#Stainless Steel Rivets

Text

Usha Precision

#ss shaft#Piston rod#Brass Rivets#Hollow Rivets#Semi Tubular Rivets#Achse#Micro Rivets#Stainless Steel Rivets

0 notes

Text

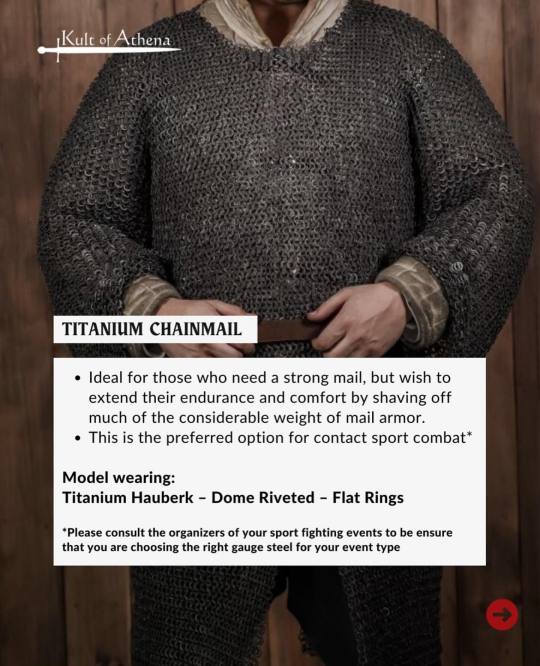

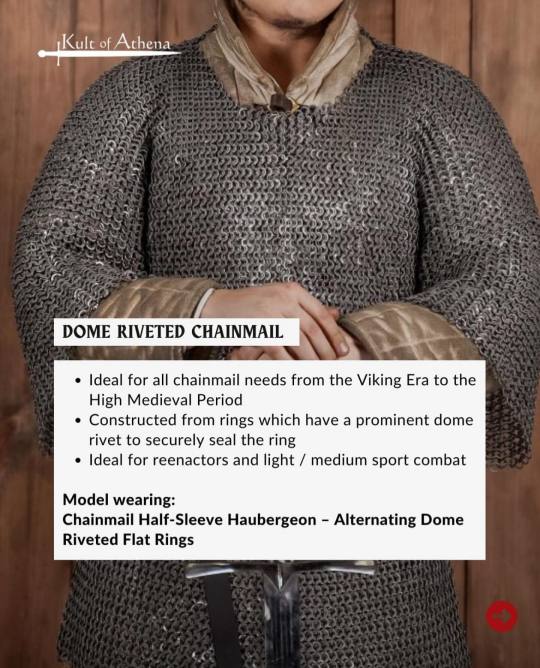

With all of this talk about chainmail, you’re probably wondering: what type is right for me? Swipe to see a curated selection of chainmail from Lord of Battles, available on Kult of Athena.

Dome Riveted: A method of riveting an open mail ring that uses a steel pin or thick wire which is then pressed and riveted to “mushroom” into a dome shape that holds the ring in place. This style of mail is common from Classical Antiquity until the later years of the High Medieval Period (Approx: 3rd Cent BC to 1300 AD)

Wedge Riveted: A method of riveting and open mail ring that uses a triangular wedge of metal which is then pressed to flatten and peen itself over the ring to hold the ring closed. Wedge-riveted mail has the advantage of the rivets having a flatter profile which is less likely to entrangle and catch on other rings and is less abrasive to any clothing or accessories worn over the mail. This style of mail becomes dominant in the later part of the High Middle Ages and the Late Medieval Period. ( Approx. 1300 to 1550 AD)

Butted: Butted Rings are Round or Flat rings which are not riveted closed, but instead have the open ends butted up and pressed against one another to close the ring. Not historically accurate.

