#Rust Prevention

Explore tagged Tumblr posts

Text

Red Lead

#red lead#bright red#orange red#lead glass#red pigment#steel#paint#rust prevention#red#lead#lead tetroxide#Pb3O4#metallic lead#Lissajous#lead monoxide#oxidation#preparation#red pyramid#Silent Hill#toxic#harmful

0 notes

Text

Protecting Cement Plant Kilns with Thermal Spray SS 316L Coating: A Game-Changer for Corrosion Resistance

In the demanding environment of cement plants, kilns are the heart of production. These massive structures are exposed to extreme temperatures, chemical reactions, and abrasive materials, making them highly vulnerable to corrosion and wear. One of the most effective ways to extend the lifespan of kilns and improve operational efficiency is through SS 316L coating.

What is Thermal Spray SS 316L Coating?

SS 316L is a low-carbon variant of 316 stainless steel, known for its exceptional corrosion resistance, particularly in aggressive environments. This alloy contains molybdenum, enhancing its ability to resist chloride-induced corrosion and acidic conditions. Its low carbon content minimizes the risk of carbide precipitation during welding, making it highly durable and suitable for industrial applications.

Why Apply SS 316L Coating Inside Kilns?

The interior of a cement plant kiln is continuously exposed to harsh conditions such as high temperatures, sulfur compounds, and alkali materials, which can lead to rapid deterioration of unprotected surfaces. Here’s how Thermal Spray SS 316L coating offers robust protection:

Superior Corrosion Resistance

Protects against chemical attacks from alkalis and sulfates commonly found in cement production.

Minimizes degradation from exposure to aggressive gases.

High-Temperature Strength

Withstands extreme temperatures without compromising structural integrity.

Reduces the risk of material fatigue and failure under thermal stress.

Extended Equipment Lifespan

Reduces frequent repair and replacement costs.

Enhances the durability of kiln linings, ensuring consistent operation.

Improved Energy Efficiency

Provides a smoother internal surface, reducing friction and energy consumption.

Helps maintain optimal heat distribution within the kiln.

Application Process of SS 316L Coating

Applying SS 316L coating inside kilns requires specialized techniques to ensure durability and effectiveness. The process generally includes:

Surface Preparation

Grit blasting or sandblasting is conducted to remove contaminants and roughen the surface for better adhesion.

Coating Application

The SS 316L coating is applied using thermal spray techniques or specialized welding methods.

Inspection and Testing

Post-application inspection ensures the coating adheres properly and meets quality standards.

Benefits for Cement Plants

Reduced maintenance costs due to longer-lasting kiln linings.

Enhanced safety by minimizing unexpected equipment failures.

Improved operational efficiency with reduced downtime.

Protection against costly shutdowns caused by corrosion damage.

Why Choose Cement Plant Painters for SS 316L Coating?

At Cement plant painters, we specialize in advanced corrosion protection solutions for industrial applications. Our SS 316L coating services are tailored to meet the rigorous demands of cement plant operations. With our best-skilled team and cutting-edge technology, we ensure:

High-quality application standards

On-time project completion

Cost-effective solutions that boost operational longevity

Contact Us Today

Protect your kiln and enhance its lifespan with our specialized SS 316L coating services.

Cement Plant Painters Phone: +91-9845063120 Website: https://cementplantpainters.com

Invest in durability, efficiency, and long-term savings today!

#Thermal spray coating#thermal spray ss coting#SS-316L coating#corrosion resistance#corrossion protection#rust prevention

0 notes

Text

Thermal Spray Galvanizing: The Future of Corrosion Protection

Introduction

Corrosion is a major challenge in industries dealing with metal structures, machinery, and infrastructure. Among the various protective coatings available, thermal spray galvanizing (TSG) has emerged as a highly effective and long-lasting solution. This advanced technology provides superior protection against rust and environmental wear, making it a preferred choice for industries ranging from construction to marine engineering.

What is Thermal Spray Galvanizing?

Thermal spray galvanizing is a process where molten zinc or zinc-aluminum alloy is sprayed onto a metal surface to form a protective layer. Unlike traditional hot-dip galvanizing, this method involves atomizing molten zinc and applying it via a high-temperature spray gun. The result is a durable, corrosion-resistant coating that bonds mechanically to the substrate.

How Does It Work?

The thermal spray galvanizing process consists of the following steps:

Surface Preparation: The metal surface is cleaned using abrasive blasting to remove rust, scale, and contaminants, ensuring proper adhesion.

Molten Zinc Spraying: Zinc wire or powder is melted using an electric arc or flame spray system and sprayed onto the prepared surface.

