#SolventExtraction

Explore tagged Tumblr posts

Text

In order to effectively separate citric acid, the extraction and stripping processes use a continuous multi-stage countercurrent process to ensure better contact between the organic phase and the aqueous phase. Multi-stage extraction can achieve an extraction yield of 90%. Email: [email protected] Whatsapp: +86 19069612820

0 notes

Text

Soxhlet Apparatus

Labexpo soxhlet apparatus is a precision tool for lipid extraction, featuring a 500 ml flask and a 50 mm diameter, 230 mm long extraction tube. It includes a condenser, siphon, connecting tube, and heating device, ensuring efficient solvent cycling and cooling for optimal results

0 notes

Text

The effluent system efficiently removes heavy metals from industrial waste using advanced technologies like , solvent extraction, and precipitation, to selectively extract valuable metals.

For more details, visit - https://watermanaustralia.com/product/metal-recovery-from-effluent/

#watermanengineersaustralia#effluenttreatment#effluentsystem#metalrecovery#solventextraction#ionexchange

0 notes

Photo

Answer the question! #subsribeouryoutubechannel #ChemDude035 #likesharecomment #followformore #learn #Chemistry #Chemistryposts #Chemistryjokes #Latestnews #aboutchemistry #trending #Chemistryknowledge #Pakistan #Solventextraction #MCQS #ChemistryMCQs #AnalyticalChemistry #Analysis #Sopvent #Extraction #AnalyticalTechnique #learnChemistry #Chemisttytricks #skillful #Chemistrylearning #besttrick #esaychemistry https://www.instagram.com/p/COmMgf2JQlw/?igshid=747k1psy7bzs

#subsribeouryoutubechannel#chemdude035#likesharecomment#followformore#learn#chemistry#chemistryposts#chemistryjokes#latestnews#aboutchemistry#trending#chemistryknowledge#pakistan#solventextraction#mcqs#chemistrymcqs#analyticalchemistry#analysis#sopvent#extraction#analyticaltechnique#learnchemistry#chemisttytricks#skillful#chemistrylearning#besttrick#esaychemistry

