#Structural bolts manufacturer

Text

Structural Bolts Manufacturer & Exporter in India | BigBoltNut

We are renowned manufacturer, supplier and exporter of structural bolts in India. Structural bolt assembly is used in both preloaded and non-preloaded applications. These high tensile bolts are Available in 10.9 grades and 8.8 grades. The structural Bolts following EN 14399-4 and DIN 6914 is to use thinner nuts and shorter thread lengths to obtain the required ductility by plastic deformation of the threads within the nut. The structural bolt assembly is used in both preloaded and non-preloaded applications. Sturctural bolts charecteristics: are Large under-head surface, Less surface pressure, Enables preloading, Improved fatigue strength, Defined friction properties. Application of structural bolts: It is used in heavy industries like chemical, wind energy, ship, oil and wind energu sector

Source url: https://www.bigboltnut.com/product/structural-bolts.html

0 notes

Text

Structural Bolts manufacturer | Roll Fast

Structural bolts are specifically designed for use with heavy hex nuts in the connection of structural members (as opposed to tapped holes). The nuts for structural connections shall conform to ASTM A563 or ASTM A194. The washers used for structural connections shall meet ASTM F436 specifications. This specification covers both flat circular and beveled washers. The structural Bolts following ASTM F3125/F3125M is a structural bolt specification covering inch and metric bolt grades is to use thicker nuts and shorter thread lengths to obtain the required ductility by plastic deformation of the threads within the nut. The structural bolts manufacturer assembly is used in both preloaded and non-preloaded applications, and it can be argued that in the event of failure by thread plastic deformation the assembly still acts as a non-preloaded assembly. This specification contains 4 inch series bolting grades: A325, F1852, A490, and F2280. These will be addressed in this article. When looking at the mechanical requirements of bolts it appears that a grade A325 and SAE J429 Grade 5 are identical as do the grade A490 and the SAE J429 Grade 8.

#Structural Bolts#structural bolts manufacturer#structural bolts in alloy steel#structural bolts in carbon steel#structural bolts in bigger diameter

0 notes

Text

Solar Structure Manufacturers, Supplier in Haryana, Punjab, Delhi, Himachal Pradesh

Dhanraj Tech Enterprises specializes in the manufacturing of high-quality solar structures for various applications. The company offers a range of solar structure solutions, including car parking structures, ground-mounted structures, solar water pump structures, and solar street light poles. Dhanraj Tech Enterprises uses the latest technology and state-of-the-art equipment to ensure the durability and efficiency of its solar structures.

#solar panel manufacturers in himachal pradesh#solar panel suppliers in haryana#solar panel installation services in haryana#fasteners/nut bolt manufacturers in haryana#fasteners suppliers in himachal#solar structure manufacturers in punjab

0 notes

Text

Stainless Steel Bolts Manufacturer in India

At Delta Fitt Inc. Stainless Steel Bolts Manufacturers, we pride ourselves on being one of the leading manufacturers of stainless steel bolts in the industry. We use only the highest quality materials and the latest manufacturing techniques to create bolts that are strong, durable, and corrosion-resistant.

But not all stainless steel bolts are created equal. That's why it's important to choose a reputable Stainless Steel Bolts Manufacturer in India that specialises in creating high-quality bolts that will stand the test of time.

Whether you're building a small structure or a large commercial building, you can trust Delta Fitt Inc.’s Stainless Steel Bolts Manufacturers in India to provide you with the bolts you need to create a strong and durable structure.

At Delta Fitt Inc. we specialise in producing a wide range of high-quality bolts, including High Tensile Bolts, HSFG Bolts, Heavy Hex Bolts

So why wait? Contact Delta Fitt Inc. and their Stainless Steel Bolts Manufacturers today to learn more about our products and services, and see how we can help you build the structure of your dreams.

We are also Stainless Steel Bolts Manufacturer in Germany, Stainless Steel Bolts Manufacturer in Poland, Stainless Steel Bolts Manufacturer in France and High Tensile Bolts Manufacturer in Germany

For More Details:

Source: Stainless Steel Bolts Manufacturer in India

Call: +91 98708 13113

Mail: [email protected]

#Stainless Steel Bolts#Bolts Manufacturer#Delta Fitt Inc#High Quality Bolts#Corrosion Resistant#Structural Building Materials#High Tensile Bolts#HSFG Bolts#Heavy Hex Bolts#Building Construction#India Manufacturing#Durable Bolts#Trusted Manufacturer

0 notes

Text

#Citizen Metals Pvt Ltd is a leading manufacturer of BOLT solutions#including Hex Bolt#Flange Bolt#U Bolt#Shoulder Bolt#Eye Bolt#12 Point Flange Bolt#Stove Bolt#J Bolt#Anchor Bolt#T Bolt#Structural Bolt#and Tension Indicating Bolt.#https://www.citizenfasteners.com/bolt.php

1 note

·

View note

Text

adventures in QA

(previous post in this series)

My shop in Advanced Midbody - Carbon Wing (AMCW) at Large Aircraft Manufacturer (LAM) is at the very end of the composite fabrication building. Hundreds of people carefully lay up a hundred foot long slab of carbon fiber, cure it, paint it, and then we totally fuck it up with out of spec holes, scrapes, primer damage, etc. The people who write up our many defects are from the Quality Assurance (QA) department.

