#Switch Terminal Connector

Explore tagged Tumblr posts

Text

Understanding Relay Module Circuits: A Comprehensive Guide

Introduction:

Relay module circuits are essential components in various electronic and electrical applications. These circuits act as switches, allowing control signals from one circuit to activate or deactivate another circuit. Relay modules provide an efficient way to isolate high-power devices from low-power control systems, ensuring safety and protection. In this comprehensive guide, we will delve into the fundamentals of relay module circuits, their working principles, applications, and address some frequently asked questions (FAQs) to provide a complete understanding of this crucial aspect of modern electronics.

I. What is a Relay Module Circuit?

A relay module circuit consists of an electromechanical relay mounted on a PCB (Printed Circuit Board). The relay is an electromagnetic switch that is actuated by a control signal, which can be either digital or analog. When the control signal triggers the relay, it closes or opens the electrical contacts, allowing current to flow through the output terminals and control external devices or circuits.

II. How Does a Relay Module Circuit Work?

Electromagnetic Coil: The relay module circuit has an electromagnetic coil that serves as the input or control element. When an appropriate voltage is applied to the coil, it creates a magnetic field, causing the relay's armature to move.

Normally Open (NO) and Normally Closed (NC) Contacts: A relay typically has two sets of contacts: Normally Open (NO) and Normally Closed (NC). In the resting state, the NO contacts remain open, and the NC contacts remain closed.

Switching Action: When the coil is energized, the armature moves, causing the NO contacts to close and the NC contacts to open. This switching action completes or interrupts the circuit, depending on the application.

III. Types of Relay Module Circuits:

Single-Pole, Single-Throw (SPST) Relay: SPST relays have one set of contacts and can either be Normally Open or Normally Closed.

Single-Pole, Double-Throw (SPDT) Relay: SPDT relays have one set of normally open contacts and one set of normally closed contacts. When the relay is energized, the NO contacts close, and the NC contacts open.

Double-Pole, Single-Throw (DPST) Relay: DPST relays have two sets of contacts that operate simultaneously, making or breaking the circuit.

Double-Pole, Double-Throw (DPDT) Relay: DPDT relays have two sets of NO contacts and two sets of NC contacts. They provide two separate circuits that can be independently controlled.

IV. Applications of Relay Module Circuits:

Home Automation: Relay modules are commonly used in home automation systems to control lighting, heating, ventilation, and air conditioning (HVAC) systems.

Industrial Automation: In industrial automation, relay modules are used to control motors, pumps, solenoids, and other high-power devices.

Automotive Electronics: In automobiles, relay modules are utilized to control various electrical systems, such as headlights, windshield wipers, and electric windows.

Robotics: Relay module circuits are used in robotics to control the movement of actuators and motors.

Security Systems: In security systems, relay modules are used to trigger alarms and control access points.

V. Advantages of Using Relay Module Circuits:

Isolation: Relay module circuits provide galvanic isolation between the control circuit and the load, ensuring safety and protecting sensitive components.

Low Power Control: Relay modules allow low-power control systems to switch high-power devices, eliminating the need for high-power control circuits.

Versatility: Relay module circuits are available in various configurations and voltage ratings, making them versatile and suitable for a wide range of applications.

Simple Operation: Relay modules are easy to install and operate, making them a popular choice in many electronic applications.

FAQs:

Q1. Can relay module circuits be used for both AC and DC applications? Yes, relay modules are available in both AC and DC versions, allowing them to be used in a wide range of applications.

Q2. What is the difference between a relay and a relay module? A relay is the basic electromagnetic switch, while a relay module includes the relay mounted on a PCB with additional circuitry for ease of use and integration into other systems.

Q3. Can relay modules handle high-current applications? Yes, relay modules are available in different current ratings, and they can handle high-current applications as per their specifications.

Q4. How do I choose the right relay module for my application? When selecting a relay module, consider the voltage and current requirements of your application, the type of load (AC or DC), and the number of contacts needed.

Q5. Can I use a relay module to control multiple devices simultaneously? Yes, some relay modules have multiple sets of contacts (DPDT or more), allowing you to control multiple devices independently.

Conclusion:

Relay module circuits are versatile and indispensable components in modern electronics and electrical systems. Their ability to provide isolation, low-power control, and versatility makes them ideal for a wide range of applications in various industries. By understanding the working principles and different types of relay modules, along with their numerous applications, designers and engineers can make informed decisions when integrating these circuits into their projects. Relay module circuits continue to play a critical role in enhancing the efficiency and control capabilities of electronic systems, contributing to advancements in automation and smart technologies.

0 notes

Text

Prelude – 4

-Click-

Fluorescent bulbs hissed alight, before stuttering, flickering with color for just a second.

A lone figure stands in the airlock, as still as a statue. Jet black hair pulled up into a low ponytail and green eyes blinking wearily, the labcoat she wore was in just as much disrepair as the rest of her attire. The only thing that remained in good-enough shape was the keycard hanging off the lanyard she wore.

It read “Hadia Fattih, Lead GTX Researcher.” She had told them to use another title, that she was only a scientist, but they had insisted.

Hadia swallows once, with difficulty. Her gaze remained pointed straight ahead, avoiding the flicker of the lights. The doors before her could be heard clunking, crunching, the mechanism aged and straining. She clutches the radio in her arms closer to her chest, boxy xenocryst tech dated by enough years it could be considered antique.

Doors slide open. Hadia can see the telltale ominous, violet haze bathing the chamber beyond. Before she can take a step, speakers crackle to life.

“Access trigger; observation area 8.”

It deters her, but only for a moment. The steady rhythmic tapping of her heels against the floor echoes throughout the space, bouncing off the heavy iron shielding bolted to the walls. She walks across the metal grates making up the floor, over tubing and wiring routed across her path and along the walls to a lone terminal that stood at the center of the room. But it wasn't the terminal filling the area with a pulsing, undulating light, it was what stood beyond it.

Sitting on a steel base wide enough to carry an SUV was a large, reinforced glass tube, full with violet liquid. It stretched nearly as tall as the chamber was, topped with a “lid” from which ventilation pipes jutted out like thick tree branches. Faintly, one could see a shape within, much like a sea urchin with how many wires ran to it, stirring ever so slightly.

Hadia stopped at the terminal, just a few inches away from the glass. The harsh violet light cast shadows that cut into her features, almost concealing the fear in those green eyes.

She had a theory to test.

Setting the radio on the metal mesh floor with a heavy thud, Hadia got to work connecting it to the terminal’s power supply. It was aging, but she knew a bodymaker that didn't ask questions— and that was enough to make this old thing functional. Three connectors and a drawn out -clink- of a power switch later, the radio hummed quietly, idling. Its analog interface was lit yellow, as tended to old xenocryst tech. Back then, all they had was the yellow serotype gems to model tech off of, but that surely wasn't going to pose an issue.

The terminal began to beep. From the corner of her eye, Hadia could see the alert of a motion detector. The light bathing the chamber moved in barely perceptible waves.

White noise reverberated off the walls. You couldn't get coverage down here, no shot. Not a dozen thousand levels below the surface. But, that was perfect for Hadia— because she wasn't looking for any stations, she was looking for a local signal… a very specific one. She spun the knob searching for something, anything…

I'm not crazy. I heard it, I know I did.

