#ToolTech

Explore tagged Tumblr posts

Text

5 Power Tools That Make Construction Projects Easier and Faster

Read on: https://safatcotrading.com/5-power-tools-that-make-construction-projects-easier-and-faster/

0 notes

Text

Bit Ripsaw Machine: Precision Cutting for High Efficiency

With the constantly changing plywood and woodworking business, there is a need for efficiency and accuracy in order to achieve peak productivity. A Bit Ripsaw Machine is a vital equipment that will increase cutting accuracy as well as improve operational efficiency. As one of the top producers of plywood machinery, we know how high-performance machines contribute to optimizing production.

What is a Bit Ripsaw Machine?

A Bit Ripsaw Machine is a heavy-duty cutting machine especially designed for tearing wood, plywood, and composite boards into desired sizes. Different from conventional saws, the sophisticated machine deploys high-velocity spinning blades to provide precise, smooth cuts with less scrap. Whether dealing with softwood, hardwood, or engineered wood products, a Bit Ripsaw Machine offers maximum efficiency and uniform output.

Why Opt for a Bit Ripsaw Machine for Your Plywood Business?

1. High-Efficiency Cutting Precision

With the latest technology, a Bit Ripsaw Machine provides accuracy to the precision, minimizing errors and wastage of raw materials. This implies that organizations can get the best out of raw materials, saving time and money.

2. Enhanced Productivity

Speed is crucial in the plywood manufacturing business. The machines are engineered to be high-speed machines so that the manufacturer can cut through more wood within a shorter duration of time. Be it a small workshop or a big plywood manufacturing plant, a Bit Ripsaw Machine boosts production volume greatly.

3. Durability and Low Maintenance

Major producers construct these machines using quality materials to ensure reliability and longevity. With regular maintenance, a Bit Ripsaw Machine offers years of effective service with little downtime.

4. Improved Safety Features

New Bit Ripsaw Machines come with safety features like blade guards, emergency stop switches, and dust extraction systems to provide operator safety and a clean working environment.

5. Flexibility for Different Applications

From making furniture to plywood cutting, a Bit Ripsaw Machine can do it all with varying materials and thickness. This versatility alone makes it an essential piece of equipment for woodworking companies.

How a Bit Ripsaw Machine Impacts Your Business Growth

Investing in a high-quality plywood machine such as the Bit Ripsaw Machine has long-term advantages. It increases the speed of production, minimizes waste, and is consistent—elements that have a direct impact on business profitability. Furthermore, with the expanding need for accurate woodworking and plywood, owning advanced technology machinery places you in the superior position in the market.

Selecting the Ideal Manufacturer for Your Bit Ripsaw Machine

When choosing a Bit Ripsaw Machine, it is vital to work with a reliable plywood machinery manufacturer that boasts quality, innovation, and after-sales service. Choose a company that provides:

•Cutting-edge technology to achieve precision cuts

•Custom-made solutions that suit your production requirements

•Strong and durable equipment for extended use

•Good customer service and maintenance packages

Final Thoughts

A Bit Ripsaw Machine is a revolution within the plywood and woodworking business because it provides for precise cutting which is highly efficient. Making that investment in suitable equipment not only increases production volume but also raises the quality of the product to give your enterprise a solid market position.

If you're on the lookout for a consistent Bit Ripsaw Machine from a prominent plywood machinery manufacturer, browse our line of high-performance products designed to meet your business requirements. Get in touch with us now and move your woodworking productivity to the next level!

#BitRipsawMachine#PrecisionCutting#HighEfficiency#Woodworking#Sawing#MachinistLife#ForestryEquipment#IndustrialMachinery#WoodworkingTools#EfficiencyBoost#TimberProcessing#ProductionQuality#WoodCuttingExperts#RipsawMelody#PrecisionEngineering#ManufacturingInnovation#ToolTech#CustomWoodwork#ShapeYourVision#CutItRight

0 notes

Text

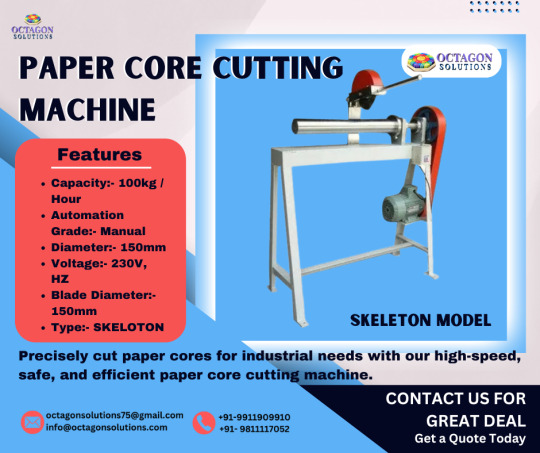

Paper Core Cutting Machine and Core Cutter blade

Paper Core Cutting Machine

Efficiently cut paper cores with our precision machine. Designed for high-speed production, our cutter delivers accurate and clean cuts. Ideal for paper mills, packaging industries, and more.

