#Stenter Pin plate

Link

Stenter Machine Pin Plate Manufacturer, Stenter Pin Plate and Stenter Pin Bar Manufacturer with heavy duty material for all Stenter Machine Manufacturer. We have been in manufacturing also, are a worldwide exporter and supplier of Pin Plates for all types of Stenter Frames. Genuine and premium quality of Pin Plates for Stenter Machine. The high quality raw material used in the Pin Plates has made our Plates more durable for high performance. All type of Bow Roll Manufacturer on desired size and length. For more information:

Website: kew.net.in

Email: [email protected]

Contact Us: +91-7940085305

1 note

·

View note

Link

Stenter Pin Bar Manufacture, Export & Supply also Stenter Plate and Pin Block, Stenter Machine, Stenter Clip, Cloth Guider and leading textile machinery exporter. Flexible Printing & Packaging, Converting, Paper, Jute, Tarpaulins, HDPE Woven Sacks, Textile, Carpet, Leather, Technical Textile, Steel, Plywood & Laminates and Tyre-Cord Industry. We also manufacturer of Textile Machinery Spare Parts like Stenter Pin Bar, Stenter Machine, Stenter Clip, Cloth Guider Rubber Roller, Rubber Fillet etc. Stenter Pin bar and Stenter Machines spares manufacturer with International Standards.

#Stenter Pin Bar#Stenter Pin Bar Manufacturer#Stenter Pin Plate#Stenter Pin Plate Manufacturer#Stenter Pin Block#Stenter Pin Block Manufacturer#Chain Link Bottom Parts#Chain Link Bottom Parts Manufacturer#Pin Bars#Stenter Clips#Stenter Clips Manufacturer#Stenter Machine#Cloth Guider#Rubber Roller

1 note

·

View note

Link

We are Leading Manufacturer, exporter and supplier of spare parts for stenter machine like pin bars Stenter Pin Plate, Stenter Pin Block for all type of Stenter Machine, Stenter Clips, Textile machinery spare parts, Pin 44/ 72 pins, also dealing on Pin Bars for all makes of Stenter Machine more accurate and easy. We are also dealing on pressure dye casted Aluminium alloy pin block and hardened and hard chromed plated pin bar. Also we are Heavy duty Rubber Roller Manufacturer for Textile Processing Machinery.

#Stenter Pin Bar#Stenter Machine Pin Bar#Stenter Pin Plate#Stenter Clip#Textile machinery spare part#Stenter Machine#stenter machine spare parts#pin bars

0 notes

Link

We are leading manufacturer, exporter and supplier of Spare Parts for Stenter Machine like Pin Bars Parts with Pin Plates. We are also dealing on pressure dye casted Aluminum alloy pin block and hardened and hard chromed plated pin bar. also Stenter Plate and Pin Block, Stenter Machine, Stenter Clip, Cloth Guider and leading textile machinery exporter Textile Machine Spare Parts Manufacturer, high quality Pin Bars Manufacturer. Stenter Machine Shaft, Textile Machinery Spare Parts, Stenter Pin Bar, Stenter Pin Plate, Chain Link Bottom Parts.

#Pin Bars Manufacturer#Pin Bar Manufacturer#Pin Bar#Stenter Pin Bar#Stenter Pin Bar Manufacturer#Textile Pin Bars#Stenter Pin Plate#Stenter Pin Plates#Chain Link Bottom Parts#Pin Bars Manufacturers#Stenter Machine Shaft#Textile Machinery Spare Parts#Textile Machine Spare Parts Manufacturer#Stenter Pin Bars

0 notes

Link

We are leading manufacturer, exporter and supplier of Stenter Chain Link Bottom Parts, Stenter Machine Spare Parts, Stenter Machine Chain, Pin Bars, Stenter Clips, Stenter Pin Plates of Stenter Machinery and high quality Textile Machinery Spare Parts ready in stock and ready to dispatch. We also manufacturing Rubber Roller for the leading industries of textiles. Chain link made of high carbon steel with good tensile strength. We manufacture & supply all types of Stenter Machine Chain Assembly.