Coating Formation: The molten zinc particles cool and solidify on contact, creating a uniform, porous coating.

Sealing & Finishing (Optional): The porous coating can be sealed with a topcoat for enhanced performance, such as epoxy or polyurethane coatings.

Advantages of Thermal Spray Galvanizing

Thermal spray galvanizing offers numerous benefits, making it an ideal choice for industries that require high-performance corrosion protection:

Superior Corrosion Resistance: The zinc coating acts as a sacrificial layer, preventing rust formation even in harsh environments.

Longer Service Life: Provides extended durability, often lasting decades with minimal maintenance.

No Heat Distortion: Unlike hot-dip galvanizing, TSG does not expose the base metal to high temperatures, eliminating the risk of warping.

Environmentally Friendly: Produces fewer emissions and waste compared to traditional galvanizing methods.

Versatile Application: Can be applied to a wide range of metals and complex shapes that are difficult to galvanize using conventional methods.

Applications of Thermal Spray Galvanizing

Industries across various sectors are leveraging the benefits of thermal spray galvanizing for enhanced durability and protection:

Bridges and Infrastructure: Protecting steel structures from corrosion due to moisture and pollution.

Marine and Offshore: Coating ship hulls, docks, and offshore platforms for resistance against saltwater corrosion.

Automotive and Aerospace: Enhancing longevity and strength of vehicle and aircraft components.

Pipelines and Industrial Equipment: Preventing degradation due to chemical exposure and extreme weather conditions.

Power Transmission Towers: Ensuring long-term performance in varying climatic conditions.

Conclusion

Thermal spray galvanizing is revolutionizing the way industries protect metal structures from corrosion. Its ability to provide long-lasting protection, adaptability to complex shapes, and environmentally friendly application makes it an excellent alternative to traditional galvanizing methods. With industries seeking cost-effective and sustainable solutions, thermal spray galvanizing is undoubtedly the future of corrosion protection.

#ThermalSprayGalvanizing#TSG#CorrosionProtection#MetalCoating#ZincCoating#SurfaceProtection#IndustrialCoatings#AntiCorrosion#Galvanizing#SteelProtection#InfrastructureSafety#MarineCoatings#LongLastingProtection#SustainableCoating#Rust Prevention

0 notes

Text

Taking care of your vehicle involves more than oil changes and engine checkups. Regular car washes are a simple but effective way to prevent rust and corrosion, which can lead to long-term damage. Professional car wash services in Katy, TX, help protect your car’s exterior and maintain its value.

0 notes

Text

Why Protodin Acid Corrosion Inhibitors Play an Important Role in Role in Acid Cleaning and pickling Processes?

The role of PROTODIN Acid Corrosion Inhibitors in acid cleaning and pickling processes is indispensable. Chemtex Speciality Ltd's innovative solutions offer industries a way to harness the powerful cleaning and pickling capabilities of acids while safeguarding their metal assets and equipment. As industries continue to seek more efficient, cost-effective, and environmentally friendly solutions, PROTODIN stands out as a key component in achieving these objectives, ensuring that the balance between aggressive cleaning and metal preservation is maintained.

#protodin acid#acid corrosion inhibitor#acid cleaning#metal surface#acid pickling#scale removal#prevent corrosion#rust prevention#chemtex

1 note

·

View note

Text

Rust Prevention: Protecting Your Investments with Rust Bullet

Rust is a relentless foe of metal surfaces, and the damages caused by corrosion each year cost businesses and individuals billions of dollars. Rust may silently eat away at your investments, whether it's your car, boat, industrial equipment, or even the infrastructure that supports our day-to-day lives, which can lead to expensive repairs and replacements. Rust Bullet is a potent ally in the fight against rust, which is fortunate given the prevalence of the problem. In this blog, let’s discuss the significance of rust prevention and how Rust Bullet may be the best answer for you.

Acquiring Knowledge of the Menace of Rust

Rust, also referred to as iron oxide in the scientific community, is produced when iron, oxygen, and moisture participate in a chemical reaction. Iron and steel surfaces will slowly corrode when exposed to these elements, which will cause them to become weakened and disintegrate over time. Rust is an issue that affects more than just the aesthetics of metal objects; it can damage the structural integrity of those products and dramatically limit the amount of time they will last.

What Happens When You Ignore Rust Prevention and Its Consequences

Rust-related repairs and replacements can put a significant dent in your finances due to the high costs associated with them. The financial ramifications of rust cannot be denied, regardless of whether you are a homeowner dealing with a rusted-out fence, a business owner managing a fleet of vehicles, or an industrial operator maintaining heavy machinery.

