#SingleAxisStages

Explore tagged Tumblr posts

Text

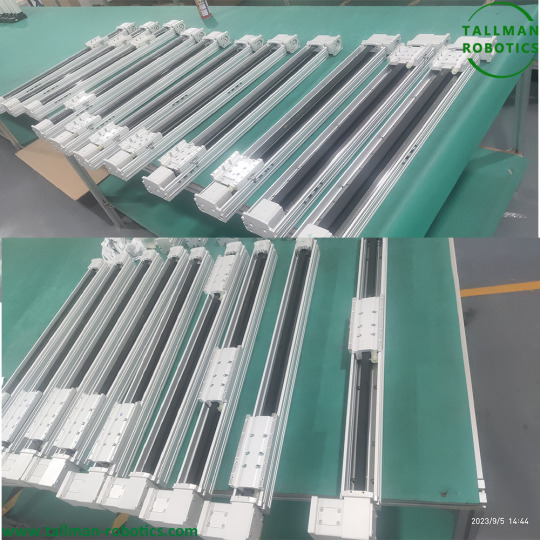

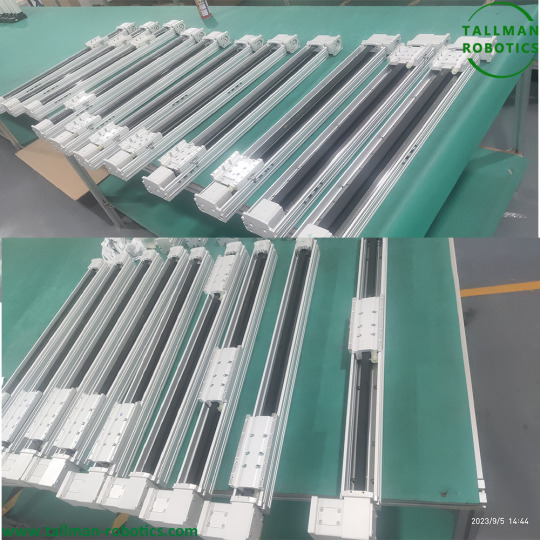

Linear Motion Actuators Are Under Assembly

Linear Motion Actuators are devices that convert rotational motion into linear motion. They are commonly used in various applications where linear movement is required, such as robotics, automation systems, industrial machinery, and automotive systems. Linear motion actuators provide controlled and precise linear displacement, allowing them to perform tasks like pushing, pulling, lifting, or positioning objects.

Linear Motion Electric Actuators are versatile and widely used in various applications where precise control, automation, and compactness are important. Some common applications of electric actuators include: 1. Robotics: Electric actuators play a fundamental role in robotic systems, enabling precise and controlled movement of robot arms, grippers, and joints. They provide the necessary motion control for tasks such as pick and place, assembly, welding, and inspection in industrial and collaborative robot applications. 2. Automation Systems: Electric actuators are extensively used in automation systems across industries, including packaging, material handling, and assembly lines. They provide linear motion for tasks like conveyor belt control, part positioning, sorting, and machine loading and unloading. 3. Medical Equipment: Electric actuators find applications in medical devices and equipment, such as hospital beds, patient lifts, surgical tables, and adjustable medical chairs. They allow for smooth and precise adjustment of the equipment's position, ensuring patient comfort and facilitating healthcare professionals' work. 4. Automotive Systems: Electric actuators are used in various automotive applications, including power windows, seat adjustments, trunk lifts, and electric steering systems. They provide controlled and reliable motion for convenience, comfort, and safety features in vehicles. 5. HVAC Systems: Electric actuators are employed in heating, ventilation, and air conditioning (HVAC) systems for controlling dampers, valves, and airflow. They enable precise adjustment of temperature, airflow direction, and ventilation, improving energy efficiency and comfort in buildings. 6. Aerospace and Defense: Electric actuators are used in aerospace and defense applications, such as aircraft wing flaps, landing gear, throttle control, and missile guidance systems. They offer precise and rapid motion control in critical aerospace and defense operations. 7. Home Automation: Electric actuators are utilized in home automation systems for tasks like opening and closing curtains, blinds, windows, and doors. They provide convenient and automated control over these household functions. 8. Entertainment and Motion Simulators: Electric actuators are employed in entertainment industry applications, including motion simulators, virtual reality systems, and amusement park rides. They create realistic and immersive experiences by providing motion and vibration effects. Linear Motion Actuators offer advantages like precise control, compact size, quiet operation, energy efficiency, and easy integration with control systems. They are well-suited for applications that require accurate positioning, automation, and control flexibility. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#1AxisGantry#LinearCarriagesAndSlides#LinearSlidingGuide#MultiAxisLinearActuator#SingleAxisGuideArm#SingleAxisLinearActuator#SingleAxislinearmotion#SingleAxisStages