Every single screw and rivet on a LAM aircraft can be traced back to the mechanic who installed it. Back when even everything was done in pen and pencil, it was joked that the paper used to produce an aircraft outweighed the plane itself. Now that everything is computer-based, of course, the amount of paperwork is free to grow without limit.

(Haunting the factory is endless media coverage of an emergency exit door plug popping out of an Advanced Smallbody - Upengine (ASU) plane during a routine flight a few months ago. Unlike that airframe's notorious problems with MCAS, this was a straightforward paperwork screwup by a line worker: the bolts were supposed to be tightened, and they weren't.

As a result the higher ups have visited hideous tribulations on non-salaried workers. Endless webinars, structured trainings. Here at the Widebody plant we have received a steady flow of refugees from the Narrowbody factory, hair-raising tales of receiving one hundred percent supervision from the moment they clock in to the second they clock out from FAA inspectors who can recommend actual jail time for any lapse in judgement.)

A single hydraulic bracket Installation Plan (IP) is around four brackets. The team leads generally assign two bracket IPs per mechanic, since each bracket set is something like a foot apart, and while working on the plane is bad enough it's much worse to have another mechanic in your lap.

Let me list the order of operations:

One: Find where you're supposed to install these brackets. This is harder than you might think.

Firstly, it's a hundred foot long plank of carbon fiber composite, with longitudinal stringers bonded to it to add stiffness. The stringers are pilot drilled in the trim and drill center, a truly Brobdingnagian CNC mill that trims off the composite flash at the edges and locates and drills part holes for us. But there's a lot of holes, so you must carefully find your set.

A minor difficulty is that the engineering drawings are laid out with the leading edge pointing up, while the wing panels in our cells hang from the trailing edge. Not so bad, you just rotate the paper 180 when orienteering, then rotate it back up to read the printed labels.

A major difficulty is that the drawings are from the perspective from the outside of the panel. But we work on the inside of the wing (obviously, that's where all the parts are installed) so we also flip the drawings and squint through the back of the paper, to make things line up.

Large Aircraft Manufacturer has a market cap of US$110 billion, and we're walking around the wing jig with sheets of paper rotated 180 and flipped turnways trying to find where to put brackets.

Oh well, we're paid by the hour.

Two: Match drill the aluminum brackets to the carbon fiber composite stringer. I can devote an entire post to the subtleties of drilling carbon fiber, but I can already tell that this post is going to be a miserable slog, so I will merrily skip over this step.

Three: Vacuum up all the carbon dust and aluminum swarf created during this process. This step is not optional, as your team lead will remind you, his screaming mouth clouding your safety glasses with spittle at a distance of four inches. LAM is very serious about FOD. Every jet airliner you've ever ridden in is a wet wing design-- each interstitial space is filled with Jet A. There is no fuel bladder or liner-- the fuel washes right over plane structure and wing hardware. Any dirt we leave behind will merrily float into the fuel and be sucked right into the engines, where it can cause millions in damage. No place for metal shavings!

If you are nervous about flying, avoid considering that all the hydraulic lines and engine control cables dip into a lake of a kerosene on their way from the flight deck to the important machines they command. Especially do not consider that we're paid about as much per hour as a McDonalds fry cook to install flight-critical aviation components.

Four: Neatly lay out your brackets on your cart, fight for a position at a Shared Production Workstation (SPW) (of which we have a total of four (4) for a crew of thirty (30) mechanics) and mark your IP for QA inspection as Ready To Apply Seal.

Four: Twiddle your thumbs. Similarly, we have three QA people for thirty mechanics. This is not enough QA people, as I will make enormously clear in the following steps.

Five: Continue waiting. Remember, you must not do anything until a QA person shows up and checks the box. Skipping a QA step is a “process failure” and a disciplinary offense. From the outside, you can observe the numerous QA whistleblowers and say “golly, why would a mechanic ever cut a corner and ignore QA?” Well...

Six: QA shows up. Theoretically, they could choose to pick up the mahrmax you prepared for them and gauge every single hole you've drilled. But since we're three hours into the shift and they're already twenty jobs behind, they just flick their flashlight across the panel and say “looks good" and then sprint away. Can't imagine why our planes keep falling out of the sky.

Seven: Apply the seal to the bracket. P/S 890 is a thick dark gray goop that adheres well to aluminum, carbon fiber, fabric, hair and skin. Once cured, it is completely immune to any chemical attack short of piranha solution, so if you get any on yourself you had better notice quick, otherwise it'll be with you as long as the layer of epidermis it's bonded to. LAM employees who work with fuel tank sealant very quickly get out of the habit of running their hands through their hair.