#Stenter Chain Link Bottom Parts#Chain Link Bottom Parts#Chain Link Bottom Part#Stenter Machine Part#Textile Machinery#Stenter Machine Pin Bar#Stenter Spare Parts#Stenter Pin Plates#Stenter Pin Plate#Stenter Clips#Chain link Fence Parts#Stenter Machine Chain Link Bottom Set

0 notes

Link

We are leading manufacturer, exporter and supplier Stenter Clip Manufacturer India, Stenter Machine Spare Parts, Stenter Clip, Artos Stenter Clip, Harish Stenter Clip, Pin bar Manufacturer. We also manufacturer of Rubber Roller, Stenter Machine Pin Bar, Stenter Chain Link Bottom Parts for the leading textiles industries. This Stenter clip can exhibit an excellent performance as a high speed clip. Our Stenter Clip are designed for the finishing of cloth which have hard tension. Also featuring as, Roller chain made of reinforced steel is capable of running at high speed and temperature for long life-cycle.

#Stenter Clip#Stenter Clips#Stenter Clip Manufacturer#Stenter Machine Clip#Stenter Machine Clips#Stenter Machine Clip Manufacturer#Stenter Pin Bar#Stenter Machine Pin Bar#Chain Link Bottom Parts#Stenter Pin plate#Spares Stenter#Textile Machinery Spare Parts#Textile Processing Machinery Manufacturer#Pneumatic Cloth Guider#Textile Machinery Spares#Textile Machinery Parts

0 notes

Link

We are leading manufacturer, exporter and supplier of Stenter Machine Krantz, all type of Stenter Machine Manufacturer with heavy duty equipment, spare parts, Textile Machinery Spare parts, Stenter Spares, Stenter Machine Chain, Stenter Machine Pin Plate, Chain Link Bottom Parts, Cloth Guider, Textile Machinery Spare Parts, Stenter Machine Famatex Primatex, Stenter Machine Artos, Stenter Machine Monfort. All type of Web Guide System Manufaturer with different type of hp power.

#Stenter Machine Krantz#Stenter Machine Manufacturer#Stenter Machine Chain#Stenter Machine Chain wheel#Stenter Machine Pin Plate#Chain Link Bottom Parts#Textile Machinery Spare Parts#Textile Machinery Spare Part#Textile Machinery Spare

0 notes

Link

Chain Link Bottom Parts offers comprehensive Stenter Machine Gear Box Parts, Stenter Machine Chain and Textile Machinery Spare parts Manufacturer. Chain Link Bottom Part, Stenter Machine Pin Bars, Stenter Clip, Stenter Machine Shaft, Stenter Machine Chain Wheel, Stenter Machine Pin Block, Stenter Machine Radiators, Stenter Machine Chain, Stenter Machine Pin Plate, Textile Machinery Spare Parts, Cloth Guider. We Are Also Manufacturer Stenter Machine Pin Plate.

#Stenter Machine Gear Box Parts#Stenter Machine#Textile Machinery#Chain Link Bottom Part#Chain Link Bottom Parts#Stenter Machine Pin Bars#Stenter Machine Pin Bar#Stenter Clip#Stenter Machine Shaft#Stenter Machine Chain#Stenter Machine Pin Plate

1 note

·

View note

Link

We “KRISHNA ENGINEERING WORKS” are the leading manufacturer of high performance Chain Link Bottom Part, Stenter Machine Spares and Chain Assembly. High quality Chain Link Bottom Part material with International Standards. Chain Link Bottom Part for all types of Stenter machines available. Pin Bar, Pin Plate, Stenter Clips, Gear, Shafts and many more. Heavy duty stenter machine and textile machinery parts in ready stock to dispatch on your desire requirements. We Are Also Manufacturer of textile machinery and equipments

#Chain Link Bottom Parts#Stenter machine spares#chain assembly#Heavy duty stenter machine#textile machinery parts

