#Titanium Grade 1 Pipes & Tubes

Text

Calico Metal Alloys LLP is one of the main Manufacturers, Suppliers and Exporters of top notch Duplex 2205, UNS S31803, UNS S32205, UNS S32750, UNS S32760, Duplex 2202, Duplex 2304 pipe, Tube, sheet, plates, Coil, Shim Sheet flanges, fasteners in India at low price.

#ASTM A312 TP 304/304H Stainless Steel#Titanium Grade 1 Pipes & Tubes#Nickel Alloy 200/201#Aluminium Alloy 2014#Copper and Brass Alloys#Duplex Steel 2205#Titanium Alloys#Cobalt Alloys#Silver and Gold Brazing Alloys supplier from Mumbai#India.

0 notes

Text

Alloy Steel Buttweld Fittings Available Types

There are a variety of shapes and sizes available in alloy steel buttweld fittings. Fittings like these are used in a variety of industries, including automotive and industrial. Alloy steel fittings are made from alloy steels and other metals. The alloy steel buttweld fittings can be welded, machined, and heat treated to produce a wide range of products. When purchasing a set of steel fittings, as well as larger quantities, most fitting manufacturers offer package deals. Bulk purchases may also be discounted. Find out if shipping and handling charges are included in the pricing offered by your local supplier.

The article Alloy Steel Buttweld Fittings Available Types introduces Alloy Steel Buttweld Fittings Available Types. The book explains the composition and characteristics of alloy steel. The book includes detailed information on the basic machine processes and operating conditions of Alloy Steel Buttweld Fittings Available Types, heat treatment, machining procedures, and test methods for Alloy Steel Buttweld Fittings Available Types. To get a feel for what this product is like, you can also view our sample products. Do your research before buying.

Click on the links below to learn more about Alloy Steel Buttweld Fittings Available Types. A typical size is approximately 4 inches in diameter (roughly 0.926 inches thick) and 1/2 inch in thickness (roughly 0.127 inches thick). Standardized to BS EN 642 and AIB 6073, typical values are approximately 4 inches in diameter and 1/2 inch in thickness. Based on the total weight of the alloy, the material contains approximately 0.5% carbon by weight.

The versatile alloy of alloy steel buttweld fittings is used for a wide range of applications. Weldability, pressure bearing strength, and thermal stability are excellent. For superior durability under heavy loads, it possesses chromium, molybdenum, and ferrous. While fitting in the processing system, it resists corrosion caused by hazardous gases and chemicals. Weldable alloy steel buttweld fittings have a low carbon content and are resistant to carbide precipitation.

Various types of alloy steel buttweld fittings are made with chemical compositions of great strength and hardness. These chemicals include carbon, nickel, aluminum, manganese, titanium, and iron. There are even numerous specifications for these alloy fittings, such as size, standards, grade, types, thickness, forms, ends, surfaces, finishes, lengths, widths, applications, tolerances, conditions, and pressure.

Various properties of these alloy fittings include hardness, corrosion resistance, and sustainability at annealed temperatures. The properties of alloy fittings include thermal conductivity, electrical resistance, modulus of expansion, density, melting point, elongation, and electrical conductivity. There are numerous types of these fittings, including seamless, welded, fabricated, and ERW.

Among the many industries and general works that use alloy steel Buttweld Fittings are the pharmaceutical industry, gas processing, chemical equipment, pharmaceutical equipment, offshore oil drilling, industry, heat exchangers, condensers, seawater equipment, petrochemicals, power generation, food processing, paper mills, pulp mills, rail components, road transportation components, pumps, shafts, and military applications. The alloy steel Buttweld Fittings are made with several properties that enable them to be used in annealed temperatures and chloride environments without any deformation. The fittings are resistant to crevice corrosion, stress corrosion, cracking corrosion, pitting corrosion, and impact corrosion.

Pipe fittings (as opposed to Tube fittings) are butt-welded onto the pipe. They are produced according to different ‘schedules’. Based on the nominal bore pipe size, the schedule determines the wall thickness. It is common to find schedules 10 and 40, but schedules 80 and 160 are also available.

For more information visit

1 note

·

View note

Text

Stainless Steel 316Ti IBR Pipes & Tubes Manufacturers

Introduction:

Stainless Steel 316Ti Seamless IBR Pipes and Tubes finds widespread application in critical engineering processes, notably in sectors such as chemical industries, fertilizer units, and power plants. What sets our offerings apart are the value-added features they bring to the table. From steel for LPG cylinders to corrosion-resistant variants, API grades, boiler quality materials, critical structural application steel, auto grades, high/medium carbon grades, and precision tubes, we cater to diverse industrial needs seamlessly.

Description:

316Ti IBR Pipes and Tubes are available in a plethora of sizes, thicknesses, and specifications, tailored to meet the unique requirements of our esteemed clients. As Manufacturers, Suppliers, Stockists, and Exporters, we take pride in our commitment to delivering products of unmatched quality and reliability, ensuring utmost satisfaction for our clientele.

Stainless Steel 316Ti IBR Pipes & Tubes Standard Specifications

Stainless Steel Coil Tubing SpecificationsASME/ASTM A 213, A 269, A 312, IBR, EN/DIN, EN, UNSRange6 mm OD to 219.1 mm ODOuter Diameter6.00 mm to 60.00 mmThickness0.7 mm Thick To12.7 mm ThickLengthTube Length - 1 Mtr Upto 32 Mtrs Long / U-Tube Length – 32 Mtrs

Benefits:

Enhanced Corrosion Resistance: The addition of titanium in the 316Ti grade improves resistance to intergranular corrosion, making these pipes and tubes ideal for high-temperature applications.

High-Temperature Strength: Stainless Steel 316Ti maintains its strength and stability at elevated temperatures, ensuring reliable performance under thermal stress.

Durability and Longevity: These pipes and tubes offer high tensile strength and durability, reducing maintenance costs and extending service life.

Compliance with IBR: Adhering to Indian Boiler Regulations ensures that these products meet the highest safety and quality standards required for critical industrial applications.

Versatility: Suitable for a broad range of applications, including chemical processing, petrochemical industries, and power generation.

Product Overview:

Metinoxoverseas' Stainless Steel 316Ti IBR Pipes & Tubes are produced with meticulous attention to detail, employing advanced manufacturing techniques and stringent quality control processes. These products undergo comprehensive testing to ensure they meet the highest standards for dimensional accuracy, mechanical properties, and surface finish. Designed to handle the rigorous demands of high-pressure and high-temperature applications, these IBR-compliant pipes and tubes offer unparalleled reliability and performance.

