#Stenter Machine Price

Explore tagged Tumblr posts

Link

KEW ENGG. & MFG. PVT.LTD. Manufacturer, exporter, and supplier of Stenter Machine. We offer high-quality stenter machines to meet international standards. The stenter is fully motorized with a heavy sprocket and a complete system of width adjustment is fitted to the machine.

For More Information:

Website: kew.net.in

Email:[email protected]

Contact us: +91-7940085305

1 note

·

View note

Link

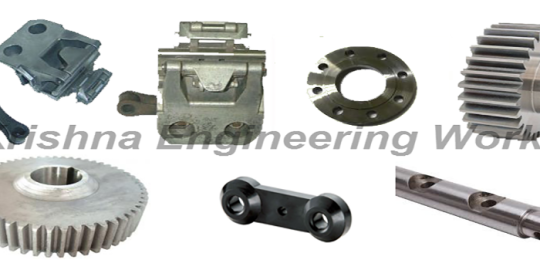

We “Krishna Engineering Works” are manufacturing, exporting & supplying of all types of spare parts for stenter machine like Chain wheels, stenter clips and many more. For more information visit our website krishnaengineeringworks.com or contact us at [email protected]

#stenter parts#stenter Chain Wheel Price#stenter machine spares#chain wheels#stenter spare parts#stenter chain wheel parts#spare parts for stenter machine#stenter machine parts

1 note

·

View note

Link

Textile Machinery Spare Parts Manufacturer India, Rubber Roller, Rubber Fillet, Stenter Machine, Jigger Machine, Cloth Guider, Rotary Printing Machine Part. chain-link-bottom-parts, Jigger Machine, Cloth Guider, Folding Machine, Rotary Printing Machine Parts, Bowl Mangle & Drying Range, Gear Set, Spinning & Weaving Machine, Rubber Rolls, and Rubber Fillet from Ahmedabad, Gujarat, India. Continuous interaction with our customers & personal good relations with them is our work policy. All type of Bow Roll Manufacturer for Textile Processing Machinery. Textile Machinery Spare Parts, Textile Machinery Parts, Textile Machinery Part, Textile Machinery Spares, Textile Machinery.

#Textile Machinery Spare Parts#'#Textile Machinery Parts#Textile Machinery Part#Textile Machinery Spares#Textile Machinery#Rubber Roller#Chain Wheels#Pin Bars#Stenter Clips#Textile Machine#Textile Machinery price#Types Textile Machine#Machinery Spare Parts#Rubber Roll#Rubber Fillet#Bow roll#stenter machine#Jigger Machine#Cloth Guider#Rotary Printing Machine Part#Rotary Printing Machine Parts

1 note

·

View note

Link

Leading manufacturer of Stenter Machine Spare Parts like Chain Link, Bottom Parts, Stenter Machine Pin Bar, Stenter Clip, textile machinery in India. A Textile Machinery Spare Parts Manufacturer, Stenter Machine, Jigger Machine, Rotary Screen Printing Machine, Mechanical Cloth Guiders, Folding Machine, Gear Sets, Nylon Gear Cuppling & Sleeve, Rubber Roller, Stenter Clip, Stenter Machine Pin Bar etc. Stenter Clips of Any Make like Artos, Dhall, Harish, Yamuna, Hi-Tech, S.M., Stenmech Lucy , Bharat Eng., Monfort, Montex, Swastik, Bruckner, Babros, Ambika, Famatex, etc. Chain Link & Bottom Parts (Pin Block, Loop Chain) of Any Make Stenter Machine. Pin Bars - Any make like Artos, Harish, Supra, Montex etc. Shaft (Main Drive, Driven Horizontal Shaft, etc.) Over Feed (Rubber Pulley Assembly, Drum Pulley Assembly, Post Pin Brush Assembly, Three Finger Uncurrler Assembly).

#Stenter Machine Spare Parts#Textile Machinery#Stenter Machine#Textile Machinery Spare Parts Manufacturer#Jigger Machine#Rotary Screen Printing Machine#Mechanical Cloth Guiders#Folding Machine#Textile Machine Manufacturer#Textile Machine price#Textile Machinery Spare Parts#Textile Machinery Industry#Textile Machinery in India

