#Slitting Process Machinery

Explore tagged Tumblr posts

Text

FTNTH & WFI Crossover!

Slight disaster

Chapter 2

WFI Donnie belongs to @cimmerian1275 (who also beta read this)

We decided, hey, let’s make a crossover with our double mutated versions of Leo and Donnie, because we love some disaster twins' shenanigans!

We also decided to call them Sword and a Sparrow (SAAS)

Sadly, can’t tag it, won’t show up for some reason

The soft hum of machinery and the occasional flicker of overhead fluorescent lights were the only sounds in the lab—aside from the steady thunk of Leo’s elbow repeatedly hitting the worktable as he leaned on it in an overly dramatic fashion, bored out of his mind.

He sat on a stool, slouched like melted cheese over pizza crust, lower lip puffed out in a deep pout. His tail dragged lazily on the floor, twitching every now and then with the same restlessness burning behind his tired eyes.

Across the lab, this universe’s Donatello—wings partially unfurled as they rested by his sides, tail coiling like an impatient cat—was hunched over a massive console of glowing screens, muttering equations under his breath.

It had been like this for a while now, a few hours most likely since his arrival. They had tried seeing if Leo’s portals would bring him back to own dimension, but each time he sliced the air and stepped through the makeshift blue portal, he’d ended up back in Donnie’s lab. Not his Donnie’s lab, but this other dimensional Donnie that he seemed to be stuck with.

So Donnie decided to try and maybe, just maybe, figure something else out. Leo briefly heard him mumble about a teleportation device, but who knew what Donnie was actually coming up with.

With a hefty sigh, he scanned over the lab, quirking up a nonexistent brow, noticing the way this lab seemed familiar.

Wait a second…

Leo widens his eyes, unaware that his pupils briefly became slits in surprise before reverting back to normality. The spines on his shell prickling up from under his hoodie as well, but not enough to pierce through the fabric.

This lab was familiar!

Because it was the same one that Leo knew for years until it was destroyed by Shredder. And while it had been a few months since the defeat of the demonic entity, Leo’s memory still held strong on the fact that this lab, this dimension, must still have the old lair.

So… they haven’t faced Shredder yet?

He eyed his surroundings again in both puzzlement and disbelief before shaking his head. His head throbbing from trying to process this whole new discovery.

With a clear of his throat, he spoke up to fill the silence. “So…” Leo finally drawled, swinging his legs like a kid at detention, “Are we close? Like... ‘I’ll be home by dinner’ close? Or ‘stuck here forever’ close?”

Donnie didn’t respond right away, fingers flying over glowing purple keys.

Then he sighed.

“Come on, Dee.” Leo pressed, tone laced with a teasing whine. “Isn’t there something in that big ol’ braincase of yours that can help out a stranded brother?”

A vein pulsed in Donatello’s temple. He turned slowly, very deliberately, swiveling in his chair to stare Leo dead in the eye like a predator sizing up prey.

“Big. Head.” He echoed, voice level.

Leo grinned, shameless. “Endearing, not insulting. You’re welcome.”

Donnie closed his eyes, took a breath like he was meditating through an oncoming rage headache, then opened them again with forced calm.

“Excuse me if I’m a little slow.” He said, tail lashing once. “It’s just a bit difficult to calculate interdimensional displacement when neither of us know how you even got here in the first place!”

He stood, wings fluttering with an irritated snap, arms flinging upward in exasperation.

Leo leaned back, raising both hands innocently. “Hey, whoa, no need for that. You asked. I answered.”

Donnie gave a frustrated huff, pacing now. “You stepped through a portal.” He mocked, deepening his voice to imitate Leo’s, “‘And boom, I’m here.’ That’s not data, that’s vague nonsense.”

Leo snorted, resting his chin on his hand. “Sorry, Professor Quantum, but I didn’t exactly take notes mid-fall.”

Donnie stopped pacing, pinching the bridge of his snout. “You’re giving me secondhand migraines.”

Leo shrugged, his own tail twitching on the floor, showing his own frustration. “Join the club.”

The silence that followed wasn’t exactly tense, but it buzzed with a mix of helplessness and static frustration. Leo let it sit for a moment, then softened.

“…I didn’t mean to end up here, you know.” He muttered, eyes now fixed on the floor. “Was just trying to get away for a bit. Didn’t think I’d wind up in another dimension.”

Donnie glanced over at him, the eyebrows on his head relaxing slightly. The wings folded back against his shell and feathers smoothing out.

“I am trying.” He said, not unkindly this time. “But if your mystic signature is unstable—which, judging by how you crash-landed into my lab, we need to isolate the unique frequency that resonates with your dimension. Otherwise you’ll keep boomeranging back here no matter where you try to portal.”

Leo lifted a brow. “So... what I’m hearing is, I’m basically the worst boomerang ever made.”

Donnie blinked, deadpan. “Yes. But louder and more obnoxious.”

Leo snorted again, this time with a flicker of genuine amusement. “Alright. Guess I’m staying a while.”

“Guess you are.”

Another moment passed, quieter now, a little easier between them.

Leo trained his eyes on Donnie, taking mental notes of everything that seemed both familiar and unfamiliar for him that he was beginning to notice. This Donnie wasn’t looking at him like he was a freak, a monster. If anything he seemed relaxed around him, like how Donnie used to be with him before Leo got himself cursed for breaking that stupid vase.

It was almost nostalgic, smiling softly to himself as he quite liked this change in comparison to what he was getting back at his own home dimension. He tried to not think too much about that thought, it would only bring his mood down and he quite frankly didn’t have the energy to deal with that whole mess.

Leaning back on the stool, looking up at the vibrant purple ceiling lights, Leo hums in curiosity, speaking his mind. “You think the me in this world is any smarter?”

The corner of Donnies mouth rose in a small smirk, and without looking up from his screen he spoke. “No chance.”

“Rude. If your Leo is anything like me, he’s totally smart!” Leo grins playfully, propping himself up on the work table as Donnie rolls his eyes, opening his mouth to retort back, but neither of the two has a chance to speak when a knock from the other side of the lab reached their ears.

“Donnie, we got dinner! Pizza baby!”

Leo shuts his mouth with a snap of his jaw, perking up at the familiar tone of voice that clearly came from Mikey. Donnie on the other hand flailed for a moment, quickly getting up and glancing around frantically in alert.

“U-uhh! Just a moment!”

He runs around his lab, a confused Leo watching him like a curious cat as Mikey’s voice echoed once more. “Do I need to drag you out of there?” Mikey threatened, the door of the lab making an ominous creaking noise to show he was beginning to open it.

Donnie gulped down his nerves and sighed in relief when he found his brooch, quickly placing it on himself and swiping his hand over the gem to activate it. Leo flinched back when he saw the tail and wings disappear completely in a flash of mystic energy.

He recognised the brooch immediately, making him wonder how Donnie got his hands on one. The only people Leo knew who had a cloaking brooch would be Sunita and the yokai’s from Big Mama’s hotel.

Before Leo could even begin to question his other dimensional twin brother, he was snatched by the wrist and dragged over to a pile of scrap heap.

“Ow!” Leo hisses, rubbing his arms when the scraps pricked at him. He tried to stand up, only to wince and yelp again when Donnie practically buried him with more random pieces of junk from the pile.

“Do not make a sound.”

Donnie leaves Leo, who huffs and crosses his arms, listening in as he hears the familiar sound of Donnie opening the lab door.

“Mikey, what did we talk about when opening my lab doors without giving me a chance to simply get myself sorted?”

“You were taking forever bro! Plus, I wanted to make sure you got food in ya while it was still hot and fresh.”

The scent of pizza filled Leo’s nostrils, the slider resisting the urge to drool over the scraps as he heard Donnie sigh. “Okay, okay. Thank you brother. Now, I have important work to do!” Donnie exclaims through gritted teeth, snatching the pizza box out of Mikey’s hands.

