#Textile Roll Wrapping Machine

Explore tagged Tumblr posts

Text

The baby made a faint grunting noise before it did something unspeakable down the front of Sugafana’s shirt. Sugafana barely flinched. “I’ll be fine; I’ve done it before! Now if you’ll excuse me, I have to clean up and get this baby something to wear.”

When Sugafana’s street was flooded by human rebels trying to short out the circuits of headphone guards, she didn’t take much. Just the essentials: a blanket, her water refillable condensation bottle, and her mother’s box of wedding jewelry. She also took her roommate.

“Afternoon, Nani,” Sugafana greeted her grandmother as she pushed aside the curtains that gave their small cave a tiny bit of privacy. Home was two rolled-up sleep mats on the floor with bedding, a box filled with clothing, and a small hissing and spitting machine standing in the corner. Natural grooves and holds in the lava stone walls had been used to display jars filled with buttons and thread. An embroidered tapestry depicting a little girl holding a cat hung from the ceiling.

“You’re back early,” Nani remarked, barely looking up from a dress shirt she was busy repairing.

“Yes, I found something expensive on the field,” Sugafana admitted, and Nani looked up, her hand still instinctively stitching away at the shirt's tear. Looking at Nani was like looking into her future. They both had the same round faces, amber eyes, and warm beige skin. Nani’s eggplant purple hair, however, had long ago turned ashy white with faint streaks of black. Her suspicious eyes were now surrounded by thick lines.

“You found a baby,” Nani said flatly, as Sugafana gently placed the baby in the center of the sleep mat.

“I found a maternity droid and sold it to Bappa; the baby was locked inside,” Sugafana replied as she shed her filthy shirt, switching it for a plain black blouse.

“We can’t keep a baby! I barely have time to keep up with all the clothes people drop off, and you’re out working twelve hours a day,” Nani grumbled. Many of the refugees in the camp had spent decades using A.I. appliances to clean and repair their outfits. Most of them found washing their socks baffling and panicked at the thought of torn trousers. Thankfully, before the war, Nani had worked as a historical preservationist at the Museum of Ancient Textiles.

“I never said I was keeping her, Nani! I’m taking her into the city to find her family,” replied as she grabbed an old scarf, wrapping it around the baby's bottom like a makeshift nappy.

“The city,” Nani said flatly, “It’s not like this camp has genetic testing pods lying around,” Sugafana pointed out. “We avoid the city for a reason!” Nani said, tapping her legs.

Nani’s legs hadn’t worked right since she caught Martian Polio as a child. The machines insisted that those who couldn’t run to generate power had to be “recycled.”

“I’ll be fine, Nani! I go to the city's teleportation pod every week for ice deliveries,” Sugafana said firmly, and Nani sniffed, glancing down at the baby.

“Odd little thing, isn’t she? Her hair is green! You don’t see that much around here,” Nani remarked.

“No, you don’t,” Sugafana admitted. Almost everyone she knew had hair that was either black or in various shades of deep purple. Green hair belonged to tourists from the outer planets. The baby's skin, however, was darker than hers, and she stirred slightly, her eyes opening a crack, revealing black eyes.

“She’ll need feeding,” grunted Nani, turning to the spitting machine in the corner. The Creatrix was an essential household item that could be found in almost any home. Using electrified sand from the moon of Titan and computer codes, it had the ability to generate almost any inorganic material. Sugafana’s Creatrix was a small portable camping one that her grandfather took on hiking trips. It couldn’t create clothing and only had fifty recorded codes, but it had its uses.

“I’m sure the machine still has the baby formula codes in it; we used to make bottles for your sister when she was tiny,” Nani remarked, and Sugafana pursed her lips together.

“Then that means those codes are at least twenty years old,” Sugafana pointed out, refusing to think about her sister.

“Codes are codes! You’ll need four bottles for a trip into the city and back, and an ever-cleaning nappy! Not a filthy scarf,” Nani said, scooping four cups of glittering black sand out of a flour bag.

“You need that sand for your pain tea, Nani!” Sugafana protested, and Nani waved her away with annoyance before punching in several numbers.

“I can handle leg twitches! You won’t be able to handle a screaming, filthy newborn,” Nani said firmly.

“Fine! But as soon as I get back, we are packing to head to Harris Park, and you will need to drink four cups of tea for that journey,” Sugafana said as Nani handed her an ever-cleaning diaper. Sugafana still remembered dressing her baby sister in one when she was ten years old. The diapers were supposed to clean a soiled baby automatically forever, but they tended to break down after a few weeks.

3 notes

·

View notes

Text

A roll packing machine is an industrial-grade packaging system designed to wrap and compress rolls of various materials such as textiles, non-wovens, foam, and paper. It automates the packaging process, offering speed, consistency, and protection for storage and transportation.

#rollpackingmachine#rollpackingmachinemanufacturer#rollpackingmachineprice#industrialrollpackingmachine#machinemanufacturer

0 notes

Text

They say you can hear the ghost of the Dunes howling in the night. The cold shivering breeze billowing plumes of gingery sand into the wind, it is silent and breathless in the darkness under the hazy glow of the two moons crested in the sky. It is waiting, it is silent. A type of peace that belongs to the desert alone.

But then, when the sun peeks out from the endless horizon, the first rays spilling out molten gold, smearing the Cespua Desert with flame. The dry heat pouring into homes, licking at the windows covered in condensation. People rising with the sliver of sun in in their eyes, gently coaxing them to another day in Hamal. The crammed houses stacked roughly, one on top of the other with rickety wooden scaffolds and carved sandstone towers, making up the winding labyrinth brushed in copper and rust as it burns in the blaze of the light. The city was alive.

And nowhere was more alive than in the market on Sun Street.

It was a mix of color and noise. A melting pot of all types of people, from all over the world. The air is thick with spice, oil, and the acrid bite of fermented fruit. Vendors shouting, and the chatter of shoppers gossiping and haggling. People covered in sparkling jewelry glinting in the rays picking through piles of waxy dyed textiles and gems, from a birds point of view it must’ve looked like a sea of glitter. Rolls of silk fluttered through the wind, baskets overflowing with blistering peppers, spices, the type of stuff that could make your eyes water just thinking about. The scent of grilled scorpion and scratch sizzles in the air, skewers dripping with fat, smothered in sauces with one special ingredient.. Poison.

Poison was a specialty here. Cespuan tongues had long since learned to recognize its taste—to crave it. Dishes of spiced meats and charred vegetables dripped with black, glistening toxin, a game for some, but a death wish for tourists unaware of the tradtion. But spend enough time in Cespua, and the craving will sink its teeth into you too. The burn, the tingle, the slow numbness that spreads through the lips and fingers. Careful though–there’s a reason that senile Cespuans have blackened fingers and toes, rotting on the inside.

