#Solid Block Making Machine Manufacturers

Explore tagged Tumblr posts

Text

Hollow Solid Block Making Machine – Trusted Solutions by Ultra Tile Machine

In the construction industry, the demand for reliable and cost-effective building materials has never been higher. With infrastructure projects on the rise, both hollow and solid blocks are rapidly replacing traditional bricks due to their structural advantages, durability, and cost efficiency. At the core of producing these essential materials lies the Hollow Solid Block Making Machine, a critical asset for modern builders and manufacturers.

When it comes to choosing a dependable manufacturer, Ultra Tile Machine stands tall as an industry leader. With years of expertise and a reputation for quality and innovation, Ultra Tile Machine is your go-to partner for high-performance block making solutions.

What Is a Hollow Solid Block Making Machine?

A Hollow Solid Block Making Machine is a versatile industrial machine used to manufacture both hollow and solid concrete blocks. These machines compact a mixture of cement, sand, and aggregates into pre-defined molds using hydraulic or mechanical pressure. The result is uniformly shaped, high-strength blocks suitable for various construction needs.

Hollow blocks are lighter and used for non-load bearing walls, while solid blocks are denser and used in load-bearing structures. A machine that can produce both types offers manufacturers maximum flexibility and better ROI.

Why Hollow and Solid Blocks Are Gaining Popularity

Construction professionals are shifting towards hollow and solid concrete blocks due to their numerous advantages over traditional bricks. Some of these include:

Better thermal insulation

Faster construction speed

High load-bearing capacity

Reduced dead load on structure

Eco-friendly materials

Lower water absorption

Uniform shape and size

This shift has directly increased the demand for machines that can produce these blocks efficiently.

Types of Hollow Solid Block Making Machines

Depending on the scale and automation needs of your business, Ultra Tile Machine offers a range of machines such as:

Manual Block Making Machines

Semi-Automatic Machines

Fully Automatic Machines

Hydraulic Press Block Machines

Vibration Cum Compression Machines

Each type caters to a different production requirement, ensuring that businesses of all sizes can find the right fit.

Advantages of Investing in a Hollow Solid Block Making Machine

High Productivity

These machines are designed to produce hundreds or even thousands of blocks in a single shift, drastically improving output.

Versatility

Manufacturers can produce a wide range of block types, including hollow blocks, solid blocks, interlocking blocks, and more using different molds.

Cost Efficiency

Modern machines reduce labor dependency and minimize raw material waste, increasing overall profitability.

Better Quality Control

Precision engineering ensures consistency in size, strength, and shape, which is vital for large-scale construction projects.

Environmentally Friendly

These machines support the use of fly ash, slag, and other industrial waste, contributing to sustainable construction practices.

Why Choose Ultra Tile Machine as Your Manufacturer?

Industry Experience

Ultra Tile Machine has built a legacy of trust and excellence in the block making machinery sector. With decades of experience, the company understands the pulse of the construction industry and delivers solutions tailored to real-world challenges.

Advanced Technology

All machines by Ultra Tile Machine are designed using the latest technology to ensure high output and consistent performance. Key features include:

High-pressure hydraulic systems

Heavy-duty steel construction

Advanced vibration technology

Precision molds

User-friendly controls

Long service life

These features enable operators to run production smoothly with minimal downtime.

Wide Product Range

Ultra Tile Machine offers a full suite of machinery for every scale of operation:

Manual Machines: Ideal for startups and small-scale units

Semi-Automatic Models: A perfect mix of manual and automatic features

Fully Automatic Machines: Best suited for large-scale continuous production

Hydraulic Block Machines: Ensures greater compression and block durability

Whether you’re a beginner or a seasoned industrialist, there's a machine that suits your business needs.

Customization Options

Ultra Tile Machine provides full flexibility in customizing:

Block size and mold design

Output capacity

Power source (electric or diesel)

Machine frame and configuration

Color and branding

Custom machines ensure that your production line aligns perfectly with market demand and your brand identity.

Quality Assurance

Ultra Tile Machine places strong emphasis on quality at every stage of manufacturing. Every machine undergoes rigorous quality checks to ensure:

Flawless operation

Durability and reliability

Resistance to wear and tear

Energy efficiency

Customers receive machines that perform consistently for years with low maintenance requirements.

Competitive Pricing

Despite offering premium features, Ultra Tile Machine maintains highly competitive prices. Their goal is to make quality machinery accessible to everyone, from small business owners to industrial giants. Transparent pricing, zero hidden costs, and a strong return on investment make them a clear choice.

Strong After-Sales Support

What truly sets Ultra Tile Machine apart is their dedication to customer satisfaction beyond the sale. They offer:

Installation and commissioning support

Operational training for staff

Routine maintenance and inspection services

Readily available spare parts

Prompt technical assistance

This helps ensure that your production stays uninterrupted and efficient.

Nationwide and Global Reach

Ultra Tile Machine serves clients across India and exports machinery to several countries. Their machines are built with global standards in mind and come with all necessary documentation, training materials, and remote support for overseas clients.

Positive Customer Testimonials

“Ultra Tile Machine gave us a powerful machine that revolutionized our block manufacturing process. Their service team was quick, professional, and helpful.” – Arjun, Hyderabad

“We use their hydraulic solid block machine, and the output is simply unmatched. Highly recommended!” – Neha, Pune

Feedback like this showcases the strong reputation Ultra Tile Machine enjoys in the industry.

How to Choose the Right Machine for Your Needs?

Before you invest in a Hollow Solid Block Making Machine, consider the following:

Production Volume: Assess how many blocks you need to produce per day

Automation Level: Go with automatic models for higher speed and lower labor costs

Block Types: Choose a model compatible with the kinds of blocks you plan to manufacture

Available Space: Some machines require more floor space for installation and raw material handling

Budget: Ultra Tile Machine offers machines in a variety of price brackets to fit your investment range

Applications of Hollow and Solid Blocks

Hollow and solid blocks produced by these machines are used in:

Residential and commercial buildings

Roadside pavements

Compound walls and fences

Industrial structures

Warehouses and godowns

Load-bearing and non-load-bearing walls

Their strength, cost-efficiency, and long lifespan make them a preferred material in construction across the globe.

Focus on Sustainability

Ultra Tile Machine is committed to promoting eco-conscious practices. Their machines support:

The use of fly ash, slag, and other industrial byproducts

Reduced water usage in block curing

Low energy consumption

Long-term recyclability of produced blocks

This not only aligns with green building standards but also appeals to environmentally responsible contractors and builders.

Conclusion

In the ever-evolving world of construction, the need for reliable, durable, and high-quality blocks is more important than ever. Investing in a Hollow Solid Block Making Machine is a strategic move that can transform your business by increasing efficiency, reducing production costs, and meeting the growing demand for sustainable construction materials.

Ultra Tile Machine, as a trusted manufacturer, offers unmatched expertise, top-tier machinery, and unwavering customer support. Whether you’re starting a new venture or expanding an existing one, Ultra Tile Machine provides everything you need to succeed in the block manufacturing industry.

#Paver Block Making Machine Manufacturer#Hollow Solid Block Making Machine#Fly Ash Brick Making Machine#Concrete Block and Brick Making Machine#Chemical Hardener Manufacturers#Interlocking Paver Block Making Machine#Automatic Brick Making Machine Manufacturer

0 notes

Note

can you do reading abt smnbg. sm already promoting these trainees likee crazy and their popularity in china already surpassed riize and nct wish so i wanna what the future holds for them bc for the first time in a while sm putting smmm effort in promoting someone

“SME Trainee Boy Group: Sparkling Stardom or Strategic Distraction?”

The ✨vibe✨ of their future post-debut:

strength + the moon + death

this group has grit. They’re resilient, even with all the illusions and confusion around them. There’s transformation energy here a total shedding of whatever “ideal” image they might have.

They’re being built to break molds, not follow them.