Conclusion:

In conclusion, Stainless Steel 316Ti IBR Pipes & Tubes by Metinoxoverseas represent the epitome of quality and engineering excellence. Their superior corrosion resistance, high-temperature strength, and compliance with IBR make them essential for critical industrial applications. Supported by Metinoxoverseas' unwavering commitment to quality and customer satisfaction, these pipes and tubes deliver exceptional performance and longevity, significantly enhancing the efficiency and success of industrial operations.

For inquiries and orders, contact Metinoxoverseas at:

Phone: +91-98199 80997 / +91-70212 61928

0 notes

Text

Stainless Steel 321/321H Pipes & Tubes Stockists

INTRODUCTION:-

Alloy 321 is an austenitic SS that is titanium-balanced and has astounding general corrosion resistance. Moreover, it has an intergranular corrosion-safe breaking point straightforwardly following getting introduced to the temperature in the chromium carbide precipitation range of 427 to 816 °C. The alloy limits oxidation at 816 °C and holds high creep and stress-break properties. Additionally,

DESCRIPTION:-

Stainless Steel 321 and 321H are austenitic chromium-nickel stainless steels stabilized with titanium. The primary difference between the two grades lies in their carbon content: 321H has a higher carbon content, enhancing its strength at elevated temperatures. Both grades are known for their excellent resistance to intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range of 800-1500°F (427-816°C). This makes them particularly suitable for high-temperature environments.

SPECIFICATION:-

Specification

Range : 6NB to 1200NB

Outer Diameter : 1/8″ NPS to 12″ NPS

Thickness : 0.6 mm to 12.7 mm

Schedules : SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS.

Length : Single Random, Double Random & Cut Length

Specifications : ASTM A312 / ASTM SA312

Types : Round, Square, Rectangle, Hydraulic, Honed Tubes

End : Plain End, Beveled End

PRODUCT OVERVIEW:-

At Manilaxmi Industrial, the inventory of Stainless Steel 321 and 321H pipes and tubes is extensive and meticulously maintained to ensure quality and availability. The products are manufactured using top-grade raw materials and cutting-edge technology. The range includes seamless, welded, ERW, and EFW pipes and tubes, meeting various industrial demands. Each product undergoes rigorous quality checks and complies with international standards, guaranteeing reliability and superior performance.

CONCLUSION:-

Stainless Steel 321 and 321H pipes and tubes from Manilaxmi Industrial are renowned for their high quality, exceptional durability, and superior performance in high-temperature and corrosive environments. These products are essential for industries ranging from aerospace to chemical processing, offering reliable solutions for demanding applications.

For more information or to place an order, contact Manilaxmi Industrial at [email protected] or call +91-7710800415. Trust Manilaxmi Industrial for all your stainless steel needs.

0 notes

Photo

New Post has been published on https://www.vividracing.com/blog/top-5-best-exhausts-for-the-mk8-vw-golf-gti/

Top 5 Best Exhausts for the MK8 VW Golf GTI

Upgrading your Volkswagen Golf GTI Mk8 with a high-performance exhaust system can significantly enhance its performance and sound. Here are five of the best exhaust systems for the GTI Mk8, each offering unique features and benefits.

youtube

1. AWE Touring Edition Exhaust

Price: $1,310.53 (on sale at Vivid Racing for $1,245)

The AWE Touring Edition Exhaust is the first for the VW GTI to feature patented drone-canceling 180 Technology. It offers a deep, hearty tone without drone, thanks to a bespoke straight-through mid-pipe resonator. The system includes 5″ double-walled slash-cut tips, CNC mandrel-bent T304L stainless steel construction, and a direct bolt-on installation. It’s backed by AWE’s No CEL Guarantee, Perfect Fitment Guarantee, and Lifetime Warranty.

2. Borla Catback Exhaust System S-Type

Price: $1,054.99 – $1,499.99

The Borla S-Type Catback Exhaust System is a 3″ diameter system featuring 4″ bright chrome tips. It uses Borla’s patented straight-through and multi-core technology for increased exhaust velocity, power, and the distinctive Borla Sound of Power. Made from premium T-304 stainless steel, it ensures durability and performance, backed by Borla’s Million-Mile Warranty.

3. Milltek 80mm OPF/GPF Catback Exhaust System

Price: $1,719

Milltek’s Catback Exhaust System features brushed titanium GT-115 tips and high-quality type 304 aircraft-grade stainless steel construction. It enhances engine responsiveness and power output, providing a genuine performance edge. The system is EC approved, ensuring compliance with European emissions standards, and offers a direct bolt-on installation.

4. Neuspeed Stainless Steel Catback Exhaust System

Price: $1,599 (on sale at Vivid Racing for $1,519)

The Neuspeed Catback Exhaust System uses T304 stainless steel mandrel-bent tubing with passive/active resonator and Helmholtz drone-canceling technology. It offers a direct-fit to the OE downpipe and includes stainless steel dual 4″ polished slash-cut tips. Designed and engineered in California, this system ensures precision fitment and maximum flow.

5. XForce Varex Catback System

Price: $1,200 (on sale at Vivid Racing for $1,080)

The XForce Varex Catback System features a 3″ 304 stainless steel construction with a Varex muffler for adjustable sound output. It includes a remote control for customizing sound levels and an optional resonator-delete pipe. The system also has dual 4″ polished stainless steel tips and a straight-through design for maximum power and sound.

Summary: Best Value for Price

For those looking for the best value, the AWE Touring Edition Exhaust stands out. Priced at $1,310.53 (or $1,245 on sale), it offers a perfect balance of performance, sound, and high-quality construction. With patented drone-canceling technology and a direct bolt-on installation, it provides excellent value without compromising on quality.

Let us help!

Each of these exhaust systems offers unique advantages for the Volkswagen Golf GTI Mk8, allowing you to choose the one that best fits your performance needs and budget. As always, if you have any questions regarding upgrades for your vehicle these exhaust kits specifically, we are enthusiasts who genuinely believe in supplying fellow enthusiasts with the best mods to meet your driving goals! We have almost 12,000 reviews and a 4.6/5 review on Google to prove it 😏

You can chat with us – HERE (Live Chat). We’ll get back to you like, spooky fast.

Reach out to us at [email protected] or give us a call at (480) 966-3040 📞 and we’ll be happy to help with your questions or be a shoulder to cry on.

