#Sheetmetal

Text

Unleash Your Creativity with Custom Fabrication and Sheet Cutting Services/easoonmade

Looking to transform your ideas into reality? Explore the world of custom fabrication and sheet cutting on our Tumblr blog. Find inspiration, learn about the latest trends, and discover how to create protective covers that are both functional and aesthetically pleasing. #SheetCuttingService #LaserCuttingService #SheetMetal #CustomFabrication #ProtectiveCovers

10 notes

·

View notes

Text

Elevate your space with Aluminum Cladding Sheets! 🏢 Our 4x8 feet sheets combine durability and aesthetics seamlessly. Transform your HVAC projects with premium quality.

👉Buy now: https://shorturl.at/crDT1

#AluminumCladding#HVACDesign#SheetMetal#ArchitecturalFinishes#PremiumQuality#HomeImprovement#IndustrialDesign#AnbiSolutions#DurableMaterials#TransformYourSpace

2 notes

·

View notes

Text

Solid brass rose from plumbing pipe scrap

5 notes

·

View notes

Text

Dni…

hey guys just a warning @mcmagnetic hit my friend over the head with sheet metal. ;-;. I am going to make him into a creepypasta.

5 notes

·

View notes

Text

Outsource SolidWorks Sheet Metal Fabrication Design Services in Washington, USA at very low cost

Looking for top-notch CAD Outsourcing Services? Look no further! We offer unparalleled SolidWorks Sheet Metal Fabrication Design Services that cater to all your design needs. As a leading Sheet Metal Design Company, we specialize in delivering innovative solutions for sheet metal fabrication projects. Our team of skilled professionals excels in providing high-quality Sheet Metal Shop Drawings Services that ensure precision and accuracy. With our expertise as a trusted Sheet Metal Design Service Provider, we deliver exceptional designs tailored to your requirements. Experience the seamless integration of cutting-edge technology and industry expertise as we bring your visions to life. Trust us to handle your sheet metal design needs, and we guarantee superior results that exceed your expectations. Contact us today for a flawless CAD Outsourcing experience!

Why choose us CAD Outsourcing for your Sheet Metal Design Services needs ?

- Expertise in sheet metal design with skilled professionals

- Precision and accuracy in shop drawings and designs

- Up-to-date industry knowledge and innovative solutions

- Customized solutions tailored to your specific requirements

- Timely delivery to meet project deadlines

- Stringent quality assurance measures for high-quality designs

- Cost-effective pricing without compromising on quality

- Exceptional customer satisfaction and attention to detail

We offer our Sheet Metal Modeling Services Washington and covered other cities: Chicago, Indiana, Illinois, Kentucky, Ohio, Minnesota, Oklahoma and New York.

Visit Us

https://www.cadoutsourcing.net/shop-drawing-services/washington-shop-drawings-service.html

License User:

AutoDesk AutoCAD, Revit, Tekla Structures, STAAD.Pro, SOLIDWORKS, ZWCAD, AutoDesk Navisworks, 3Ds Max, Inventor, Showcase, ReCap, Infraworks 360, Civil 3D.

Choose CAD Outsourcing for accurate and reliable Sheet Metal Shop Drawing Services that cater to your specific needs.

For more Information:

Website: https://www.cadoutsourcing.net/cad-design-drafting/sheet-metal-design-services.html

#SheetMetal#Fabrication#SheetMetalDesign#SheetMetalDesignServices#Detailing#Engineers#ShopDrawing#BIMServices#Engineering#CadOutsourcingServices#CadOutsourcingCompany#CADDesign#CADServices

2 notes

·

View notes

Text

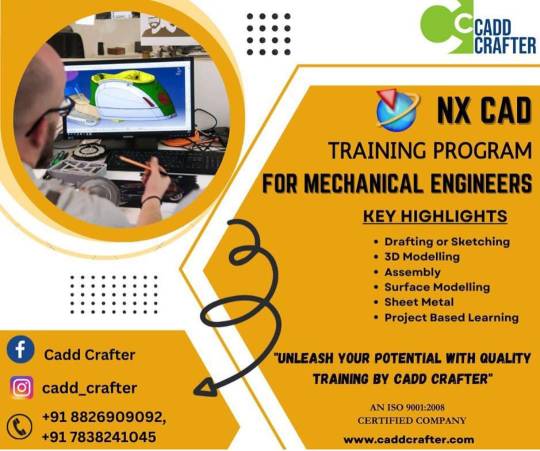

Announcing NX Cad Training program for Mechanical Engineers.