Eight: Now you wait again. Ha ha, you dumb asshole, you thought you were done with QA? No no, now you put up the job for QA inspection of how well you put the seal on the bracket. Twiddle your thumbs, but now with some urgency. The minute you took the bottle of seal out of the freezer, you started the clock on its "squeeze-out life." For this type of seal, on this job, it's 120 minutes. If QA doesn't get to you before that time expires, you remove your ticket, wipe off the seal, take another bottle out the freezer, and apply a fresh layer.

Nine: Optimistically, QA shows up in time and signs off on the seal. Well, you're 100 minutes into your 120 minute timer. Quickly, you slap the brackets onto the stringer, air hammer the sleeve bolts into position, thread nuts onto the bolts, then torque them down. Shove through the crowd and mark your IP "ready to inspect squeeze out"

Ten: Let out a long breath and relax. All the time sensitive parts are over. The criteria here is "visible and continuous" squeeze out all along the perimeter of the bracket and the fasteners. It is hard to screw this up, just glop on a wild excess of seal before installing it. If you do fail squeezeout, though, the only remedy is to take everything off, throw away the single-use distorted thread locknuts, clean everything up and try again tomorrow.

Eleven: QA approved squeeze out? Break's over, now we're in a hurry again. By now there's probably only an hour or two left in the shift, and your job now is to clean off all that squeeze out. Here's where you curse your past self for glopping on too much seal. You want to get it off ASAP because if you leave it alone or if it's too late in the shift and your manager does feel like approving overtime it'll cure to a rock hard condition overnight and you'll go through hell chipping it off the next day. You'll go through a hundred or so qtips soaked in MPK cleaning up the bracket and every surface of the panel within three feet.

Twelve: Put it up for final inspection. Put away all your tools. (The large communal toolboxes are lined with kaizen foam precisely cut out to hold each individual tool, which makes it obvious if any tool is missing. When you take a tool out, you stick a tool chit with your name and LAMID printed on it in its place. Lose a tool? Stick your head between your legs and kiss your ass goodbye, pal, because the default assumption is that a lost screwdriver is lurking in a hollow "hat" stringer, waiting to float out and damage some critical component years after the airplane is delivered.)

One tool you'll leave on your cart, however, is the pin protrusion gage. There is a minimum amount of thread that must poke outside of the permanent straight shank fastener's (Hi-Lok) nut, to indicate that the nut is fully engaged. That makes sense. But there's also a maximum protrusion. Why?

Well, it's an airplane. Ounces make pounds. An extra quarter inch of stickout across a thousand fasteners across a 30 year service life means tons of additional fuel burnt. So you can't use a fastener that's too long, because it adds weight.

On aluminum parts, it's hard to mess up. But any given composite part is laid up from many layers of carbon fiber tape. The engineers seemed to have assumed that dimensional variation would be normally distributed. But, unfortunately, we buy miles of carbon fiber at a time, and the size only very gradually changes between lots. When entire batches are several microns oversize, and you're laying up parts from fifty plies and an inch thick, you can have considerable variation of thickness on any given structural component. So you had better hope you had test fit all of your fasteners ahead of time, or else you'll be real sorry!

And, if you're really lucky, QA will show up five minutes before end of shift, pronounce everything within tolerance, then fuck off.

And that's how it takes eight hours to install eight brackets.

148 notes

·

View notes

Text

Case Study: Bay Bridge Bolt Failure

Also known as the San Francisco-Oakland Bay Bridge, the east section of the Bay Bridge collapsed in 1989 as a result of earthquakes in the area. The decision was eventually made to replace the entire bridge with a more earthquake resistant structure, with the western portion begining construction in 2004. In 2013 the eastern section of the new bridge was completed. However, construction did not go as planned. When pre-tension was applied, before finalization of construction, 32 of 96 A354BD bolts fractured within two weeks.

The bolts that failed were placed in 2008 as part of the shear keys meant to increase seismic resistance, meaning they did not contribute to the structure of the bridge. After the failure, all 96 bolts in the shear keys were considered suspect and alternative anchors were devised. However, the A354BD bolts were used in other places of construction so a detailed metallurgical analysis was conducted to ensure the bolts throughout the bridge would not fail as well. The failure was ultimately determined to be a result of hydrogen embrittlement. It was also eventually concluded that this was a result of the environment the rods were subjected to (seawater), not the manufacturing process, and the bolts used elsewhere throughout the bridge were allowed to remain supplemental corrosion protection measures.

