trucks are still reversing into position. Forklifts beep relentlessly as they maneuver crates full of equipment and spare parts into the skeletons of hospitality units. Crew members are swarming everywhere, setting up gantries, rigging screens, connecting endless tangles of cables that will power the broadcast feeds and telemetry systems by the time Friday rolls around.

You weave through it all, your race bag rattling behind you on uneven asphalt, escorted by an AlphaTauri staffer who barely introduces himself -Ignacio?- before setting off at a brisk pace. You don’t mind. The chaos feels oddly comforting- this kind of frantic, half-formed scene is something you know well. Setup days at Indy weren’t so different, at least in terms of sheer logistical madness.

What’s different is the scale.

Even in its unfinished state, this place radiates money. The equipment, the infrastructure, the sheer size of it all- everything is dialed up to a level you’ve never touched before. You pass Red Bull’s hospitality build, where scaffolding and tarps still cover half the façade, and for a split second, you think maybe that’s where you’re headed.

It’s not.

You’re led into the actual racetrack offices instead- concrete hallways and plain glass doors, a far cry from the polished luxury the public sees when the paddock is camera-ready. This is the backstage, the practical side of the circus, where decisions happen before anyone ever hears an engine fire up.

Your escort leaves you at the door of a conference room, gesturing for you to go in. You smooth your jacket, square your shoulders, and step inside.

They’re all waiting. You register them, of course, briefly as they all look up.. A set of suits that look like they may have slept even less than you in the last twenty-four hours, two bright eyed, pleasant looking professionals decked out in team kits. But they’re not who earn your attention first. It’s not Mattia Spini that gets it, either. It’s not even Franz Tost- to most, you’d be crazy not to defer to him first- he is the man that this entire opportunity rides on, after all.

But that’s not the truth. Not entirely. Because the Godfather is here.

Helmut Marko.

He’s not seated at the table with the others. Instead, he stands off to the side, leaning against the windowsill like he’s still trying to decide if this meeting is even worth the energy of taking a proper seat. His arms are crossed, head tilted slightly, expression settled somewhere between bored and mildly inconvenienced. He looks at you the way a banker looks at a loan applicant with no credit history- no malice, no warmth, just a quiet, clinical assessment of risk versus reward. It’s not dismissive, but it’s not encouraging, either. It’s the exact amount of respect you’ve earned from him so far, which is to say- none. Not yet.

It’s not a surprise. If anything, you’d expected worse.

Helmut Marko isn’t just some team advisor who drops in for the important meetings. He’s the architect of the entire Red Bull driver development program- the gatekeeper of every seat that exists within this brand. Every junior driver with a Red Bull patch on their chest lives under his thumb, or the thumb of someone who does. He decides who gets opportunities, who gets second chances, and who gets left to rot in feeder series obscurity.

And if you’re not his, if you didn’t come up through his system- if you weren’t plucked from karting at age 12 and molded in the image of what Helmut Marko believes a Red Bull driver should be- you’re already starting with a strike against you.

You’re twenty-two. By Helmut’s standards, that’s practically geriatric for a driver who still needs to prove themselves. Most of his prospects would have either succeeded or washed out entirely by your age. They would have either earned a seat, or been shuffled off to sports cars, endurance racing, somewhere that didn’t matter to him anymore.

But you’re here.

And that’s the part that matters.

Because Helmut Marko doesn’t suffer charity cases. He doesn’t tolerate time-wasters. The fact that you’re standing in this room at all means that, somewhere along the line, something about you caught his attention. Maybe it was your handful of substitute drives this season and last. Maybe it was something Christian Horner said. Maybe it was sheer desperation on AlphaTauri’s part to find anyone who could possibly hold the line in Yuki’s absence.

It doesn’t matter why.

All that matters is that Helmut Marko allowed this meeting to happen. He doesn’t have to like you. He doesn’t have to be impressed. He just has to leave the door open exactly this much. It’s your job to kick it the rest of the way in.

You move like you belong here. Like this is normal- being thrown into a meeting with a room full of people who hold your future in their hands. Like you weren’t on the other side of the world less than twenty-four hours ago, driving a shitbox for a team that treated you like nothing.

The first few minutes are pure formalities. Introductions, pleasantries, nods exchanged. You shake hands with everyone, making sure your grip is firm, your eye contact direct. You sit where they gesture, hands folded in front of you, posture perfect. Professional, measured. No jokes, no awkwardness, no nerves.

Franz Tost sits at the head of the table, his posture composed but his expression unreadable. Franz starts with the basics- introductions, a brief overview of what they’re hoping to achieve this weekend. You keep your tone perfectly professional, measured, micromanaging every aspect of yourself to project exactly what they need to see. Capable. Likable. Smart enough to understand the stakes. Hungry enough to take whatever they give you. You ask exactly the right questions at exactly the right moments- about the car, about expectations, about media requirements, about everything that will determine whether or not you make it to the weekend.

To his left is Mattia Spini, the man who will be your race engineer this weekend- if you earn the car. He’s quiet, thumbing through the small stack RedBull’s assembled that you can assume is all your career -your life’s work- mounts to, on paper.

The legal team- the two suits- sit with carefully neutral expressions. When they slide over a stack of documents that might as well be a brick, and you pick up the pen without hesitation, signing where they point, asking the occasional smart, concise question to show you’re paying attention.

Media relations is here too- the kitted-out pair you had noted before. You nod along to their every ask, perfectly agreeable. You’ll do every interview they want, every promo shot, every press availability. You don’t care. You’ll stand in front of cameras all day if that’s what it takes to earn the seat.

"I’m happy to do whatever the team needs."

It’s not a lie. It’s not even an exaggeration. You will do anything.

And then, it’s your turn. You pull your own packet from your bag- a meticulously prepared file containing every piece of critical data they could possibly need about you. The Holy Bible. This is your life’s work- not the measly six or seven pages they had scraped together and set in front of each seat before you arrived. Mattia takes the folder without much thought at first, flipping it open with the kind of casual disinterest of someone who has sat through way too many meetings just like this one. But the second his eyes land on the first page, the shift is almost imperceptible- almost.

You see it, though.

It’s in the way his fingers slow against the edge of the paper, in the way his posture changes just slightly. His gaze sharpens, scanning the structured layout, taking in the color-coded tabs along the side, the neatly labeled sections that break everything down into digestible, categorized data points.

