#Structural bolt grades

Text

Structural bolt Manufacturer and Exporter India | Bigboltnut

Bigboltnut are a renowned manufacturer, supplier and exporter of high tensile structural bolts. Structural bolt assembly is used in both preloaded and non-preloaded applications. These bolts are available in 8.8 and 10.9 grades and its depends on our customer requirement. Structural bolts are used in connection between two towers, marine , ship building , wind enery sector . and also manufacturing EN 14399-4 10.9 bolts & nuts in hot dip galvanised condition. We export our range of products to over 50 countries including USA, Europe, Middle east and Africa. Our agencies sales team is present in Oman, Qatar, Saudi Arabia, Dubai, Abu Dhabi, Nigeria, Switzerland, France, Holland, Belgium etc.

Structural bolts characteristics and its Application

It used to two create force that holds two or more components.

Structural bolts used in heavy Industry to hold heavy components

Structural bolts are zinc electroplated in blue, yellow, black colour.

Source Url : https://www.bigboltnut.com/product/structural-bolts.html

#structural bolts#structural bolts suppliers#Structural bolts manufacturer#8.8 grades#10.9 grades#bolt & Nuts grades#Structural bolt grades#high tensile bolts

0 notes

Text

Some insight into how @sloaners @kiro-sveta @uintuva and I arrive at some of these incredibly specific JJK AUs:

Talking about tattoos we or the people in our lives want

Talking about how Nanami needed to look as hot as possible in Shibuya

Talking about people who didn’t die because they’re our best friend and can’t die, hope this helps, said at the drive-thru

Talking about how Nanami would seriously get this tattoo (“Certified Management Accountant”) but Gojo would actually give him this tattoo (a Rubik’s cube, some equations/formulas, two lightning bolts, an ink-splatter, a little Pac-Man ghost, a transparent rectangular prism and the structural formula of a chemical compound, all overlapping)

Talking about Gojo’s Best Friend Tattoo Parlour, which is also a drive-thru, and all the incredible tattoos that would come out of it. Somehow all of Gojo's apprentices are still teenagers and Megumi has no tattoos but has been tattooing people since first grade

Megumi keeps letting Yuji design the silliest tattoos that Megumi puts on Yuji. Everyone just thinks that’s Megumi’s art style now. They are baffled when he puts genuinely nice artwork on Nobara

Gojo has a tattoo for his ex-bestie Geto that looks like this tattoo ("Brenda Brenda Brenda Brenda Brenda Brenda" x 100) but eventually he and Nanami get ones that are like these tattoos ("Love Her" "Respect Him") except they say "Love Him" "Trust and Have Faith But Don't Respect Him"

It’s actually a reverse drive-thru where Gojo pays people to let him and his apprentices tattoo them. Nanami keeps coming back. He is saving for a house

#apparently this blog is 8 years old today. happy birthday anime me#kento nanami#satoru gojo#nanago#megumi fushiguro#yuji itadori#nobara kugisaki#jujutsu kaisen#jujutsu kaisen spoilers#jjk spoilers#jjk series#just for the implication on the shibuya stuff LOL#ayesha talks anime

34 notes

·

View notes

Text

(Redesign) Atomix

Species: Mendol (pl. Mendolee)

One of the most powerful aliens in Ben's arsenal, Atomix is an alien with the ability to see, hear, and manipulate the shape, location, and elements of all atomic structures around him. Even living material and the air around him is not exempt.

Because he only perceives things made of atoms, Atomix cannot be fooled by energy optical illusions such as light-refracting cloaks and ID mask disguises. However, this puts him at risk from energy weapons and projectiles, which he can't see or hear (but very much feel when they hit).

Atomix's body is sturdy, and can withstand the vacuum of space. His skin is tough but with some bounceback to it. Though a Mendol's body is entirely organic, with the more obviously fleshy bits and ichor being internal, exposed only by clear membranes like his eye, arm nodes, and torso, many species have mistaken them for an automatonous species, such as Synthroids or Sylonnoids.

His eye is lidded, and the slits on the sides of his head are gills through which he breathes.

Atomix can hold his breath for lengthy stretches of time, by choice or by retracting his head into his collar. He can also do this to protect his head, eye, or the Omnitrix badge on the back of it.

His base strength is great, capable of picking up cars, busting through solid brick and concrete, and tearing up stop signs and lampposts from blacktop. Being crushed under rubble, buildings, boulders or vehicles is easy to shake off and escape from. His weight and density also make it hard to knock him around, as easy as tripping him would be.

Atomix is capable of running with great force and endurance, though with a slow start. Though his thick fingers lack manual dexterity, his eye for detail and pinpoint accuracy make up for it, if not negating it entirely.

Ben could use Atomix to hold his own in a fight, completely without his unique abilities, just due to Mendol durability and strength.

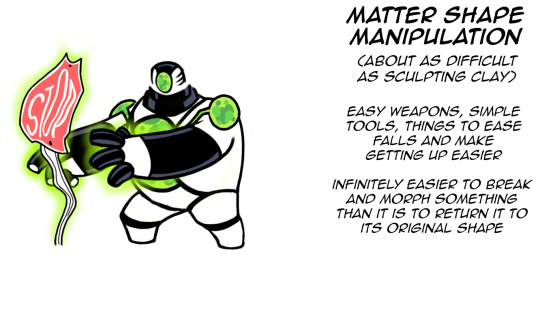

Moving the general atom positioning of matter allows Atomix to bend it into useful shapes.

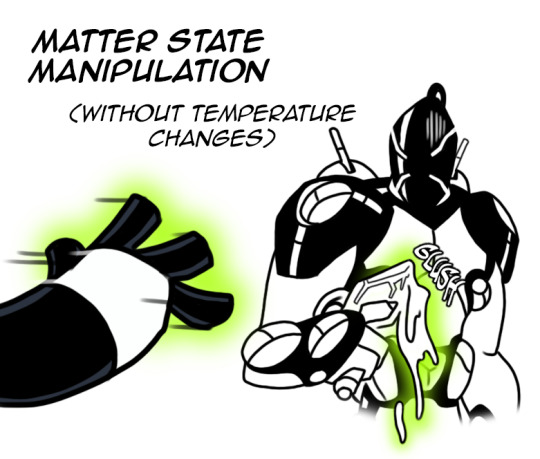

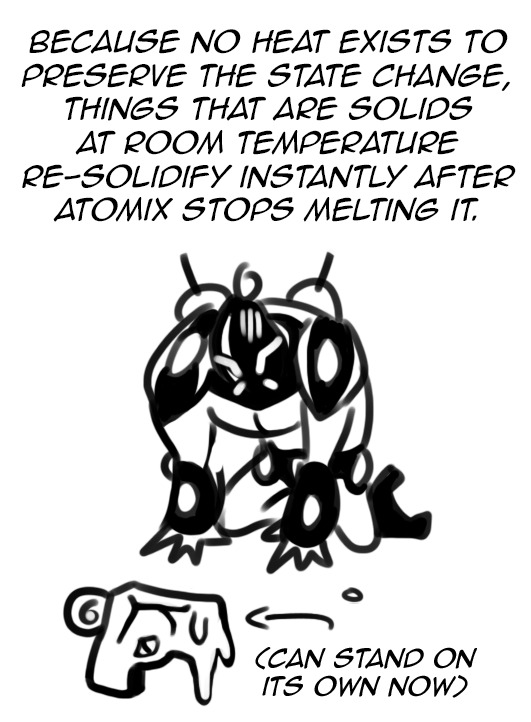

By changing atomic densities, Atomix can shift the phases of matter around him, in any direction, even rarer occurrences like sublimation.