1 note

·

View note

Link

#Chain Link Bottom Parts Manufacturer#Chain Link Bottom Parts#Stenter Machine Pin Bar#Stenter Spare Parts#Stenter Clips#Stenter Machine Clip

0 notes

Text

Open Width Compactor: Parts, Functions, Working Principle and Specifications

Open Width Compactor: Parts, Functions, Working Principle and Specifications #compactor #compacting #compactormachine #opencompactor #openwidthcompactor #compactingmachine

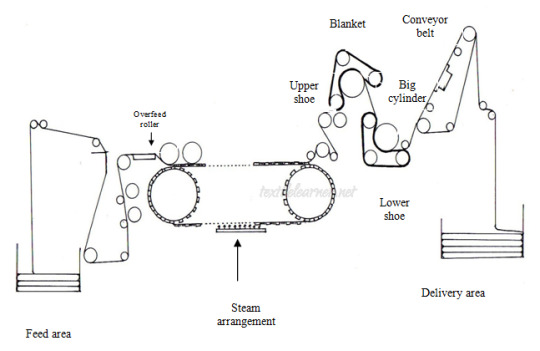

Open Width Compacting Machine:

Open width compactor machine is used for compacting the open form fabric. Here, slitting machine is used for open the fabric from the tubular form. Open width compacting machine is a combination machine of pin plate stenter and felt compactor, it is used for the processing of 100% cotton, wool, hemp natural fabrics and chemical fabrics in open width form. It is also…

View On WordPress

0 notes

Link

Spares Textile Processing Machinery, Textile Machinery Spare Parts Manufacturer India, Stenter Machine, Jigger Machine, Rotary Screen Printing Machine. Universal (Multi Repeat) Bridge Assembly Drive & Pump Side for 640,820,914. Single Repeat Bridge Assembly Drive & Pump Side for 640,820,914. Universal Screen Setting Assembly (RH / LH). Screen Setting Assembly (RH / LH). Screen Guide Bearing Bracket. Screen Guide Bearing & Pin. Stenter Machine Spare Parts like, Stenter Clips, Chain Link Bottom Parts, Pin Block, Loop Chain, Pin Bars, Gear Box Parts, Shaft, Over Feed and Chain Wheels. Cloth Guider Spare Parts, Bracket left & right, Base Plate Alluminium Left, Base Plate Alluminium Right, Tope Fiber Roller Laminated complete, and Fiber Roller Laminated only. Healed Frames and Healed Frame Accessories. Reeds, Heralds and Drop Pins. Spinning Weaving Machinery Spare Parts.

https://youtu.be/NqBr-6efPf8

#Stenter Machine#Textile Machinery Spare Parts#Textile Machinery#Textile Machine price#Textile Machine spare parts#Textile Machine Manufacturer#Jigger Machine#Rotary Screen Printing Machine#Textile Machinery Spare Parts Manufacturer India#Spares Textile Processing Machinery#Spinning Weaving Machinery Spare Parts#Stenter Machine Spare Parts#Cloth Guider Spare Parts#Folding Machine Spare Parts

0 notes

Link

Stenter Machine Parts are manufactured from qualitative range of raw materials. We offer these Stenter Machine Shaft at most competitive prices. Stenter Shaft Manufacturer, All type of Stenter Machine Spare Parts, Stenter Machine Shaft and Textile Machinery Spares Manufacturer, Exporter, Supplier.

Visit our Website: conpaptex.com

Contact us: [email protected]

#Stenter Machine Parts#Stenter Machine Shaft#Textile Machinery Parts#Stenter Machine Gear Shaft#Stenter Machine Pin Bar#Stenter Pin Plate#Stenter Machine Shaft manufacturer