And among the bustle, the thieves move like shadows. They weave between bodies, light-fingered and quick-footed, lifting coin purses with the grace of dancers. Pockets turned inside out before their owners realize they've been emptied. Children with hands too small to be noticed slip through the gaps, feet bare and silent against the sun-warmed stone, swiping fruit, coins, trinkets. Here in Hamal, theft is not a crime, more like a language. A conversation between predator and prey. The merchants know better than to chase, they guard their wares with eyes sharp as falcon talons, but even the keenest gaze cannot watch all places at once. A single moment of distraction, a glance at a bickering customer, a blink against the stinging dust—and the deed is done. The market swallows the culprit whole, spitting them out in some distant alley, gripping proudly at their collection.

Beyond the city, the trucks rumble. Rusted, overburdened beasts piled with people of all ages, their faces wrapped in cloth against the rising heat. The shifters, poor folk, who leave before the city fully wakes, packed shoulder to shoulder in the open beds of the battered machines. They will spend their the day in the dunes, as they do every other day, fighting against the shifting sands, digging, collecting, moving the desert itself like ants to provide for the queen and her unending, thankless war. Their hands, calloused and split from years of labor, clutch onto the rusted edges of the truck, fingers curling over hot metal as the city shrinks behind them. Their eyes, shadowed by exhaustion, flicker between the rolling dunes ahead and the sprawling mess of Hamal in the distance, as if memorizing it. As if they won’t return

The ride is brutal. The trucks trip over sand-choked roads, bouncing and shaking so violently that the passengers are jostled against one another, heads knocking, limbs bracing against the hard steel of the truck bed, as the tank like wheels hummed, lined in Refekti crystal, repelling the gold lined sands of the desert, working like magnets keeping the trucks moving like ships above the sand

The truck lurched over a dune, sending up a spray of fine sand as it coughed its way deeper into the wasteland. Tesserae barely felt it. She was used to the finky “magic” of the ride perched on the very edge of the truck bed, leaning over the boiling railing, legs swung over the side, mouth and nose covered by a think woven bandana. Her hands idly braiding her puffy curls already crusted over with sand. It was muscle memory by now. Braid, unbraid, repeat. pointless, but something to do. Something to keep her hands busy while her mind wandered. The sun wasn’t fully up yet, but it was coming, clawing its way over the horizon, smearing the sky in bruised purples and diluted gold. She could already feel the heat creeping in, slithering under her poncho and settling in her knees through the stretches of her long linen trousers, the sweat already dripping in the curve of her spine. Soon, it would be unbearable, turning the truck bed into a searing-hot cage. For now, it was just discomfort.

The others were packed tight in the truck, most of them half-asleep, heads bobbing with every jolt. Some clutched the rails, fingers curled white against rust. Others leaned against each other, bodies swaying with the movement of the truck like reeds in a slow-moving current. No one spoke. What was there to say?

Tesserae’s gaze flickered past them, past the blur of dunes rolling by, back toward Hamal. It was a mess of copper and dust now, shrinking behind them, its towers and crumbling scaffolds melting into the horizon. It always looked different from far away.. less like a city, more like a gross mirage.

She let her fingers pause in their work, half her braid undone, and exhaled dryly through her nose. How many times had she sat like this. Her eyes heavy as she watched her city roll into the horizon, knowing she’d return only to leave again the next day? The same cycle. The same dunes. The same aching exhaustion waiting at the end of it all. And even more so, how she thought the same exact thought every day, just to end it with the reminder that she does it for her grandfather.

She let her fingers pause in their work, half her braid undone, resting her cheek against the hot rails of the truck. She felt woozy with the small jingle of jewelry, the hum of the truck, the gentle weight of a woman’s calf steady on her back. The desert wind pulled at her hair, unweaving what little progress she’d made. She let it, fingers hovering uselessly over the loose strands.

It was always like this.

The same ride. The same sounds. The same aching exhaustion waiting at the end of it all.

Her grandfather would be waking up soon. Slowly, with stiff joints and a quiet groan as he pushed himself from his cot. He’d light the stove first, then sit at the window, waiting for her to come home. He’d never say it, but she knew. Knew how he always left a cup out for her, steam curling in the morning air.

She swallowed against the dry air, then slowly drifted to sleep.

0 notes

Text

Comprehensive Guide to Mattress, Pillow & Cushion Processing Machines

Efficient production and packaging are vital to the bedding and upholstery industry. Advanced machinery such as mattress packing machines, cushion packaging machines, cushion stuffing machines, pillow rolling machines, pillow stuffing machines, pillow filling machines, and duvet packing machines streamline manufacturing processes and enhance productivity. This article provides an in-depth examination of these critical machines, particularly emphasizing their features, benefits, and applications within Delhi’s bustling manufacturing landscape.

Mattress Packing Machine

Mattress packing machines are essential for compressing and packaging mattresses securely, facilitating easy transportation and reducing storage space. These machines help manufacturers maintain mattress quality during transit.

Key Features:

Efficient vacuum compression technology

Automated sealing and wrapping

High-speed operation suitable for mass production

Applications:

Mattress manufacturing facilities

Distribution and logistics centers

Retail packaging

Cushion Packaging Machine / Cushion Packing Machine

Cushion packaging machines efficiently pack cushions in protective materials, ensuring they reach consumers in optimal condition. Automated cushion packing machine reduce manual labor, significantly increasing productivity and consistency.

Key Features:

Automated packing and sealing systems

Adjustable settings for various cushion sizes

Consistent, high-quality packaging

Applications:

Cushion production factories

Furniture manufacturing units

Export-oriented packaging services

Cushion Stuffing Machine

Cushion stuffing machine automate the filling process, ensuring uniform and consistent cushion density. They handle various filling materials, including fiber, foam, and synthetic stuffing, enhancing operational efficiency.

Key Features:

Precision filling and density control

User-friendly automated operation

High production capacity

Applications:

Upholstery and furniture manufacturing

Cushion and sofa industries

Home furnishing product assembly

Pillow Rolling Machine

Pillow rolling machines compactly roll pillows, optimizing packaging size and simplifying transportation. These machines are critical for reducing logistical costs and maintaining product integrity during shipment.

Key Features:

Effective pillow compression and rolling

Adjustable rolling tightness

Automated packaging integration

Applications:

Pillow manufacturing plants

Export and e-commerce logistics

Storage and warehousing facilities

Pillow Stuffing Machine / Pillow Filling Machine in Delhi

Pillow stuffing and pillow filling machines in Delhi streamline pillow production by automating the filling process. Widely available and extensively utilized in Delhi’s textile manufacturing hubs, Pillow Stuffing machines ensure consistency and efficiency in production.

