#Sheet and Tube Laser cutting machine

Explore tagged Tumblr posts

Text

THE ULTIMATE GUIDE TO PRESSES, SHEARS, LASER CUTTERS AND PUNCHES

In the world of metal fabrication, several key machines play a vital role in shaping and cutting metal with precision and efficiency. This ultimate guide provides comprehensive knowledge and insights into the essential products of the industry: Press Brake, Press Brake Tools, Shearing Machine, Laser Cutting Machine, and Power Press. Whether you are a beginner or an experienced professional, this guide will equip you with the necessary information to understand, select, and optimize the use of these machines for your metalworking needs.

Press Brake:

1.What is a Press Brake?

A press brake is a key equipment used in the field of metal fabrication for bending and folding metal sheets. It utilizes pressure to bend the metal sheet into the desired shape. It is commonly used to create bent parts, enclosures, tubing, and other metal components.

A press brake consists of an upper die and a lower die, with the upper die fixed to the frame and the lower die movable through a hydraulic system or mechanical drive system. The metal sheet is placed between the two dies and then bent into the desired angle and shape by applying pressure.

Press brakes typically have the following features and capabilities:

(1)Bending capacity: Press brakes can achieve bends at different angles and radii to meet various workpiece requirements.

(2)Precision: High precision bending results can be achieved by adjusting the position of the upper and lower dies.

(3)Automation: Some modern press brakes are equipped with CNC systems, allowing for automated operation and programming.

(4)Versatility: Press brakes can be used for various bending tasks and different types of metal materials by changing different tools and dies.

(5)Safety: Press brakes are typically equipped with safety devices such as light curtains, protective covers, and emergency stop buttons to ensure operator safety.

Press brakes are widely used in industries such as automotive manufacturing, aerospace, construction, electronics, and more. They are essential equipment for achieving precise and efficient metal fabrication.

2.Types of Press Brakes

There are several types of press brakes commonly used in metal fabrication:

Mechanical Press Brake: Uses a mechanical flywheel and clutch system for bending.

Hydraulic Press Brake: Utilizes hydraulic cylinders for precise bending control.

Servo-Electric Press Brake: Uses electric servo motors for high precision bending.

Pneumatic Press Brake: Relies on compressed air for lighter applications.

CNC Press Brake: Equipped with computerized controls for automated and precise bending operations.

The choice of press brake depends on factors such as material type, thickness, bending requirements, and production volume.

3.Components and Working Principles

A press brake consists of several key components that work together to perform the bending operation. Here are the main components and their functions:

Frame: The frame provides structural support and stability to the press brake.

Bed: The bed is a flat surface where the material to be bent is placed.

Ram: The ram is the moving part of the press brake that applies force to the material for bending.

Die: The die is a tool that shapes the material by providing a specific bending angle.

Punch: The punch is another tool that presses against the material, working in conjunction with the die to bend it.

Backgauge : The backgauge is an adjustable device that positions the material accurately for consistent bending.

4.Key Features and Benefits

Material Placement: The operator places the metal sheet or plate on the bed of the press brake.

Tool Setup: The appropriate die and punch are selected and installed on the press brake.

Backgauge Adjustment: The backgauge is adjusted to position the material correctly for the desired bend.

Bending Process: The ram moves downward, applying force to the material, which is sandwiched between the punch and the die. This bending action creates the desired angle in the material.

Material Removal: Once the bending is complete, the operator removes the bent material from the press brake.

5.Applications and Industries

Press brakes are widely used in various industries for different applications, including:

Metal Fabrication: Press brakes are commonly used in metal fabrication shops to bend and shape metal sheets and plates for various products such as enclosures, brackets, frames, and panels.

Automotive Industry: Press brakes are used in the automotive industry for manufacturing components like chassis, brackets, and body panels.

Aerospace Industry: Press brakes are utilized in the aerospace industry for bending and forming metal parts used in aircraft structures and components.

Construction and Architecture: Press brakes are used in the construction and architectural sectors for bending metal components used in building structures, facades, and decorative elements.

Electronics and Appliances: Press brakes are employed in the manufacturing of electronic enclosures, appliance components, and consumer products.

Press Brake Tools:

1.Importance of Press Brake Tools

Press brake tools play a crucial role in the performance and efficiency of press brake machines. Here are some key points highlighting the importance of press brake tools:

(1) Precision Bending: Press brake tools are designed to provide precise and accurate bending angles. They ensure consistent results and help meet the required specifications for the final product. The quality and precision of the tools directly impact the overall quality of the bent parts.

(2) Versatility: Press brake tools come in various shapes, sizes, and configurations to accommodate different bending requirements. They can be customized or interchanged to achieve different bending angles, radii, or complex shapes. This versatility allows manufacturers to produce a wide range of products using the same machine.

(3) Durability and Longevity: Press brake tools are made from high-quality materials such as hardened steel or special alloys, which make them highly durable and resistant to wear and tear. Proper maintenance and regular tool inspections ensure their longevity, reducing the need for frequent replacements.

(4) Efficiency and Productivity: Well-designed press brake tools optimize the bending process, reducing setup time, and increasing productivity. They enable faster bending cycles, allowing manufacturers to produce more parts in less time. Efficient tooling also minimizes material waste and improves overall production efficiency.

(5) Cost Savings: Using the right press brake tools can lead to cost savings in multiple ways. Accurate bending reduces material waste, saving on raw material costs. Efficient tooling reduces setup time and increases machine productivity, maximizing the output per hour. Additionally, durable tools have a longer lifespan, reducing the frequency of replacements and maintenance costs.

(6) Safety: Press brake tools are designed with safety features in mind. They provide proper clamping and holding mechanisms to secure the material during bending, minimizing the risk of accidents. Additionally, using high-quality tools reduces the chances of tool failure or breakage, ensuring operator safety.

(7) In summary, press brake tools are vital for achieving precise and accurate bending results, improving productivity, reducing costs, and ensuring operator safety. Selecting the right tools and maintaining them properly is essential for the efficient operation of press brake machines.

2.Types of Press Brake Tools (including ARC Press Brake Tools)

There are several types of press brake tools available, each designed for specific bending applications. Here are some common types of press brake tools:

V-Die: V-dies are the most commonly used press brake tools. They consist of a bottom die with a V-shaped groove and a punch with a matching V-shaped tip. V-dies are versatile and can be used for a wide range of bending angles and materials.

(1) Bottoming Die: Bottoming dies, also known as flat dies, have a flat surface instead of a V-shaped groove. They are used for achieving sharp bends or bending thicker materials where a tighter radius is required.

(2) Gooseneck Punch: Gooseneck punches have a curved shape that allows for deep and offset bends. They are commonly used for bending channels, boxes, and other complex shapes.

(3) Hemming Tool: Hemming tools are used for creating hems or flanges on the edge of a sheet metal part. They consist of a punch and die set that folds the material over itself to create a secure edge.

(4) Radius Tool: Radius tools, also known as radius punches or radius dies, are used for creating curved bends with a specific radius. They are available in various sizes to accommodate different bending requirements.

(5) Multi-V Die: Multi-V dies have multiple V-shaped grooves of different sizes on a single die. They allow for quick and easy tool changes without the need for separate dies for different bending angles.

(6) ARC Press Brake Tools: ARC press brake tools are specialized tools used for bending sheet metal into arc shapes. They are designed to create precise and consistent curved bends, commonly used in applications such as cylindrical parts, tubes, or curved profiles.

ARC press brake tools typically consist of a bottom die with a curved groove and a punch with a matching curved tip. They enable the accurate and repeatable bending of sheet metal into various arc shapes.

3.Material Selection and Coatings

When it comes to press brake tools, material selection and coatings play an important role in their performance and longevity. Here's a brief overview of material selection and coatings for press brake tools:

Material Selection:

(1) Tool Steel: Tool steel, such as D2 or A2, is commonly used for press brake tools due to its high hardness, wear resistance, and toughness.