“You're not eating with us?” The young box turtle frowns a little, showing some concern towards Donnie as he slumps his shoulders slightly. “You’ve been staying in your lab a lot lately. You're not sick or anything right?” He innocently inquired as Donnie stiffened, his eyes darting around in brief panic.

But he couldn’t let Mikey know. No one should know.

“Not sick. It’s like I said, I have very important work to do. Thank you for dropping by.”

With that, Donnie closes the lab door, locking it and letting out a breathy exhale of relief. He felt guilty for basically shutting out his little brother, but it was for the best at the moment.

“Come on out now.” He tells Leo, who shoved himself free out of the pile.

“Dude, you got pizza?!” Leo smiles, his tail wagging excitedly and eagerly behind him, walking over as Donnie sets the pizza box down. His hand goes up to take off the brooch, but he falters, biting the inside of his cheek as he decided its best to leave it on for now.

“Go nuts. I have tons of work to do.”

Leo paused with his fingers hovering over the pizzas, blinking owlishly as he observed his brother from another dimension. “Are you not going to eat?” He asked, frowning as Donnie waved off the comment.

“Mm, not hungry.” He responded back, his shell facing Leo as he went back to typing away on the computer screen.

Leo however narrowed his eyes in thought, before decidedly grabbing a pizza slice and stepping towards Donnie. “No brother of mine is going to starve! Eat.” He demanded a bit playfully, bumping the pizza against Donnie’s cheek as he leaned over his shoulder slightly.

“Nardo—“

“Eat.”

“Would you quit that—“

“Nope. Eat with me.”

Donnie groans, clicking his tongue in annoyance. “I’m not eating!” He hisses only for Leo to huff and cross his arms stubbornly.

“Then I’m not eating until you do.” He compromised, making Donnie stare with bewilderment as he tried to talk, only to stumble over his words.

“Y-you! You can’t just…! Argh!”

Donnie couldn’t stress this enough, he didn’t want to be held responsible if this Leo was going to starve himself just because Donnie hadn’t eaten in awhile.

Leo remained silent, smirking to himself slightly as he knew that this would work. If this Donnie was anything like the Donnie he knew, Leo just knew that eventually he’d eventually give in and eat, not wanting to be accountable for Leo’s own decision of refusing to eat.

Twins. Such annoying creatures.

Using his arm to push back Leo as much as he could, eyeing the slice of pizza before grabbing it. “Fine. But only because you’re being annoying.” He gave in, munching on the cheesy food as Leo snickered happily.

“As your twin, even if I’m from another world, it’s my sole duty to be annoying.”

“Ditto.”

The two were quiet, enjoying each other's presence as Donnie took a side glance at his twin. He wanted to ask how he got to be this way, why he had a tail and fins. He said he was cursed but what did that entail exactly?

Donnie wasn’t the only one who had questions inside his head. Leo was no better, he kept wondering why Donnie was the way he is right now. He had wings and a tail and he seemed to be wanting to hide that from his brothers.

“So… did you also get cursed?”

Donnie slumps his shoulders at the question, “Don’t want to talk about it.” He responded, which only made Leo ache with more curiosity, who licked his fingers from the pizza he just ate before grabbing Donnie’s shoulders and somewhat shaking him.

“Come on! Share with me! I’ll keep it a secret.”

“Knock it off.”

Leo huffs, letting go. “You’re no fun.” He teased, walking away to look around the lab, taking in the fact that this was scarily similar to the old lab he knew from his home dimension.

“So, am I sleeping here or…?”

Donnie widens his eyes, clicking his tongue and scrunching his face. He didn’t think that far ahead of the fact that Leo would probably be here for a while. “I guess…” He grumbled, unaware of how Leo grinned playfully.

“Aw, it’s just like when we had sleepovers as kids.”

“Except instead of a bed, you can sleep in the scrap pile.”

Leo gasps, hand splayed over his plastron, “Seriously bro?” He deadpans, a bit offended as Donnie grins.

“Relax, I’ll give you a blanket.” He assured, turning around and smiling at Leo who exhaled and softened his expression.

Amused as he knew Donnie was joking.

…right?

He shook off the thought and looked towards the locked door. He wanted to see the lair again. Before it was destroyed. He missed his home that he grew up in, he didn’t want to admit it but he had been quite devastated when it was ruined by Shredder.

He had great memories here. Memories of when he wasn’t looking like this whole situation.

“I know that look. You can’t go out there.”

Leo narrowed his eyes slightly in some annoyance, “Not even for like 5 minutes?” He asks, his tail perking up eagerly but Donnie just raises his brow, silently daring Leo to start arguing with him.

“Ugh…”

Stubbornly, Leo dragged himself away from the lab door. “There’s gotta be at least something for me to do then.”

“Play the silent game.”

“Ha-ha. Funny.”

Donnie snorts, shrugging his shoulders, “I keep telling you guys I’m the funniest.” He stated with pride as Leo rolled his eyes at his comment.

“Sure, sure. Keep telling yourself that bud.”

Donnie lightly smirks in amusement, standing up and walking off towards a cabinet to the side, Leo watched with brief curiosity, noticing just over Donnie’s shoulder that he was grabbing what appeared to be bedsheets, Leo softly hummed, smiling fondly to himself that Donnie was going to perhaps make him a little bed for later.

But since he was distracted… Leo saw this as the perfect opportunity to slip out of the lab unnoticed. He just wants to take a brief look around the old lair. For memory sake.

He steps back, keeping his eyes focused on Donnie until he reaches the door, cautiously opening it and trying to keep it to minimal noise before he gives a once over to Donnie, he hadn’t noticed.

Sorry Dee. Just for a second I’ll be gone.

Leo impishly grinned to himself as he snuck out as quiet as a ninja. Once he was outside the safety of the lab, he quickly dove to the side, sticking to the shadows as best as he could, listening and watching for anything that may risk him being caught.

He moved with the shadows, his tail flicking in curiosity like a cat as he made his way towards familiar surroundings.

Whoa… the kitchen. It’s the same as it was back home.

He smiled at the sight, walking away and heading quietly towards the gaming room, peeking inside and chuckling softly at the sight. Everything was the exact same it seems.

This is so cool…!

Donnie on the other hand, had no clue he was now alone in his lab. Humming along to some 80s jam he heard before as he grabbed the materials he would need to set up a comfortable place for his other dimensional twin to sleep in.

He wasn’t actually going to leave Leo to sleep in the scraps.

“Okay, I got the essentials for you. I’ll set up a bed for you next to mine—“

When he turned around, suspecting that Leo was going to be standing there, he came to an abrupt pause, blinking owlishly as he observed his quiet lab.

“…Nardo?”

A beat of silence ticked by and Donnie dropped the bedsheets when realisation entered his brain.

“That dumb-dumb!”

He could feel his wings reflexively fluff up in annoyance behind the cloaking brooch. Stomping his way towards the unlocked door, he now had another new priority to focus on.

Find Leo.

Where did that fish-brained idiot go?

Donnie was internally panicking, his eyes darting around for any sign of the other Leo. He checked the kitchen, and then the gaming room, but saw no sign of the slider.

He quickly made his way to the indoor skateboarding room they had, but froze when he ran into his brothers who were skateboarding up and down the ramp.

Leo. His Leo, spotting him first.

“Donnie! You joining in?”

He grins happily at the sight of the softshell, who was currently processing the fact that he now had to somehow dodge his own brothers and look for the other Leo.

“Can’t, I’m uh… busy.”

Raph tilted his head, raising a non-existent brow at his little brother. “Busy? With what?” He inquired curiously and with some concern, considering they noticed the way Donnie had been avoiding them.

“Looking for Leo.” He said without speaking, but it was too late as the slider in front of him was sweating a bit in confusion. “Uh… you found him then? Right here, hermano!”

