#Servo Motor Encoder

Explore tagged Tumblr posts

Text

Analog 0-5V Linear Draw Wire and Cable Displacement Sensor Transducer

Explore a range of premium Servo Motor Encoders at Briter Encoder, featuring high-precision optical technology for accurate position feedback. Choose from single-turn and multi-turn options with optical encoding that ensures reliable performance. From the RS Series-SH for Single & Multi-Turn to the RZ Series-ZH with a robust design and wide operating temperature, find encoders tailored for demanding applications. Benefit from precision speed measurement and rugged construction in the Servo Motor Spindle Absolute Encoder, ideal for industrial environments requiring speed and accuracy. Upgrade your servo motor systems with our advanced encoder solutions.

0 notes

Text

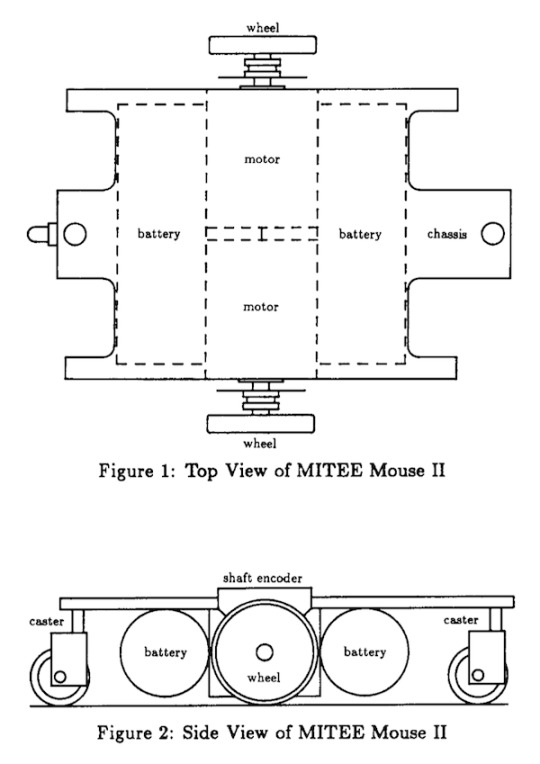

MITEE Mouse II (1987) by Dave Otten, MIT. "The IEE World Micromouse Championship in London saw 13 micromice competing. The winner was Dave Otten who managed to win both first and second prize with Mitee Mouse I and Mitee Mouse II." – Micromouse History, UKMARS.

"Figures 1 and 2 show the basic chassis and drive components of MITEE Mouse II. One drive wheel is located on either side of the mouse near the center of mass, much like a wheel chair. Each wheel is mounted on the shaft of a DC motor along with an incremental encoder to sense position. Casters at the front and back of the mouse provide additional support. NiCd batteries mounted adjacent to the motors provide power for the mouse. A printed circuit board mounted above the chassis contains a microprocessor for control and two H-bridge switching converters to drive the DC motors. All control of the mouse is through the two drive wheels. The differential speed between the two wheels is used to steer the mouse, and changes in the common-mode component of the speed provides for forward acceleration and braking. Ultimately the position of each wheel determines the position and heading of the mouse in the maze. Fast, accurate, and stable control of each wheel is therefore a clear requisite of a high performance robot." – Feedback Controller Design for Servo Systems with Dominant Mechanical Resonances, by David M. Otten et al.

3 notes

·

View notes

Text

We provide a reliable, cost effective and efficient service to various industries throughout the UK and indeed worldwide. Our key areas of expertise are repairing, variable speed drives including; Frequency Inverters, Spindle, Servo, Stepper; HMI’s, Power Supplies, Programmable Logic Controller’s (PLC’s), Printed Circuit Boards (PCB’s), Servo Motors, Encoders and many other types of industrial equipment. Occasionally we use our worldwide network of suppliers to effect a repair.

#electronic restoration services#circuit board repair#printed circuit board repair#electronics repairs#pcb repair

2 notes

·

View notes

Text

Technical features and operating precautions of integrated servo motors

1.Basic components of integrated servo motors Integrated servo motors are mainly composed of servo motor body, encoder and driver. The servo motor body is the component that performs mechanical movement. The encoder is used to feedback the position and speed information of the motor, and the driver is responsible for receiving control signals and driving the motor to operate. The control circuit is responsible for generating control signals and monitoring the operating status of the motor to ensure accurate control and stable operation of the system.