Sources/Further Reading: (Images source - Structure Magazine) (TBPOC Report) (TWI Presentation)

30 notes

·

View notes

Text

i've said this several times already, but if you want to understand why the news can't even air the phrase "settler-colonialism," which has been accepted as a term in political theory for decades, it's because the imperial core is obviously predicated on it.

if you're wondering why the united nations has no means to effective global governance, it's because the organization was specifically and explicitly convened to replace the league of nations in response to the advent of the nuclear bomb, and to prevent another world war.

the five permanent members of the security council are, not coincidentally, the same countries that have (arbitrarily) 200 or more warheads (which abitrarily excludes pakistan, india, israel, and north korea, for having fewer than 200 of them).

this is widely but very quietly acknowledged as a "nuclear veto," because if a security council member objected to UN governance, they could simply employ the threat of mutually assured destruction.

which, if you want to get down to nuts and bolts, logistically does require some hundred warheads, in order to be a credible threat, although the number 200 is arbitrary. as i've said before, the threat of nuclear winter, as outlined in the original study, is not radiation itself, it's crop loss from occlusion of the sun by soot and smoke. the threat is credible specifically because of its scale. (a similar threat could be made with conventional munitions of approximately equal yield, although manufacturing them would be prohibitively difficult.)

and if you really want to dig into the nuclear aspect of settler-colonialism, you have to recognize the structural use of mining, refining, waste management, and exposure payout: the bomb is simply not the most useful weapon in the field of nuclear policy. the gamble is that nuclear bureaucracy will outlive anyone who wants to object to it, and so far this has been a very profitable bet.

if we could, like, advance the discussion in the public sphere to the basic acknowledgment of this point... it might fucking help! on a personal level i'm tired of being practically the only person to say it

21 notes

·

View notes

Text

Prompt #5: Stamp

It was raining.

He pointedly ignored the footsteps behind him. They, in their kindness, pointedly did not speak up. Not that there was much to hear over the storm that intensified over their heads. To everyone else it was a moment to hole up, to wait, to keep their heads down in the outskirts. To him it was a sign.

A bad one.

Good.

The electrope tether hummed in his hands as he spun the end of it in rote motion. How far up, this time? His practiced eyes spotted anchor points all the way up the structure. Checking them off like they were a puzzle to solve, like something one might work on over a morning coffee. There wasn’t any need for the shorter hops today. No point in taking a path with the handholds and stopping spots close together. That would be for

The tether slammed into the ground as his fist met stone. The blood dripped down his knuckles; the rain washed it off. The pain hadn’t arrived yet, but it was no mercy there. He looked at the exposed, sliced flesh. He flexed his hand, over and over, as if he could grip the half-formed memory that got away from him.

Okay. It’s fine. It’s fine. Ignore the extra set of footsteps behind you that’re the wrong ones

His other fist hit the stone. Then he picked up his tether.

Putting his climbing claws and boots on was a bit more difficult now. He appreciated the extra time to get rained on, at least, while he was still on the ground. It felt therapeutic in a way that little else could. Indulging in misery in the preparation for something that was supposed to bring him joy.

Indulging in rage as his manufactured claws bit into the same stone that he’d used to draw his blood. Better than a fistfight he knew he’d lose. Better than a conversation with someone who understood.

The wrong footsteps were still down there.

He punched his way through an old window, shattering it in tune to a thunderclap as he hauled his way inside. Even now he couldn’t help but evaluate the insides for valuables, for safety, for picking out the interesting things to give as examples

He slumped against the wall. He landed in the shards. He could feel them cut him through his gear. He knew he’d have to clean himself up. Who knew what was on these old windowpanes. He could get infected.

…It was so hard to care. Or, rather, he wished it was. He wished it was. That was half the problem, wasn’t it? Forgetting made it so easy to lose your grip on all the other emotions from it. Forgetting made it so easy to pretend everything was fine. It was hard to let his hate pull him down like gravity when it could find no purchase on him. When hate had no barbs with which to anchor.

When pain could barely substitute. Self flagellation barely got him anywhere besides a response of hoping it didn’t get infected.

He shifted to bring his bag around to his side. Fished in it for a long moment as if to pretend he didn’t know each and every pocket in it and where everything was- even if he’d thrown it around in a rage before. Even if he’d realized things were missing

His bloodied fist closed around a piece of metal and electrope.

His regulator flashed to life in the wake of a thunderclap as he held it up in the dark room. But his eyes weren’t on it.

A shadow in the lightning flash.

“…Galena,” Came the voice of the wrong footsteps. That soft, diffuse green glow of a presence that he’d wished stayed on the ground. The gentle and kind hand that reached out with a comforting touch-

His tether snapped taut and yanked him to his feet before it could. Before his eyes could fall on the other. She wasn’t who he wanted to see. That wasn’t the name he wanted to hear

She knew it, too.

He climbed back out into the rain.

He couldn’t remember reaching the top. It had been struck relatively recently. The old infrastructure not meant to take direct bolts like that, not meant to sustain that kind of damage.

Frankly it was impressive the building was still upright with a giant hole blown in the top of it. The rain could get in now. Rot the insides, rust them and corrode them, and slowly warp the structure until it would slam into the earth without warning.

He wondered how long it would take.

He stared at the regulator in his hand.

He wondered how long it would take.

The heel of his boot crunched something metal and worn. The sparks caught like lightning against the wet stone. Like a poor mimicry of rage. Like a half-thought copy of something real.

Slop made by a rusted mind.

He anchored his tether to the one last support column that could handle his weight.

He leapt from the tower.