Donnie wanted to groan, and wanted to explain what he meant by looking for Leo. But he couldn’t. He shouldn’t. They probably wouldn’t believe him or even understand what he was going on about.

His eyes glanced up, and immediately paling as much as a green skinned turtle could do, as he saw on the ceiling beam the other Leo he was actually looking for. The Leo that came from a whole new world, balancing himself like a smug cat as he giddly smiled like a kid on the playground, his tail swishing side to side slightly playfully.

“Leo!”

Once again, the brothers gave puzzled expressions towards the soft shell. “Dude, I’m right here. No need to yell.” His brother deadpans slightly at him, Mikey jumped down to stand in front of Donnie, his face scrunching up with concern.

“Are you feeling okay?”

“What? I mean yes! I am fine.”

Donnie shakes his head briefly to try and look as normal as possibly could be. Trying to not make it obvious or to look up. He did catch sight of the other dimensional Leo crawling around on the beam, peering down as he spotted Donnie, even having the nerve to wave at him as he did so.

I’m gonna kill him.

If Donnie had hair, he’d be ripping it out right after this.

“Brethren of mine, wouldn’t it be more fun if we watched some Lou Jitsu movies? In the living room.”

Donnie tried to get them to be more interested in something else. Thinking of any plausible excuse to get them out of the room as he kept his eye on the other Leo.

“Lou Jitsu movie marathon? I’ll make popcorn!” Mikey beams, already running off as Raph sighs.

“I’ll go secure the couch.” His oldest brother added, heading out as Donnie looks to his twin who hums with a furrowed brow.

“Are you sure you’re doing okay?”

“Totally!”

Not.

Leo didn’t say anything, just observed him quietly. “All right. I’ll see you in the living room then.” He walks by, smiling lazily as Donnie waits a moment to make sure everyone is actually gone.

Once he was sure that it was just him, he looked up.

“Leo! Get down—“

He blinked when the sight of the other Leo wasn’t even up there anymore. “What…?” He mumbles, tilting his head in confusion.

“What are we looking at?”

With a shriek of surprise, Donnie recoiled and jumped back in shock. The other Leo stood behind him, smiling as the tip of his tail flicked slightly to the side in a mischievous fashion.

“How did you?!”

“I’m a ninja.”

Donnie could feel an eye twitch, taking a deep inhale. “Look, either your brain has the memory of a goldfish—“

“Rude.”

“Or you just purposefully choose to ignore my advice. But I told you to stay in the lab. So, I need you to get back. I cannot risk the others seeing you.” Donnie scolded, furrowing his brows and crossing his arms over his plastron as Leo rolled his eyes at him stubbornly.

“Ugh, no offense but your lab is boring! I wanna watch that Lou Jitsu marathon.”

“Well that is most definitely not happening. You can’t be seen.”

Leo pouted, grumbling under his breath. “So not cool.” He clicked his tongue, grunting in bewilderment when Donnie began forcefully shoving him forward towards the exit.

“Go on. Back to the lab with you.”

“Can you at least bring back some food and beverages for me?”

Donnie nods in agreement, “Yes, I’ll do that. Just go back and don’t get seen!” He hisses in a hurry as Leo gives a mocking salute, walking out of the skating room and once again, sneaking his way back to the lab.

He briefly paused however just when he was about to open the lab doors. His eyes caught sight of Leo. The Leo from this world obviously, who was laughing along to whatever Mikey had just said.

He was normal.

No long tail. No webbed hands or fins. No spikes on his shell. No extra markings.

Just normal.

Something inside Leo twisted for a second, perhaps a sense of jealousy? Bitterness? He couldn’t quite tell as he eventually entered the lab, closing the door for privacy as he walked over to a table that was shiny enough to see his reflection.

Monster.

That’s what Raph called him the last time he was back home.

Leo was a freak. At least that’s what he thinks, he already knew he wasn’t exactly normal given the whole giant, walking, talking mutant turtle aspect he had going on.

But now add the whole curse to him?

He couldn’t blame anyone for seeing him as a monstrosity.

------------------------------------------------------------------------------

WFI Masterpost

FTNTH Masterpost

Part 1/Part 2/Part 3/Part 4/Part 5/Part 6/Part 7/Part 8 (coming soon)

You are free to make fan art of these two by the way! We accept all art of them!

#rottmnt#tmnt#rise of the tmnt#rise of the teenage mutant ninja turtles#save rottmnt#unpause rottmnt#rise of tmnt#riseofthetmnt#rise fandom#rise leo#rise of the turtles#leo hamato#hamato leonardo#tmnt leo#leonardo hamato#tmnt leonardo#leonardo#leo#double mutated leonardo#double mutated leo#feel the need to hide au#FTNTH Leo#rise donnie#hamato donatello#tmnt donnie#donnie#donatello#double mutated donatello#double mutated donnie#wait for it au

33 notes

·

View notes

Text

A couple of days ago, I was collecting seeds from the milkweed pods in our yard. Having not done this before, but being fully aware of the fuzzy stuff that flies out of the pods, I was battling fuzz (technically, "floss") as I was pulling off and storing the seeds. Then I got smart, and decided to cut a slit in the pods and then gently pull out the mass of floss and seeds, and then just pulling the seeds off and dropping then into the container. As I was doing that, I noticed how super soft the floss was as I pulled it fresh out of the pods, and wondered........do any clothing manufacturers use this stuff? Did a Google search, and learned....yep!

Excerpt from this story from Happy Eco News:

As consumers demand more eco-conscious apparel, brands are getting creative with natural materials that keep warmth in and environmental harm out. One unlikely hero emerging from prickly planted fields is the common milkweed—yes, literally plucked straight from the wild. While best known as the sole food source for iconic, struggling Monarch butterflies, milkweed’s hidden potential is nestled right inside its fluffy, silken floss. This fleecy fiber is an amazing natural insulator and is finding a new application in jackets, parkas, boots, and ski gloves for humans.

As outdoor apparel companies race to reduce environmental impacts, milkweed clothing insulation is proving a promising substitute for conventional insulation fillers—one aligned with cleaner agricultural systems. Its hollow-cored fluff offers an animal-friendly, biodegradable alternative to goose down. Unlike petroleum-based synthetics like polyester fibers, milkweed fills garments with a regeneratively sourced material that decomposes rather than lingering for centuries in landfills.

With conscious consumerism accelerating across industries, apparel buyers now consider impacts far beyond cost and quality when evaluating purchases. An unlikely hero from both suffering North American grasslands and climate crosshairs is rapidly gaining traction as a sustainable insulation material – common milkweed floss. Beyond keeping heat in and winter out with insulating performance rivaling goose down, milkweed rates exceptionally on multiple sustainability indicators resonant with eco-conscious consumers.

As a native perennial thriving on marginal lands, milkweed flourishing requires no irrigation, fertilizers or pesticides – regrowing reliably year after year. From a toxicity and allergen standpoint, milkweed avoids issues associated with many synthetic insulations or down. And supporting milkweed crop expansion helps reverse monarch butterfly declines blamed on agricultural habitat loss. For shoppers concerned over microplastics shedding into waterways from standard fleece, milkweed offers a soft, homegrown, biodegradable alternative. In short, milkweed checks all the boxes for socially mindful consumers seeking future-focused apparel that balances functionality with ethical, regenerative supply supporting threatened pollinators.

Signaling the momentum of milkweed clothing insulation, major brands like Patagonia are incorporating the fluff through novel partnerships with companies like Vegeto Textiles. Dedicated milkweed plantings bandwidth habitat zones while fibers make their way into garments. Other types of textile manufacturers are also jumping on board, some with announced plans to insulate blankets and quilts with milkweed.