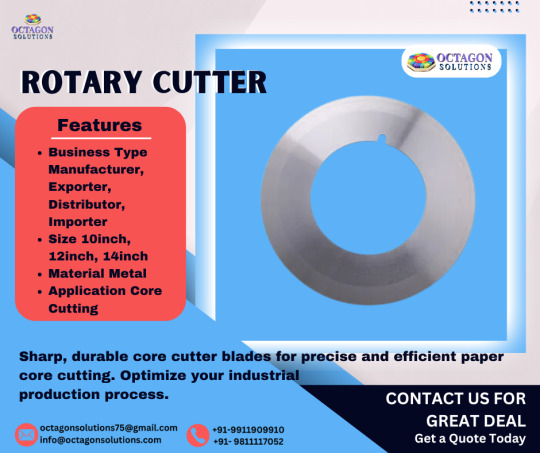

Core Cutter Blade

Sharp and durable core cutter blades for precise cutting. Engineered for optimal performance, our blades ensure clean cuts and extended lifespan. Compatible with various paper core cutting machines.Sources and related content

#PaperCoreCutting#CoreCutterBlade#IndustrialTools#CuttingMachine#PrecisionCutting#Manufacturing#Engineering#ProductivityBoost#TechInnovation#CuttingEdge#Machinery#QualityTools#IndustryLeaders#Efficiency#CleanCuts#ToolTech#EngineeringSolutions#CuttingSolutions#FactoryEquipment#InnovationInIndustry#HeavyDuty#TechSavvy#ProfessionalGrade#IndustrialMachinery#AdvancedTechnology#MachineTools

0 notes

Text

Troubleshooting a Milwaukee Transfer Pump

Introduction

Milwaukee transfer pumps are reliable tools used in various applications, from dewatering to transferring water and other fluids. However, like any mechanical device, they can encounter issues that may hinder their performance. Understanding how to troubleshoot these problems can save time, reduce downtime, and extend the life of your pump. This guide will provide a detailed troubleshooting approach, covering common issues, diagnostics, and solutions.

Understanding the Milwaukee Transfer Pump

Milwaukee transfer pumps are designed to move water and other fluids efficiently. They are commonly used in construction, plumbing, and emergency dewatering scenarios. These pumps feature durable construction and battery-powered operation, making them portable and convenient.

Common Issues with Milwaukee Transfer Pumps

No Power

One of the most common issues is the pump not turning on. This can be due to battery problems, faulty switches, or electrical connections.

Low Suction

Low suction can hinder the pump's performance, often caused by clogged filters, air leaks, or impeller issues.

Overheating

Overheating can damage the pump and is usually due to overuse, blocked cooling mechanisms, or operating in high-temperature environments.

Leaks

Leaks can occur in hoses, seals, or the pump housing, leading to reduced efficiency and potential damage to the surrounding area.

Initial Diagnostics

Visual Inspection

Begin by visually inspecting the pump for obvious signs of damage or wear. Look for loose connections, worn seals, or any visible cracks.

Basic Checks

Perform basic checks such as ensuring the battery is fully charged, the pump is properly assembled, and all connections are secure.

Tool Requirements

Have the necessary tools ready, including screwdrivers, wrenches, and a multimeter for electrical testing.

No Power Troubleshooting

Battery Issues

Check if the battery is properly charged and seated. Swap with a known good battery to rule out battery failure.

Electrical Connections

Inspect all electrical connections for corrosion or loose wires. Tighten or clean as necessary.

Switch Problems

Test the power switch for continuity using a multimeter. Replace the switch if it is faulty.

Low Suction Troubleshooting

Clogged Filters

Remove and clean the inlet and outlet filters. Replace them if they are damaged.

Air Leaks

Check all hose connections for tightness. Apply sealant or replace hoses if air leaks are detected.

Impeller Problems

Inspect the impeller for damage or obstructions. Clean or replace the impeller as needed.

Overheating Troubleshooting

Cooling Mechanisms

Ensure that the cooling vents are not blocked. Clean any debris from the vents.

Usage Limits

Do not operate the pump continuously for longer than recommended. Allow the pump to cool down if it overheats.

Environmental Factors

Avoid using the pump in extremely hot conditions. Provide shade or ventilation if necessary.

Leak Troubleshooting

Seal Inspections

Inspect all seals for wear or damage. Replace any faulty seals to prevent leaks.

Hose Connections

Ensure that all hose connections are tight and secure. Use hose clamps if necessary.

Housing Cracks

Check the pump housing for cracks or damage. Repair or replace the housing if needed.