2.Working steps of integrated servo motors 1. Receiving control signals: The servo motor receives control signals from the external controller through the driver. These signals tell the servo system where to move, at what speed or direction to move. 2. Driving the motor: The driver sends power to the servo motor to drive it to rotate according to the received control signal. 3. Feedback monitoring: The encoder or other feedback device inside the servo motor measures the current position and speed of the output shaft and feeds this information back to the control circuit. 4. Adjustment control: The control circuit compares the feedback signal with the target value, adjusts the motor's current, voltage and other parameters to ensure that the motor can accurately reach and maintain the set position or speed.

3.Technical features of integrated servo motors

1.High-precision control: The integrated servo motor adopts advanced closed-loop control technology, and the encoder provides real-time feedback of the motor's position and speed information to achieve precise control. Its positioning accuracy can reach 0.001mm or even higher.

2.Fast response: The integrated servo motor has fast response capability and can reach the target position and speed in a very short time. This gives it a significant advantage in situations where high-speed and high-precision motion is required.

3.Good stability: The integrated servo motor adopts advanced control algorithms and drive technologies, which can maintain stable operating performance in various complex environments. At the same time, it has strong anti-interference ability and can effectively resist external interference and noise.

4.High flexibility: The integrated servo motor can be customized according to actual needs to meet the needs of different applications. In addition, it also supports multiple control modes, such as position control, speed control and torque control.

5.Intelligent design: The integrated servo motor usually adopts high-performance DSP to achieve precise and smooth motor control, which greatly improves the system integration and reduces the workload of wiring. Its opto-isolated differential signal input and multiple communication methods (such as CAN communication and Modbus communication) further improve the system's integration and maintainability. 6. High efficiency and energy saving: The integrated servo motor can maintain low temperature and energy consumption during operation, ensuring high efficiency and energy saving. For example, Schneider Electric's Lexium MDrive motor achieves high stability and low operating temperature through closed-loop control, thus ensuring high efficiency and energy saving.

4.Precautions for the operation of the integrated servo motor 1. Use environment: Try to use the servo motor in a clean and dust-free environment, and avoid using it in heavy oil, dusty or humid places to prevent damage to the motor. 2. Regular maintenance: Regularly check the housing, screws, bearings and other parts of the integrated servo motor to ensure that they are not damaged or loose. At the same time, keep the motor clean and dry to avoid the influence of moisture and dust. 3. Avoid overload work: During use, avoid overloading the integrated servo motor, and always observe the working condition of the motor to ensure that it operates within a safe range. 4. Avoid overheating: Regularly check whether the cooling fan of the integrated servo motor is working properly to prevent the motor from overheating. If the motor is found to be overheating, check the cause immediately and take measures. 5. Standard operation: When operating the integrated servo motor, follow the operating procedures to avoid misoperation and barbaric operation. Adjust the motor's speed, position, load and other parameters according to actual needs to ensure the stability and safety of the motor. 6. Cable protection: Ensure that the cable of the integrated servo motor is not subjected to torque or vertical load due to external bending force or its own weight, especially at the cable outlet or connection. The elbow radius of the cable should be as large as possible to avoid immersion in oil or water. 7. Parameter configuration: The parameter configuration of the integrated servo motor is directly related to its motion performance and load capacity. When configuring the parameters, select and adjust according to factors such as the motor model, specification, and application scenario to ensure that the motor operates in the best condition.

Source:https://olgana.pixnet.net/blog/post/180444976

0 notes

Text

The main functions and common applications of servo motors

1.A brief introduction to servo motors A servo motor is an engine that controls the operation of mechanical elements in a servo system. It is an auxiliary motor indirect speed change device. A servo motor can convert voltage signals into torque and speed to drive the control object. Its core features are very high control speed and position accuracy. It can be used as an actuator in an automatic control system and has characteristics such as small electromechanical time constant and high linearity.