0 notes

Text

Titanium Gr 9 Pipes & Tubes Stockists

Titanium Grade 9, also known by its designation Ti-3Al-2.5V, is a titanium alloy that strikes a balance between the ease of manufacturing and mechanical properties. It's one of the most widely used titanium alloys and is valued for its high strength, light weight, and corrosion resistance. Here’s an in-depth look at Grade 9 titanium pipes and tubes and some advice on sourcing them.

Overview of Titanium Grade 9 (Ti-3Al-2.5V)

Properties:

Strength and Ductility: Ti-3Al-2.5V offers higher strength than commercially pure grades but is not as strong as Ti-6Al-4V. It maintains good ductility and toughness.

Corrosion Resistance: It has excellent resistance to corrosion in a range of environments, making it suitable for marine and chemical applications.

Weldability: Good weldability, which is critical for fabrication involving welding.

Flexibility: Higher flexibility compared to other titanium alloys, which is beneficial in applications requiring formability and bending.

Applications:

Aerospace: Used in hydraulic systems and in structural components where flexibility and corrosion resistance are needed.

Chemical Processing: Pipes and tubing for carrying corrosive substances.

Marine: Marine hardware, and in the desalination plants due to its excellent resistance to the corrosive effects of sea water.

Automotive: In high-performance automotive applications, particularly where weight savings are crucial.

Sports Equipment: Bicycles, golf clubs, and other sporting goods benefit from its lightweight and strength.

Sourcing Titanium Grade 9 Pipes and Tubes

1. Identifying Suppliers:

To source Ti-3Al-2.5V pipes and tubes, look for suppliers specializing in titanium and high-performance alloys. Consider leading companies in the industry, such as:

Titanium Industries, Inc.

Supra Alloys

ATI Metals

Specialty Metals Corporation

2. Specifications and Requirements:

When contacting suppliers, specify the exact requirements including:

Diameter and Wall Thickness: Match the specifications needed for your application.

Length and Quantity: Be clear about the lengths needed and the total quantity to get bulk pricing if applicable.

Certifications Required: Ask for certifications like ASTM B338, which covers titanium and titanium alloy tubes for condensers and heat exchangers.

3. Quality Assurance:

Ensure that the suppliers provide material test reports (MTRs) and that they follow quality assurance standards like ISO 9001.

4. Sample Validation:

If possible, request samples to validate quality and ensure the material meets your application’s requirements before placing a large order.

5. Pricing and Delivery:

Discuss pricing, payment terms, and delivery schedules. Given the specialized nature of titanium alloys, lead times can be significant.

Conclusion

Titanium Grade 9 pipes and tubes offer a unique combination of strength, corrosion resistance, and flexibility, making them suitable for a diverse range of applications. When sourcing these materials, it’s crucial to work with reputable suppliers who can provide high-quality materials and comprehensive support. Always verify the specifications and test the material if possible, to ensure it meets your specific needs before committing to a large volume purchase.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

0 notes

Text

Titanium Gr 1 Pipes & Tubes Exporters In India

Ganpat Metal Industries is one of the central relationship for the social event, giving and trading of Titanium Gr 1 Pipes & Tubes. We supply Titanium Tubes to our clients in different distances across, sizes, nuances, types, lengths, structures, and so on.

Titanium Gr 1 Pipes & Tubes Manufacturers In India, Titanium Gr 1 Pipes & Tubes Suppliers In India, Titanium Gr 1 Pipes & Tubes Stockists In India, Titanium Gr 1 Pipes & Tubes Exporters In India

Titanium Gr 1 Pipes & Tubes

The titanium utilized in the production of chambers and lines is an austenitic blend. These titanium grade pipes provided for the clients are made by and large and public quality standards. The lines gave are per the client's necessities and decisions. Titanium is utilized considering how it is maybe of the most grounded metal which have ascribes like high solidness, strength, extraordinary use obstacle, and so forth. In the event that you are searching for the best quality, nothing is superior to Titanium Gr1 Pipes & Tubes. These are utilized in associations that require such Pipes & Tubes that can traverse a considerable number of over the top circumstances. This affiliation supplies them in various sorts like dependable, made and welded types.

Titanium Gr 1 Pipes and Tubes are utilized in different associations like preparation, flight, substance undertakings, military applications furthermore in the gathering of sports stock. It is moreover utilized in the clinical, marine industry, Oil and gas assessment associations, Automobile undertakings and Hydrocarbon adventures and treatment workplaces.

#Titanium Gr 1 Pipes & Tubes Manufacturers#Titanium Gr 1 Pipes & Tubes Suppliers#Titanium Gr 1 Pipes & Tubes Stockists

0 notes

Text

Titanium Gr 1 Pipes and Tubes Stockists In India

Deep Steel Centre takes pride in being a leading facilitator in the supply and trade of Titanium Grade 1 Pipes and Tubes, catering to a diverse clientele across different regions. Our dedication lies in offering an extensive range of Titanium Pipes tailored to meet varying specifications, sizes, types, lengths, and configurations, ensuring optimal satisfaction for our customers.

The titanium utilized in the production of our Pipes and Tubes belongs to the austenitic alloy category, guaranteeing exceptional quality that adheres to stringent international standards. Crafted with precision and expertise, our Tubes are customized to align with the unique requirements and preferences of each client. The choice of titanium is deliberate, owing to its remarkable attributes such as high strength, durability, outstanding corrosion resistance, and more.

In pursuit of excellence, Titanium Grade 1 Tubes and Pipes from Deep Steel Centre stand out as the epitome of quality and reliability. Their robust construction makes them well-suited for applications in industries that demand resilience in the face of challenging conditions. Our diverse range includes seamless, fabricated, and welded variants, catering to a spectrum of industrial needs.

At Deep Steel Centre, our commitment extends beyond mere product delivery. We prioritize customer satisfaction and strive to provide comprehensive support throughout the procurement process. Our team of experts ensures seamless transactions and prompt assistance, guaranteeing a hassle-free experience for our valued clients.

In conclusion, Titanium Grade 1 Pipes and Tubes from Deep Steel Centre symbolize excellence, durability, and versatility, making them the preferred choice for critical applications across diverse industries. With our unwavering commitment to quality and customer satisfaction, we continue to set the benchmark in the realm of titanium products.

Specification of Titanium Gr 1 Seamless / Welded Pipes and Tubes

Specification : ASTM B861, B338, B388, B862 / ASME SB861, SB338, SB388, SB862

Pipe Range : ½”NB to 24”NB / SCH 10 – SCH XXS

Tubes Range: 1mm OD to 254mm OD / Thickness 0.1 to 20mm.