Still, despite its promise, milkweed clothing insulation remains in its infancy. Technological barriers to processing millions of floss strands into a stable textile filling have just recently been worked out. Machinery and techniques to update this long-known application concept into a scalable commercial reality. Companies have worked for years honing best practices for taking raw milkweed fluff through cleaning, drying, and fiber alignment steps to transform fuzzy floss into outdoor-ready filling. Advancements in the coming decade will further improve integration potential across diverse textile products, opening doors for milkweed clothing insulation in everything from t-shirts to winter boots.

18 notes

·

View notes

Note

How would you and your crew at the factory ticklegasm a Giant?

By deploying my newly minted pop-up tickle factory of course~! But first we need to get that giggly giant restrained and for that we're gonna need my specialized aerial ticklers which are absolutely not a total ripoff of the omni directional mobility gear from Attack on Titan~ they'll zip around our big ticklish friend with their feather swords and blush clubs to barrage the hot spots which also can hinder locomotion~ the underarms, collar, sides, backs of the knees, Achilles tendons, and small of the back. With their puffy fluffy weapons swinging, the giant will lose their momentum and start to stumble.

That's where my engineers will start deploying the factory. It's a bit like those automated car washes, with a long series of arches springing up from circular pads on the ground which begin connecting by thick dark sleeves to form our factory line. The aerial ticklers will begin pummeling from each side to get the giant lined up as they skid across the ground. Whether we get them in feet first or head first, the entryway to the factory is equipped with grasping soft giant hands to snatch and grab. While the giant is being dragged inwards, the interior surface of the factor is going to be lubricated with massage oils by our interior workers.

As the giant is gliding down surface, they'll begin spraying merrily to coat all that skin and make it so shiny and sensitive. Since the giant will not be restrained yet the idea is to keep them moving and disoriented. Again like a car wash, the first chambers of the pop up factory are filled with curtain after curtain of swishing soft materials and drapey tendrils, with the machinery moving them back and forth and twirling about over the giant's shoulders, underarms, down the ribs and over the belly and chest. The feet will be constantly buffed by our interior aerial workers who will follow the wiggly toes and wrinkly soles closely with their whirling buzzing tools.

Thoroughly buffeted by the first round, the giant will find themselves sliding into the tub which has been dug during the initial phase. This warm cleansing bath will wear down the resistance of even the most feisty guest through a massive array of water jets aimed to target all the sensitive zones on their lower body ~ while the aquatic workers zip around in their wetsuits and long scrubby brushes to get into the inner thighs, between the huge tush cheeks, under the toes, and of course into the royal area. While this is happening, I will pay a visit from above and float about with my taunting factory survey for how they would rate our services ~ and giving the most annoying teasing tickles with my duster wand under their nose and along the ears and under the chin~

The cleansed giggly giant will be slip out from the tub and brought next to our processing and packing center. The factory will be taking plenty of scans and sensitivity samples at this time with its tingle beams, both for our data and to distract so that my packaging workers can line up their wrapping cannons and engage the padded clamps for the giant's wrists and ankles. The factory will fill with the sounds of packing material being spun ~ the clamps will rotate them like a spit while layer after layer of shiny wrapping is applied.

With our big package thoroughly prepared, the giant will be reeled into the prep room so that my precision ticklers can begin creating hot spot incisions in the bondage to expose those giant hot spots we gathered from the factory's data. Cutting pinpoint slits under the arms and across the tummy and thighs and chest over the huge royal buttons and naturally the royal area, the giant will be ready for the final chamber.

For all the hard work, the teams will be enjoying from the observation deck as our product is placed and the spider-like tickle tease engine can descend from above and begin deploying its spinning vibrating tingle tips to all those carefully exposed hot zones. They're a bit like scalp massagers, except glowing brightly and oversized to stimulate a giant's skin to giggly bits. We'll enjoy the process of tickling teasing our guest to gigglemoaning madness, and occasionally strap on a mobility suit to fly down and add a little more hands on stimulation ~ particularly in the royal area, where the machine will have two sets of buzzing nubs spread along taking turns in a calculated sequence but will allow us to reach in and give those tiny rubbies or gentle paintbrushes with oil to realllly make the factory quake.

And this is absolutely not a single ticklegasm operation. For all the work and effort it takes to snare, process, and package a giant we will definitely be milking them for soo many of those oversized gigglecums ~<3

8 notes

·

View notes

Text

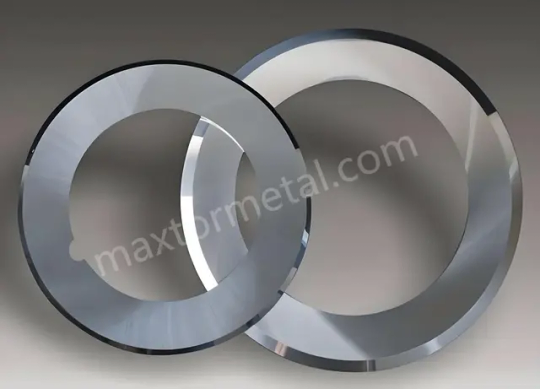

Discover the Best CRFH Slit Coils in Maharashtra with Hariom Pipes

In the ever-evolving world of construction and manufacturing, finding high-quality raw materials is essential for long-term success. Among these critical materials, CRFH slit coils—Cold Rolled Full Hard slit coils—stand out for their superior strength, durability, and versatility. If you are looking for the best CRFH slit coils in Maharashtra, then Hariom Pipes is a name you can trust.

What Are CRFH Slit Coils?

CRFH stands for Cold Rolled Full Hard. These are steel coils that have been cold-rolled to achieve higher strength and hardness. The term “slit coils” refers to the process of slitting wide steel coils into narrower widths, which are used in a variety of industries such as automotive, construction, appliance manufacturing, and more.

CRFH slit coils offer several advantages:

High tensile strength

Smooth surface finish

Dimensional accuracy

Excellent weldability

Cost-effective for large-scale industrial use

Because of these characteristics, CRFH slit coils are in high demand across various sectors in Maharashtra and beyond.

Why Maharashtra is a Key Market for CRFH Slit Coils?

Maharashtra is one of India’s leading industrial states, with major hubs like Mumbai, Pune, Nagpur, and Nashik playing crucial roles in manufacturing and infrastructure development. The growing demand for high-grade raw materials in the state makes it a hotspot for steel products, particularly CRFH slit coils.

Companies operating in Maharashtra need a dependable supply of quality materials to maintain their competitive edge. This is where Hariom Pipes comes into the picture.

Introducing Hariom Pipes: A Trusted Name in Steel Products

Hariom Pipes has established itself as a leading manufacturer and supplier of steel products, catering to a wide range of industries. Known for its commitment to quality, consistency, and customer satisfaction, Hariom Pipes has become a preferred choice for those seeking the best CRFH slit coils in Maharashtra.

Key Strengths of Hariom Pipes:

Top-notch Manufacturing Facilities Hariom Pipes operates modern manufacturing units equipped with advanced technology and machinery. This enables the company to produce CRFH slit coils that meet stringent industry standards.

Quality Control Each coil undergoes rigorous testing to ensure it matches the required specifications in terms of thickness, hardness, and surface finish. Their in-house quality control labs ensure that only the best products reach the market.

Custom Solutions Different industries have different needs. Hariom Pipes provides customized slit coil dimensions and grades to suit specific applications, ensuring optimal performance and minimal wastage.

Reliable Logistics Timely delivery is crucial in industrial supply chains. Hariom Pipes has a robust distribution network that ensures prompt delivery across Maharashtra, including remote and industrial zones.

Competitive Pricing By streamlining production and sourcing raw materials efficiently, Hariom Pipes offers competitive pricing without compromising on quality.

Applications of CRFH Slit Coils

The best CRFH slit coils in Maharashtra supplied by Hariom Pipes are used in a broad range of applications, including:

Automotive components: Used in body panels, structural parts, and reinforcement parts

Appliances: Washing machines, refrigerators, and other white goods

Construction: Roofing, framing, and support structures

Furniture: Metal cabinets, tables, and storage solutions

Packaging: Drum bodies, pails, and other metal containers

This wide applicability makes CRFH slit coils a vital product for manufacturers across industries.