2. Structural components of servo motors 1. Stator: Made of laminated silicon steel sheets, with three-phase windings embedded to form a rotating magnetic field. The stator is the fixed part of the motor, usually called the excitation winding of the motor. 2. Rotor: Made of permanent magnetic material, it rotates with the rotating magnetic field. The rotor is the rotating part of the motor, usually called the armature winding. 3. Encoder: Used to detect the position and speed of the rotor, usually installed on the rotor shaft. The encoder has an approximate sensor that can determine the speed and revolutions per minute of the motor. 4. Driver: Receives instructions from the controller and converts them into drive signals to control the operation of the servo motor. The driver controls the speed and direction of the rotating magnetic field by controlling the current of the three-phase coil, thereby controlling the speed and direction of the servo motor.

3.The main functions of the servo motor 1. Accurately control the speed and position: The servo motor can accurately control the speed and position according to the change of the voltage signal to achieve uniform and stable movement. It is positioned by pulse signals. Every time a pulse current is received, it will rotate a corresponding angle, thereby achieving high-precision positioning with an accuracy of up to 0.001mm. 2. Convert voltage signals into torque and speed: The servo motor can convert the input voltage signal into torque and speed to drive the control object. This feature makes it an important actuator in the automation control system. 3. Fast response and high-precision feedback: The servo motor has the characteristics of fast response and can respond to the input signal in a short time. At the same time, it uses a closed-loop control system to feedback pulse signals in real time to ensure the accuracy of motion control. 4. Suitable for high-precision positioning scenarios: Servo motors are widely used in scenarios that require precise positioning, such as CNC machine tools, steering gears, etc. Its fast start-stop speed, small rotational inertia, large starting torque and rapid braking make it perform well in these fields. 5. Core role in servo system: The servo motor is a key component in the servo system, used to control the operation of mechanical elements. It achieves high-precision motion control by converting electrical signals into angular displacement or angular velocity output.

4.Common application industries of servo motors 1. Industrial automation: Servo motors are commonly used in CNC machine tools, printing equipment, packaging machinery and food processing equipment, etc., which can achieve high-precision and high-speed motion control and significantly improve production efficiency and product quality. In automated production lines, servo motors are used in robotic arms, conveyor belts, assembly machines, etc. to achieve precise position and speed control. 2. Robotics: Servo motors are key components of robot joint drives, which can convert electrical energy into mechanical energy, enabling robots to perform precise movements according to predetermined paths and motion modes. 3. Aerospace: Servo motors are used for attitude control and rudder drive of aircraft to ensure stable flight of aircraft in various environments. 4. Automotive manufacturing: Servo motors are used in engine management, brake systems, steering systems, etc. in automotive manufacturing to improve the performance and safety of automobiles. 5. Medical equipment: Servo motors are widely used in surgical robots, X-ray machines, CT scanners and other equipment to improve the accuracy and safety of medical operations. 6. Research equipment: Servo motors are used in scientific research for precision measurement, data analysis and other equipment to improve the accuracy and reliability of experiments. 7. Other industries: Servo motors are also used in medical examination equipment such as CT machines, B-ultrasound machines, and MRI machines to move patients; in the food packaging industry, such as the vacuum packaging production of snacks such as French fries; in the logistics and transportation industry, such as AGV vehicles in large storage warehouses for the transportation and allocation of goods; in microelectronics production and processing, such as chip production; and in cutting machines, such as water jet machines, which require servo motors to move the cutter head.

0 notes

Text

Siemens Servo Motors: High-Performance Motion Control Solutions

In industrial automation, Siemens Servo Motors are the hallmark of precision, reliability, and efficiency. Motion control applications find a major role for these motors in versatile industries such as manufacturing, robotics, and packaging, ensuring dynamic performance. With state-of-the-art technology and superior integration possibilities, Siemens Servo Motors are the most preferred in high-speed, high-accuracy operations.

Why Choose Siemens Servo Motors?

Siemens Servo Motors are constructed to deliver high performance with energy efficiency. Following are some key features which make these servo motors unique:

High Precision & Accuracy: Serves well for the application needing very tight positioning and speed tracking.

Robust Design: Tough and designed for long life even under severe industrial conditions.

Compatible with Siemens Automation Solutions: This completes the motion control chain for complete automation.