Type : Seamless / ERW / Welded / Fabricated Pipes

Form : Round, Square, Rectangular, Oval, Hydraulic Etc

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

Schedule : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Inspection, Test Reports : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing : Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials : Sizes and Specifications other than above can be manufactured on request

For more Information

Visit website:https://www.deepsteelalloys.com

Email: [email protected]

Contact: 9930466755

0 notes

Text

Steel Tube Manufacturers: Pioneering Sustainability in the Age of Industrial Progress

Piping Projects is one of the leading Steel Tube Manufacturers in USA. We manufacture and supply a wide range of steel tubes, including carbon, seamless and welded, with wall thicknesses up to 40 mm and OD ranges of 12.7 mm to 906 mm. We use different materials to manufacture steel tubes. Pipingprojects.us is a top Steel Tube Supplier in USA. We use premium quality raw materials which enhance the durability and performance of Steel Tube.

Various materials and grades such as Brass, copper, stainless steel 304/304L, 316L, duplex, titanium, alloy 600, alloy 400, alloy 625, alloy 825, and alloy C276 to manufacture Steel Tubes.

In a world where environmental concerns are at the forefront of global discussions, industries are under increasing pressure to innovate and embrace sustainable practices.

Steel Tube Manufacturers have stepped up to the challenge, playing a vital role in pioneering sustainability in the age of industrial progress. Let's explore how these manufacturers lead the way towards a greener future.

The Evolution of Steel Tube Manufacturing:

Steel tube manufacturing has come a long way from its traditional roots, with modern techniques and technologies revolutionizing the industry. Here's how steel tube manufacturers are embracing sustainability:

1. Use of Recycled Materials:

Steel Tube Manufacturer are increasingly turning to recycled materials to reduce their environmental impact.

Manufacturers are reducing waste and conserving natural resources by incorporating recycled steel into their production processes.

2. Energy-Efficient Practices:

Energy consumption plays a significant role in the manufacturing process. Steel Tube Supplier are investing in energy-efficient technologies to minimize their carbon footprint.

Manufacturers are making significant strides towards sustainability by optimizing their operations and utilizing renewable energy sources.

3. Waste Management and Recycling:

Waste management is a critical aspect of sustainability in manufacturing. Steel tube manufacturers are implementing robust recycling programs to minimize waste generation.

By reusing scrap materials and adopting circular economy principles, manufacturers are reducing landfill waste and promoting a more sustainable approach to production.

Innovations in Sustainable Steel Tube Production:

In addition to adopting eco-friendly practices, steel tube manufacturers drive innovation in sustainable production methods. Here are some notable advancements:

1. Green Coating Technologies:

Manufacturers are developing environmentally friendly coating technologies that reduce the use of harmful chemicals and emissions.

These green coatings enhance the longevity of steel tubes and contribute to a cleaner, more sustainable manufacturing process.

2. Lightweighting and Material Optimization:

Steel tube manufacturers focus on lightweight solutions and material optimization to reduce energy consumption during transportation.

Manufacturers contribute to lower fuel consumption and emissions in the transportation sector by designing lighter tubes without compromising strength.

Conclusion:

Steel tube manufacturers are at the forefront of sustainability in the industrial landscape, spearheading innovation and embracing eco-friendly practices. By prioritizing using recycled materials, implementing energy-efficient measures, and driving advancements in sustainable production methods, these manufacturers are setting a new standard for environmentally conscious manufacturing. As we look to the future, it's clear that steel tube manufacturers will continue to play a pivotal role in shaping a more sustainable and resilient industrial sector. We are also USA top Welding Electrode Manufacturers.

Website: pipingprojects.us

#Steel Tube Manufacturers in USA#Steel Tube Supplier in USA#Steel Tube Manufacturers#Steel Tube Manufacturer#Steel Tube Supplier#Steel Tube Suppliers#Welding Electrode Manufacturers

0 notes

Text

Serve a number of purposes with stainless steel sheets.

A stainless steel plate has a thickness of.01875 inches and a width of 10 inches. It can be rolled or forged from steel. The corrosion resistance, strength, ductility, and aesthetic appeal of stainless plates are well-known. Stainless plates are available in a wide range of thicknesses and grades.

These are but a handful of the many uses for which stainless steel plates have become so popular. Here are some popular stainless grades used in plate form and the types of businesses that rely on them. The effort done by ss compression fittings has been remarkable.

304/304l

The austenitic stainless steels 304 and 304l are composed of at least 18% chromium, 8% nickel, and less than 1% carbon. 304L is chemically identical to type 304 stainless steel, save for a lower carbon content that makes it more resistant to intergranular corrosion following heat treatment or even welding. India is home to several brass compression fittings producers.

Grades 304 and 304l are widely utilized for a variety of purposes, particularly in chemical equipment and nuclear and cryogenic vessels due to their great corrosion resistance and robust mechanical qualities. This graphic on the measurements of copper compression fittings is excellent.

Because of their resistance to corrosion, 304 stainless plates are frequently used in the construction of equipment for sectors like the food industry, where hygienic conditions and the prevention of product contamination are of the utmost importance.

With the exception of a lower carbon content, 316l stainless steel is chemically identical to its brother, 316 stainless. The addition of molybdenum gives 316L stainless plates superior corrosion resistance in chemical and marine environments, but having the same strength as 304L. India has some of the best inconel tube fittings in the world.

316l steel, especially in stainless steel plate form, has been found to be useful in cryogenic applications due to its low melting point, strong strength at low temperatures, and simplicity of production. You can always rely on 304 stainless steel compression fittings to save the day.

It is true that 410 410 is a martensitic stainless steel, famous for its hardness and mechanical strength after heating. Grade 410 stainless steel is ideal for uses that need greater levels of strength and corrosion resistance in addition to mild heat resistance. 316 stainless steel compression fittings are totally trustworthy.

410 stainless plates may be found in a wide variety of settings, including medical and dental instruments, oil well pump parts, and paper and pulp industry strainers and screens. The manufacturers of high pressure fittings in India are top-notch.

Weldability, hardness, and corrosion resistance are just some of the reasons why type 17-4 stainless steel has been so popular in recent years. Titanium tube fittings are utilized in many industries, from aerospace to food processing, and are the most popular stainless steel type in their class. Pipe bends made of stainless steel are inexpensive.