1 note

·

View note

Text

Choosing fabric and fabric types

fab-5.jpg Choosing fabric can be overwhelming, there’s often too much choice. When I can’t decide, I ask for small samples that I take away, so I have time to think - even if its just while I have a cup of coffee. Try not to buy on price alone, some of my ‘bargains’ have never been used. Here is a brief overview of the types of fabric used and some tips on working with them. Fab3.jpg Woven Fabric Basic woven fabric is constructed with threads interwoven at right angles to each other. The threads running down the length of the fabric are called the warp and the threads that run across the width are called the weft. This form of construction usually creates a fabric that is rigid or non-stretch in the warp or weft direction although flexible on the bias – an angle of 45 degrees to warp or weft. There are also stretch woven fabrics where Lycra or Elastomeric yarns are included in the weave construction. These fabrics can stretch in one or both directions depending on how the stretch yarn is added in the weaving process. The other form of stretch woven is called a mechanical stretch. This is when a chemical finish is applied to the flat fabric causing it to shrink creating a stretch when pulled. The stretch quality in a mechanical stretch fabric is not as strong or long lasting and will not keep bouncing back. For example if a tight fitting skirt is made in a mechanical stretch fabric it will ‘seat’ and not bounce back until it is washed again. Terms such as denim, canvas or twill, refer to the type of weave pattern. To sew with woven fabrics is fairly straightforward. Use a universal needle and straight stitch setting on your sewing machine. Vary the size of needle and stitch length to suit your fabric weight. fab6.jpg Knitted or Jersey Fabric Knitted fabric is more complex in construction than woven fabric. In its most basic form it is made from a series of interlocking loops formed by a single thread continually looping through the last row of loops created. The resulting fabric is much more flexible than a woven fabric and can stretch in any direction. In a similar way to mechanical stretch woven fabrics, if there is no Lycra or elastomeric content in the yarn used, tight fitting garments will ‘seat’. T-shirts are often made from basic jersey with no added stretch content. The fabric used to make leggings will usually contain 4% - 6%stretch fibres whereas performance sportswear and swimwear require a high percentage approximately 18%. Terms such as single or double jersey refer to the looped construction created by the needle bed set up of the knitting machine. Single jersey is knitted on one bed, either flat or circular, so the loops always fall to the same side, creating a right and wrong side. Double jersey is knitted on a twin bed set up so there is usually two right, though sometimes differing, sides to the fabric. It is generally thicker and more stable to work with. To sew with knitted fabrics use a Ballpoint or jersey needle, these are designed to push the threads aside as they stitch. This prevents any laddering resulting from broken stitches. Selecting the best stitch for jersey fabrics is dependent on the amount of stretch required. Too little stretch and the sewing thread can break when the seam is stretched. For most side seams I like to use a plain straight stitch however I apply a little tension to the fabric as I feed it under the machine foot. For waistbands and hems I use a zigzag stitch to allow for more stretch. If my jersey fabric splays out, I generally use a steam iron, without pressing the fabric, to relax the fabric back into shape. In the Stretch Pencil Skirt project there are a number of alternatives given for tackling hems in different ways. Fab-2.jpg Fine silky fabrics I find these the trickiest to work with but sometimes I can’t resist because of the luxurious delicate handle. Always use a finer needle whether it’s a Universal or Ballpoint. You can also get specialist needles for Microfibre that I have used on natural silks as well as synthetic silky fabrics. For buttonholes try using a stick on fabric stabiliser as used by embroiderers, I use Stitch and Tear. This will stop your fabric puckering up. fab-7.jpg Technical Fabrics This is a term that refers to either woven or knitted fabrics that are coated or bonded with a chemically produced fabrication. PU and PVC are terms used for imitation leathers – PVC stands for plastic Polyvinyl plastic coated woven fabric with a high sheen like patent leather. PU is a Polyurethane coated jersey fabric with a sheen finish and stretch qualities. Neoprene or scuba fabrics are bonded imitation rubber like fabrics with a jersey backing for increased flexibility. For technical fabrics with a jersey backing I’ve found I get the best results from using a ballpoint or jersey needle. For woven backed technical fabrics I use a Universal needle but if that has difficulty puncturing the fabric I use a leather needle. I also lengthen the stitch length to get a smoother result. The shiny surface of these fabrics can stick when in contact with the presser foot or machine plate. To avoid this happening use a Teflon foot and make a template of non-stick baking parchment to place over the machine plate, secure this with tape. For some PVC fabrics It can be impossible to pin your seams in place before stitching so try using a double-sided basting tape or alternatively hold the pieces together with small bulldog or paper clips. Always keep your technical fabrics rolled rather than folded this will stop any permanent creasing. fab4.jpg Leather When sewing with leather select skins that are reasonably lightweight and flexible. If you have never sewn with suede or leather, but would like to have a go, most suppliers have off cuts or part skins at reduced prices, so you can try out before investing in the materials for a whole garment. As leather is neither woven nor knitted fabric it has a tendency to tear at the seams, if there are too many stitch perforations. To avoid this increase your stitch length and always use a leather needle, its spear like point cleanly cuts the stitch hole. Try out the strength of your seam on an off cut. As with technical fabrics, leather can be impossible to pin the seams in place before stitching so try using a double-sided basting tape or alternatively hold the pieces together with small bulldog or paper clips. As with technical fabrics, keep your leather or suede rolled not folded. Before you start making - Once you‘ve bought your fabric always wash it before sewing. If you are not sure it’s washable, cut a 20cm square and place it in a 30-degree wool wash. Then when it’s washed and dried re-measure to check shrinkage and also to review the handle of the fabric. If you don’t like the result, make sure you only dry-clean the garment you are going to make. Before washing lengths of fabric, unfold them and iron out any creases. Loosely load into your machine and use a liquid detergent. These steps should avoid any unevenness in the colour fading especially with indigo and pigment dyed denim or coloured linens. The reason for pre-washing fabric is that during the manufacturing process, fabrics are often ‘stentered’. This is when they are pulled into a uniform width and length and a finishing chemical applied. The problem with this is, that when the fabric is subsequently washed, it ‘relaxes’ back or shrinks. So by washing it before making, you can make sure what you make doesn’t shrink. Do not wash suede, leather or PVC. I have washed PU not because it would shrink but because it can have an unpleasant chemical smell. This article is taken from the book The Makers Atelier - Essential Collection available HERE http://dlvr.it/PQyg9r

