#TI6AL4V

Explore tagged Tumblr posts

Text

#TitaniumAlloy#MedicalTitanium#DentalTitanium#TI6AL4V#BiocompatibleMaterials#MedicalInnovation#DentalTechnology#TitaniumImplants#MedicalMaterials#DentalMaterials

0 notes

Text

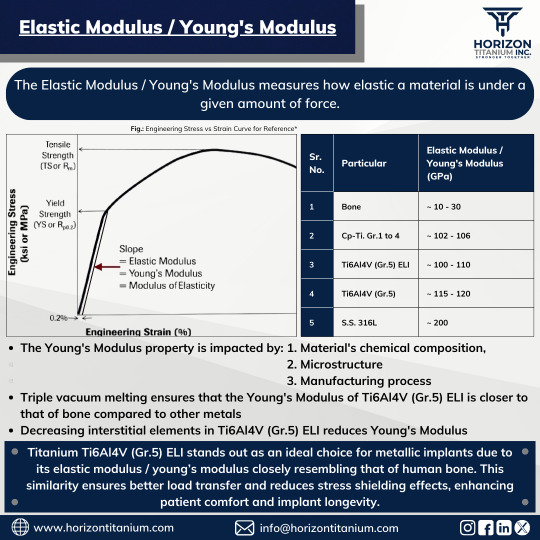

Metal implants play a crucial role in biomedical engineering, offering durability and reliability for bone reconstruction.

With superior mechanical properties compared to ceramics and polymers, metals like Titanium Ti-6Al-4V (Gr.5) ELI are preferred for handling heavy loads. In fact, 80% of implants are made from metal, with Titanium Ti-6Al-4V (Gr.5) ELI being the major choice, especially due to its higher fatigue strength and fracture toughness.

The value of the Elastic Modulus / Young's Modulus, should closely match that of the bone to minimize the stress-shielding effect between the bone and the implant. We will delve into more details about the stress-shielding effect in our next post.

Ti-6Al-4V ELI closely matches bone's Young's modulus as compared to other metallic implantable materials, making it a top choice for bone replacements.

For more information, contact us at [email protected]

#KnowYourTitanium#Titanium#ElasticModulus#YoungsModulus#ModulusofElasticity#Elasticity#StressStrainCurve#EngineeringStressStrainCurve#BoneYoungsModulus#TitaniumYoungsModulus#StainlessSteelYoungsModulus#StressShieldingEffects#CPTitanium#Ti6Al4V#Ti6Al4VELI#SS316L#ChemicalComposition#Microstructure#3VAR#ELI#TitaniumImplant#OrthopeadicImplant#PatientComfort#ImplantLongevity#HorizonTitanium#StrongerTogether

1 note

·

View note

Text

Maxilla Implant: Precision Solutions for Upper Jaw Restoration

The Maxilla Implant, made from biocompatible Ti6Al4V-ELI Grade 23 Titanium, restores upper jaw function and aesthetics with a customized fit. Designed for maxillary defects, dental rehabilitation, and cleft palate reconstruction, it ensures strong osseointegration, enhanced facial symmetry, and robust support for prosthetics. Perfectly tailored for patients and surgeons, it streamlines procedures and delivers lasting, reliable results.

0 notes

Text

Advanced Patient-Specific Cranial Implants for Optimal Recovery

Discover how 3D-printed cranial implants from Incredible AM are transforming the field of cranial reconstruction. These implants are custom-designed for each patient's anatomy, offering superior aesthetics, improved functionality, and faster recovery. With high-quality materials like Ti6Al4V ELI, PEEK, and PMMA, our implants ensure biocompatibility, strength, and comfort. Learn more about how our patient-specific implants are revolutionizing cranial surgeries, reducing surgical time, and minimizing risks.

0 notes

Text

Precision Manufacturing Technology and Application of Large Titanium Discs

As a high-performance material product, titanium discs have shown wide application potential in many fields. Especially in the aerospace, medical, petrochemical and power industries, large titanium discs have become indispensable components due to their high strength, corrosion resistance, high temperature resistance and lightweight.

Precision Manufacturing Technology of Large Titanium Discs Large titanium discs are mostly made of high-quality titanium alloy materials, such as Ti6Al4V, Ti60, etc. These materials have excellent mechanical properties and chemical stability and are suitable for use in harsh environments. Before manufacturing, the titanium alloy materials need to be strictly pretreated, including surface cleaning, degreasing, pickling and other steps to ensure the purity and processing performance of the material surface.