0 notes

Link

Spares Textile Processing Machinery, Textile Machinery Spare Parts Manufacturer India, Stenter Machine, Jigger Machine, Rotary Screen Printing Machine. Universal (Multi Repeat) Bridge Assembly Drive & Pump Side for 640,820,914. Single Repeat Bridge Assembly Drive & Pump Side for 640,820,914. Universal Screen Setting Assembly (RH / LH). Screen Setting Assembly (RH / LH). Screen Guide Bearing Bracket. Screen Guide Bearing & Pin. Stenter Machine Spare Parts like, Stenter Clips, Chain Link Bottom Parts, Pin Block, Loop Chain, Pin Bars, Gear Box Parts, Shaft, Over Feed and Chain Wheels. Cloth Guider Spare Parts, Bracket left & right, Base Plate Alluminium Left, Base Plate Alluminium Right, Tope Fiber Roller Laminated complete, and Fiber Roller Laminated only. Healed Frames and Healed Frame Accessories. Reeds, Heralds and Drop Pins. Spinning Weaving Machinery Spare Parts.

https://youtu.be/NqBr-6efPf8

#Stenter Machine#Textile Machinery Spare Parts#Textile Machinery#Textile Machine price#Textile Machine spare parts#Textile Machine Manufacturer#Jigger Machine#Rotary Screen Printing Machine#Textile Machinery Spare Parts Manufacturer India#Spares Textile Processing Machinery#Spinning Weaving Machinery Spare Parts#Stenter Machine Spare Parts#Cloth Guider Spare Parts#Folding Machine Spare Parts

0 notes

Text

Manufacturer of Stenter Machine Famatex Primatex, Stenter machine at Best price – Krishna Engineering Works

Stenter Machine Famatex Primatex Manufacturer, We are the leading manufacturer, exporter, and supplier of Famatex Primatex with international standards for the last 25 years from India. Heavy-duty and high-quality Textile Machinery Spare Parts and Stenter Machine Spare Parts like Stenter Clip, Stenter Pinbar. For more information:

Website: krishnaengineeringworks.com

Email: [email protected]

Contact Us: +91-7940085305

2 notes

·

View notes

Text

Reasons How Rubber Rollers Makes Life Easy For Industries

Rubber Rollers

The rubber roller is one of the most important parts of the manufacturing and processing industry. It’s mainly used in the Textile, steel, paper, and packaging industry. These rollers are crafted according to the industry requirements and offer optimal performance. There are many different kinds of rollers, built according to the requirement of the industry.

Rollers for various industrial use

Silicone rubber rollers

Silicone Rubber rollers come in many different colors & sizes with required hardness (25 to 85 shore) along with surface grinding and suitable Bearing size. It is made up of ultimate quality silicon raw material. This material has an extremely high-temperature range and it is the best electrical insulator too. The silicon rubber roller has a heating base in it. Silicon Rubber Rollers are used for many different applications. It is used for cutting the sealing, hot melt coating, extrusion coating, foil processing, holography, poly coating, heat & press lamination, and thermal lamination to name a few.

Groove rollers

The Groove rollers are manufactured at a very economical price for industry use. These rollers are made by using ultra-modern machinery & ultimate quality raw material that is available in different lengths and diameters. These rollers are known for their effective working & accurate finishing. It has various properties like longer stability, corrosion & moisture resistance. There are many different types of grooves available according to their use like vertical groove, helical groove, screw cut groove, horizontal groove, double-helical groove, diamond cut groove, and all types of grooves. And these grooves are used for sealing machines, pouch machines, and remove all types of wrinkles & slips.

Ebonite Roller

Ebonite roller is manufactured of supreme quality that is designed and fabricated with the use of the latest tools and advanced technology. It is capable of surviving the high temperature of steam and water. That's why it provides excellent performance and long service life. These rollers are available in various sizes.

Ebonite rollers are very easy to install, has precise dimension, long service life with high functionality.

Nips Rubber rollers

Rubber roller made of the different compound as per their use and working environment. Nip Rollers are high-quality rubber rollers, used for the Textile industry. These are used under different working conditions for better Squeezing efficiency. These rollers are chemical resistant, have stable strength and uniform hardness which protects the roller core and shaft. It is used for varied processes like Singeing, DE sizing, Impregnating, Bleaching (PTR), Mercerize Range, Stenter m/c, Washing, and Dyeing, etc. for the textile industry.

Teflon roller

These rollers are Teflon coated, are widely used in the textile industry. The Teflon rollers prevent corrosion and use for non-stick applications. The Teflon coated surface of the rollers provides great resistance against general wear & tear and heat. Teflon roller manufacturers in India export an extremely wide range of industrial rollers, which are designed according to advanced industrial standards. Customization can be done to meet specific dimensions.