0 notes

Text

100T/D Soybean Oil Solvent Extraction Plant Equipment List&Quotation

NO. P/N Equipment name Model Q.T.Y Power kw Equipment inside of workshop 1 L301 Seal auger LSM30 1 2.2 2 V301 Storage tank CLX100 1 0 3 V302 Solvent extractor JP470 1 2.2 4 L303a/L303b Solvent extractor MGSC20 2 6 5 L302 Solvent extractor LSM30 1 2.2 6 T301 Solvent extractor DTC200 1 37 7 X302 Wet-type trap PJS100 1 0 8 T301a Sealing discharge FBFD5 1 2.2 9 X301 Trap XL55-D100 1 0 10 F302 Fan 4-72-5 1 15 11 L303c Meal supply buried scraper MGSC20 1 5.5 12 V303 Safety oil tank AG120×200 1 0 13 F301a,b Miscella filter GLQ80 1 0 14 V304 Miscella oil tank GH120×400 1 0 15 V306 Spray tank PLG50 1 0 16 E305 First evaporator ZFQ30 1 0 17 V305 First Flash tank SFX80 1 0 18 E307 Second evaporator ZFQ20 1 0 19 V307 Second flash tank SFX80 1 0 20 T302 Stripper QTDT60 1 0 21 T302 Oil-oil heater HRY20 1 0 22 V313 Crude oil tank MYG120 1 0 23 E310 Atmospheric condenser WLN150 1 0 24 E308 Vacuum condenser WLN150 1 0 25 E312 Strip condenser WLN150 1 0 26 E311 Tail gas condenser WLN150 1 0 27 V311 V310 Water assorted ark FSG200 1 0 28 V313 Wax Oil tank YSLG100 1 29 V312 Cooking Pot ZZG120 1 0 30 V303a Steam distribute drum FQB32.5 1 0 31 V303b Steam distribute drum FQB32.5 1 0 32 E303 Desolventizing preheater GRQ32.5 1 0 33 E309 Strip preheater GEQ21.9 1 0 34 E301 Solvent heater RRQ21.9 1 0 35 F303 Tail gas fan BG11-3A 1 0.55 36 P307a Evaporate vacuum pump 1ZP20-40 1 0 37 P307b Strip vacuum pump 1ZP10-20 1 0 38 P301a-f Miscella oil circulate pump YBLR30-10 6 9 39 P302 Strong miscella oil tank YBLW12-32 1 3 40 P311 Residual discharge pump IS32-125 1 0.75 41 P303 Stripper extract pump IS32-125 1 2.2 42 P304 Water pump IS32-125 1 0.75 43 P305 Solvent pump YBLW12-32 1 3 44 P312 Catcher pump YCB5-0.6 1 1.5 45 P313 First feed pump YBLW12-32 1 3 46 P314 Second feeding pump YBLW12-32 1 3 47 P315 Second Oil extract pump YBLW12-32 1 3 48 P317 Crude oil pump YCB5-0.6 1 2.2 49 T304 Paraffin absorption tower YSXT25 1 50 T305 Paraffin absorption column YSJT25 1 51 P306a Rich oil pump IS40-125 1 52 P306b lean oil pump IS40-125 1 53 E314 Condenser BR15 1 54 Solvent cooling pump 1 3 55 E315 Heat exchanger LGJ20 1 56 E316 Heater LGJ20 1 57 Electronic control pump DKG100 3 0 58 Operate cabinet FBG100 1 0 SUB TOTAL 65 107.25 Equipment outside of workshop 1 Underground Solvent storage WRG280 1 0 2 Solvent pump YBX50-160 2 6 3 Lightning rod BLT32 2 0 4 Circulate water pump IS150-125-315 2 44 5 Feeding scraper MGSS20 1 5.5 6 Meal scrape MGSS20 1 5.5 7 Cooling tower 1 SUB TOTAL 9 61 Other cost 1 Installation materials fee 2 Switching control system 3 Automatic control system 4 Antiseptic and heat preservation 5 Freight and other cost in domestic Read the full article

#100t/d#solventextraction#solventextractionplant#solventextractionplantequipment#soybean#soybeanoil#soybeanoilsolventextraction

0 notes

Photo

The Stargazer Lily.

Some find its rich, damp pungent scent too much to bear. Too overpowering. Many are allergic to its pollen. Cats die from it. Yet for centuries, lily lovers have been olfactory obsessed with Stargazers, describing their scent as ‘creamy clove’ and ‘spicy bubblegum’, so I couldn’t help but wonder: is it possible to extract that magic? Or how is it translator in fine fragrance?

A few thousand tonnes of rose petals of the correct variety (Rosa damascena) will distill or extract into the very expensive Rose Otto, the natural ingredient still used in some perfumes today. But there is no such thing as Lily essential oil or Lily absolute, is there?

Naively, I dive into the world of basic everyday chemistry to find out.

Solvent extraction beautifully explained: (with credit to Andy Parsons from University of York in his Basic Everyday Chemistry course on www.futurelearn.com)

“Some fragrant organic compounds in plants are sensitive to heat, so to extract them we need methods other than steam distillation. One of these is to use an organic solvent. Typically, a solvent like hexane is used to extract the fragrant organic compounds from the plant. For my experiment i used olive oil, a mixture of organic compounds which can act in a very similar way to extract fragrant organic compounds from flowers.”

Into a jar went a sacrifice of two cups of precious olive oil and the pungent bruised petals of four perfect Stargazers. Wait 48 hours.

The result? A brown mess of oily petal mass. The scent? Distinctly green, like olives. Not a hint of creamy clove or spicy bubblegum.

Now i know it first-hand: Stargazer does not surrender it’s seductive scent to a solvent. Either.