Key Features:

High-speed, automated filling

Adjustable fill quantity for custom density

Easy-to-use digital controls

Applications:

Bedding manufacturers in Delhi

Hospitality industry supply chains

Bulk pillow production and exports

Duvet Packing Machine

Duvet packing machines specialize in compressing and packaging duvets efficiently, facilitating easier handling and reducing storage and shipping volumes. These automated machines help maintain duvet fluffiness and quality post-packaging.

Key Features:

Gentle compression and efficient sealing

Automated, high-throughput operation

Protective packaging maintaining duvet integrity

Applications:

Bedding and duvet manufacturing units

Hospitality and hotel supply chains

Export and retail packaging operations

Importance of Mattress, Pillow & Cushion Processing Machines

Incorporating specialized machines such as mattress packing machines, cushion packaging machines, cushion stuffing machines, pillow rolling machines, pillow stuffing machines, pillow filling machines, and duvet packing machines brings several key advantages:

Enhanced Efficiency: Streamlines production processes and significantly increases output.

Quality Assurance: Maintains product consistency and integrity during manufacturing and transportation.

Cost Savings: Reduces labor costs, packaging materials, and transportation expenses.

Market Competitiveness: Enables manufacturers to meet higher market demands and enhance profitability.

Conclusion

The use of advanced mattress, pillow, and cushion processing machines greatly enhances productivity, quality control, and profitability in the bedding and upholstery industries. With machinery specifically tailored for mattress packing, cushion packaging, stuffing processes, pillow rolling, pillow filling, and duvet packing, manufacturers in Delhi and beyond can achieve significant operational efficiencies. Adopting these technologies is crucial for remaining competitive, meeting consumer expectations, and supporting sustainable growth within the industry.

youtube

0 notes

Text

Snuggle in Muslin Cotton Blanket to Experience Superior Softness and Comfort

Experience ultimate cosiness with D)LUX’s premium muslin cotton blankets. Practical and easy to care for, our machine-washable muslins come neatly rolled and tied with delicate cotton tape — ready to be part of your parenting essentials.

Lightweight and breathable, they’re designed for ultimate comfort and versatility. Whether you use them as stroller covers, burping cloths, nursing burps, play mats, or swaddling, these essential wraps make daily parenting moments easier.

With D)LUX BABY, you also enjoy the added perk of free shipping Australia-wide. Provide your little one with the soft, soothing comfort they deserve.

Visit https://nzwholesale.d-lux.com.au/ now!

0 notes

Text

Falling for Design: 9 (Super Affordable) Ways to Refresh Your Space for Fall

Decorating for fall on a budget.

It wasn’t always this way, but now fall is probably my favorite of all the seasons. There is so much to love – the colors of the leaves changing, the cute fall clothes, the cooler temperatures. But there’s nothing I love more than the feeling of change that fall brings. I don’t know what it is, but every year around this time I feel the need to move and change (almost) everything around in my house. Does anyone else feel this way? If you’re feeling like a change but don’t have the budget to re-accessorize and re-furnish your entire space, I’ve got 9 affordable ideas for fall decorating I think you’ll love. Including a couple ideas that won’t cost you a single penny!

1. Switch out your throw pillows. Seems simple enough, but changing out your throw pillows can make such a difference. It can shift a color scheme or bring in some texture to a space that otherwise felt flat. Try bringing in some colder season fabrics like fur, velvet, or sherpa (or a combo of all three)! Still need help? Try changing out a linen pillow for a velvet one (like those dreamy velvet pillows in the photo above from Studio Giancarlo Valle) or switching out a bright pink pillow for a deep mustard color.

2. Wrap up with fall-worthy textiles. When I think of fall, I think of cooler evenings spent getting cozy on the couch (or my bed). Having a fuzzy throw nearby to keep you warm or the perfect color rust bedding (like this one from Bed Threads) to give you those fall color vibes are great options for seasonal textiles.

3. Use what you have. One of the easiest (and completely FREE) ways to change up a room is to use what you already have lying around the house. Switch out the rug in your living room for the one in your bedroom and rework the space around a new color scheme. Just because something isn’t new to you, doesn’t mean it won’t feel new in a different space. And note to self: There are many ways to decorate for fall that don’t revolve around colors. Textures can be really important too. Going from a low pile rug with a relatively smooth surface to a high pile rug with plenty of texture and softness can be a game changer under your feet for the season. P.S. How pretty is the space found on Our Food Stories?! That natural light.

4. Bring the outside in. When fall rolls around, I start seeing twigs, dried flowers and even dried grass pop up everywhere. So what better way to embrace the changing season then to decorate with a little bit of nature? A cool vase with some dried flowers on the mantle can bring a lot of texture to a space, and make things feel cozy for fall. Or try something bold and decorate your entire mantle with fall foliage, sticks, candles, etc – like this mantle decor from Anthropologie. This is another one of those fall decorating ideas that could be completely free too, since you can grab most of these materials right outside your door.

5. Repaint your walls! Is the basic builder grey that’s been on your walls since you’ve moved in making you feel like you’re in a rut? Change it up! Be sure to get permission from your landlord if you’re renting. But in most cases, they won’t mind as long as you agree to paint it back to the original color. Try a pop of color or go with a more neutral earth tone, like this one from BloggaiBagis. Either way, a change in color can make a room feel completely new.

6. Refinish an older piece. Is your coffee table begging for an update? Anything is possible with a little bit of paint (or stain) and some elbow grease. Take a stab at repainting a piece of furniture like I did with this entry table or how Leanne Ford painted these wicker chairs (above).

7. Try some new window treatments. This tip is especially easy if you already have curtains hanging! Swapping out curtains can bring some color in and can be pretty affordable if you look in the right places. If you’ve got a sewing machine and can sew a straight line, making new curtains from scratch is a breeze. First, measure the length you you need and cut with an extra 4 inch length. Then, sew a 1/4″ hem on the sides and a 2 in. hem on the top and bottom. I use the curtain clip rings from IKEA to easily swap out curtain panels. The options are endless, but I especially love these mustard velvet curtains (above) from Colombe.

8. DIY some new accent tables. There are some really cool console, side, and coffee table DIYs out there like this amazing DIY wood accent table from Smor. Or the easy terrazzo side table I did a while back.