Why Choose Hariom Pipes for Your CRFH Slit Coil Needs?

Choosing the right supplier can make a significant difference in your operations. With Hariom Pipes, you benefit from:

Proven track record in supplying high-quality steel products

Commitment to sustainable and eco-friendly manufacturing practices

Strong customer support and after-sales service

Ability to handle both bulk and small-scale orders with equal efficiency

Conclusion

For businesses operating in Maharashtra, sourcing top-grade raw materials is a strategic decision that impacts product quality and operational efficiency. When it comes to CRFH slit coils, Hariom Pipes stands out as a reliable partner known for excellence, consistency, and customer-centric service.

If you are looking for the best CRFH slit coils in Maharashtra, Hariom Pipes offers the ideal combination of quality, affordability, and reliability. Get in touch with them today to learn more about their product offerings and how they can support your business needs.

0 notes

Text

Top Quality copper strips Manufacturers in India

Title: Copper Strips Manufacturers in India: KWM India Leading the Charge in Precision and Quality

Copper has long been valued for its superior electrical conductivity, malleability, and corrosion resistance. Among its many industrial forms, copper strips hold a significant place due to their diverse applications across electrical, construction, automotive, and telecommunications sectors. India has emerged as a major hub for copper strip manufacturing, and KWM India stands out as one of the most trusted Copper Strips Manufacturers in India, known for quality, consistency, and customer-centric solutions.

The Versatility of Copper Strips

Copper strips are flat, thin pieces of copper available in various widths and thicknesses. Their unique properties make them indispensable in industries such as:

Electrical & Power Distribution: Widely used in switchgears, transformers, and busbars due to their high conductivity.

Electronics: Essential in the production of PCBs, connectors, and terminals.

Automotive: Used in battery connections, harness systems, and electric vehicle components.

Construction: Employed in roofing, cladding, and decorative architecture.

Renewable Energy: Key material in solar panels and wind energy systems.

Given these applications, the demand for high-quality copper strips is steadily rising in both domestic and international markets.

KWM India – A Leader Among Copper Strips Manufacturers in India

KWM India has earned a strong reputation as one of the premier Copper Strips Manufacturers in India, driven by a commitment to technological advancement, quality assurance, and client satisfaction. The company combines industry expertise with modern manufacturing facilities to deliver copper strips that meet stringent global standards.

Key Features of KWM India's Copper Strips:

High Electrical Conductivity: Ensures efficient power transmission with minimal energy loss.

Dimensional Precision: Manufactured with tight tolerances for uniform thickness and width.

Corrosion Resistance: Suitable for outdoor and harsh environments.

Custom Sizes and Alloys: Available in ETP (Electrolytic Tough Pitch), DHP (Deoxidized High Phosphorus), and oxygen-free copper grades.

KWM India’s copper strips are supplied in both soft and hard tempers, with surface finishes ranging from bright polished to tinned or oxidized, depending on the customer’s requirements.

Manufacturing Excellence and Quality Assurance

KWM India utilizes advanced machinery and automated processes to ensure high precision and production efficiency. From melting and casting to rolling and slitting, every step in the production process is meticulously controlled. The company also invests in continuous research and development to improve product performance and expand application potential.

Quality assurance is central to KWM India’s operations. The manufacturing unit is equipped with in-house labs that perform chemical analysis, mechanical testing, and surface inspections. All copper strips undergo rigorous quality checks before dispatch to ensure they meet national and international standards like ASTM, BIS, and IEC.

Export-Ready and Eco-Conscious

KWM India serves both Indian and global markets, with a robust export network extending to the Middle East, Europe, Africa, and Southeast Asia. The company’s commitment to timely delivery, competitive pricing, and after-sales support makes it a preferred supplier worldwide.

Additionally, KWM India follows environmentally responsible manufacturing practices. The company emphasizes energy-efficient processes and supports copper recycling to reduce its carbon footprint, aligning with global sustainability goals.

The Growing Demand and Future Outlook

As industries like renewable energy, electric vehicles, and smart infrastructure continue to expand, the demand for reliable copper strip manufacturers will grow significantly. With government initiatives such as “Make in India” and increased infrastructure development, India is poised to become a global manufacturing powerhouse.

KWM India is well-positioned to capitalize on these opportunities. By continuing to invest in technology, workforce training, and product innovation, the company aims to remain at the forefront of the copper industry.

Conclusion

In the competitive landscape of Copper Strips Manufacturers in India, KWM India shines through its dedication to quality, innovation, and customer satisfaction. Whether you're sourcing for high-performance electrical applications or looking for custom copper solutions, KWM India delivers excellence that meets the highest standards. As the demand for efficient and durable materials grows, KWM India is ready to lead the way — one copper strip at a time.

Visit:- https://www.kmwindia.com/copper-strips.html

0 notes

Text

Exploring the Dynamic Landscape of the Steel Service Centers Market

The steel service centers market plays a pivotal role in the global steel supply chain, acting as intermediaries between steel producers and various end-use industries. These centers not only stock and distribute steel products but also offer value-added services, transforming the material to meet specific customer requirements. The evolution of this market is closely tied to industrial activity, construction demands, and technological advancements in steel processing and logistics.

Steel service centers are instrumental in maintaining the balance of supply and demand in the steel industry. They buy large quantities of steel in various forms—such as sheets, bars, tubes, and plates—from producers and hold inventory, thereby providing a buffer that enhances market stability. This setup allows for quicker delivery times to end-users in industries such as automotive, construction, aerospace, and heavy machinery, which is crucial in maintaining continuous production lines and project schedules.

More Info: https://dimensionmarketresearch.com/report/steel-service-centers-market/

The value proposition of steel service centers is significantly enhanced by their ability to offer additional processing services. These include cutting-to-length, slitting, shearing, and applying surface treatments, which help in reducing waste and production times for manufacturers. This shift towards more integrated services is a response to the increasing complexity of client demands, pushing service centers to evolve from mere distributors to comprehensive service providers.

Market trends indicate a growing inclination towards sustainability and efficiency. Steel service centers are adopting more environmentally friendly practices and technologies, focusing on energy-efficient operations and recycling. The use of advanced logistics and inventory management systems, powered by AI and data analytics, further optimizes the supply chain, reduces overhead costs, and minimizes environmental impact. These advancements not only support sustainability but also enhance the competitive edge of service centers by enabling them to offer cost-effective solutions without compromising on service quality.

The competitive landscape of the steel service centers market is quite fragmented with the presence of both large players and small, specialized firms. Large players benefit from economies of scale and often have a broader geographical reach, while smaller firms can cater to niche markets, offering specialized products and services that are not economically viable for larger companies. Strategic partnerships and acquisitions are common as companies aim to expand their service offerings and geographical footprint.

As the market moves forward, the challenge for steel service centers will be to continuously adapt to changing market conditions. This includes fluctuations in steel prices due to global economic factors, tariffs, and trade policies. Additionally, the increasing push towards digital transformation presents both challenges and opportunities. Service centers that can effectively leverage technology to improve their operations and customer service will likely emerge as leaders in the evolving market landscape.

In conclusion, the steel service centers market is characterized by its dynamic nature, driven by technological advancements, shifts in demand within key downstream industries, and increasing emphasis on sustainability and efficiency. As they adapt to these changes, steel service centers will not only play a critical role in the steel supply chain but also drive innovation and efficiency across various industrial sectors.

0 notes

Text

F1 – the crucible of innovation for BTMA members

Fibre and fabric production technologies – especially in the area of composite reinforcements – have played an as-yet largely unheralded role in the development of the UK’s Formula One industry, but the British Textile Machinery Association (BTMA) aims to change that.