BUT the moon + magician reversed screams: not everything is what it seems.

Think: industry games, some smoke, some mirrors, and maybe a bit of PR manipulation.

Will SM protect & promote them properly?

honestly... it’s giving half-assed commitment with flashy packaging.

Temperance reversed + six of pentacles reversed + judgment reversed

SM’s approach might be unbalanced they’ll definitely push this group hard publicly, but the support behind the scenes? not as solid.

There’s a chance of burnout, overworking, or favoritism creeping in.

Plus, four of cups + eight of swords says this group may feel emotionally stuck at times almost like they’re being used more as a brand or product than nurtured as artists.

The “why now?” energy:

three of cups reversed + tower reversed + high priestess

SM’s cooking up this debut not just to cash in on popularity, but to quietly bury scandalous headlines.

It’s VERY "look at the shiny new thing!" energy, while the legal fires burn behind the curtains.

High Priestess + magician reversed is big on illusion, control, and calculated silence classic misdirection move.

Will the public fall for it?

Initially? yes. long-term? depends.

ace of pentacles + seven of cups + page of swords

They’ll have a strong debut, a ton of options, and curiosity will work in their favor think: virality, CFs, sold-out albums.

But people will start asking questions. The group might become a symbol of “manufactured success,” even if the members themselves are talented and hardworking.

Internal dynamics / risks for the group?

Queen of wands reversed + king of wands reversed + six of wands reversed

Whew. Watch for power struggles and possible ego clashes or worse, them being pitted against each other for attention or roles.

Success might not feel earned to them, or worse, they might not get the success their hype promised.

And ace of wands reversed = blocked creative expression.

Translation: SM might not give them room to experiment or find their own artistic identity.

Final vibe check:

seven of pentacles + king of pentacles + strength

This group has potential. The talent is not the issue.

But it’s going to be a slow burn to real legacy status, not an overnight legend story.

They’re a calculated project, yes. But if they play the long game, protect their mental health, and find their voice beyond the company machine?

They could absolutely make their mark even outshine the intention behind their creation.

Overview:

SM is pushing them HARD, maybe as a PR distraction.

There’s real talent here, but also a risk of being over-controlled or used as a smoke screen.

Public reception = strong at first, but sustainability depends on how real they’re allowed to be.

Behind the scenes? Messy, political, possibly toxic.

They deserve better than the game they’re being thrown into.

Tag yourself: are you the high priestess catching the lies, or the tower waiting to explode?

#tarot & tea#dreamweavers#kpop#tarot reading#kpop tarot#tarot#dreamweaverz#tarot cards#sm#smtown#rookie boys

2 notes

·

View notes

Text

Top Tips for Fast and Safe Panel Assembly

Panel assembly is a critical process in the electrical industry that directly impacts safety, performance, and efficiency. Whether you’re building distribution panels, control boards, or switchgear systems, the goal is to assemble panels quickly without compromising safety or quality. In this post, we’ll explore proven tips to help electricians, technicians, and panel builders streamline their workflow while ensuring compliance with safety standards.

1. Plan Thoroughly Before Assembly

Efficiency starts with preparation. Before you begin, study the layout drawings and electrical schematics carefully. Make a checklist of all the required components — circuit breakers, relays, terminal blocks, wire ducts, and enclosures.

· Pre-arrange tools and materials

· Verify component compatibility with design

· Identify high-priority tasks and dependencies

A well-organized plan saves time and avoids costly errors during installation.

2. Use Modular and Pre-Fabricated Components

Using modular devices like DIN-rail mountable circuit breakers or pre-assembled terminal blocks can reduce build time significantly.

Benefits:

· Faster mounting and wiring

· Easier upgrades and replacements

· Reduced wiring complexity

Where possible, opt for plug-and-play components or pre-terminated wiring kits.

3. Maintain a Clean and Organized Work Area

A tidy workstation boosts productivity and prevents mistakes. Use labeled bins, trays, and tool organizers to keep everything accessible.

· Segregate power, control, and signal cables

· Keep fasteners and tools sorted by size/type

· Remove scrap materials and wire offcuts regularly

A clean work area also improves safety and reduces trip hazards.

4. Label Components and Wiring Clearly

Proper labeling speeds up installation and future maintenance. Use heat-resistant wire markers or automated labeling machines for consistency.

Label:

· All wires at both ends

· Control devices (relays, contactors, timers)

· Terminal blocks and busbars

Clear identification is essential for testing, fault isolation, and panel certification.

5. Use the Right Torque Tools

Over- or under-tightened terminals can cause failures or fire risks. Always use torque screwdrivers or wrenches calibrated to the manufacturer’s specifications.

· Ensure solid mechanical and electrical contact

· Reduce the risk of arcing or overheating

· Document torque settings for quality records

Following torque guidelines is a best practice for long-term reliability.

6. Apply Effective Cable Management

Good cable routing isn’t just about aesthetics — it enhances performance and safety.

· Use wire ducts, cable ties, and strain reliefs

· Maintain minimum bend radii, especially for data cables

· Separate AC power and control wiring to avoid interference

Neatly routed cables simplify inspections and future modifications.

7. Conduct Final Visual and Electrical Inspection

Before energizing the panel:

· Inspect all terminations and mounting

· Check for exposed conductors or loose parts

· Test insulation resistance and continuity

· Verify grounding and bonding paths

A comprehensive inspection reduces commissioning delays and ensures compliance with safety standards.

8. Document As-Built Changes

If any field modifications were made during assembly, update the panel drawings and documentation to reflect those changes.

Include:

· Wiring diagrams

· Component serial numbers

· Torque test records

· Electrical test results

Accurate documentation is essential for maintenance, certification, and future upgrades.

9. Train Your Assembly Team

Skilled workers build faster and safer panels. Provide regular training on:

· Electrical safety and lockout/tagout

· Schematic interpretation

· Safe use of hand and power tools

· Latest panel-building standards (e.g., IEC, UL, NEC)

An informed and competent team minimizes rework and enhances build quality.

Final Thoughts

Fast panel assembly doesn’t mean cutting corners. By following structured processes, using the right tools, and prioritizing safety, you can consistently deliver high-quality panels — on time and within budget.

Looking for top-tier switchgear accessories and panel-building solutions? Contact us today to explore how we can support your projects with reliable, efficient, and cost-effective products.

5 notes

·

View notes

Text

Hi, before I explain my post, I want to say something important.

• What you see my blog has become a major overhaul. And despite the changes, I decided that my 2nd account will be now my artwork blog with a secret twist.

⚠️NEW RULE! (W/ BIGGER TEXT!)⚠️

⚠️ SO PLEASE DO NOT SHARE MY 2nd ACCOUNT TO EVERYONE! THIS SECRECY BLOG OF MINE IS FOR CLOSES FRIENDS ONLY!⚠️

• AND FOR MY CLOSES FRIENDS, DON’T REBLOG IT. INSTEAD, JUST COPY MY LINK AND PASTE IT ON YOUR TUMBLR POST! JUST BE SURE THE IMAGE WILL BE REMOVED AND THE ONLY LEFT WAS THE TEXT.