Learn to create and design mechanical parts using NX CAD.

NX CAD will allow you to create 3D models and assemblies, and to generate detailed drawings and specifications.

It’s widely used for-:

✅Product design

✅Engineering Analysis

✅Manufacturing

✅Documentation

✅Collaboration

Schedule your free demo session now

#nxcad#3dcad#designengineering#productdesign#manufacturing#industrialdesign#prototyping#engineeringstudents#mechanicalengineering#mechanical#machinedesign#partdesign#cam#cadcam#instrumentdesign#sheetmetal#assembly#reverseengineering#3dprinting#mechanicalengineers#caddcrafter#productdesigner#productiondesign#mechanicwork

3 notes

·

View notes

Text

Aluminium sheet metal brackets. CNC punched and CNC folded. Barrel deburred to remove sharp edges, ready for shipping to our customer.

http://www.vandf.co.uk/gallery/bracket-angle-gallery/

#sheetmetal#sheet metal bending#sheet metal fabrication#cnc punching#cnc brake press#cnc bend#aluminium

2 notes

·

View notes

Text

The Manufacturing Process of Shim Sheet Metal – Step-by-Step Guide

This article helps in understanding shim sheet metal as it refers to thin, flat pieces of metal that are used for fine adjustments in the alignment of machinery or structural components. They can be made from a variety of materials, including stainless steel shims, brass shim sheet, and even plastic, depending on the application.

Shims are often used when precise spacing or leveling is required between parts. In industries like automotive or aerospace, accuracy down to the last millimeter can make all the difference, and that’s why shim manufacturers create high-precision products.

This article further helps in most commonly used materials in shim manufacturing include:

Stainless Steel: Ideal for high-strength and corrosion resistance, widely used by stainless steel shim manufacturers.

Brass: Known for its machinability and electrical conductivity, often used in brass shim sheet applications.

Aluminum: Lightweight and corrosion-resistant, commonly used in aerospace.

Plastic: Used in environments where non-conductivity and non-reactivity are important.

Each material has specific properties that make it suitable for different applications. For example, ss shims are commonly used in environments exposed to moisture or chemicals, while bimetallic washers and precut shims are used for specific industrial purposes.

This guide will equip you with the knowledge to take your garment construction skills to the next level and create clothes that look and feel truly professional.

0 notes

Text

DUCT P.I SHEET

Purpose:

The Duct Pressure Inspection Sheet is a detailed document used to record and monitor pressure levels within HVAC duct systems. It is essential for ensuring that the ductwork operates efficiently and maintains proper airflow throughout the building.

System Details:

HVAC System Type (e.g., central air, split system)

Duct System Design (e.g., rectangular, round)

Duct Size and Material

Fan Type and Specifications

Inspection Points:

Point ID: Unique identifier for each measurement point

Location: Specific location within the ductwork (e.g., supply duct, return duct)

Pressure Reading: Measured static pressure at each point

Units: Typically in inches of water column (in. WC) or Pascals (Pa)

Usage: This sheet is used by HVAC technicians, engineers, and inspectors to ensure that the duct system is functioning within the designed pressure ranges and to diagnose any issues that could affect system efficiency or comfort.

#alramiz#hvac#machines#wholesale#rewinding materials#thermostat#tools & safety#heater & element#are#acsparta#ARE#AL#RAMIZ#DuctPISheet#Insulation#HVAC#AirDucts#ThermalInsulation#BuildingMaterials#Ductwork#SheetMetal#EnergyEfficiency#Construction

1 note

·

View note

Text

Metal Stamping Market worth $257.1 billion by 2028

The report "Metal Stamping Market by Process (Embossing, Blanking, Bending, Coining, Flanging), Material Thickness (≤0.4mm, >0.4mm), Press Type (Hydraulic Press, Mechanical Press, Servo Press), Material, End-Use Industry, Region - Trends and Forecast to 2028", is approximated to be USD 213.8 billion in 2023, and it is projected to reach USD 257.1 billion by 2028, at a CAGR of 3.7%. Growth in the automotive and construction industries, advancements in manufacturing technology, a focus on lightweight materials, and increase in product customization, all have an impact on the metal stamping market. These factors are expected to boost demand for metal stamping products while also encouraging the development of more advanced and efficient metal stamping processes.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=43712960

By process, Blanking accounted for the largest share in 2022.