Atomix can even cause matter to change elements. By adding and subtracting particles, he also alters their weight and mass.

Atomix is capable of replicating more complex weapons, such as grenades or guns, but only with a provided example for visual reference. His atomic sight means he has 24/7 X-ray vision in a sense, so he can replicate the smallest internal seams, bolts, and wires. However, while he can create the base of a tech-heavy weapon, if it requires an energy source, Atomix cannot provide it (exception being if it's powered by radioactive material).

With such great power is an intense drawback: the sensory overload that comes from being able to see and hear even the smallest electron in every single atom, including the air. The background noise of every piece of matter in the immediate vicinity drowns out most other noises, including the voices of friends and enemies alike. The visual static of seeing every moving part of every atom also drowns out his ability to distinguish friend and foe, much less people from the environment.

Transforming into a Mendol overwhelms Ben and puts him in a spacey mindset, where he might become more occupied with examining walls or an object on the floor than the fight he was transforming for.

With concentration and practice, Ben can strain his hearing to pay attention to others, and with the human part of him to ground Atomix (by referring to others by titles to remind him that a particular pile of atoms is Friend, and the other is Cousin, one is a Foe, etc.), he can become more and more like Ben and use his powers responsibly and effectively. Study of chemistry in and out of Mendol form assists his alchemizing ability (and bump up his grade in high school chem).

Even organic material is manipulatable, so Atomix is technically capable of healing powers, but it is infinitely easier to break and morph something than it is to restore its original form or make fine-tuned details.

So, to not the cross the line of accidentally mangling civilians or using this to melt or kneecap his villains, all organic matter-shifting is off-limits by Ben's choice. He's willing to use his powers on himself like morph a hand into a blade, because he understands the risks, it won't hurt anyone but himself if it goes awry, and it will be fixed by the Omnitrix via detransformation.

If he wants to bend the universe, he must first bend himself.

Mendolee are most comfortable in space or in environments with a minimal atmosphere, where there is the least atomic sound, only the faint roar of distant planets and stars, or the rock beneath their feet. They are extremely asocial, because they see every single atom and its particles, as well as hear every sound every atom makes. So, Mendolee don't really hear much over the collective atomic sound of the universe. They do not prioritize one kinda noisy, extra-moving pile of atoms over the other inanimate, slightly-more-still equally noisy piles of atoms. So they generally don't respond to anyone trying to talk to them.

They are significantly better at recognizing other Mendolee, but only through pattern recognition of their own atomic structures.

Idling through space, they often crash onto planets by drifting into its gravitational pull, where they wander aimlessly only to examine their surroundings' make-up. Then, they terraform a little corner to live in.

Millennia ago, Mendolee fell to the original Galvan Prime, and terraformed the landscape, to the aid and awe of the residing Galvans. The Omnitrix icon, a Galvan symbol and universal peace sign, was based off the natural membrane on a Mendol's torso.

Different Mendolee have different preferences. Some insist on flattening everything so all is perfectly level. Others like making tall towers like anthills, others make these as a consequence of making valleys to wedge themselves into for rest.

—

I'm not the first person to, though I want to say I independently came to this conclusion without seeing the other people who had done it first, think that Atomix should've been based on or be the species of beings Azmuth's biosuit was based on, the "ancient machine gods primitive Galvans used to worship"

Because radiation is N.R.G.'s thing, I changed his powers to alchemy/matter manipulation.

I wasn't sure what colors to make Atomix, because I knew he shouldn't be the same colors as Azmuth's suit, so I went with his concept art by Tom Perkins. It was meant to be temporary but I really liked and ended up keeping it.

This is more of an afterthought but looking at canon Atomix's page pissed me off cause he's got the big Omni shape (with kirby dots) on him which is a Galvan symbol with the explicit note in the trivia "yeah it is a Galvan symbol but just cause it's Galvan doesn't mean Atomix has anything to do with them"

Like shut up. What if, in an opposite but also reverse way, it's a Galvan symbol BECAUSE it is a naturally occurring shape on Mendolee. Same way we see doves and make them a symbol of peace. We see a heart and make it a symbol of love. Do you see my vision.

Mendol/Mendolee is a reference to Dmitri Mendeleev, the Father of the Periodic Table of Elements. The "dol" part is a play on doll because of their artificial and articulated appearance.

#PSST the majority of art is underneath the cut#nerd stuff#my art#scarletta doodles#ben 10#fan design#redesign#Atomix

69 notes

·

View notes

Text

It’s crazy how fast a rumour can spread. One morning, you’re in prison, spreading a rumour about yourself to your friends. Then, just a few short years later, that rumour is repeated as if it were gospel truth. The new guy at the Pick Your Part is afraid of you, purely by reputation. This is all from the power of sharing information in groups: the true power of humanity.

There are those who would dare to restrict the explosive growth of this power, who would curb your rhetoric from gaining such legendary status that it allows you to walk out of the junkyard, carrying a starter battery, without paying for it. While major politicians may be the only ones unlucky enough to be dogged by so-called “fact-checkers” who hand out tut-tuts and scolds for genocide-level mistruths, anyone who casually dips their toe into the fetid waters of professional-grade lying will be called out from time to time. How do you respond to those who demand that you actually provide evidence for your claims?

One way to defuse this threat is through violence. This has been the historic method of humanity up until this point. Get a big enough mob, say what you want, stomp on anyone who disagrees. This is not your writer’s stance. For one thing, the integrity of my knees is not up to the task of stomping on a drinking glass at a Jewish wedding, let alone an angry hater. And my crowd of weirdos is less violent than they are “looking for a really good deal on car parts.” For me, I have to rely to the second method: a greater quantity of, and more complex, lies.

All I have to do is just come up with more bullshit, and soon the original bullshit will seem small and trivial by comparison. How is it that I drove a Detroit Diesel-powered Corvette when it is completely impossible that a 4-53 will fit inside the engine bay? Well, that’s because I had cut and extended the Corvette in an almost comical fashion, using old stolen cruise-ship parts as a frame. That makes no fucking sense, how did you weld structural steel from a cruise ship onto the space frame of a C3 Corvette? Well, you see, my cousin, the former Shah of Iran, has given to me a magic welder capable of spraying flimsy, birdshit welds with crappy penetration onto any two pieces of metal that I want to present to it. So how did it hold up a super-heavy Detroit Diesel engine?

As you can see, I have a particularly devoted opponent in this simulation. At this point in reality, I would throw a smoke bomb and escape. These smoke bombs are easy to get, available at any local ninja supply store, but in a pinch you can also make them out of discarded vape batteries and a tincture of Seafoam. In my next lecture, we’ll be covering the importance of making a false lining for your junkyard bag, so that you can hide bolts and relays inside it without the checkout cashier noticing.

267 notes

·

View notes

Note

finally this gets to 8e less one sided

📝

Oh please, you love my waves of whatever thought enters my head and gets turned into a curiosity. Now, to answer:

📝 - Story from your childhood.

Being hideously traumatized *and* plural, I remember precious few of those, but there's one I couldn't forget, and it involves brain damage.