⚠️ SHARING LINKS, LIKE POSTS, REBLOG POSTS, STEALING MY SNAPSHOT PHOTOS/RECORDED VIDEOS/ARTWORKS (a.k.a. ART THIEVES) OR PLAGIARIZING FROM UNKNOWN TUMBLR STRANGERS WILL IMMEDIATELY BE BLOCKED, RIGHT AWAY!⚠️

😡 WHATEVER YOU DO, DO NOT EVER LIKED & REBLOG MY SECRET POST! THIS IS FOR MY SECRET FRIENDS ONLY, NOT YOU! 😡

Okay? Capiche? Make sense? Good, now back to the post…↓

#OnThisDay: Jun 9th, 2019

Title: Cuteness Member - Sammir

I missed his old version of Sammir 🥰💙💛🐻🌩️🤗, even in 5 years throughout our friendship between myself and G-Pal, rafacaz4lisam2k4. 🇵🇭🤝🇬🇹🥰🤗 That's why, I'm posting today's throwback from 2019's Sammir debut in the "Cuteness Defender Academy". 🤖😁

• In his old day, Sammir the bear with a "thunderbolt" ⚡ (or I should say "Wonderbolt" I should say derived from MLP) image from his outfits seems I found a perfect armor suit for him; speed, quick maneuver and quickly dodge any on coming fire range obstacles. And thus the armor "Zudah" 🤖 was here from the Zeon manufactures yours truly, with a tall shaped fin on his front helmet makes him a lead of the "HTF Wonderbolt Team" 🐻⚡.

Nowadays, his entire personality was changed, since June of 2023. You've already saw his new color uniform, and someday I'll update his "Cuteness Mecha Armor" colors, too. 😊

Zudah Sammir Based on: EMS-10 Zudah [CLICK ME!]

Armament(s):

M-120A1 120mm Zaku Machine Gun • This is the same machine gun model used by the MS-06 Zaku series. It is a shell firing gun that does not require energy to be used, however its effectiveness against heavy armor is very limited. It holds 100 rounds per drum with spare drums that can be stored on Zudah's waist armor racks, while the gun can be stored on Zudah's calf-mounted hard points when not in use.

H&L-SB25K/280mmA-P Zaku Bazooka • The 280mm Zaku Bazooka was another standard weapon that could be equipped to a Zaku-type armor suit. The bazooka fired explosive rounds that were quite effective against the armor of enemy suit(s) and battleships.

135mm Anti-Ship Rifle • Developed in the early phase of One Year War, the long-barreled 135mm anti-ship rifle is used by various models of Zeon armored suits for long-range sniping attack against opponent's warships.

Heat Hawk Type 3 • The Heat Hawk Type 3 is an axe-like weapon used by the original MS-06 Zaku II, whose name is short for "tomahawk". Thermal energy is relayed through the armor suit's hand to heat the heat hawk's blade, allowing it to slice through the armor of enemy warships or armor suits. The Heat Hawk can be stored on Zudah's calf-mounted hard points when not in use.

Shield • Attached to Zudah's left shoulder, it is capable of limited movement and can store two Sturm Fausts, a Flare Launcher, and a pair of foldable spikes for close-quarter combats.

Sturm Faust • A simplified, disposable rocket launcher. As the warhead is not equipped with a guidance device, it is extremely hard to use the Sturm Faust to hit a moving target accurately. However, it is still a highly destructive portable weapon.

Spikes • Fixed to the front of the shield, these two long spikes swing forward for use in high-speed charging attacks.

Flare Launcher • Zudah's shield can be equipped with a Flare Launcher near the inside tip of the shield. Solid rounds of pyrotechnic rockets can be fired from the Flare Launcher for signalling friendly forces nearby.

Big Gun • A armor suit-use sniping turret, it is equipped with a powerful, long-range beam cannon.

Sammir (HTF OC) - owned by rafacaz4lisam2k4 Armor (Mobile Suit Gundam MS IGLOO) - Gundam series © Bandai Namco Filmworks, Inc. (SUNRISE), Sotsu

2 notes

·

View notes

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Text

Concrete Blocks - Manufacturing, Classification & Uses

Concrete blocks are nowadays replacing bricks in masonry construction, notably in many multi-storeyed buildings. They are available in three types namely solid, hollow and cellular, widely used for the construction of filler walls and boundary walls in RC framework.

Concrete blocks are usually made in large sizes to make blockwork faster and consume less cement in joints than the brickwork. If the percentage of the voids is more than 25%, then they are hollow blocks and blocks with voids less than 25% are only perforated blocks.

The cellular concrete blocks are generally referred to as lightweight aerated concrete blocks. All these blocks are extensively used for compound walls and non-loadbearing walls.

Hollow blocks are specially made for loadbearing walls, which are useful in reducing a dead load of masonry in buildings. Blocks can also be with cement and sand called cement-sand blocks or with cement and soil called soil-cement blocks which are of low strength and use for low-cost construction.

Manufacturing of Concrete Blocks

BIS recommends a fineness modulus of the combined aggregate between 3.6 to 4 and coarse aggregates used are of size 6 to 12 mm. Lean mixes up to 1:8 are generally used. Concrete mix for concrete blocks should not be richer than one part of the cement to six parts of the volume of combined aggregate.

Concrete blocks can be handmade and also machine-made. The cast block is then cured in a water tank or yard for at least 14 days (water need to be changed at least every 4 days).

After curing, the blocks are dried for 4 weeks before being used in masonry construction. They should be stacked with voids in the horizontal direction to facilitate easy drying, or they should be steam cured and dried.

The whole process allows the complete shrinkage of the block to take place they are laid on the wall, which is very important for strong walls.

Classification of Concrete Blocks

Hollow concrete blocks

Open and Closed cavity-type hollow concrete blocks are classified into three grades:

Grade A - They possess a minimum density of 1500 kg/m³ and are used for load-bearing walls.

Grade B - They have a density below 1500 kg/m¬³ and used for load-bearing walls.

Grade C - These blocks are used for non-load bearing walls and have density more than 1000 kg/m³.

All these blocks are available in decorative facings like fluted facing to provide artistic effects.

Solid concrete blocks

They should be manufactured for specific concrete strength of 4.0 and 5.0 N/mm² in 28 days. These blocks are used as load-bearing walls and have a density of not less than 1800 kg/m³.

Paver blocks

These blocks are solid concrete blocks of different shapes specially made for exterior ground paving on sidewalks, parking lots, driveways, petrol pumps, industrial floors, etc.

AAC Blocks

AAC blocks refer as Autoclaved Aerated Concrete Blocks. These blocks are also termed as light-weight hollow blocks.

They are prepared as solid blocks from cement, water and materials like ground sand, pulverized fly ash together with additives to aerate and stabilize the air bubbles.

The final result is a mixture of thick liquid which is then poured into steel moulds to form large cakes. After some time, the mixture sets and ready to cut into a serious of individual blocks of required size using taut steel wires.

Very light blocks for partition and moderate-weight blocks for light loadbearing walls can be obtained from aac blocks. These blocks do not shrink on drying as the material is obtained by autoclaving.

The autoclaved cement product is crystalline, which is different from the product obtained by normal wet curing or by ordinary steam curing.

Sizes and Tolerances

The nominal dimensions of concrete block as per BIS are as follows:

Length - 600, 500, 450 or 400 mm

Height - 100 or 200 mm

Width - 50, 75, 100, 150, 200, 250 or 300 mm

Actual sizes will be less than 10 mm of mortar thickness. For Concrete and Hollow concrete blocks nominal length 390 mm and height 190 mm. The thickness for loadbearing walls is 190 mm, compound walls 140 mm and for filler walls 90 mm.

These dimensions can easily be achieved in machine-made blocks than handmade blocks. The width of blocks use for load-bearing walls is 200 mm and for parapet or filler walls is 100 mm.

Points to Remember:

The mortar strength should not be more than the strength of the blocks. With high mortar strength, cracks will be less and very large, but with low mortar strength, cracks will be small and distributed.

We should use only blocks that are cured properly for at least 14 days and dried for 4 weeks to avoid shrinkage during construction.

We should not wet the blocks while placing in masonry construction.

Freshly-made and uncured concrete blocks should never be allowed on the work.

Blockwork, particularly ordinary cement sand blocks and soil-cement blocks should not be used as loadbearing walls for concrete slab roof which favours to expand and contract with temperature.

The maximum difference in sizes allowed is ±5 mm in length and ±3 mm in height and width.

They should be protected from rains while being stored as they absorb moisture by wetting and shrinking on drying.