His brow creases just slightly, his fingers smoothing over the paper as he scans the biometric data. Stress tests, reaction times, endurance tracking. He turns another page, and another. Height, weight, exact body measurements for suit fittings, seating position requirements. Flip. Car history, setup preferences, personal notes on what has worked for you and what hasn’t. Flip. On-track strengths, biggest flaws, areas you’ve personally identified as weaknesses and your own methods of mitigating them.

You keep your expression even, but you know exactly what’s happening here.

Mattia is a data guy. That’s how he got this job in the first place. Numbers, telemetry, analysis- it’s what he does. He’s used to drivers walking in with an opinion on how a car should feel, sure, but not with this.

Because this? This is what he does. This is his job. Synthesize the data, break it down, make it digestible, work on it with the driver. Not the other way around. And that’s interesting.

Tost glances at him briefly, but Mattia doesn’t look up, doesn’t acknowledge the way the room has subtly shifted. He keeps flipping through, fingers moving slightly faster now, like he’s searching for something, like he needs to confirm that this is actually what he thinks it is.

“Did Dale Coyne’s engineers put this together for you?” Mattia’s voice is casual, but the surprise isn’t hidden. It bleeds through the edges, slipping into the slight lift of his brow, the way his fingers hesitate for half a second before flipping to the next page.

You almost laugh- almost. Because the idea of those half-competent, half-bored bastards at Dale Coyne assembling something this polished, this comprehensive? It’s ridiculous. Those men wouldn’t waste the paper to print you a fucking data readout, much less do you the courtesy of organizing your career data into something usable. And if they had? It wouldn’t look like this. It wouldn’t be color-coded within an inch of its life, wouldn’t have cross-references or a table of contents, wouldn’t read like a military dossier written by someone who knows exactly how much weight every ounce of detail could carry.

“No,” you say smoothly, keeping your face as neutral as your tone. “I keep all my data myself.”

There’s a reaction. A small one, but you catch it- Mattia’s head tips just slightly, the folder resting heavier in his hands now, no longer just a pile of papers but a point of interest. His fingers tighten against the edge, not out of irritation but out of concentration. It’s the look of a man who’s just found something unexpected in a sea of the predictable.

You know this moment. You know it.

Because your mother, Marissa LeChriste, made sure you could recognize this kind of moment before you could even spell leverage.

Marissa is a masterclass in influence- not the shallow kind you see on social media, but the real thing. The art of making herself seem indispensable to a room full of men who hadn’t planned on respecting her, let alone considering her. She can read a person like a teleprompter, knows exactly how to shift her tone, adjust her posture, time her smiles. Knows the exact point where charm turns into control, when friendliness becomes power.

You grew up watching her do it- absorbing every glance, every pause, every moment where she turned skepticism into loyalty. Your first major sponsorship? It wasn’t talent alone that landed you that. It was Marissa, walking into meeting after meeting armed with laminated proposals, strategic data points, and a smile so warm it was damn near a weapon.

And God help the poor bastards who said no- because Marissa never walked out of a room without leaving at least one person regretting it.

So when Mattia’s posture shifts- when his fingers curl just a little tighter around the folder- you see it for exactly what it is.

This isn’t a foot in the door. You’re not stupid enough to believe that. You’re a long way from safe, a long way from in. But this? This is a crack. The smallest sliver of daylight peeking through a door that should have stayed sealed shut. And if there’s one thing Marissa LeChriste taught you, it’s that a crack is more than enough.

Because a crack can become a gap. A gap can become a doorway. And a doorway, with enough pressure, with enough carefully applied force, can be shoved wide open until the whole goddamn wall collapses.

You can work with a crack.

It’s quiet- the way the room adjusts around you, your bible, your life laid out on the table. A glance exchanged between Franz and Mattia, a note scribbled down by one of the legal guys, a slight shift in how the media reps hold themselves, sitting forward like maybe- just maybe- you could be someone worth building a campaign around, if even just for a weekend. They’re not sold, not yet. But they’re considering it. You can feel the air change, like the whole meeting tilts half a degree in your favor.

Helmut doesn’t react.

He hasn’t so much as blinked in your direction, not since you sat down. But you can feel him watching, the same way a snake watches something small and scurrying across the ground, waiting to decide if it’s prey or just scenery.

That’s fine.

That’s good enough for now.

Because here’s the truth: the business side of this? It’s not hard for you. It never has been. You know how to smile at the right people, how to dress the right way, how to be charming without being threatening, how to crack a joke that makes people want to root for you instead of against you. It’s all manipulation, but not the ugly kind - it’s survival. And you are fucking excellent at survival.

But none of that - none of the paperwork you just signed, none of the polite nods from Franz, none of the cautious optimism radiating off Mattia - none of it matters unless you can back it up where it counts.

On the track.

You can dazzle them in the boardroom all you want, but this sport isn’t won in a goddamn boardroom. It’s won with lap times. With split-second reactions. With the brutal, intimate understanding of what a car needs, what it can take, what it’s asking for through every bump and twitch of the wheel. If you can’t master that, everything else - the marketing, the PR games, the networking - it’s all just performance art. A nice, neat obituary for a career that never got off the ground.

You won’t be that driver. So you ask for one thing. Not money. Not special treatment. Not even extra setup time with the car - because you know that will get you about as far as asking for a unicorn. You ask for the only thing that will actually make a difference.

“A dedicated sim rig,” you say, voice level, hands folded on the table like you’re asking for something as ordinary as a cup of coffee. “Set to car specs. Six hours of uninterrupted drive time every day until Friday.”

Mattia blinks, caught slightly off guard by how quickly you’ve shifted from polite first impressions to cold, practical demands.

You keep going. “I don’t care when. Middle of the night, middle of the day. I’ll work around the press obligations, the strategy meetings, the media work - all of it. But I need six hours. Preferably eight, if you can swing it.”

The room goes quiet.

Not hostile, not disapproving - just quiet.

Because you know what they’re thinking. They’ve had rookies before, juniors promoted too soon, kids drunk on their own hype. They’ve seen the swagger, the bravado, the ones who show up convinced that talent is enough, that instinct will save them.

But that’s not you.

You don’t believe in talent like it’s some divine gift. You believe in work. In attrition. In being the last one standing when everyone else has burned themselves out. You believe in cramming yourself so full of knowledge that instinct becomes irrelevant- you won’t need instinct, because you’ll already know.