Concerns Regarding Safety: Rust can have a significant impact both financially and in terms of the safety risks it presents. Corroded metal structures have the potential to fail suddenly, which can result in accidents, injuries, and even fatalities in the worst-case scenario. It is not only important to protect your investments by ensuring rust prevention, but it is also important to protect people's lives.

Rust is not only harmful to your property, but it can also have a negative effect on the surrounding environment. The deterioration of metal structures can cause potentially harmful substances to seep into the surrounding soil and water, which poses a risk to the health of ecosystems.

The Benefits of Using Rust Bullet

The revolutionary anti-corrosion product known as "Rust Bullet" is a rust prevention treatment that takes corrosion head-on. Because of its one-of-a-kind formulation and forward-thinking approach, it is quickly becoming the product of choice for individuals and industries that are looking to safeguard their priceless assets. The following are the reasons that Rust Bullet stands out:

Innovative Technology: Rust Bullet uses cutting-edge technology to penetrate rusted surfaces and eliminate corrosion. This allows the product to deliver its intended results more effectively. It does not only cover up the rust; rather, it prevents the rust from occurring in the first place.

Versatile Product: Rust Bullet is a versatile product that may be used on a wide variety of surfaces, ranging from automotive applications to industrial equipment, marine vessels, and even domestic items. Its versatility allows it to be utilized on a wide range of surfaces. Because of its versatility, it is an excellent solution for a wide variety of rust prevention problems.

Durability: Protection that lasts for a very long time is one of the most notable advantages offered by Rust bullets. It produces a barrier that, for a period of years, protects metal surfaces from additional corrosion, ensuring that your investments will continue to be in excellent shape.

Ease of Application: The application of Rust Bullet is a simple process that does not require any particular abilities on the part of the user. Protecting your valuables with Rust Bullet is simple to do, regardless of whether you are an experienced professional or a do-it-yourself enthusiast.

Environmentally Responsible: Rust Bullet is safe for the environment because it does not include any potentially hazardous ingredients. Its low VOC (Volatile Organic Compounds) formula guarantees that it will not contribute to air pollution or cause damage to the environment in any way.

Combating Rust Through Preventative Measures

Let's take a more in-depth look at how Rust Bullet operates and the various ways it may be put to use:

Automotive: Rust may quickly eat away at the value of your vehicle, which is one of the most significant expenditures you will make in your lifetime. The automotive formulas offered by Rust Bullet help prevent rust and corrosion from forming in your vehicle's frame, undercarriage, and other susceptible areas. Your vehicle will last longer and retain more of its value if you perform this proactive or preventative maintenance.

Industrial Equipment: Rust can cause expensive downtime and maintenance issues in industrial settings, which can be a significant financial burden. Rust Bullet Industrial provides reliable protection for a variety of industrial assets, including heavy machinery, pipelines, and storage tanks. It reduces the amount of maintenance that is required, boosts operating efficiency, and increases the amount of time that key equipment can remain in service.

Home and Do-It-Yourself: Rust doesn't pick and choose what it attacks; it can attack outside structures, tools, and even domestic things. The simple-to-use DIY formula that Rust Bullet offers is a great option for homeowners and hobbyists who want to protect their valuables from rust. Rust Bullet has got you covered with anything from wrought iron fences to garden tools.

In the relentless battle to stop rust, the significance of robust rust prevention cannot be overstated. Left unchecked, rust wreaks havoc on valuable assets, leading to costly rust repair and maintenance. Fortunately, there are potent solutions like Rust Bullet that not only combat rust but also offer long-lasting protection. Whether you're safeguarding your vehicle, industrial equipment, or household items, products like Rust Bullet Industrial ensure durability and peace of mind. Don't let rust corrode your investments or compromise your safety. Embrace this rust-fighting solution to fortify your assets against the menace of rust and maintain a resilient, rust-free future.

1 note

·

View note

Text

If I were a more productive man, I’d go through the entirety of the Magnus Archives and note down every Archive Don’t the characters commit, because after being reminded Sasha stapled Archived documents, I have to know how deep this horror goes.

#TMA#the magnus archives#for elaboration: stapling is very bad for preservation as it can cause lasting damage particularly if they rust#in fact typically in preservation if a document already has a pin or staple etc it’s usually replaced with brass paper clips if needed#so stapling is VERY COUNTER PRODUCTIVE#loose document bundles as well are usually stored in folders/boxers that fit their exact size — this prevents things like dust gathering#which is also a risk#I know the archive is intentionally handled with little care but also Sasha is meant to be qualified for this if I recall?#cinema sins who? get ready for archive sins.