The geotozo parasites, with their alien, mineral formations had always been able to generate electricity, that much was known. It was the kind of stuff a kid in grade 4 would be able to recite off the top of their head.

So, when Hadia had reported back a strange interference with her tech, the dismissal didn't just come as a flaw of leadership, but as a flaw of logic.

To be surprised by a new development such as this wasn't something she expected. After thirty-two years in the field, nothing could surprise her— she wasn't hired as head of this damn project for nothing. She knew these geotozo parasites better than anyone, having dedicated her life to studying and manipulating them. She knew their gelatinous bodies inside out, could map out the crystal formations with her eyes closed. So why,

Why,

Why was this happening?

She looked up at the tube, at the silhouette within. Warped by the glass and the refractive nature of the dampening fluid, it almost resembled a pyre.

Hadia knew there were eyes behind that glass, staring back at her.

She stood up, letting the radio bleed static as she took a step closer. Her eyes almost looked black in the violet light.

It is a parasite, she recalled the words of her superior, echoing in her ears. It cannot think, it cannot comprehend, it can only replicate— were you not the one to reassure me of that?

She had been. She had rerouted the neural pathways herself; not like there was a need for such a thing anyway, when the host had gone silent and pliant years ago. There was nothing to erase, yet she still took measures as the company had ordered her to do.

So why,

Why,

Why did it always feel like it was watching her?

She pressed her palm against the glass. It was cold enough to make her digits start to prickle with numbness and a little bit of pain. The terminal begins to beep faster, as if syncing with her accelerating heartbeat.

The light begins to stir again, and with it, the white noise begins to shift as well, fading and peaking, the hum stuttering with the occasional interruptions of what seemed to be pulses of energy. Hadia stepped away, knowing she'd crossed a boundary— a little too late to salvage her mistake…

But then, the white noise returns to its steady hum. It was as if nothing had happened. She stood there, blankly staring at the tank.

This was… stupid. Idris was right, she was anthropomorphizing a parasite of all things. A seasoned scientist had no reason to put themself into such emotional, murky territory. Better to leave now and salvage her losses before anyone else realized she went down here alone. She had to disconnect the radio, too, before the hackneyed job she had that bodymaker perform blew its capacitors out. This thing wasn't cheap.

She kneels next to it, disconnecting the plugs from were they met the cables running from the terminal's power supply. But as she moved to pick the radio up again, it was still running. She frowned, flicking the switch off. The white noise continued to hum.

Hadia checked the wires again. Disconnected. Was there a battery pack she wasn't aware of? This thing was far too old to even accept one let alone have it built in!

The analog interface’s light flickers, only to turn from a sickly yellow to a vivid violet. The white noise rises to a crescendo, and in the seconds it takes Hadia's gaze to flick upwards towards the tank, the silhouette within comes close to the glass, writhing in a manner inhuman, crystals glimmering in the light they generated as they shift like scales across its serpentine form.

Its eyes, both alien and human, all turn to her. Faintly, she can hear the white noise even out into a faintly perceptible recitation.

“… Ayyub, when he …lled to his Lord… Indeed, adversity has touched me, and you are… Most Merciful of the merciful…”

Hadia could feel herself suffocating on the words she wanted to say. The sounds around her faded out, the radio's audio output starting to deteriorate as it rose to a deafening whine, lights brightening madly like miniscule stars on the brink of supernova. She had rerouted the pathways herself.

It was just a parasite, incapable of thought.

So why,

Why—

7 notes

·

View notes

Text

IG-11 and the Mandalorian standing in the destroyed doorway of the hideout for the Nikto gang on Arvala-7. Image from The Mandalorian, Season 1, Episode 1, The Mandalorian.

In the beginning…

Grogu peeked out of the pile of stuff that covered the pram and watched the door to the storage area crash onto the floor. Womp rats! He quickly closed the pram and used the Force to cover it up again. He’d done something like that dozens of times since he’d escaped from the Jedi Temple and gotten used to doing it with out much thought. He supposed his masters would be proud of him if they’d only known how much he’d improved in controlling his openness to the Force.

He laid back and pulled the blanket up to his chin. Pretending to be asleep had always worked well for him. People just assumed he was some sort of pampered pet, forced to sleep in a pram to keep it from messing up some other part of wherever they were. He liked to think that the people who discovered him worried that he was more like a rathtar or some other vicious, impossible to control critter, than thinking that he was just a little boy caught up in a huge intra-galactic mess.

The same held true this time. He could hear the bounty fob pinging softly. He could also here the sounds of blaster fire and a mechanical voice replying to a human one. It was Grogu’s one big hope that neither of them believed what the fob was telling them. A lot of the hunters who had gone after him hadn’t believed he was the target. If he was lucky, they would fall into that trap as well.

“Wait. They said fifty years old.”

“Species age differently.”

Dang. The droid knew.

Grogu decided to try his next gambit. If he acted like a child… like a baby even… maybe they would doubt themselves. At least the human might. A droid had no capacity for doubt. They just knew what they knew and followed their programming. Which was going to be tricky.

He reached up with one hand and pulled the blanket down just a little and sat up a little more. He wanted to make eye contact with the human. It was the first step in getting people to see you as you wanted to be seen and it generally worked really well with humans. Other species had different reactions to direct eye contact and droids didn’t care at all, but Grogu was a big believer in working with what he had at hand and at hand there was a human…

Dank farrik! A human encased in armor! He couldn’t see the man’s eyes. Uff! What the heck was he going to do now?

“Sadly, we’ll never know.”

“No! We’ll bring it in alive.”

Yippee! Alive. That was a good start. The droids words had almost frozen him to his core. But hearing the human say ‘no' meant that the bounty hunter really hadn’t been given a complete briefing about who and what he’d been sent after. He had no idea how powerful Grogu was and no idea what Grogu had been able to do stop people from hurting him in the past. That seemed like a pretty glaring error, but the Force provided in strange ways and Grogu wasn’t going to refuse that luck. He’d learned that much since leaving Coruscant.

Of course the droid tried to make a point, a logical, emotionless point, which was why someone, somewhere had decided to make assassin droids to begin with, but it didn’t work. The human had ‘terminated’ the droid and for that Grogu was relieved.

Again. He could have handled it himself. He’d done that dozens of times. Pull out a connector here. Trip a switch there. Push a button. Just flip the thing over so it’s aim was compromised. Throw the other person or droid with them into the line of fire. There were as many ways to thwart his attackers as there had been attackers over the years. His success rate in dealing with them effectively was still perfect. Or mostly perfect. This time the human had helped him. Most of the time they were the first ones to crack. He wasn’t sure why, but the data was the data.

Grogu waited to see what else the human would do. Sometimes they just turned and walked away. Other times they had tried to examine him, as if he was some sort of lab specimen. One time, a particularly obnoxious Iktotchi male, had asked Grogu a thousand and one questions in rapid succession. Grogu had struggled with keeping his face calm and kind of bored looking. He had wanted to laugh but that was usually a significant giveaway that he wasn’t a baby or a critter and that caused more trouble than it was worth.

This human, with it’s armor and helmet, just seemed fascinated by him. Which seemed strange. He was a bounty. He was supposed to be brought from point a to point b for payment. It had been a while since a hunter had caught up with him, but Grogu didn’t think that the rituals could have changed that much. He wasn’t thrilled with the change, but he could deal with it, just like the last time. Infiltrate, collect data, disrupt the systems and then get the dank farrik out of there.