You don’t have the luxury of leaning back on raw talent. You never did. You came up scrapping for every seat, scraping every inch of track time you could get, making your own damn data because no one else was willing to care enough to collect it for you. And now?

Now you’re at war.

Not with Mattia, not with Franz, not with Liam or Pierre or even Max-fucking-Verstappen.

You’re at war with yourself.

With the version of you that lived in the Dale Coyne pit, who ate shit and smiled politely and took every ounce of disrespect because you thought it was the only way to keep your career breathing. With the part of you that still remembers your parents taking out a mortgage on a paid off house just to buy you a seat at that team. With the younger version of you that believed you could make it in this sport if you were just good enough.

There is no "good enough" here. There’s only ruthless.

And if it means you work yourself into the fucking ground for the next four days, so be it. If it means you sleep three hours a night and run on caffeine and adrenaline, fine. If it means you fake your way through every press conference, smiling so wide your cheeks cramp, then collapse in a heap of exhaustion afterward, you’ll do it. Because there’s no going back. You will burn yourself to the ground before you let this opportunity slip.

Mattia glances toward Franz, some unspoken communication passing between them, and then he nods. “Done.” You’re certain it’s not a concession. You’re certain it’s not a favor. You’re certain it’s a test.

You’re certain they want to see if you’ll actually do it. If you’ll show up to that sim rig at some ungodly hour and run laps until your eyes blur, until the seat bruises your back, until the muscle memory starts to override the fear gnawing at the edges of your composure.

They want to see how badly you want this.

They have no idea. They have no idea that you will work every single person sitting here under the table. They have no idea you won’t stop until you’ve outworked every strategist, engineer, pit crew member practicing tracking the tire with his gun. That you’ll outwork the race marshalls, the officials, the fucking janitor sweeping the crusty, smushed french fries from the grandstand floorboards come Sunday night.

“Thank you,” you say. They have no fucking idea.

════════════════════ஓ๑♡๑ஓ══════════════════

Hey guys! Happy season kickoff! Apologies for being gone for so long, I've spent the last few weeks editing and re-writing like a madman as I wanted to be able to bulk publish at least to where the story starts to get more involved with Max, which meant I had to hold back the earlier chapters. So, enjoy the next few posts, we will settle into a more regular updating schedule soon. I promise we are getting to the meat soon- but I want to really nail this exposition, fully flesh out the characters and their relationships with others because it makes everything hit SO much harder when we get to where we're going. Just lean into the ride, it will be fun :).

Working on getting a series master list up for easy navigation. As always, your response and interaction are a huge part of how I stay motivated to do what I do, thank you to everyone who followed, reblogged, or commented on the introductory chapter! I read every single one and so appreciated!

#f1#max verstappen#max verstappen x reader#f1 x reader#formula one#f1 fanfic#max verstappen x y/n#max verstappen x you#mv1 fic#mv1 x reader#mv33 x reader#mv33 fic

95 notes

·

View notes

Text

Every song counts on The Bear.

Note: This is adding to what @ambeauty posted about Sydcarmy songs and how music serves as part of the story telling.

We all know that music is a very necessary part of television or any kind of motion picture for that matter, if for nothing else, for its aesthetic value. But many times it goes way beyond the aesthetics- it contributes to the mood, depth and even acts as a narrative device.

The Bear nails down the latter perfectly. Music in The Bear is not to be overlooked at all. It is in itself a conveyor of not just mood, depth and narration – but intention. It lets you know what these mostly quiet (haha) voices are really trying to say. It spells out the between the lines.

Storer establishes this firmly in The Bear’s pilot System. They come out swinging with giving us the music as its own voice.

After Carmy’s very lovely, not at all disturbing dream, we’re plunged right into his immediate, very frantic world at The Beef with “new noise” which later blends in perfectly with “old engine oil” while he tries to innovate in the midst of lack. The music is chaotic, it’s urgent. There’s Carmy running against time contrasted with visuals of old photos- time passed. There are no words but the music tells you that what’s happening here is an attempt to blend new ideas into an old system. The moment he catches a break, everything goes quiet.

After meeting with Syd and receiving some confidence boosting last words, Carmy is back in the kitchen to give some orders and get the day rolling. Don’t Give A Damn by Serengeti starts playing. Here’s part of the lyrics:

I personally view Serengeti’s music as Carmy’s main voice for season 1 (because it reads very stream-of-consciousness, is very attuned with his struggles of the day lyrically and always plays when he needs to be in control of the kitchen). Meanwhile he faces a lot of objections to the changes he’s trying to make but he is standing his ground. You can tell he doesn't have the utmost respect of the people he is dealing with but it’s clear that he’s the one in charge, regardless. The dominant voice. Until Richie appears, that is.

The change in the atmosphere as Richie enters The Beef is so jarring. It is immediately obvious that he's the favorite of the two in that kitchen. A new rock and roll song overpowers Serengeti (I tried to find out what song that was without any success). Notice how when they go into the walk in away from everyone else except Syd, the music goes quiet.

After Carmy takes a good shot at Richie with the subject of inheritance, Serengeti (Don’t Blame Steve) starts playing and a battle of voices and sounds ensue. It’s white millennial rap vs Gen X rock and roll and each song gets louder and dominates when the respective character is making their argument. This time Richie comes out on top, having the last word. Carmy is looking humiliated in front of his girl his new employee while Richie's Gen X rock and roll closes out the scene.

Later, when Carmy taste tests the new sandwich with The Beef staff, the same mix of “new noise” and “old engine oil" plays again in the same mix.

Also we see Tina trying to assert herself as well by putting on her own music on the stereo but Syd shuts it down immediately by manually turning it off, kind of foretelling how their own relationship will go.

The Bear wants you to understand that the music is saying something. It’s a part of the story in such an integral way. So we always have to take into consideration what the music is implying in any given scene. Storer is letting you know there’s nothing wasted, there’s nothing offhand.

Everything is intentional.

#the bear#the bear meta#sydcarmy#carmy berzatto#sydney adamu#richie jerimovich#the bear fx#carmy x sydney#carmy x richie

54 notes

·

View notes

Text

19th's Steam Next Fest Impressions Feb 2025 Edition - Day 4

Day 0/Day 1/Day 2/Day 3

Rusty Rabbit

youtube

If I had a nickel for every game I've played this next fest featuring cute characters and whose protagonist is voiced by Takaya Kuroda, voice of Kiryu Kazama, I'd have two nickels, which is not a lot but it's weird it happened twice.