408 notes

·

View notes

Text

I've used one as an alternative to Christmas gift wrap.

tl;dr: The inside of them is not coated to prevent rust. Not an issue if they're still in prime condition and undamaged, and you only store dry things in them. Not great if you want to run it through a dishwasher or store candy that isn't heat sealed in it. If you want an ammo can full of fun size Snickers, go for it, but I'd still recommend a container of dessicant at the bottom. (PSA: don't put baggies of dessicant in with baggies of candy.)

Long story: Mine had rust, and arrived just at the point of holiday madness where a town of 40,000 people had bought up every household acid in a 7km radius, so I had to get it off with cola (Yea children's science projects) which meant hand washing the thing. Dawn dishsoap and water, as with so many things, is fine. They don't fit a standard size kitchen or bathroom sink, so for minimal mess, go to a laundry sink, shower or bathtub, and don't forget to hand dry with a towel as well as you can. You can coat them with several products to prevent re-rusting (hairspray is one of them), but none that I know of are food safe, unless you want to enamel the inside. Easiest is preventing rust by preventing moisture getting trapped in there.

@natalieironside i picked up an old ammo can at the thrift shop awhile back and just now had the idea to use it as a candy jar. you seem like the person to know: is that shit dishwasher safe or will it strip the paint so it doesnt tell me how many of what kind of munitions fit in it anymore?

pinging @unbossed also for a 2nd opinion

#these are not the household hints I ever thought I would be giving#oh well#rust removal#rust prevention#candy bowls#safe Halloween#ammo cases#if you can't find containers of dessicant that fit - 3D print some#bonus: you can get them in fun shapes#fill with your favorite silica gel and done

49 notes

·

View notes

Text

Quick sketch since I haven't drawn for a while lol

17 notes

·

View notes

Text

let's try for characters you might think i'm familiar with?

6 notes

·

View notes

Text

THEY DIDNT BELIEVE I COULD DO IT NO ONE DID AND YET

maybe now i will describe it in writing (<- me when i lie)

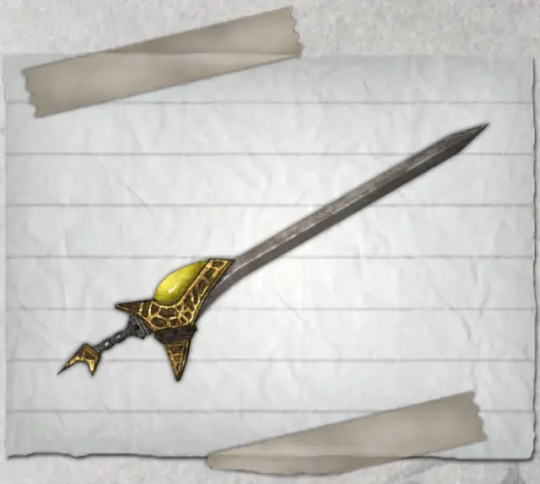

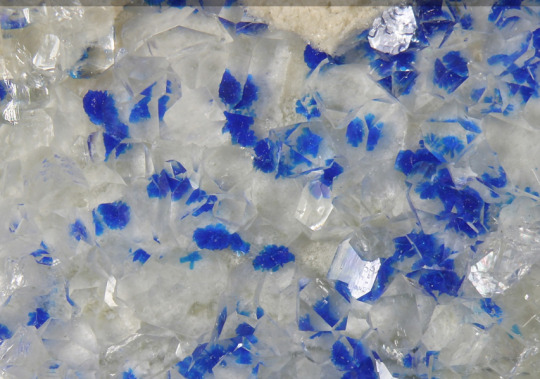

Here is my inspo everyone say thank you NieR Moonrise and the lovely mineral photos on Mindat

#i drew something#erebus#the gem is fluorapophyllite with kinoite clusters suspended in it#this is a naturally occurring thing they grow like that they are friends see the picture that's them#fluoropophyllite can be teal tho so i went with that instead of clear#what does the gem do?#the earth element fluorapophyllite keeps the blade sharp and prevents it from rusting or breaking#as for the kinoite? that's a secret :)#next chapter is pretty much written now i worked on it last night#just need to do edits 😔

10 notes

·

View notes

Text

Degreasing Chemicals for metal, Automotive & Heavy Duty Cleaning | Chemtex Speciality Limited

Chemtex,s degreasing chemical is a game changer for heavy duty cleaning tasks, effortlessly cutting through stubborn grease and grime. Designed for industrial and commercial applications chemtex's degreaser delivers superior performance, ensuring a sparkling clean surface, renowned as a leading manufacturer company Chemtex Speciality Limited offers an extensive selection of degrasing chemicals tailored for heavy duty cleaning