#Kult of Athena#KultOfAthena#chainmail#chain mail#Lord Of Battles#WorldOfKoa#LARP#battlefield#Live Action Role Play#Butted Chain Mail#Wedge Riveted Chain Mail#Dome Riveted Chain Mail#Loose Chain Mail#Zinc Coated#Mild Steel#Aluminum#High Tensile Wire#Stainless Steel#Roman Chainmail

9 notes

·

View notes

Text

Fastening Elements for Robotic Manufacturing

In the realm of robotic manufacturing, where efficiency and accuracy are paramount, fastening elements serve as the backbone of seamless assembly processes. From traditional screws to cutting-edge adhesive technologies, selecting the right fastening elements is crucial for achieving optimal performance and reliability. In this comprehensive guide, we delve into the best fastening elements that are transforming robotic manufacturing operations worldwide.

Precision Screws and Bolts:

Traditional yet indispensable, precision screws and bolts are the cornerstone of fastening in robotic manufacturing. Engineered for accuracy and reliability, these fasteners provide the structural integrity needed for robust assembly. With advancements such as self-tapping screws and high-torque bolts, manufacturers can streamline assembly processes and achieve tighter tolerances in their robotic systems.

Advanced Riveting Techniques:

Riveting remains a staple in robotic manufacturing, offering strong and durable joints for a variety of materials. From aluminum to composite materials, robotic riveting systems ensure precise and consistent fastening results. Modern advancements in riveting technology include blind rivets and programmable riveting robots, which enhance productivity and versatility in manufacturing operations.

Cutting-Edge Welding Technologies:

Welding robots are indispensable for joining metal components in robotic manufacturing processes. Whether it's arc welding, spot welding, or laser welding, these technologies offer unparalleled strength and durability in fastening. Robotic welders equipped with advanced controls and sensing capabilities ensure precise welds, even in complex geometries, thereby enhancing the structural integrity of robotic assemblies.

Structural Adhesives and Sealants:

The use of structural adhesives and sealants is on the rise in robotic manufacturing, offering high-strength bonding and sealing solutions for diverse materials. Robotic dispensing systems accurately apply adhesives and sealants, ensuring uniform coverage and minimizing waste. Structural adhesives enhance joint strength, while sealants provide protection against environmental factors, making them essential for reliable and long-lasting fastening in robotic systems.

Interlocking Mechanisms and Snap Fits:

Interlocking mechanisms and snap fits provide efficient and reliable fastening solutions without the need for additional hardware. Robotic assembly systems are programmed to align and interlock mating components with precision, ensuring a secure fit without compromising assembly speed. Snap-fit designs and dovetail joints are particularly popular for their simplicity and versatility in robotic manufacturing applications.

In conclusion, the selection of fastening elements plays a crucial role in the success of robotic manufacturing operations. By leveraging precision screws and bolts, advanced riveting techniques, cutting-edge welding technologies, structural adhesives, and interlocking mechanisms, manufacturers can achieve unparalleled efficiency, accuracy, and reliability in their robotic assembly processes. As the robotic manufacturing industry continues to evolve, so too will the innovative fastening solutions that drive its success.

Smart solutions for the Robotic Sector : Download Now

Have more questions? Contact us right now: -

Call us: +91-1262-205-205

Visit Our Website: www.bossard.com

View product details in the E-Shop.

#Robotic Manufacturing#Industrial Robots#Automation#Wedge-locking fasteners#Self-clinching nuts#Collaborative Robotics#Stainless steel fasteners#Blind rivets#Rivet Technology

0 notes

Photo

Master Bedroom

Mid-sized modern master bedroom with gray walls and a laminate floor

#stainless steel firebox#transitional#water front#mediterranean#century furniture#modern mediterranean#phillip jeffries rivets wallpaper

0 notes

Photo

Master Bedroom

#Mid-sized modern master bedroom with gray walls and a laminate floor stainless steel firebox#transitional#water front#mediterranean#century furniture#modern mediterranean#phillip jeffries rivets wallpaper

1 note

·

View note

Photo

Portland Roof Extensions Deck

#Example of a large urban backyard deck design with a roof extension indoor-outdoor#stainless steel hardware#rivet#wood shelf#raw#wood beams

0 notes

Text

Give a gift of galactic proportions. Art.