Motor Issues

Motor Noise

Unusual noises from the motor can indicate wear or damage. Inspect the motor and lubricate or replace parts as needed.

Stalling

If the motor stalls, check for blockages in the impeller or hoses. Ensure the power supply is consistent.

Motor Replacement

If the motor is beyond repair, refer to the manufacturer’s guidelines for replacing the motor.

Electrical Problems

Wiring Checks

Inspect all wiring for wear, damage, or corrosion. Replace any faulty wiring.

Fuse Replacement

Check and replace any blown fuses. Ensure the correct fuse rating is used.

Circuit Testing

Use a multimeter to test the electrical circuit for continuity and proper voltage.

Impeller Maintenance

Cleaning

Regularly clean the impeller to remove debris and prevent clogs.

Replacement

Replace the impeller if it shows signs of wear or damage.

Performance Testing

Test the pump's performance after cleaning or replacing the impeller to ensure proper operation.

Battery Maintenance and Replacement

Battery Life

Monitor the battery life and replace it when it no longer holds a charge.

Charging Practices

Follow the manufacturer's guidelines for charging to extend battery life.

Replacement Guidelines

Use only recommended batteries to ensure compatibility and performance.

Filter Cleaning and Replacement

Types of Filters

Familiarize yourself with the types of filters used in your pump model.

Cleaning Process

Clean filters regularly to maintain optimal performance.

Replacement Steps

Replace filters according to the manufacturer's instructions.

Pump Assembly and Disassembly

Step-by-Step Guide

Follow a detailed guide to disassemble and reassemble the pump safely.

Tool Requirements

Ensure you have all necessary tools before beginning.

Safety Tips

Always disconnect the power source before performing maintenance.

Usage Best Practices

Correct Operation

Operate the pump within its specified parameters to avoid damage.

Preventive Measures

Implement preventive measures such as regular maintenance and proper storage.

Storage Tips

Store the pump in a cool, dry place when not in use to prevent damage.

Regular Maintenance Routines

Scheduled Checks

Perform regular checks to identify and address issues early.

Parts Replacement

Replace worn parts to prevent breakdowns.

Lubrication

Lubricate moving parts to reduce friction and wear.

Signs of Wear and Tear

Identifying Issues Early

Look for signs of wear such as reduced performance or unusual noises.

Impact on Performance

Address wear and tear promptly to maintain pump efficiency.

When to Call a Professional

Major Repairs

For complex issues, seek professional repair services.

Warranty Issues

Contact the manufacturer if the pump is under warranty.

Expert Services

Utilize expert services for thorough inspections and repairs.

Frequently Asked Questions About Milwaukee Transfer Pump

Q. Why is my Milwaukee transfer pump not turning on?

A. Check the battery, power switch, and electrical connections.

Q. How can I improve the suction of my transfer pump?

A. Clean the filters, check for air leaks, and inspect the impeller.

Q. What should I do if my pump overheats?

A. Allow the pump to cool, clean the cooling vents, and avoid using it in high temperatures.

Q. How do I fix a leak in my transfer pump?

A. Inspect and replace seals, tighten hose connections, and check for housing cracks.

Q. What causes unusual noises in the pump motor?

A. Noises can indicate motor wear or damage. Lubricate or replace motor parts as needed.

Q. When should I replace the battery of my pump?

A. Replace the battery when it no longer holds a charge or fails to power the pump adequately.

Conclusion

Maintaining and troubleshooting a Milwaukee transfer pump involves regular inspections, timely repairs, and understanding the common issues that can arise. By following the guidelines outlined in this article, you can ensure your pump operates efficiently and reliably, minimizing downtime and extending its lifespan.

#MilwaukeeTransferPump#PumpTroubleshooting#MilwaukeeTools#TransferPump#ToolRepair#MilwaukeePower#WorkshopTools#PumpMaintenance#DIYRepair#PumpEfficiency#MilwaukeeEquipment#PowerTools#ToolTech#PumpPerformance#ReliableTools

0 notes

Text

🔧 How Do Deep Impact Sockets Work?

Deep impact sockets are engineered to handle high torque and heavy impacts, making them essential for tough jobs.

They feature a robust construction with thick walls and a deeper well, designed to withstand the force generated by impact wrenches. Their 6-point grip ensures a secure hold on fasteners, reducing the risk of slipping or rounding off bolts.

This makes them ideal for automotive repairs, machinery assembly, and other heavy-duty tasks where standard sockets may not suffice. Upgrade your toolkit and experience the efficiency of deep impact sockets!

Detail: How Do Deep Impact Sockets Work?