The precision manufacturing of large titanium discs is inseparable from advanced CNC processing technology. CNC processing technology uses computer digital control to achieve high-precision and high-efficiency processing. During the manufacturing process, through precise programming and advanced control systems, CNC machine tools can achieve precise processing of complex shapes and structures of titanium discs, meeting the micron-level or even nano-level processing accuracy requirements.

Electrolytic machining is an efficient machining method that is not limited by the mechanical properties of metal materials. It is particularly suitable for the manufacture of complex parts such as large titanium disks. By controlling parameters such as the composition of the electrolyte, current density and machining time, the surface of the titanium disk can be precisely removed and the shape can be controlled, and a high-quality surface without recasting layer, residual stress and microcracks can be obtained.

Heat treatment is an important means to improve the mechanical properties and corrosion resistance of large titanium disks. Through processes such as solution treatment and aging treatment, the microstructure of titanium alloys can be optimized and the strength and toughness of the material can be improved. In addition, surface treatment technologies such as electroplating, electrophoresis, sandblasting, passivation, etc. can further improve the surface quality and corrosion resistance of titanium disks.

Application of large titanium disks In the field of aerospace, large titanium disks are widely used in the manufacture of aircraft, rockets and other aircraft due to their light weight, high strength and corrosion resistance. For example, the integral blade is a core component of the new generation of aircraft engines. It is made of titanium alloy materials, which can significantly simplify the engine structure and improve the thrust-to-weight ratio and reliability.

In the medical field, large titanium discs are widely used in the manufacture of medical devices such as artificial joints and dental implants due to their good biocompatibility and corrosion resistance. Through precision manufacturing and surface treatment technology, a surface with good compatibility with human tissue can be obtained, which can improve the use effect and safety of medical devices.

In the petrochemical and power industries, large titanium discs are mainly used for the production of heat exchangers. Titanium coil heat exchangers have become indispensable and important equipment in these industries due to their corrosion resistance, high temperature resistance, and high heat exchange efficiency. Through optimized design and precision manufacturing, the performance and reliability of heat exchangers can be improved, and energy consumption and maintenance costs can be reduced.

The precision manufacturing technology and application of large titanium discs are one of the hot spots in current materials science and engineering technology. By adopting advanced CNC processing technology, electrolytic processing technology, heat treatment and surface treatment technology, high-precision and high-quality manufacturing of large titanium discs can be achieved. At the same time, the wide application of large titanium discs in aerospace, medical, petrochemical and power industries also provides strong support for the development of these fields. In the future, with the continuous advancement and innovation of science and technology, the precision manufacturing technology of large titanium plates will develop towards higher precision, higher efficiency, greater intelligence and greater environmental protection, contributing to innovation and development in more fields.

0 notes

Text

Porous Titanium in Next-Generation PEMFCs

Porous titanium has found a wide variety of unique and important applications including filtration, separation, catalyst supporting, gas absorbing, gas sparging, current collection, and medical implantation.

Manufacture process for porous titanium

Raw titanium powder preparation—Cold isostatic pressing or rolling—Sintering in high temperature & vacuum furnace-Machined to size-Assembled to filter if required

Liquid/gas diffusion layers (LGDLs) play a crucial role in electrochemical energy technology and hydrogen production, and are expected to simultaneously transport electrons, heat, and reactants/products with minimum voltage, current, thermal, interfacial, and fluidic losses.

Porous titanium exhibits excellent properties when it is used as the anode GDL, because of its unique three-dimensional strut structure promoting highly efficient catalytic reactions. Furthermore, it shows superior corrosion resistance with almost no thickness and weight changes in the accelerated corrosion test, as opposed to considerable reductions in the weight and thickness of the conventional GDL.

Porous Titanium provides a longer-term reliability and chemical stability, which can reduce the loss of Pt catalyst and, hence, the cost of PEMFCs.

0 notes

Text

AM PravaH: 3D Printing Software By Paanduv Applications

About the case study

This document will help you run your first AM PravaH LPBF simulation for macroscale and microstructure modeling. The case study is done for a standard alloy of titanium i.e. Ti6Al4V widely used for aerospace and biomedical applications. The simulation is carried out for a multilayer, multi-track scan pattern. The process parameters for the laser are e.g. 300 W power and e.g. 1 m/s scan speed. D4 sigma or spot dia is 0.1 mm.