Blanking process is the largest and fastest-growing segment of the market globally, followed by embossing process. Blanking is widely used in the metal stamping industry mainly due to its ability to produce precise, uniform shapes for subsequent manufacturing. The blanking process allows manufacturers to produce parts with consistent dimensions and high accuracy. Another advantage is high production (in terms of quantity) at a low cost.

By material, Steel accounted for the largest share in 2022.

Steel material is preferred for metal stamping because of their high strength and low cost. Stainless steel is popular for metal stamping projects due to its high corrosion resistance, strength, and durability. It offers resistance to various environmental conditions and chemicals, making it suitable for marine and chemical tank applications. Additionally, stainless steel has a high tensile strength that can be further improved through cold working or heat-treating. It is also cost-effective in the long term due to its durability and long lifespan.

By material thickness, ≤0.4 mm material thickness to be the fastest growing during the forecast period.

Materials with thicknesses of ≤0.4 mm are commonly called “thin-gauge materials” in metal stamping. As they are frequently used to create complex and precise parts with high strength-to-weight ratios, thin-gauge materials play a crucial role in metal stamping. High-strength alloys, such as stainless steel or aluminum, are frequently used to produce these materials due to their ability to offer the strength and durability required for the final stamped part. They are usually easier to work with when stamping as they are more elastic and flexible than thicker materials.

By press type, mechanical press accounted for the largest share in 2022.

Mechanical presses can achieve the highest possible production rates in the market due to their use of flywheels, which store kinetic energy for transfer. The larger the flywheel, the more power it generates. These presses ensure fast and repeatable results with a simple setup and operation. Mechanical presses are less prone to leakage as they do not require hydraulic fluid. However, they are limited in their application due to the lack of variable stroke lengths.

By end-use industry, automotive accounted for the largest share in 2022.

The automotive is the largest end-use industry for the metal stamping market. Automakers can design complex and highly accurate stamping dies using CAD and CAM technologies, which has increased the precision and effectiveness of the stamping process. Metal stamping enables the manufacturing of custom components that fulfill specific design requirements, increasing manufacturing flexibility and versatility. Ultimately, metal stamping significantly impacts the automotive industry since it allows producers to create high-quality components rapidly and cost-effectively, thereby improving the overall efficiency, safety, and safety performance of vehicles.

Sample Request-https://www.marketsandmarkets.com/requestsampleNew.asp?id=43712960

By region, Asia Pacific accounted for the largest share in 2022.

The metal stamping market has been studied in Asia Pacific, North America, South America, Europe, and Middle East & Africa. Asia Pacific leads the overall metal stamping, followed by Europe. Rapid industrialization and the increasing number of end-use industries in the region will fuel the metal stamping market. The market in China is growing rapidly and is projected to witness high growth due to the demand from the medical and automotive industries. Manufacturers of metal stamping products are targeting this country due to the advantages of setting up production facilities, the low cost of production, and the ability to better serve the local emerging markets.

Major players operating in the metal stamping market include Gestamp Automoción, S.A. (Spain), Arconic Corporation (US), American Axle & Manufacturing Holdings, Inc. (US), CIE Automotive S.A. (Spain), Interplex Holdings Pte. Ltd. (Singapore), AAPICO Hitech Public Company Limited (Thailand), Clow Stamping Company (US), Wiegel Tool Works, Inc. (US), Harvey Vogel Manufacturing Co. (US), ACRO Metal Stamping (US), Boker’s, Inc. (US), and Kenmode, Inc. (US) are covered in the metal stamping market. Expansions, acquisitions, joint ventures, and new product developments are some of the major strategies adopted by these key players to enhance their positions in the metal stamping market.