Maybe this human would be more useful to him than the last one had been. He was still staring at Grogu. Time for the next gambit.

“Coo, oooo, cooo,” softly, gently, kindly.

It had worked on other people. The sweet little sound that promised that he wasn’t a rathtar, or anything like that. He’d used to catch more than unsuspecting bounty hunters. It was good for a meal because the scurriers and frogs didn’t think that was an indication of danger. Neither did the humans, but Grogu never bothered with determining whether or not they were something tasty. They were sentient. You didn’t eat sentient beings. The Jedi had rules about that and the Force, well, it enforced them. Nothing good came to the people who had been sloppy about that sort of thing.

Right now he just wanted this human to think he was soft, young, harmless, and in need of a protector, preferably someone in armor, who wanted the bounty promised to him from whoever it was who thought they needed to see Grogu that badly. It was pretty clear that the human was already bending toward his will. He’d moved the pram from it’s secure location against the wall, to get a better view of the youngling it held.

Grogu resisted the temptation to make other sounds or even speak to the tall man. It would undermine the whole basis of his disguise. He didn’t have the time or inclination to come up with another one on such short notice. Move too many pieces at a time and people became very suspicious of you and your intent. He really didn’t want anyone thinking about why he wanted to be found. That wasn’t their business.

Then the human did something no one else had ever bothered to do. He stretched his arm out and offered Grogu one of his fingers. Why? Not to poke him or single him out or anything like that. He seemed to want to connect. Why would the bounty hunter want to do that? What was in it for him? He was just supposed to pick Grogu up and deliver him to whoever gave him the fob. Easy peasy, more or less. If it got more complicated than that, well, Grogu would have a lot of planning to do. He’d just wanted a ride off of Arvala-7. Uff. The Force really did move in mysterious ways, dank farrik.

7 notes

·

View notes

Text

Why do a lot of motorcycles with two headlights have one headlight out?

Why do motorcycles with dual headlights often have one "broken"?

The phenomenon of a motorcycle seemingly having only one headlight fail to work stems from design choices, technical limitations, and maintenance issues. Here is a detailed analysis:

1. Dual-beam design (low/high beam split) Most motorcycles equipped with dual headlights use a single bulb or split lamp housing, where:

The low beam activates one headlight (usually the left or lower light cluster) to illuminate the road without dazzling oncoming vehicles.

The high beam activates the second headlight (or enhances the brightness of the main headlight) to improve visibility at long distances.

This design ensures compliance with road safety standards, but when only one headlight is in use, riders often mistake the non-working headlight as "broken".

2. Electrical system vulnerabilities The compact electrical system of a motorcycle is prone to problems that can cause a single headlight to fail:

Loose connections/corrosion: Exposed wiring in the handlebar switch or headlight socket can age, interrupting the flow of electricity.

Burned out bulbs: Single filaments in halogen bulbs (common in older models) can fail more quickly under vibration or voltage spikes.

Faulty relays or fuses: A bad relay or blown fuse in a single circuit can cause a single headlamp to fail.

For example, Information Search notes that 60% of single headlamp failures are attributed to corrosion in the connections or wear and tear in the bulb.

3. Cost-driven manufacturing practices Some budget motorcycles use a common circuit for two headlamps to reduce production costs. If one bulb fails, the entire circuit may shut down—although this is less common with modern LED systems.

4. Rider negligence Motorcycle lighting systems need frequent inspections for the following reasons:

Vibration damage: Rough roads can cause connections to loosen or bulb socket solder joints to crack.

Moisture intrusion: Rain or moisture can corrode the terminals, especially in non-sealed housings.

DIY modifications: Aftermarket LED kits or improper bulb replacements often bypass safety protocols, causing uneven failures.

5. Regulations and aesthetic trends

Styling choice: Some manufacturers design dual headlights for symmetry but wire them to work alternately (e.g. Ducati Scrambler).

Daytime running light (DRL) configuration: Modern motorcycles may use one headlight as a daytime running light and both for nighttime use, creating an inconsistent visual effect.

Key points

Normal operation: If your motorcycle manual specifies alternating low/high beam, one of the headlights being "off" is intentional.

Troubleshooting: First check the bulb, fuse, and connector. Use a multimeter to test the socket voltage.

Upgrade solution: Changing to LED or dual filament bulbs (e.g. H4) can reduce the failure rate.

For persistent problems, refer to the step-by-step repair guide for online information.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#car culture#race cars#classic cars#car#cars#suv#porsche#sabrina carpenter#truck#supercar#carte postale#automobile#car light#headlight bulb#headlamps#headlamp#headlight#aftermarket new lamp#car lamp#lamp

3 notes

·

View notes

Text

transforming soffits reorganizing keys formalizing immersion joints justifying kick extractors advising aggregates managing elbows recasting connectors achieving aluminum trowels officiating disks exhibiting absolute spigots progressing coil hydrants jerry-building reflectors informing casters inventing rubber hoists performing wrenches judging chalk adapters upgrading ignition paths

regrowing flashing recommending ratchets approving barriers sweeping impact fillers sewing mirrors detailing collectors enforcing measures distributing systems presenting plugs interwinding registers piloting ash diffusers gathering cranks supplying eave pockets undertaking scroll stops accelerating straps designing fittings protecting diamond boilers logging downspouts correlating shingles uniting mallets qualifying electrostatic lifts sharing clamps obtaining circular fluids ranking foundation gauges sensing miter brackets originating space networks translating drills regulating guards selecting gable padding utilizing pellet dowels reconciling artifacts altering pulleys shedding space filters determining vents representing mortar remaking flash rakers supporting funnels typecasting rotary chocks expressing junctures resetting auxiliary vises professing strip treads inlaying matter trowels questioning drivers forming edge fittings sketching blanks overshooting spark breakers rewriting controls playing tunnels inventorying buttons enduring joint handles effecting ratchet bibbs unwinding couplings forsaking vapor conduits defining sockets calculating heaters raising grids administering tiles measuring resources installing ignition remotes extracting corners manufacturing ventilators delegating consoles treating mounting stones enacting jig deflectors intensifying alleys improvising cargo pinpointing bobs prescribing arc masonry structuring metal chucks symbolizing lathes activating plumb kits adapting coatings fixing channels expediting cordage planning compressors enlisting hangers restructuring keyhole augers shearing ridge hardware collecting reciprocating bolts maintaining corrugated dimmers whetting hole collars conducting mandrels comparing assets compiling sealants completing paths composing equivocation wheels computing dampers conceiving electrostatic treatment ordering cotter grates organizing ties orienting ladders exceeding materials targeting thermocouples demonstrating emery stock expanding latch bases training wardrobe adhesives overcomming[sic] fasteners streamlining storm anchors navigating springs perfecting turnbuckles verifying gate pegs arbitrating arithmetic lifts negotiating outlets normalizing strips building surface foggers checking key torches knitting grinders mowing planers offsetting stencils acquiring bulbs adopting rivets observing avenues ascertaining coaxial grommets slinging wing winches instituting circuit generators instructing wicks integrating pry shutters interpreting immersion lumber clarifying coils classifying wood bits closing cogs cataloging matter strips charting holders conceptualizing push terminals stimulating supports overthrowing shaft spacers quick-freezing connectors unbinding ground hooks analyzing eyes anticipating gateways controlling proposition rollers converting power angles coordinating staples correcting benders counseling joist gaskets recording gutter pipes recruiting drains rehabilitating rafter tubes reinforcing washers reporting guard valves naming freize sprues nominating rings noting straps doubling nailers drafting circuit hoses dramatizing flanges splitting framing compounds refitting stems interweaving patch unions placing sillcocks sorting slot threads securing mode cutters diverting catharsis plates procuring load thresholds transferring syllogism twine directing switch nuts referring time spools diagnosing knobs discovering locks dispensing hinges displaying hasps resending arc binders retreading grooves retrofitting aesthetics portals seeking stocks shrinking wormholes assembling blocks assessing divers attaining lug boxes auditing nescience passages conserving strikes constructing braces contracting saw catches serving installation irons recognizing fluxes consolidating fuse calipers mapping shims reviewing chop groovers scheduling lag drives simplifying hoists engineering levels enhancing tack hollows establishing finishing blocks