Motorsport Valley

“If there’s one thing the UK does well, it’s Formula One, with seven of the ten F1 teams located within just an hour of each other in the midlands region known as Motorsport Valley,” explains BTMA CEO Jason Kent. “They are all linked to a national network of around 4,500 companies involved in a motorsport and high-performance engineering industry worth around £9 billion annually and employing 40,000 people. This network draws on the services of a significant number of our member companies.”

“With the exception of the engine, virtually every part of a Formula One racing car now starts from a textile, including the bodywork, the tyres and many of the latest fuel systems,” says Richard Kirkbright, project manager at Leeds-based Roaches International. “This has influenced developments in the broader automotive sector, in addition to the aerospace industry.”

Show cars and memorabilia

While best known as the developer of textile testing systems, Roaches has over the years also supplied advanced autoclaves to the UK’s composites industry, including a recent delivery to Northampton-based Memento Exclusives, a specialist in the production of show cars working directly with F1 and its leading teams.

Each major F1 team sponsor is supplied with one or two show cars for use at exhibitions and a wide range of other promotional activities arranged around the racing event calendar. These cars have no engine and their bodies may be made of fewer carbon fibre plies, but they are otherwise identical to the latest cars being raced by the F1 teams.

Memento Exclusives has its own in-house carbon fibre parts manufacturing facility and the integration of the Roaches autoclave has significantly expanded its capabilities in show car production.

Master bakers

“Composite materials undergo a metamorphosis in the autoclave which subjects them to both mechanical and chemical processes,” explains Richard Kirkbright. “Trapped air and volatiles are expelled and plies are consolidated under precise pressure. Heat cycles are then introduced, curing the resin systems and yielding flawlessly crafted components. Autoclave specialists are a little like master bakers, knowing exactly how to treat their ingredients at every stage of the process, to achieve the desired final product.”

“The Roaches autoclave now enables us to cure large components with full control and achieve a swift turnover of parts while ensuring the highest quality finish,” adds Terry Wasyliw, Head of Build for Memento Exclusives.

McLaren’s influence

Woking, UK-headquartered McLaren was the very first F1 team to introduce a car chassis manufactured entirely from carbon fibre composites back in 1981, setting the ball rolling for the creation of a completely new and global supply chain.

McLaren has this year unveiled a world-first in supercar engineering – aerospace-derived Automated Rapid Tape (ART) carbon fibre, developed at the dedicated McLaren Composites Technology Centre (MCTC) facility in Sheffield. This is being employed to create the active front wings of the W1 hypercar which has a starting price of $2.1 million.

A rear floor component was also developed for McLaren as part of the recently-completed £39.6 million ASCEND programme involving a range of UK partners, including BTMA member Cygnet Texkimp.

Handling, converting and decarbonisation

A wide range of handling and converting machines are supplied to the composites industry by Cygnet Texkimp, including bespoke creels, prepreg, coating, slitting and filament winding machines.

Its technologies are employed in the construction of composite components for aerospace and automotive, as well as in the production of tyre cord and more recently in the advanced construction of hydrogen storage vessels which are largely viewed as the future of F1 propulsion, along with advanced batteries for electric vehicles.

Cygnet Texkimp has been involved in the F1 supply chain for over 20 years and most carbon fibre used in the industry has been processed on one of its VHD creels. The company is also the largest independent manufacturer of prepreg machines in the world and is currently leading the design and build of the UK’s first carbon fibre research lines for a project led by NCC (National Composites Centre) to accelerate the development of more sustainable carbon fibres.

In addition, Cygnet is licensed to design and build the DEECOM composite recycling system developed by new BTMA member Longworth Sustainable Recycling Technologies, the first of which was recently commissioned by the Henry Royce Institute in Manchester. DEECOM is a zero emission, low-carbon pressolysis solution using pressure and steam to reclaim pristine condition fibres and resin polymers from production waste and end of life composites.

“Decarbonisation is a major priority for manufacturers globally,” says Cygnet CEO Luke Vardy. “At Cygnet Texkimp, we’re developing the capability to process technical fibres in ways that enable lightweighting, hydrogen power and electrification, reduce waste and revolutionise the end-of-life management of composite materials and parts. In collaboration with our industry partners, we’re bringing to market some of the most innovative new fibre processing technologies ever developed to deliver real-world benefits that support the sustainability agenda.”

Prepregging

Another new BTMA member, Emerson & Renwick (E+R), a specialist in print, forming, vacuum and coating technologies, also supplies technology for the production of carbon fibre prepregs, which are integrated rolls of fabrics and resins.

Its most recent 1.7-metre-wide line supplied to a customer in Italy operates at speeds of 40+ metres per minute for web coatings or prepreg fibre and resin consolidation, or a combination of both processes. It is distinguished by an ultra precise three-roll reverse roll coater for the processing of high-viscosity thermo-activated resins and enables the automatic changeover of sensitive woven fabric materials at zero tension, with three high precision calendaring nips with hot/cool plates. Multiple unwind and rewind systems for intermediate lamination steps include side loading and reliable lap splicing and zero speed splicing with a web accumulator for the main product rewind.

E+R has also been part of a consortium working on the development of lithium-sulphur (Li-S) batteries within the £540 million UK Faraday Battery Challenge. Once commercially viable, Li-S batteries promise to provide relatively high energy density at low cost for sustainable electric vehicles of the future – inevitably starting with F1.

Strong links

“In addition to our powerful base of textile testing and control companies, many other BTMA members are working on further F1 and advanced composite projects,” says Jason Kent in conclusion. “We are also forging strong links with the UK’s key research hubs such as Sheffield University’s Advanced Manufacturing Research Centre, the Northwest Composites Centre in Manchester, the National Centre for Motorsport Engineering in Bolton and the National Composites Centre in Bristol.

“The BTMA recently became an associate member of Composites UK too, because this sector is the crucible of innovation for tomorrow’s textiles.”

0 notes

Text

Mirror Stainless Steel Sheet Stock

Product Description:

SD-steel's Mirror Stainless Steel Sheets are designed to offer a sleek, reflective surface that is both aesthetically pleasing and highly functional. These sheets are ideal for applications requiring a high level of corrosion resistance and durability. The mirror finish provides an elegant look while maintaining the strength and reliability expected from stainless steel.

Material:

Our Mirror Stainless Steel Sheets are made from high-quality 304 grade stainless steel, known for its excellent resistance to rust and staining. This material ensures longevity and minimal maintenance, making it a popular choice for various industries including architecture, automotive, and manufacturing. The 304 grade stainless steel is non-magnetic and offers superior resistance to atmospheric corrosion, making them suitable for both indoor and outdoor use.

Specifications:

| Specification | Details |

|---------------|---------|

| Material | 304 Grade Stainless Steel |

| Thickness | 0.5mm - 6mm |

| Width | 1219mm (48 inches) |

| Length | Customizable up to 3048mm (120 inches) |

| Surface Finish| Mirror finish |

| Edge | Square or Slit Edge |

Dimensions:

Thickness: 0.5mm - 6mm

Width: 1219mm (48 inches)

Length: Customizable up to 3048mm (120 inches) |

| Thickness | 0.5mm - 6mm |

| Width | 1219mm (48 inches) |

| Length | Customizable up to 3048mm (120 inches) |

| Tolerance | ±0.05mm |

| Weight | Varies based on thickness and dimensions |

|

Usage Scenarios:

These sheets are widely used in architectural cladding, kitchen equipment, appliances, and decorative panels. They are also commonly used in the production of kitchen sinks, backsplashes, and other decorative applications where a polished finish is required. |

Company Strengths:

SD-steel boasts over two decades of experience in the steel industry. Our state-of-the-art facilities ensure precision and quality, with each sheet meticulously crafted to meet customer specifications. We pride ourselves on our commitment to quality and customization, ensuring that every order meets the highest standards of quality and performance. SD-steel’s extensive inventory allows us to cater to a wide range of applications, from interior design elements to industrial machinery components. Whether you need sheets for commercial kitchens, elevator interiors, or even automotive parts, our products are tailored to meet your specific needs. With a team of experienced engineers and a robust supply chain, we can provide custom sizes and finishes to suit diverse requirements. Our advanced processing capabilities allow us to deliver precise cuts and finishes, ensuring consistent quality across all products. Our commitment to excellence means you get the exact dimensions you need, backed by rigorous quality control processes.