The main disadvantage of concrete blocks is shrinkage due to the movement of moisture content which is not present in bricks. As these blocks are much larger than bricks, any foundation movement will cause blockwork to crack more than the brickwork.

Cement blocks, Concrete blocks, Hollow concrete blocks, solid concrete blocks, Paver blocks, AAC blocks Concrete blocks in Hyderabad

#aac Blocks#aac blocks online#aac block size#Cement blocks#Concrete blocks#Hollow concrete blocks#solid concrete blocks#Paver blocks#AAC blocks

2 notes

·

View notes

Text

How Does a Concrete Pan Mixer Work and Why Should You Use One

Let’s be honest—concrete mixing isn’t glamorous, but it’s the heart of just about every construction project. You could have the best materials and crew in the world, but if the mix isn’t right, the end result is going to suffer.

That’s why more and more builders, block manufacturers, and contractors are turning to a machine that doesn’t always get the spotlight: the Concrete Pan Mixer Machine.

It’s not huge. It’s not flashy. But it delivers a consistently solid mix—and that’s what really matters on-site.

So, What’s a Concrete Pan Mixer, Anyway? Think of it like a big steel bowl—kind of like a giant kitchen mixer, only tougher. It’s round, flat on the bottom, and fitted with rotating blades that churn everything together—cement, sand, gravel, water, additives—you name it.

The pan either stays still while the blades rotate, or in some models, both the pan and the blades rotate in opposite directions. The idea is to keep everything moving so every bit of the mix is touched, turned, and blended.

What comes out? A smooth, even concrete mix that’s ready for blocks, tiles, flooring, or whatever else you’re working on.

How Does It Work? Here’s the process in plain terms:

Load It Toss your materials in—cement, sand, aggregates, water. If you’re using fibers, colors, or chemicals, now’s the time to add them.

Fire It Up You switch on the machine and the paddles start spinning. Some mixers have fixed pans; others rotate the whole pan while the paddles turn inside. Either way, the mix gets pulled, scraped, and folded thoroughly.

Mix Until It’s Right Most batches are done in about 2 to 5 minutes. You’ll know when it’s ready—the mix looks uniform and the consistency is right for your job.

Discharge There’s usually a trap door or chute at the bottom. Open it, and your concrete flows out into a trolley, bucket, or mold.

No dead corners. No unmixed pockets. Just a clean, reliable batch.

Why Builders Like Using Pan Mixers Here’s the thing: not every job needs a concrete truck or a big drum mixer. And when you’re doing work that needs precision—like making fly ash bricks or casting colored concrete—pan mixers are the way to go.

More Control You’re in charge of the batch size and the exact mix. No guessing. No waste.

Better Mix Quality The blades scrape the sides and base of the pan, so nothing gets left out. That means a smoother, more consistent mix—especially important for decorative or structural work.

Smaller Batches, Less Waste You don’t need to mix a ton of concrete if you’re doing a small run of blocks or prepping for a flooring job. Pan mixers let you make exactly what you need.

Easy to Clean Anyone who’s cleaned a drum mixer knows the struggle. Pan mixers are easier to rinse and scrape down between batches, saving time and effort.

Different Types of Pan Mixers Out There Depending on your site and your work, you’ve got a few options:

Stationary Pan Mixers Great for block plants or small factories where the mixer stays in one place. Built for volume and consistency.

Portable Pan Mixers These come with wheels and can be moved around the site. Handy if you need to shift between work zones.

Electric vs. Diesel Electric models are quieter and good for indoor or city-based work.

Diesel models are better suited for rugged, off-grid jobs with no reliable power source.

What Should You Look for in a Pan Mixer? Buying a pan mixer? Here’s what to consider before handing over your money:

Capacity: Small batches or high-volume work? Get the right size for your needs.

Power Source: Will you have electricity where you’re working, or do you need the independence of diesel?

Build Quality: Heavy steel body, good motor, strong paddles—no compromises here.

Discharge System: Bottom discharge is ideal for quick emptying without leaving material behind.

Ease of Maintenance: Fewer moving parts = fewer breakdowns. Check how accessible the pan and paddles are for cleaning.

Manufacturers like Lino Sella and Shuanglong have been around for years, and they’ve got solid reputations in the industry. Go with a name that’s trusted.

Where Do You Actually Use One? You’ll find concrete pan mixers in all kinds of places:

Fly ash brick and solid block production

Paver and tile plants

Plaster and mortar mixing

Precast concrete units

Lab testing for concrete strength

Decorative or colored concrete mixing

Flooring and renovation work

Basically, if you’re doing work where mix quality matters, a pan mixer belongs on-site.

Wrapping It Up: Is It Worth the Investment? If you’re still mixing by hand or using an old drum mixer that leaves half the cement stuck to the walls—yes, it’s absolutely worth it.

The Concrete Pan Mixer Machine is one of those pieces of equipment that just makes sense: easy to use, reliable, and built to handle real job site conditions.

You save time, reduce waste, and get a better-quality product. Whether you're running a small production unit or working on custom construction projects, this machine will quickly become one of your go-to tools.

FAQs – No-Nonsense Answers About Pan Mixers Q1: Is a pan mixer better than a drum mixer? For smaller, precision jobs—yes. It gives you a more consistent mix and is easier to clean.

Q2: Can it be used for mortar or plaster? Definitely. In fact, many people use them specifically for mortar, plaster, and colored mixes.

Q3: How long does a batch take to mix? Usually about 3–5 minutes, depending on the machine and material.

Q4: Are they hard to clean? Nope. Most models are open and easy to rinse or scrape down.

Q5: Will it work for large-scale jobs? If you're doing massive pours all day long, you might want a bigger mixer. But for most small and medium-scale jobs, a pan mixer is ideal.

#arecaleafplatesmakingmachine#automaticinterlockingblockmakingmachine#automaticpaverblockmakingmachine#automaticflyashbrickmakingmachine#interlockingblockmakingmachine#hydraulicshearingmachinemanufacturers#automaticsolidblockmakingmachine#brickandblockmanufacturers#fullyautomaticflyashbrickmakingmachine#concretepanmixermachine

0 notes

Text

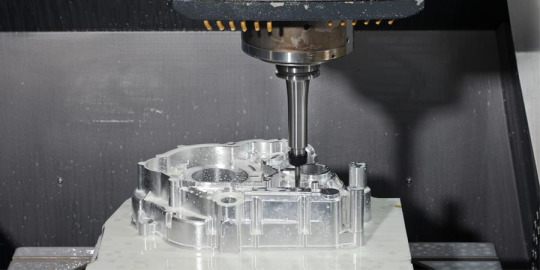

How CNC Machining Services Work: An Overview

CNC machining is a cornerstone of modern manufacturing, offering high precision, speed, and flexibility for producing intricate parts and components. From aerospace to automotive, electronics to industrial machinery, CNC machining services are critical in fabricating parts that meet exact specifications. Whether you're a product designer or a manufacturing engineer, understanding how CNC machining works can help you leverage its benefits effectively.

What Is CNC Machining?

CNC machining is a subtractive manufacturing process where material is removed from a solid block—known as a blank or workpiece—using a variety of cutting tools. The process is controlled by pre-programmed computer software that dictates the movement of machines such as mills, lathes, routers, and grinders. Unlike manual machining, CNC systems operate with extraordinary precision and repeatability, making them ideal for high-tolerance, complex parts.

Key Components of CNC Machining Systems

Computer-Aided Design (CAD): Everything starts with a 3D model or a technical drawing of the desired part. Engineers or designers use CAD software to define dimensions, geometries, and tolerances.

Computer-Aided Manufacturing (CAM): The CAD file is then imported into CAM software, which generates a toolpath and converts the design into G-code—a programming language that CNC machines understand.

CNC Machine: The G-code is uploaded to the CNC machine, which follows the programmed instructions to execute precise movements and tool changes. Machines may be 3-axis, 4-axis, or even 5-axis, depending on the complexity of the part and the number of simultaneous movements required.