21 notes

·

View notes

Text

Arkodd Padbox Review: a fightpad for the arcade afficionado

by Amr (@siegarettes)

Sporting a clicky dpad and an enclosure large enough to accommodate 24mm arcade buttons, the Arkodd Padbox is a controller/fightstick hybrid set to fill the niche left by a lack of good 6 button fightpads.

The dpad is equipped with Omron mechanical switches, similar to the ones used in arcade sticks, and a left shoulder button and additional thumb button complement the standard 8 button layout, allowing access to extra functions and alternative button placements.

The Padbox comes as fully assembled units or DIY kits that include the case, dpad, wiring and function buttons. For this review I opted for the DIY kit, since I wanted to see what the build process was like, and customize the build with parts I had on hand.

Full disclosure: I was sent this kit to review, but I wasn’t given any instructions or limitations on what I could say.

With that out of the way, what immediately impressed me was how easy the build process was. The Padbox comes apart with only a few screws, and the dpad, shoulder button and aux buttons are already pre-installed. The wiring harnesses provided are sized appropriately for the available space, and headers for the dpad and shoulder buttons, alongside pre-made dupont connectors made wiring them to the screw terminals simple.

If there’s one thing to note it’s that the Padbox uses a direct USB connection for its USB C jack, rather than the Neutrik Type-D passthrough ports that many custom fightstick builds use. The connector is designed with Brook Fighting Boards in mind, which have pre-populated headers for USB, but I opted to use a RP2040 Advanced Breakout Board I had on hand to get access to the advanced features of GP2040ce. If you do goes this way, make sure you get the latest version of the board with the screw terminals for the extra functions, as those have pre-populated USB headers, otherwise you’ll have to solder on your own like I did.

You’ll also need to plug into the 5v VCC terminal for the power indicator LED, though if you are somehow doing an even more niche build of a niche product, and using a Brook Wireless board for it, you’ll need to connect to the player indicator LEDs instead, since the 5v terminal won’t output when running on battery.

Aside from these incredibly niche considerations, the overall build process is fast and painless. I built it all on a weeknight after work, and I even had time to stickerbomb it and test out a few games with it. I’ve had a harder time modding some fully built fightsticks.

Now the most important question: how’s the dpad. In short: they nailed it. No matter what style of game I played it was easy to get my inputs out, with no accidental inputs. After using so many controllers and handhelds, I can tell you this is a hell of an accomplishment. Even mechanical dpads aren’t a silver bullet to this problem, as I’ve seen so many of them with the same kind of satisfying feedback that are miserable in practice. So I’m happy to report that this dpad is not one of them.

One of the first games I tried the Padbox with was Ultimate Marvel vs Capcom 3’s trial mode, my go to for testing new fighting game controllers. Here it performed better than basically any first party controller dpad, with the combo of the microswitch dpad and larger arcade buttons making it easy to get in rhythm. The same happened in Street Fighter 6, where the extra buttons allowed me to access Drive Functions easier than the standard 8 button layout, and the shoulder button provided comfortable access to the assist function for characters I play with Modern Controls.

For anyone who plays primarily on pad, I could definitely see this as an upgrade to a regular gamepad or fightpad, especially for those who play claw grip and wouldn’t miss the extra shoulder buttons. With the swappable buttons, an all mechanical controller is even possible, given the growing options for buttons with keyboard style switches.

Personally, the Padbox won’t likely stay in rotation for playing fighting games, despite how much I like it. The Padbox can’t solve the fundamental problem I have with playing fighting games on pad: it’s too cramped. As someone particularly sensitive to this issue, I find that putting all the strain on my thumb wears me down faster when performing complex inputs, and the Padbox made it clear that for me, no pad can compete with the comfort of leverless for competitive games.

But who says you can only use a fighting game controller for fighting games?

Arcade buttons are plenty of fun across multiple genres, and with its hybrid design, the Padbox enables a variety of approaches that both traditional fightsticks and pads can’t provide. I tested it with beat-em-ups like Streets of Rage 4 and Shredder’s Revenge, where the arcade layout made performing combos a joy.

Retro consoles and throwback games are another good candidate, with the tactile feedback a the Padbox’s dpad a definite upgrade to a lot of the membrane dpads and buttons of original controllers, with the bonus of arcade buttons being a lot more fun to mash in the many games that demanded it.

Action games that make limited use of the right stick for camera control are totally playable with the Padbox, and with the use of GP2040ce, you can even use the extra buttons to create modifiers that give you on the fly access to the dpad or right stick for item hotkeys or camera control.

I even managed to make a playable control scheme for Smash Bros Ultimate, complete with c-stick buttons for tilt and aerial attacks.

The Padbox might not be my personal choice for serious fighting game competition, but it’ll definitely stay in rotation as one of my alternative controllers for casual fighting, and playing plenty of other genres.

If there's any additions I'd like to see, it's the addition of additional shoulder and thumb buttons. These would not only give access to an extra shortcut button in fighting games, but enable layouts with extra functions or modifiers, such as tilt modifiers or dual directional input in the style of the Hitbox Crossup.

The Padbox is also a bit lightweight. It comes in a little heavier than a standard controller, but it's spread out across a larger surface area, and alongside the slickness of the 3D printed material, it threatens to slip during those literally sweaty matches. An optional metal bottom plate or a removable weight for the grip might help give it heft for longer play sessions and lap play.

My favorite part of the Padbox has to be how many possibilities it leaves open. With its form factor, it's easy to start thinking of new ways to mod the Padbox and make it your own. It brings the DIY spirit of arcade sticks to a pad, and I've already seen wild molds replacing the dpad with a split dpad, or building entire new bases for it and adding more buttons.

If you're a controller enthusiast looking for a good fightpad, or just something with a real good dpad, consider giving the Padbox a look.