Energy Efficiency: Lower power-consumptions with better operational efficiency.

Enhanced Feedback Mechanism: Provides encoders for an improvement in the accuracy of motion control.

Siemens Motor and Its Coupling with Servo Systems

Siemens provides a large variety of Siemens Motor solutions, which have in place integration with its servo drive systems. These motors have been developed to function harmoniously with the technology of Siemens Servo Drive, hence being able to deliver precise movement as well as high-speed performance. The function of the Siemens Motor and servo drives act as a highly efficient, fully automated system applied in industries.

Siemens Servo Drive is used to enhance the performance of a motor.

Siemens Servo Drive-an inseparable part of Siemens Servo Motors-therefore controls speed, torque, and position. Intelligent drive technology, therefore, allows industries to achieve extreme motion control with par-level energy expenditures. The salient features of Siemens Servo Drives include:

Dynamic response time results in very fast acceleration and deceleration.

Communication with automation systems via PROFINET and other industrial protocols does not cause any bottlenecks.

Easy configuration means parameter setting and operation are child's play.

The safety functions are implemented in the drive for safety assurance during operation.

Siemens V90 Servo System: An Ideal Motion Control Solution

The Siemens V90 Servo System represents an economical solution for the motion control application that calls for precise and trustworthy operation. In consideration of differing industrial needs, it has consigned the V90 PN Servo System and V90 PTO Servo System as its two configurations.

V90 PN Servo System: A model prepared for PROFINET communication, which makes it ideal for the networked automation system.

V90 PTO Servo System: A pulse train output solution that allows for fast and precise positioning in standalone applications.

Both the Siemens V90 Servo System variants provide a high torque density, smooth operation, and easy commissioning and are approbated by various industries aiming at productivity enhancement.

Conclusion

Siemens Servo Motors with Siemens Servo Drive technology and V90 Servo System are a superlative solution in industrial automation. From precise motion control to seamless integration and energy efficiency, there's a one-stop solution for all servo motor applications offered by Siemens. Investing in Siemens automation technology is the gateway to superior performances, lower downtimes, and high operational efficiencies for businesses.

Siemens Servo Motors from Naksh Technology Solutions LLP are still the best choices for most industries seeking reliable and reliable performance in servo motor solutions. Optimize your automation systems today with Siemens' technologies in motion control!

0 notes

Text

Encoder

Servo motors are the unsung heroes of modern automation, powering everything from robotic arms to 3D printers with remarkable precision. But behind their seamless operation lies a critical component: the encoder. This blog post explores how encoders enable servo motors to deliver unmatched accuracy and control in dynamic applications. What is an Encoder? An encoder is a sensor that measures the…

0 notes

Text

CNC machine components includes CNC controller, AC Servo Motor, AC Servo driver, Spindle motor, Spindle drive, Rotary encoder, Electric turrets, Etc.

www.paycnc.com

#servomotor #servodrive

0 notes

Text

Premium Servo Motor Encoders - High-Precision Optical Technology

Explore a range of premium Servo Motor Encoders at Briter Encoder, featuring high-precision optical technology for accurate position feedback. Choose from single-turn and multi-turn options with optical encoding that ensures reliable performance. From the RS Series-SH for Single & Multi-Turn to the RZ Series-ZH with a robust design and wide operating temperature, find encoders tailored for demanding applications. Benefit from precision speed measurement and rugged construction in the Servo Motor Spindle Absolute Encoder, ideal for industrial environments requiring speed and accuracy. Upgrade your servo motor systems with our advanced encoder solutions.

0 notes

Text

What are the advantages of ARMxy Embedded Computer BL410 Series in the AGV Solution?

We have previously published two articles on ARMxy Embedded Computer for AGV solutions.

AGV links MES to Create Intelligent Warehousing System 1--How to use ARM Embedded Computer to build AGV System?

AGV links MES to Create Intelligent Warehousing System 2--How to connect AGV to MES via BLIoTLink?

In this article, let’s talk about the advantages of ARMxy Embedded Computers for AGV solutions.

What is BL410 Series ARM Embedded Computer?