All work 10% now through December 24th

“Captain’s log, stardate 12.17.2023. Space… the final frontier… These are the voyages of rogue taxidermy. My 25-year-old mission: to explore strange new works. To seek out new life via new amalgamations. To boldly go where no man has gone before”

#FemaleTaxidermist

#ExperimentalTaxidermy

#OutOfThisWorldTaxidermy

TITLE: You Have a Wonderful Future Behind You

MATERIALS: Tanned and dehaired squirrel hide covered with schlagmetal (body), recycled platinum mink remnants (tail), mirrored stainless steel marbles (eyes), nickel-plated bank pins (rivets), antique jewelry box feet, vintage Swarovski cut crystal acorn, deco-style black lacquer wood plinth, artificial turf

One of my taxidermy sculptures that recently landed at Lovetts Gallery in Tulsa. The theme for this particular exhibition was “Area 51”. I enjoy the challenge of coming up with concepts that fit into themed shows and one pushed taxidermy to the outer limits. This piece was inspired by a theory that suggests extraterrestrials are time traveling humans from Earth’s future. No one can predict the future, but there are inevitabilities in the foreseeable. More flora and fauna will go extinct. Technology will increasingly replace organic processes. Our world will slowly fill up with artificially created plants. Artificially created animals. Artificial environments. Artificial intelligence. Artificial everything. After we are gone, there will only be monuments to what once was. This piece is intended not only to evoke the feeling of a monument, but also to mimic a trophy; a satirical award for our stellar stewardship of the planet.

~

Link here to see all work currently available

#EnvironmentalArt#EcologicalArt#EcoArt#TaxidermySculpture#TaxidermyArt#PopSurrealism#LowbrowArt#SquirrelArt#SquirrelSculpture#Squirrels

2 notes

·

View notes

Note

Hello! I’m super curious as to wear you get your biothane from and where you get the bits for it? (Not sure what to call em but I mean the buckles and screws/bolts for them)

I’m very interested in making biothane for my service dog and I’m not sure where to start :’)

Hi! I'm happy to help, making biothane gear is a lot of fun!

I get my biothane and hardware from a few different places usually. For biothane, I'm going to assume you are looking for beta biothane (the matte, soft, leather-ish textured biothane that most makers use for dog gear) since that's what I use. Generally, for whole rolls (25 ft minimum,) I go to Strap Warehouse. When I don't need (or can't afford) a whole roll, I tend to purchase from The Lucky Hound since they sell by the foot! Occasionally I will buy from Paracord.eu (sells by the meter) or Lennie Equipment (sells by the meter or by the roll) because sometimes they have widths/thicknesses I'm looking for that American distributors don't sell.

The Lucky Hound and Paracord.eu also have some exclusive/limited edition biothane colors that other distributors don't have, because they had them custom produced with the Biothane company! These include discontinued colors Biothane no longer produces, and completely custom new colors. Recently a lot of new colors have been coming out this way and it's really exciting!!

As for hardware (rings, buckles, snaps, clips, rivets, eyelets, etc.,) it's not always easy to find exactly what I'm looking for--I like solid stainless steel and solid brass the best, and I like to use double cap rivets rather than tubular style or Chicago screws, and so I tend to shop around to different trusted suppliers to find who has the exact pieces I need. Ohio Travel Bag, Tandy Leather, Buckle Guy, Weaver Leather, Stecks Store, Strap Warehouse, Paracord.eu, and Lennie Equipment all have an assortment of good quality hardware that I trust to choose from and have bought from in the past. Specifically for stainless steel rivets (hard to find!), I buy from Collars by Kitt. In general, I would avoid buying hardware from like...sketchy Amazon sellers, just because the quality is very hit or miss with them.

Those are the sources for materials I use most often, but if there's anything you can't find specifically, I might have it bookmarked somewhere, so feel free to ask!

Aside from that, some general tips: here is a handy resource to see what colors/thicknesses/widths of beta biothane are currently being produced mainstream by the company and what their specs are (break strength, size, etc.)