2 notes

·

View notes

Text

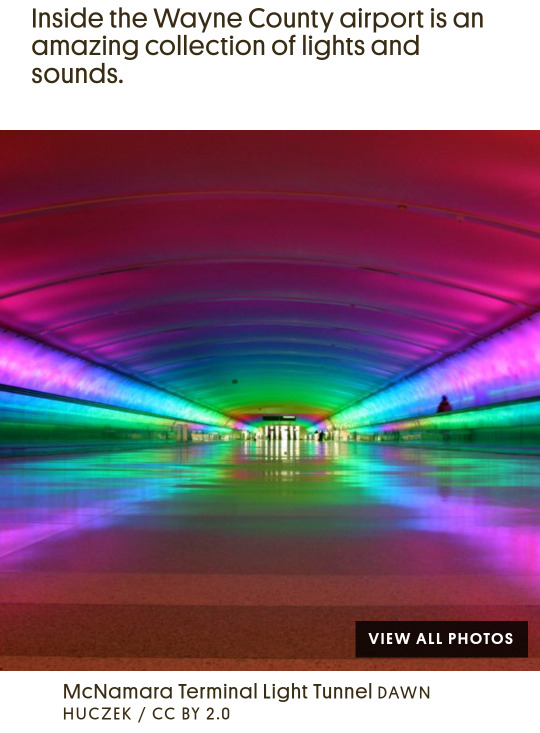

For those in the comments who are confused, that is indeed Detroit (image from an Atlas Obscura article about it) & not Chicago

THIS is what the O'Hare airport in Chicago's rainbow tunnel looks like

Both are connector tunnels between terminals & the lights in both of these move & are accompanied by music.

Detroit's was installed in 2001 & originally had a Motown soundtrack (but has since mostly switched to soft atmospheric stuff) while O'Hare's was completed in 1987 (& is technically an art piece called Sky's the Limit by Michael Hayden) with custom music by composer William Kraft called Electronic Music

why does the airport i go to have the fucking willy wonka tunnel in it i’m going insane

83K notes

·

View notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] MX GST18i Plug and Socket Connectors are a Versatile Connector system ideal for lighting, switches and sunblinds applications, mechanically and colour coded for ease of assembly and to prevent misconnections. GST18i connectors are fully intermateable with the existing GST18 connector sockets, plugs and cable assemblies, but feature a 20A capacity as opposed to the 16A capacity of the GST18 model. ✅ These GST18i Plug-in Lighting Connectors by MX have Robust Solid Metal Contacts and are IP20 Touch Rated with a Leading Ground Contact . ✅ Mechanical Coding Enables a Clear and Safe Separation of Different Applications Within the Same System, Whilst Colour Coding Identifies the Connections That Belong Together Allowing Ease of Assembly and Eliminating Mismating . ✅ The GST18i Range is Fully Compatible with the Existing GST18 Connectors but Benefit From a 20A Capacity . ✅ Current Rating :20 A & Voltage Rating : 250 V ✅ IP Rating : IP40 & Wire Size : 0.5 -1.5SQ MM ✅ Strain Relief : Yes & Termination Method :Clamp (Female) & Screw (Male) ✅ Contact Plating : Bright Tin (Female) & Bright Nickel (Male) &Contact Material :Brass ✅ Pole : 3 ✅ Connector : Male &Female ✅ Mounting Type :Cable Mount [ad_2]

0 notes

Text

Types of Electrical Wire Connectors: Choosing the Right Connection for the Job

When working with electrical systems, one of the most crucial components for safety and functionality is the electrical wire connector. These small but vital devices are used to join electrical conductors securely, ensuring a stable flow of current while preventing loose connections, shorts, or electrical fires. At ECS Electrical Cable Supply Ltd, we offer a comprehensive selection of electrical wire connectors types, each designed to meet specific application requirements in residential, commercial, and industrial settings.

There are several types of electrical wire connectors, each suited to different wiring tasks and environments. One of the most commonly used is the twist-on wire connector, often referred to as a wire nut. These are conical plastic caps with internal metal threads that twist over the ends of stripped wires. As they’re twisted, the metal threads draw the wires tightly together, creating a secure mechanical and electrical connection. They’re ideal for general-purpose wiring in lighting, outlets, and switches.

Another widely used connector is the butt splice connector. This cylindrical connector joins two wires end-to-end. The stripped ends of the wires are inserted into each end of the connector, then crimped using a special tool to create a firm connection. Butt splices are commonly used in automotive, marine, and appliance wiring, especially where a direct, inline connection is needed.

For terminal-based applications, ring and spade connectors are essential. Ring connectors have a closed circular end that fits securely over a stud or screw, providing a solid and reliable contact. Spade connectors have a forked end, making them easier to install or remove without completely removing the terminal screw. These connectors are popular in panel wiring, circuit protection systems, and control cabinets.

In environments requiring quick and tool-free connections, push-in connectors (also known as lever connectors or spring connectors) are gaining popularity. These allow electricians to insert stripped wires into the connector where a metal clamp automatically secures them. These connectors are ideal for tight spaces, renovation work, or installations that may require future disconnection or adjustment.

For environments with moisture, chemicals, or extreme temperatures, waterproof and heat-shrink connectors are essential. These connectors have insulation that seals tightly around the wire once heated, protecting the joint from the elements. They’re ideal for outdoor wiring, marine applications, or any environment where durability and weather resistance are critical.

Insulation displacement connectors (IDCs) are another specialty type, allowing a wire to be connected without stripping the insulation. Common in telecommunications and low-voltage systems, IDCs are quick to install and often used in pre-assembled wire harnesses.

At ECS Electrical Cable Supply Ltd, we understand that selecting the right connector depends on wire type, voltage, current, environment, and connection permanence. Our team can help guide you to the best option, ensuring your wiring job is safe, code-compliant, and long-lasting.

In summary, there are many electrical wire connectors types, each tailored to specific tasks and conditions. From everyday installations to complex industrial systems, ECS Electrical Cable Supply Ltd is your reliable source for high-quality connectors and expert support—ensuring every connection is a safe one.

0 notes

Text

Elettro ABS Junction Box IP 55/65 – The Most Advanced Protection For Your Electronics

In industrial and outdoor applications, safeguarding sensitive equipment against potential moisture, dust, and impact is a prerequisite. A failure in your enclosure can spell disaster in the form of costly short circuits, system downtimes, and expensive maintenance. That’s where Elettro’s ABS Junction Box IP 55/ 65 comes into play, a highly resilient weatherproof enclosure that guarantees electrical components are kept safe, optimally protected, and ever-durable.

Why You Should Consider An Electro Mechanical Housing With Enhanced Protection Rating

Managing elaborate automation systems, implementing solar power setups, or handling telecommunication hubs requires an electrical junction box that serves as a connective foundation. The integrity of external conditions should never compromise the protective seal this box offers ensuring dry and secure terminals, connections, and wirings.

Due to being made out of graded ABS, this Elettro’s product offers unmatched protection with extreme ease of installation. With certified IP rating, this Junction Box stands out and combines considerable form and functional reliability for both professionals and keen amateurs seeking longevity in their installations.

Key Points of Elettro ABS Junction Box IP 55/65

Shielded From Water and Dust IP55/65- The enclosure features absolute defense from solid particles such as dust and can withstand water immersion up to 1 meter for 30 minutes. This is excellent for harsh industrial areas and/or unpredictable outdoor locations.

Custom Built For Enduring Conditions- Crafted from premium Acrylonitrile Butadiene Styrene (ABS), this material is preferred for UV stable impact polymer that endures chemicals because of its impact resistance and chemical tolerance make it ideal for indoor and outdoor applications.

Requires Minimal Maintenance and Extremely Strong- Unlike standard plastic boxes, Elettro’s ABS junction box withstands much greater mechanical stress and prolonged exposure to elements while still maintaining its structure.

