#Singleaxisrobots

Explore tagged Tumblr posts

Text

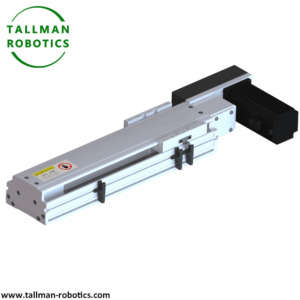

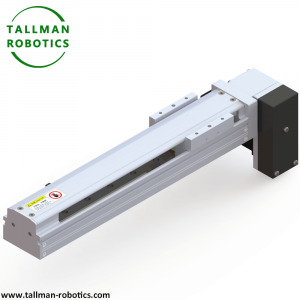

Linear Actuators Robots

Linear Actuators Robots are a pivotal technology in modern robotics due to their versatility, precision, and scalability. They have a broad range of applications in various fields. Here's an overview of how Linear Actuators Robots are integrated into robotic systems and their benefits: Classification and Mechanisms: Types: Linear Actuators Robots can be driven by different mechanisms including screw type, belt drives, and linear motors. Each mechanism offers unique advantages; for instance, screw-based actuators driven by stepping motors are highly suitable for precise positioning but may be underpowered for certain applications requiring servo motors. Motion and Force: These actuators provide both horizontal and vertical motion. They can handle travel distances up to 500 feet and speeds up to 600 inches per second, and manage loads up to 10,000 pounds, making them suitable for a variety of industrial applications. Applications: Manufacturing Automation: Linear Actuators Robots are prominently used in automation for repetitive, tedious, or dangerous tasks. They help in streamlining processes and maintaining high precision and consistency in manufacturing, greatly reducing production costs. Prosthetics: The introduction of micro linear actuators has revolutionized prosthetics, enabling more natural and powerful motions in prosthetic hands. These tiny actuators offer significant strength and precision, essential for driving individual fingers directly. Drones and Aerospace: In drones, actuators are used for functions such as camera gimbals, retractable landing gear, and arms for manipulating objects. They are also incorporated into aerospace applications, such as the International Space Station, demonstrating their reliability and precision in high-stakes environments. In conclusion, Linear Actuators Robots are vital components in the development of robotic systems, offering a broad spectrum of applications from industrial automation to advanced prosthetics and space exploration. Their adaptability, precision, and robustness make them indispensable in advancing robotics technology into the future. Here, we introduce our Screw drive linear modules by model TMS45 semi-closed type for general environment.

You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#ActuatorsinCartesianRobot#AutomationandRoboticswithElectricLinearActuator#Cartesianrobotic#Electriclinearactuators#IndustrialRobotslinearactuators#inearActuators#LinearActuator#Linearactuatorrobots#LinearActuatorsforRobotics#LinearMotionandActuatorsforSurgicalRobotics#Linearmotorsingleaxisrobots#LinearMotors&Actuators#Linearrobots#MicroLinearActuators#MultiStationBeltLinearActuator2AxisRobot#PrecisionLinearActuators#RobotActuators#RobotLinearActuators#RoboticArmwithLinearActuators#roboticslinearactuator#SingleAxisRobotLinearActuators#SingleAxisRobots#XYActuator(SingleRail)

0 notes

Text

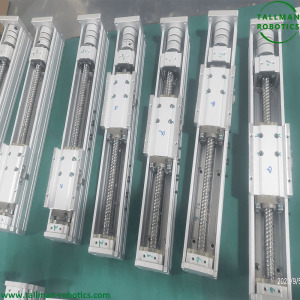

Linear Guide Way Modules are finished for Clients from India

Linear Guide Way Modules are ready for delivery to Clients from India. Linear guide way modules are mechanical components used in various applications to provide linear motion and support. They consist of a linear guide rail and a carriage or slider that moves along the rail. The guide rail typically has precision-machined surfaces, such as grooves or tracks, that allow the carriage to slide smoothly and accurately. Linear guide way modules offer several benefits, including: 1. Precise and smooth motion: The design of linear guide way modules ensures accurate and smooth linear motion, making them suitable for applications that require precise positioning and high repeatability. 2. Load-bearing capacity: Linear guide way modules can support significant loads, making them suitable for applications that involve heavy equipment or machinery. 3. Rigidity and stiffness: These modules are designed to provide high rigidity and stiffness, which helps minimize deflection and ensure stability during operation. 4. Low friction and wear: Linear guide way modules often incorporate rolling elements, such as balls or rollers, to reduce friction and wear. This design choice improves efficiency and prolongs the lifespan of the module. 5. Configuration flexibility: Linear guide way modules are available in various sizes, lengths, and configurations, allowing for flexibility in design and integration into different applications. Linear modules find applications in numerous industries, including manufacturing, automation, robotics, machine tools, semiconductor equipment, and more. They are commonly used in CNC machines, linear motion systems, industrial robots, and other precision equipment that require controlled linear motion. It's worth noting that there are different types of linear actuators available, such as ball guides, roller guides, and magnetic guides. Each type has its own advantages and is suitable for specific applications based on factors like load capacity, speed, precision requirements, and environmental conditions. Overall, linear modules play a crucial role in providing reliable and precise linear motion in a wide range of industrial and automation applications. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#1-axislinearmodule#DustproofLinearGuide#LinearCarriagesAndSlides#LinearMotionGuide#LinearSlidingGuide#SingleAxisGuideArm#SingleAxisRobot