It's a Metroidvania about evolved rabbits digging through the ruins of humanity after the apocalypse.

Written by Gen Urobuchi. I'm liking the premise and tone, and enjoy the running gag of "no one in the rival group The BB's can agree on what their name actually stands for." But aside from that there's not much "hook" to the plot yet.

Your starting mech has a nice balance between being agile and feeling appropriately "stiff," since it's a homebrew pile of junk. Nothing gets in the way but it feels right.

The game has an experience system, where both fighting enemies and digging through rubble blocks gives XP. Worried the latter might encourage drudgery, but it's not there yet.

The combat was kinda boring, but they barely threw any enemies at you anyways. I'm hoping getting actual upgrades and actual combat will make it interesting.

There's supposedly going to be a crafting system but the demo stops before you can touch it.

Mashina

youtube

One game about digging deserves another.

compared to Rusty Rabbit, this game's idea of digging is a lot more freeform. Fly about on a 2d plane and drill through rock. Get minerals for items and, assumedly, upgrades. A conveyor belt building system suggests there will be a layer of automation. But the demo didn't really fully explore that.

The demo was very barebones in general. It seems mostly there to show off Jack King Spooner's trademark visual style: Mixed media, assets created by molding real clay and other items, cutscenes shot on a real camera, faces on the characters drawn with marker. From what I've seen this is always been his forte, but it feels like a step up from his previous game, Judero.

No idea how plotty it's going to be compared to Judero. There were a lot of characters, but trying to talk to most of them got an abrupt "NOT AVAILABLE IN DEMO."

The Electrifying Incident: A Monster Mini-Expedition

youtube

A Monster's Expedition was a puzzle game that was both incredibly relaxing and incredibly in depth. I'm glad the devs are going back to this particular well.

A Monster's Expedition was about pushing and rolling trees by hand, sokoban style. This game is about picking up and placing boxes using a grappling hook, putting them on buttons to turn off electrical grids, create bridges, or open doors.

There are some strong limitations, as expected for a puzzle game. For one, once you grab a box, the grappling hook functions like holding it at the end of a stick. Considering the large amount of bottomless pit in the map, this can make getting the box to solid ground a problem. Not only can your character not step on electrified ground, but if a box they're grabbing touching electrified ground, the shock will carry over. Not only can your character not step on electrified ground, but if a box they're grabbing touching electrified ground, the shock will carry over.

The demo was painfully short, and cut off abruptly, but it's already surprised me with a couple of its mechanics. I'll be keeping an eye on this.

The Path of Ren

youtube

Celeste-like precision platformer. The two main differences are 1) While there's wall and ceiling climbing, there's no stamina system limiting it. 2) the dash is not the central mechanical pillar like it was in Celeste. It's one of many very limited power ups.

The other power-up the demo offers is, for lack of a better word, "ghost mode." For a short period of time, your speed and jump height double, and transparent platforms become visible. Useful for when you need to do a long distance obstacle course quickly, but gets in the way when you want to do precision jumping in closed areas.

The game also plays more with enemies, or at least "obstacles with player-reactive behavior" The earliest is a spider that drops from above when you go under it, but it leaves a web you can climb. There are also grasping hand obstacles that do some light tracking, forcing you to give them a wider berth than expected.

While its pixel art and music can't fully match Celeste's quality, I do like the zen atmosphere they're going for.

Grimshire

youtube

If I'm going to follow themes today, might as well throw another bunny game in the mix while I'm at it.

Thinking about it, it's kind of odd that "farming" became synonymous with "cozy." I mean I get why, it's a good mechanical backdrop for daily routines, and there's a lot of idyllic pastoral imagery surrounding it but… aside from the labor aspect, farming can be pretty precarious.

That's the sort of scenario this game is exploring. It takes Stardew Valley and adds more pressure.

Your character arrives in the hamlet of Grimshire after being saved by a merchant ship, after the unnamed capital went in flames. You've given some abandoned farmland as is the norm in this type of game, but soon learn that the capital event is tied to a plague outbreak. With the majority of trade gone… your farm is the town's main source of food.

While there is individual buying and selling, the majority of your crops will be heading to a communal cellar. While I didn't test this, since I only played for a few in-game days… if you don't keep up, villagers will start dying. The woodland creature characters isn't just an aesthetic choice. It's a community of herbivores and carnivores, and you need to keep both fed.

There's also a voting system where the townsfolk will decide on emergency measures. While the first one is simply "do we build an herb garden or mushroom garden to try and keep up the medicine supply" I can imagine this will be used for dramatic effect later.

This isn't to say that the game is constantly bearing down on you aesthetically, or abandons any connection to the "cozy" games before it. Both the visuals and audio have a sort of soothing aspect to them, and there's still a sense of getting lost in the momentary tranquility. But the tally at the end of the day telling you exactly how many days of food are left in the communal cellar kind of snaps you out of it.

The game is in pre-alpha so a lot is up in the air of how the final product will look and play but this is a cool seeming twist on the formula.

I really need to dip further into Stardew so I can better experience the formula straight, though.

Hypogea

youtube

If I had a nickel for every time I've seen an indie game platformer about a decrepid robot exploring an impossibly large superstructure, I would have two nickels, (the other being Lorn's Lure.) It's not a lot but it's weird that it happened twice.

Also if I had a nickel for every time I got to say the "it's weird that it happened twice" joke today I would have two nickels. Which isn't a lot but it's weird that it happened twice twice.

The main gimmick is your staff. Your character doesn't exactly have spring loaded heels, so you need to use it to boost yourself, pole vaulting and grasping distant ledges and hooks to swing from. These small hiccups add a nice sense of friction and momentum to what otherwise would just be "press a to jump."

There's only two "characters," your robot and another, one armed one that recussitated you. There's no dialogue, everything is expressed via body language. This makes me think it'll either be story lite, or try for abstractly heart wrenching a-la Team Ico's ouvre.

You do get to see some memories from now deactivated robots, showing there used to be humans in whatever superstructure this is, as well as some artefacts that give some very vague clues at what's happening.

I do worry the environments will get samey if it's all going to be blue-grey cavernous industrial stuff. Hopefully the final release will expand on the visual palette.

Kejora

youtube

I see time loop game, I click. I then get disappointed.

Kejora is an Indonesian puzzle adventure game about the titular girl realizing her village is stuck in a time loop and also there are monsters hiding around. Also her mom is sick and her dad is dead which will probably be used for a good heartstring tug.