(2) Carbide: Carbide inserts or tips are used for heavy-duty applications or when bending abrasive materials. Carbide provides excellent wear resistance but is more brittle than tool steel.

(3) High-Speed Steel (HSS): HSS is another option for press brake tools. It offers good toughness and wear resistance, but not as high as tool steel.

Coatings:

(4) Nitride Coating: Nitride coatings, such as TiN (Titanium Nitride) or TiCN (Titanium Carbonitride), improve the surface hardness and wear resistance of the tool. They are suitable for general-purpose bending applications.

(5) DLC Coating: DLC (Diamond-Like Carbon) coatings provide excellent hardness, low friction, and high wear resistance. They are ideal for bending stainless steel and other difficult-to-form materials.

(6) PVD Coating: Physical Vapor Deposition (PVD) coatings, like TiAlN (Titanium Aluminum Nitride), enhance the tool's performance by reducing friction and increasing wear resistance.

(7) Chrome Plating: Chrome plating is a common coating for press brake tools. It provides good corrosion resistance and reduces friction during bending operations.

The selection of material and coating depends on factors such as the type of material being bent, the bending application, and the desired tool life. It's important to choose the right combination of material and coating to ensure optimal performance and durability of the press brake tools.

4.Tooling Configurations and Considerations

When it comes to press brake tools, the tooling configurations and considerations are crucial for achieving accurate and efficient bending operations. Here are some important aspects to consider:

Tooling Configurations:

(1) V-Die: The V-die is the female tool that provides the desired bend shape. It comes in various widths and angles to accommodate different material thicknesses and bending requirements.

(2) Punch: The punch is the male tool that contacts the material and applies force to create the bend. It also comes in different shapes and sizes to achieve specific bend angles and radii.

(3) Multi-V Die: Multi-V dies have multiple V-shaped grooves of different widths and angles. They allow for bending different material thicknesses and angles without changing the die.

(4) Gooseneck Punch: Gooseneck punches have a curved shape that allows for deep or offset bends where space is limited.

(5) Hemming Tools: Hemming tools are used for creating hemmed edges or flanges on sheet metal.

Considerations:

(1) Material Thickness: The tooling configuration should be selected based on the material thickness being bent. Thicker materials may require larger tooling to accommodate the increased force and prevent tool damage.

(2) Material Type: Different materials have varying properties, such as hardness and ductility, which can affect the tooling selection. Harder materials may require tougher tooling materials or coatings.

(3) Bend Angle and Radius: The desired bend angle and radius dictate the selection of punch and die configurations. Sharp bends require smaller punch radii, while larger radii are needed for gentler bends.

(4) Tooling Alignment: Proper alignment between the punch and die is essential for achieving accurate and consistent bends. Misalignment can result in uneven bends or tool damage.

(5) Tooling Maintenance: Regular inspection and maintenance of the tooling are necessary to ensure optimal performance and longevity. This includes cleaning, lubrication, and replacement of worn-out components.

By considering the tooling configurations and these important factors, you can select the appropriate press brake tools for your specific bending requirements. This will help you achieve precise and efficient bending operations while prolonging the tooling life.

5.Tool Maintenance and Longevity

(1) Regular cleaning: Clean the press brake tools regularly to remove debris, dirt, and metal shavings. Use appropriate cleaning agents and tools to avoid damaging the tool surfaces. Ensure that the tools are completely dry before storing them.

(2) Lubrication: Apply lubrication to the press brake tools as recommended by the manufacturer. Lubrication helps reduce friction and wear, improving the tool's lifespan. Follow the manufacturer's guidelines for the type and frequency of lubrication.

(3) Inspection and repair: Regularly inspect the press brake tools for signs of wear, damage, or deformation. Check for any cracks, chips, or excessive wear on the cutting edges. If any issues are detected, promptly repair or replace the damaged parts to prevent further damage and ensure accurate bending results.

(4) Proper storage: Store the press brake tools in a clean and dry environment to prevent corrosion and damage. Use dedicated tool racks or boxes to keep the tools organized and protected. Avoid placing heavy objects on top of the tools to prevent deformation.

(5) Operator training: Proper training of operators is essential for tool maintenance and longevity. Educate operators on the correct usage techniques, operating limits, and safety precautions. Encourage operators to report any issues or abnormalities with the tools promptly.

By following these maintenance tips, you can extend the lifespan of your press brake tools and ensure consistent and accurate bending operations. Regular maintenance not only improves tool performance but also contributes to the overall safety and efficiency of the bending process.

6.Advanced Tooling Technologies and Innovations

Advanced tooling technologies and innovations have significantly improved the performance and capabilities of press brake tools. Here are some key advancements in press brake tooling:

(1) High-strength materials: Press brake tooling is now made from high-strength materials such as hardened steel alloys or carbide. These materials offer superior durability, wear resistance, and longer tool life compared to traditional tooling materials.

(2) Coatings and surface treatments: Advanced coatings and surface treatments, such as TiN (Titanium Nitride) or DLC (Diamond-Like Carbon), are applied to press brake tools to enhance their performance. These coatings reduce friction, improve wear resistance, and prevent material adhesion, resulting in improved bending quality and longer tool life.

(3) Precision tooling systems: Modern press brake tooling systems feature precision-ground tooling with tight tolerances. These systems ensure accurate and repeatable bending results, reducing setup times and increasing productivity.

(4) Quick-change tooling systems: Quick-change tooling systems allow for rapid tooling setup and changeovers. These systems utilize standardized tooling holders and clamping mechanisms, enabling operators to switch between different tooling setups quickly and efficiently.

(5) 3D modeling and simulation: Advanced software tools enable 3D modeling and simulation of bending processes. These tools help optimize tooling designs, simulate bending sequences, and detect potential collision or interference issues before actual production. This reduces setup time, minimizes errors, and improves overall efficiency.

(6) Custom tooling solutions: Tooling manufacturers now offer custom tooling solutions tailored to specific bending applications. These solutions include specialized tool profiles, custom tool coatings, and even tooling with integrated sensors for process monitoring and control.

These advancements in press brake tooling technologies have significantly improved productivity, accuracy, and tool life. By adopting these innovations, manufacturers can achieve higher efficiency, reduce downtime, and produce high-quality bent parts consistently.

Shearing Machine:

1.Understanding Shearing Machines

Shearing machines are industrial mechanical devices used for cutting metal sheets and other materials. They apply shearing force to cut the materials into desired shapes and sizes. Shearing machines are widely used in manufacturing and metalworking industries to produce various products and components.

The working principle of shearing machines involves placing the material on a shear table and applying force through cutting blades to cause the material to fracture. Shearing machines can perform operations such as straight cutting, curved cutting, and angle cutting. Depending on the specific requirements, shearing machines can have different cutting capacities and precision.

There are various types of shearing machines, including hydraulic shearing machines, mechanical shearing machines, and manual shearing machines. Hydraulic shearing machines use hydraulic systems to provide cutting force and offer high power and precision, making them suitable for large-scale and heavy-duty cutting tasks. Mechanical shearing machines use mechanical mechanisms to provide cutting force and are typically more compact and cost-effective, suitable for medium-sized cutting tasks. Manual shearing machines require manual operation and are suitable for small-scale and simple cutting work.

The cutting capacity of shearing machines depends on their maximum cutting thickness and cutting width. Larger shearing machines generally have higher cutting capacity and can handle thicker and wider materials. The cutting precision of shearing machines is influenced by factors such as blade sharpness, adjustment of blade clearance, rigidity of the frame, and material characteristics.

Safety considerations are important when operating shearing machines. Operators should receive proper training on the operation procedures and safety precautions of shearing machines. Additionally, appropriate personal protective equipment, such as safety goggles and gloves, should be worn. Regular inspection and maintenance of shearing machines are necessary to ensure their proper functioning and safe operation. Following the operation manual and manufacturer's recommendations is crucial to ensure the safety and effectiveness of operating shearing machines.