Cutting Tools: Depending on the material and design, different cutting tools are used, such as end mills, drills, or turning tools. The choice of tool affects surface finish, cutting speed, and overall efficiency.

Workholding: Fixtures and vises secure the workpiece in place during machining, ensuring stability and accuracy.

The CNC Machining Workflow

Here’s a simplified breakdown of the typical CNC machining process:

1. Design & Planning

The journey of custom CNC machined parts begins with a detailed design. Engineers define all technical requirements, including geometry, material selection, surface finish, and tolerance. This stage is crucial because the CAD model directly influences machining feasibility and cost.

2. Programming

CAM software interprets the CAD model to produce G-code. This code tells the CNC machine what actions to perform—movements along the X, Y, and Z axes, spindle speeds, feed rates, tool changes, and more.

3. Setup

A technician sets up the machine by loading the workpiece, installing the required tools, and configuring the machine based on the program. This step may also involve calibrating the tool offsets and checking initial positions.

4. Machining

Once everything is set up, the machine starts removing material as per the G-code instructions. The process could involve multiple operations such as drilling, milling, turning, or tapping. Multi-axis machines can produce complex geometries in a single setup, reducing lead time and improving precision.

5. Inspection & Quality Control

After machining, the part is inspected using precision measurement tools such as calipers, micrometers, or Coordinate Measuring Machines (CMM). This step ensures that the final product meets all specified dimensions and tolerances.

6. Finishing Operations

Depending on the application, post-machining processes like deburring, anodizing, or powder coating may be applied. These finishing steps enhance durability, corrosion resistance, or aesthetics.

Types of CNC Machining

There are several types of CNC machining processes, each suited for specific applications:

Milling: A rotating cutting tool moves along multiple axes to remove material.

Turning: The workpiece rotates while a stationary cutting tool shapes its exterior or interior.

Drilling: Straight holes are created using a rotating drill bit.

EDM (Electrical Discharge Machining): Material is removed using electrical sparks—ideal for hard materials or intricate cavities.

Grinding: A rotating wheel removes material to achieve high surface finish and tight tolerances.

Advantages of CNC Machining

Precision: CNC machines can achieve tolerances as tight as ±0.001 inches, ideal for high-performance industries.

Repeatability: Once programmed, the machine can produce thousands of identical parts with minimal variation.

Flexibility: CNC services can handle one-off prototypes or high-volume production runs.

Efficiency: Faster turnaround times and reduced manual labor.

Material Versatility: Supports a wide range of materials including metals (aluminum, steel, titanium), plastics (nylon, ABS, PEEK), and composites.

Applications of Custom CNC Machined Parts

Custom CNC machined parts are essential in industries where performance and reliability are non-negotiable:

Aerospace: Complex components such as turbine blades, housings, and brackets.

Medical Devices: Surgical instruments, prosthetics, and diagnostic equipment.

Automotive: Engine components, transmission parts, and custom performance mods.

Robotics & Automation: Gears, end-effectors, and structural parts.

Consumer Electronics: Housings, frames, and connectors.

At MS Machining, our team specializes in producing high-quality custom CNC machined parts tailored to exact client specifications. Whether you need prototypes or full-scale production, MS Machining delivers consistent quality with fast lead times.

Why Choose MS Machining?

When it comes to custom CNC machined parts, choosing the right partner can make all the difference. Here's what sets MS Machining apart:

State-of-the-Art Equipment: We operate a fleet of advanced 3-, 4-, and 5-axis CNC machines.

Experienced Technicians: Our machinists have years of hands-on experience across multiple industries.

Fast Turnaround: We streamline production timelines without compromising quality.

Material Expertise: From exotic alloys to engineering plastics, we handle diverse materials with precision.

Quality Assurance: Every part undergoes rigorous inspection to ensure it meets or exceeds your requirements.

Whether you're a startup developing your first prototype or a large enterprise needing scalable production, MS Machining is your trusted source for dependable CNC machining services.

The Future of CNC Machining

CNC machining is constantly evolving, with emerging technologies like AI, machine learning, and automation pushing the boundaries further. Predictive maintenance, adaptive toolpath optimization, and real-time quality monitoring are enhancing productivity and reliability. As industries continue to demand higher performance and customization, CNC machining will remain a foundational technology for manufacturing innovation.

Final Thoughts

CNC machining is more than just a fabrication method—it's a bridge between concept and reality. With its unparalleled accuracy, versatility, and efficiency, it enables manufacturers to produce everything from simple fixtures to complex aerospace components. Companies like MS Machining are at the forefront, delivering precision-crafted custom CNC machined parts that help bring ambitious designs to life.

Whether you're exploring rapid prototyping or full-scale manufacturing, understanding how CNC machining services work empowers you to make informed decisions and achieve superior results.

0 notes

Text

Dry Ice Production Cost Report by Procurement Resource

Procurement Resource, a trusted provider of procurement intelligence and market research, presents the latest Dry Ice Production Cost Report. This comprehensive study offers detailed insights into the cost structure of setting up and operating a dry ice manufacturing unit, assisting businesses, investors, and stakeholders in making informed financial and strategic decisions.

Overview of Dry Ice

Dry ice is the solid form of carbon dioxide (CO₂), widely utilized for its cooling properties and sublimation characteristics. It is essential in cold chain logistics, food preservation, pharmaceutical transportation, and industrial cleaning processes. Its increasing adoption across logistics, healthcare, and food industries is driving market growth and demand for cost-effective production.

Dry Ice Production Cost Analysis

The report delivers an in-depth breakdown of all critical cost components involved in the dry ice manufacturing process. It outlines capital and operational expenditure, offering a clear view of the financial outlay required to establish a viable production facility.

Key Cost Components Covered:

1. Raw Material Costs

Procurement of liquid carbon dioxide (LCO₂) as the primary input

Sourcing, transportation, and storage costs

2. Utility and Energy Costs

Electricity consumption for compression, cooling, and pelletizing

Water and other utility usage

Energy efficiency parameters

3. Equipment and Machinery Costs

CO₂ storage tanks and refrigeration systems

Dry ice pelletizers or block machines

Compressors, purifiers, and auxiliary systems

Cost variations based on capacity and automation level

4. Labor and Overhead

Skilled/unskilled workforce wages

Maintenance and quality control staffing

Administrative and operational overheads

5. Packaging and Logistics

Insulated containers and specialized packaging

Transport and cold chain management for distribution

6. Capital Investment

Land, plant setup, and infrastructure development

Installation and commissioning charges

Cost Structure and Financial Indicators

The report provides detailed financial modeling and projections:

Total Production Cost per Ton/Kilogram

Break-even Analysis

Profit Margins and Return on Investment (ROI)

Sensitivity Analysis based on Input Price Fluctuations

Cost Trends Over Time

Regional and Market Insights

The report also highlights regional cost variations, influenced by factors such as:

Local CO₂ availability and prices

Utility rates and labor costs

Regulatory compliance and environmental standards

The Asia-Pacific region, particularly India and China, exhibits competitive production cost advantages due to abundant feedstock and low labor costs.

Why Choose Procurement Resource?

Procurement Resource offers expert-driven, data-backed production cost analysis reports that empower decision-makers with the tools needed to optimize manufacturing operations and control costs. Services include:

Accurate and detailed cost modeling

Price trend forecasts for raw materials and utilities

Customized economic feasibility reports

Benchmarking against global cost standards

Get a Free Sample Report

Interested in exploring the Dry Ice Production Cost Report in more detail?