Guide rollers

These rollers are installed for direction control of the unit loads. The application of the guide roller is to maintain the guided direction of a moving object like a drawer, door, fence, or tank track. This roller provides easy movement of the objects with less resistance. Guide Rollers allows easy lifting of the object without causing any damage.

Printing rollers

The Printing rollers are assembled with three different rollers. First is the ink ductor roller that first receives the ink. The second is the ink form rollers that give the ink to the printing plate and the third is distributor rollers through which paper comes back after printing. It is used for paper printing or press purposes.

Lamination Rollers

Lamination rollers are used for laminating important stuff like important documents. This roller includes hard chrome plated surface & Rubber roller. lamination rollers mechanism is to apply a thin plastic cover to paper documents with the combination of heat and pressure. Lamination rollers are used for Paper laminators, Printed circuit board laminators, Dry film laminators, Cold lamination, Hot lamination.

With four decades of industry experience in its quiver, Arvind Rub-Web Controls Ltd. has established itself as an industry leader in manufacturing, supplying, and export of a range of industrial rubber rollers!

#Rubber Roller#Silicone Rubber Roller#Groove Roller#Ebonite Roller#Nip Roller#Teflon Roller#Guide Roller#Printing Roller#Lamination Roller#Manufacturers#India

14 notes

·

View notes

Link

We have been dealing on manufacture and export for textile machinery. We are a leading Textile Machinery Spare parts manufacturer and supplier. We are leading manufacturer, exporter and supplier of Spare Parts for Stenter Machine like Stenter machine chain wheels with international standard from last 25 years from India. For more information Visit our website: conpaptex.com

#Stenter machine chain wheels#Stenter chain manufacturers#Stenter chain#Stenter spares#Stenter machine parts#Stenter spare parts#Stenter wheel#Stenter Textile Machine Chain

1 note

·

View note

Link

0 notes

Link

Krishna Engineering Works is known as a biggest manufacturer & Exporter of textile machinery Parts with standard quality and Best Price. Textile Machinery for Stenter Machine, Jigger Machine, Rotary Screen Printing Machine, Mechanical Cloth Guiders, Folding Machine, Gear Sets, Nylon Gear Cupping & Sleeve, etc.

#textilemachinery#spareparts#textile#machinery#sparepartsmfg#textilemachineryparts#textilemachineryspareparts#textilespinningmachineryspareparts#textilesparepartssuppliers#textilemachineryspares

0 notes

Link

Stenter Machine Artos Clip Manufacturer, Stenter Clip and all type of Stenter Machine Clips Manufacturer, Stenter Pin Bar and Pin Block Spares available. All type of Stenter Clips, and Textile Machinery Spare Parts Manufacturer in lowest rates. More Information visit our site: krishnaengineeringworks.com

0 notes

Link

We “KRISHNA ENGINEERING WORKS” are leading Manufacturer, Exporter and Suppliers of Stenter machine Shaft with the best price. Stenter Machine Pin Bar, Spare Parts of Stenter Machine for Textile Machinery Industries, high-quality Stenter Machine Shaft. All our Textile Shafts are dimensionally accurate and functionally superior shafts, meeting with international standard and per our client’s requirement. All textile shafts are highly durable due to the high-quality material.

1 note

·

View note

Link

Krishna Engineering Works is Best Stenter Machine Manufacturer in India also Manufacturing Spare Parts like Overfeed for Stenter Machine at best price and Standard Quality, We have a highly qualified engineering team who proper analysis and surveying every products quality. For more information contact us.

#Stenter Machine Spare Parts Manufacturer#Machine Parts Manufacturer#Machine Manufacturer#Stenter Machine#Stneter Machine Parts Supplier#Stenter Machine Parts Exporter#Parts Manufacturer