Exclusive features of AM PravaH include consideration of 4 phases, with no explicit formulation for recoil pressure because evaporation and recoil pressure effects are included in the vapor phase. AM PravaH takes the thermophysical properties of the 4 phases as inputs along with the process parameters such as laser power, laser scan speed, shielding gas flow angle and velocity, layer thickness, spot diameter, preheating temperature, chamber initial pressure, and substrate initial height, scan pattern, particle size distribution and number of layers. Macroscale modeling will generate the following outputs melt pool dimensions, porosity %, thermal gradients, cooling rates, and thermal cycling plots. The Microstructure module generates outputs such as grain size distribution, angular chord length distribution, misorientation angles, and Euler angles. AM PravaH leverages the amalgamation of computational modeling solvers performing multiphase macroscale modeling, microstructure modeling, and Artificial Intelligence (AI) at a unified platform.

Keywords: Additive Manufacturing, 3D printing, Meltpool dynamics, porosity, thermal gradients, cooling rate, microstructure analysis, grain size, angular chord length, 3D printing software

AM PravaH: 3D printing simulation software

Introduction

AM PravaH is a 3D printing simulation software that facilitates end-to-end solutions for Additive Manufacturing physics-based simulations. Additive Manufacturing is commonly known as 3D printing. This 3D printing software is the “World’s first all-inclusive 3D computational software for Additive Manufacturing”. This 3D printing software will be useful for new alloy development, process parameter optimization, and reducing defects. Not to confuse with other 3D printing software that only performs thermomechanical analysis and deformation, AM PravaH software offers much more.

The software capabilities in brief are as follows:

There are three modules in AM PravaH

(i) Macroscale modeling

(ii) Microstructure analysis

(iii) Integrated Deep Learning (AI) module

Relevance of the 3D printing software; AM PravaH

This 3D printing software is relevant for researchers, academicians, and industry professionals from large and small-sized companies working in the Additive Manufacturing field. Where the primary focus is to understand the in-depth physics, microstructures, and effect of process parameters on the melt pool dynamics and distribution and the root cause of the defects. If we have a much closer look at the fundamental processes of 3D printing; this is a transient, very quick, and very dynamic process, which can't be captured with the naked eye. Therefore, AM PravaH simulations can be extremely useful in understanding this part.

Based on that, one makes important decisions such as

Which alloy is better?

How do we get solidification, melting, and cooling rates information?

what are the best operating process conditions to get a defect-free and dense part

What do the microstructures look like?

What are the grain distribution and mean grain size?

What are the melt pool sizes?

How much will be the porosity %?

#3d printing simulation software#3d printing software#additive manufacturing software#additive manufacturing#3d printing#simulation software for additive manufacturing

1 note

·

View note

Text

Bonshape

プッシュピアス 10G 8G 全4色 ストーンピアス ラブレットスタッド 金属アレルギー対応 チタンピアス つけっぱなし 軟骨ピアス ボディピアス Brand: BONshape 【素材】・ASTM F-136 TI6AL4V ELI TITANIUM(チタニウム)・キュービックジルコニア 【サイズ】・ゲージサイズ10G/8G・ストーンサイズ(台座含む)約4mm・ラブレット(内径)サイズ選べます 【特徴】・きらきら輝く人気のストーンピアスは、台座がチタン素材で金属アレルギーの方でも比較的安心して使えます。何と言っても装着が挿すだけの簡単プッシュピアスなのでネイルされている方や不器用な方にもオススメです。※キャッチは、専用のプッシュピアスなら20G/18G/16G/14G/10G/8Gどれにもはまります(6Gは不可) More Details: 商���URL: 10G|8G|6G…

View On WordPress

#10G#6G#8G#へそピアス#カスタムピアス#ステンレスピアス#トラガスピアス#プッシュピアス#ヘリックスピアス#ボディピアス#ボディピアス専門店#メンズピアス#bodyjewelry#金沢ボディピアス

0 notes

Text

Hmm. Given a composite-metal foam is 30% the density of the parent material but with comparable mechanical properties, you could get Ti6Al4V alloy (the titanium armor sometimes used on tanks and combat aircraft) with a density of only 1.33 g/cc. Kevlar is 1.44, just under 10% more.

That presumably means you can replace all the polypropylene plates in riot armor with titanium alloy and it only increase the weight by not quite half. Except apparently the preferred thickness for titanium plate vs. bullets, e.g. the thinner parts of the “titanium bathtub” in the A10 Thunderbolt II, is 13 millimeters—half an inch—which doubles the mass since riot gear plates are normally a quarter inch thick (they’re for thrown rocks, knives, etc., not bullets or fragments). And while it’s twice the weight of something like the Interceptor body armor used for most of the War on Terror (if you include the SAPI plate-inserts), or more, that was much less coverage, and future militaries would have exosuit assistance to help move it.

So yeah guess I’m not gonna bother with multiple degrees of armoring, for my setting’s human military. The standard issue can be plenty tough. (Think whether the exosuit is soft or rigid will vary, with the limbs being rigid and the torso soft.)