2.Hydraulic vs. Mechanical Shearing Machines

Hydraulic and mechanical shearing machines are two common types of shearing machines used in industrial applications. Here's a comparison between the two:

Power Source:

(1) Hydraulic Shearing Machines: These machines use a hydraulic system to generate the cutting force. The force is applied through hydraulic cylinders powered by a hydraulic pump. Hydraulic shearing machines offer high power and can handle heavy-duty cutting operations.

(2) Mechanical Shearing Machines: These machines use mechanical mechanisms, such as gears, levers, and flywheels, to generate the cutting force. The force is applied directly through the mechanical components. Mechanical shearing machines are generally more compact and cost-effective.

Power and Precision:

(1) Hydraulic Shearing Machines: Due to the hydraulic system, hydraulic shearing machines can provide high cutting power. They are capable of cutting thick and hard materials with precision. The hydraulic system allows for better control and adjustment of the cutting force, resulting in accurate and consistent cuts.

(2) Mechanical Shearing Machines: Mechanical shearing machines provide a lower cutting power compared to hydraulic ones. They are suitable for medium-duty cutting tasks. However, the cutting precision of mechanical shearing machines can be affected by factors such as mechanical wear and tear, which may require more frequent adjustments and maintenance.

Size and Space:

(3) Hydraulic Shearing Machines: Hydraulic shearing machines are generally larger and require more space due to the hydraulic system components, such as the hydraulic pump, cylinders, and hoses.

(4) Mechanical Shearing Machines: Mechanical shearing machines are more compact and take up less space. They are often preferred in smaller workshops or where space is limited.

Cost:

(1) Hydraulic Shearing Machines: Hydraulic shearing machines are typically more expensive due to the complexity and cost of the hydraulic system components.

(2) Mechanical Shearing Machines: Mechanical shearing machines are generally more affordable and cost-effective.

In summary, hydraulic shearing machines provide high power and precision, making them suitable for heavy-duty cutting operations. They are larger and more expensive. On the other hand, mechanical shearing machines are more compact, cost-effective, and suitable for medium-duty cutting tasks. The choice between hydraulic and mechanical shearing machines depends on the specific cutting requirements, available space, and budget considerations.

3.Components and Operation

Components of a Shearing Machine:

(1) Shear Table: This is the flat surface or bed on which the material to be cut is placed. It provides support and stability during the cutting process.

(2) Cutting Blades: These are the sharp blades that perform the actual cutting of the material. They are typically made of high-quality tool steel and are securely mounted on the machine. The blades can be straight, curved, or angled, depending on the desired cutting operation.

(3) Blade Clearance Adjustment: Shearing machines often have a mechanism for adjusting the clearance between the upper and lower blades. This adjustment allows for precise control of the cutting gap, ensuring clean and accurate cuts.

(4) Back Gauge: The back gauge is a movable stop or fence located behind the shear table. It helps in positioning the material accurately for repetitive cutting operations. The back gauge can be manually adjusted or controlled by a motorized system.

(5) Drive System: The drive system provides the power to move the cutting blades. In hydraulic shearing machines, the drive system consists of a hydraulic pump, cylinders, and valves. In mechanical shearing machines, it typically involves mechanical components such as gears, levers, and flywheels.

(6) Control Panel: The control panel houses the controls and switches for operating the shearing machine. It allows the operator to start and stop the machine, adjust settings, and monitor the cutting process.

Operation of a Shearing Machine:

(1) Material Preparation: The material to be cut is prepared by ensuring it is clean, straight, and properly aligned with the shear table. Any protective coatings or films on the material should be removed.

(2) Material Placement: The material is placed on the shear table, ensuring it is aligned with the back gauge if applicable. The operator should take care to position the material securely and avoid any obstructions that could interfere with the cutting process.

(3) Blade Clearance Adjustment: The blade clearance is set according to the thickness and type of material being cut. This adjustment ensures proper shearing without damaging the material or the blades. The manufacturer's guidelines or machine manual should be followed for the correct blade clearance settings.

(4) Cutting Operation: Once the material is properly positioned and the blade clearance is set, the operator initiates the cutting operation. In hydraulic shearing machines, the hydraulic pump is activated to provide the necessary cutting force. In mechanical shearing machines, the operator engages the drive system, which transfers power to the cutting blades.

(5) Monitoring and Control: During the cutting process, the operator monitors the operation to ensure smooth and accurate cutting. The control panel may provide indicators or displays for monitoring the cutting speed, blade position, and other parameters. Any abnormalities or issues should be addressed promptly.

(6) Material Removal and Repeat: After the cutting operation is complete, the cut pieces are removed from the shear table. The process can be repeated for subsequent cuts, adjusting the back gauge if necessary.

It's important to note that the specific operation of a shearing machine may vary depending on the machine model and manufacturer. Operators should always refer to the machine's manual and receive proper training before operating the shearing machine.

4.Cutting Capacity and Accuracy

Cutting Capacity and Accuracy are important considerations when using a shearing machine. Let's discuss each of them:

Cutting Capacity:

(1) Shearing machines have a specified cutting capacity, which refers to the maximum thickness and width of the material that can be effectively cut. The cutting capacity is determined by factors such as the power of the machine, the strength of the blades, and the rigidity of the shear table.

(2) It is crucial to choose a shearing machine with a cutting capacity that matches the requirements of the materials you will be working with. Attempting to cut materials beyond the machine's capacity can result in poor cutting quality, blade damage, or even machine malfunction.

Cutting Accuracy:

(1) Cutting accuracy refers to the ability of the shearing machine to make precise and consistent cuts. It is influenced by several factors, including the design and condition of the machine, the sharpness and alignment of the blades, and the control and monitoring systems.

(2) To achieve high cutting accuracy, it is important to maintain the shearing machine properly. Regular blade sharpening and replacement, as well as routine maintenance and calibration, can help ensure accurate cuts.

(3) The operator's skill and experience also play a significant role in achieving cutting accuracy. Proper material positioning, adjustment of blade clearance, and careful monitoring of the cutting process are essential for obtaining precise and clean cuts.

Factors Affecting Accuracy:

(1) Blade Condition: Dull or damaged blades can lead to uneven cuts and reduced accuracy. Regular inspection and maintenance of the blades are necessary to maintain cutting precision.

(2) Blade Clearance: Incorrect blade clearance can result in distorted or incomplete cuts. It is important to set the appropriate blade clearance for the material being cut.

(3) Material Alignment: Proper alignment of the material with the shear table and back gauge is crucial for accurate cuts. Misalignment can cause crooked or uneven cuts.

(4) Machine Rigidity: The rigidity of the shearing machine, including the shear table and frame, affects cutting accuracy. A sturdy and well-maintained machine provides better stability and reduces the chances of deflection during the cutting process.

It is recommended to follow the manufacturer's guidelines and recommendations for the specific shearing machine being used. Regular maintenance, blade inspection, and operator training are essential to ensure optimal cutting capacity and accuracy.

5.Safety Considerations

Safety considerations are of utmost importance when operating a shearing machine. Here are some key safety measures to keep in mind:

(1) Read and Follow the Manual: Familiarize yourself with the manufacturer's instructions and safety guidelines provided in the machine's manual. Understand the machine's features, controls, and potential hazards before operating it.

(2) Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses or goggles, gloves, and ear protection. Depending on the specific machine and the materials being cut, additional protective gear such as a face shield or apron may be required.

(3) Machine Inspection: Before starting the machine, inspect it for any signs of damage, loose parts, or malfunctioning components. Ensure that all safety guards and devices are in place and functioning correctly.

(4) Training and Competence: Only trained and authorized personnel should operate a shearing machine. Proper training should cover machine operation, safety procedures, emergency shutdown, and handling of materials.

(5) Material Handling: Use caution when handling materials, especially large or heavy ones. Use lifting equipment or assistance when necessary to avoid strain or injuries.