0 notes

Text

Choosing fabric and fabric types

fab-5.jpg Choosing fabric can be overwhelming, there’s often too much choice. When I can’t decide, I ask for small samples that I take away, so I have time to think - even if its just while I have a cup of coffee. Try not to buy on price alone, some of my ‘bargains’ have never been used. Here is a brief overview of the types of fabric used and some tips on working with them. Fab3.jpg Woven Fabric Basic woven fabric is constructed with threads interwoven at right angles to each other. The threads running down the length of the fabric are called the warp and the threads that run across the width are called the weft. This form of construction usually creates a fabric that is rigid or non-stretch in the warp or weft direction although flexible on the bias – an angle of 45 degrees to warp or weft. There are also stretch woven fabrics where Lycra or Elastomeric yarns are included in the weave construction. These fabrics can stretch in one or both directions depending on how the stretch yarn is added in the weaving process. The other form of stretch woven is called a mechanical stretch. This is when a chemical finish is applied to the flat fabric causing it to shrink creating a stretch when pulled. The stretch quality in a mechanical stretch fabric is not as strong or long lasting and will not keep bouncing back. For example if a tight fitting skirt is made in a mechanical stretch fabric it will ‘seat’ and not bounce back until it is washed again. Terms such as denim, canvas or twill, refer to the type of weave pattern. To sew with woven fabrics is fairly straightforward. Use a universal needle and straight stitch setting on your sewing machine. Vary the size of needle and stitch length to suit your fabric weight. fab6.jpg Knitted or Jersey Fabric Knitted fabric is more complex in construction than woven fabric. In its most basic form it is made from a series of interlocking loops formed by a single thread continually looping through the last row of loops created. The resulting fabric is much more flexible than a woven fabric and can stretch in any direction. In a similar way to mechanical stretch woven fabrics, if there is no Lycra or elastomeric content in the yarn used, tight fitting garments will ‘seat’. T-shirts are often made from basic jersey with no added stretch content. The fabric used to make leggings will usually contain 4% - 6%stretch fibres whereas performance sportswear and swimwear require a high percentage approximately 18%. Terms such as single or double jersey refer to the looped construction created by the needle bed set up of the knitting machine. Single jersey is knitted on one bed, either flat or circular, so the loops always fall to the same side, creating a right and wrong side. Double jersey is knitted on a twin bed set up so there is usually two right, though sometimes differing, sides to the fabric. It is generally thicker and more stable to work with. To sew with knitted fabrics use a Ballpoint or jersey needle, these are designed to push the threads aside as they stitch. This prevents any laddering resulting from broken stitches. Selecting the best stitch for jersey fabrics is dependent on the amount of stretch required. Too little stretch and the sewing thread can break when the seam is stretched. For most side seams I like to use a plain straight stitch however I apply a little tension to the fabric as I feed it under the machine foot. For waistbands and hems I use a zigzag stitch to allow for more stretch. If my jersey fabric splays out, I generally use a steam iron, without pressing the fabric, to relax the fabric back into shape. In the Stretch Pencil Skirt project there are a number of alternatives given for tackling hems in different ways. Fab-2.jpg Fine silky fabrics I find these the trickiest to work with but sometimes I can’t resist because of the luxurious delicate handle. Always use a finer needle whether it’s a Universal or Ballpoint. You can also get specialist needles for Microfibre that I have used on natural silks as well as synthetic silky fabrics. For buttonholes try using a stick on fabric stabiliser as used by embroiderers, I use Stitch and Tear. This will stop your fabric puckering up. fab-7.jpg Technical Fabrics This is a term that refers to either woven or knitted fabrics that are coated or bonded with a chemically produced fabrication. PU and PVC are terms used for imitation leathers – PVC stands for plastic Polyvinyl plastic coated woven fabric with a high sheen like patent leather. PU is a Polyurethane coated jersey fabric with a sheen finish and stretch qualities. Neoprene or scuba fabrics are bonded imitation rubber like fabrics with a jersey backing for increased flexibility. For technical fabrics with a jersey backing I’ve found I get the best results from using a ballpoint or jersey needle. For woven backed technical fabrics I use a Universal needle but if that has difficulty puncturing the fabric I use a leather needle. I also lengthen the stitch length to get a smoother result. The shiny surface of these fabrics can stick when in contact with the presser foot or machine plate. To avoid this happening use a Teflon foot and make a template of non-stick baking parchment to place over the machine plate, secure this with tape. For some PVC fabrics It can be impossible to pin your seams in place before stitching so try using a double-sided basting tape or alternatively hold the pieces together with small bulldog or paper clips. Always keep your technical fabrics rolled rather than folded this will stop any permanent creasing. fab4.jpg Leather When sewing with leather select skins that are reasonably lightweight and flexible. If you have never sewn with suede or leather, but would like to have a go, most suppliers have off cuts or part skins at reduced prices, so you can try out before investing in the materials for a whole garment. As leather is neither woven nor knitted fabric it has a tendency to tear at the seams, if there are too many stitch perforations. To avoid this increase your stitch length and always use a leather needle, its spear like point cleanly cuts the stitch hole. Try out the strength of your seam on an off cut. As with technical fabrics, leather can be impossible to pin the seams in place before stitching so try using a double-sided basting tape or alternatively hold the pieces together with small bulldog or paper clips. As with technical fabrics, keep your leather or suede rolled not folded. Before you start making - Once you‘ve bought your fabric always wash it before sewing. If you are not sure it’s washable, cut a 20cm square and place it in a 30-degree wool wash. Then when it’s washed and dried re-measure to check shrinkage and also to review the handle of the fabric. If you don’t like the result, make sure you only dry-clean the garment you are going to make. Before washing lengths of fabric, unfold them and iron out any creases. Loosely load into your machine and use a liquid detergent. These steps should avoid any unevenness in the colour fading especially with indigo and pigment dyed denim or coloured linens. The reason for pre-washing fabric is that during the manufacturing process, fabrics are often ‘stentered’. This is when they are pulled into a uniform width and length and a finishing chemical applied. The problem with this is, that when the fabric is subsequently washed, it ‘relaxes’ back or shrinks. So by washing it before making, you can make sure what you make doesn’t shrink. Do not wash suede, leather or PVC. I have washed PU not because it would shrink but because it can have an unpleasant chemical smell. This article is taken from the book The Makers Atelier - Essential Collection available HERE http://dlvr.it/PQyg9r