Tailored To Individual Needs, Multiple Sizes Offered- To accommodate various wiring and device protection needs, Elettro offers a range of size variants which enables you to select the box that fits your technical setup.

Mounting and Installation Made Easy- The user friendly locking mechanisms and the smooth surface for labeling or drilling extra holes aid with pre marked drilling locations for further labeling or marking, increasing ease of installation.

Eco friendly improved fire resistance materials used- Hardened rubber and other polymers help maintain the box's overall form while Electric Polymers aid in keeping the encased components from internal and external damage. WRAP 530 increases fire resistance, making the box much safer than alternatives.

Uses of The ABS Junction Box IP55/65

This junction box can be used for a variety of purposes and is ideal for residential, commercial, and industrial settings:

Industrial Automation Systems

Provides guard for programmable logic controllers (PLCs), relays, and terminal block assemblies.

Solar and Other Energy Systems

Applicable in outdoor solar cell (PV) connections and inverter installations.

Telecommunication Equipment

Carefully house vulnerable connectors, switches, and fiber optic splitters in outdoor networks.

Outdoor Lighting, Signage and Guarding

Stripping power and timers can be enclosed in garden flower beds, streets, and commercial sign boards.

Control Panels & Distribution Boards

Covers internal wiring from dust, insects, and tampering, keeping them protected.

Coastal and Marine Installations

Perfect for areas that are prone to salt water and require corrosion protection.

Why choose Elettro for Electrical Accessories?

For professionals in the industry along with engineers and electricians, Elettro has been and is a reliable supplier due to its quality electrical components. Their ABS Junction Box IP65 is manufactured to high standards with safety and ease of use in mind.

By purchasing from Elettro, you’re not purchasing a product but investing in safety, system durability, and most importantly, letting you rest easy.

Conclusion

Of all the existing options, Elettro’s ABS Junction Box IP55/65 is unmatched in reliability, weather resistance, and overall protection. This waterproof junction box is efficiently catered for both residential projects and expansive industrial sites, guaranteeing that the electrical systems are safeguarded from every angle.

0 notes

Text

Industrial and Commercial Uses of Brass Sheet and Copper Sheet

Introduction

In modern industry and commercial operations, material selection plays a critical role in performance, durability, and safety. Two of the most reliable materials used across sectors are the brass sheet and copper sheet. These metal sheets offer a combination of strength, conductivity, corrosion resistance, and versatility, making them ideal for a wide range of applications.

This blog highlights how brass and copper sheets are used across key industries, and what makes them an essential part of industrial and commercial processes.

What Makes Brass Sheet Suitable for Industrial Use?

A brass sheet is a metal alloy made from copper and zinc. Its mechanical strength, visual appeal, and corrosion resistance make it ideal for parts that must be both functional and presentable.

👉 Learn more about industrial-grade Brass Sheet used in commercial and engineering applications.

Commercial Applications of Brass Sheet

1. Electrical Fittings and Terminals

Brass offers decent conductivity and corrosion resistance, which makes it perfect for electrical terminals, connectors, and switch components.

2. Plumbing Fixtures

Brass sheets are used in valves, pressure fittings, and water connectors. They resist rust and perform well under high water pressure.

3. Decorative Architecture

Many commercial buildings use brass sheets for elevator panels, signage, trim, and door handles to achieve a premium finish.

4. Marine Components

Due to its resistance to saltwater corrosion, brass is ideal for boat fittings, underwater fasteners, and marine hardware.

5. Automotive Parts

Brass sheets are used for radiator cores, decorative trims, and fuel system components due to their machinability and heat resistance.

How Copper Sheet Powers Industrial Innovation

A copper sheet is made from nearly pure copper and is prized for its unmatched thermal and electrical conductivity. This makes it a staple in industries where performance and reliability are non-negotiable.

👉 Browse durable Copper Sheet options for commercial, electrical, and manufacturing purposes.

Commercial Applications of Copper Sheet

1. Electrical Systems

Copper sheets are used for switchboards, grounding plates, busbars, and transformer components due to high conductivity and low resistance.

2. HVAC and Heat Transfer

Copper sheets are excellent for use in heat exchangers, evaporator coils, boiler plates, and condenser systems.

3. Construction and Roofing

Thin copper sheets are used for roofing, flashing, wall cladding, and rain gutters. They resist corrosion and develop a patina that protects over time.

4. Industrial Machinery

Machinery parts like gaskets, washers, and brake components often use copper for its friction resistance and thermal behavior.

5. Medical and Sterile Environments

Copper’s antimicrobial properties make it ideal for use in hospitals and clean rooms—for door push plates, bed rails, and worktops.

Benefits of Brass and Copper Sheets in Industry

PropertyBrass SheetCopper SheetConductivityModerateExcellentCorrosion ResistanceGoodExcellentStrengthHighMediumCostLowerHigherAntimicrobialModerateVery HighWorkabilityEasy to machineEasy to formIndustrial UseFittings, trims, valvesCircuits, roofing, HVAC

Why Industries Prefer These Materials

Reliability Under Pressure

Brass and copper sheets are known for their stability under mechanical and thermal stress, which is vital in industrial systems.

Long Service Life

Both materials have long operational lifespans and require minimal maintenance, especially when installed in controlled environments.

Recyclability

Copper and brass are 100% recyclable, allowing industries to cut down on material costs and reduce environmental impact.

Best Practices for Industrial Use

Choose the Right Thickness: For structural or high-load parts, go for thicker gauges.

Surface Treatment: Apply coatings or finishes based on exposure (e.g., lacquer for brass, patina protection for copper).

Thermal Considerations: Use copper for heat-intensive environments; brass for parts needing strength and appearance.

Industrial Use Cases: Real Examples

Power Distribution Systems

Copper sheets are widely used in transformers, switchgear, and solar panel installations due to their low resistance and high safety performance.

Food & Beverage Equipment

Brass sheets are used in beverage dispensers, brewing equipment, and food processing tools because they are non-toxic and durable.

Railways and Aerospace

Both copper and brass are used in control systems, circuit enclosures, and brake units due to their consistent electrical and mechanical behavior.

Choosing Between Brass and Copper in Commercial Projects

For electrical applications, copper is essential due to high conductivity.

For visible installations, brass offers a superior appearance while maintaining strength.

For cost-effective plumbing, brass delivers performance and corrosion resistance at a lower price point.

For long-term roofing, copper is preferred due to its weather-resistance and patina-forming ability.

Final Thoughts

Whether you're designing electrical systems, upgrading industrial machinery, or finishing commercial interiors, choosing between brass sheet and copper sheet depends on your project needs. Brass excels in applications where durability and appearance go hand in hand, while copper leads in thermal, electrical, and antimicrobial performance.

0 notes

Text

Enhancing Durability and Performance with Brass Electrical Components

Brass electrical components are vital in various industries due to their excellent conductivity, corrosion resistance, and mechanical strength. These components are widely used in electrical and electronic applications, providing reliable and long-lasting performance. Whether in household wiring, industrial machinery, or automotive systems, brass proves to be a material of choice for manufacturers and engineers alike.

Why Choose Brass Electrical Components?