#degreasers#chemical manufacturing#chemical industry#industrialdegreasing#heavydutydegreasers#solventdegreasers#automotive#cleaners#cleaningchemical#rust prevention#rust removal#chemistry#vapourizingdegreaser#chemtex

1 note

·

View note

Text

0 notes

Note

Do you think (past life???) eamk would have been just a force of Chaos or a being with his own agenda and strings to pull? I'm leaning towards the later with the whole not being mindless thing

I think his agenda would have been to cause Chaos, to enjoy and revel in the sheer freedom of it

Like, you're a lot less likely to get hurt if you just don't care. If you just do whatever you want, and hurt whoever you want, then there's NO pain involved in that for you! You're free to do absolutely whatever, with no morals bogging you down.

He's not mindless, but he is rather unhinged and detached.

#still manifesting our next antagonist using Chaos to prevent pain (in a way)#It's still on theme but also distinct from Azure and LBD#And the whole ''doing whatever you want'' thing ties into past Wukong's desire for freedom#Like. It fits#eamk theory#verdigris-rust#asks#lmk#lego monkie kid

7 notes

·

View notes

Text

Mineral Admixtures for Rust Prevention: A Sustainable Solution for Durable Concrete

Adding effective mineral supplements to concrete mixes is now standard practice for engineers seeking long-lasting, corrosion-resistant structures. As cities grow, budgets tighten, and climate challenges multiply, shielding embedded steel from rust has become a pressing concern. When rust spreads, it pushes apart the surrounding concrete, causes visible cracking and spalling, and eventually threatens safety. By including protective mineral admixtures in the batch, builders boost corrosion resistance while simultaneously upgrading strength, shrinkage control, and surface finish.

These additives are ultra-fine natural or recycled powders that replace part of the Portland cement, lowering carbon footprints and materials costs. Common choices are fly ash, silica fume, ground granulated blast-furnace slag (GGBFS), and metakaolin. Each one improves flow and strength, yet more importantly it drastically cuts concrete permeability, the key pathway for moisture and chlorides that accelerate rust.

Mineral admixtures protect steel in concrete mainly by making the paste denser at a microscopic level. When these materials are mixed in, they react with excess calcium hydroxide left after the cement has hydrated and generate extra calcium silicate hydrate, or C-S-H. The new C-S-H plugs tiny pores, lowers permeability, and thus slows the entry of water, chlorides, and other corrosive agents that start rusting.

Fly ash is one of the most popular choices; it not only fights rust but also improves resistance to sulfate attack and alkali-silica reaction. Its pozzolanic reaction keeps pH swings small, helping maintain the passive oxide layer on reinforcing steel and curbing corrosion. Likewise, ground-granulated-blast-furnace-slag (GGBFS) boosts density and chemical durability, protecting concrete in coastal and industrial settings.

Silica fume offers even stronger rust protection thanks to its extremely fine particles. It cuts porosity, raises compressive strength, and makes a dense, bonded matrix that shields embedded steel. Paired with good curing and adequate cover, silica-fume mixes can resist corrosion for decades, even under harsh exposure.

Beyond their obvious protective role, mineral additives aimed at curbing rust also offer clear environmental gains. When engineers incorporate by-products such as fly ash or granulated blast-furnace slag, they shrink the carbon output usually linked to cement. That approach not only promotes greener building but also yields concrete that often outperforms ordinary mixes.

Such rust-preventing blends are becoming the go-to choice for bridges, roads, sea structures, parking decks, and reservoirs alike. Designers value them because they extend a projects service life while cutting future repair bills.

In short, these Mineral admixtures for rust prevention a wise, eco-smart option for todays concrete work. By boosting durability, sealing pores, and resisting harsh chemicals, they keep reinforced elements robust, secure, and free of corrosion for many years. As the industry increasingly favors solutions that last and protect the planet, use of rust-fighting mineral admixtures can only rise.

0 notes

Text

Rust Preventive Car Paint: Shield Your Vehicle from Corrosion

Rust is one of the most common enemies of vehicles, especially in regions with high humidity, salty roads, or poor maintenance. Over time, corrosion can damage a car’s body and undercarriage, reducing its appearance, performance, and value. That’s where rust preventive car paint comes in—designed to stop rust before it starts and prolong your car’s lifespan. rust preventive car paint What is…

#anti rust automotive paint#car underbody rust protection#corrosion resistant car paint#rust preventive car paint#rust proof car coating

0 notes