(6) Emergency Stop: Familiarize yourself with the location and operation of the emergency stop button or switch. Be prepared to use it in case of any emergency or unsafe situation.

(7) Blade Safety: Never reach into the cutting area while the machine is in operation or attempt to adjust the blades without proper training. Always wait for the machine to come to a complete stop before making any adjustments or maintenance.

(8) Housekeeping: Maintain a clean and organized work area. Remove any debris, scraps, or obstructions that may interfere with the machine's operation or cause accidents.

(9) Lockout/Tagout: Follow proper lockout/tagout procedures when performing maintenance or repairs on the machine. This involves disconnecting the power source and ensuring that it cannot be re-energized accidentally.

(10) Regular Maintenance: Adhere to the recommended maintenance schedule for the shearing machine. This includes blade sharpening, lubrication, and inspection of mechanical and electrical components.

Remember, safety should always be the top priority when operating any machinery. If you have any concerns or encounter any issues with the shearing machine, stop the operation immediately and seek assistance from a qualified technician or supervisor.

Laser Cutting Machine:

1.Introduction to Laser Cutting:

Laser cutting is a highly precise and versatile method of cutting various materials using a high-powered laser beam. It has revolutionized the manufacturing industry by providing a faster, more accurate, and more efficient alternative to traditional cutting methods. Laser cutting machines are used in a wide range of industries, including automotive, aerospace, electronics, signage, and jewelry making.

2.Types of Laser Cutting Machines:

There are different types of laser cutting machines available, each with its own advantages and suitable applications. The most common types include CO2 lasers, fiber lasers, and neodymium lasers.

CO2 lasers are the most widely used type of laser cutting machine. They use a mixture of carbon dioxide, nitrogen, and helium as the laser medium. CO2 lasers are versatile and can cut a wide range of materials, including non-metallic materials such as plastics, wood, and fabrics, as well as metals.

Fiber lasers use optical fibers as the laser medium. They are highly efficient and are primarily used for cutting metals, including stainless steel, aluminum, and copper. Fiber lasers offer high beam quality, which results in faster cutting speeds and improved precision.

Neodymium lasers use neodymium-doped crystals (such as neodymium-doped yttrium aluminum garnet or Nd: YAG) as the laser medium. They are known for their high energy and are used for precision cutting and engraving. Neodymium lasers are commonly used in applications that require high power and fine detail, such as jewelry making and micro-machining.

3.Advantages and Limitations:

Laser cutting offers several advantages over traditional cutting methods. One of the key advantages is its high precision and accuracy. Laser cutting machines can achieve intricate and complex cuts with minimal distortion. They also provide excellent edge quality, eliminating the need for additional finishing processes.

Another advantage is the speed and efficiency of laser cutting. Laser cutting machines can cut at high speeds, resulting in faster production times and increased productivity. They can also cut multiple parts simultaneously, further improving efficiency.

Laser cutting is a non-contact cutting method, which means there is no physical contact between the cutting tool and the material. This reduces the risk of damage to the material and allows for cutting delicate or fragile materials.

However, laser cutting does have some limitations. The thickness capacity of a laser cutting machine depends on the power of the laser and the type of material being cut. Thicker materials may require multiple passes or a more powerful laser to achieve a clean cut. Additionally, laser cutting machines can be expensive to purchase and maintain, making them more suitable for high-volume production environments.

4.Material Compatibility and Thickness:

Laser cutting machines can cut a wide range of materials, including metals, plastics, wood, textiles, and more. The compatibility of a material with laser cutting depends on its ability to absorb the laser energy. Materials that are highly reflective, such as copper or aluminum, may require higher laser power for cutting.

The thickness of the material that can be cut depends on the power of the laser and the type of material. Laser cutting machines can typically cut thin materials with high precision. For example, a CO2 laser cutting machine can cut up to 25mm thick steel, while a fiber laser cutting machine can cut up to 30mm thick steel. However, the maximum thickness capacity may vary depending on the specific machine and laser power.

It is important to consider the material compatibility and thickness capacity of a laser cutting machine before selecting the appropriate machine for a specific application. Consulting with a laser cutting machine supplier or manufacturer can help determine the best machine for a particular material and thickness requirement.

Power Press:

1.Exploring Power Press Machines:

Power press machines, also known as press machines or stamping presses, are versatile machines used in metalworking for various operations such as punching, bending, forming, and blanking. They are commonly used in industries such as automotive, manufacturing, construction, and appliance production. Power press machines come in different sizes and configurations to accommodate different applications and production requirements.

Power press machines are designed to apply force to a workpiece using mechanical or hydraulic systems. They are capable of exerting high pressure to shape, cut, or form metal sheets or other materials. Power press machines can be categorized into mechanical and hydraulic types based on their power source and operation.

2.Mechanical vs. Hydraulic Power Press:

Mechanical power presses use mechanical force, typically generated by a flywheel and a crankshaft, to perform operations. They are known for their high speed and productivity. Mechanical power press machines have a mechanical clutch or brake system that controls the stroke and stopping motion of the ram. They are suitable for high-volume production environments where speed and precision are important.

Hydraulic power presses, on the other hand, use hydraulic systems to generate force. They utilize hydraulic cylinders to apply pressure to the ram and perform operations. Hydraulic power press machines offer more control and flexibility in terms of force adjustment and speed modulation. They are often used for operations that require precise force control or for applications that involve deep drawing or forming of materials.

The choice between a mechanical or hydraulic power press depends on the specific requirements of the application. Factors such as the type of operation, material thickness, production volume, and precision requirements should be considered when selecting the appropriate power press machine.

3.Components and Operation:

Power press machines consist of several key components that work together to perform various operations. These components include the frame, slide or ram, bolster, die, clutch or brake system, and control system.

The frame provides the structure and support for the machine. It is usually made of cast iron or steel to withstand the forces exerted during operation. The slide, also known as the ram, moves up and down to apply force to the material. It is guided by the frame and can be driven by a crankshaft or hydraulic cylinders.

The bolster is a flat surface on which the material is placed. It provides support to the workpiece during the operation. The die is a specially shaped tool that performs the desired operation, such as punching a hole or bending a metal sheet. The die is mounted on the bolster or the ram, depending on the type of operation.

The clutch or brake system controls the stroke and stopping motion of the ram. In mechanical power press machines, a mechanical clutch or brake is used to engage or disengage the flywheel, controlling the motion of the ram. In hydraulic power press machines, the hydraulic system controls the movement of the ram.

The control system of a power press machine can vary depending on the specific machine and its features. It can range from simple manual controls to advanced computer numerical control (CNC) systems. CNC systems offer precise control over the machine's operation, allowing for programmable and repeatable processes.

4.Punching, Bending, and Forming Capabilities:

Power press machines are capable of performing various operations, depending on the tooling and dies used. Some common operations include punching, bending, forming, blanking, coining, embossing, and deep drawing.

Punching is a process of creating holes or shapes in a material using a punch and die set. Bending is the process of deforming a material to form angles or curves. Forming involves shaping a material to create three-dimensional objects or complex geometries. Blanking is the process of cutting out a flat shape from a larger piece of material. Coining is a process that involves compressing a material to create a precise shape or pattern. Embossing is the process of creating raised or depressed

Conclusion:By delving into the comprehensive knowledge provided in this ultimate guide, you have gained a solid understanding of Press Brake, Press Brake Tools, Shearing Machine, Laser Cutting Machine, and Power Press. Armed with this knowledge, you can confidently select, operate, and optimize these machines to achieve precise and efficient metal fabrication results. Remember to prioritize safety, regular maintenance, and stay updated with the latest advancements in the industry to stay ahead in the ever-evolving world of metalworking.

https://www.mihating.com/

3 notes

·

View notes

Text

#BUTECH2025 – AORE Keeps Shining! ✨ Don’t miss AORE’s spotlight booth (Hall 1, G-02)! 💥 ✨ PHK Series – Korea’s #1 choice for sheet laser cutting ✨ TH Series – Precision tube laser cutting machine Our team’s here until May 23rd – Come chat tech, see live demos, and explore solutions! 어서 오세요~! ✨🇰🇷

Learn more: https://www.aorelaser.com/

0 notes

Text

Best Tube Laser Cutting Machine

Most metal fabricators have a strong understanding of what fiber laser cutting technology has done for flat sheet processing, but just what has the fiber laser done for tube cutting? A high-powered fiber laser coupled with automation can feed an enormous number of downstream processes. It has made modern metal fabrication extraordinarily productive, even if some parts need deburring - pipe profile machine.