#MetalStamping#Manufacturing#Industrial#Metalworking#PrecisionStamping#Engineering#AutomotiveIndustry#MetalForming#SheetMetal#Tooling#DieCasting#Fabrication#Production#HeavyMachinery#SteelStamping#CNCMachining#ManufacturingInnovation#CustomStamping#Industry40#MetalFabrication

0 notes

Text

"Precision in Every Bend: Shaping Excellence at Omnific Solutions, Koperkhairne"

Address :

Plot No.A- 814, Khairane Village, TTC Industrial Area, MIDC Industrial Area, Kopar Khairane, Navi Mumbai, Maharashtra 400705, Navi Mumbai (New Mumbai), India, 400705

+91 87670 77801

Mobile

[email protected]

Email

Websites and social links

http://omnificsolutions.co.in/

Website

https://in.pinterest.com/omnificsolutions/

Pinterest

https://twitter.com/OmnificSol10826

Twitter

https://www.tumblr.com/dashboard

Tumblr

https://www.instagram.com/omnificsolution/

Instagram

https://www.linkedin.com/feed/

LinkedIn

@omnificsolution

#SheetMetal#MetalBending#PrecisionBending#Manufacturing#OmnificSolutions#IndustrialEngineering#Fabrication#Metalworking#Engineering#MIDCKoperkhairne#NaviMumbaiIndustry#MechanicalEngineering#SheetMetalFabrication#CNCBending#manufacturingprocesses

0 notes

Text

Sheet Metal and Steel Profile Handling Equipments

In the previous blog, we have mentioned many times that the good partner of the laser cutting machine is our excellent Roll-Out Sheet Metal Rack. However, our racks with laser cutting machines are still a fly in the ointment. The missing link is the equipment to move the steel plates. Only in this way can it be more convenient and fast in the transportation process. Today, I will introduce in detail the equipment and methods for handling sheet metal and taking sheet metal, taking the Roll-Out Sheet Metal Rack as an example.

Three ways to move steel plate bundles onto rack

1. Crane Plus Lifting Chain with Hooks

2.Crane Plus wire rope or strap

3. Forklift

Two ways to access sheet metal

With crane:

In the case of crane, we can use the Vacuum Lifter, Lifting Chain with Hooks and Permanent Lifting Magnet collocation to access the steel plate. This method is not only efficient, but also high security.

Vacuum Lifter: At the heart of the Vacuum Lifter lies an imported oil-free vacuum pump and valves that ensure high efficiency, safety, and rapid operation with minimal effort. It’s fitted with an accumulator and pressure monitoring to guarantee utmost safety during every lift. The adjustability of the suction pad positions and the ability to manually shut them off allows for tailored handling for each task, aligning with CE safety standards. For example, in the manufacturing industry, metal processing: in the handling of metal sheets, steel plates, aluminum plates, stainless steel plates and other materials, the vacuum hoist can be efficiently and safely operated to reduce the damage to the material surface. As well as in the handling of various mechanical parts, especially for large size, heavy parts, vacuum suction crane provides a convenient handling method. In the construction industry, like glass installation, in the installation process of building glass, window glass, large glass curtain wall, etc., the vacuum suction crane can easily and safely grasp and move the glass, avoiding the safety risks and damage risks in the traditional handling methods. And stone handling: In the handling and installation of marble, granite and other stone, the vacuum hoist can stably grasp and move heavy stone to improve work efficiency.

Lifting Chain with Hooks: Crafted from premium grade 100 chains, these lifting accessories are specifically designed to operate flawlessly in environments exposed to heat or chemicals, making them a perfect complement to construction sites and industrial settings, so I would recommend using hooks for the thicker steel plates. We provide a variety of configurations and hooks to suit the unique demands of your lifting operations. Sourced from the finest manufacturers in China and meticulously assembled by reputable rigging houses, our chains are synonymous with durability and reliability. Suitable for construction sites, chain hook is widely used in construction sites for lifting and moving heavy construction materials, such as steel beams, concrete prefabricated parts, etc. Its high strength and durability enable it to cope with a variety of harsh construction environments. At the same time, in the industrial manufacturing process, the chain hook is used for handling and loading and unloading heavy equipment and materials, such as machine parts, large steel plates, pipes and so on. They can withstand high loads, ensuring safe and efficient operation.