0 notes

Text

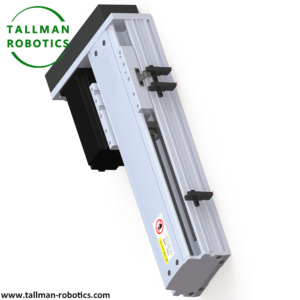

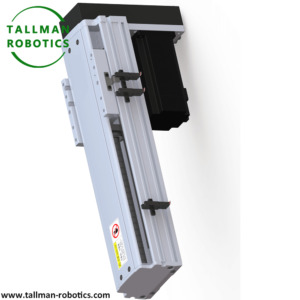

Single Axis Linear Robot Will Be Delivered To Singapore

Single Axis Linear Robot from Tallman Robotics Limited Will Be Delivered To Singapore.

A Single Axis Linear Robot is a type of robotic system that is designed to perform linear motion along a single axis. A single axis linear robot, also known as a linear actuator or cartesian robot, is an essential piece of machinery in numerous industrial applications. These robots provide precise, efficient, and highly customizable linear motion solutions, making them ideal for repetitive tasks or processes that require strict accuracy and control. Components: 1. Rigid frame: This provides the structural foundation for the robot's operation. Often made of metal such as aluminum extrusion or steel, the frame is responsible for maintaining rigidity and stability during movement. 2. Motorized drive system: This is the component responsible for generating and controlling the robot's motion. The drive system typically consists of an electric motor (stepper, servo or brushless DC motor) that converts electrical energy into linear motion via a mechanical translation system such as ball screws, linear motors, or belt and pulley systems. 3. Linear guide system: The linear guide ensures smooth, precise, and highly accurate movement along the single axis while also preventing undesired motion in other directions. Linear guides can include profiled rails with rolling bearings, linear bushings, or magnetic guidance systems. 4. End effector or tooling: This is the part of the robot that interacts with the workpiece or material. Depending on the specific application, the end effector could be a gripper, a vacuum cup, a welding tool, or even a small camera. 5. Control system: The control system manages and synchronizes the motion of the single-axis linear robot. The system typically consists of a programmable automation controller (PAC) or microcontroller, which receives input from sensors, user interfaces, or other devices and sends the desired motion commands to the motorized drive system. Applications: Among the various scenarios where single-axis linear robots are employed, these are some of the most common ones: 1. Assembly automation: Linear robots are essential in the assembly of electronic devices, automotive components, and various consumer products. They can quickly and accurately position parts for assembly or perform tasks such as screw tightening, adhesive dispensing, or press-fitting. 2. Material handling: Single-axis robots are frequently employed in conveyor systems and packaging lines to load/unload materials or transport goods between different stations. 3. Quality control and inspection: Attaching cameras or sensors to linear robots can automate inspection processes, thus ensuring consistent quality and production speed. This is particularly useful in industries like food processing, pharmaceuticals, and semiconductors. 4. Laboratory automation: In life sciences and clinical laboratories, single-axis linear robots can simplify tasks such as sample handling, tube sorting, and liquid dispensing. In conclusion, single-axis linear robots are fundamental tools in modern manufacturing, as they provide accurate, reliable, and customizable motion control. They help enhance the efficiency of various industrial tasks and enable businesses to maintain high standards of quality and productivity. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#1-axisrobot#AutomatedPickingSystems#Automatedsolderingrobot#ChinaSingleAxisRobotManufacturers#Linear&GantryRobots#LinearActuators#Linearmotorsingleaxisrobots#LinearStageAxisSingleLinearRobotArm#RoboticPicking#RoboticSystems#Singleaxisrobots#SingleAxisStages#Single-AxisRobotLinearModule