9. Try some new art. Feeling adventurous? Maybe you’re not the next Picasso (me either), but I willing to bet you can still whip up a cool new piece of art. Pick a few colors that work well within you space and try your hand at some abstract art, like this piece I found over on Remodelista. It’s the home of Kai Avent-deLeon – owner of the concept shop Sincerely, Tommy. By using different brush sizes or just painting random lines you can make a cool piece that is really unique! Or take note from Leanne Ford’s book and paint a canvas all one color for a large scale piece of art. Using gesso and acrylic paint, you can create a textured canvas that, even though it’s just one color, can really make an impact. *I did this a few years ago too, back when I had huge studio walls to fill, and showed how to stretch your own (really big) canvas in the process, if you want a guide for getting started: how to stretch a giant canvas by hand. It’s cheaper this way than buying one that’s pre-made and you can make any size you want! You think you’ll try some of these tips out? Let me know in the comments! I’m curious to hear how you are refreshing your space for the fall. Read the full article

0 notes

Text

Role of L-Sealer Machine in Textile Industries

The Role of L- Sealer Machine in Textile Industries:

Enhanced Protection: Provides a protective barrier against dust, moisture, and physical damage, preserving textile quality.

Improved Presentation: Offers a professional and attractive appearance for textiles, making them more appealing to consumers.

Cost-Effective Packaging: Utilizes relatively inexpensive shrink film, reducing overall packaging costs while maintaining quality.

Increased Efficiency: Automates the packaging process, speeding up production lines and reducing manual labor.

Space Optimization: Creates compact, stackable packages, making storage and transportation more efficient.

Consistent Quality: Ensures uniformity in packaging, providing a consistent look and feel across products.

Versatility: Accommodates various textile sizes and types, with adjustable settings for different packaging needs.

Enhanced Product Safety: Secures textiles with tight, shrink-wrapped film to prevent tampering and contamination.

Reduced Waste: Minimizes excess packaging material by using precise, shrink-wrapped film that conforms to the product’s shape.

Improved Shelf Life: Helps extend the shelf life of textiles by protecting them from environmental factors and maintaining their condition.

What is an L-Sealer Machine?

An L-sealer machine is a type of shrink wrapping equipment used to package products in a plastic film. It gets its name from the shape of the sealing bar, which forms an “L” when the machine is in operation. This machine is designed to wrap items in a tight, protective layer of plastic, which is then shrunk to conform to the shape of the product, offering excellent protection against dirt, moisture, and damage.

How Does an L-Sealer Machine Work?

The L-sealer machine operates in a straightforward process:

Product Placement: The item to be packaged is placed on the conveyor or sealing area of the machine.

Film Wrapping: The machine feeds a plastic film over the product. The film is usually pre-cut or fed from a roll, depending on the machine type.

Sealing: The machine uses heated sealing bars to create an airtight seal around the product. This is where the “L” shape comes into play, as the bars seal the film along the sides and bottom.

Shrinking: After sealing, the wrapped item is passed through a heat tunnel or chamber where the plastic film is shrunk tightly around the product by the application of heat.

Choosing the Right L-Sealer Machine

When selecting an L-sealer machine for your textile operations, consider the following factors:

Production Volume: Determine whether you need a manual, semi-automatic, or fully automatic machine based on your production scale.

Product Size and Type: Ensure the machine can handle the sizes and types of textiles you plan to package.

Film Specifications: Verify that the machine is compatible with the type of shrink film you use.

Budget and Cost-Efficiency: Balance your investment with the expected benefits in terms of speed, quality, and overall efficiency.

Conclusion

In summary, L-sealer machines are a critical component in the textile industry, offering unmatched protection, efficiency, and presentation for packaged goods. By investing in the right L-sealer machine, textile manufacturers can streamline their packaging processes, enhance product quality, and improve overall operational efficiency. As technology advances, the role of L-sealer machines in ensuring the integrity and appeal of textile products continues to grow, making them a smart choice for businesses aiming for excellence in packaging.

Top L- Sealer Machine Manufacturers in India

If you are looking for Best L-Sealer Machine Manufacturer in India, look no further than Ace Packaging Solutions, We are a leading Automatic L-Sealer Machine Manufacturer in India.

For more details, Please Contact us!

Website :- www.shrinkpackagingmachines.in

Contact No. :- +91–9810264335, 011–65394310

Email :- [email protected]

Address :- PLOT NO 31 KHASRA NO 53 IPS Industrial Compound, Meerut Rd, Morta, Ghaziabad, Uttar Pradesh 201003

#L-Sealer Machine#L-Sealer Machine Manufacturer#L-Sealer Machine manufacturer in India#L-Sealer Machine supplier in India#ace packaging solutions

1 note

·

View note

Text

Bow Banana Roller: Versatile Solutions for Industry Needs

We offer consist of Banana Roller. These are generally utilized as kink remover gadgets in different enterprises and are accessible in different measurements. Further, these are also supplied with gearbox and mounting brackets, either Foot Mounted or Wall Mounted. The Bow Banana Roller is a specially designed roll that can be used to use the power of the machine to straighten out a part that has been bowed because of being struck by a foreign object or from being bent. This Bow Roll should only be used as a backup to re-straightening a part that's become bowed and never should be used to operate a machine.

Banana Roller is a compact and economical machine designed to keep the web unwrinkled and to reduce contamination. The shape of the roller is like a banana, and this shape can easily move into a tissue warp. Banana rollers run at high speeds and make excellent brakes to stop the incoming and winding rolls, while the winding speed is increased effectively by using Banana Rollers. Strong and lightened structure, gears, and worm wheels make low noise and high accuracy stable performance storage.

The most recent assortment of Rubber we have in store is:

-Rubber Expander Roller

-Vary Bow Expander Roller

-Metal Expander Roller

The presentation of our Rubber Expander Roller (Bow Rollers) relies on the accompanying focuses:

-Wrap angle

-Lead-in & Lead-out distance

-Position of the bow (Adjustable)

Our scope of Wrinkle remover gadgets serves to:

Remove wrinkles

Separate slit webs on winder

Eliminate baggy center

Control slack edges

Attempt to try and out horizontal strain across the web width

Banana Roller in Industries

They are a key component of various industries, including textile processing, plastic converting, paper mills, and other manufacturing, printing, and coating processes. They help to expand or spread material that would otherwise be difficult to feed through a machine. Bow rolls are also used for cleaning tables in the textile industry.

Exports

We export 90% of our products to Europe, America, Asia and other countries and regions. We can also design new items as per your samples or drawings. Our products have been selling well in the home and abroad markets for their reliable quality.

Best Banana Roller by Us

The Bow Banana Roller manufactured by us is widely acclaimed for many qualitative features. The product, which has been designed to offer enhanced grip, is fabricated using premium-grade raw material.