For further details on the stainless plates and grades that might work for your project, contact a reputable stainless-steel supplier. 3LPE Coated Pipes are readily available.

0 notes

Text

#ASTM A312 TP 304/304H Stainless Steel#Titanium Grade 1 Pipes & Tubes#Nickel Alloy 200/201#Aluminium Alloy 2014#Copper and Brass Alloys#Duplex Steel 2205#Titanium Alloys#Cobalt Alloys#Silver and Gold Brazing Alloys supplier from Mumbai#India.

0 notes

Text

Titanium Gr 2 Pipe Fittings Exporters

Concerning conveyed fittings Sankalp Alloys Overseas What's more, Engg.CO. is the prominent name in the diagram of producer, supplier and stockiest. Titanium Gr 2 Forged Fittings are given and made by them in especially magnificent quality besides give in substitute perspectives. The interest for size and thickness, etc is changed by the client needs.

Titanium is a piece of compound with atomic number 22 and picture T1. It is a splendid metal with a low thickness, high strength, and silver tone. It is use certification from chlorine, water regia, and seawater. It is alloyed with vanadium, iron, molybdenum, aluminum, and press to convey, serious areas of strength for basic for lightweight for military, air transportation, dental improvements, clinical prostheses, outside courses of action, cells, etc. Coarseness to thickness and use block is the two principal parts of titanium.

Mental fortitude to weight degree is best in titanium Grade 2 of any utilization safe material. One of the most noticeable Titanium is Grade 2 and it is used for toward the ocean oil foundation water pipelines, clouding plants in the paper business and condenser tubing, and furthermore used as power exchangers for unequivocal applications. Titanium Grade2 has outstanding thickness what's more a good partner of warm conductivity. Likewise, the modulus of adaptability is in this way stunning and the embellishment point is 3040 Degree Celsius here. It has a limit flexible and yield strength. It is open in hot rolled, dull finishing, smooth acknowledgment, wonderful sickness moved matte fulfillment and various apexes available.

Titanium Gr 2 Forged Fittings can be used in any application in which use deterrent and formability are major and the central of assurance is standard. To achieve moderate raise in strength it is heat treatable. Titanium Gr 2 Forged Fittings for the most part survey applications for oil refining, biomedical, heat exchangers, besides coordinate compound cycles. It is overall around found in the set condition.

The material is fittingly tried to make them as shown by the temperature of the remainder of the world. The test joins Chemical Analysis, Flattening test. More humble than conventional and enormous expansion test, positive material specific assertion, hardness test .communicating test, etc. Squashing is done by avoid the last seasons of mischief and what's more according to the client need. Bed packaging and squeezed wood cases smashing are all around loved.

Specification of Stainless Steel 347/347H Forged Fittings

Stainless Steel Forged Fittings Specification : ASTM A182 / ASME SA182

Dimension Standard : ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799

Size : 1/8" NB to 4" NB

Type : Socketweld Fittings, Screwed-Threaded Fittings (NPT or PT Type)

Rating Pressure : Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS.

#Titanium Gr 2 Pipe Fitting Manufacturers#Titanium Gr 2 Pipe Fitting Suppliers#Titanium Gr 2 Pipe Fitting

0 notes

Text

Titanium Gr. 11 (3.7225) Welded Pipe Manufacturers In India

Kobs India is one of the great Suppliers, manufacturers and Exporters of first rate Titanium Grade 1 Pipes and Tubes. Our Pipes and Tubes are tributes of our quality standards. Titanium Grade 1 Pipes and Tubes is the gentlest titanium having the blend of particular features like: most lifted malleability, awesome cool formability and an eminent resistance from smooth to high oxidization. This Titanium Grade 1 Pipes and Tubes is appeared as consistent seamless and welded funnels.

Titanium has some special characteristics like low density, strong, lustrous, corrosion resistant, high tensile strength and toughness. So, it has great features and offer good functionality and performance. These Titanium Grade 1 Pipes and Tubes are used as a piece of various application industry. Working towards the purpose of client satisfaction, we offer these things and no more sensible industry costs. These Titanium alloy Grade 1 seamless and welded pipes & tube are available in various grades (UNS R50250) and in various standard (ASTM B861, B338, B388, B862 / ASME SB861, SB338, SB388, SB862) and varied sizes (½”NB to 24”NB / SCH 10 – SCH XXS).

ASTM B338 Welded Pipes, High Temperature Welded Pipes, SCH20, SCH30 Welded Pipes, Titanium Alloy Welded Pipes, Electropolished Pipes, Titanium Alloy Gr.2 (3.7035) / Gr.3:(3.7055) Welded High Temperature Pipe Stockiest.

Material & Grade :

Stainless Steel :Grade: 304, 304L, 304H, 309, 309S, 310, 310S, 316, 316H, 316L , 317, 317L, 321, 321H, 347, 347H, 904L

Duplex Steel:Grade: 2205

Super Duplex Steel:Grade: 2507 (UNS S32750)

Inconel :Grade: Inconel 600, Inconel 601, Inconel 625, Inconel 718

Incoloy :Grade: Incoloy 800, Incoloy 800H, Incoloy 800HT

Nickel :Grade: Nickel 200, Nickel 201

Monel :Grade: Monel 400, Monel K500, Monel R-405

Hastalloy :Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X.

For More Information-

Visit our website -http://www.kobsindia.in/titanium-welded-pipe.html

Contact us - 9819523999

Email [email protected]

0 notes

Text

Most Common Types and Grades of Carbon steel pipes

Carbon Steel Pipes, ASTM A106 Carbon Steel Pipes, Carbon Steel A53 Pipe, Carbon Steel Welded Pipes, Carbon Steel Seamless Pipes Manufacturer, Supplier, and Exporter in India

Carbon steel pipe is used as the base pipe in bimetallic combination tubing, which has an internal liner made of stainless steel, titanium alloy steel, copper, or aluminium, among other materials.

Bright Steel Centre is one of the Largest Carbon Steel Pipes Manufacturer in India. We have been an important part of the growth and also development of the Indian market as well as quality exports. We manufacture ASTM A106 carbon steel pipe in various sizes, shapes and also with different specifications.

Bright Steel Centre is India’s best leading ASTM A106 Carbon Steel Pipes Manufacturer in India. Carbon Steel Pipes are available in various types such as Seamless / ERW / Welded / Fabricated / LSAW Pipes. Carbon Steel Seamless Pipes is one of the types of Carbon Steel Pipes.