0 notes

Text

Industrial Linear Motion

Industrial Linear Motion As a professional Industrial Linear Motion, Tallman Robotics supplies wide range of TM linear motion actuators, including Screw and Belt driven linear modules by different driven solution, also Semi and fully closed linear modules for different use environment. Industrial Linear Motion, also named as Modular Linear Actuator, Linear Motion Module, Linear Actuator Bundle, Linear Modular Actuator, Single Axis Linear Actuator etc. Industrial Linear Motion can be in combination with range of brand motors by 50W,100W,200W/400W /750W/1000W or 42, 57,86 stepper motors or NMEA17, NMEA23, NMEA34 stepping motors in extruded base aluminum profile to get precise and speed target of various precision and common linear robot application. There is option of brake and no brake. TM Industrial Linear Motion of type TM65 with body with by 65mm have 4 series respectively by Ball Screw drive semi closed, Ball Screw drive fully closed, and Timing Belt drive semi closed, Timing Belt drive fully closed. These linear modules have strokes from 0mm to 800 mm, and payload from 2.5kg to 30kgs. It could applied in auto feeding before CCD visual inspection, components picked at the appointed position, flexible picking, gluing the sealant between the work piece, large-scale parts rack picking and placing, electronic components inspection etc.

Basic Specification of TM65 series Model No TMS65-CM TMS65-CR TMB65-CM TMB65-CR Drive solution Ball screw Ball screw Timing belt Timing belt Sealed or not Semi closed Fully closed Semi closed Fully closed Motor power AC (W) 50/100W Repeatability (mm) ±0.01/±0.005 ±0.04 Ball screw outer diameter (mm) 12 Reduction Ration: 1:1 lead (mm) 5 10 5 10 66 Fastest speed Motor speed 3000 (rpm) 250 500 250 500 3300 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 15/30 7.5/15 15/30 7.5/15 2/4 Vertical 0.3G 5/10 2.5/5 5/10 2.5/5 - Rate Thrust (N) 170/341 85/170 170/341 85/170 15/30 Linear guide (mm) 42*9.5-1 Origin sensor: Plug-in EE-SX674(NPN)EE-SX674P(PNP) Related knowledge: Laser marking machine for linear module application The word laser stands for "light amplification of stimulated radiation". Simply put, light particles (photons) excited by an electric current release energy in the form of light. The lamp was pointed at a bunch. The laser beam is formed in this way. Lasers are one of the most important inventions of human beings and they play an important role in our daily life; they are used in almost every field we can imagine, including electronics, modern medicine, defense and so on. With four basic characteristics of laser radiation: monochrome, high directivity, high consistency, and high energy density, lasers are used in many fields of modern material processing. Due to coherence, strength can be maintained for a long time, and can be further guided with the help of lenses. The laser beam engraves the surface of the material, is absorbed and heats the material. This heat generation causes the material to be removed or completely evaporated. This makes it possible to engrave, mark or cut various materials. In industry, lasers are used every day: engraving, marking, welding, cutting, drilling, cleaning, measuring, testing, etc. Laser has become one of our powerful production tools! Let's take a look at laser marking. As a modern processing method, it has great advantages compared with traditional processing methods such as printing, mechanical scribing, and EDM. Laser marking machine has maintenance-free, high flexibility, high reliability and other properties, especially suitable for areas with high requirements for fineness, depth and smoothness, so it is widely used in the hardware industry. Copper, stainless steel, gold, alloy, aluminum, silver and all metal oxides. The laser marking machine can mark various characters, serial numbers, product numbers, barcodes, QR codes, production dates, etc. on hardware products, and the time, date or serial number, product number can be automatically skipped. The laser-marked text and graphics are not only clear and fine, but also cannot be erased or modified, which is very beneficial to the tracking of product quality and channels, and can effectively prevent the sale of expired products, anti-counterfeiting and prevent cross-products. The hardware products engraved by the laser marking machine have fine patterns and long-lasting, beautiful and clear marks. The laser marking machine can meet the needs of printing large amounts of data on very small hardware products, and can print two-dimensional barcodes with higher resolution. Compared with the imprinting or jet marking methods, the powerful functional advantages allow the laser Standard machine has a broader market at home and abroad. As a new marking equipment, laser marking machine gradually shows better and better performance quality. The trend of using laser marking machine is increasing year by year, especially in the application of hardware products. Read the full article

#BeltDriveActuators#Beltdrivelinearactuator#BeltDriveLinearSystems#BeltDrivenActuators#BeltDrivenLinearStages#BeltDrivenLinearSystems#Beltdrivenmodularactuators#LinearBeltDriveActuators#Linearbeltdrivenactuators#MotorizedLinearStages#SealedBeltdrivenactuators#SingleAxisRobot#Timingbeltdrivenactuator#Timingbeltlinearactuators

0 notes