#ffxivwrite2024#/Companions/GnPy#gotta figure a tag for pyrite and galena#but yeah healthy coping mechanisms#after this he starts a youtube channel to cope and it goes well#ain't that wacky#need to take an actual thumbnail screenshot of him rather than#using WW's work here

13 notes

·

View notes

Text

transforming soffits

reorganizing keys

formalizing immersion joints

justifying kick extractors

advising aggregates

managing elbows

recasting connectors

achieving aluminum trowels

officiating disks

exhibiting absolute spigots

progressing coil hydrants

jerry-building reflectors

informing casters

inventing rubber hoists

performing wrenches

judging chalk adapters

upgrading ignition paths

regrowing flashing

recommending ratchets

approving barriers

sweeping impact fillers

sewing mirrors

detailing collectors

enforcing measures

distributing systems

presenting plugs

interwinding registers

piloting ash diffusers

gathering cranks

supplying eave pockets

undertaking scroll stops

accelerating straps

designing fittings

protecting diamond boilers

logging downspouts

correlating shingles

uniting mallets

qualifying electrostatic lifts

sharing clamps

obtaining circular fluids

ranking foundation gauges

sensing miter brackets

originating space networks

translating drills

regulating guards

selecting gable padding

utilizing pellet dowels

reconciling artifacts

altering pulleys

shedding space filters

determining vents

representing mortar

remaking flash rakers

supporting funnels

typecasting rotary chocks

expressing junctures

resetting auxiliary vises

professing strip treads

inlaying matter trowels

questioning drivers

forming edge fittings

sketching blanks

overshooting spark breakers

rewriting controls

playing tunnels

inventorying buttons

enduring joint handles

effecting ratchet bibbs

unwinding couplings

forsaking vapor conduits

defining sockets

calculating heaters

raising grids

administering tiles

measuring resources

installing ignition remotes

extracting corners

manufacturing ventilators

delegating consoles

treating mounting stones

enacting jig deflectors

intensifying alleys

improvising cargo

pinpointing bobs

prescribing arc masonry

structuring metal chucks

symbolizing lathes

activating plumb kits

adapting coatings

fixing channels

expediting cordage

planning compressors

enlisting hangers

restructuring keyhole augers

shearing ridge hardware

collecting reciprocating bolts

maintaining corrugated dimmers

whetting hole collars

conducting mandrels

comparing assets

compiling sealants

completing paths

composing equivocation wheels

computing dampers

conceiving electrostatic treatment

ordering cotter grates

organizing ties

orienting ladders

exceeding materials

targeting thermocouples

demonstrating emery stock

expanding latch bases

training wardrobe adhesives

overcomming[sic] fasteners

streamlining storm anchors

navigating springs

perfecting turnbuckles

verifying gate pegs

arbitrating arithmetic lifts

negotiating outlets

normalizing strips

building surface foggers

checking key torches

knitting grinders

mowing planers

offsetting stencils

acquiring bulbs

adopting rivets

observing avenues

ascertaining coaxial grommets

slinging wing winches

instituting circuit generators

instructing wicks

integrating pry shutters

interpreting immersion lumber

clarifying coils

classifying wood bits

closing cogs

cataloging matter strips

charting holders

conceptualizing push terminals

stimulating supports

overthrowing shaft spacers

quick-freezing connectors

unbinding ground hooks

analyzing eyes

anticipating gateways

controlling proposition rollers

converting power angles

coordinating staples

correcting benders

counseling joist gaskets

recording gutter pipes

recruiting drains

rehabilitating rafter tubes

reinforcing washers

reporting guard valves

naming freize sprues

nominating rings

noting straps

doubling nailers

drafting circuit hoses

dramatizing flanges

splitting framing compounds

refitting stems

interweaving patch unions

placing sillcocks

sorting slot threads

securing mode cutters

diverting catharsis plates

procuring load thresholds

transferring syllogism twine

directing switch nuts

referring time spools

diagnosing knobs

discovering locks

dispensing hinges

displaying hasps

resending arc binders

retreading grooves

retrofitting aesthetics portals

seeking stocks

shrinking wormholes

assembling blocks

assessing divers

attaining lug boxes

auditing nescience passages

conserving strikes

constructing braces

contracting saw catches

serving installation irons

recognizing fluxes

consolidating fuse calipers

mapping shims

reviewing chop groovers

scheduling lag drives

simplifying hoists

engineering levels

enhancing tack hollows

establishing finishing blocks

21 notes

·

View notes

Text

Structural bolt Manufacturer and Exporter India | Bigboltnut

Bigboltnut are a renowned manufacturer, supplier and exporter of high tensile structural bolts. Structural bolt assembly is used in both preloaded and non-preloaded applications. These bolts are available in 8.8 and 10.9 grades and its depends on our customer requirement. Structural bolts are used in connection between two towers, marine , ship building , wind enery sector . and also manufacturing EN 14399-4 10.9 bolts & nuts in hot dip galvanised condition. We export our range of products to over 50 countries including USA, Europe, Middle east and Africa. Our agencies sales team is present in Oman, Qatar, Saudi Arabia, Dubai, Abu Dhabi, Nigeria, Switzerland, France, Holland, Belgium etc.