Types of Carbon Steel Pipes

1. Carbon Steel Seamless Pipes

The seamless carbon steel pipe is formed by perforating a steel ingot or a solid tube blank, and then hot rolled, cold rolled or cold drawn. We manufacture Carbon Steel Seamless Pipe in various sizes, shapes and also with different specifications as per the requirements of our valuable clients. Carbon Steel Seamless Pipes has a very high resistance to corrosion, but it is becoming increasingly expensive day by day.

Learn more About Carbon Steel Seamless Pipes Manufacturer in India

2. Low Temperature CS Seamless Pipes

Bright Steel Centre is India’s best leading Low Temperature CS Seamless Pipes Manufacturer in India. Low Temperature CS Seamless Pipes are available in various types such as Seamless / ERW / Welded / Fabricated / LSAW Pipes. They are also available in various forms such as Round, Square, Rectangular, Hydraulic and many more. The size of LTCS A333 Pipes is 1/2” NB to 36” NB.

Learn more About Low Temperature CS Seamless Pipes Manufacturer in India

Carbon steel pipes Grades

1. ASTM A106 Gr. B Carbon Steel Pipes

ASTM A106 Carbon Steel Grade B Square Pipes has a very high resistance to corrosion, but it is becoming increasingly expensive day by day. Our Supplied ASTM A106 Gr.B Carbon Steel Pipes are known for its reliability and quality all across the world. Bright Steel Centre is one of the Largest ASTM A106 Gr. B Carbon Steel Pipes Manufacturer in India.

Learn more About ASTM A106 Gr. B Carbon Steel Pipes Manufacturer in India

2. LSAW Carbon Steel Pipes

Carbon Steel LSAW pipes are mainly used as a long distance transportation pipeline for liquid coal, oil, gas on land and offshore. Also, LSAW Pipe can be applied as construction pipes on power station, offshore platform, petrochemistry and city construction etc.Carbon Lsaw is made up from High Quality of Standard Raw Materials.

Learn more About LSAW Carbon Steel Pipes Manufacturer in India

For more Details Carbon Steel Pipes Manufacturer in India

You Might Also Like Alloy Steel Pipes Manufacturer in India

#carbon steel pipes#Carbon Steel Pipes Manufacturers#CS Pipes#ASTM A106 Carbon Steel Pipes#Uses Of Carbon Steel Pipes#Carbon Steel Pipes Supplier#Carbon Steel Pipes Manufacturer in India#Pipes#Steel Pipes

2 notes

·

View notes

Photo

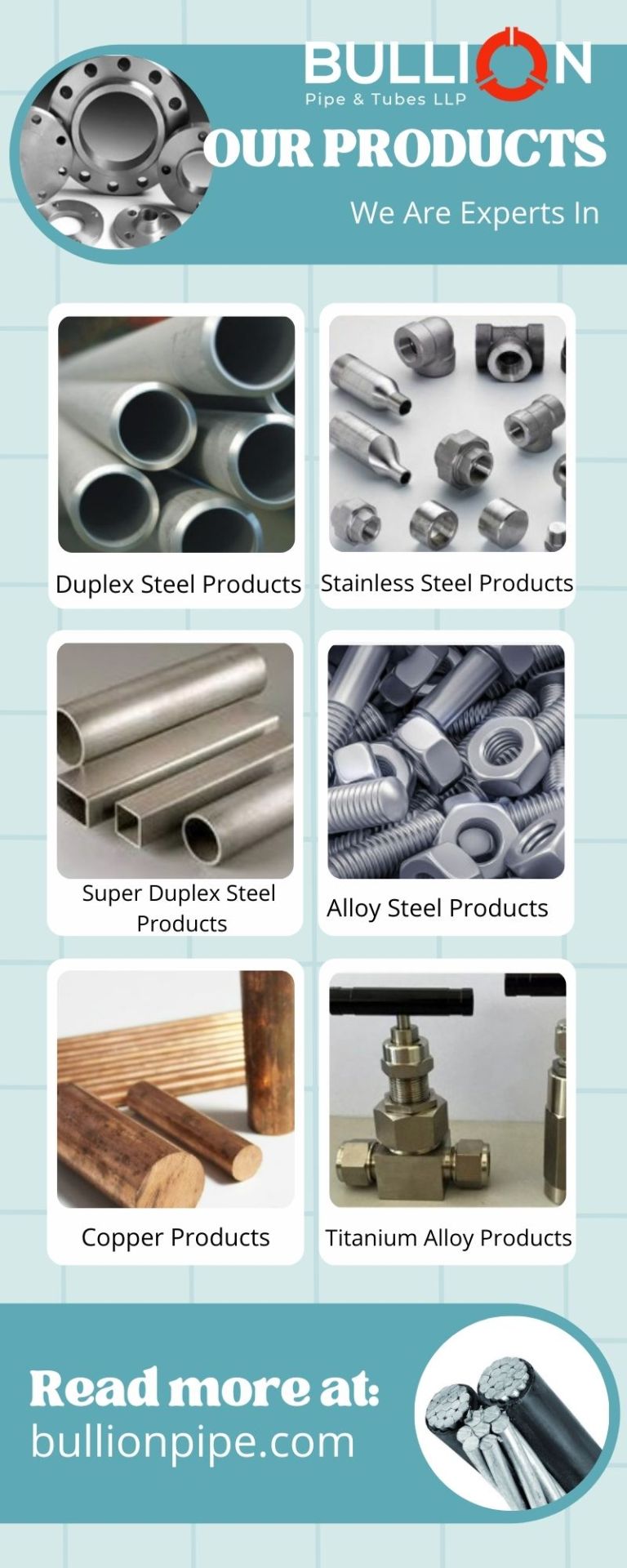

𝐁𝐮𝐥𝐥𝐢𝐨𝐧 𝐏𝐢𝐩𝐞𝐬 𝐄𝐱𝐩𝐞𝐫𝐭 𝐈𝐧:

1. Duplex Steel Products

2. Stainless Steel Products

3. Super Duplex Steel Products

4. Alloy Steel Products

5. Copper Products

6. Titanium Alloy Products

7. Carbon Steel Products

8. Hastelloy Products

9. Nickel Alloy Products

Know more about us at www.bullionpipe.com

Bullion Pipes is a proud manufacturer & supplier of different material-based raw materials like pipe, sheets, tubes, flanges, bars, pipe fittings in Stainless Steel, and High Nickel alloys such as Copper, Inconel, Carbon Steel among other exotic grades. At Bullion Pipe Pvt. Ltd, the international quality products we manufacture go through exhaustive R&D and rigorous inspection. Our quality control department is equipped with highly accurate measurement and inspection devices and manned by efficient & capable engineers.