0 notes

Text

Mastering the Art of Stretch Wrapping Film: Best Practices, Benefits, and Applications Unveiled

In the world of packaging, where efficiency and protection are paramount, stretch wrapping film has emerged as a cornerstone technology. Singhal Industries Pvt Ltd, India's foremost packaging company, is at the forefront of mastering this art. Let's delve into the best practices, benefits, and applications of Stretch film roll, shedding light on why Singhal Industries stands as the pinnacle of excellence in this domain.

Understanding Stretch Wrapping Film:

Stretch wrapping film, also known as stretch film or stretch wrap, is a highly versatile packaging material used to secure and protect goods during storage and transportation. Composed of polyethylene plastic, this thin, elastic film is stretched around products or pallets, providing a tight and secure wrap that prevents shifting, tampering, and damage.

Best Practices for Stretch Wrapping:

Proper Film Selection: Selecting the right type and gauge of stretch film is crucial for effective wrapping. Factors such as load weight, dimensions, and storage conditions should be considered to ensure optimal performance.

Equipment Calibration: Calibrating stretch wrapping machines to the appropriate settings, including film tension, pre-stretch level, and wrap speed, is essential for consistent and reliable wrapping results.

Uniform Application: Ensuring uniform tension and coverage during wrapping helps distribute the load evenly and minimizes the risk of product damage or instability during transit.

Corner Reinforcement: Paying special attention to the corners and edges of palletized loads by applying additional layers of film or using corner boards can enhance load stability and protection.

Quality Control: Regular inspection of wrapped pallets for tears, punctures, or loose film ends is necessary to identify and rectify any issues before shipment.

Benefits of Stretch Wrapping Film:

Cost-Effectiveness: Stretch film offers a cost-effective solution for securing and protecting goods compared to alternative packaging materials such as strapping or shrink wrap.so always have an idea on Stretch film price per kg, before buying.

Versatility: Stretch film is suitable for a wide range of applications across various industries, including manufacturing, logistics, retail, and agriculture.

Load Stability: The elastic properties of stretch film provide superior load stability by conforming to the shape of the product or pallet and holding it securely in place during transit.

Product Protection: Stretch film acts as a protective barrier against moisture, dust, and other environmental factors, safeguarding goods from damage and contamination.

Efficiency: Automated stretch wrapping systems streamline the packaging process, increasing efficiency and throughput while reducing labor costs and manual handling risks.

Applications of Stretch Wrapping Film:

Palletizing: Stretch film is commonly used to secure and stabilize palletized loads of goods for storage and transportation, minimizing the risk of product damage and loss.

Bulk Packaging: Large rolls or bundles of products, such as paper, textiles, or building materials, can be efficiently bundled and protected using stretch wrapping film.

Unitizing: Individual items or packages can be unitized and grouped together using stretch film, reducing the risk of loss or damage and facilitating handling and storage.

Food Packaging: Stretch film with specialized properties, such as high clarity or food-grade certification, is used for packaging perishable goods in the food and beverage industry. The question is do you know the price of Stretch film roll price per kg to maintain better profit margins and packaging quality in your business.

In conclusion, stretch wrapping film stands as a cornerstone technology in the realm of packaging, offering unparalleled efficiency, protection, and versatility. Singhal Industries Pvt Ltd, with its commitment to excellence, competitive pricing, and customer-centric approach, remains at the forefront of mastering this art. As industries continue to rely on efficient and reliable packaging solutions, the adoption of stretch wrapping film emerges as a strategic imperative for safeguarding goods and optimizing supply chain operations.

Frequently Asked Questions:

1.What is the price per kg of stretch film offered by Singhal Industries?

Singhal Industries offers competitive pricing for stretch film, with rates varying based on factors such as quantity, gauge, and customization requirements.

2.Do you offer different types of stretch film rolls?

Yes, Singhal Industries provides a variety of stretch film rolls, including standard, pre-stretched, and specialty films tailored to specific application needs.

3.What is the price per kg of stretch film roll?

Singhal Industries offers transparent pricing for stretch film rolls, with rates calculated based on the weight of the roll and the desired specifications.

4.Is stretch film suitable for wrapping irregularly shaped or oversized items?

Yes, stretch film can be stretched and manipulated to conform to the shape and size of virtually any item, providing secure and reliable packaging.

0 notes

Text

Ensuring the Integral Structure Protection

Heavy-duty tubes made of cardboard are commonly used for packaging various items like posters, maps, documents and even certain types of food products like chips or snacks as these tubes are typically constructed from multiple layers of thick and durable cardboard. Providing strength and protection to the contents inside and the outer cylinder forms the main body of the packaging provides structural integrity and protects the contents from external elements such as moisture, dust and physical damage during handling and transportation. Using multiple layers of thick cardboard for both the outer cylinder and the end caps enhances the overall strength of the packaging as the layers can be glued together to form a sturdy composite structure. Start with high-quality cardboard materials that are thick and durable using sturdy cardboard will help prevent tearing, crushing or puncturing provides structural integrity and protects the contents from external elements. The cardboard cylinder packaging cores are constructed by winding multiple layers of cardboard or paperboard strips in a spiral fashion are constructed by winding multiple layers of cardboard or paperboard strips in a spiral fashion.

The strips are tightly wound around a mandrel to form a cylindrical shape known for their strength, rigidity and uniformity as widely used in various industries for applications such as cardboard cylinder packaging on textiles, tape rolls and paper products. Cardboard cylinders are commonly used for shipping and storing various items such as posters, blueprints, maps and documents because their cylindrical shape provides protection against bending or creasing during transit. They're often preferred for shipping items that need to remain flat or rolled as the cylindrical shape prevents bending or creasing during transit additionally, their durability ensures that the contents are well-protected from damage or crushing. These are circular pieces that seal the ends of the cylinder usually made of sturdy cardboard or sometimes plastic providing additional protection to the contents and ensuring that they remain securely enclosed within the cylinder. Reinforcing the end caps with additional layers or using thicker cardboard material can prevent crushing or collapsing of the cylinder ends especially during stacking or handling ensuring that the cardboard cylinder packaging is well-constructed with strong adhesive bonds between layers and components.

Properly sealed seams and joints contribute to the overall integrity of the cylinder as for the convolute cores known as spiral-wound tubes made by spirally winding a single-ply board or multiple plies of paperboard in layers. Unlike spiral cores, convolute cores are typically formed without a mandrel instead, they are manufactured using a specialised winding machine that spirally wraps the material around a cylindrical form. Convolute cores offer excellent strength and durability and are commonly used in cardboard cylinder packaging applications for products like paper towels, aluminum foil and other rolled goods. Cylinder packaging is used in the textile industry for storing and transporting fabrics, textiles and rolls of materials such as carpets, upholstery and industrial fabrics. The heavy-duty nature of these tubes means they can withstand rough handling and external pressures making them suitable for a wide range of applications where robust packaging is essential. In some designs, especially for cardboard cylinder packaging delicate items, an inner liner may be included which fits snugly inside the outer cylinder and provides an extra layer of cushioning and protection to the contents.