3 notes

·

View notes

Text

Flat Screen Printing Machine VS Rotary Screen Printing Machine

Flat Screen Printing Machine Brief Introduction: Flat-screen printing machines can be manual, semi-automatic or completely automatic. One type of machine, which is still commonly found in printing houses, can be described as follows. The fabric is first glued to a moving endless belt. A stationary screen at the front of the machine, is lowered onto the area that has to be printed and the printing paste is wiped with a squeegee. Afterwards the belt, with the fabric glued on it, is advanced to the pattern-repeat point and the screen is lowered again. The printed fabric moves forward step by step and passes through a dryer. The machine prints only one color at a time. When the first color is printed on the whole length of the fabric, the dried fabric is ready for the second cycle and so on until the pattern is completed.

Rotary Screen Printing Brief Introduction: Rotary screen printing is a continuous printing process. A perforated cylinder or spherical screen are used which are automatically fed with paste from inside by special pump. Each screen is independently driven. The transfer of printing paste through the perforations of the screen into the fabric is governed by specially designed squeeze blades. During printing, the paste is pressed through the surface via openings in order to obtain the desired design. The cylindrical screens allow more screens to be arranged per unit length than is the case with flat screen printing. Speed range from 30 to 50 metres/min. The standard internal circumference of cylindrical screens is 640 - 640.1 mm. However, other dimensions· are also possible. Production efficiency of rotary screen printing is high though printing cost is high due to high price of screen. Besides, different screens are needed for varying colors.

1. In Flat Screen Printing Technology the screen is flat and moves up and down. Beside, the Rotary screen is round in size and it rotates.

2. In Flat screen printing the Squeeze is used. In Rotary Screen Printing, just Roller is used.

3. Small width fabric (45-50″) is printed on Flat Screen Printing. On the other side, large width fabric is printed on Rotary screen printing.

4. In flat screen printing pattern, there are only 6 to 8 color is available. But if you use the Rotary Screen printing, then you will be able to use 16 to 24 colors in a pattern.

5. Flat screen printing process gives a lower production rate. And the Rotary Screen printing is comparatively faster than Flat Screen printing and production rate is 3 times higher than that.

6. The initial investment cost for Flat screen printing machine is low, so that it’s less expensive. But, the initial cost of investment in Rotary screen printing is too high; so, it’s expensive.

Hotairstenter.com is real manufacturer of a series Flat Screen Printing Machine. Our goal is to provide high-quality Hot Air Stenter Machine and Flat Screen Printing Machine products to customers and market. Welcome your visit.