Personally I prefer to use "standard" thickness beta biothane for most of my gear. I use rivets with 8mm-9mm long posts when I need to fasten thru 2 layers of standard thickness biothane, and rivets with 10mm-12.7mm long posts when I need to fasten thru 3 layers of standard. As a general rule, for any hardware being set through the strap (rivets, eyelets, snaps, etc.) you want a post length that's ≥2mm longer than the total thickness of material you're going through (that said, there is a such thing as post that's TOO long.)

For setting rivets, you can get hand setters that are just a post and a little anvil that you use with a hammer (don't use a hammer with a metal head, you will damage your tools and hurt your hand over time.) But unless you're well-practiced with those hand rivet setters, it can be difficult to get consistent quality results (and trying to set a stainless steel rivet by hand would be rough!) so if you have the budget for it, I highly recommend a hand press with a lever arm--you can get different dies for it for hole punching or setting rivets, eyelets, snaps, etc. of different sizes. I have one similar to this one which is relatively cheap but still works well (and the tool dies for it are affordable,) but there are fancier ones for much more expensive. This one is the dream I would love to have someday, since it has a lot of nifty accessories you can get for it like a self-centering guide for punching.

For punching holes, you can use a hand press like the aforementioned ones for rivet setting, or you can get hand punches that you use with a hammer, or a rotary punch from any of the above leathercraft shops, or most craft stores. Punching by hand can easily give fine results (it's not as prone to issue as setting rivets by hand) and the rotary punch is convenient, but if you're doing a lot, the rotary punch can get pretty tiring to use since most of them take a lot of hand strength to use, lol. So I really like my press for punching holes too!

Hmm I think that is all I can think of off the top of my head, but if you have any other questions, feel free to ask! Hope this helps! :)

11 notes

·

View notes

Text

1. always buy cookware with double rivet stainless steel handles if u want it to last. 2. always buy stainless steel pots. 3. you can’t do high heat in nonstick pans (and steak needs high heat) but you can in stainless steel. 4. do not scratch a nonstick pan. 5. olive oil burns easily so find something with a high smoke point. 6. never use commercial spray oils. please trust me. this has been a psa

4 notes

·

View notes

Text

Usha Precision

We are renowned manufacturer & supplier of a wide range of industrial flat head rivets as well as round head rivets, Our various types of solid metal rivets are made using superior quality material which is tested before the production process.

#Micro Rivets#Micro Screws#Steel Rivets#Stainless Steel Rivets#Metal Rivets#ss rivet#stainless steel dowel pins#stainless steel dowels#precision turned components#machined parts#stainless steel#metal parts manufacturing

0 notes

Text

instagram

Ideal for mending gaps in mail armor, replacing lost rings and for making small alterations in sizing.

You can find our loose chainmail here.

#Kult of Athena#KultOfAthena#Chain Mail#Chainmail#Armor#Armour#Dome Riveted Chain Mail#Wedge Riveted Chain Mail#Butted Chain Mail#Loose Chain Mail#Zinc Coated#Mild Steel#Aluminum#High Tensile Wire#Stainless Steel#Instagram

1 note

·

View note

Text

Test fit works so far. I'll need some stainless steel stock and more rivets, then I'll bolt on some leather belts to act as straps. That way I can get it off the jacket for cleaning.

4 notes

·

View notes

Text

Blast From the Past?

A look at Brownells Retro Style 20 round mags.

With the popularity of Retro ARs these days, it was no surprise Brownells supplied and encouraged the trend. With their line of Retro parts, one can build a clone of the rifles of the past. One part of any XM177, Colt 601, or M16A1 clone is the twenty round mags common to the era.

With this rise in popularity, the price of original mags from the era has risen. The Colt and Universal Industry Mags have gotten to the point of price no one but die hard cloners and collectors were buying them. Why spend $20-$25 for an old mag, when new GI style could be had for $12? That’s where Brownells stepped in. The 20 round Brownells mags come in at about $15. A much better price than some of the old original mags. But are they exact clones? Let’s take a look.