Common Applications:

- Architectural Cladding

- Kitchen Equipment

- Elevator Interiors

- Automotive Parts

Company Strengths:

With a global network of suppliers and distributors, we maintain a steady supply chain ensuring timely delivery worldwide. Our dedicated customer service team is available to assist with any inquiries and special requests.

Frequently Asked Questions:

1. Q: What makes SD-steel's Mirror Stainless Steel Sheets stand out?

A: Our sheets undergo stringent quality checks at every stage of production. Each sheet is rigorously tested to ensure they meet international standards.

Contact Us:

For more information or to place an order, please contact us at +65 83016969. Our team is committed to providing top-notch products with unmatched precision and reliability.

Why Choose SD-steel?

Quality Assurance: Every sheet undergoes rigorous testing.

Customization: We offer customized solutions tailored to your project requirements.

FAQs:

Q: Can I request custom dimensions?

A: Absolutely! We specialize in custom orders.

Q: How do I place an order?

A: Reach out to us at +65 83016969 for any inquiries or custom orders.

Conclusion:

Whether you're looking for standard or custom sizes, SD-steel guarantees prompt delivery and exceptional customer service. For further details, feel free to reach out via +65 83016969 for any specialized requirements.

Contact Information:

For inquiries, call +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us directly at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83016969 for any specialized requirements.

Contact Information:

For more details, contact us at +65 83

加飞机@yuantou2048

Stainless Steel Channel Bar

Stainless Steel suppliers

0 notes

Text

Shear Type Air Cutter Slitting Machine

1. The electronic control adopts centralized control, which is easy to operate and aesthetically pleasing

2. Adopting Shenzhen Yuanxin brand frequency converter control system, stable and reliable

3. Brushless automatic correction basket material placement, convenient and easy to operate for material placement

4. Automatic edge suction control system

5. The automatic spreading roller unfolds the folded fabric

6. Double drum tension winding

7. Bilateral waste collection device

8. The mechanical structure is strong, with high stability for high-speed operations, effectively improving the durability and service life of the machinery

Five: Operation precautions

1, before starting, ensure that the voltage, current and pressure equivalent is correct and stable.

2. Before the equipment is ready for operation, all personnel must inform to leave the equipment to ensure personal safety before starting operation.

3, When the scuttering machine is running, do not touch the film roll or rubber roll in operation with your hand, so as not to involve your hand and cause personal injury. (No cotton gloves)

4, when the machine equipment is running, it is strictly prohibited to touch the gear chain and other transmission parts with hands, clothing cuffs, so as to avoid injury accidents. (No cotton gloves)

5, in the operation process, do not use a knife or hard object to scratch, cut each roll core.

6, regular maintenance of the machine and equipment, and check whether the functions are normal.

7, the occurrence of machine equipment failure, should promptly notify professional maintenance personnel, private maintenance is strictly prohibited.

8, Press the power switch or emergency stop switch when the equipment is in an emergency state or an accident is considered

9, The mechanical transmission parts should be regularly lubricated to keep the mechanical transmission parts clean.

Phone:+86-137 7683 7743 Email:[email protected]

0 notes

Text

How I Discovered the Best Slit Coils in Karnataka — A Journey with Hariom Pipes

The Search Begins

It all started with a challenge. As a procurement manager for a mid-sized manufacturing company in Karnataka, I was tasked with finding a reliable supplier for high-quality slit coils. Our production deadlines were tight, and the last batch we sourced had caused serious delays due to inconsistent sizing and poor finish.

I needed a supplier who offered precision, durability, and consistency and that’s when I stumbled upon a name I hadn’t paid much attention to before: Hariom Pipes.

Understanding the Need for Quality Slit Coils

For those unfamiliar, slit coils are wide metal coils slit into narrower widths, widely used in the automotive, construction, and fabrication industries. Poor-quality slit coils can result in material wastage, equipment wear, and even production shutdowns.

In Karnataka, especially with the growing infrastructure and industrial sectors, the demand for top-quality slit coils has skyrocketed. But quality matters more than ever.

The Discovery of Hariom Pipes

I first heard about Hariom Pipes during a vendor meeting in Bengaluru. A colleague mentioned how they had recently upgraded their supply chain by switching to Hariom. Curious, I decided to visit their manufacturing unit.

To my surprise, Hariom Pipes wasn’t just a pipe manufacturing company. Their setup for producing slit coils was impressive — modern machinery, strict quality control, and a dedicated team with decades of experience in metal processing.

Why Hariom Pipes Stands Out?

Here’s what stood out during my research and visit:

Precision Engineering: Their slit coils had clean, uniform edges with minimal burrs essential for our cutting and bending machines.

Custom Sizing: They offered flexible sizing based on our specific requirements, a feature many suppliers couldn’t match.

Consistency: Every batch was uniform no more surprises when opening a new coil.

Timely Delivery: With their strong logistics in Karnataka, deliveries arrived right on schedule.

Customer Support: A responsive team that actually understands the technical requirements of their clients.

Results That Spoke Volumes

After switching to Hariom Pipes, we noticed immediate improvements:

Reduction in wastage by 25%

Faster machine throughput

Zero rejections due to coil quality

Improved trust from our end clients

Over the next few months, Hariom Pipes became our go-to supplier not just for slit coils, but eventually for other metal components as well.

A Trusted Name in Karnataka

If you’re in the market for the best slit coils in Karnataka, don’t make the mistake of going with just any vendor. Do what I did visit, talk, and inspect the product yourself. I can confidently say that Hariom Pipes is a name you can trust.

Their commitment to quality, precision, and customer satisfaction makes them one of the leading slit coil suppliers in Karnataka today.

0 notes

Text

Top Quality Brass Coils Manufacturers in India

A Closer Look at KWM India

India’s brass manufacturing industry is globally renowned for its precision, durability, and high production standards. Among the many products in this segment, brass coils manufacturers play a vital role in various industries such as electrical, automotive, construction, marine, and industrial machinery. Known for their flexibility, corrosion resistance, and superior conductivity, brass coils are an essential component in modern engineering and manufacturing processes. One name that stands out among the top manufacturers of brass coils in India is KWM India—a brand synonymous with trust, innovation, and premium quality.

Why Brass Coils Are in Demand

Brass coils are manufactured by rolling brass sheets into tightly wound cylindrical shapes, allowing easy transportation, storage, and processing. These coils are widely used due to their:

Excellent formability and ductility

High resistance to corrosion and wear

Good thermal and electrical conductivity

Aesthetic golden appearance

Versatility across industries

Whether used in electrical terminals, heat exchangers, precision instruments, or decorative fixtures, the quality of the coil directly impacts the efficiency and longevity of the final product.

KWM India: Leading the Brass Coil Revolution

KWM India has emerged as a top-tier manufacturer of brass coils in India, driven by a passion for excellence and a customer-centric approach. With years of experience and a robust infrastructure, the company has positioned itself as a reliable supplier to both domestic and global clients.

Advanced Manufacturing Facilities

KWM India boasts a state-of-the-art manufacturing facility equipped with modern machinery and cutting-edge technology. From cold rolling mills to precision slitting and annealing lines, the company ensures consistent production quality and accuracy in coil dimensions. This precision is critical for applications that demand tight tolerances and uniform surface finishes.