The BL410 series is an industrial-grade ARM Embedded Computer with flexible IO port configuration. It is based on the Quad-core ARM Cortex-A55 designed based on Rockchip RK3568J/RK3568B2 processor, with a main frequency of up to 1.8GHz/2.0GHz, equipped with 8/16/32GByte eMMC, 1/2/4GByte LPDDR4X RAM and ROM in various combinations, and built-in 1TOPS computing power NPU, supporting deep learning. It can be used as a smart gateway, energy storage system EMS/BMS, motion control, edge computing, industrial control and smart terminals, etc.

Advantages of BL410 Series ARM Embedded Computer

Flexible IO interface, fully adaptable to peripheral devices

Multiple RS485 and CAN interfaces: used to communicate with LiDAR, encoder, motor controller to ensure positioning and motion accuracy.

Optional IO modules interfaces: meet the switch signal requirements of AGV, such as start, stop and safety detection.

3 LAN interfaces: support high-speed network communication, work with central system or other devices.

Wi-Fi/4G/5G expansion support: realize wireless real-time data transmission to meet the needs of complex scenarios.

Powerful data processing and AI computing power

1 TOPS AI computing power, support complex intelligent tasks:

Real-time path planning: combine LiDAR or visual algorithm to optimize the path and improve transportation efficiency.

Obstacle recognition and avoidance: realize accurate object detection through cameras and sensors to ensure safe operation.

Equipment status prediction: real-time analysis of operation data, prevention of equipment failure and reduction of downtime.

Industrial-grade design to ensure reliability and durability

Wide temperature adaptability: supports -40℃ to 85℃, adapting to complex environments such as cold storage and high-temperature workshops.

Anti-interference design: EMC/EMI anti-interference and IO port protection to avoid equipment failure caused by electromagnetic interference.

Low power operation: Optimize energy efficiency design, extend the battery life of AGV system, and improve work continuity.

Path planning and navigation control

BL410 is equipped with CANbus interface, which can be seamlessly connected with laser radar, encoder and inertial navigation module, support high-precision path planning and real-time navigation, and achieve more efficient and accurate operation.

Multi-device collaboration and data integration

With RS485 and Ethernet interfaces, BL410 can simultaneously connect multiple sensors (such as obstacle detection sensors, barcode scanners) and actuators (such as servo motors, drives) to ensure efficient collaboration and stable operation of AGV.

Remote monitoring and intelligent maintenance Through Wi-Fi, 4G network expansion, BL410 can transmit real-time data to the cloud platform, allowing users to monitor the operating status of AGV and quickly complete fault diagnosis and remote maintenance.

Human-computer interaction expansion BL410 provides HDMI and LVDS interfaces, which can be connected to display devices or touch screens, support the deployment of human-computer interaction functions, and meet higher-end intelligent needs.

More information about ARMxy BL410 series ARM Embedded Computer : https://www.bliiot.com/industrial-computer-p00464p1.html

0 notes

Text

AC Servo Motor Control System: A Step-by-Step Tutorial

Introduction

AC servo motor control system is a part of contemporary automation, robotics, and industrial machinery. It offers accurate control of speed, torque, and motion and therefore it occupies an important position in those systems where accuracy is required. Here in this blog post, we are going to study about what is an AC servo motor control system, its operation, main components, uses, and benefits. A newbie to the servo motors or looking to study more on the topic, this tutorial is a simple and easy-to-follow tutorial.

What is an AC Servo Motor Control System?

An AC servo motor control system is a combination of a servo motor, a controller, and a feedback system managing the motor’s motion. The system maintains the motor running effectively at the desired position, speed, and torque. Servo motors differ from ordinary motors because they are applied for precise motion control, which is applied in robotics, CNC machines, and automation fields.

How does an AC Servo Motor Control System Function?

The processes of an AC servo motor controller are three elementary in nature:

Input Signal Processing: Controller accepts desired motion commands of the system from the outside, i.e., computer or programmable logic controller (PLC).

Motor Movement: According to input, the controller controls the voltage and current input to the motor in such a way that it generates the desired movement.

Feedback Mechanism: A feedback sensor, i.e., an encoder, continuously monitors the motor’s position and speed and gives feedback to the controller. The controller is real-time adjusted to keep it correct.