It’s common these days to see one high-powered fiber laser replace multiple CO2 machines. Fabricators now rely on fewer cutting machines to produce more than ever. That being said, if one of those extraordinarily productive fiber machines happens to produce bad parts that need to be recut, all those efficiency gains go out the window. If the machine crashes, the downtime can throw a serious wrench into the schedule and, at worst, starve the rest of the fab shop. Work flow grinds to a halt. You can avoid this by following a few best practices, both at the machine and, most critically, during nesting and programming - laser cutter.

For thicker stainless or aluminum, an operator might focus the beam near the bottom of the cut. He might not achieve optimal speed, but a low focus does tend to produce the best cut edge and the least amount of dross. All that concentrated heat near the bottom of the kerf evacuates the metal before it has a chance to solidify on the bottom edge.

Over the years machine manufacturers have mapped out focal points for various material grades. Some materials even have two optimal focal points, either very high or very low in the kerf, and both result in very good edge quality. Regardless, all these results have been entered into a machine’s factory settings. If these factory settings stay the way they are, the focus usually remains optimal. There’s rarely a need to adjust the focus unless a machine is cutting a material grade or thickness that’s not in the standard library. And even then, the focus adjustment is likely to be very small. For more information, please visit our site https://impactmachinery.com.au/

0 notes

Text

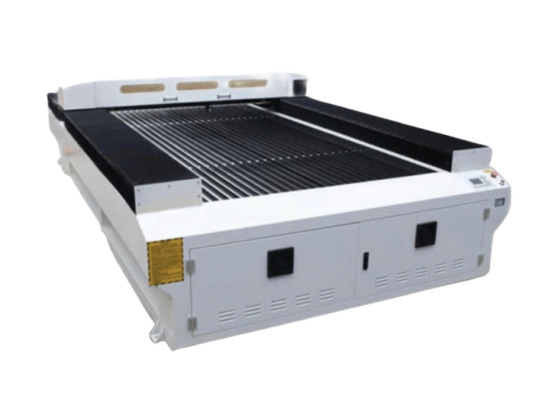

Double-Table Fiber Optic Laser Cutting Machine

This fiber laser cutting machine been worked to help you cut several metal sheet, such as stainless steel, aluminum alloy sheet, carbon steel sheet copper etc.and it has the exchange platform for you choose to automatic feed the sheet to improve work efficiency.

Sheet/tube cutter available Single table, double auto feeding table, with or without protective cover optional professional CNC system designer, laser machine designer to meet all your customized request, offer professional and fast service.

0 notes

Text

The Best Stainless Steel Door Manufacturer in Dwarka

You've come to the right place if you're searching for the top stainless steel producers in Dwarka. This energetic neighborhood of Delhi is home to a number of respectable brands in the metal fabrication and production sector. Known for providing excellent stainless steel goods and solutions, these businesses serve a variety of industries, such as infrastructure development, automotive, kitchenware, and construction. High-quality sheets and coils, long-lasting fittings, or unique stainless steel fabrication are all available from Dwarka's stainless steel producers.

The constant commitment to quality standards is one of the main factors contributing to the increased demand for stainless steel from Dwarka-based producers. To guarantee that their goods fulfill customer requirements, the majority of these businesses employ premium raw materials and adhere to global manufacturing standards. Stainless steel pipes, tubes, sheets, coils, angles, rods, and fittings are typically among their products. They are a one-stop shop for bulk and bespoke stainless steel needs because many of them also provide value-added services, including cutting, bending, welding, and finishing.

Manufacturers in Dwarka that prioritize sustainability and innovation are another noteworthy feature of the stainless steel sector. These businesses frequently make investments in cutting-edge technologies like CNC machines, laser cutting equipment, and sophisticated polishing methods to improve the accuracy and quality of their output. In response to the increasing demand for ecologically friendly products, a number of stainless steel producers make sure that their production methods minimize waste and energy usage.

Additionally, the greatest manufacturers stand out for their dependability and customer service. In Dwarka, companies and private consumers respect producers who provide prompt delivery, clear pricing, and robust post-purchase assistance. Due to their established supply chain and logistics networks, many of these businesses are able to efficiently serve orders throughout Delhi NCR and beyond. Their dedication to client satisfaction guarantees enduring partnerships and repeat business from customers in a variety of industries.

0 notes

Text

From Alloy to Excellence: Brass & Copper Production Explained

In the intricate world of metals, brass and copper hold a revered place for their blend of strength, beauty, and utility. From antique sculptures and musical instruments to modern-day machinery and architectural elements, these metals have shaped civilizations and industries alike. But what lies behind their enduring brilliance? What journey do they take before becoming essential components of everyday life?

In this article, we explore the step-by-step production process of brass and copper — from their origins in raw ore to their transformation into high-performance, high-quality products across various industries.

Step 1: Mining the Foundation — Copper Extraction

The story begins deep beneath the earth’s surface, where copper ores such as chalcopyrite, bornite, and malachite are mined. These ores contain valuable copper but are often interlaced with other elements and impurities. The raw material undergoes crushing and grinding, followed by concentration processes like froth flotation to isolate copper-rich particles.

Once concentrated, the copper ore is roasted in large furnaces and smelted to produce a product called matte, which is then converted into blister copper. After further refining — particularly through electrolytic purification — the copper achieves a purity level of up to 99.99%, ready for industrial applications or for alloying into brass.

Step 2: Alloying — The Art of Making Brass

Unlike copper, brass is an alloy, made by combining copper with zinc in varying proportions. The ratio between these two metals is what gives brass its unique properties — including corrosion resistance, machinability, and its iconic golden hue.

For example:

70% copper and 30% zinc yields a bright yellow brass, ideal for decorative items.

60% copper and 40% zinc makes for stronger, harder brass suited for mechanical parts.

To create brass, copper and zinc are melted together in controlled furnaces. Precision in alloying is critical — even small deviations in the metal ratios can lead to significant differences in color, hardness, or durability. Many Copper And Brass metals Products Manufacturer now use computer-controlled melting systems to ensure perfect consistency batch after batch.

Step 3: Casting — Giving Shape to Potential

Once molten, the brass or copper alloy is poured into molds to take on a basic form. This process, known as casting, varies depending on the end-use:

Continuous casting is used for rods, bars, and sheets.

Sand casting or die casting is used for custom shapes and parts.

Ingot casting produces blocks that will be later rolled or forged.

Each casting method demands accurate temperature control and the right cooling time to prevent flaws such as porosity or internal stress, which could compromise the metal’s performance.

Step 4: Shaping — Rolling, Forging, and Extruding

After casting, the metal moves on to shaping through hot or cold working processes such as:

Rolling into thin sheets or plates.

Forging into structural or load-bearing components.

Extruding into wires, tubes, and specialized profiles.

Each process improves the grain structure, density, and strength of the material. Cold-working (working the metal at room temperature) also increases its hardness, while hot-working allows for more significant reshaping with less risk of cracking.

For products like precision brass tubes or copper wires, dimensional accuracy and uniformity are essential. Machines equipped with laser measurement systems and digital feedback loops help ensure exact tolerances.

Step 5: Machining — Crafting with Precision

Machining gives brass and copper components their final dimensions and functional features. Using advanced CNC (Computer Numerical Control) machines, manufacturers drill holes, add threads, or create intricate profiles with exceptional precision.