0 notes

Link

If we compare the present business situation of knit sector with one decade earlier, FOB price significantly reduced, on the other hand, direct labor cost increased 4.8 times more, utility cost and crisis increased, the huge investment required to ensure occupational health & safety, have to face huge competition i.e. business environment become volatile, uncertain, complex and ambiguous day by day. Factories are falling in profitability crisis for different reasons, here I want to narrate a few management failure cases which impact greatly on profitability. Sometimes, factories fall in the sinking point from where turning back to the race become more and tougher. If leaders / CEO‘s decision was not appropriate, the amount of loses becomes huge. Surely it will impact profitability, in the long run, organizations have to pass a tough time to survive in the competition. I want to share a few case studies which will be an eye opener for others. Expansion: Many factories did not study the feasibility and consider Return on Investment before invest further to increase production capacity. One of a renowned factory KFMA (not really name), invest in a fabric manufacturing plant to make the capacity double by sanctioning loan from the bank. CEO does not take any advice from any technical expertise. He does not believe and rely on technical persons/subordinates. He loves to take a vital decision by himself. His dream was, by selling fabric to other RMG units, he will be able to pay the installments of bank loan. After completing the multistoried building and installed all the machinery, he found two drawbacks, All the machinery cannot run with existing approved gas connection. The government does not approve any connection for the industry at that moment. Gas consumption of boiler crossed the approved limit when all the dyeing machine runs. There is a chance of disconnection from Titas if repeatedly exceed the approved limit for consecutive months. So, the CEO decided to run 50% dyeing machines. Captive electricity is not sufficient to run finishing range as well as, 50% finishing line remains Stenter runs by CNG gas even though it was not economical. Managing the payment of monthly bank installment became tougher than ever. Dream broken just after installing all the machines. So the consequence of the above bad investment, disbursement of wages and salary of the workforce can’t maintain on time, due by several months. Huge credit on the supplier’s receivable, facing liquidity problems. Can’t open L/C for yarn, dyes, chemical etc. and on time shipment became a dream. The organization is passing a tough time. Many factories have also fallen in trouble with this type of immature investment. So, before any investment, we have to calculate the ROI. Project implementation: I know few factories, project implementation time takes more than 3-4 estimated times. By this way, the project cost has become much higher. Most of the cases entrepreneur himself follow up the project implementation activities. And implemented events not in the sequence, a few examples are like machinery arrives in factory before completion of new building, factory is ready for production but can’t obtain environmental clearance, factory is ready but gas connection was not obtained, lift or chiller arrived in the factory before the completion of the building etc. by this type of disorganization, the cost of manufacturing become high which leads to low profit. In case of new project implementation, Project evaluation and review technique (PERT) should follow by assigned technical persons. Who can help to implement the project on time, reduce the cost of the project & ROI will be less. Product Diversification: FOB price of all brands going down day by day. For our clear understanding, declined trend of FOB of legging orders of one of the top retailer in the county, 10 % price reduce within 4 years, in some case figures are higher. Minimum Wages of direct labor increase 51 % from 2013. Thousands of factories can produce basic products. All the buyers have alternative suppliers, due to unhealthy competition, the price of basic products are going down drastically. On the other hand, wages already increased 51%, which will be a big threat for textile industries. The organization should invest to increase the capability of doing value-added products. We should consider our workforce as a resource. We can covert our workforce into a strength by giving proper training. Most of the industries are focusing to train their people. By this way, we will be able to produce value-added higher price product which leads to higher profit. Own style Management: many entrepreneurs does not have enough knowledge on modern management. Successors are in the board immediately after completing the education. Entrepreneurs are thinking, their present successes indicate their previous strategy was right, they are more knowledgeable than professional employees. A renown textile industry KFMB, introduce the below strategy to increase accountability to their management staffs and workers. Everybody should submit their targets or to do lists to the concerned team in the morning. Before leaving the workstation in the evening, everybody again submits the job completion list to the concerned team. Salary & wages will be equivalent % of achieved average productivity. Every employee spends a noticeable amount of time and papers to comply above rules. 100% Verification of the performance cannot possible. Staff’s become demotivated after getting a repeated thread of salary deduction. Skill & talented staff’s leave the organization. After a few months, scrap the above strategy and try to adopt another new formula. Due to this type of experiment of management concept, productivity and profitability become low day by day. Many industries also practice their own management style, sometimes it gives positive results & sometimes gives negative results. We should follow the proven management philosophy like Lean/TQM/Six Sigma. Successors of entrepreneurs i.e. son/daughter should not be a board member after graduation. They should serve in the organization as a management trainee for a certain period so that he will become a mature leader. Unstable Management team: human beings are unique in all aspect, every top executive also have a unique concept and management techniques, many entrepreneurs want quick results even within 3-4 months from top executives. If results are not as per their desire, they change the executives. Found no consistent in any good practice causes a very frequent change in top position. Sometimes vital positions also changed when top executives leave the organization. Organizational reputation also fades. Recruitment of reputed performer become tougher than before. Failure of individuals, not for his capability, most of the causes due to systems/environments. All the transport drivers of Bangladesh will run the vehicle by maintaining 100% traffic rules in the cantonment area. Though same drivers are careless in other areas. So system and accountability is more important to ensure appropriate productivity as well as profitability.

0 notes