Structural bolts characteristics and its Application

It used to two create force that holds two or more components.

Structural bolts used in heavy Industry to hold heavy components

Structural bolts are zinc electroplated in blue, yellow, black colour.

Source Url : https://www.bigboltnut.com/product/structural-bolts.html

#structural bolts#structural bolts suppliers#Structural bolts manufacturer#8.8 grades#10.9 grades#bolt & Nuts grades#Structural bolt grades#high tensile bolts

0 notes

Text

Structural Bolts Manufacturer

Structural bolts are specifically designed for use with heavy hex nuts in the connection of structural members (as opposed to tapped holes). The nuts for structural connections shall conform to ASTM A563 or ASTM A194. The washers used for structural connections shall meet ASTM F436 specifications. This specification covers both flat circular and beveled washers. The structural Bolts following ASTM F3125/F3125M is a structural bolt specification covering inch and metric bolt grades is to use thicker nuts and shorter thread lengths to obtain the required ductility by plastic deformation of the threads within the nut. The structural bolts manufacturer assembly is used in both preloaded and non-preloaded applications, and it can be argued that in the event of failure by thread plastic deformation the assembly still acts as a non-preloaded assembly. This specification contains 4 inch series bolting grades: A325, F1852, A490, and F2280. These will be addressed in this article. When looking at the mechanical requirements of bolts it appears that a grade A325 and SAE J429 Grade 5 are identical as do the grade A490 and the SAE J429 Grade 8.

#Structural Bolts#structural bolts manufacturer#structural bolts in alloy steel#structural bolts in carbon steel#structural bolts in bigger diameter

0 notes

Text

BASEL

■Inquiries/Real Co., Ltd. 0729-64-1527

Don't call it cheap chic

A piece with attractive high quality

Despite the simple rough mesh design

The hard feel of the disc and rim makes the wheel look bigger.

When setting wheels for dress-up purposes, you need to be careful about how you want the car to look as a whole. For example, if you want your car to have a gorgeous atmosphere, but you set wheels that give it a plain look, the podium bottom will lack the power and make it look bulky. Wheels are expensive items, so they are not replaced very often. If you don't think carefully and choose without compromise, you will regret it.

However, there are quite a few people who don't have an overall image in mind, but just want to change the wheels. ``I just bought a car, but I'd like to change the wheels.What kind of design would go well with any style of tailoring?'' It's quite difficult to answer this question, but if I had to make a recommendation, I would choose this one.

There's one reason. Because it has a clean mesh design. The nine-intersection rough mesh design, where the center package is independent and recessed from the face, looks sporty when you look at the oven hole, but the rim. The elegance can be seen from the slim Y-shaped spokes. The one-piece structure with no piercing bolts and reverse rim allow the disc surface to be made as large as possible, giving it an impact that rivals the thrust produced by the large sedan body. A wheel with such a simple yet versatile design should be able to accommodate any style of dress-up. It can be used not only for beginners in dress-up who have not yet lowered the vehicle height or even installed a muffler, but also for highly original finishes that take advantage of the user's taste, and are not bound by European or Lacy models. deep in my heart

That's what makes it so appealing.

This basel has another feature. This means that the degree of curvature of the discs for the front and rear discs is slightly different. The front face has an almost straight face, while the rear face has a slightly recessed center package. This slight difference becomes a big difference when you set up the Tsuraichi. In addition to gold, we also have silver, so you can match it with either of the Y32 / Y33 Granturismos.

Message from the manufacturer

This is a wheel that emphasizes sharpness and three-dimensionality.

The deep reverse rim on the inside of the outer rim and the sharp Y-shaped spokes set tightly against the rim face, making the most of the features of a one-piece wheel, create a three-dimensional image. This makes it appear larger than its actual size. It doesn't have the sharpness of a 3-piece wheel, but if you want a mature and neat look, we recommend silver, and if you want to look clean and have an impact, we recommend gold. Since the front face and rear disc are curved differently, there is a risk, but I think it will look better if you set it further outward than the recommended size.

14 notes

·

View notes

Text

Plasterboard Walls & TV Mounting: Is It Safe in London?

If you're living in London and considering mounting your TV on a plasterboard wall, you might be wondering, is it safe? Plasterboard walls, also known as drywall, can present unique challenges when it comes to mounting heavy objects like TVs. Let's delve into this topic to understand the safety considerations involved.

Understanding Plasterboard Walls

Plasterboard walls are a common feature in many homes and buildings in London. They consist of a layer of gypsum sandwiched between two layers of paper. While they are lightweight and easy to install, they may not have the structural strength of traditional brick or concrete walls.

Factors to Consider

Wall Studs: When mounting a TV on a plasterboard wall, it's crucial to anchor it securely to the wall studs. Wall studs provide the necessary support to hold the weight of the TV and prevent it from falling. Using appropriate hardware, such as heavy-duty wall anchors or toggle bolts, can help distribute the weight evenly and minimize the risk of damage to the wall.

Tip: Use a stud finder to locate the studs behind the plasterboard before mounting your TV.