Brass is often favored in machining because of its smooth cutting properties, while copper’s softness requires slower speeds and sharper tools to avoid burrs or deformation.

This step is especially crucial in sectors like aerospace, electronics, and plumbing, where precision determines performance and reliability.

Step 6: Surface Finishing — Beauty Meets Protection

To enhance appearance and durability, the final products undergo surface finishing treatments. Common methods include:

Polishing for a mirror-like shine.

Anodizing or coating for corrosion resistance.

Electroplating with metals like nickel or chrome.

Antique or brushed finishes for aesthetic appeal.

These finishes also serve functional purposes — for instance, a protective lacquer can prevent copper from oxidizing or tarnishing when exposed to air and moisture.

Step 7: Quality Control — Ensuring Excellence

Before Brass Products manufacturer in india and copper products hit the market, they are subjected to rigorous quality control. Inspection teams perform tests for:

Composition analysis using spectrometers.

Mechanical strength (tensile, yield, and hardness testing).

Dimensional accuracy using calipers and micrometers.

Surface integrity under magnification or x-ray imaging.

Manufacturers often follow international quality standards such as ISO, ASTM, or RoHS, ensuring that the products meet both safety and environmental guidelines.

Conclusion: From Ore to Outstanding

From their extraction as raw materials to their transformation into engineered masterpieces, the journey of brass and copper is one of craftsmanship, innovation, and relentless quality. These metals are more than just materials — they’re cornerstones of modern industry and design.

Whether it’s a gleaming door handle, a reliable pipe fitting, or an intricate electronic connector, the process behind brass and copper ensures each item is not only functional but crafted to last. With efficiency, durability, and sustainability at the core of their production, brass and copper continue to set the standard for metal excellence in the modern world.

0 notes

Text

Level Up Your Production in Vietnam! ⚙️

Hey Vietnam's Innovators and Manufacturers! 👋

Exciting news! Adhmt, a globally recognized leader in sheet metal machinery with 40 years of experience and over 10,000 machines sold worldwide, is now bringing its expertise directly to you through Adhmt.Vietnam!

Our Core Machinery Expertise:

Adhmt specializes in cutting-edge equipment for sheet metal processing:

Press Brakes: For precise bending of sheet metal and plates.

Fiber Laser Cutting Machines: High-speed, high-accuracy cutting for sheets, tubes, and pipes.

Hydraulic Shears: Powerful and reliable cutting solutions.

Panel Benders: Automated and efficient bending for various applications.

(Maybe another image here: A collage showcasing different Adhmt machines like press brakes and laser cutters)

Get Started with Adhmt.Vietnam Today!

Ready to enhance your manufacturing capabilities with reliable, efficient, and advanced machinery? Adhmt.Vietnam is here to provide expert solutions, competitive pricing, technical support, and prompt delivery (standard machines often within 45 days!).

Explore our full range of solutions and learn more on our official Vietnamese website:

👉 ADHMT.VN 👈

Let's build the future of Vietnamese manufacturing together!

#AdhmtVietnam#ADH#ManufacturingVietnam#SheetMetal#Engineering#QualityMachinery#CNCMachining#Automation#Technology

1 note

·

View note

Text

Welding or Fabrication – Which One Is Best Suited for Custom Metal Fabrication?

Considering the case of custom metal fabrication, industries or businesses usually debate whether to select welding or fabrication. Both techniques are an integral part of metalwork, they provide distinct functions and contribute differently for custom projects. Understanding the roles of fabrication and welding will help you to make an informed decision about the best fitted technique for your particular needs.

Understanding Metal Fabrication

Metal fabrication is a wider procedure encompassing bending, cutting and assembling metal structures for the final product. This procedure includes different techniques including forming, machining, and welding. Fabrication is usually used to make complex structures from raw materials, transforming plates, tubes, and sheets into usable parts. Custom metal fabrication allows unique, tailor-made solutions suitable for different industries, including industrial manufacturing, aerospace and automotive.

What is Welding?

Welding is a unique technique within metal fabrication that joins two or more metal pieces by applying pressure and heat. This procedure makes a strong bond between metals, making it an important step in constructing durable components and structures. Different welding techniques include MIG welding or Metal Inert Gas welding, TIG welding or Tungsten inert Gas welding, laser welding or stick welding each suitable for various applications.

Welding plays a vital role in assuring the structural integrity of fabricated metal parts. It is widely utilized in sectors for example, automotive manufacturing, shipbuilding and pipeline construction. Since welding is an important factor of the fabrication procedure, it is usually used in combination with other metalworking techniques to achieve the desired outcomes.

The Role of Fabrication in Custom Metal Projects

Fabrication is considered as a comprehensive technique that begins with raw metal and transforms it into complete products. It includes different steps such as — designing, forming and assembling. Fabrication shops use advanced machinery, including CNC — Computer Numerical Control- cutters, laser cutting tools, and press brakes to shape metal with the right precision.

Custom fabrication is perfect for projects that need unique designs, intricate components or large-scale production. Whether it is making industrial machinery, structural frameworks or decorative metalworks, fabrication assures that metal parts are made to precise specifications.

This blog is originally published here: https://crescocustommetals.com/best-suited-for-custom-metal-fabrication/

0 notes

Text

"Laser Cutting Machine Price in Pune: What You Need to Know Before Investing"

Pune, a growing industrial hub in India, is witnessing a surge in demand for laser cutting technology. From manufacturing to signage, automotive to fabrication, industries in Pune are increasingly relying on laser cutting machines for precision, efficiency, and cost-effectiveness. Whether you're searching for the best laser cutting machine in Pune, comparing laser cutting machine prices in Pune, or looking for a trusted laser cutting machine manufacturer in Pune, this guide will help you make an informed decision.

Why Choose a Laser Cutting Machine in Pune?

Laser cutting machines have revolutionized metal, plastic, and wood processing industries by providing:

High Precision – Laser technology ensures accurate cuts with minimal material wastage.

Speed and Efficiency – Faster cutting speeds boost productivity and reduce turnaround time.

Versatility – Suitable for cutting metals, acrylic, wood, plastics, and even glass.

Automation & Ease of Use – Modern CNC laser cutting machines require minimal manual intervention.

Cost Savings – Reduces labor costs and material wastage, leading to long-term profitability.

Best Laser Cutting Machine in Pune: How to Choose the Right One

When selecting a laser cutting machine in Pune, several factors come into play:

1. Material and Application

Different laser cutting machines are designed for specific materials. Common types include:

Fiber Laser Cutting Machines – Ideal for cutting metals like stainless steel, aluminum, and copper.

CO2 Laser Cutting Machines – Suitable for non-metallic materials like wood, acrylic, and plastic.

Hybrid Laser Machines – Can cut both metals and non-metals.

Understanding the material type and industry-specific applications will help businesses choose the right laser cutter. For example, manufacturers in the automobile industry need fiber lasers for cutting metal sheets, while the signage industry often uses CO2 lasers for acrylic cutting.

2. Power and Performance

Low-Power Lasers (Up to 500W) – Suitable for engraving and light cutting tasks.

Mid-Power Lasers (500W – 2kW) – Used for industrial applications with moderate thickness.

High-Power Lasers (Above 2kW) – Best for heavy-duty industrial applications with thick materials.

Higher power lasers offer better cutting capabilities, but they also come at a higher cost. It’s crucial to analyze business needs before investing in a machine.

3. Cutting Speed and Efficiency

The best laser cutting machines optimize cutting speed without compromising precision. High-speed machines with automatic feeding and smart software integration are preferred for high-volume production. Companies in Pune’s manufacturing sector benefit from fast processing speeds, leading to increased efficiency and production rates.

4. Maintenance and Durability

A good laser cutting machine manufacturer in Pune provides robust machines with minimal maintenance needs. Key factors to consider:

Build Quality – Machines made from high-quality components last longer.

Cooling System – Essential for preventing overheating.