Key Components of an AC Servo Motor Control System

Servo Motor: The core of the system, which converts electric power to accurate mechanical motion.

Servo Drive: Also known as the amplifier, controlling power to the motor.

Controller: The mental organ of the system that accepts input commands and regulates motor performance.

Feedback Sensor: Provides immediate feedback on motor position, velocity, and torque.

Power Supply: Provides electricity to energize the system.

Applications of AC Servo Motor Control Systems

The AC servo motor control system is widely prevalent in industrial applications due to its accuracy and consistency. Some of its primary uses are

Robotics: Robot arms employ servo motors for precise and smooth movement.

CNC Machines: CNC machines employ servo motors for precision machining, drilling, and cutting.

Automated Production Lines: Servo systems are employed in conveyor belts and robot assembly lines in production facilities.

Medical Equipment: Servo motors are used by machines such as MRI machines and surgical robots for precise performance.

Printing Presses: Servo motors are used in high-speed presses to provide precision and efficiency.

Advantages of AC Servo Motor Control Systems

High Precision: The feedback system offers high-precision positioning and motion control.

Energy Efficiency: Power consumption is optimized to reduce energy usage.

Fast Response Time: Servo motors have a fast response time to varying inputs, which makes them suitable for dynamic applications.

Smooth Operation: Reduces vibrations and extends the life of machinery.

Versatility: Use in a broad spectrum of industries, from manufacturing to health care.

Differences Between AC and DC Servo Motors

Though both AC and DC servo motors are used in automation, several distinct differences include:

AC Servo Motors: Harder in nature, better suited for those applications with high speed and require less maintenance.

DC Servo Motors: Better for design purposes but require routine maintenance due to wear on brushes.

Efficiency: AC is more efficient compared to DC motors.

Performance: AC servo motors offer better torque control and smoother performance.

Choosing the Right AC Servo Motor Control System

When choosing an AC servo motor control system, take the following into account:

Load Requirements: Determine the torque and speed your application needs.

Accuracy Needs: Select a system with a suitable feedback mechanism to enable precise control.

Environmental Conditions: Consider temperature, humidity, and dust conditions that will affect performance.

Budget and Maintenance: Invest in a long-term, durable, and low-maintenance system.

Future Trends in AC Servo Motor Control Systems

Technological advancements bring better AC servo motor control systems. Future trends are:

Integration with IoT and AI: Smart servo systems will be capable of making decisions based on data and optimizing performance on their own.

Wireless Control: Wireless monitoring and control may be enabled in future servo systems.

Miniaturization: Servo motors will be miniaturized, energy-efficient, and suitable for robotics and medical devices.

Energy Harvesting: Future technologies may make it possible for servo systems to harvest energy from motion and make them more sustainable.

Conclusion

An AC servo motor control system is a core element of modern automation and industrial technology. Its precision, energy efficiency, and reliability make it a top technology in various industries. Employed in robotics, CNC machines, or medical equipment, the systems get better over time, delivering better performance and smarter solutions.

If you are going to include an AC servo motor control system in your project, decide your requirements and choose a system that is best for your requirements. With the latest developments in technology, the future of servo motor systems holds great promise, bringing more efficiency and automation to industries all over the world. Originally Published Here:- https://nmagroup.in/ac-servo-motor-control-tutorial/

0 notes

Text

How Advanced Servo Drives Improve Motion Control in Automation?

In the rapidly evolving world of industrial automation, Advanced Servo Drives play a crucial role in enhancing motion control, efficiency, and precision. These sophisticated drives offer seamless integration with robotic and automated systems, ensuring that machines perform with high accuracy and minimal downtime. As industries continue to push the boundaries of automation, companies like Oracle Robotics are pioneering innovative solutions to improve manufacturing processes through advanced motion control technology.

Understanding Advanced Servo Drives

Servo drives are essential components in motion control systems, responsible for regulating the torque, speed, and position of motors in automated machinery. Unlike traditional motor control systems, Advanced Servo Drives provide superior feedback mechanisms, allowing for precise adjustments based on real-time conditions. This level of control is critical in industries that require high-speed and high-precision operations, such as robotics, aerospace, automotive manufacturing, and electronics production.