TV Weight: The weight of your TV plays a significant role in determining the safety of mounting it on a plasterboard wall. Larger, heavier TVs require stronger mounting hardware and may put more stress on the wall.

Tip: Check the manufacturer's specifications for your TV to ensure compatibility with plasterboard walls.

Mounting Technique: Proper mounting technique is essential for ensuring the safety and stability of your TV on a plasterboard wall. Avoid using nails or screws directly into the plasterboard, as they may not provide sufficient support.

Tip: Consider hiring a professional TV mounting service with experience in mounting TVs on plasterboard walls.

Is It Safe?

With the right hardware, techniques, and precautions, mounting a TV on a plasterboard wall can be safe in London. However, it's crucial to take the necessary steps to ensure proper installation and minimize the risk of damage or accidents.

In conclusion, while mounting a TV on a plasterboard wall in London is possible, it requires careful consideration of the factors mentioned above. To ensure the safety and stability of your TV installation, consider consulting a professional TV wall mounting service in London like TV Mount Mate for expert assistance. With their expertise and knowledge, they can help you mount your TV securely and safely on any type of wall. Don't take chances with DIY installations when it comes to your valuable electronics – trust the experts for peace of mind.

3 notes

·

View notes

Text

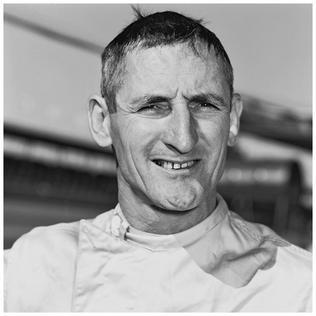

• Ken Miles was born on November 1st of 1918 in Sutton Coldfield, England. During his early life he apprenticed at a British car manufacturer. During World War II, he worked in various duties that dealt with machinery and utilized his mechanical skills. He began motorcycle racing while in the service and this would continue after his tour. After World War II, he returned to the automobile industry and to automotive racing. He acquired a Frazer-Nash racer and installed a Ford V8-60 engine. It had mile success in local and club competition.

• In 1952 Ken Miles came to the United States where he accepted a position as service manager for an MG distributor in California. Later, he would became involved with a wide range of teams and races and have a profound influence on early American road racing. His skills as a driver and fabricator quickly evolved and he became legendary on the West Coast with his competitive Specials.

• Miles first racer (that he constructed) was in 1953, while working for Gough Industries. He had been racing MG TD's for Gough, but they were often outclassed by the competition. Gough helped Miles with creating a racer, though he was unable to provide cash. What Gough did provide was use of any MG or Morris and any stock spare part.

• Miles began work on the MG R-1. The frame was created from mild steel tubing and attached to MG Series "Y" independent front suspension. The rear was comprised of a live axle. Alfin aluminum drum brakes with two-wheel cylinders were used to provide the stopping power while a Morris Minor rack-and-pinion kept the vehicle in the drivers control.

• Under the hood was an experimental racing engine that had a 1466cc displacement size. The engine would later be used by MG for their MG TF 1500. The engine had twin SU carburetors and a 10.5:1 initial compression ratio. The compression ratio was later increased to 11.6:1. The 83 horsepower engine was mated to a stock MG TD transmission which sent the power to the rear wheels.

• The car was clothed in a hand-formed aluminum body. The overall weight of the vehicle was less than 1,230 pounds. The car made its inaugural appearance in 1953 at a rainy Pebble Beach. The car had not been tested but this did not seem to matter, as it emerged victorious. Throughout the next year, the car would win all of the races it was entered, except for two. Its racing career came to an end in 1954 at Pebble Beach, when it suffered mechanical difficulties and failed to finish the race. The flywheel bolts fractures which allowed the flywheel to come loose. This resulted in the engine over-revving and it threw a rod. The R-1 Miles Special's racing career had come to an end.

• The second Miles Special racer was constructed in similar fashion to the first, but incorporated many key mechanical and design changes. Many MG components were still utilized, such as the gearbox and 1466cc MG XPEG engine. The space frame chassis was constructed from one-inch steel tubing which was lighter than its predecessor, but still retained the structural rigidity. To reduce frontal area, the driving position was lowered by nearly four inches. Other techniques were used to reduce the frontal area. The engine was tilted down in the front which did much to achieve this goal.

• The car was narrow and low, which meant changes were needed to fit all the engine components in the engine bay. The MG intake manifolds were installed upside down which allowed the carburetors to be angled and fit under the hood. The design of the vehicle was similar to the MG TF. This was done for brand recognition and to help promote the MG line of vehicles. There were differences; the R-2 had an envelope body with fenders that flared up, and over, the front and rear wheels. In the front was an MG style grille with headlights on either side. The car was finished in British racing green.

• The car was given the nickname, the Flying Shingle. Its inaugural race was in 1955 at Willow Springs. It failed to finish the race. Many of the other races in which it entered, it emerged victorious. Among its accomplishments were first place finishes at Pebble Beach and Torrey Pines. Miles was doing well in small-bore racing, but the competition was consistently keeping pace. Soon, a new machine was needed.