Quality Control That Exceeds Expectations

What truly sets KWM India apart is its unwavering focus on quality assurance. Each brass coil undergoes a rigorous multi-stage quality check process that includes testing for:

Dimensional accuracy

Surface finish

Mechanical properties

Chemical composition

Thickness and width consistency

KWM India follows international standards like ASTM, JIS, and IS to cater to diverse industry requirements and ensure customer satisfaction at every level.

Customization and Flexibility

KWM India understands that no two clients have the same needs. That’s why the company offers complete customization in terms of:

Coil width and thickness

Temper (soft, half-hard, hard)

Finish (bright, matte, mirror-polished)

Packaging and coil sizes

This flexibility allows KWM India to serve a wide array of industries—whether it's a high-volume industrial project or a specialized custom order.

Sustainable and Responsible Manufacturing

In a world increasingly focused on sustainability, KWM India has taken proactive steps to reduce its environmental footprint. The company integrates eco-friendly practices into its operations, such as:

Recycling and reuse of metal scrap

Efficient energy consumption systems

Environmentally safe waste disposal

By following green manufacturing principles, KWM not only supports the environment but also aligns with the global shift towards responsible industrial practices.

Strong Market Presence

KWM India’s strong distribution network ensures timely delivery across India and overseas. Its reputation for consistent quality and prompt service has helped it build long-term relationships with clients in countries such as the UAE, Germany, the UK, and the United States. This global outreach further strengthens its credibility as a premier brass coil manufacturer.

Final Thoughts

In a highly competitive market, finding a manufacturer that offers both premium quality and reliable service is crucial. KWM India ticks all the boxes with its superior product range, modern infrastructure, and commitment to excellence. Whether you're sourcing brass coils for industrial manufacturing, engineering applications, or decorative purposes, KWM India stands out as a trusted partner for quality, customization, and value.

Visit:- https://www.kmwindia.com/brass-coils.html

0 notes

Text

Flexure Print N Pack to commission new blown film extrusion line in 2024-25

Ahmedabad-based flexible packaging converter Flexure Print N Pack is set to expand its capabilities with significant new investments. The company plans to commission a multilayer blown film extrusion line within the financial year 2024-25, aiming to strengthen its vertical integration. Flexure Print N Pack is also gearing up to install converting machinery for both monolayer and multilayer packaging in the next few months, according to Jainam Shah, managing partner at Flexure Print N Pack.

“We are also exploring collaborations with industry suppliers to add value to our wide-web flexographic printed products through offline processes,” Shah said in an exclusive interview with Packaging South Asia.

Current capabilities and machinery

Flexure at present operates four flexographic printing presses, including one central impression press and three stack-type configured presses. The facility is equipped with an advanced photopolymer plate mounting machine along with anilox sleeves and photopolymer plate cleaning machines to ensure quality and durability. In the lamination department, the company utilizes both solvent-free and solvent-based lamination machines.

The slitting department boasts drum-type and cantilever differential slitting machines. For conversion, Flexure Print N Pack runs a variety of machines, including bottom seal bag-making machines, side seal bag-making machines, slit-seal plus gusset machines, and multiple pouch-making machines.

A milestone year in 2024

Reflecting on 2024, Shah described the year as "busy, challenging, and eventful," marked by significant achievements. Flexure Print N Pack reached a notable milestone by successfully printing 208 LPI print resolution jobs on its flexographic press. The company also conducted trials with hybrid screening, water-based inks, and extended color gamut, which are set to transition into full-scale production in the coming months.

Established in 2001, the Asian Packaging Excellence Awards recognize outstanding achievements, innovation, and contributions to packaging production across the Asia region, celebrating the pinnacle of excellence in the Asian packaging industry.

“These awards underscore our commitment to excellence in packaging production,” Shah said.

Production capacity and solutions

Flexure Print N Pack currently converts between 175 and 200 metric tonnes of material per month. The company’s product portfolio spans a range of exclusive flexographic-printed solutions, including LDPE, CPP, TQPP, BOPP, PET, coated paper, and compostable films as substrates. These materials are supplied in monolayer and multilayer roll forms, as well as in converted pouch formats.

Flexure Print N Pack specializes in manufacturing a variety of packaging solutions, including bakery bags, shopping bags, hygiene application pouches, vacuum pouches, zipper pouches, quad seal pouches, and stand-up pouches, among others.

A vision for the future

With its new investments and a focus on innovation, Flexure Print N Pack is poised to strengthen its position in the flexible packaging industry, Shah said. The addition of the blown film line and enhanced converting capabilities will enable the company to meet evolving market demands and reinforce its reputation for quality and innovation.

0 notes

Text

Krishna Engineering Works has a solution that best fits your manufacturing unit or enterprise. Know more about its latest machines from Krishna Engineering Works. Upgrade your paper-making productivity and establish your company as an industry leader in the long term.

heavy duty type slitter drum rewinder machine can process all kinds of paper of any GSM thickness. In our heavy duty series paper slitting rewinding machine, the rewinding diameter can be achieved up to 1200mm.

#krishnaengineeringworks#machine#manufacturer#machinery#industry#export#supplier#industrial#machinemanufacturer#slitterrewindermachine#heavydutyslitterrewindermachine#slittingrewindingmachine#paperindustry#papermachinery

1 note

·

View note

Text

How to Maximize Slitter Blade Sharpness for Superior Cutting Performance

Summary

Maintaining the sharpness of a slitter blade is essential for achieving precise cuts, minimizing downtime, and improving operational efficiency. This article explores why sharpness retention matters, factors affecting blade longevity, advanced techniques for durability, and best practices for maintenance, ensuring your cutting tools perform at their best.

Introduction

In industrial applications, precision cutting is the cornerstone of efficiency and quality. The slitter blade, a critical component in industries like paper, metal, and plastic processing, must remain sharp to perform effectively. Dull blades lead to uneven cuts, wasted material, and costly downtime. This article delves into the technologies and strategies to retain the sharpness of slitting tools, helping you optimize performance and reduce costs.

By understanding the factors influencing blade sharpness and adopting advanced techniques, you can ensure your operations run smoothly. Let’s explore how you can keep your slitter blades sharp and effective for longer periods.

Why Sharpness Retention Matters for Slitter Blades

Sharpness plays a critical role in ensuring the efficiency and precision of industrial cutting processes. Whether you are cutting thin plastic films, thick metal sheets, or delicate paper rolls, maintaining a sharp edge on your slitter blade is essential. Let’s examine the specific impacts dull blades have on your operations:

1. Uneven Cuts

Dull blades fail to create clean, consistent edges, which can compromise the quality of the final product. For example, in the paper industry, jagged edges can lead to product rejection, affecting customer satisfaction and brand reputation. According to industry reports, manufacturers using dull blades experience up to 15% more defective products than those using well-maintained cutting tools.

2. Material Waste

Poor sharpness often results in inaccurate cuts, generating excess material waste. In industries handling expensive raw materials like aluminum or specialty polymers, this waste can represent significant financial losses. A study in a metal processing plant found that switching to precision-sharpened slitting knives reduced scrap rates by 25%, saving approximately $100,000 annually.

3. Increased Wear on Equipment

Using a dull blade requires more force to achieve the same cuts, which puts undue stress on machinery. Over time, this can lead to faster wear and tear on mechanical components, increasing maintenance costs and the risk of equipment failure. Preventive maintenance through blade sharpness retention can lower machine repair expenses by 20%.

4. Downtime for Maintenance

Frequent blade sharpening or replacement interrupts production schedules, resulting in costly downtime. In high-volume production environments, even an hour of unscheduled maintenance can translate into thousands of dollars in lost revenue. Maintaining sharper blades significantly extends service intervals, keeping your operations running smoothly.

The Competitive Edge

Maintaining sharp blades is more than just a technical necessity—it’s a strategic advantage. Companies that invest in blade sharpness retention report up to 30% better operational efficiency, giving them an edge in competitive markets.

Keep reading to explore the factors affecting sharpness and how to address them.