Permanent Lifting Magnet: Permanent Lifting Magnet, which are advanced permanent magnets, generate a magnetic field much more potent than standard magnets due to their composition of rare-earth elements and ferrite alloys. They are extensively utilized across multiple sectors for the purpose of moving metal objects or substantial loads. A distinct category of these magnets, known as permanent magnets, offers the advantage of being toggled between active and inactive states. This feature allows for the convenient relocation of the attached object to its designated location, after which the magnet can be deactivated. Opting for a Permanent Lifting Magnet to handle metallic objects such as plates, pipes, and disks represents a highly effective and economical method. In the automotive manufacturing industry, permanent lifting magnets are indispensable for moving hefty parts during the assembly process, thereby minimizing physical exertion and boosting productivity. And it is also crucial on construction sites and in steel workshops, facilitating the lifting and accurate placement of large steel structures like beams, columns, and plates.

2. Without Crane

If there is no crane, you can use the KBK CRANE or JIB CRANE with Vacuum Lifter to pick up goods. These two kinds of equipment are widely used in small and medium-sized workshops, flexible operation, and are not limited by the site.

KBK CRANE: The KBK CRANE is a modular design of lifting equipment, mainly composed of rails, brackets, tackles and cranes. Its tracks can be flexibly combined according to needs, suitable for a variety of working environments. The KBK CRANE is usually installed on top of the workshop, forming a lifting system that covers the entire work area. KBK CRANE is suitable for work environments that require coverage of a wide range of operations, especially in line production and large-scale warehousing. Specific applications include:

Automotive Manufacturing: On the automotive assembly line, KBK CRANE can cover the entire assembly area, facilitating the lifting and moving of individual components.

Machine building: In large machine building workshops, KBK CRANE can flexibly respond to different processing and assembly needs.

Warehouse logistics: In large warehouses, KBK CRANE can quickly and efficiently complete the access and handling of the steel plates.

JIB CRANE: JIB CRANE is a kind of lifting equipment with fixed arm, which is mainly composed of column, rotating arm and CRANE. The cantilever can be rotated and is usually mounted on a fixed column or wall, covering a fixed circular or semi-circular work area. JIB CRANE is suitable for small operating areas, especially where materials need to be lifted and moved frequently. Specific applications include:

Process assembly: On a small process assembly line, the JIB CRANE can easily complete the lifting and transfer of parts.

Machine tool assistance: In the machining shop, the JIB CRANE can be used as an auxiliary device of the machine tool for loading and unloading and workpiece handling.

The importance of handling tools

Through the above introduction, I believe you have a clear idea of what kind of handling tools you need. Handling tools not only play an important role in logistics and production processes.

Increase efficiency

Efficient handling tools can greatly reduce operation time and improve work efficiency. For example, the combination of driving and Lifting Chain with Hooks, wire ropes or straps can quickly and accurately complete the handling and placement of the plate.

2. Stay safe

Safe handling tools can reduce operational risks and ensure the safety of workers. For example, the use of Vacuum Lifter, permanent magnet hoist and other tools can be firmly fixed to prevent the sheet from slipping or tipping during handling.

The perfect combination of handling equipment and Roll-Out Sheet Metal Rack

Combining efficient handling equipment with Roll-Out Sheet Metal Rack maximizes production efficiency and operational safety.

Seamless connection

Efficient handling equipment such as truck, forklift, KBK CRANE and the hand drawer plate shelf seamless docking, can achieve the rapid transfer and access of steel plates. After the handling equipment transport the steel plate to the rack position, the plate can be stored in the drawer by hand operation, greatly simplifying the operation process.

2. Reduce labor intensity

The use of efficient handling equipment can reduce the labor intensity of manual handling and reduce the fatigue of workers during operation. Combined with the convenient design of Roll-Out Sheet Metal Racks, the work burden of workers is further reduced.

3. Improve production efficiency

Through reasonable design and use, efficient handling equipment and Roll-Out Sheet Metal Racks can greatly improve production efficiency. Fast and easy access reduces downtime and improves line continuity and stability.