The art direction is for the most part good, and while the effort is unevently distributed, there's proof that they CAN animate here. It's just that the areas that are stiffer are the moment to moment game interactions. The stuff you see most often.

the puzzles are either standard adventure game "bring object A to area B" or "summon one of your friends to use one of their abilities." Those latter ones especially felt... kind of like busywork. Especially since your friends just teleport to you when you call them. No reason to consider their positioning when setting up the puzzle.

The translation is… ass. Weird wording, constantly shifting tenses, everyone has a robotic tone. And yet I can't blame the entirety of the writing on the translation, because the game has an exposition problem. Everyone is constantly restating things and saying the obvious.

Anyways I looked at the Dev's youtube and apparently this used to be a Metal Slug-like???

Nitro Express

youtube

Since I already got Metal Slug on the mind might as well try this.

A run and gun where you're a gun freak girlfailure who has been hired to be part of the special taskform for when companions, multipurpose autonomous vehicles, go rouge. in other words, shoot robbit.

The pixel art is gorgeous. There is a slight problem of the screen feeling a bit busy though, Kinda wish they pulled a CAVE and did purple bullets.

The combat overall feels good. The dodge roll feels nice, and it's not a free get out of jail free card, since you can only roll forward. You get your I-Frames in exchange for staring right down the enemy's barrel.

The gunplay feels nice. I kinda wish there wasn't a reload system though, even if it happens automatically. I'm already dealing with positioning and aiming, I don't want to have to track my mag at the same time.

My other complaint is that if you cause a car to explode right in front of your face you take damage. Which. makes sense. But I'm still mentally going off Metal Slug rules.

Lastly, I like that the health pickups are you shooting down a food delivery drone and stealing someone's meal.

Worth checking out.

#19th's steam next fest impressions#Rusty Rabbit#Mashina#The Electrifying Incident#The Path of Ren#Grimshire#Hypogea#Kejora#Nitro Express#Youtube

10 notes

·

View notes

Text

A band of robbers targets a train in the remote desert of Arizona, sneaking on board, slashing an air hose and forcing the locomotive to come to a dead halt. Then they take the goods and flee.

No, it's not the 1800s. It's 2025.

In less than a year, at least 10 such train heists in California and Arizona have netted about $2 million worth of Nike shoes, USA TODAY has confirmed after the Los Angeles Times first reported the string of robberies. More than 60 people are being charged in federal court in connection with the 10 heists, as well as other thefts in 2023 and 2024.

The robberies work like a “human conveyor belt,” with the goods passed from the train to the ground, to a truck, according to Keith Lewis, vice president of operations at CargoNet, a private company that provides supply-chain theft intelligence to law enforcement.

“It’s done fast. It’s fast as lightning,” Lewis told the Arizona Republic, part of the USA TODAY Network, adding that the thieves like conducting the heists in isolated areas so they have time to flee. “A lot of those areas you can't get to other than with a helicopter ... You can't even get to some of those rail tracks with off-road vehicles.”

The majority of the thefts have targeted trains operated by BNSF. The company says it's working with local authorities to address the problem.

"We work hard to protect our customers' freight from pickup to delivery and have security measures in place to help ensure these goods arrive safely," BNSF said in a statement to USA TODAY on Tuesday. "We are working with federal, state, local, and tribal police departments to coordinate our approach to disrupting criminal activity and arresting offenders."

Train, ground, truck: a quick process

In multiple affidavits submitted in federal court filings and obtained by USA TODAY, Homeland Security Investigations special agent Brynna Cooke describes how the heists are done.

Robbers scout containers to identify those that could have valuable cargo like Nike shoes and electronics, Cooke says.

They usually board trains in staging areas before they begin rolling. Then while the train is moving, they move from container to container, opening them with saws and bolt-cutters.

When they find something worth stealing, they’ll often force the train to stop by cutting the braking system air hose, causing it to “go into an emergency stop.” According to Cooke, once the train comes to a halt, box trucks are sent in to unload the merchandise and flee.

Lewis has seen the process firsthand.

“I've watched them through binoculars,” he told the Republic. “I just couldn't get there in time.”

Jan 13: More than $400,000 in shoes are stolen in Arizona

One of the most recent train thefts happened on Jan. 13 in northern Arizona, when police arrested 11 people in connection with the robbery of Nike shoes from a BNSF train in a remote area outside of Williams, some 170 miles north of Phoenix, according to court records obtained by USA TODAY.

Robbers who were on board the train cut its air hose around 11 a.m., causing the train to automatically go into an emergency stop.

Shortly after the thieves cut the Arizona train's air hose on Jan. 13, a BNSF police officer who was in the area spotted several cases of Nike shoes beside the train and later saw several people loading Nike cases into a U-Haul truck and a Ford Econoline truck nearby.

There were trackers inside some of the boxes that authorities then used to conduct a traffic stop on the van, court records say. When authorities later searched both trucks, they found 1,985 pairs of unreleased Nike shoes worth over $440,000, according to court records.

The shoes targeted were a new Air Jordan 4 style, a striking red-orange collaboration with BMX athlete Nigel Sylvester, dubbed “Bike Air.” When they go on sale in the spring, they will retail for $225.

But not all train heists end in arrests. When thieves cut air hoses in remote areas, conductors and engineers are stranded along with the disabled train. Ill-equipped to stop a robbery, they can’t do much beyond call 911.

“I've had conductors telling me that they actually watched them unload it," Lewis told the Republic. "But by policy they can't confront them because they're not armed, and the bad guys could be armed."

Jan: 10, $18,000 in shoes are stolen

In Southern California, two suspects are accused of stealing about $18,000 worth of merchandise in a remote area known as the Wonder Valley. According to a news release from the San Bernardino Sheriff's Department, BNSF Police contacted authorities for help.

Police said they were notified that several suspects were robbing a train. On the way to the scene, police said they saw a box truck driving in the area.

“Deputies conducted a traffic enforcement stop on the vehicle and, through investigation, located approximately $18,000 in stolen items inside the truck,” police said.

Two men, 28-year-old Oscar Sosa of Apple Valley, California, and 45-year-old Jose Villalobos-Infante of Phoenix, were arrested in connection to the robbery. They've since been charged with second-degree burglary, grand theft and conspiracy, according to the Hi-Desert Star.

USA TODAY was not able to immediately find attorneys representing the men.