Software & Automation – Advanced software ensures smooth operations.

Local Support – Availability of service centers in Pune helps in easy maintenance.

5. Budget and Cost Considerations

The laser cutting machine price in Pune varies depending on power, size, and features. It's crucial to balance budget with quality and long-term ROI. Businesses must factor in not only the machine’s upfront cost but also:

Operating Costs – Electricity and consumables like laser tubes and lenses.

Maintenance Costs – Regular servicing and spare parts.

Software & Upgrades – Compatibility with future upgrades.

Laser Cutting Machine Price in Pune: Factors Affecting Cost

The cost of a laser cutting machine in Pune can range from INR 5 lakh for entry-level models to INR 50 lakh or more for high-end industrial machines. Several factors influence the price:

Machine Type – Fiber lasers are generally more expensive than CO2 lasers.

Power and Features – Higher wattage and advanced features increase the cost.

Brand and Manufacturer – Established brands like SLTL Group offer premium machines with exceptional after-sales support.

Automation and Software – CNC integration and smart software functionalities add to the price.

Customization Options – Custom-built machines tailored for specific applications tend to be more expensive.

Many businesses in Pune seek financing options or leasing plans to make purchasing a laser cutter more affordable.

Top Laser Cutting Machine Manufacturers in Pune

Choosing a reputed laser cutting machine manufacturer in Pune ensures quality, durability, and excellent after-sales support. Some of the top manufacturers include:

1. SLTL Group – A Pioneer in Laser Cutting Solutions

SLTL Group is a global leader in laser technology, offering cutting-edge solutions for industrial applications. Their fiber laser cutting machines are known for precision, efficiency, and reliability. SLTL Group provides:

State-of-the-art fiber laser cutting machines

Customizable solutions for various industries

Excellent customer support and after-sales service

Competitive pricing and financing options

Smart software for automation

2. Other Notable Manufacturers

Apart from SLTL Group, other manufacturers in Pune offer laser cutting solutions. However, when considering aspects like quality, durability, and service, SLTL Group remains a preferred choice.

Industries Using Laser Cutting Machines in Pune

Laser cutting machines have become indispensable across various industries in Pune:

Automobile Industry – For precise metal cutting in vehicle components.

Aerospace Industry – Ensures high accuracy in aircraft parts manufacturing.

Signage & Advertising – Used to create intricate designs on acrylic and plastic.

Jewelry & Fashion – Laser technology helps craft delicate metal jewelry pieces.

Sheet Metal Fabrication – Used in large-scale metal processing and manufacturing.

Electronics Industry – Laser cutting is widely used in circuit board manufacturing.

Construction Sector – Architects and interior designers use laser cutting for decorative panels and intricate designs.

Why Choose SLTL Group for Laser Cutting Machines in Pune?

If you’re looking for the best laser cutting machine in Pune, SLTL Group is the go-to brand. Here’s why:

Innovative Technology – SLTL is at the forefront of laser innovation, offering high-speed and precise cutting solutions.

Custom Solutions – Machines tailored to specific business needs.

Affordable Pricing – Competitive rates with financing options.

Excellent Customer Support – Nationwide service network ensures smooth operations.

Proven Industry Expertise – Trusted by businesses across multiple sectors.

Energy-Efficient Designs – Machines designed to minimize power consumption.

User-Friendly Interface – Easy-to-operate systems requiring minimal training.

Conclusion

Investing in a laser cutting machine in Pune can significantly enhance productivity and quality across various industries. Whether you’re evaluating laser cutting machine price in Pune or looking for a trusted laser cutting machine manufacturer in Pune, it’s essential to choose a reliable provider like SLTL Group. With cutting-edge technology, excellent support, and a proven track record, SLTL Group offers the best laser cutting machine in Pune to meet all your industrial needs.

For more information, visit SLTL Group and explore their advanced laser cutting solutions tailored for your business!

0 notes

Text

youtube

🔥 #BUTECH2025 is HERE! 🔥

Don’t miss AORE’s spotlight booth (Hall 1, G-02)! 💥

✨ PHK Series – Korea’s favorite sheet laser cutter in LIVE action!

✨ TH Series – Precision tube laser cutting machine that’s impressive!

Our team is READY & WAITING to meet you — 어서 오세요! ✨🇰🇷

📍 Hall 1, G-02 | NOW-23 May, 2025

Learn more: https://www.aorelaser.com/

#AOREWorldTour2025#AORETech#AORELASER#LaserCutting#fiberlasercuttingmachine#lasercuttingmachine#metalfabrication#metalwork#Youtube

0 notes

Text

Best Laser Cutting Machines

At Impact Machinery, expertise in equipment manufacturing and structural fabrication. Our company has manufacturing facility based in New Zealand, where it manufactures high quality/ certified pressure vessels, columns, heat exchangers and other process equipment. We specialize in offering high-quality metal fabrication and sheet metal fabrication solutions for a wide range of industrial, commercial, and residential applications. As one of the trusted fabrication companies in across Australia and New Zealand, we provide a comprehensive range of services, including heavy steel fabrication for complex and large-scale projects. Our team is equipped to handle all types of steel fabrication work, ensuring durability, precision, and efficiency - pipe profile machine.

With extensive experience in the industry, we deliver custom solutions for various sectors, such as construction, manufacturing, and infrastructure. Whether you need structural steel works, metal welding, or custom steel products. Tube laser cutting is also widely applied in furniture construction, particularly for metal and wood tubes. For instance, metal tubes are often used for furniture legs, while wood tubes are used for edging. Additionally, industries such as automotive parts, medical equipment, and even jewelry and accessories benefit from the precision and efficiency of tube laser cutting. The sports equipment industry benefits significantly from tube laser cutting, particularly in the manufacturing of bike frames, golf equipment, and hockey sticks - Tube laser.

The precision and speed of laser cutting allow for complex designs and smooth edges, which are critical for the performance and durability of these products. Understanding the mechanics of tube laser cutting reveals a method that utilises a high-powered laser beam for precise and efficient tube cutting. We are proud to have reduced material waste due to the highly precise nature of our laser cutters. Our investment in advanced machinery maximises material usage, further reducing costs and enhancing overall efficiency. Furniture builders use tube lasers to cut through wood and plastic tubes quickly and easily. This allows them to create complex designs and shapes that wouldn't be possible with traditional methods. The use of touch-probe technology enhances accuracy by allowing the machine to touch the tube before cutting, ensuring very precise parts, although it may slow down the process. For more information, please visit our site https://impactmachinery.com.au/

0 notes

Text

Why Polycarbonate Tubes Are the Best Choice for Strength and Transparency

When it comes to materials that combine strength and transparency, polycarbonate tube stands out as an exceptional choice. Its unique properties make it an ideal solution for a variety of industrial and commercial applications, ranging from construction to design and beyond. Let’s explore why polycarbonate tubing is a top choice for professionals across industries.

Unparalleled Strength and Durability

Polycarbonate is renowned for its incredible impact resistance. Unlike glass or other materials, polycarbonate tubing is virtually unbreakable, making it suitable for environments that demand robust and long-lasting materials. It resists cracking, shattering, and UV damage, ensuring reliability even in extreme conditions.

Exceptional Transparency

One of the defining features of a polycarbonate tube is its glass-like clarity. With light transmission capabilities comparable to glass, it is perfect for applications requiring high visibility, such as protective barriers, display cases, and industrial lighting. Unlike traditional materials, polycarbonate retains its clarity over time, even when exposed to harsh elements.

Versatility Across Industries

Polycarbonate tubes are widely used in industries ranging from construction to manufacturing. Alongside products like FRP Wall Panels and FRP MFG solutions, they provide unmatched versatility. They are also a preferred choice for custom projects requiring advanced fabrication methods, such as CNC Toronto and Laser Cutting Canada.

Applications of Polycarbonate Tubing

Polycarbonate tubes are commonly used in:

Protective Barriers: Offering safety without compromising visibility.