0 notes

Text

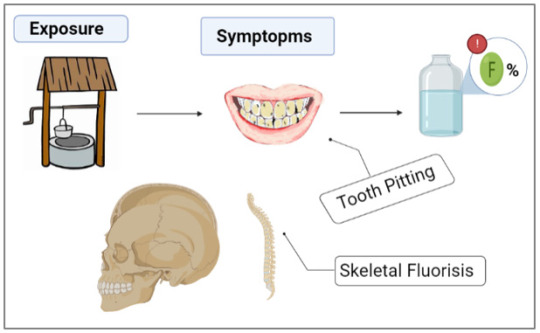

Bio-Filtration as a Solution for the Detrimental Health Effect of Excess Fluoride in Drinking Water - BJSTR Journal

Bio-Filtration as a Solution for the Detrimental Health Effect of Excess Fluoride in Drinking Water by Maha M Khayyat* in Biomedical Journal of Scientific & Technical Research

The research on clean water production is of critical importance worldwide. Excess fluoride pollutant has direct correlation with bones deformation. Bio-filters are of multilateral advantages. This study is focused on the physical treatment to prepare lowcost biochar adsorbents made from cow bone. The produced bio-filter was tested for fluoride removal from aqueous solutions containing control amounts of fluoride. The bone sample was calcined at 400 °C. Scanning electron microscopy, energy dispersive X-ray analysis, and ionic chromatography were performed to characterize the filtration performance of the charcoal adsorbent. The adsorption effectiveness of fluoride was estimated at 94%. The proposed charcoal bio-filter is economically and environmental advantageous, given its lack of energy consumption. It also provides health benefits. Furthermore, the overall performance of this bio-filter could be enhanced in the future by using nanocomposites. One of the main importance of water filtration is to prevent water-related illnesses and diseases. To this day, various explored methods were used in the remediation of water of different types of contaminants such as flocculation [1,2], coagulation [3], solventextraction [4], co-precipitation [5], precipitation [6], ion-exchange [7], photo catalysis [8], adsorption-desorption [9], reverse-osmosis [10], nano-membrane filtration [11].

For more articles Journals on vaccination please click here

bjstr

Follow on Twitter : https://twitter.com/Biomedres01 Follow on Blogger :https://biomedres01.blogspot.com/ Like Our Pins On : https://www.pinterest.com/biomedres/

#journals on regenarative diseases#journals on neuro imaging#biomedical open access journals#biomedical journal articles#biomedical journal impact factor

0 notes

Link

read more :->>>>>>https://goo.gl/SivW2A

#SolventExtraction #SolventExtractionPlant #SolventPlant #India #Brazil #Argentina #Russia #Turkey #Philippines #SaudiArabia #Germany #Canada #Nepal #Myanmar

call :-01244700800 visit :-www.mectech.co.in

#solvent extraction plant#solvent extraction#solvent plant#solvent plant machinery#solvent extraction plant manufacturer

0 notes

Text

The centrifugal extractor has a significant operating effect in the treatment of high-concentration organic wastewater in the chemical industry.

Email: [email protected] Whatsapp: +86 19069612820

0 notes

Text

Soxhlet Apparatus

Labexpo.com soxhlet apparatus is a precision tool for lipid extraction, featuring a 500 ml flask and a 50 mm diameter, 230 mm long extraction tube. It includes a condenser, siphon, connecting tube, and heating device, ensuring efficient solvent cycling and cooling for optimal results

0 notes

Text

Laboratory Glass RDC Extraction Column

The RDC extraction column is a chemical extraction equipment used for liquid-liquid extraction. The extraction column can be made of stainless steel, high borosilicate glass, etc., which can be selected according to customer needs.

Email: [email protected] Whatsapp: +86 19069612820 https://www.tyextractor.com/industry-trends/laboratory-glass-rdc-extraction-column.html

0 notes

Text

As a new type of extraction equipment, the CWL-M centrifugal extractor is essentially different from traditional extraction equipment in terms of working principle. The centrifugal extractor relies on centrifugal force to quickly mix and separate the two-phase liquids, with a short mixing and mass transfer time, high extraction efficiency, simple and convenient operation, and no entrainment.

Email: [email protected] Whatsapp: +86 19069612820

0 notes

Text

CWL-M series centrifugal extractor is used as the extraction equipment, which has low energy consumption and high extraction and stripping efficiency. Email: [email protected] Whatsapp: +86 19069612820

0 notes