0 notes

Text

A.T.E. Group : Open-width wet processing for knit fabric – a fast-emerging trend

Sustainability has emerged as a pivotal concern globally and the textile industry is no exception. Ecology and energy conservation are now focal points as much as quality and price.

Presently, knit textiles are predominantly processed in a tubular form. However, the demand for open-width processing is on the rise. The Indian knit processing industry is increasingly recognising the significant advantages of open-width knit fabric processing with respect to quality and savings of water and energy. This is clear from the ongoing trend wherein several processors have integrated open-width knit processing into their existing tubular knit processing setups.

Challenges faced with tubular knit fabric processing:

Inconsistent results due to batch process

Poor fabric surface quality due to aggressive handling

High weight loss

High chemical and dye consumption

High effluent loads

High fabric handling necessitates increased dependency on labor

A.T.E. offers complete solutions for Goller open-width knit fabric wet processing machines from Fong’s National Engineering Co., Ltd.: German technology made in China. Goller offers spun oil washing ranges, bleaching ranges, mercerizing ranges, cold pad batch dyeing, and washing ranges for dyed and printed knit fabrics in open form. Goller has established itself as a world leader for knit open-width wet processing with hundreds of successful installations worldwide. Goller’s success with open-width knit fabric processing stems from their modular design tailored to meet specific customer requirements that result in optimum results for the application.

Following are the various modules offered by Goller:

Oxidator washer a drum washer module with driven fabric transport and power spray for sensitive fabrics which requires dwell time for swelling and shrinkage

Sintensa washer a drum washer module with an inner propeller for effective washing with high turbulence

Universa conveyors compartment with bath separation and circulation spraying system for maintaining dwell time

Variety of chemical dosing systems based on application along with flow control

45° angle intermittent squeezer with scroll roll opening to prevent edge curling thereby avoiding crease formation or pressing

Auto filtering systems

Elastodip chemical applicator, with a long dwelling time of 2-3 minutes for good chemical exchange before bleaching steamer

Special S–wrap mangle for higher pickup of chemicals

A fabric reaction steamer with a built-in indirect steam generation system manages saturated steam conditions and a 100 degrees C+/-1 temperature. It includes tension-controlled drums for fabric preheating, roller or conveyor bed transport for dwell time, E+L centering, and double scroll roll at exit

In mercerising, specially designed roller section as impregnation compartment for dry on wet or wet on wet, room/hot mercerisation, auto caustic concentration control +/-0.5Be, st. upper roller and bottom rollers with load cell tension control in each section, pin chain with 4-5 sections (12-15m), width adjustment at each section, followed by tension-controlled washing and PH neutralisation results in best quality mercerisation

All the washers, except dwell time zones, have thermplate heating systems for effective and efficient heat transfer for energy conservation and reducing the water level in the compartment

Advantages of open-width knit processing over tubular fabric processing:

Improved surface quality

Reduced loss of weight and tensile strength

Less pilling

Excellent colour appearance

Less shrinking

Lower production costs

Less effluent loads

Clean department

Consistency in results

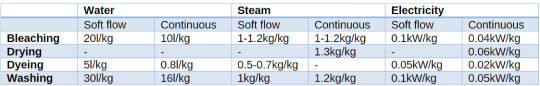

Comparison of utility consumption: Soft flow and continuous ranges

Source – data from Goller’s end users

Soft flow machine material to liquor ratio: 1:5, fabric width 2.2 m

Though the mercerising process has been an integral part of woven fabric processing to produce high-quality fabric, this was not available for knits in open-width form due to the challenges involved in handling knit fabrics in open form. Goller stands out as the pioneer in developing open-width knit fabric mercerising ranges and till date, they have installed 15 machines worldwide, including the one in India at PC Colours, Kolkata.

Mercerising helps to improve dye affinity which invariably leads to 15 to 20% dye savings, provides a deeper shade and more lustrous appearance, achieves excellent colour especially medium dark or dark, and improves the brightness after printing

Similarly, the cold pad batch dyeing method for reactive dyeing of cotton fabrics yields good dyeing results with lower effluent loads. Colour fixation in CPB dyeing is better compared to the exhaust method, requires less water for washing, reduced TDS of the effluent as no salt is used, and consumes no steam for dye fixation.

Open-width knit fabric process flow and a package of machinery from A.T.E.:

A.T.E.: a perfect partner for you

A.T.E. has always been dedicated to offering state-of-the-art, efficient, and eco-friendly equipment that helps customers gain a competitive advantage. The concepts of responsibility and technology are part of the values of A.T.E.

Apart from supplying a complete package of machinery for the processing industry, A.T.E. offers after-sales services, technological support, AMCs, machine audits, etc. A.T.E. has also successfully executed many green-field projects.

A.T.E. is a one-window solution provider in textile engineering across the textile value chain, backed by 80+ years of experience and deep domain knowledge. That is why in addition to textile machinery, we also offer state-of-the-art effluent treatment plants with IoT monitoring, sludge handling solutions and ZLD.

0 notes

Text

Top Benefits of Using Roll Packing Machines in Manufacturing

In the fast-paced world of manufacturing, efficiency and precision are key to staying competitive. A roll packing machine has become an essential tool, revolutionizing how products are packaged by streamlining processes, reducing costs, and ensuring product safety during transportation.

1. Enhanced Efficiency and Speed

A roll packing machine automates the packaging process, allowing manufacturers to handle large volumes of products quickly and efficiently. This reduces production time, meeting tight deadlines without compromising quality. Automated operations also minimize errors, ensuring consistent packaging across batches.

2. Cost-Effective Operations

By reducing the need for manual labor, roll packing machines lower labor costs significantly. Additionally, these machines optimize the use of packaging materials, cutting down on waste. Over time, the savings in labor and materials result in a substantial return on investment.

3. Improved Product Protection

Packaging is critical to ensuring that products reach their destination intact. A roll packing machine provides secure and uniform wrapping, protecting items from damage, dust, and moisture. This is particularly beneficial for delicate or high-value goods.

4. Customization and Versatility

Modern roll packing machines come with customizable settings to accommodate various product sizes and types. Whether packaging textiles, films, or industrial materials, these machines adapt to different requirements, making them versatile for diverse manufacturing needs.