Edit: No never mind between the actuators and the suit itself, we’re talking a suit weight of 53 kilos, which is an entire fucking woman. Guess that’ll be the heavy one.

1 note

·

View note

Text

Comparing Fatigue Strength: Ti6Al4V (Gr.5) vs. Ti6Al4V (Gr.5) ELI

High fatigue property in titanium implants is crucial, as it ensures the implants can withstand the constant mechanical stresses and strains experienced within the human body, maintaining structural integrity and longevity.

Titanium Ti6Al4V (Gr.5) ELI contains fewer defects, discontinuities, and stress concentrations as compared to Ti6Al4V (Gr.5), which results in high fatigue strength.

This leads to prolonged life duration of implants made from Titanium Ti6Al4V (Gr.5) ELI in comparison to Titanium Ti6Al4V (Gr.5).

For more information, contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#TitaniumSheets#Ti6Al4V#Ti6Al4VELI#Grade5#Grade5ELI#FatigueStrength#CyclicLoad#FatigueFracture#FractureMechanism#Metallurgy#Quality#TitaniumImplants#MedicalImplants#OrthopaedicImplants#MedicalDevices#TitaniumSupplier#HorizonTitanium#StrongerTogether

0 notes

Text

Sea-Doo RXP RXT GTX GTR 4TEC Titanium Retainer 12 retainers per set All of the these titanium retainers are made from titanium alloy Grade 5 (Ti6Al4V).

https://www.hosnti.com/titanium-valve-spring-retainers/

#titaniumretainer#seadoo#seadootitaniumretainer#titanium#valveretainers#springretainers#tiretainers#valvespringretainers

0 notes

Text

BJMK specialize in Titanium Materials for 16 years with rich experience, especially in melting & forging, we have a special forging process for ultrasonic parts, that can ensure the quality of the ultrasonic cleaning, cutting, welding horns.

0 notes

Photo

#DIN7991 #steeringwheel #steeringbolt #ti6al4v #racingbolts #racingcarbolts #tiboltls(在 China) https://www.instagram.com/titaniumgr5bolt/p/Bwnht48gHtP/?utm_source=ig_tumblr_share&igshid=11qggzibkt36c

0 notes

Text

1 note

·

View note

Text

Bonshape

18g 16g 三日月 MOONピアス チタンピアス インターナル ラブレットスタッズ 【特徴】・キュービックジルコニアの輝きがとても綺麗です。遠くからでもわかるくらいに輝くのでかなり高級感があります。 人気の月デザインがオシャレに決まりますよ。ロブやトラガスピアス、ヘリックスピアス、アウターコンク、インナーコンクなど軟骨ピアスにもオススメです。 バーベルも台座も医療用のハイグレードチタンを使用しているので、お肌に優しく金属アレルギーの方でも比較的安心してご利用頂けます。 Brand:BONshape 【素材】・ASTM F-136 TI6AL4V ELI TITANIUM(チタニウム)・キュービックジルコニア 【サイズ】・ゲージサイズ18G/16G・デザインサイズ約7.3mm×5.7mm・ラブレットサイズ選べます Official website Base…

View On WordPress

#おしゃれピアス#へそピアス#インスタグラム#インダストリアルピアス#カスタムピアス#ステンレスピアス#ダイスピアス#ディースアクセサリー#トラガスピアス#トンネルピアス#プレミアムピアス#ヘリックスピアス#ボディピアス#ボディピアス専門店#メンズピアス#メンズファッション#ラブレットピアス#レディースピアス#bodyjewelry#金沢ボディピアス#舌ピアス

0 notes

Text

•Anodic Oxidation•

Losing my mind over the possibilities of using methods like anodic oxidation for changing the colour of titanium parts for medical, industrial and aesthetical reasons.

Also planning papers is always a ride.

Sources:

Graphic- Zaniolo, K.M., Biaggio, S.R., Bocchi, N. et al. Properties of colored oxide films formed electrochemically on titanium in green electrolytes under ultrasonic stirring. J Mater Sci 53, 7294–7304 (2018). https://doi.org/10.1007/s10853-018-2070-5

shown paper- Velten D, Biehl V, Aubertin F, Valeske B, Possart W, Breme J. Preparation of TiO(2) layers on cp-Ti and Ti6Al4V by thermal and anodic oxidation and by sol-gel coating techniques and their characterization. J Biomed Mater Res. 2002 Jan;59(1):18-28. doi: 10.1002/jbm.1212. PMID: 11745533.

13 notes

·

View notes