It was in elementary school, 1st grade if memory serves. I was at recess, yelling "Imp!" at a pair of 4th graders, the reason for this escaped my memory at some point, but I'm like 95% sure it was echolalia. I was trying to piss them off, though. Whether it worked or I just thought it did, I don't remember, but I fucking *bolted* at some point. I looked back, to see how far behind me they were (I could not see them), and when I turned back, I was met with a face-first collision into a piece of the metal playground structure.

I come to maybe like 10 seconds later, cognizant of what happened. I checked for blood, which there was. In my childlike innocence, and potential concussion, my first thought was "I can't let anyone see this, they're gonna take me to the office and I'm gonna miss part of recess". So I, with all the nonchalantness of a socially awkward child with a chunk of their skull knocked loose, put my hand up to the wound to hide it. This worked for all of 3 seconds before the blood started coming from between my fingers.

I remember one of my classmates told me I should see a teacher, to which I responded "No, it's fine." A 4th grader then proceeded to *physically drag me* to the nearest teacher, who, as per the prophecies entering my mind through the hole, took me to the office, where I not only missed the rest of recess, but due to my passing out both from the injury and possibly blood loss, I missed the rest of the school day. I think I actually made it home an hour or two later than normal.

For the record, I never went to the hospital for this injury. I got whatever care a public school nurse's office could give me, and I went home. I actually still have the scar from it to this day, almost 20 years later, and I suspect it'll never go away unless I get the dent in my skull filled in or something.

4 notes

·

View notes

Text

Good afternoon TUMBLR - July 8th - 2024

“Mr. Plant has owed me a shoe since July 5, 1971.”

Gazoducto Samalayuca - Sasabe. Mexico - Nuevos Casas Grandes - Chihuahua.

Part 6

M.R.I. Magnetic Resonance Image.

The long flights from London to Bogota, from Bogota to Mexico City, to Chihuahua, had left their mark: a pain in my left knee that left me at no peace!

Doc. Norma prescribed me an MRI at the local NCG Radiology Center.

Beautiful structure, well-kept garden, apparently efficient machines. After a couple of days I went to collect the results, and it was like a bolt from the blue!

Rupture of the right anterior cruciate ligament - left knee

Grade III tear of the posterior horn of the internal meniscus and the posterior horn of the external meniscus.

Bursitis of the patella

Tenosynovitis of the patellar tendon.

Hoffitis of the left patella.

My left knee was basically ''gone'' but I didn't know it and I insisted on walking on it!! I took the report to Doc Norma, who - it seemed to me - didn't get too upset (it was characteristic of her not to get upset, perhaps deriving from the religious faith she adhered to: Mormonism). Norma told me that I needed a consultation with a specialist, identified as Dr. Jose' Alvarez Obregon of the Star Medica Clinic in Ciudad Juarez.

I saw him two days later and it was again a great surprise: a young and affable person, who, after having taken a look at the MRI, immediately put me at ease by saying that the report contained a lot of ''inaccuracies' ( not to mention worse).

- Listen to me – he told – if you really had all the pathologies described in the report, you would be sitting in a wheelchair by now.

So why did they write all these ''inaccuracies''?

But to do business, right? The patient worried by the first report will want to have counter-proof, and will ask for new tests, always from them. By doing this the laboratory will earn more money!

That's incredible to me Doc.….

This is Mexico, Dear Sir – go ahead, take an anti-inflammatory if you want and you will see that within a few days the pain will be gone. Until we meet again!

And so it was: after 4 days the knee pain was just a bad memory of the intercontinental flights.

Mexican Travel and Holidays.

During the three years of my stay in Mexico, I had the opportunity to take some trips and holidays within the vast Mexican territory. Although, I must admit, I would have liked to visit more places. Like Baja California for example. Cabo San Lucas was a destination on my bucket list, but unfortunately for various reasons I couldn't see it. Chiapas was also a state I would have liked to visit, especially with its ancient evidence of the Mayan civilization in Palenque.

However, apart from the recurring trips to Mexico City, I managed to have some nice holidays in Yucatan and Quintana Roo. They are truly enchanting places, with vestiges of their important past, and splendid nature. The Mexican Caribbean is one of the top world destinations. Since my first trip to Cancun, in 1984, much has been done to make the Riviera Maya attractive to high-level international tourism.

I particularly appreciated Tulum, where you truly live in a sort of ''magical atmosphere''. The Mayan archaeological site, well cared for by the local authorities, is something grandiose. The only site directly on the shore of the splendid sea of the Gulf of Mexico. Its particular position, on the coast overlooking the sea, meant that it was the first Mayan city to be sighted by the Spaniards on March 3, 1517.

Its favorable geographical position had previously made it successful, making it an important trading post for products such as fish, honey, salt, obsidian and quetzal feathers.

The most important building in Tulum is undoubtedly El Castillo located near the landing, a small inlet that served as a port.

A destination for tourists from all over the world, the charm of Tulum is also given by its beaches of fine sand, typical of the Caribbean coast.

The Mayan city of Chichen Itza is also spectacular, perhaps the most important archaeological site in Mexico. The Castillo or Temple of Kukulcan, dominates the ancient city, which prospered from 600 AD. to about 1200. Graphic stone sculptures survive in structures such as the playing field, the Temple of the Warriors and the Wall of Skulls.

The journey from Cancun to Tulum, approximately 300 km, takes place along a modern highway totally immersed in an intricate equatorial forest.

I also had the opportunity to visit Coba', an archaeological site built by the Mayan civilization located 44 km north-west of the Tulum site. Coba' is a relatively ''new'' site where important archaeological discoveries have been found, but which is still being excavated and promises to reveal more hidden treasures. Cobá is located around two lagoons. There are some sacbé («saq′i b′e», white road), it is a typical road of the Mayan civilization that goes eastwards on the Caribbean coast and the longest covers over 100 km of distance going westwards to the Yaxuná site. The site has several large pyramids, the largest of which is in the Nohoch Mul group of pyramids, 42 meters high.

Another great place to visit is the local attraction called ''Xcaret''. It's an enormous natural reserve directly to the sea, where numbers of live animals can be seen.

I had also the opportunity to re-visit ''Isla Mujeres'' where I had my honeymoon in 1984. Lot of changes since, some of them not for good. The once tiny naif island has become a mass tourist destination nowadays.

Anycase its lagoon is still spectacular, and it's pristine waters provide a safe place to swim and snorkel.

Cancun has first-rate hotel facilities and a coastline washed by a beautiful sea. Its colors and shades are among the most beautiful I have ever seen in the world.

Final return from Mexico

The project - after many difficulties, was well underway. We had managed to have a good number of local workers who had been taught to work according to our parameters and specifications. Finally our Client was also convinced of the goodness of our work, and was showing us signs of trust. For example by removing sections of gas pipeline from other small contractors, and assigning them to us.

But the unexpected was just around the corner. When I was convinced that I would complete the project, one morning in May, I had just arrived at the office, I got a call from Italy.

Company's owner: what do you think about returning to Italy? We need a Works Director for the project in Abruzzo-Molise. (Central-South Italian region)

When Gino?

Tomorrow.

Ok, tell Franca to send me the plane ticket.

It was like that, a little sad way, I left ''Querido Mexico''. Without the so called ''despedida'' (farewell party).