Architectural Projects: Their lightweight nature makes them easier to install compared to glass.

Industrial Equipment: Ideal for machine guards and transparent piping.

Complementary Products for Complete Solutions

In addition to polycarbonate tubes, Acrylic Plexiglass offers a range of complementary materials to meet your project needs:

Multi-Wall Polycarbonate Sheets for insulation and structural integrity.

PTFE Film for chemical resistance in demanding environments.

Acrylic Mirrors for sleek, reflective designs.

Plastic Sheets Toronto for various industrial uses.

For projects requiring precision, our Acrylic Laser Cutting and Laser Cutting Toronto services ensure high-quality, custom finishes.

The Eco-Friendly Advantage

Choosing a polycarbonate tube also supports sustainability. Its lightweight nature reduces transportation emissions, and its long lifespan minimizes material waste. These attributes make it an eco-conscious choice for businesses aiming to reduce their environmental footprint.

Why Choose Acrylic Plexiglass?

At Acrylic Plexiglass, we provide high-quality polycarbonate and acrylic solutions tailored to your needs. Whether you’re sourcing FRP Panels Wholesale or exploring innovative designs with CNC Toronto, we are your trusted partner. Our comprehensive inventory and cutting-edge services ensure your projects achieve professional-grade results.

Contact Acrylic Plexiglass Today

Website: https://acrylicplexiglass.ca/

Email: [email protected]

Address: 622 Magnetic Dr, North York, ON M3J 3J2, Canada

Phone: 647-825-1324

Discover why polycarbonate tubes are the perfect blend of strength, transparency, and versatility. Visit Acrylic Plexiglass to get started on your next project today!

#polycarbonate tube#polycarbonate tubing#Acrylic Mirrors#acrylic mirror canada

0 notes

Text

Laser Cutting Machines by SLTL Group: All You Need to Know

What Is a Laser Cutting Machine?

A laser cutting machine is an advanced tool designed to cut materials like metal with high precision and speed. Using focused laser beams, these machines can carve intricate designs, cut thick metals, and shape sheet metal into desired forms. They are widely used in industries like automotive, aerospace, and manufacturing for their accuracy and efficiency.

These machines primarily operate on different techniques, including fusion cutting, flame cutting, and sublimation cutting. Fusion cutting uses inert gases to blow molten material away, while flame cutting involves oxygen to increase the cutting speed. Sublimation cutting is used for finer details, vaporizing the material directly. Whether it’s creating prototypes or mass production, sheet metal laser cutting machines play a crucial role in industrial processes.

Types of Laser Cutting Machines

Laser cutting machines come in various types, each catering to different cutting needs. 2D cutting machines are the most common, used for cutting flat sheets of metal. SLTL Group’s machines like Future X, Infinity F1, Vector, Prime, and IntegreX are specifically built for precision 2D metal cutting, ensuring clean edges and accurate shapes.

For more complex tasks, 3D cutting machines like SLTL’s X5 are ideal. These machines allow for multi-dimensional cutting, perfect for industries requiring curved or angled cuts. If you work with tubes, specialized tube cutting machines ensure perfect results. SLTL Group’s Tube Cutting Machine handles round, square, and other tubular shapes efficiently.

SLTL Group also offers hybrid solutions like Rapid G, a machine combining 2D and tube cutting functionalities. Moreover, their Special Purpose Machines (SPM) are fully customizable, tailored to meet specific customer requirements, delivering the ultimate flexibility for unique cutting needs.

About SLTL Group

Established in Gandhinagar, Gujarat in 1989, SLTL Group has been a pioneer in laser technology. With over 25,000+ installations across more than 45+ countries, it is a global leader in manufacturing innovative laser solutions. Their wide range of products and commitment to quality make them a trusted name in the industry.

Making Laser Cutting Machines Accessible

SLTL Group strives to make fiber laser cutting machines affordable and accessible to businesses of all sizes. Investing 10% of their revenue into in-house R&D ensures continuous improvement and innovation. They also offer personalized demos, allowing businesses to test the machines with their own materials. Expert consultations are available to guide companies in choosing the best solutions for their needs.

Connect for More Information

For more details or to know the laser metal cutting machine price in India, reach out to SLTL Group. Call at +919925036495 or visit their website at SLTL.com. Get started with cutting-edge technology to elevate your business!

0 notes

Text

CO2 Laser Cutting and Engraving Machine

CO2 laser cutting and engraving machines have revolutionized industries by offering precision, speed, and versatility in material processing. For businesses like GK Laser Enterprises, located in Mira Bhayandar, CO2 laser machines are key assets that enhance manufacturing capabilities. Whether you're working with wood, acrylic, leather, or glass, these machines provide exceptional accuracy, making them indispensable for a variety of applications, from prototyping to mass production.

This article will explore the workings, benefits, and applications of CO2 laser cutting and engraving machines, and how they can transform your business at GK Laser Enterprises.

What is a CO2 Laser Cutting and Engraving Machine? A CO2 laser cutting and engraving machine is a type of laser that uses a carbon dioxide gas mixture to generate a powerful beam. This laser beam is highly concentrated, allowing it to cut or engrave through different materials with remarkable precision.

How It Works: Laser Generation: The CO2 laser is produced by electrically stimulating a gas-filled tube containing carbon dioxide. This produces infrared light, which is then directed towards a lens that focuses the beam onto the material. Cutting or Engraving: The focused laser beam either vaporizes or melts the material along the desired path, allowing for precise cuts or intricate engravings. Control System: Most CO2 laser machines are controlled via computer software, which allows for high levels of customization and accuracy. Designs are created digitally and then executed flawlessly by the machine. Key Benefits of CO2 Laser Machines for Businesses For companies like GK Laser Enterprises, CO2 laser cutting and engraving machines offer numerous advantages:

High Precision CO2 laser machines can cut intricate patterns and engrave fine details with extreme accuracy. The focused laser beam allows for minimal material waste and ensures consistent results, whether you're cutting through thin sheets of acrylic or engraving on glass. This level of precision makes these machines ideal for industries requiring detailed designs, such as jewelry making, signage, and custom crafts.

Versatility Across Multiple Materials One of the biggest strengths of CO2 laser machines is their ability to process a wide range of materials. From organic materials like wood and leather to synthetic ones like plastic and acrylic, the CO2 laser can handle them all. This makes it a versatile tool for a variety of industries, from furniture manufacturing to electronics.

Some common materials that CO2 laser machines can cut and engrave include:

Wood (hardwood, plywood, MDF) Acrylic and plastics Glass and crystal Leather and fabric Paper and cardboard Rubber and foam

Cost-Effective CO2 laser machines reduce costs by minimizing material waste and lowering labor expenses. The precision of the laser ensures fewer mistakes, which reduces the need for rework. Additionally, the machines operate quickly, allowing for higher production output without compromising on quality. This increased efficiency translates to savings in both time and money, providing a higher return on investment.

Automation and Easy Operation With modern CO2 laser machines, many tasks are automated. Operators only need to upload designs and input material specifications, and the machine handles the rest. This reduces the need for highly skilled labor, allowing businesses to streamline their workforce while maintaining high levels of production. Automation also reduces errors and ensures consistency across batches.

Environmentally Friendly CO2 laser cutting is a non-contact process, meaning it doesn’t require physical force to cut materials, which helps to reduce energy consumption. Since it produces less waste and fewer harmful emissions compared to traditional cutting methods, CO2 laser technology is a more eco-friendly option.

Applications of CO2 Laser Cutting and Engraving Machines CO2 laser cutting and engraving machines are used across a wide range of industries. Here are a few examples of how GK Laser Enterprises can utilize these machines:

Signage and Advertising Custom signs, banners, and display pieces are easily created with CO2 laser machines. The ability to cut and engrave materials like acrylic and wood allows for the creation of high-quality signage with a professional finish. This is ideal for retail stores, offices, and trade show displays.