An Original Universal Industries on the left, Brownells on the Right.

The Brownells mag features a few changes from originals. Most likely this steams from updated manufacturing processes. The first thing is the follower. The originals feature an aluminum follower. These followers appear to have anti tilt properties(which do not matter in any case for straight mags). The Brownells is a black plastic that’s appears to be identical to the aluminum original, but isn’t anti-tilt(again no issue).

The brownells has a stainless steel spring, and the original has a blued steel spring. The body construction is slightly different processes also between the two. The originals were stamped from one piece of aluminum, and spot welded on the rear spine of the mag. The brownells is like the current style of 30 round mags, with two half’s spot welded on front and rear.

Noticed the half’s welded together on the Brownells mag. The original has 3 rivets on the front to hold the floor plate retention spring.

The floor plate is also slight different. The originals have a piece of spring steel in the body riveted to the body via 3 rivets on the front of the mag. By pressing down on the spring retention, the floor plate slides out. On the Brownells mags it is like a modern 30 round. To retention ears on the rear, and you slightly lift up to slide it out.

How do they run, and are they right for clone rifles?

I’ve had zero issues with the Brownells mags. They fit all my rifles fine, and feed ammo fine. Are they clone correct? Most people won’t even notice it’s not exactly constructed like the originals. I feel like they did a good job updating them to newer materials, and giving them the correct look, while also implementing modern construction practices. And for the money it’s a great way to get the look you want, for around $5+ less per mag over finding originals.

If you’d like to have some yourself they can be found at the link below. If you spend more than $150, use my friend Alex’s (he can be found on here and IG under the handle pipeguy) discount code : pipeguy10 to save you 10%.

2 notes

·

View notes

Photo

✔️ .Made of 2mm thick stainless steel laser cut with satin finish. Includes ABS (Acrylonitrile butadiene styrene) anti-vibration inserts for a perfect fit. Valid for both glued methacrylate license plates and for riveted / screwed plate license plates. #TopMiata #JDM #Mazda #Miata #MX5 #roadster #namiata #nbmiata #vrscustoms #miataparts #topmiataparts https://www.instagram.com/p/CkOPKZToztf/?igshid=NGJjMDIxMWI=

2 notes

·

View notes

Text

Nuts and Bolts: The Foundation of Automotive Engineering

Fasteners like nuts and bolts are often overlooked but crucial components in the complex world of automotive engineering. Without them, even the most advanced engines or chassis would fail. Fasteners hold everything together, from the engine to the suspension, ensuring vehicles operate safely and efficiently.

What Are Nuts and Fasteners?

Fasteners are devices that secure components together. Nuts, paired with bolts or screws, form a strong connection, providing stability for engine components, the chassis, suspension systems, and wheels.

Types of Automotive Fasteners

Hex Nuts and Bolts: Commonly used for engine mounts and suspension parts.

Lock Nuts: Resist loosening due to vibrations, essential for suspension systems.

Flange Nuts and Bolts: Provide even pressure distribution to reduce wear.

Stud Bolts: Used in parts needing frequent disassembly, like cylinder heads.

Rivet Nuts: Provide permanent fastening, often used in body panels.

U-Bolts: Secure heavy-duty parts like suspension leaf springs.

The Evolution of Fasteners in Automotive Engineering

Standardized fasteners revolutionized the automotive industry during the early 20th century, especially with Henry Ford’s assembly line in 1913. This made vehicle production and repair more efficient. Today, high-strength materials like stainless steel and alloy steel have further improved fastener durability and performance.

The Importance of High-Quality Fasteners

Using high-quality fasteners is critical for vehicle safety:

Strength and Durability: Automotive fasteners must withstand high pressure and stress.

Vibration Resistance: Fasteners that resist loosening due to constant movement prevent components from falling apart.

Corrosion Resistance: To maintain strength, fasteners exposed to the elements must resist corrosion.

DIY Maintenance: When to Replace Fasteners

Regular Inspections: Check for rust or wear during routine maintenance.