Request your free sample copy here: https://www.procurementresource.com/production-cost-report-store/dry-ice/request-sample

Contact Us

Company Name: Procurement Resource Contact Person: Ashish Sharma (Sales Representative) Email: [email protected] Location: 30 North Gould Street, Sheridan, WY 82801, USA Phone: UK: +44 7537171117 USA: +1 307 363 1045 Asia-Pacific (APAC): +91 8850629517

#DryIce#manufacturing units#procurement intelligence#market research#food industries#healthcare#cleaning processes

0 notes

Text

Building a Sustainable Future: The Rise of Fully Automatic Fly Ash Brick Machines in India

India's construction sector is booming, and with it, the demand for efficient, sustainable building materials. In this landscape, fully automatic fly ash brick machines are emerging as a game-changer, revolutionizing brick manufacturing across the nation. These advanced machines not only offer high productivity but also contribute significantly to environmental conservation by utilizing industrial waste.

What are Fully Automatic Fly Ash Brick Machines?

At its core, a fully automatic fly ash brick machine is an industrial marvel designed to produce high-quality bricks from fly ash – a byproduct of coal combustion in thermal power plants – mixed with other raw materials like sand, lime, gypsum, and cement. The "fully automatic" aspect signifies that the entire production process, from raw material feeding and mixing to pressing, molding, and often even stacking, is automated, requiring minimal human intervention.

These machines leverage sophisticated technologies such as:

Hydraulic Pressure Systems: Ensuring uniform compression and high-density bricks with excellent strength.

Vibro-Compaction Technology: Combining vibration with pressure to eliminate air bubbles and achieve superior compaction and dimensional accuracy.

PLC (Programmable Logic Controller) Control: For precise management of the entire operation, enabling consistent quality, adjustable pressure settings, and real-time monitoring.

Automated Raw Material Feeding and Batching Systems: Ensuring precise proportions of materials for optimal brick composition.

Mould Flexibility: Allowing for the production of various brick types, including solid, hollow, paving blocks, and interlocking bricks, using interchangeable molds.

Auto-Stacker Systems: In advanced models, bricks are automatically stacked post-production, reducing manual labor and improving efficiency.

The Unmatched Advantages in the Indian Context

The adoption of fully automatic fly ash brick making machines in India offers a multitude of benefits, both economic and environmental:

High Production Capacity: These machines are designed for large-scale output, with some models capable of producing 1500-2500 bricks per hour, or even up to 30,000 bricks per day. This high volume helps meet the escalating demand in the rapidly growing Indian construction market.

Consistent Quality and Durability: Automation eliminates human error, leading to uniformly shaped, high-strength bricks with low water absorption and excellent thermal insulation. This translates to better structural integrity and longer-lasting buildings.

Environmental Sustainability: By utilizing fly ash, a significant industrial waste product, these machines contribute to:

Waste Utilization: Reducing the burden on landfills and promoting a circular economy.

Reduced Carbon Footprint: Less reliance on traditional clay bricks, which often involve topsoil excavation and energy-intensive firing processes.

Lower Water Usage: Fly ash brick production typically requires less water compared to conventional clay bricks.

Compliance with Regulations: The Indian government, through notifications from the Ministry of Environment & Forests (MoEF&CC), has mandated the utilization of fly ash in construction activities within a certain radius of thermal power plants, further driving the demand for these machines.

Cost-Effectiveness and Quick ROI: While the initial investment might seem substantial (prices for fully automatic plants can range from INR 10.5 Lakh to over INR 2 crore, depending on capacity and features), the long-term cost savings are significant. Reduced labor requirements, minimal maintenance, and high production output lead to a faster return on investment (ROI).

Reduced Labor Dependency and Enhanced Safety: Automation minimizes the need for manual labor, addressing concerns about labor availability and reducing occupational hazards associated with traditional brick-making.

Versatility: The ability to produce various types of bricks and blocks caters to diverse construction needs and market segments, from residential and commercial buildings to infrastructure projects and landscaping.

Energy Efficiency: Modern machines are optimized for lower power consumption, contributing to reduced operational costs.

Leading Manufacturers and Market Trends in India

India boasts a strong ecosystem of manufacturers specializing in fully automatic fly ash brick machines. Companies like Narsinh Industries, Endeavour Intelligent Equipments Private Limited, HVB Exports, Revomac Industries, Laxmi Engineering Works, and Kailash Engineering are prominent players, offering a wide range of machines with varying capacities and features. Many manufacturers are based in industrial hubs like Ahmedabad, Morbi, Mehsana, and Coimbatore.

The market trend is clearly towards more advanced, energy-efficient, and highly automated solutions. Manufacturers are focusing on:

Integrating IoT and remote monitoring capabilities for enhanced control and diagnostics.

Developing machines with even higher pressing capacities for denser bricks.

Offering customized solutions to meet specific client requirements.

Ensuring robust build quality for long operational life and minimal wear and tear.

Investing in a Sustainable Future

For entrepreneurs and construction companies in India looking to scale up their operations while embracing sustainable practices, investing in a fully automatic fly ash brick machine is a strategic decision. These machines not only promise high productivity and superior product quality but also align with the nation's growing emphasis on green building and responsible waste management. As India continues its infrastructure development, the demand for eco-friendly and high-performance building materials like fly ash bricks, produced efficiently by these advanced machines, is set to soar.

#automatic bricks making machine manufacturer#automatic paver block machine manufacturer#fly ash block making machine#paver block manufacturing machine#semi-automatic block making machine#vibrating paver block machine

0 notes

Text

Best Paver Block and Brick Making Solutions from Ultra Tiles Machine

When it comes to producing high-quality paver blocks, bricks, and other concrete products, having the right equipment is crucial. Ultra Tiles Machine has established itself as a leading name in the industry, providing top-notch machinery for all your block and brick-making needs. With a wide range of machines designed to meet the demands of various construction projects, we cater to businesses that require efficiency, reliability, and precision in their manufacturing processes.

In this blog, we’ll explore the different types of machines offered by Ultra Tiles Machine, including Paver Block Making Machine, Hollow Solid Block Making Machine, Fly Ash Brick Making Machine, Concrete Block and Brick Making Machine, Chemical Hardener Manufacturers, Interlocking Paver Block Making Machine, and Automatic Brick Making Machine Manufacturer.

Paver Block Making Machine

A Paver Block Making Machine is essential for creating durable, aesthetically pleasing paving stones used in roads, driveways, walkways, and other outdoor spaces. At Ultra Tiles Machine, we offer advanced paver block machines that produce high-quality interlocking paver blocks in various shapes and sizes.

Our machines are designed to cater to both small and large-scale production needs, ensuring consistent output with minimal labor.

These machines are designed for optimal performance, ensuring that each paver block produced has the desired strength, texture, and finish.

Whether you need blocks for residential, commercial, or industrial projects, our Paver Block Making Machine will meet your specific requirements, ensuring efficiency, precision, and cost-effectiveness.

The Hollow Solid Block Making Machine offered by Ultra Tiles Machine is designed for producing high-strength blocks that are both cost-effective and versatile. Hollow blocks are widely used in the construction of walls, foundations, and other structures, offering excellent insulation and soundproofing properties. Our machine can produce both hollow and solid blocks, depending on your project’s requirements.

The machine is engineered with precision and advanced technology, ensuring that the blocks produced are uniform in size and shape. This ensures a smooth construction process, reducing material wastage and improving overall building quality. Additionally, our Hollow Solid Block Making Machine is designed to be durable, ensuring a long service life with minimal maintenance.

Fly Ash Brick Making Machine

Ultra Tiles Machine is a prominent Fly Ash Brick Making Machine manufacturer, offering state-of-the-art machines that are environmentally friendly and economically viable. Fly ash bricks are an eco-conscious alternative to traditional clay bricks, made from industrial waste products like fly ash, cement, and sand. These bricks are stronger, lighter, and more durable than conventional bricks, making them an ideal choice for modern construction projects.

Our Fly Ash Brick Making Machine uses innovative technology to ensure the production of high-quality fly ash bricks with consistent strength and size. This machine is perfect for businesses looking to reduce their environmental footprint while maintaining high standards of construction. With high automation and low energy consumption, it helps reduce production costs and enhances overall operational efficiency.