The next day I board a plane in Chiuhuhua to Mexico city. And than onward to Madrid-Milan.

ADIOS MEXICO!

2 notes

·

View notes

Text

SS 316 Blind Flange at the Lowest Price

Looking for a durable and corrosion-resistant flange for your industrial applications? The SS 316 blind flange is your go-to choice, offering superior performance in harsh environments. At Udhhyog, we provide the SS 316 blind flange at the lowest price, making high-quality stainless steel products accessible to all industries. In this article, we’ll explore its key features, benefits, and why Udhhyog is your trusted supplier.

What is an SS 316 Blind Flange?

An SS 316 blind flange is a circular steel plate with all the bolt holes but no central opening, designed to seal off the end of a pipeline or pressure vessel. Made from 316-grade stainless steel, it provides enhanced resistance to corrosion, especially in marine and chemical environments. This makes it ideal for industries dealing with highly corrosive substances.

Key Features of SS 316 Blind Flange

Superior Corrosion Resistance: The addition of molybdenum in SS 316 enhances its resistance to chloride pitting and general corrosion.

High Temperature and Pressure Resistance: Capable of withstanding extreme conditions, making it suitable for high-pressure applications.

Versatility: Available in various sizes and pressure ratings to fit different industrial needs.

Benefits of Using SS 316 Blind Flange

Long-Lasting Durability: The robust structure ensures a longer lifespan, even in challenging environments.

Cost Efficiency: At Udhhyog, we offer the SS 316 blind flange at the lowest price, providing excellent value for your investment.

Safe and Secure: Prevents leaks and ensures safe operation of pipelines and pressure vessels.

Applications of SS 316 Blind Flange

Marine Industry: Resistant to saltwater corrosion, making it ideal for shipbuilding and offshore platforms.

Chemical Industry: Suitable for handling aggressive chemicals and acidic environments.

Pharmaceuticals: Used in sterile and sanitary applications due to its hygienic properties.

Why Choose Udhhyog for SS 316 Blind Flange?

Udhhyog is committed to delivering high-quality industrial products at competitive prices. By choosing us, you benefit from:

Top-Quality Products: We source only the best materials to ensure the highest quality standards.

Affordable Pricing: Get the SS 316 blind flange at the most competitive price in the market.

Exceptional Service: Our team is dedicated to providing the best customer experience.

How to Order

Ordering from Udhhyog is simple. Visit our website and click on SS 316 blind flange lowest price to place your order. We ensure timely delivery and hassle-free service.

#SS316BlindFlange#StainlessSteelFlange#IndustrialFlanges#MarineIndustry#ChemicalIndustry#Udhhyog#FlangeSupplier#LowestPriceFlange

1 note

·

View note

Text

A Complete Guide to B7 Stud Bolts – Quality Solutions from Delta Fitt Inc.

As a trusted B7 Stud Bolts Manufacturer in India, Delta Fitt Inc. takes pride in offering top-quality B7 stud bolts that meet the highest industry standards. When it comes to industrial fasteners, B7 stud bolts are widely recognized for their exceptional strength and reliability, especially in high-pressure and high-temperature applications. For industries such as oil and gas, petrochemicals, and power generation, choosing the right fasteners can make all the difference.

In this complete guide, we’ll explore the characteristics of B7 stud bolts, their applications, benefits, and why Delta Fitt Inc. should be your go-to B7 Stud Bolts Supplier in India.

What Are B7 Stud Bolts?

B7 stud bolts are a type of threaded fastener made from alloy steel that is heat-treated to increase its tensile strength. The material used for B7 stud bolts is typically AISI 4140 or 4142 steel, which has excellent mechanical properties, including resistance to corrosion, high temperatures, and pressure. These fasteners are primarily used in the assembly of flanges, valves, and pressure vessels.

Due to their ability to withstand extreme environments, B7 stud bolts are highly sought after in industries where durability and safety are paramount. Their high tensile strength makes them ideal for critical applications, including those in oil refineries, chemical plants, and other sectors that demand long-lasting and secure fastenings.

Key Features of B7 Stud Bolts

Material Composition: B7 stud bolts are made from alloy steel, which ensures their superior strength and durability. The combination of chromium, molybdenum, and carbon in the alloy enhances its performance in harsh environments.

Heat Treatment: These bolts undergo heat treatment processes to improve their mechanical properties, especially their tensile and yield strengths.

High-Temperature Resistance: B7 stud bolts are designed to perform under extreme temperatures, up to 450°C (842°F), making them ideal for applications involving high heat and pressure.

Corrosion Resistance: With a good level of corrosion resistance, B7 stud bolts are capable of withstanding aggressive chemical environments, which is why they are favoured in industries dealing with corrosive substances.

Applications of B7 Stud Bolts

B7 stud bolts are versatile fasteners and are used across multiple industries. Some of the most common applications include:

Oil & Gas: In refineries and oil rigs, where equipment must endure extreme conditions, B7 stud bolts are used to secure flanges, pressure vessels, and heat exchangers.

Petrochemical Plants: The ability of B7 stud bolts to resist corrosion and high pressure makes them ideal for fastening components in chemical processing units.

Power Generation: B7 stud bolts are used in power plants, particularly in steam turbines and boilers, due to their heat resistance and tensile strength.

Construction: Heavy infrastructure projects such as bridges, dams, and large buildings rely on B7 stud bolts for structural stability and endurance under load.

Why Choose Delta Fitt Inc. as Your B7 Stud Bolts Supplier?

As a leading B7 Stud Bolts Manufacturer in India, Delta Fitt Inc. stands out for its commitment to quality and precision engineering. Here’s why partnering with Delta Fitt Inc. is the right choice for your fastener needs:

High-Quality Materials: At Delta Fitt Inc., we use premium-grade alloy steel to manufacture our B7 stud bolts. This ensures our products meet international quality standards and deliver long-lasting performance in any application.

Advanced Manufacturing Techniques: Our state-of-the-art manufacturing facility is equipped with the latest technology to produce B7 stud bolts with consistent quality. Each bolt is carefully crafted and inspected to meet rigorous specifications.

Custom Solutions: We understand that different industries have unique requirements. Delta Fitt Inc. offers custom-made B7 stud bolts to match the exact specifications of our clients, ensuring perfect fit and performance.

Timely Delivery: As a trusted B7 Stud Bolts Supplier in India, Delta Fitt Inc. is known for its reliable and timely delivery of products. We prioritise the needs of our customers and ensure that our products are delivered as promised, no matter the size of the order.

Competitive Pricing: Despite the high quality of our products, Delta Fitt Inc. offers competitive pricing for all our B7 stud bolts. We believe that top-quality fasteners should be accessible to businesses of all sizes without compromising on performance.

Delta Fitt Inc. – Your Reliable B7 Stud Bolts Manufacturer

Whether you’re looking for a B7 Stud Bolts Manufacturer or a B7 Stud Bolts Supplier, Delta Fitt Inc. provides top-tier solutions for all your industrial fastener needs. With years of experience in the industry, we have built a reputation for delivering high-quality products that perform under the most challenging conditions.

Our expertise in fasteners goes beyond B7 stud bolts; we also offer a wide range of other industrial fasteners, including nuts, washers, and other specialty bolts. Each product is meticulously designed and manufactured to meet the specific demands of our clients, ensuring the highest levels of safety and performance.