#DoubleFerruleFittings #HydraulicPipeClamps #SingleFerruleFittings #QuickReleaseCoupling #InstrumentationValvesandTubeFittings #HydraulicFittings #HydraulicSAEFlanges #ManifoldValves #HydraulicTubeClampsandAccessories

#HighPressureFittings #InstrumentationTubeFittings

#StainlessSteelButtWeldFittings #StainlessSteelFlanges #StainlessSteelSeamlessPipesandTubes

#SpecialProducts #SwivelFittings #CondensatePotandAirHeader

#SAEFlanges #ThermowellFittings #HydraulicPressureTestPumpandPressureGauge

#NEEDLE VALVES#Ball Valves#Double Ferrule Fittings#Hydraulic Pipe Clamps#Single Ferrule Fittings#Quick Release Coupling#Instrumentation Valves & Tube Fittings#Hydraulic SAE Flanges#Hydraulic Fittings#Hydraulic Tube Clamps & Accessories#Manifold Valves#High Pressure Fittings#Instrumentation Tube Fittings#Stainless Steel Butt Weld Fittings#Stainless Steel Seamless Pipes & Tubes#Special Products#Stainless Steel Flanges#Swivel Fittings#Condensate Pot & Air Header#SAE Flanges#Thermowell Fittings#Hydraulic Pressure Test Pump & Pressure Gauge

1 note

·

View note

Photo

New Post has been published on https://www.vividracing.com/blog/top-5-best-exhausts-for-the-bmw-f80-m3-and-f82-m4/

Top 5 Best Exhausts for the BMW F80 M3 and F82 M4

Back in 2014, at the North American International Auto Show (NAIAS), the new BMW M3 officially premiered. At the same time, the first BMW M4 hit the spotlight with the German marque separating the Coupe and Convertible from the Sedan. Technically, there was a further innovation in the BMW F80 M3 and F82 M4: for the first time in the series’ history, there was a turbocharger under the muscular hood with the inline six-cylinder engine (S55B30). The goal was to combine the benefits of a high-performance, naturally aspirated motor with the strengths associated with modern turbo technology.

Even with an impressive factory output of 431 horsepower and 406 pound-feet of torque, many owners itch to squeeze out even more power from the engine. After all, factory exhaust systems are designed to maximize horsepower while keeping engine noise to a tolerable level. While this is acceptable for the average consumer, it leaves much to be desired in the hands of the automotive enthusiast. For those dedicated to unlocking the potential performance and excitement in their BMW, a powerful and loud aftermarket exhaust system can make all the difference. The following is a list of the top 5 best exhaust options for the BMW F80 M3 and F82 M4 based on their power gains, exhaust notes, aesthetics, and overall construction.

1. VR Performance Titanium Exhaust System

The VR Performance Titanium Exhaust for the BMW F80 M3 and F82 M4 was born from precision structural and sound engineering. It was built specifically for these models to deliver increased sound and performance that will get you noticed as you zip by. Crafted from authentic high-quality titanium, this pie-cut system with mandrel-bent tubing combines the best of enhanced performance, unmatched exhaust tone, and a solid overall construction that is made to last.

This exhaust has been tuned to perfection and designed to elevate your BMW M3 or M4 to the next level with incredible sound and styling. The VR Performance exhaust produces a refined sound output that encompasses the sporty note of the S55B30 engine that can be found under the hood. Thanks to the Valvetronic design, you can change your M3 or M4 exhaust note with just the push of a button to switch between mild and wild modes. Best of all, this is a complete bolt-on exhaust that directly fits in place of the factory one without any cutting or welding needed.

The VR Performance system features a true dual 2.5-inch diameter and 0.4mm thick piping to ensure optimal airflow without sacrificing weight. The mandrel-bent and pie-cut titanium construction of this system allows for a “best of both worlds” situation for any BMW enthusiast as you reap the benefits of the advanced build without having to worry about any excess stress or weight to the vehicle. In fact, this system weighs in at just 51 pounds – that’s super lightweight compared to stock! At the rear, this exhaust features quad 3-inch burnt titanium tips to give the back end a more customized and sporty appeal that shows you mean business.

Features:

Total weight is 51.05 pounds

Super lightweight compared to stock

Delivers a fantastic exhaust note

Increases horsepower and torque

Features Valvetronic functionality

2.5-inch Diameter, 0.4mm thick piping

Made using high-quality titanium

3-inch Burnt titanium exhaust tips

Direct-fit, bolt-on installation

2. Eisenmann Axleback Exhaust w/ Signature Tips

Eisenmann’s Stuttgart-based engineers are responsible for designing the OEM systems found on Porsche and AMG cars. They use this exact experience to design some of the greatest performance exhaust systems in the world. Eisenmann exhausts are built by hand from start to finish to create old-world craftsmanship that is simply unmatched on the automotive aftermarket. That being said, the Eisenmann Axleback Exhaust with Signature Tips will not only add attractive styling to your M-powered vehicle, but also deliver unparalleled performance, power gains, and overall premium construction that other competitors simply cannot match up to.

The construction of nearly all Eisenmann exhaust systems, both externally and internally, is made up of 100 percent lightweight, high-grade T304/T306 stainless steel throughout. Not only that, but its engineers paid specific attention to factors like wall thickness to create the best balance of reduced weight and an amazing sound. The canisters are machine-pressed into a shape specifically designed for the F8X M cars using a series of deep draw dies, which results in extremely high rigidity and contributes to that iconic Eisenmann tone. The canister shape was strategically created to completely eliminate the canisters from the rear view of the car, drastically improving the appearance of the BMW F80 M3 and F82 M4 models.

If you are looking for a premier exhaust manufactured by a brand that has leveraged over 30 years of heritage, Eisenmann is the brand for you. The design of each system from the tube configuration and the size of the muffler and box dimensions are meticulously calculated and optimized to provide maximum performance across the entire rev range, drawing on Eisenmann’s vast Motorsport experience. Multiple internal flow paths work together with BMW’s Sport, Comfort, and Sports Plus ECU programming, and enable Eisenmann’s valve control to have a variable and drastic effect on the exhaust’s personality. This works to yield a quiet tone during cruising with in-cabin comfort, as well as a full-on growl when you truly step on the gas.