Concrete Block and Brick Making Machine

Our machines are designed to create blocks and bricks in various sizes, including standard, interlocking, and custom designs. The flexibility of our Concrete Block and Brick Making Machine ensures that it can cater to the specific needs of different construction projects. Whether you're building residential complexes, commercial buildings, or infrastructure projects, our machines deliver the perfect solution.

Chemical Hardener Manufacturers

In the production of paver blocks, bricks, and other concrete products, it’s essential to ensure high strength and durability. This is where the role of chemical hardeners comes into play. Ultra Tiles Machine is a trusted Chemical Hardener Manufacturer, offering top-quality hardening agents that improve the overall strength and resistance of concrete products.

Chemical hardeners are used to enhance the surface hardness of concrete products, providing them with greater resistance to wear, moisture, and weathering. By using the right chemical hardeners in your production process, you can ensure the longevity and durability of your paver blocks, bricks, and other concrete products.

Interlocking Paver Block Making Machine

At Ultra Tiles Machine, we ensure that the Interlocking Paver Block Making Machine we offer delivers precision and consistency in every block produced. With advanced technology and efficient production processes, these machines provide excellent results in a variety of sizes and designs to suit different project needs.

As an Automatic Brick Making Machine Manufacturer, Ultra Tiles Machine offers machines that automate the process of brick production, resulting in reduced labor costs and increased efficiency. Our Automatic Brick Making Machines are designed to produce high-quality bricks with minimal manual intervention. These machines are ideal for businesses that need to produce large volumes of bricks quickly while maintaining high standards of quality.

Our automatic machines are equipped with advanced features such as automated brick molding, high-pressure forming, and easy-to-use control systems. This ensures that each brick produced meets the highest quality standards while reducing the need for manual labor and increasing overall productivity.

Why Choose an Ultra Tiles Machine?

At Ultra Tiles Machine, we are committed to providing our customers with the best machinery solutions for their block and brick-making needs. Here’s why you should choose us:

Advanced Technology: We use the latest technology to manufacture machines that deliver high-quality products with minimal labor.

Customization: We offer customized solutions tailored to your specific production needs, ensuring that you get the perfect machine for your requirements.

Durability and Reliability: Our machines are built to last, with high-quality materials and precision engineering ensuring long service life.

Eco-friendly Solutions: We are committed to providing eco-friendly machinery, including Fly Ash Brick Making Machines that help reduce your carbon footprint.

Customer Support: We offer excellent customer support, ensuring that you have the assistance you need at every step of the way.

Conclusion

Whether you're looking for a Paver Block Making Machine, Hollow Solid Block Making Machine, Fly Ash Brick Making Machine, Concrete Block and Brick Making Machine, Chemical Hardener Manufacturers, Interlocking Paver Block Making Machine, or Automatic Brick Making Machine Manufacturer, Ultra Tiles Machine is the trusted partner for all your block and brick-making needs.

With our high-quality machines, advanced technology, and exceptional customer service, we guarantee that your production process will be efficient, cost-effective, and reliable.

Contact Ultra Tiles Machine today to learn more about our products and how we can help you take your construction business to the next level.

#Paver Block Making Machine Manufacturer#Hollow Solid Block Making Machine#Fly Ash Brick Making Machine#Concrete Block and Brick Making Machine#Chemical Hardener Manufacturers#Interlocking Paver Block Making Machine#Automatic Brick Making Machine Manufacturer

0 notes

Text

Shop Quality Gym Equipment in Adelaide: Your Guide to Fitness Gear

Finding the right tools to support your fitness journey can be the difference between average results and true transformation. In today’s health-conscious world, having access to reliable Gym Equipment Adelaide is essential. Whether you're starting your home gym or upgrading your current setup, understanding what to look for in quality gear can help you make smart and lasting choices.

Understanding Your Fitness Needs

Before you even begin shopping, it's important to assess your goals and limitations. Are you focused on strength training, cardio endurance, flexibility, or a combination of these? Understanding what you’re working toward allows you to prioritize which pieces of gear are necessary. For instance, a beginner interested in general wellness might need basic resistance bands and a yoga mat, while a seasoned athlete may look for a power rack, adjustable bench, or air bike.

Additionally, the amount of space you have available plays a significant role. Compact apartments require smart, space-saving solutions like foldable machines or multi-functional equipment. If you have a dedicated room, you have more flexibility to create a full setup that includes larger gear.

Essential Categories of Fitness Gear

When exploring the market, most items fall into a few key categories. Each has its own benefits depending on your training goals.

1. Strength Training Tools

Strength training is a foundation for building muscle, boosting metabolism, and improving overall function. Equipment like adjustable dumbbells, kettlebells, resistance bands, and squat racks allow for progressive overload and varied routines. If you prefer barbell work, a quality Olympic bar and weight plate set can offer a wide range of compound movements.

For home users, compact multi-gyms or all-in-one trainers can be excellent space-saving options. These systems offer multiple attachments and pulley stations for performing full-body workouts with a single machine.

2. Cardio Machines

Cardiovascular training supports heart health, endurance, and calorie burn. Common options include treadmills, rowing machines, upright bikes, and ellipticals. Some modern designs even integrate smart tracking features that sync with your phone or tablet for real-time feedback and virtual classes.

The right cardio machine depends on your preferences and joint considerations. For example, rowing machines provide low-impact full-body workouts, while spin bikes are popular for interval training and endurance rides.

3. Recovery and Mobility Gear

Fitness is not just about pushing hard—it’s also about helping your body recover. Recovery tools like foam rollers, massage balls, and percussion massage guns can aid in muscle release, reduce soreness, and prevent injury. Yoga blocks, stretching straps, and mobility mats are also essential for anyone looking to increase flexibility or enhance movement quality.

Including these items in your fitness area ensures you can cool down effectively and recover smarter after tough sessions.

Material Quality and Build Durability

One of the key indicators of good gear is its build quality. For items that undergo high impact, like weight plates, benches, or treadmills, you need materials that will stand the test of time. Look for solid steel frames, quality welds, and powder-coated finishes that resist wear and tear.

Handles and grips should be ergonomic and non-slip. Upholstery on benches should be firm, tear-resistant, and moisture-proof to handle sweat and regular use. In the case of resistance bands or cables, elasticity and tension consistency are crucial to avoid snapping or uneven performance.

It’s also worth checking load capacities and warranties. A solid warranty shows that the manufacturer stands behind their product’s durability. For more info, click here

Multi-Functionality and Storage Solutions

For many people, limited space means they must be strategic with their purchases. Multi-functional tools like adjustable dumbbells, all-in-one gym machines, or stackable plyo boxes save space while delivering versatility. Folding or collapsible equipment—such as foldable benches or wall-mounted racks—are ideal for compact setups.

Storage solutions also play a role in keeping your training area safe and organized. Consider wall hooks for bands and ropes, vertical plate trees for weight storage, and small bins for accessories like jump ropes or ankle straps. A tidy area encourages consistency and minimizes the risk of injury from clutter.

Noise Level and Flooring Considerations

Some equipment can generate considerable noise—especially treadmills, rowing machines, or heavy weight drops. If you're setting up your fitness area in a shared space or an apartment, look for features that reduce operational sound. Machines with magnetic resistance, rubberized contact points, or belt-drive systems tend to run quieter.

Protective flooring is another important factor. Interlocking foam mats or heavy-duty rubber tiles not only safeguard your floor but also provide cushioning for your joints during high-impact movements. They can also muffle sound and reduce vibration, enhancing your overall workout experience.

Portability and Transport Features

For those who like to rearrange their workout area or take gear on the go, portability matters. Many benches, racks, and machines now come with transport wheels or fold-flat capabilities. Even heavier items like rowing machines and spin bikes often have tilt-and-roll designs for ease of movement.