Jan: 15, $400,000 in shoes are stolen again

Only two days after the Arizona heist and five days after the robbery in San Bernardino County, robbers allegedly targeted a train in the same area of California.

According to a news release from police, BNSF Railroad police notified the San Bernardino County Sheriff's Department of a train robbery. Deputies again spotted a white van leaving the area.

"However, the vehicle failed to yield, and a pursuit ensued," a sheriff's department statement said. "The vehicle became disabled on a dirt berm, two occupants fled, and a foot pursuit ensued."

Two teenagers, whose names have not been released, were arrested in connection with the robbery. Police said they were able to recover 218 cases of Nike shoes valued at about $408,000.

Police have identified possible “ringleader”

According to federal court records, a man identified as Felipe Avalos-Mejia is alleged to be the ringleader of some of the train heists, operating out of Phoenix and Los Angeles.

Investigators say that Avalos Mejia had a network of scouts who helped him select trains to target. Investigators also said Avalos-Mejia provided cars and paid burglary crews to rob the trains.

Police raided 11 homes and 16 storage units connected to Avalos-Mejia in June, arresting 43 suspects and recovering $3 million in merchandise believed to have been stolen from BNSF trains.

Avalos-Mejia was arrested one day later on June 21. Court documents say police found $120,000 in cash, as well as a "detailed ledger that listed Nike and other merchandise that is typically burglarized from BNSF trains, as well as dollar amounts detailing what the merchandise is worth and for what it is sold."

Avaloz-Mejia's attorney declined USA TODAY's request for comment on Tuesday.

6 notes

·

View notes

Text

um I'm shadowbanned so I'll have to rb this once that gets fixed but anyways had an idea and it keeps growing so have my bare bones of an idea

um ok rambles now under the cut bcuz I said so

SO UM. I DONT REMEMBER WHO. but someone had an au where the dca had a music box and a windup thing. so I thought. huh. cool. and moved on

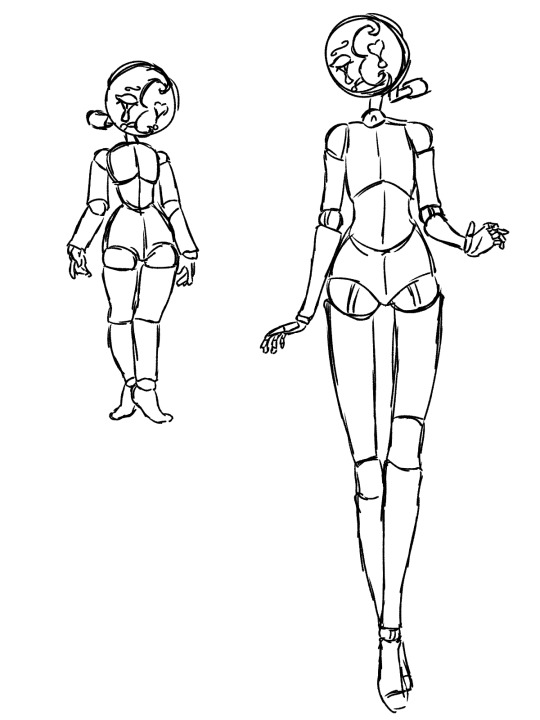

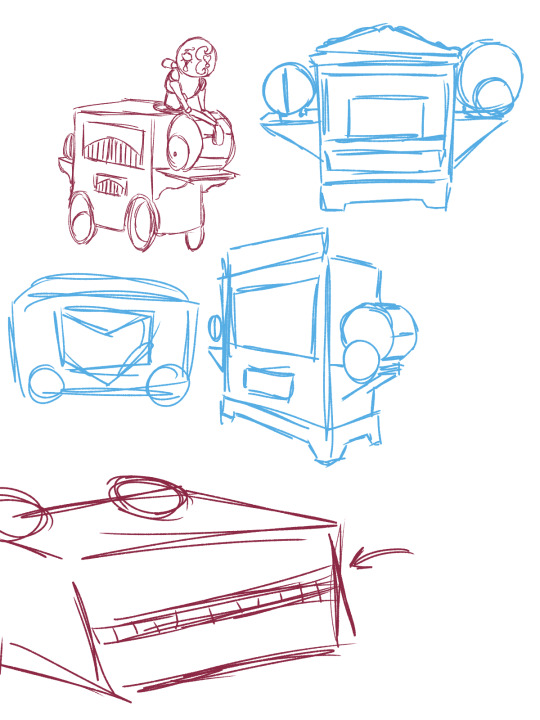

actually I didn't. it turned into a 'what if their main function was to be a music box?' which I've kinda abandoned. but it's still where this all branched out from.

so I had to figure out what would fit their theme and still need music boxes. so I thought of moon being the sound system for a carousel, bcuz of hw2, and then sun being a theater character that used music in his shows. he's still under debate, because carousels are so much more fun

Apparently, the(traditional) sound system for a carousel is called a calliope. pronounce it however you want I haven't figured it out either lol. but I decided to turn him into a calliope, which is where we start getting to what I drew above the cut. I've been very off and on about having him be the calliope or run it, or even be both, which I think might become the outcome

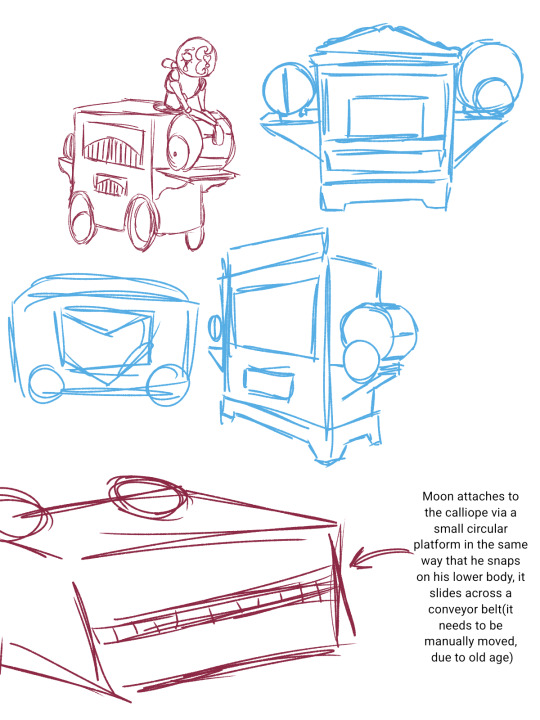

and so centaurs have popped up one or two times on my dash. so why don't we make a doodle of him being a centaur sorta thing? like where people make everyday things into creatures. yeah. my thought process is everywhere here, and I apologize. So I'm thinking about how Moon could handle the calliope while he's attached to it, via a small platform that rolls from side to side with help from a conveyor belt. so. he can still have legs I guess. if he's good. they'll attach the same way he attaches to the platform.

haven't started working on sun or clothes yet but stick around lmao.