How to choose the right handling equipment

When selecting transportation equipment, consider the actual requirements and working environment. Here are a few suggestions:

Consider your work environment

Different working environments have different requirements for handling equipment. For example, a workshop with a small space may be more suitable for JIB CRANE or KBK CRANE, while a large warehouse may have the option of a truck or forklift.

2. Consider sheet size

The size and weight of the plate are also important factors in the selection of handling equipment. For heavier plates, it is recommended to choose a driving or permanent magnet crane with strong carrying capacity; For lighter plates, wire ropes or strap with high flexibility can be selected.

3. Consider ease of operation

The convenience of operation directly affects the production efficiency. Choosing handling equipment that is easy to operate and maintain can reduce training time and improve the operational proficiency of workers.

Through the introduction of this article, we explain in detail the advantages of efficient handling equipment and Roll-Out Sheet Metal Racks and the method of combined use. Handling equipment plays an important role in logistics and production processes, directly affecting production efficiency and operational safety. The Roll-Out Sheet Metal Rack as an important supporting equipment of laser cutting machine, through its efficient access, space saving, safety and stability and flexible adaptation advantages, has brought great convenience to the production line. When selecting transportation equipment, you need to comprehensively consider the actual needs and working environment to ensure that the most suitable equipment is selected to improve production efficiency and operation safety. We can not only provide excellent racks, but also handling tools can be trusted! Looking forward to your contact! In the future, we will continue to be committed to providing customers with better products and services to help enterprises achieve efficient, intelligent and safe production management. If you have any needs or questions, please feel free to contact us. We will be happy to serve and help you.

1 note

·

View note

Text

Another little brass and copper rose

3 notes

·

View notes

Text

Metal Stamping in Automotive, Aerospace, and Consumer Electronics

The global metal stamping market size is expected to reach USD 316.72 billion by 2030, registering a CAGR of 4.2% over the forecast period, according to a new report by Grand View Research, Inc. The increasing production of automobiles is anticipated to drive the demand for metal stamping as it is used in the manufacturing of car body panels, transmission components, and interior and exterior structural components. Automobile consumers are shifting their focus towards lightweight vehicles on account of rising concerns about environmental pollution. According to LMC Automotive, U.S. light vehicles sales reached around 14.5 million in 2020 and are expected to reach nearly 15.8 million by 2022. The growing demand for lightweight vehicles is encouraging auto component manufacturers to increase their production capacities and engage in new product developments.

Metal Stamping Market Report Highlights

Based on process, the blanking segment is anticipated to progress at a significant CAGR over the forecast period, owing to the increasing demand from the automotive industry on account of its precise and superior stamping ability.

The bending segment accounted for a revenue share of over 16.0% in 2022. Products manufactured using this process ensure stability and durability, thus it is mostly used in auto components.

Based on application, consumer electronics is projected to be the fastest-growing segment over the forecast period. The growth is attributed to the increasing utilization of lightweight metal components to improve the durability of electronics.

Industrial machinery held the second-largest revenue share of the global market in 2023. The segment growth is attributable to the rising demand for machinery and automation to improve output efficiency.

Asia Pacific held the largest revenue share of more than 36.0% in 2023 owing to increasing demand for cars and consumer electronics in the region

For More Details or Sample Copy please visit link @: Metal Stamping Market Report

This, in turn, is anticipated to augment market growth over the coming years. Major automobile manufacturers that have in-house component manufacturing facilities are expanding their production capacities to meet the growing demand for automobiles. Moreover, the telecommunications industry is also projected to witness lucrative demand for stamped products owing to the growing investments in 5G technology. For instance, in November 2020, FAIST Precision Suzhou announced its investment in the installation of a new die casting machine, called the FRECH GDK3200T, which will be used to run 5G projects for mass production. In the Asia Pacific, increasing demand for consumer electronics, such as mobile phones, computers, laptops, and headphones, is likely to boost the demand for metal stamping as it is used in manufacturing metal frames, such as metal headbands, which are used in headphones.

Change in consumer preferences towards enhanced audio experience along with a rapidly growing music industry, and advancement in VR technology are the major factors that are expected to drive the demand for headphones. This, in turn, is likely to propel market growth over the coming years. The market is highly competitive with the presence of local as well as global players including Alcoa Corp., Lindy Manufacturing Co., Tool & Manufacturing Company, and D&H Industries. These companies are focusing on long-term agreements, capacity expansions, and mergers and acquisitions to meet the growing product demand from potential customers. For instance, in October 2021, Shiloh Industries completed the acquisition of two stamping plants fromBenteler for the automotive business. These plants are equipped with modern precision laser cutting and hot-formed steel stamping products for the production of chassis components.