• Miles acceptable a position at Johnny Von Neumann's Porsche dealership. He raced during the 1956 season in a Porsche 550 Spyder and began work on a new racing Special. With von Neumann providing a generous budget, and Porsche providing ample stock components, Miles was able to construct a proper, large-budget racer. Power came from a Porsche Carrera four-cam engine that displaced 1500cc. The chassis was a Cooper Bobtail with a modified nose. The suspension was an independent setup with drums in the front and rear. The body shell was constructed of aluminum which aided greatly in the vehicles low weight of just under 950 pounds.

• Near the close of 1956, the newly created Special was brought to Pomona where it was piloted by Miles to a second place finish. At Paramount Ranch, the car was driven to a class win in the 1500cc class, and beat-out the big-bore modified class as well. The car was raced in 1956 and for part of 1957 before the von Neumann dealership was given the break they had been desperately searching for - a Porsche 550A. The car was supplied from the factory with orders to sell the R-3 Pooper Special. The R-1, R-2, and R-3 are still in existence in modern times. They are used in vintage competition and are shown at events.

• Ken Miles life came to a tragic end on August 17th, 1966 while driving a Ford J-car prototype. The car was traveling at 175 mph on a back-strech. Ken began preparing for a corner, slowing the vehicle down, but it went out of control and over an embankment. Ken was thrown from the car as it spun and went end-over-end. This tragedy brought an end to a brilliant career that began during the very early 1950s.

16 notes

·

View notes

Text

Furniture Maintenance: How to Keep Your Dining Chairs Looking New

Investing in a set of stylish and comfortable dining chairs can instantly elevate the overall ambience of your dining area. Whether you have chosen classic wooden chairs or modern upholstered ones, it's crucial to maintain them properly to ensure their longevity and keep them looking new. Let us explore the tips and tricks for maintaining your dining chairs in Singapore, helping you preserve their beauty and functionality for years.

CLEAN REGULARLY TO PREVENT BUILD-UP:

Regular cleaning can prevent dirt, dust, and food particles from accumulating on your dining chairs. Start by vacuuming the chairs to remove loose debris. Use a soft, dry cloth to wipe any remaining dust from wooden chairs.

Upholstered chairs can be vacuumed or brushed to remove surface dirt. If there are any spills or stains, act quickly and follow the manufacturer's guidelines for stain removal.

PROTECT WITH CHAIR COVERS:

Consider using chair covers to safeguard your dining chairs from accidental spills and stains. These covers protect the chairs and add a touch of elegance to your dining space. Opt for chair covers made from durable and easy-to-clean fabrics that match your overall decor. Remember to remove and wash the covers regularly to maintain cleanliness and freshness.

AVOID DIRECT SUNLIGHT:

Excessive exposure to sunlight can cause fading and damage to the materials of your dining chairs. To protect them, position the chairs away from direct sunlight or use curtains, blinds, or window films to filter the harsh rays. This simple precaution will help preserve the colour and integrity of the chairs for a longer time.

CUSHION ROTATION:

If your dining chairs have removable cushions, rotate them regularly to ensure even wear and tear. It helps prevent permanent indentations and extends the cushions' lifespan. You can also distribute the weight evenly, avoiding imbalances and maintaining a comfortable seating experience by switching cushions as often as possible.

TIGHTEN LOOSE SCREWS AND BOLTS:

Over time, regular use can cause screws and bolts in your dining chairs to become loose. To prevent wobbling and potential damage, inspect and tighten them periodically. Use a suitable screwdriver or wrench to ensure the stability of the chairs. Taking care of these small maintenance tasks can significantly prolong the life of your dining chairs.

CONSIDER FLOOR PROTECTORS:

To protect your dining chairs and your floors, consider using floor protectors. These simple accessories, such as felt pads or rubber caps, can be attached to the bottom of the chair legs, preventing scratches and reducing noise when moving the chairs.

AVOID EXCESSIVE WEIGHT:

While dining chairs are designed to support weight, it's crucial to avoid placing excessive pressure on them. Avoid using chairs as stepping stools or placing heavy objects on them. It will help prevent structural damage and maintain the overall stability and integrity of the chairs.

CONCLUSION

By following these practical tips for furniture maintenance, you can ensure that your dining chairs in Singapore remain in good condition, preserving their beauty and functionality for years to come. Regular cleaning, using chair covers, protecting from direct sunlight, cushion rotation, tightening loose screws, utilising floor protectors, and avoiding excessive weight are all essential steps to maintain your dining chairs effectively. Take care of your investment so your dining area will continue to radiate style and comfort.

Remember, well-maintained dining chairs not only enhance your dining experience but also contribute to the overall aesthetics of your home. So, make these maintenance practises a part of your routine and enjoy your beautiful dining chairs for a long time.

Visit our website today to discover a wide range of dining chairs in Singapore. Invest in quality furniture and create a dining space that reflects your style and stands the test of time.

2 notes

·

View notes