3 notes

·

View notes

Link

We are leading manufacturer, exporter and supplier of Stenter Machine Shaft Manufacturer of High-Quality Stenter Machine Shaft for all types of Stenter Machines, Textile Machinery Spare Parts Manufacturer, Pin Bar, Pin Plate, Shaft, Chain Link Bottom Parts, Gear Box, Pin Bars, Stenter Clips, Stenter Pin Block, Stenter Machine Chain. Meeting with international standard and per our client’s requirement. All textile shafts are highly durable due to high quality material. Stenter Machine Shaft Manufacturer of High-Quality Stenter Machine Shaft.

#Stenter Machine Shaft#Stenter Machine#Textile Machinery Spare Parts#Textile Machinery Spare Parts Manufacturer#Stenter Pin Bar#Stenter Pin Bars#Stenter Pin Bar Manufacturer#Stenter Pin Plate#Stenter Pin Plate Manufacturer#Chain Link Bottom Parts#Stenter Machine Clips#Stenter Machine Clip#Stenter Machine Clip Manufacturer#Stenter Machine Chain#Stenter Machine Chain Manufacturer

0 notes

Link

We are leading manufacturer of Stenter Clip, Stenter Machine spare parts, Stenter Machine Clip of any make like Artos, Bruckner, Harish, Stenter Machine Pin Bar, Textile Machinery Parts, Stenter Machine Pin Plate, Chain Link Bottom Parts, Textile Machinery Spare Parts, Stenter Machine Pin Plate, Stenter Machine Pin Block. Specialized manufacturer, exporter and supplier of Rubber Roller from India. Flexible Packaging, Paper, Tire-Cord, Textile Machinery with custom application for different industries specific requirements.

#Stenter Clip#Stenter Machine Clip#Stenter Pin Bar#Stenter Machine Pin Bar#Stenter Pin Plate#Chain Link Bottom Parts#Textile Machinery Spare Parts#Stenter Machine Pin Plate#Stenter Machine Pin Block

0 notes