List of major companies in the Metal Stamping Market

Acro Metal Stamping

Manor Tool & Manufacturing Company

D&H Industries, Inc.

Kenmode, Inc.

Klesk Metal Stamping Co

Clow Stamping Company

Goshen Stamping Company

Tempco Manufacturing Company, Inc

Interplex Holdings Pte. Ltd.

CAPARO

Nissan Motor Co., Ltd

For Customized reports or Special Pricing please visit @: Metal Stamping Market Forecast Report

We have segmented the global metal stamping market report based on process, press type, thickness, application, and region.

Metal Stamping Process Outlook

Blanking

Embossing

Bending

Coining

Flanging

Others

Metal Stamping Press Type Outlook

Mechanical Press

Hydraulic Press

Servo Press

Others

Metal Stamping Thickness Outlook

Less than & up to 2.5 mm

More than 2.5 mm

Metal Stamping Application Outlook

Automotive

Industrial Machinery

Consumer electronics

Aerospace

Electrical & Electronics

Building & Construction

Telecommunications

Others

Metal Stamping Regional Outlook

North America

Europe

Asia Pacific

Central & South America

Middle East & Africa

Research Methodology

We employ a comprehensive and iterative research methodology focused on minimizing deviance in order to provide the most accurate estimates and forecasts possible. We utilize a combination of bottom-up and top-down approaches for segmenting and estimating quantitative aspects of the market. Data is continuously filtered to ensure that only validated and authenticated sources are considered. In addition, data is also mined from a host of reports in our repository, as well as a number of reputed paid databases. Our market estimates and forecasts are derived through simulation models. A unique model is created and customized for each study. Gathered information for market dynamics, technology landscape, application development, and pricing trends are fed into the model and analyzed simultaneously.

About Grand View Research

Grand View Research provides syndicated as well as customized research reports and consulting services on 46 industries across 25 major countries worldwide. This U.S. based market research and consulting company is registered in California and headquartered in San Francisco. Comprising over 425 analysts and consultants, the company adds 1200+ market research reports to its extensive database each year. Supported by an interactive market intelligence platform, the team at Grand View Research guides Fortune 500 companies and prominent academic institutes in comprehending the global and regional business environment and carefully identifying future opportunities.

Contact:

Grand View Research, Inc.

Phone: 1-415-349-0058

Toll-Free: 1-888-202-9519

Email: [email protected]

Web: https://www.grandviewresearch.com

Explore Horizon, the world's most expansive market research database

#MetalStamping#Manufacturing#MetalIndustry#IndustrialProcesses#MetalFabrication#AutomotiveManufacturing#AerospaceManufacturing#ConsumerElectronics#MetalForming#IndustrialMachinery#PrecisionStamping#MetalParts#Engineering#StampingTechniques#SheetMetal#MetalComponents#ProductionEfficiency#IndustrialInnovation#SupplyChain#MetalMarket

0 notes

Text

Announcing software training programs for Civil Engineers, Architects & Interior Designers.

Master diploma in Interior and Exterior design

The best CAD training institute in Delhi.

✅Drafting floor plans, sector and elevations

✅3D Modelling

✅Animations and Walkthrough

✅Interior and Exterior Design

✅Materials and Lighting

✅Renderings

https://www.caddcrafter.com

#nxcad#3dcad#designengineering#productdesign#manufacturing#industrialdesign#prototyping#engineeringstudents#mechanicalengineering#mechanical#machinedesign#partdesign#cam#cadcam#instrumentdesign#sheetmetal#assembly#reverseengineering#3dprinting#mechanicalengineers#caddcrafter#productdesigner#productiondesign#mechanicwork

3 notes

·

View notes

Text

Discover precision and quality with Parul Industrial Corporation's high-quality sheet metal parts. Your reliable partner for custom solutions and exceptional performance.

For More Information : https://www.parulinduscorp.com/

0 notes