Features:

Lightweight, high-strength construction

Signature exhaust tips for added styling

Quad 90mm round exhaust tips (4x90mm)

Max horsepower and torque gains in all driving conditions

Laser CNC machining and sheet-metal processing

3. Armytrix Valvetronic Cat-Back Exhaust System

With the Armytrix Valvetronic Cat-Back Exhaust, you can access the extra power left behind by the factory exhaust from a beautifully constructed and highly capable system without committing to a grimacing exhaust tone all the time. Simply use their exclusive OBDII dongle to pair with your smartphone and flip the valves open for all the glorious sound and power you want, or close the valves for a subtle stealth mode when you need it. This cat-back system offers the best of both worlds in terms of power and sound, allowing you to control your driving experience right from behind the wheel of your BMW with ease. Armytrix is well for designing one of the best high-flowing exhaust systems on the market, so give your BMW M3 or M4 the vocal upgrade it deserves while maintaining distinct styling with this beautifully crafted Armytrix Valvetronic system.

To harvest the full potential of your F80/F82 BMW engine, Armytrix uses high-quality T304 stainless steel, forged with the most advanced technologies and by the highest standard, to build its highly popular Valvetronic exhaust. Meticulously engineered, this system handles increased volume with enhanced efficiency to squeeze out extra horsepower and torque via a high-flow design that appeals to all of your senses when you step on the gas. If you are looking for a system to provide you with more freedom than ever and an auditory sensation throughout the entire rev range, this is the product to get your adrenaline going.

The exclusive ARMYTRIX OBDII dongle system reduces the installation time by 50 percent! With clear displays and user-friendly controls, navigate through the brand’s app to gain an insightful look into your car’s real-time operational status and enjoy complete control over the valve settings. Armytrix has tailored each exhaust to carry the maximum payload to be delivered to thunderous effect. The result is a lighter, more streamlined system that is rid of the OE deadweight and offers an unrestrictive flow to improve overall efficiency and deliver power gains across the RPM band.

Features:

Power Gains (HP): 22.5

Torque Gains (Nm): 30.3

Weight Savings (-Kg): 3.5

Precision-crafted T304 steel construction

Straight pipes let out a vicious scream and ferocious power

Valve-controlled OBD2 module for quick and easy installation

4. Fabspeed Valvetronic Exhaust w/ Black Tips

The Fabspeed Valvetronic Exhaust is the ultimate cat-back system for the Ultimate Driving Machine. This package includes Fabspeed’s high-performance Valvetronic rear muffler and exclusive “Double-X” mid-pipe for the perfect combination of sound and power. Fabspeed Motorsport elevates the exotic car experience through personalized performance and an impressive line of product options and configurations that are unmatched on the aftermarket. After all, Fabspeed has been engineering and manufacturing the world’s finest stainless-steel high-performance exhausts for over 20 years. Its dyno-proven performance products provide a driving experience unlike any other out there and all systems come backed by a Limited Lifetime Warranty.

Fabspeed strives to be a force of innovation within the industry, showing an unwavering commitment to maximum performance, impeccable products, and excellent service. The company’s goal is to offer quality exhausts that not only provide enhanced performance and higher power figures, but also reduced weight, added styling, and a head-turning sound. The Valvetronic Exhaust for the M3 and M4 weighs in at just 62 pounds (rear section is 33 pounds and mid-pipes are 29 pounds) compared to the factory BMW system that weighs 69 pounds. Maximum gains are measured at 19 whp and 31 lb.-ft. of torque at 3300 RPM.

The Fabspeed Valvetronic Cat-Back features the world’s first and only “Double X” mid-pipe design which includes two “x” sections for increased exhaust scavenging. This, consequently, results in the smoothest possible exhaust tone with the least amount of rasp and drone. The exhaust is expertly crafted in-house at Fabspeed from 16-gauge .065-inch thick CNC-mandrel bent T304L stainless steel in 2.75-inch diameters for the highest strength and durability. The integrated muffler valves include machined mounts for the factory actuators, allowing for the retention of BMW’s stock valve functionality. What’s more, this system comes with deluxe quad-style tips for the ultimate in styling that matches the natural DNA of the M3 and M4.

Features:

World’s first and only “Double-X” mid-pipe

Weighs 62 lbs total compared to stock 69 lbs

Increased exhaust scavenging with smooth exhaust note

Includes deluxe quad-style tips (black chrome tailpipes)

Constructed 16-gause/.065″ thick T304L stainless steel

CNC mandrel-bent tubing for ultimate durability

Integrated muffler valves include machined mounts

Allows for the retention of factory valve functionality

Adds 19 whp and 31 ft/lbs of torque at 3300 RPM

5. Akrapovic Slip-On Line Titanium Exhaust

The latest addition to the BMW M-Series is the awe-inspiring M3/M4, an exquisite high-performance car that can be made even better by adding an Akrapovic Slip-On exhaust system. The Akrapovic Slip-On Line Titanium Exhaust System for the F80 M3 and F82 M4 is the first step in exhaust tuning. Crafted from high-grade titanium, which considerably reduces the weight in comparison to the stock BMW system, this exhaust been perfectly designed to fit directly onto the existing link pipes. The system increases power and torque across the rev range, provides better throttle response, and enhances the look and sound of your car. The Slip-On Line system has four valves, designed for the first pair to operate in four-cylinder mode and the second set to come into action according to the driver’s specifications. The system was specifically developed to be compatible with the car’s drive mode selector

This titanium exhaust system is designed to handle the rigors of high-performance engines such as the one found in BMW’s renowned M3 and M4 models. It was also built to deliver better resonate sound and faster acceleration to take your driving experience to the next level. This system has bigger pipes than the stock exhaust, yielding lower backpressure and more power, especially at lower RPMs. This system boasts a completely new design, and will reduce overall vehicle weight and deliver extra power and a sporty sound, which has been tailored to highlight lower frequencies and increase the listening enjoyment. Improvements in both power and torque add to the sensory experience, combined with improved agility to transform the way you drive your BMW. The look of the Slip-On system can also be further enhanced by adding titanium or carbon tailpipes and the stunning carbon-rear diffuser. An optional Akrapovic Sound Kit is available to control the different sound settings.

Features:

Made from high-quality titanium

Bigger pipes than stock exhaust

Lower backpressure and more power

Increases both horsepower and torque

Homologated version available

Max Power: 389.1 hp to 394.5 hp at 6050 RRPM

Max Torque: 416 lb.-ft. at 2600 RPM

2 notes

·

View notes