#scrib talks#fnaf#dca fandom#art#fnaf dca#scribbits art#five nights at freddy's#my art#dca au#au idea#fnaf daycare attendant#moon fnaf#fnaf moon#might turn this into a fic#who knows#carcass of a carnival

12 notes

·

View notes

Text

Rolling Conveyor Systems Manufacturers in the UK: A Guide to Quality and Innovation

Introduction In today’s fast-paced industrial world, efficiency is everything. Whether it's warehousing, packaging, or assembly lines, rolling conveyor systems play a vital role in streamlining operations and improving productivity. The UK is home to some of the most reputable manufacturers of rolling conveyor systems, known for their engineering excellence, innovation, and compliance with high safety standards. In this blog, we’ll explore what makes UK manufacturers stand out, key features to look for in a rolling conveyor system, and top sectors that benefit from this essential material handling equipment.

Why Choose Rolling Conveyor Systems?

Rolling conveyor systems, also known as roller conveyors, are used to move products efficiently with minimal effort. They are ideal for transporting goods across long distances in manufacturing plants, warehouses, distribution centres, and airports. Key benefits include:

Improved workflow efficiency

Reduced manual handling and labour costs

Customisable configurations for different products and spaces

Durability and low maintenance

What Sets UK Manufacturers Apart?

The UK manufacturing sector is recognised globally for its adherence to high-quality standards, custom engineering solutions, and customer support. Leading UK-based rolling conveyor system manufacturers typically offer:

Bespoke system design tailored to specific business needs

High-grade materials including stainless steel, aluminium, and zinc-coated rollers

Integration with automated systems, sensors, and software

CE and ISO certifications for safety and quality assurance

Responsive customer service and reliable after-sales support

Key Features to Consider When Choosing a Rolling Conveyor System

Load Capacity: Ensure the system can handle the weight of your products consistently.

Roller Material: Stainless steel for hygiene and durability; PVC for lighter items.

Adjustability: Telescopic conveyors and height-adjustable designs add flexibility.

Modularity: Scalable systems allow for easy expansion as your business grows.

Drive Mechanism: Gravity rollers for simplicity or powered rollers for automation.

Industries That Rely on Rolling Conveyor Systems

Logistics & Distribution: For fast, efficient sorting and packaging of goods.

Food & Beverage: Hygienic designs with easy-to-clean materials.

Manufacturing: Assembly lines with integrated automation.

E-commerce & Retail: Fulfilment centres that require high-speed processing.

Automotive: Transport of components across assembly stations.

Top UK Rolling Conveyor System Manufacturers

Here are some of the leading names in the UK known for their expertise:

Conveyor Systems Ltd (CSL) – Based in West Sussex, offers bespoke solutions.

L.A.C. Conveyors & Automation – Known for end-to-end turnkey systems.

Amber Industries – Specialises in gravity and powered roller conveyors.

Daifuku Logan – Focuses on airport baggage and industrial conveyor systems.

Coveya Ltd – Offers rapid deployment conveyors for hire and purchase.

Note: Always verify certifications and customer reviews before finalizing a supplier.

Final Thoughts

Investing in a high-quality rolling conveyor system can revolutionise your operations by improving speed, safety, and efficiency. With a range of innovative manufacturers in the UK, businesses can find tailor-made conveyor solutions to suit their unique needs. From robust construction to cutting-edge automation, the UK market is well-equipped to deliver world-class conveyor technology.

0 notes

Text

@tiredsn0w Here are the first 3 pages of a revise of - Do you know where your Doctor is - But I might call it something like - If found, call 6118 - lol. My longest chapters are 3 pages, but can be as short as one page. Then I use a larger text size. You’re probably familiar with the events here cause you’ve seen an earlier draft. Hopefully things have changed enough to be entertaining- I invite any other 6118+049 fans out there to also have a look. Take your time, this is mostly an excuse for me to quit re-reading this for a while. :P

If Found Call, 6118 2nd draft installment 1.

5a82 rolled out his collar, shoved his hands in his pockets and tried his best to ignore the abrasive cold of the brutalist, concrete arcology. Shivering made him look like a fairy, as in, the little floating guys from Terran lore. He was unusually small for his species and the graceful, satyr’s gait aided by corrective braces under his leggings certainly wasn’t helping. If a life of hard combat and an overlong incarceration on a foreign world hadn’t prematurely aged him, then this non-Euclidean mass of putrid politics certainly had.

How was it possible to have been on the front-lines of a war and to have learned nothing of the convoluted machinations behind it? Oh, right. Twos were stupid, stupid and often suicidal, suicidal, by design.

Over and over he wondered if leaving Earth with the tall Terran had been selfish.

But again, the man had been a monster among the humans. At least here, an alien could be forgiven for being just a little weird.

He strode toward a crowd of high-ranking medical staff gathered outside the Doctor’s apartment. Instead of getting out of his way they surged forward to block the hall.

Stopping was difficult due to the braces and it being somewhat easier to move faster rather than slower on Keplerian legs. Fortunately he wasn’t big enough to do much damage and would certainly have been forgiven if he had been.

“Woah there, Five-aye, I’m sure he’ll be very glad to see you, but that - I’m afraid is the problem.”

7cb7 lifted the small Two clear off his feet and carried him backward several steps from the crowd. No one turned to look at them. That was unusual, as 5a82 was currently, not that he wanted to be, the most noticeable thing on the planet.

“You see, 049 is helping some of our people with some trouble we’ve been having and it turns out he’s got some pretty good ideas, so - let’s not interrupt them. I’ve got some new Terran media for us. Ever hear of Warehouse 13?”

7cb7 continued to sing the praises of Warehouse 13 (an Earth tv show about a secret organization that protected the world from haunted objects) as they rushed 5a82 further and further away.

An ink-dark form was collapsed against the far wall of the closed apartment. Down the side of a long rostral structure, was a thin stream of fresh, red Earth blood.

Part 2.