Conclusion

B7 stud bolts are a critical component in many industrial applications where strength, reliability, and durability are paramount. Choosing the right B7 Stud Bolts Manufacturer and supplier is essential to ensure your operations run smoothly and safely. Delta Fitt Inc. is proud to offer high-quality B7 stud bolts that meet the most stringent industry standards.

With our commitment to quality, customization, and timely delivery, we are your trusted B7 Stud Bolts Supplier in India. For more information on our products and services, feel free to contact Delta Fitt Inc. and experience the difference our expertise can make in your projects.

We are also leading B8 Stud Bolts Manufacturer in India, and B8M Stud Bolts Manufacturer in India

Website: deltafitt.com

#B7StudBoltsManufacturerinIndia#B7StudBoltsManufacturer#B7StudBoltsSupplierinIndia#B7StudBoltsSupplier

0 notes

Text

Fixings and Fasteners: Essential Components for Secure and Durable Installations

In construction, manufacturing, and DIY projects, Fixings And Fasteners are essential components that ensure materials are securely attached, stable, and capable of withstanding stress over time. From securing heavy structural elements to holding smaller parts in place, the right choice of fixings and fasteners can make a significant difference in the safety, strength, and durability of an installation.

This guide will explore the different types of fixings and fasteners, their uses, and how to select the right ones for various applications.

What Are Fixings and Fasteners?

Fixings and fasteners are hardware devices used to join or secure materials together. They come in various forms, including screws, bolts, nails, rivets, anchors, and clips, each designed for specific tasks. These components can be used for permanent or temporary connections and are critical in ensuring that structures and assemblies hold up under mechanical forces such as tension, compression, and shear.

Types of Fixings and Fasteners

Screws

Screws are one of the most commonly used fasteners. They are designed to be driven into materials like wood, metal, or plastic with a twisting motion. Screws come in a wide range of types, such as wood screws, machine screws, and self-tapping screws, each suited to different materials and applications.

Common Applications: Furniture assembly, decking, and general construction.

Bolts and Nuts

Bolts are threaded fasteners typically used with nuts to secure two or more parts together. They are ideal for applications where high strength and durability are required. Bolts and nuts come in different sizes, grades, and materials, including steel, stainless steel, and brass.

Common Applications: Heavy machinery, automotive, structural steelwork, and construction.

Nails

Nails are used to fasten materials by driving them through one or more layers using a hammer or nail gun. Unlike screws or bolts, nails do not have threads, making them suitable for applications where high shear strength is needed.

Common Applications: Framing, roofing, and carpentry.

Anchors

Anchors are used to secure fasteners to surfaces like concrete, brick, or drywall, where screws or bolts alone would not be effective. There are several types of anchors, including wall plugs (also known as rawl plugs), toggle bolts, and concrete anchors.

Common Applications: Hanging heavy objects like shelves, fixtures, and cabinets on walls.

Rivets

Rivets are permanent fasteners used to join two or more materials by deforming the head after insertion. They are commonly used in applications where access to both sides of the material is limited.

Common Applications: Aircraft assembly, shipbuilding, and metalworking.

Washers

Washers are thin plates with a hole in the middle, used to distribute the load of a threaded fastener, like a screw or bolt. They help prevent the fastener from loosening and can protect the material surface from damage.

Common Applications: With screws and bolts in mechanical and structural installations.

Clips and Clamps

Clips and clamps are fasteners that hold objects together or secure cables and pipes in place. They are often used in scenarios where frequent disassembly or adjustment is necessary.

Common Applications: Cable management, piping systems, and automotive assembly.

Staples

Staples are U-shaped fasteners driven into materials using a staple gun or hammer. They are commonly used for attaching thin materials like fabric, paper, or insulation to wood or other surfaces.

Common Applications: Upholstery, packaging, and light construction.

Choosing the Right Fixings and Fasteners

Selecting the appropriate fixing or fastener for a project depends on several factors:

Material Type: Different materials require specific types of fasteners. For example, wood screws are designed for timber, while machine screws are suitable for metal or plastic.

Load Requirements: The strength and load-bearing capacity of the fastener should match the weight and mechanical forces it will need to withstand. Bolts and anchors are often used in high-load applications, while screws and nails are better for lighter tasks.

Environmental Conditions: In outdoor or corrosive environments, such as marine or chemical industries, materials like stainless steel or galvanized fasteners are preferred for their resistance to rust and wear.

Installation Method: Consider how the fastener will be installed. Some fasteners, like nails and staples, are hammered in, while others, like screws and bolts, require tools like screwdrivers or wrenches.

Permanent vs. Temporary: If the assembly needs to be frequently disassembled and reassembled, choose fasteners like screws, bolts, or clamps. For permanent installations, rivets or nails might be more appropriate.

Common Applications of Fixings and Fasteners

Construction: Fasteners such as screws, bolts, and nails are used to assemble structures, secure frameworks, and attach components like doors and windows.

Manufacturing: In industries such as automotive and aerospace, fasteners like bolts, rivets, and clips ensure the secure attachment of parts that undergo mechanical stress.

Home Improvement: From hanging shelves to assembling furniture, various fixings and fasteners are used in everyday home projects.

Electrical Installations: Fasteners like anchors, clips, and clamps are essential for securing wiring and electrical components in place.

Conclusion

Fixings and fasteners are fundamental to nearly every construction, manufacturing, and DIY project. Selecting the right type based on material, load, and environmental factors ensures that your installation is secure, durable, and safe. With the vast range of options available, understanding the specific requirements of your project will guide you in choosing the most appropriate fixing or fastener for the job.

0 notes

Text

Nickel Alloy 201 Bolt Exporters In India

Nickel Alloy 201 bolts are a critical component in industries where resistance to corrosive environments and high temperatures is essential. Supplied by Nascent Pipe and Tubes, these bolts are well-known for their excellent mechanical properties, making them ideal for applications in harsh industrial settings. Whether it's chemical processing, marine applications, or the aerospace sector, Nickel Alloy 201 bolts offer unmatched performance.

What is Nickel Alloy 201?

Nickel Alloy 201 is a commercially pure nickel alloy, known for its high electrical and thermal conductivity, corrosion resistance, and excellent workability. The alloy contains low carbon content (below 0.02%), which makes it suitable for applications requiring resistance to corrosive environments, particularly in reducing conditions. Its ability to withstand temperatures of up to 1230°C makes it an attractive choice in industries with extreme heat exposure.

Why Choose Nickel Alloy 201 Bolts?

Nickel Alloy 201 bolts offer a range of benefits due to the inherent properties of the alloy:

Corrosion Resistance: Nickel Alloy 201 is highly resistant to various forms of corrosion, particularly in caustic environments. This makes the bolts ideal for chemical processing plants and petrochemical applications where exposure to corrosive chemicals is common.

Heat Resistance: With exceptional high-temperature properties, Nickel Alloy 201 bolts perform reliably in furnaces, reactors, and heat exchangers. They maintain their strength and integrity even when exposed to extreme heat.

Electrical and Thermal Conductivity: The alloy’s superior conductivity makes these bolts perfect for electrical applications, ensuring reliable connections and performance in high-conductivity environments.

Versatility: Nickel Alloy 201 bolts are used in a wide array of industries, including oil and gas, food processing, marine environments, and aerospace. Their ability to withstand varying pressures, temperatures, and corrosive environments makes them highly versatile.