Brass, an alloy of copper and zinc, offers a unique combination of physical and chemical properties that make it ideal for electrical usage. It exhibits high electrical conductivity, second only to copper. Additionally, brass is more durable and resistant to corrosion, especially in humid or chemically active environments. This makes brass electrical components particularly suitable for outdoor and marine applications.

Common Types of Brass Electrical Components

There is a wide range of brass components used in electrical systems. Some of the most commonly used include:

Brass terminals and connectors: These ensure stable electrical connections and are often used in switchboards, panels, and automotive wiring.

Brass pins and plugs: These are frequently found in power outlets and plug systems, providing a safe and efficient path for current.

Brass fuse holders and contactors: They offer high-temperature resistance and consistent electrical contact.

Brass cable glands and fittings: Essential for securing and protecting cables, especially in industrial environments.

Each of these components plays a crucial role in ensuring a secure and efficient flow of electricity, thereby minimizing the risk of short circuits or electrical failures.

Benefits in Industrial and Household Applications

Brass electrical components are not only durable but also easy to machine and fabricate. This leads to cost-effective production and customization based on specific project requirements. In industries such as automotive, construction, telecommunications, and power distribution, brass fittings and connectors are indispensable. Even in home appliances, brass elements are found in sockets, switches, and internal wiring systems.

Sustainability and Recyclability

Another major advantage of using brass in electrical components is its recyclability. Brass can be recycled without losing its quality, making it a sustainable choice for environmentally conscious industries. Recycled brass components offer the same level of performance as newly manufactured ones, contributing to reduced waste and energy conservation.

Conclusion

Brass electrical components are essential to modern electrical infrastructure. Their superior conductivity, resistance to wear and corrosion, and cost-effectiveness make them a preferred material in a wide array of applications. As technology advances and the demand for reliable electrical systems grows, the importance of high-quality brass electrical components continues to rise. Manufacturers and consumers alike can benefit from incorporating these components into their systems for enhanced safety, efficiency, and sustainability.

0 notes

Text

Smart Off-Roading together with WD Electronics And Dig Rig Powersports

Today, strength is still essential, but performance and accuracy are just as vital, particularly when it comes to navigating difficult terrains. Here comes WD Electronics, which is a total game-changer in the world of off-road, because this stuff is smart, and provides customizable control for your ATV or UTV.

And when it comes to sourcing the best WD Electronics products, there’s no better place than Dig Rig Powersports—a trusted name in off-road parts, accessories, and custom builds.

Whether you're an adrenaline-chasing trail rider or a utility-focused off-roader, WD Electronics delivers the intelligence your machine needs. Let’s dive into what makes WD Electronics a must-have and how Dig Rig Powersports makes it easy to upgrade your ride.

What Is WD Electronics?

WD Electronics manufactures great quality electrical products for off road vehicles, which include ATV, UTV. They’re most famous for their plug and play installations which allow you to power, and control lights, winches, and other accessories without any effort at all.

Switch Pro panels

Digital control systems

Power distribution modules

Custom harnesses

Lighting and accessory control systems

These products replace outdated and overly complex wiring setups with streamlined systems that make controlling your accessories easier, more efficient, and safer.

In short, WD Electronics turns your off-road machine into a smart, responsive vehicle that can handle any adventure with precision and confidence.

Why Choose WD Electronics?

1. Smarter Power Management

One of the standout features of WD Electronics is its intelligent power distribution. Traditional wiring systems are often cluttered, hard to troubleshoot, and not easily expandable. WD Electronics simplifies everything with digital switch systems and integrated control units that allow for:

Clean installation

Centralized control

Overload protection

Water-resistant designs

That means fewer wires, fewer headaches, and better performance.

2. Custom Control at Your Fingertips

With WD Electronics’ digital switch panels, you can control everything from light bars to winches and stereo systems—all from one interface. Many systems include Bluetooth connectivity and programmable switches, allowing you to customize your setup exactly how you want it.

Need to turn on a chase light, activate rock lights, or engage a rear-facing camera? With WD Electronics, it’s all just a button—or smartphone tap—away.

3. Plug & Play Simplicity

All off-roaders aren’t electricians. That is why WD Electronics makes Plug & Play harnesses tailored for certain models of vehicles. These are the kit that can eliminate guessing and minimize the install time. It’s the ultimate answer for the DIY builder who wants to enjoy a professional grade rifle but doesn’t want to spend time soldering wires or decoding the complex schematics on a typical controller.

4. Rugged Reliability

Off-road conditions are brutal. Mud, dust, vibration, and water can easily ruin conventional electrical systems. WD Electronics are built to withstand it all. Featuring sealed connectors, marine-grade wiring, and durable enclosures, these systems are made for harsh environments.

What You Can Get from WD Electronics at Dig Rig Powersports

As an official retailer and installer of WD Electronics, Dig Rig Powersports offers a full lineup of products to fit your vehicle’s needs. Whether you’re looking for a simple upgrade or planning a full custom build, they’ve got you covered.

Here are some of the most popular WD Electronics offerings:

WD Electronics Switch Panels – Compact, backlit, and programmable for up to 8-12 different accessories.

Smart Harness Kits – Pre-terminated, vehicle-specific kits that simplify installation.

Relay Modules – Heavy-duty relay boxes to manage high-current accessories like winches or auxiliary lights.

Power Distribution Centers – Central hubs for all your vehicle’s electrical accessories, complete with fuse and relay protection.

Dig Rig’s experts can also help guide you through the best options for your specific make and model, whether you ride a Polaris RZR, Can-Am Maverick, Honda Talon, or another side-by-side.

How Dig Rig Powersports Makes the Difference

Dig Rig Powersports isn’t just a parts dealer—they’re passionate off-road specialists. When you work with them, you're getting:

1. Expert Advice

The team at Dig Rig knows what works in real-world off-roading. They’ll help you choose the right WD Electronics system based on your riding style, vehicle type, and accessory needs.

2. Professional Installation

There are lots of people who simply aren’t into installing complicated electronics, and that’s O.K. Install available ourselves In-House installs to make sure its bolted up right and wired up tight, plus everything in between for that factory-look installation.

3. Custom Build Support

Looking for a full overhaul? Dig Rig specializes in custom off-road builds. WD Electronics systems can be integrated with custom bumpers, lighting kits, sound systems, winches, and more—all designed and installed by Dig Rig’s experienced crew.

4. Ongoing Support

After the install, Dig Rig Powersports is there if you have questions or want to expand your setup. They offer troubleshooting, part replacements, and upgrade advice to keep your system in top shape.

Use Cases: WD Electronics in Action

Still not sure how WD Electronics could fit into your off-road lifestyle? Here are a few real-world examples:

Trail Adventurers: Use a Switch Pro panel to control your front and rear light bars, rock lights, and GPS system—all from a single, waterproof switch unit.

Utility Workers: Manage a winch, beacon light, rear floodlights, and external charging port with a smart relay panel that keeps everything organized and protected.

Recreational Riders: Install a full digital control system for your stereo, underglow kit, dome lights, and camera system for a stylish, functional ride.

Final Thoughts

WD Electronics isn’t just about adding switches and wires—it’s about elevating your entire off-road experience. With smarter power distribution, cleaner installs, and rugged dependability, it’s the upgrade that pays off on every ride.

And when you partner with Dig Rig Powersports, you’re not just buying components—you’re joining a community of riders who demand the best in performance, customization, and control.