Replace Stripped Fasteners: Damaged fasteners should be replaced to maintain vehicle safety.

Follow Torque Settings: Use the manufacturer's recommended torque to avoid over- or under-tightening.

Leaders in Automotive Fasteners

Companies like Bulten AB and Stanley Black & Decker have been at the forefront of fastener innovation, supplying high-quality products for automotive use.

Sandhri Associates: Your Trusted Fastener Supplier

Sandhri Associates offers a range of nuts and fasteners, from hex bolts to U-bolts, ensuring your vehicle stays safe and functional. Contact us or visit our Fasteners Collection to learn more.

Contact Us: +91-9315518391 | +91-7290814098

Email: [email protected]

Product Link: Nuts and Fasteners

#autospareparts#auto parts supplier#oemparts#aftermarket#motorcycle#sandhriassociates#fasteners#nuts and bolts

0 notes

Text

Fastener Failures: Common Problems and Preventative Measures

Bolts, screws, and rivets are common fasteners used in construction and manufacturing, forming the foundation of many structures and products. Despite its important role, fastener failures are a common occurrence that can lead to larger structural failures, safety risks, and increased costs. Understanding why fasteners fail and how to avoid them is crucial for anybody designing, manufacturing, or maintaining goods and structures.

Caliber Enterprise is a renowned Fastener Manufacturer in India. Fasteners like bolts, nuts, screws, and washers are what we manufacture. Our specialty is producing and offering for sale stainless steel fasteners in a range of sizes at competitive prices. Our bolt fasteners are all compliant with International Quality Standards (IQS), ensuring that you will consistently receive high-quality products. We are also a well-known fastener supplier in India.

What is Fasteners?

A fastener is a mechanical device that securely or temporarily connects two surfaces or things. Non-permanent fasteners can be easily removed without damaging the attached materials. Permanent fasteners may need to be removed with considerable force, causing damage to the attached surfaces. Permanent fasteners are designed to offer a long-lasting, secure fastening.

Common Causes of Fastener Failures

Material Defects: Any fastener's material needs to be suitable for the intended use. For instance, rust may result from using untreated steel screws outside. The presence of impurities and improper material properties might weaken fasteners and lead to their failure.

Improper Installation: Incorrect fastener installation is a primary cause of failure. Overtightening can produce excessive stress and eventually fracture, whereas undertightening may not effectively secure the components, resulting in slippage or loosening over time. Torque standards must be followed exactly as specified by the manufacturer.

Environmental Factors: Environmental variables can significantly affect the integrity of fasteners. Moisture, seawater, and corrosive substances can all induce corrosion, which weakens fasteners. Similarly, extreme temperatures can cause materials to expand and compress, resulting in loosening or cracking.

Preventative Measures

To minimize the risk of fastener failures, consider the following strategies:

Select the Right Material and Coating: Always use fasteners made of materials appropriate for the climate and loading circumstances. Furthermore, applying the appropriate coatings, such as zinc plating for corrosion protection, can extend the life of fasteners.

Follow Installation Guidelines: Use the correct tools and follow the manufacturer's torque specifications during installation. It’s often helpful to use torque wrenches to ensure that fasteners are neither too tight nor too loose.

Regular Maintenance and Inspections: Regular checks can help identify potential issues before they lead to failure. Look for signs of corrosion, loosening, or wear and address them promptly.

Countries We Supply Fasteners

Fasteners Manufacturer in India

Fasteners Manufacturers in USA

Fasteners Manufacturers in UK

Fasteners Manufacturers in Russia

Fasteners Manufacturers in Germany

Fasteners Manufacturers in Australia

Fasteners Manufacturers in Saudi Arabia

Understanding the key causes of fastener failures and applying these preventative approaches allows you to significantly reduce the risks associated with fastener failures, hence enhancing the safety, dependability, and durability of your projects and products. Remember that each fastener is vital to the structural integrity of a building or product, therefore careful selection and maintenance are required for success.

Product Source: Fasteners Manufacturers

0 notes