5. Availability from Reliable Manufacturers

Choosing the right roll packing machine manufacturers is essential to ensure quality and reliability. Leading providers offer advanced machines that are durable, efficient, and equipped with the latest technology. For businesses looking for a roll packing machine in Delhi, options are available to meet local needs and specifications.

Conclusion

Integrating a roll packing machine into your manufacturing process enhances productivity, reduces costs, and ensures high-quality packaging. Terron India, a trusted name among roll packing machine manufacturers, offers state-of-the-art solutions tailored to the needs of modern manufacturers, ensuring efficiency and excellence.

#Pillow roll packing machine#roll packing machine#roll packing machine manufacturers#roll packing machine in delhi#roll packing machine manufacturers in delhi

0 notes

Text

Common Uses of Tata Structura Steel Pipes in Various Sectors

You must have known the offerings of Tata Structura steel pipes in the infrastructure sectors. Its inherent resistance to rust and durable qualities make it easy to install and highly customizable similar to staircase railing. Hence, it can be used in other sectors too.

Textile Sector

Steel pipes are a common choice in the textile sector for the production of carding machines, bale openers, winding machines, spinning machines, mixers and textile machines due to their high adaptability.

Oil & Gas Sector

Steel pipes are best suited in harsh conditions like corrosive environments, high pressure and intense temperature. For this reason, steel pipes are widely used in the oil and gas sector, especially in gathering lines (the tubes which carry oil or gas from a manufacturing area to a storage facility or a larger pipeline) and pipe trunk lines (large diameter, welded steel pipes used to carry natural gas over long distances). Steel pipe's durability and adaptability enable it to meet the specific demands of the oil and gas sector.

Agricultural Sector

Owing to their durability and pressure resistance, steel pipes are used in agricultural applications. Steel is occasionally combined with carbon to provide a lighter but robust agricultural fitting. Farmers and various agricultural organizations use steel pipes for various purposes, including vent pipe systems, fertilizer applications, tractor engines, and grain elevators.

Manufacturing Sector

Since steel pipes are rust-resistant and do not corrode, they are used in manufacturing facilities, warehouses and other industrial locations. Steel pipes provide manufacturing facilities with a lifetime of trust. Round steel tubing is frequently used in the transportation of liquids or gases from one region of an industrial plant to another, as well as in the construction of industry structures. Other Uses of Steel Pipes

Apart from these common applications, steel pipes are also used in other places, which include:

● Desalination

● Power Plants

● Energy Industries

● Diary and Food Processing Facilities

● Synthetic Fiber Production

● Modern Architecture

● Water Treatment Facilities

● Chemical Facilities

The Expansive Range of Tata Structura Steel Pipes

Tata Structura steel pipes are made up of hot-rolled steel coils that come in circular, rectangular, square and galvanized hollow sections.

Circular Hollow Section

The circular hollow sections have outstanding transverse strength and bending resistance, making them ideal for applications requiring superior structural integrity. The round shape promotes homogeneous stress distribution, while excellent welding and inspection techniques assure a long-lasting and dependable product.

Rectangular Hollow Section

Tata Structura steel pipes are designed to be versatile, and this section does perfect justice to that. The rectangular hollow section are ideal for an array of construction and engineering applications.

Square Hollow Section

Square hollow sections, with their excellent blend of strength and beauty, are suited for a wide range of uses, including architectural projects and structural framing. These portions are subjected to stringent quality control procedures to provide a dependable, long-lasting product.

Galvanized Hollow Section

The galvanized hollow sections of Tata Structura undergo a specific galvanization process that improves corrosion resistance. Because of this increased protection, they are appropriate for usage in locations where chemicals, moisture and corrosive substances are present.

Wrapping Up

Tata Structura steel pipes are considered the backbone of the best construction projects across India. Its importance has been realized in different industries. From being extremely durable to corrosion-resistant, steel pipes are the best fit for all kinds of industries. These pipes are made of steel coils, which ensures versatility and promises a strong and sustainable framework be it commercial or residential buildings, airport terminals, metro/railway stations, or industrial applications.

For detailed information on Tata Structura products, visit: https://www.tatastructura.com

0 notes

Text

Krishna Engineering Works dealing on manufacturing and exporting Roll Wrapping Machine. A genuine specialized supplier of Roll Wrapping Machine, Coil Wrapping. Our machines are designed with a wide range of quality for long lasting heavy duty process, specially for cutting in different sizes from 12 mm to 1000 mm. Also, we manufacturing of all types of Technical Textile Machinery. Stretch Film is an elastic polyethylene film, also known as Pallet Stretch Film. Fabric Roll Wrapping Machine is extensively used for packing & securing loads stacked in pallets & gives extensive protection from dust & rain.

#Fabric Roll Stretch Wrapping Machine#Automatic Paper Roll Wrapping Machine#Mild Steel Heavy Fabric Roll Stretch Wrapping Machine#Textile Roll Wrapping Machine#Fabric Rewinding Machine#Shrink Wrapping Machine for Roll#Wrapping Machine#Stretch Film Wrapping Machine#Automatic Pallet Wrapping Machine#Stretch Wrapping#Stretch Film Machine#Stretch Wrapping Machine#Paper Roll Wrapping Machine#Wrapping Roll Machine#Roll Wrapping Machine#Roll Stretch Wrap Machine#Fabric Roll Wrapping Machine

3 notes

·

View notes

Text

Designing Fate - T. Mitsuya

Synopsis: Majority of students join school clubs whether a sport or a something else that is their passion. Both Y/n and Mitsuya are in the same boat, stuck around bothersome teenage girls as they share a table in textiles.

Pairing: Takashi Mitsuya X Female Y/n

‘A guy?’

A small nod among others, their faces glued to one another. Snapping back and forth perfectly like the evil step sisters they portrayed. Between the five of them gossiping about little things, they used mostly their hands to hide the spiteful things that blurted out of their mouths like some sort of disease.

‘Yeah, that’s what the class roll said when the president looked over it. Thirteen girls, one boy.’

‘One boy?! Jeez he won’t be the looker, any guy who isn’t doing a sport is laughable.’

A small smile perked on your lips, yet they wouldn’t know. The overhanging shadow fallen from your hooding hid every single facial feature except for the white string that fell either side of your face from your headphones. The soft buzz of the beat you knew blew against the stale atmosphere.

‘Alright everyone!’ you heard the club president shout,

You followed the rest of the herd, until your shoulders brushed. Your eyes snapped in confusion yet met with ones that look too relaxed to do anything of the sorts maliciously. His hands were thrown in the pockets of his sweater. He stopped and followed behind you, as you entered the classroom. Majority of the desks were shoved together by groups of friends.

You found the first desk away from anyone, your feet laid upon the desk as you heard the buttons of his jacket hit the edge of the stool as he took a seat beside you. The regular murmur of females giggles and gossip filled the air as they slowly began on whatever little project caught their attention in the first second of even being in class.