0 notes

Text

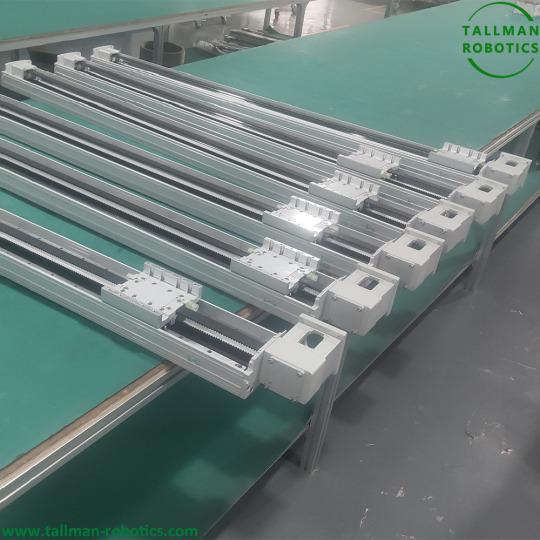

Single Axis Linear Robot Will Be Delivered To Singapore

Single Axis Linear Robot from Tallman Robotics Limited Will Be Delivered To Singapore.

A Single Axis Linear Robot is a type of robotic system that is designed to perform linear motion along a single axis. A single axis linear robot, also known as a linear actuator or cartesian robot, is an essential piece of machinery in numerous industrial applications. These robots provide precise, efficient, and highly customizable linear motion solutions, making them ideal for repetitive tasks or processes that require strict accuracy and control. Components: 1. Rigid frame: This provides the structural foundation for the robot's operation. Often made of metal such as aluminum extrusion or steel, the frame is responsible for maintaining rigidity and stability during movement. 2. Motorized drive system: This is the component responsible for generating and controlling the robot's motion. The drive system typically consists of an electric motor (stepper, servo or brushless DC motor) that converts electrical energy into linear motion via a mechanical translation system such as ball screws, linear motors, or belt and pulley systems. 3. Linear guide system: The linear guide ensures smooth, precise, and highly accurate movement along the single axis while also preventing undesired motion in other directions. Linear guides can include profiled rails with rolling bearings, linear bushings, or magnetic guidance systems. 4. End effector or tooling: This is the part of the robot that interacts with the workpiece or material. Depending on the specific application, the end effector could be a gripper, a vacuum cup, a welding tool, or even a small camera. 5. Control system: The control system manages and synchronizes the motion of the single-axis linear robot. The system typically consists of a programmable automation controller (PAC) or microcontroller, which receives input from sensors, user interfaces, or other devices and sends the desired motion commands to the motorized drive system. Applications: Among the various scenarios where single-axis linear robots are employed, these are some of the most common ones: 1. Assembly automation: Linear robots are essential in the assembly of electronic devices, automotive components, and various consumer products. They can quickly and accurately position parts for assembly or perform tasks such as screw tightening, adhesive dispensing, or press-fitting. 2. Material handling: Single-axis robots are frequently employed in conveyor systems and packaging lines to load/unload materials or transport goods between different stations. 3. Quality control and inspection: Attaching cameras or sensors to linear robots can automate inspection processes, thus ensuring consistent quality and production speed. This is particularly useful in industries like food processing, pharmaceuticals, and semiconductors. 4. Laboratory automation: In life sciences and clinical laboratories, single-axis linear robots can simplify tasks such as sample handling, tube sorting, and liquid dispensing. In conclusion, single-axis linear robots are fundamental tools in modern manufacturing, as they provide accurate, reliable, and customizable motion control. They help enhance the efficiency of various industrial tasks and enable businesses to maintain high standards of quality and productivity. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#1-axisrobot#AutomatedPickingSystems#Automatedsolderingrobot#ChinaSingleAxisRobotManufacturers#Linear&GantryRobots#LinearActuators#Linearmotorsingleaxisrobots#LinearStageAxisSingleLinearRobotArm#RoboticPicking#RoboticSystems#Singleaxisrobots#SingleAxisStages#Single-AxisRobotLinearModule

0 notes