Applications of Nickel Alloy 201 Bolts

Chemical Processing: Nickel Alloy 201 bolts are widely used in equipment handling caustic soda, salt, and other aggressive chemicals. Their corrosion resistance ensures long service life in these environments.

Marine Applications: These bolts are favored in seawater environments due to their excellent resistance to corrosion, especially from saltwater and harsh marine conditions.

Aerospace: The ability of Nickel Alloy 201 to maintain structural integrity under extreme temperatures and pressure makes it an essential material in aerospace components, where reliability and performance are non-negotiable.

Food Processing: In industries where purity and contamination resistance are key, Nickel Alloy 201 bolts are used for equipment that must maintain sanitary conditions. The alloy's resistance to a wide range of acids and its non-reactive nature make it a safe choice for food processing machinery.

Why Trust Nascent Pipe and Tubes?

At Nascent Pipe and Tubes, we pride ourselves on supplying top-grade Nickel Alloy 201 bolts that meet the highest industry standards. Our bolts are tested for quality, durability, and performance to ensure they withstand even the most challenging environments. With years of expertise, we cater to industries around the globe, providing tailored solutions to meet specific needs.

We believe in building long-term relationships with our clients by delivering superior products that exceed expectations. Our Nickel Alloy 201 bolts are available in various sizes, ensuring you find the right fit for your project.

Conclusion

Nickel Alloy 201 bolts are a dependable solution for industries that require strength, corrosion resistance, and high-temperature performance. At Nascent Pipe and Tubes, we provide premium-quality Nickel Alloy 201 bolts designed to meet the toughest industrial challenges. Whether you’re operating in the chemical, marine, or aerospace industry, you can rely on our bolts for long-lasting and reliable performance.

For more information on Nickel Alloy 201 bolts and other high-performance fasteners, contact Nascent Pipe and Tubes today!

0 notes

Text

Structural Bolts Manufacturer & Exporter in India | BigBoltNut

We are renowned manufacturer, supplier and exporter of structural bolts in India. Structural bolt assembly is used in both preloaded and non-preloaded applications. These high tensile bolts are Available in 10.9 grades and 8.8 grades. The structural Bolts following EN 14399-4 and DIN 6914 is to use thinner nuts and shorter thread lengths to obtain the required ductility by plastic deformation of the threads within the nut. The structural bolt assembly is used in both preloaded and non-preloaded applications. Sturctural bolts charecteristics: are Large under-head surface, Less surface pressure, Enables preloading, Improved fatigue strength, Defined friction properties. Application of structural bolts: It is used in heavy industries like chemical, wind energy, ship, oil and wind energu sector

Source url: https://www.bigboltnut.com/product/structural-bolts.html

0 notes

Text

Why Venus Wires is Your Trusted Source for Premium Stainless Steel Bright Bars and Steel Bars

When it comes to bright bar steel and stainless steel bars, Venus Wires is one of the leading manufacturers in the market. By combining the expertise of over thirty years, adherence to the highest standards, and international presence, Venus Wires has earned its position as a reliable partner for companies of various fields. Be it superior stainless steel bars for construction, automotive, engineering, etc; Venus Wires assures the best quality manufacturing and service.

What Makes Venus Wires Unique?

The fundamental of Venus Wires’ success is the corporate culture of maintaining quality. The company employs the latest technology and practices in the production and quality assurance of its bright bar steel and stainless steel bars to meet international standards.

The manufacturing capacity of Venus Wires is excellent. The company operates an accurate strategy where each of the stainless steel bars manufactured meets the required standard. Every process of manufacturing the bright bar steel and stainless steel bars is closely monitored from the selection of the raw materials to the finishing stage.

The Process of Manufacturing Bright Bar Steel

Bright bar steel’s manufacturing process is quite intricate to provide strength, endurance, and aesthetic surface. The process commonly starts with cold drawing, which is a method of making the cross-sectional area of the steel smaller without heating. This results in improved surface finish and mechanical characteristics of the coated material.

The steel is cold drawn and then passes through the straightening and polishing stage. Venus Wires uses high-tech polishing equipment to produce shiny bar steel that is essential for markets that demand both form and function.

Another benefit of Venus Wires’ bright bar steel is increased dimensional stability. Cold drawing provides better control of tolerance which is essential in applications such as precision machining, automotive parts, and engineering parts. Furthermore, the bars of Venus Wires are highly resistant to corrosion and can thus be used in places where moisture or chemicals are likely to come into contact with the bar.

Types of Stainless Steel Bars Offered by Venus Wires

Venus Wires has a range of stainless steel bars to suit all the requirements of the industries. These bars are manufactured in various grades and surface finishes, and can therefore be used in various applications. Some of the most common types of stainless steel bars include:

1. Round Bars: Round bars are commonly used and find their application in automotive, construction, and marine industries. These round bars manufactured by Venus Wires are made of stainless steel and the qualities include high tensile strength, excellent corrosion resistance, and perfect machinability.

2. Hex Bars: Hexagonal bars are used most commonly in the production of fasteners, bolts, and nuts. Due to their consistent shape and strength, hex bars manufactured by Venus Wires from stainless steel are perfect for these applications.

3. Square Bars: Square bars are used mainly for construction purposes and other sectors that need strong and compact materials. Venus Wires produces stainless steel square bars with improved dimensional tolerance and surface finish, which are ideal for structural uses.

4. Flat Bars: Flat bars are used for various structural and ornamental purposes. Venus Wires’ stainless steel flat bars are ideal for various applications in architectural and industrial projects due to their high strength, good surface finish, and versatility.

Applications of Bright Bar Steel and Stainless Steel Bars

The uses of bright bar steel and stainless steel bars are diverse and include many sectors. Some of the key industries that rely on Venus Wires' high-quality steel products include:

- Automotive Industry: Many automotive parts are made with Venus Wires’ stainless steel bars because of their strength, corrosion resistance, and accurate dimensions. The products range from small wirings for automobile engines to bigger frameworks that are used to construct cars and other automobiles.

- Construction Industry: The construction industry uses steel products, especially in the reinforcement and support structures for construction purposes. Venus Wires offers stainless steel bars and bright bar steel that are preferred by builders and engineers due to their durability and performance.

- Aerospace Industry: The aerospace industry requires precision and durability in the products that they deal with. The bright bar steel of Venus Wires meets all the dimensional requirements and has the necessary tensile strength for manufacturing aircraft parts.

- Machinery and Engineering: In machinery and heavy equipment, durability and strength are important for proper functioning and safety. Stainless steel bars manufactured by Venus Wires are ideal for manufacturing and engineering applications because of their easy machinability and durability.

- Oil & Gas Industry: The oil and gas sector requires components that are resistant to moisture, chemical, and temperature fluctuations. Some of Venus Wires’ products include Stainless Steel Bars used in pipelines, valves, and other equipment used in the sector.

Quality Assurance and Certifications

Quality assurance is another key area that Venus Wires takes a lot of pride in. The company has many international certifications such as ISO 9001:2015 to show its concern for quality production. Every bright bar steel and stainless steel bar manufactured by Venus Wires is tested and inspected to ensure that it meets the requirements of customers.

The quality control checks that the company uses include dimensional control, surface control, and mechanical control. This guarantees that the stainless steel bars are not only standard but also superior in their performance and durability as per the customers’ expectations.