Key Benefits of Advanced Servo Drives in Automation

1. Enhanced Precision and Accuracy

One of the most significant advantages of Advanced Servo Drives is their ability to deliver exceptional precision. By utilizing high-resolution encoders and sophisticated control algorithms, these drives can achieve extremely accurate positioning and motion control. This is particularly beneficial in applications such as CNC machining, robotic arms, and pick-and-place operations, where even minor deviations can lead to quality issues.

2. Higher Efficiency and Energy Savings

Energy efficiency is a top priority for modern industries aiming to reduce operational costs and minimize environmental impact. Advanced servo systems optimize energy consumption by dynamically adjusting motor output based on demand. Regenerative braking and energy recovery features further contribute to reducing power usage, making automation systems more sustainable and cost-effective.

3. Seamless Integration with Automation Systems

The latest Advanced Servo Drives are designed for easy integration with a variety of industrial automation platforms. They support multiple communication protocols such as EtherCAT, Modbus, and CANopen, ensuring compatibility with different control systems. This flexibility enables manufacturers to create highly customized and interconnected automation solutions tailored to their specific needs.

4. Increased Speed and Responsiveness

High-speed manufacturing processes demand fast and reliable motion control. Servo drives with advanced feedback and control mechanisms allow for rapid response times, reducing cycle times and increasing overall production output. Whether in conveyor systems, robotic automation, or material handling, these drives enhance operational speed without compromising accuracy.

5. Improved Reliability and Reduced Downtime

Downtime can be costly in any manufacturing setup. Advanced servo technology incorporates predictive maintenance capabilities, monitoring system health in real time to detect potential issues before they lead to failures. With self-diagnostic features and automated fault recovery, companies can prevent unexpected breakdowns and ensure continuous operation.

6. Adaptive Control and AI Integration

The future of Advanced Servo Drives lies in artificial intelligence (AI) and machine learning. Modern servo systems are incorporating AI-driven algorithms that can analyze performance data and adapt to changing conditions. This adaptive control improves efficiency, reduces wear and tear on components, and allows for real-time optimization of motion control processes.

Applications of Advanced Servo Drives in Industrial Automation

1. Robotics and Automated Assembly

In robotic automation, precise motion control is essential for tasks such as welding, assembly, and material handling. Servo drives enable robotic arms to move with high accuracy, improving consistency and reducing errors in production lines.

2. CNC Machining and Manufacturing

CNC machines rely on servo-driven motion control for precision cutting, drilling, and milling. With the help of Advanced Servo Drives, these machines achieve greater accuracy and smoother motion, leading to improved product quality and reduced material waste.

3. Packaging and Material Handling

From conveyor belt systems to automated packaging machinery, servo drives play a vital role in ensuring smooth and efficient movement of materials. Their ability to adjust speed and torque in real-time ensures seamless operation, reducing bottlenecks and increasing throughput.

4. Textile and Printing Industries

In textile manufacturing and high-speed printing applications, servo-driven motion control ensures precise fabric handling, accurate ink deposition, and synchronization of moving components. This results in consistent product quality and minimal defects.

The Future of Motion Control with Advanced Servo Drives

As industries continue to embrace automation, the demand for Advanced Servo Drives will only grow. Innovations in AI, IoT connectivity, and cloud-based monitoring will further enhance the capabilities of servo-driven systems, making them smarter and more efficient. Companies like Oracle Robotics are at the forefront of this technological revolution, providing cutting-edge motion control solutions that redefine the future of automation.

With continuous advancements in servo technology, manufacturers can expect even greater levels of precision, reliability, and energy efficiency. By integrating these sophisticated drives into their automation strategies, businesses can stay ahead of the competition, optimize production, and drive industrial progress into the future.

Conclusion

Advanced Servo Drives are transforming industrial automation by providing unparalleled precision, speed, and efficiency. From robotics to CNC machining and packaging, these drives enhance motion control across various applications, improving productivity and reducing operational costs. As the industry moves towards smarter automation, embracing advanced servo technology will be key to achieving next-level manufacturing excellence. With leaders like Oracle Robotics driving innovation, the future of motion control is brighter than ever.

0 notes