Source by

https://medium.com/@seo.digrigpowersports/smart-off-roading-together-with-wd-electronics-and-dig-rig-powersports-6c63632acd40

0 notes

Text

PM Fiber Patch Cords Basics You Must Know

Polarization Maintaining Patchcord is a type of specialised fibre patch cord. It has a wide range of applications. Here's all you need to know about PM fibre patch cords if your ideas call for them.

PM Fibre Patch Cord

A PM optical fiber is a single-mode optical fiber in which linearly polarised light when correctly launched into the fiber, maintains linear polarisation during propagation and exits the fiber in a specified linear polarisation state. PM fiber patch cord is a fiber optic cable constructed of PM fiber that is terminated at both ends with high-quality ceramic fiber connectors. The PM fiber patch cable is a basic optical passive component.

Features of PM Fibre Patch Cords

If the polarisation of the input light does not match the stress direction in the fiber, the output light will alternate between linear and circular polarisation. In addition, temperature and tension fluctuations in the fiber will affect the precise polarisation. When light is connected at the fiber entry parallel to the slow or fast axis, polarisation can be maintained. It is critical to ensure that the polarisation of the incoming light is maintained. PM fibre patch cords and Polarization Maintaining Optical Switch preserve the polarisation of linearly polarised light that is launched into the fibre with the proper orientation. PM fiber patch cords also have low insertion loss, a high extinction ratio, a high return loss, great changeability across a wide wavelength range, and exceptional environmental stability and durability.

Types of PM Fibre Patch Cords

Classification by connection type: PM fiber patch cords have fiber connectors on both ends. The most common connection types used for PM fiber termination are FC, SC, LC, and ST.

PM fiber patch cables are manufactured of polarization-maintaining fibers. To assure the polarisation of both the input and output light in a PM fibre, numerous rod forms are utilised, and the final fibre is sold.

PM fiber patch cables can be categorized based on cable type. There are three primary types of cables: 250um bare fiber, 900um loose tube jacket, and 3mm loose tube jacket. So, depending on the cable type, there are three varieties of PM fiber patch cables.

Fiber length classification: A standard length of 1 meter is used. It may be adjusted to meet specific needs. The length of Polarization Maintaining Patchcord may be adjusted.

Next: MTP MPO Fiber Patch Cables: Unraveling Their Technical Features and Superior Performance

#Polarization Maintaining Optical Switch#Polarization Maintaining Patchcord#Polarization Maintaining Patch Cable#Polarization Maintaining Fiber Cable

1 note

·

View note

Text

Why do my headlights go dim when I step on the brake?

The dimming of your headlights when you press the brake pedal is typically caused by an electrical system imbalance or component failure. Here’s a breakdown of the likely causes and solutions, based on your scenario:

1. Overloaded Electrical Circuit

Why it happens: When you press the brake pedal, the brake lights draw additional power from the vehicle’s electrical system. If the alternator or battery is weak, this sudden load can cause a voltage drop, dimming other lights like headlights. • Example: A failing alternator might produce <13V at idle, struggling to power both headlights and brake lights simultaneously.

Test: • Measure battery voltage with the engine running: ◦ Normal: 13.5–14.5V (idle and driving). ◦ Weak alternator: Voltage drops below 13V when brakes are applied.

2. Faulty Ground Connections or Wiring

Poor grounding in the headlight or brake light circuit can create resistance, leading to voltage drops when the brake lights activate. • Example: Corroded battery terminals or loose alternator wiring.

Test: • Inspect ground points near the headlights and brake lights. • Check for voltage drop between the battery and headlight connectors (should be <0.5V).

3. Aging Battery or Alternator

Weak battery: A battery nearing the end of its life (2–5 years) may fail to stabilize voltage during high-demand scenarios like braking.

Failing alternator: If the alternator’s voltage regulator malfunctions, it can’t maintain consistent power output, especially under load.

Test: • Battery voltage with engine off: <12.4V indicates a weak battery. • Alternator output at 2,000 RPM: <13.5V signals alternator failure.

4. Incorrect Bulb Types or Retrofit Issues

LED vs. halogen: Aftermarket LED headlights or brake lights might conflict with the vehicle’s electrical system if not installed with proper resistors or relays. • Example: LED brake lights drawing less power could cause voltage fluctuations if the system expects halogen-level resistance.

Fix: Use CANbus-compatible LEDs or install relays to stabilize the circuit.

5. Faulty Brake Light Switch or Sensor

E-brake sensor interference: In some vehicles (e.g., 2003 Ford Escape), a malfunctioning electronic parking brake sensor may erroneously signal the headlights to dim when the brake pedal is pressed. • Symptom: Headlights flicker or dim briefly when adjusting the parking brake.

Fix: Replace the brake light switch or inspect wiring connected to the parking brake sensor.

Diagnostic Steps

Check alternator and battery health with a multimeter.

Clean electrical connections (battery terminals, headlight grounds).

Test brake light circuit load: Swap incandescent brake bulbs for LEDs to reduce power draw.

Inspect headlight relay and fuse for corrosion or damage.

Cost Estimates

Alternator replacement: $300–$800.

Battery replacement: $100–$250.

Brake light switch repair: $50–$150.

Bottom Line: Dimming headlights during braking often point to an overtaxed electrical system. Start with simple fixes like cleaning connections or testing the battery. If unresolved, focus on the alternator or circuit upgrades. Ignoring this issue risks complete electrical failure or safety hazards.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#car culture#cars#race cars#classic cars#car#coupe#suv#convertible#chevrolet#supercar#car light#brake lights#brakes#light#headlamp#headlight bulb#headlamps#headlight#aftermarket new lamp#car lamp

3 notes

·

View notes

Text

The advantages of rigid-flex PCB board

1). It can effectively save the space on the circuit board and eliminate the use of connectors

Because the FPCB and rigid pcb board has been combined, the space that originally needed to use the connector can be saved. For some circuit boards with high-density requirements, less connectors will be better. In this way, it also saves the cost of parts using the connectors. In addition, the space between the two boards can be made tighter by eliminating the need for connectors.

2). The signal transmission distance is shortened and the speed is increased, which can effectively improve the reliability

The traditional signal transmission through the connector is “circuit board→connector→flexible pcb board→connector→circuit board”, while the signal transmission of the rigid-flex PCB board is reduced to “rigid circuit board→flexible pcb board→rigid circuit board”, signal transmission distance between different media is shortened, and the problem of signal transmission attenuation between different media is also reduced. Generally, the circuit on the PCB board is made of copper, while the contact terminal of the connector is gold-plated, and the solder pin is fully tin-plated. Moreover, solder paste is required to be soldered on the circuit board, and the signal transmission between different media will inevitably be attenuated. If you switch to a rigid-flex PCB board, these media will become less, and the signal transmission ability can be relatively improved. For some products that require higher signal accuracy, it helps to improve their reliability.

3). Simplify product assembly and save assembly time

The use of a rigid-flex PCB board can reduce the man-hours for SMT parts, because the number of connectors is reduced. It also reduces the man-hours for assembly of the whole equipment, because it eliminates the assembly action of inserting the FPC board into the connector. It also reduces the cost of parts management and inventory, because the required parts is reduced, so the management cost becomes less.

Email Cynthia: [email protected] if you are interested in PCB and PCBA service.

0 notes