Why Choose Venus Wires?

Over the years, Venus Wires has established itself as a reputable supplier of bright bar steel and stainless steel bars. As a client-centric company, Venus Wires offers customized services for businesses across different sectors. Being a company that values innovation, quality, and sustainability, the company is the right partner for those in need of top-notch stainless steel bars.

Venus Wires should be your number one choice if you are in search of a supplier for bright bar steel and stainless steel bars. Whether for massive industries or accurate and fine components, Venus Wires is the company that provides products, knowledge, and commitment to make you successful.

0 notes

Text

Center Enamel Welded Steel Tanks are Durability and Customization for a Wide Range of Applications

Shijiazhuang Zhengzhong Technology Co., Ltd., a leader in the tank manufacturing industry with over 30 years of experience, offers high-quality welded steel tanks designed to meet the specific needs of various industries. Our welded steel tanks are custom-engineered to provide reliable, long-term storage solutions for liquids, bulk materials, and chemicals. We combine advanced production techniques with strict quality control measures to deliver storage tanks that meet international standards and customer expectations.

Design and Durability of Welded Steel Tanks

Welded steel tanks are storage solutions formed through specialized welding techniques that ensure strength and durability. The material selection for these tanks is based on the properties of the stored substances, environmental factors, and safety standards. To maintain resistance against corrosion, high pressure, and extreme temperatures, our welded steel tanks are constructed using top-grade materials, ensuring their longevity and performance.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, welded steel tanks ,pressure vessels and storage tanks roof, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs Solution

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Key Advantages of Welded Steel Tanks:

High Customization: We offer flexibility in the design of tank size, shape, and capacity to suit various storage requirements. This customization enables us to create welded tanks for small-scale storage or large industrial applications.

Durability: Built with premium steel and advanced welding techniques, our tanks withstand harsh conditions and offer long-lasting performance. Rigorous quality control ensures structural integrity.

Superior Sealing: Our welding process guarantees excellent sealing, preventing leaks and ensuring the safe storage of liquids or bulk materials.

Compliance with International Standards: Our welded steel tanks comply with stringent standards, including API 650, BS EN 14015, and GB50341-2014, ensuring their reliability and performance in global markets.

Welded Steel Tank Coating and Corrosion Protection

At Shijiazhuang Zhengzhong Technology Co., Ltd., we prioritize the protection of our welded steel tanks against corrosion. We follow the ISO 12944 standard for corrosion protection, using different primer and topcoat thicknesses based on customer requirements. This approach ensures that our tanks are highly resistant to corrosion and suitable for a range of storage environments.

Applications of Welded Steel Tanks

Our welded steel tanks serve multiple industries, including:

Water Storage: Drinking water, irrigation water, fire water

Wastewater Treatment: Industrial wastewater, sewage

Petroleum and Chemical Storage: Crude oil, refinery distillates, acids, alkalis

Biofuels and Agricultural Storage: Ethanol, vegetable oils

Dry Bulk Goods: Grains, fertilizers

Manufacturing Process and Quality Control

Our production process includes laser cutting, beveling, shot blasting, and priming of steel plates to ensure that our tanks meet the highest quality standards. After fabrication, we conduct rigorous testing to ensure the welds and materials meet the required strength and safety standards.

Welded Steel Tank Manufacturing Process:

Laser cutting of steel plates

Beveling of steel plates

Shot blasting for surface preparation

Application of primer for corrosion resistance

Arc pressing of steel plates to achieve the required shape

On-Site Installation and Professional Support

Once the production of the tanks is complete, we provide professional logistics to ensure safe delivery. Our experienced installation team works on-site to ensure smooth assembly and installation, coordinating with other project teams to deliver tanks that meet client specifications.

Why Choose Shijiazhuang Zhengzhong Technology Co., Ltd. for Welded Steel Tanks?

Over 30 Years of Experience: We are a trusted name in tank manufacturing, with extensive experience in producing durable, high-quality welded steel tanks.

Custom Solutions: Our tanks are highly customizable to meet diverse storage needs across various industries.

Global Projects and Standards: We have successfully implemented projects in over 100 countries, and our tanks meet international standards like API 650, BS EN 14015, and ISO 12944.

Professional Installation and Support: From production to installation, our team ensures that your tanks meet the highest standards of safety and performance.

Shijiazhuang Zhengzhong Technology Co., Ltd. continues to lead the tank manufacturing industry with innovative solutions, outstanding quality, and a commitment to customer satisfaction. For customized welded steel tanks that deliver reliable performance and durability, partner with us for your next storage project.

Contact us today to learn more about our welded steel tanks and how we can tailor a solution to meet your specific needs.

0 notes

Text

High-Quality S32750 Fasteners: Super Duplex Fasteners Manufacturer in India

Introduction to Super Duplex Fasteners

In the world of high-performance fasteners, Super Duplex stainless steel stands out for its remarkable combination of strength and corrosion resistance. Super Duplex Fasteners, crafted from Super Duplex stainless steel, are designed to handle the toughest industrial challenges. In India, manufacturers are providing high-quality Super Duplex Fasteners, including the notable Grade S32750, renowned for its superior performance in extreme environments.

About Super Duplex Fasteners

Super Duplex stainless steel is a category of stainless steel that combines both austenitic and ferritic structures. This unique composition provides Super Duplex Fasteners with exceptional mechanical properties, enhanced toughness, and superior resistance to corrosion and stress corrosion cracking. These fasteners are an ideal choice for applications exposed to harsh environments, such as offshore and chemical processing industries.

Super Duplex Fasteners Grade S32750

Grade S32750, also known as Super Duplex 2507, is a high-performance alloy that falls under the Super Duplex stainless steel category. It is particularly known for its excellent corrosion resistance in chloride-rich environments and its high yield strength. Grade S32750 is widely used in industries that demand durability and reliability under severe conditions.

Key Properties of Grade S32750:

Corrosion Resistance: Offers outstanding protection against pitting, crevice corrosion, and stress corrosion cracking.

High Strength: High yield and tensile strength, making it suitable for heavy-duty applications.

Toughness: Good impact toughness at both room temperature and cryogenic temperatures.

Specifications of Super Duplex Fasteners

When selecting Super Duplex Fasteners, understanding their specifications is important for ensuring they meet the requirements of your application. Here are the typical specifications for Super Duplex Fasteners, particularly those made from Grade S32750:

Material Grade: S32750

Type: Bolts, nuts, washers, screws, and studs

Standard Compliance: ASTM A182, ASTM A240, ASTM A276

Size Range: From M6 to M64 or 1/4" to 2" in diameter, depending on the application

Finish: Various finishes are available, including passivated, coated, or as-machined

Mechanical Properties:

Tensile Strength: Minimum 750 MPa

Yield Strength: Minimum 550 MPa

Elongation: Approximately 15% in 50 mm

Dimensions and Tolerances:

Bolts and Screws: Available in various diameters and lengths, often customized to meet specific application requirements.

Nuts: Standard and custom sizes, typically matching bolt specifications.

Washers: Various types including flat, spring, and locking washers, tailored to the application.

Standards and Certifications:

Conforms to ASTM A182, ASTM A320, ASTM A276, and other relevant international standards.

Certified for quality with ISO 9001 and ISO 14001 standards.