Seedy almost lost their grip on the slick, amphibious eel when an alarm emanating from the stronghold of the neighbors rattled the windows of the processing building. The eel was unfazed. It had already spawned, but hadn’t yet begun to waste away, it was now or never. Seedy reset the blade and sent the Uhmishie lungfish back down the conveyor - SHOOP! a clean cut. They put the head in a box of ice and left it to rest with the others.

They were reaching for the next eel when the alarm came again. “Could you knock it the Fuck off, already!” They roared into their phone. It had been going off constantly so the big One had put it on silent. Had they no respect? These fine specimens had been raised lovingly from mere larvae and now it was time to dismiss them, with all due respect, to the void.

“Sir, we are just testing the systems, wouldn’t you want to evacuate if there was going to be a battle next door?”

“I know the timing is off, what the hell do you want?!”

“3cd6? We want to talk to your sister, Tasha. She seems to not be answering her calls.” Seedy handed the phone to an assistant and stomped an empty battery case flat before kicking it out an open door. There was a brief complaint from outside, but no follow up. The assistant returned the phone. “That’s because she’s removing bladder stones from a hideous Earthen rat who’s owner is more than capable of turning us all into a crater!”

A slightly shorter One in a tightly woven hairnet pounded the floor of the viaduct connecting the great glass mountain outside to the far-smaller processing facility by the tramway. Tasha had heard the alarms too - but it was far more amusing to assume her sibling could really yell that loud. “They’re called Chihuahuas and this one’s been keeping the Aven entertained.”

“Aven Blaven, just see what the neighbors want!”

She took the phone. “May I help you?”

“Ma’am, you need to get over here fast there’s a problem.”

“With what?”

“I’m not authorized to say anything else. If you’re so curious, come see for yourself.”

Part 3.

A pair of squat towers bristling with haphazard weaponry emerged from the region’s persistent mists as Tasha parked the armored vehicle issued as a kind of apology - for the looming threat at the very doorstep of her family’s farm.

Once upon a time a few rouge bureaucrats met secretly in the attic of an unauthorized bar and secretly hoped that the near by heritage sites and eel operations encased as they were in fragile conservatories would cause the powers that be to go easy on the bombs. Now, by the looks of it, bombs were expected, bombs or invasion by the notorious flesh robots that adorned the propaganda posters of the United Federation.

She froze when a spot light snapped on.

Guards rushed fourth and ushered her through a side entrance then along halls and up stair ways until an unsuspecting door flew off its hinges with a very surprised Two laying on top of it. Very surprised meaning that surprise was clear despite a covered face and generations of genetic engineering meant to remove emotion. The Two nonetheless sprang to the balls of it’s feet, door in hand, and rushed back into the room to pin the offender against the wall with its new found shield.

An eerie, synthetic voice spoke an Earth language with an odd echo it was hard to account for. “Unhand me, by god, and what is this filthy contraption you’ve put on me?”

“Oxygen equipment for animal, yes, not filthy though, sterile, never reuse!” cajoled an uncertain One in broken English.

Tasha had started to suspect that her patient might be the Earthen Paramore. Perhaps it had passed out or some other scary thing that could happen to a being with largely unknown biology.

The Two re-emerged and caught her arm. It was mostly indistinguishable from the other guards, (no visible face) less armor though and a glowing, blue symbol that marked it as a combat medic. That was interesting, it had seemed these things were mostly used as weapons. Still, what was a Federation flesh robot doing working for the Resistance?

It talked over her head, it’s voice reduced to a static buzz by the coms of it’s helmet. The helmet was mostly to prevent infection and people getting too attached to the face beneath. “We have the mammalogist.”

5 notes

·

View notes

Text

Absolutely galaxybrained concept depicted here: double-decker trams that dock with an overhead bus system so that passengers can transfer using airstairs and elevators at 50kmh, and then the overhead buses accelerate to 100kmh to dock with long-distance high-speed monorails.

This is better than Heinlein's conveyor belts in "The Roads Must Roll".

2 notes

·

View notes

Link

Modernization today even includes new flooring UAZ continues to modernize the plant, in particular, a robotic system for rolling front doors has been introduced on the SGR welding line, and the floor covering on the main conveyor has been replaced. Before innovation on the main conveyor, modular PVC tiles were tested in a small area of 50 square meters. m. for two months. After a successful test, the central passage of the main conveyor was covered with PVC tiles. “The use of such material will reduce the cost of repairs and maintenance of floors in the future,” reports Panorama. Such tiles are characterized by high strength and wear resistance; they can withstand large static and dynamic loads. In addition, the new floors can absorb sound and vibration vibrations, and thanks to the springing effect, the load on the back and joints when walking is reduced. Therefore, in the future, they plan to cover the entire floor of the main conveyor with PVC tiles and use them in other areas. UAZ modernized production and improved the quality of “Loaf” [caption id="attachment_77858" align="aligncenter" width="780"] UAZ[/caption] At the SGR welding site, a robotic system for rolling front doors was put into operation: “Modern manufacturing technology will improve the productivity of the site, improve assembly quality, eliminate the production of defective parts, and achieve an economic effect by improving quality.” The car plant did almost everything on its own: “For several months, from October to December 2022, toolmakers on their own produced the necessary equipment that met all mathematical parameters and features. The employees also developed a pneumatic system for fixing parts. Specialists from the industrial electronics department were simultaneously developing and writing a part processing program. We also took into account the safety system of the robotic complex.”

#Auto_engineering#automobile_production#automotive_engineering#automotive_technology#car_manufacturer#Car_manufacturing_company#off_road_vehicles#Russian_automobile#Russian_automotive#Russian_automotive_industry#Russian_carmaker#Russian_cars#UAZ#UAZ_vehicles#Utility_vehicle_models#Utility_vehicles#vehicle_manufacturing

3 notes

·

View notes

Text

No. 1 Plummer Block manufacturer in Ahmedabad, India

Introduction

In heavy industries where machines run nonstop, maintaining the alignment and stability of rotating shafts is essential. This is where Plummer Blocks play a key role. A plummer block houses the bearing and provides support for a rotating shaft. It also helps reduce vibration and extend the life of machinery.

Ahmedabad, a major industrial hub in India, is home to some of the top plummer block manufacturers. Known for quality engineering and reliable performance, these manufacturers have earned a strong reputation in both domestic and international markets. Being closely connected to allied industries like gearbox manufacturing, pulley systems, and suspension magnet solutions, they offer an all-in-one source for industrial mechanical needs.

What is a Plummer Block?