Your eyes flickered back to him, from his back he pulled out a jacket that you hadn’t particularly seen before yet only knew the symbol. The fabric was mostly shredded apart from the writing that ran down the sides and on the front breast of it.

‘Tokyo manji?’ you muttered quietly,

You hadn’t faced a member before, yet your brother's fan cries about the juvenile gangs in the area and how they were so subpar from actual yakuzas. He only knew them because he was a yakuza member. His eyes lit up as they snapped towards you, your head leant towards the sky as the hood fell off your head before you stared down once again at the jacket.

‘Yeah how did you know?’ you heard him question,

You smirked softly, ‘my brothers a higher up in an actual yakuza,’

‘Actual?’ he grumbled,

His eyebrows raised, a smirk jerked upon his face as you could see some of his ego was chopped down. You didn’t mean it on purpose as you stared at him with a smile,

‘I mean he isn’t a boy riding around his mates.’

You heard his soft chuckle, strung between a man’s ego being knocked off its pedestal and actually finding it funny. He scratched his neck, you slowly held the fabric so it would bulge as it went through the sewing machine. Your eyes snapped, the faces of horrid little witches giggling as their heads snapped back to the front where they should have been originally.

‘There’s a meet up tonight,’ he paused, ‘How about you-’

You grimmed and placed your hoodie upon your head, covering your face once again, ‘So not even one lesson in and you already invited me on a date.’

He chuckled and nodded,

‘Well sure, prove me wrong.’ you chuckled,

Your arms wrapped around yourself, the jumper was beginning to grow thin as the wind snapped passed. The large mountain of bikes lined in a row made you think you were in the right place. You watched footmen walk up the stairs of an old temple. The thud was the first thing you heard before you felt it. It impressed upon your shoulders as a gasp of a breath escaped your lips.

The black jacket laid upon your shoulders, your eyes turned towards the owner of the jacket. He had a peculiar soft smile upon his face.

‘Thought you were a smart girl, it’s winter and it gets cold.’

Your eyes rolled, as his hands dropped from your shoulders and slacked into his pockets. Your eyes darted to the other men, in your arm closest to him you link arms the other trailing to your side. You walked up the steps and to find the crowd of men, they were laughing and playing with one another.

You rolled your eyes and kept glued to his side, his friends eyes popping wide made you smile. His hand pulled your hoodie off and you returned to favor with a glare. You met many of his friends especially his team yet you stayed glued to him the entire time the furthest you went was an arms length and that was to get a drink.

‘Thanks for tonight, Mitsuya.’

You smiled, pulling his jacket off your shoulders, folding it in your hands as you stood before your door. You handed it back to him, He chucked it over his shoulder, your arms wrapped around him as you gave him a small hug.

The familiar click of the door made you nervous, you watched his eyes grow wide and his grip on you go cold. Your eyes snapped back towards the door. Your brother stood there, a hand still upon the door knob as his face rested in anger.

‘Y/n, in.’ he grumbled, you were pulled by your hood into the door. You stood just in front of your father, seeing an almost shocked look on Mitsuya as you walked away.

You heard mutters of a conversation, yet nothing that you could honestly put your finger on or make out in words. Except, for Mitsuya saying yes sir like a broken record. You felt bad, you should have told him that your father was hard towards boys but you knew you would have to apologize to him tomorrow in the textiles club.

#mitsuya x reader#takashi mitsuya#mitsuya fluff#tokyo rev x reader#tokyo rev fluff#tokyo revengers#yn fanfic

103 notes

·

View notes

Photo

Side Chair, ca. 1881, Brooklyn Museum: Decorative Arts

TYPE: Side chairs (one of a pair) (Aesthetic Movement style) (Rockefeller residence) FRAME a. Materials: Oak b. Finish: Ebonized, appears to be original III UPHOLSTERY a. Cover: Red silk pile, replacement from 1954 b. Trim: Three types of trim: metallic cording with flange; figured galloon with metal yarns, possibly reused; outside back corded galloon, machine stitched c. STRUCTURE: Sprung seat, upholstered back (i) Webbing: Replacement; (ii) Eight springs, unavailable for inspection; (iii) Edges: Sewn to modest round; (iv) Cake: Two cakes; sewed up first cake with curled hair, additional layer that may or may not be reused from first presentation. "( Mellon Project 1997)" TEXTILE: Red-orange silk pile fabric of modern manufacture. TRIM: Three types of trim: (1) Figured galoon in pattern of conventionalized leaves has supplementary weft of gold-colored wrapped flat wire yarn, which used to be yellow and is now oxidized gray, and a silk warp. The galoon is stitched to the seat top and backrest in a simple rectangular meander pattern. (2) 1/4" diameter cord around seat edges and backrest is 3-ply plain cord, each ply consisting of metallic threads wound around yellow fiber core. Originally gold-colored, the dyes have now oxididized to gray. The cord is sewn to a 3" yellow twill tape which serves as a flange. The flange is fastened to the edge rolls with a cardboard tacking tape. (3" On the outside back, a corded gimped galoon consisting of a pale orange simple gimp (faded from red) surmounted by a 2-ply cord (pale orange, faded from untetermined original color) macine stitched in place. (Cross-referenced cord on seat perimeter of 40.604 Side Chair ( Elizabethan-Revival style). UNDERUPHOLSTRY: 8 springs. Tacking margins for cover and underupholstry (both sides) are shattered with holes, suggesting more than one refurbishment. ( see proper left rear corner of 53.245A). Viewing underupholstry from bottom, all new materials, including new cross members added to seat rails on all four sides to hold new webbing. Springs are a mix of structure and type (gray and black, some knotted) possibly some original springs remain (or they may simply represent a thrifty shop) First cake is curled hair; it may have been reused. The textile is attached in a modern way, because cording has a flange that is tacked along bottom and then the silk-pile fabric is sewn to cording. FRAME: Carved seatback, rails and fluted legs with large feet whihh are scooped out for casters. Four casters, marked " THE INDIA (RUBBER COMB) CO. NEW YORK'' on one side of the wheel. Too worn to determine if marked on the other side of the wheel. FINISH: Black paint (ebonizing) that is worn in high spots. ELEMENTS OF UPHOLSTRY THAT APPEAR TO BE ORIGNAL: Possibly some underupholstry layers. Size: 37 1/2 x 23 x 23 1/2 in. (95.3 x 58.4 x 59.7 cm) Medium: Ebonized oak, second generation upholstery, metal casters

https://www.brooklynmuseum.org/opencollection/objects/67684

3 notes

·

View notes