Applications of Super Duplex Fasteners

Super Duplex Fasteners are utilized in a wide range of applications due to their robust properties. Key applications include:

Offshore Platforms: For structural components exposed to seawater.

Chemical Processing Equipment: In environments where exposure to corrosive chemicals is prevalent.

Desalination Plants: Handling brine and other harsh conditions.

Marine Environments: For components exposed to saltwater.

Manufacturing Super Duplex Fasteners in India

India is home to several leading manufacturers of Super Duplex fasteners, leveraging advanced technology and stringent quality control measures to produce high-quality components. These manufacturers utilize state-of-the-art equipment for forging, machining, and testing, ensuring that their fasteners meet global standards.

Ananka Group stands out as a leading manufacturer of Super Duplex fasteners in India, renowned for its expertise in producing high-performance components. Utilizing advanced technology and rigorous quality control, Ananka Group ensures that its Super Duplex fasteners, particularly those made from grade S32750, meet global standards for strength and corrosion resistance.

By combining cutting-edge manufacturing processes with a deep understanding of industry needs, Ananka Group delivers reliable, durable fasteners that excel in demanding applications across various sectors.

Key Advantages of Indian Manufacturers:

Competitive Pricing: Affordable solutions that maintain top-notch quality.

Expertise: Skilled professionals with extensive experience in working with Super Duplex alloys.

Custom Solutions: Ability to manufacture fasteners to specific requirements and tolerances.

Timely Delivery: Efficient production processes ensure timely delivery for domestic and international clients.

Conclusion

Super Duplex Fasteners, particularly those made from Grade S32750, are engineered to withstand the most demanding conditions while providing superior strength and corrosion resistance. Indian manufacturers offer high-quality fasteners that meet international standards, ensuring reliability and performance in critical applications. Whether you’re in the offshore, chemical, or marine industry, choosing Super Duplex Fasteners can significantly enhance the durability and efficiency of your equipment.

Super Duplex fasteners, particularly those made from grade S32750, offer exceptional strength and corrosion resistance, making them indispensable in industries facing extreme conditions. Indian manufacturers are well-equipped to produce these high-performance fasteners, providing a valuable resource for global markets.

FAQs

1. What is the primary advantage of using Grade S32750 Super Duplex Fasteners?

Grade S32750 offers superior corrosion resistance and high strength, making it ideal for applications in harsh environments.

2. Are Super Duplex Fasteners more expensive than other types of fasteners?

Yes, due to their advanced properties and manufacturing processes, Super Duplex Fasteners are generally more expensive than standard fasteners.

3. Can Super Duplex Fasteners be used in high-temperature applications?

While they excel in corrosive environments, Super Duplex Fasteners are also suitable for applications with moderate temperature ranges. For extremely high temperatures, other materials might be preferred.

4. How can I ensure the quality of Super Duplex Fasteners?

Choose reputable manufacturers who comply with international standards and offer certifications for their products.

0 notes

Text

Can Metal-made Industrial Sheds for Sale Save Time and Money?

In today's Australia, well-established businesses prefer industrial sheds for sale in commercial or industrial needs. Some Australian metal structure providers have earned a reputation for decades by constructing home, rural, and industrial sites such as big industrial buildings, infrastructure, bridges, airport terminals, heavy industrial facilities, and more.

In addition, when someone needs metal sheds for small businesses like garages or carports, they will typically find a variety of pre-engineered buildings made of metal structures, including factories, warehouses, workshops, community halls, commercial showrooms, commercial exhibitions, cold storage, stadiums, parking sheds, railway platforms, and so on.

In general, the trend of creating metal structures is growing and has become the ultimate building need due to the benefits stated here.

People looking for low-cost, high-quality metal structures for a short-term facility can find sturdy yet lightweight materials such as specialist C/Z shed structure frames from reputable steel structure providers in Melbourne.

Advantages of Installing Industrial-grade Metal Sheds:

Many businesses want their structures to be operational with as little downtime as possible. Well-known steel structure manufacturers produce steel based on the requirements and types of construction.

They also prioritise giving their innovative skills to make the building flexible and simple to operate and oversee each of their productive operations effectively.

These vendors provide structurally galvanised, high-quality RHS frame steel to ensure structural safety. They stock structural steel for fixing gutters and wall sheets, as well as completely welded and bolted frames with thick fascia for a variety of applications. They also stock structural steel for all types of metal buildings in Australia.

How to Select Reliable Steel Construction Suppliers?

Find reputable steel construction suppliers for a successful building project.

People can analyse their track record, and read reviews, testimonials, and case studies.

Verify their credentials and compliance with industry standards to ensure the quality of materials and workmanship.

Experience is always important, so look for vendors with a track record in steel building.

Analyse other important aspects to consider including competitive pricing and quote transparency.

Finally, carefully evaluate these factors to select a dependable and experienced steel construction supplier to match the project's needs and expectations.

Source: https://precastpanels.blogspot.com/2024/09/can-metal-made-industrial-sheds-for.html

0 notes

Text

The Premier Choice for Bolts: Rajal Industries

When it comes to precision and reliability in the world of industrial fasteners, Rajal Industries stands out as a leading Bolts Manufacturer. Renowned for our unwavering commitment to quality and innovation, Rajal Industries has built a reputation for producing high-performance bolts that meet the diverse needs of various industries.

Why Choose Rajal Industries for Your Bolts?

At Rajal Industries, we understand that bolts play a crucial role in the structural integrity and functionality of machinery and equipment. Whether you're involved in construction, automotive, aerospace, or any other industry that relies on high-quality fasteners, our bolts are engineered to deliver exceptional performance. Our state-of-the-art manufacturing processes ensure that each bolt meets stringent industry standards and exceeds customer expectations.

Unmatched Quality and Precision

Quality is at the core of everything we do at Rajal Industries. Our bolts are crafted from premium materials, including stainless steel, high-tensile steel, and alloy steel, to ensure durability and strength. Our advanced manufacturing techniques, coupled with rigorous quality control measures, result in bolts that are not only strong but also resistant to corrosion and wear. Each bolt undergoes thorough testing to ensure it can withstand extreme conditions and maintain its integrity over time.

Diverse Range of Bolts

Rajal Industries offers a comprehensive range of bolts to suit various applications. From standard hex bolts to custom-designed solutions, we provide fasteners that meet the specific needs of our clients. Our product lineup includes:

Hex Bolts: Ideal for general-purpose applications, our hex bolts are available in various sizes and grades to match different load requirements.

Carriage Bolts: Designed for smooth and easy installation, our carriage bolts are perfect for wood and metal applications.

Eye Bolts: Suitable for lifting and rigging, our eye bolts are manufactured to provide secure and reliable connections.

U-Bolts: Used for clamping pipes and tubes, our U-bolts are engineered for strength and durability.

Customer-Centric Approach

At Rajal Industries, we prioritize customer satisfaction. Our dedicated team of professionals works closely with clients to understand their specific requirements and provide tailored solutions. Whether you need standard Bolts Manufacturer or custom-designed fasteners, we are committed to delivering products that meet your exact specifications and deadlines.

Conclusion

Rajal Industries is your go-to partner for high-quality bolts that deliver exceptional performance and reliability. With our focus on quality, precision, and customer satisfaction, we continue to set the standard for excellence in the fasteners industry. Explore our range of bolts and experience the difference that Rajal Industries can make for your business.

0 notes