Lighter accessories like bands, sliders, and resistance loops are perfect for travel or outdoor training. A small duffel bag of portable tools can allow for a solid workout in almost any location.

Smart Features and Tech Integration

Modern gear often integrates technology for a more interactive experience. Many cardio machines now feature LCD screens, app connectivity, and built-in programs tailored to your fitness level. Some strength training tools include sensors that track rep count, rest time, or form feedback.

Wearables and smart scales can also be synced with your gear to track your progress over time. These features can help keep you accountable and informed about your performance trends.

When exploring these options, ensure the software or apps are compatible with your existing devices and that any subscriptions or add-ons are clearly explained.

Budget and Value Assessment

The wide range of pricing in the fitness equipment market can be overwhelming. Budget-friendly options often focus on basic function, while premium models offer additional features, durability, and enhanced user experience. Before investing, identify what truly matters to you. It may be worth spending a bit more on items you use frequently, like a bench or dumbbells, and saving on less-used gear.

Reading customer reviews and comparing multiple sources can help you make better choices. Online forums, video demonstrations, and third-party tests provide insights beyond promotional claims.

Safety Features and User Accessibility

Safety should always come first, especially for home setups. Look for gear with locking mechanisms, anti-slip surfaces, and rounded edges to reduce the risk of accidents. Adjustable machines should have clear instructions and user-friendly design for quick and safe transitions between exercises.

Additionally, accessible design is important for all users. Those new to fitness should be able to operate machines without complex instructions, and advanced users should have the freedom to customize resistance, speed, or incline with ease.

Creating a Motivating Space

Finally, creating an inspiring environment can boost your motivation to train regularly. Good lighting, a mirror to monitor form, uplifting music, and a layout that flows naturally can make your space feel more inviting. Wall-mounted timers, chalkboards for goal tracking, or a TV for streaming workouts can enhance your experience.

0 notes

Text

How Briquetting Machines Improve Industrial Efficiency

Briquetting machines have revolutionized the way industries handle waste materials by transforming them into compact, efficient briquettes. These machines compress various raw materials, such as biomass, metal chips, and industrial waste, into solid blocks, making them easier to store, transport, and use. Their role in reducing environmental impact and improving operational efficiency is significant, especially in manufacturing sectors focused on sustainability.Get more news about Briquetting Machine,you can vist our website!

The Working Principle of Briquetting Machines Briquetting machines operate by applying high pressure to loose materials, forcing them to bind together into solid briquettes without the need for additional binders. The process typically includes the following stages:

Material Preparation: The raw materials are shredded and dried to ensure optimal compression.

Compression: The material is fed into the machine, where hydraulic or mechanical pressure is applied to compact it.

Formation: The compressed material is shaped into uniform briquettes.

Cooling & Storage: The briquettes are cooled and stored for future use.

This process significantly reduces the volume of waste, making it more manageable for transportation and repurposing.

Applications Across Industries Briquetting machines have versatile applications across various industries:

Biomass & Renewable Energy: Compressing organic waste, such as sawdust and crop residues, into briquettes used as fuel.

Metal Recycling: Compacting metal shavings and scraps into briquettes for re-melting or reuse.

Industrial Waste Management: Handling hazardous waste materials efficiently and reducing disposal costs.

By integrating briquetting technology, industries can lower their carbon footprint while optimizing their production processes.

Environmental & Economic Benefits The adoption of briquetting machines offers both ecological and financial advantages:

Waste Reduction: Minimizes landfill waste and promotes sustainable material reuse.

Lower Transportation Costs: Reducing bulk and improving handling efficiency.

Energy Efficiency: Provides an alternative fuel source for heating and manufacturing operations.

Enhanced Profitability: By repurposing waste, businesses can generate additional revenue streams.

Conclusion Briquetting machines are essential in industrial sustainability, offering efficient waste management solutions and contributing to greener manufacturing practices. Their ability to transform waste into valuable briquettes highlights their significance in modern industries. As technology advances, briquetting machines will continue to play a crucial role in optimizing production and enhancing environmental conservation.

0 notes

Text

Advancements in Industrial Respiratory Protection Technology

Advancements in industrial respiratory protection technology have transformed how workers stay safe in hazardous environments. In workplaces using powerful tools like the Industrial Machine by Lattel, reliable respiratory gear is essential for protecting against harmful dust, chemicals, and fumes.

Modern respirators have come a long way from simple masks. For example, today’s models feature better filters, smart sensors, and improved comfort. Moreover, these upgrades help reduce the risk of workplace illnesses while making it easier for employees to focus on their tasks.

“The future of workplace safety is here — and it starts with smarter, stronger respiratory protection.”

The Importance of Respiratory Safety in Industrial Work

Respiratory safety is crucial in industries like manufacturing, construction, and chemical production. Machines such as the Industrial Machine by Lattel often release fine dust, fumes, and vapors that can harm the lungs.

For example, welding or sanding creates airborne particles too small to see. However, these particles can settle in the lungs, leading to long-term health problems. Moreover, without proper respiratory protection, workers risk illnesses such as asthma, lung damage, or respiratory infections.

New Filter Materials Improve Protection

One major advancement in respiratory technology is the development of new filter materials. Modern filters use electrostatic fibers that trap particles more effectively than older designs.

For example, many masks now feature multi-layer filters that block both solid particles and liquid aerosols. Moreover, these materials remain breathable while providing better protection, making them ideal for use with the Industrial Machine by Lattel in dusty or chemical-heavy environments.

Smart Respirators Add Real-Time Monitoring

A recent innovation in respiratory protection is the smart respirator. These advanced masks feature built-in sensors that monitor air quality, breathing patterns, and filter status.

For example, if a worker near an Industrial Machine by Lattel encounters dangerous fumes, the respirator alerts them with a visual or audio warning. Moreover, smart respirators can track filter life, reminding users when it’s time for a replacement, which reduces the risk of using ineffective equipment.

Improved Fit and Comfort for All-Day Use

Comfort is a key factor in making sure workers consistently wear their protective masks. Many modern respirators now offer adjustable head straps, softer materials, and lightweight designs.

For example, newer mask models contour to the face, providing a tighter seal and reducing pressure points. Moreover, these improvements make it easier for workers operating the Industrial Machine by Lattel to focus on their tasks without constant discomfort or mask adjustments.

How Industrial Machine by Lattel Benefits from New Respirators

Advancements in respiratory protection are especially helpful in workplaces with machines like the Industrial Machine by Lattel. These powerful machines often generate fine particles and fumes, making reliable masks essential.

For example, during sanding or metal cutting tasks, upgraded respirators with high-efficiency filters trap more harmful dust. Moreover, smart respirators provide real-time alerts when air quality drops, allowing workers to act quickly and stay safe.

Powered Air-Purifying Respirators (PAPRs) Gain Popularity

Powered Air-Purifying Respirators (PAPRs) are another growing trend in industrial respiratory protection. These systems use a battery-powered fan to pull air through filters, delivering clean air to the wearer.

For example, workers near an Industrial Machine by Lattel can wear a PAPR to reduce fatigue while breathing, even during long shifts. Moreover, PAPRs offer higher protection levels for workers exposed to fine dust or hazardous vapors.

“New technologies like PAPRs show how industrial safety gear is evolving to meet the demands of modern work environments.”

Hands-Free Respirator Designs

Another advancement includes hands-free designs for workers who need full freedom of movement. For example, half-mask or hood-style respirators allow wearers to talk, move, and work comfortably without needing to adjust their gear.

Moreover, these designs work well in environments with Industrial Machine by Lattel, where handling tools and equipment requires steady hands. Workers can stay protected without interrupting their workflow.

Better Training Tools and Fit-Testing Equipment

Technology isn’t just improving the masks themselves — it’s also enhancing how workers are trained. New fit-testing equipment helps ensure masks form a proper seal on each worker’s face.