0 notes

Text

#ToolEssentials#EquipmentExcellence#GearGurus#CraftsmanTools#ToolTech#EquipmentEnthusiasts#PrecisionTools#ToolMastery#GearUp#ToolBoxTreasures#EquipmentInnovation#ProfessionalTools#ToolSavvy#QualityEquipment#ToolTime#EquipmentElegance#ToolTechies#IndustrialInstruments#GearGalore#ToolMania#usa#canada

0 notes

Text

✨ IMTEX & Tooltech 2025 – A Huge Success! ✨

We’re thrilled to share that IMTEX & Tooltech 2025 has officially wrapped up, and it was an incredible experience! 🙌

From showcasing the latest in cutting-edge tech to meeting passionate professionals in the manufacturing industry, the event was a fantastic opportunity to connect, learn, and grow together.

A big thank you to everyone who stopped by our booth and supported us along the way. We’re excited about the future and can’t wait to continue pushing boundaries in innovation and technology! 💡🔧

Stay tuned for more exciting updates! 🚀

0 notes

Video

youtube

Bluetooth Micrometer #diy #precisiontools #garagestorage

📏✨ Look how easy it is to use a Micrometer with Bluetooth Data Logging! ✨📲 With the iGaging Bluetooth Smart Adapter Dongle, you can: ✔️ Enable wireless connectivity for your compatible iGaging measuring tools. ✔️ Seamlessly transfer measurement data to your PC, tablet, or smartphone. ✔️ Boost efficiency and precision with hassle-free data logging. Say goodbye to manual data recording and hello to streamlined workflows! Perfect for machinists, engineers, and precision measurement professionals. 🛠️ #Micrometer #BluetoothDataLogging #iGaging #PrecisionTools #MachinistLife #DataDriven #EngineeringTools #ToolTech #PennToolCo" https://www.penntoolco.com/igaging-bluetooth-smart-adapter-dongle---35-bt-28/

0 notes

Text

Tooltech: Empowering Industries with Quality Industrial Solutions

http://dlvr.it/T1T418

0 notes

Photo

If you haven’t seen my video from Friday, be sure to check it out #newvideo #youtube #tools #tooltech #educational #begineersguide #4diyers #mechanic https://www.instagram.com/p/CbDRUwVrdR8/?utm_medium=tumblr

0 notes

Video

#lunchtime #chicken #greenbeans #hotsauce #mustard #foodporn #eattogrow #bodybuilding #fitness #gym #supplements #gains #bodybuilder #fit #focused #gymlife #GymTime #bodybuildinghumor #bodybuildingismylife #fuel #protein #carbs #fats #nutrition #tooltech (at The Tech Group)

#gymtime#lunchtime#mustard#focused#fats#gym#bodybuilding#eattogrow#protein#carbs#bodybuildinghumor#greenbeans#fuel#supplements#nutrition#tooltech#bodybuilder#chicken#fit#gains#foodporn#fitness#gymlife#bodybuildingismylife#hotsauce

1 note

·

View note

Photo

Tool Techs just tool teching. #tooltech #makersgonnamake #makerlife #makerspace #lasercut #3dprinting #drillpress https://www.instagram.com/p/B9b4pQCJTjq/?igshid=71xr0fg2ti2d

0 notes

Text

What Does a Diamond Drill Bit Look Like?

Introduction

Diamond drill bits are essential tools in various industries, known for their superior cutting capabilities and durability. Understanding what a diamond drill bit looks like, its components, and how it functions can help users choose and utilize these tools effectively. This article provides an in-depth look at diamond drill bits, covering their types, materials, applications, and more.

Understanding Diamond Drill Bits

Definition of Diamond Drill Bits

Diamond drill bits are specialized tools designed to cut through hard materials using industrial diamonds embedded in their cutting surfaces. These diamonds provide the necessary hardness and abrasion resistance to efficiently drill through tough materials like concrete, stone, glass, and ceramics.

Purpose and Uses

The primary purpose of diamond drill bits is to create precise holes in hard materials. They are widely used in construction, manufacturing, and by hobbyists for various drilling tasks. Their applications range from large-scale industrial projects to small DIY jobs.

Types of Diamond Drill Bits

Core Drill Bits

Core drill bits are cylindrical and designed to remove a core of material, leaving a hole with a smooth finish. They are often used in construction and engineering for drilling large holes in concrete and masonry.

Tapered Drill Bits

Tapered drill bits feature a conical shape, making them ideal for creating precise, narrow holes. They are commonly used in tasks requiring detailed and accurate drilling.

Hole Saw Bits

Hole saw bits are circular and designed to cut out large, round sections from materials. These bits are frequently used for plumbing, electrical installations, and other tasks requiring large holes.

Materials Used in Diamond Drill Bits

Industrial Diamonds

The cutting edges of diamond drill bits are embedded with industrial diamonds, which are synthetically produced to provide the hardness and wear resistance needed for drilling tough materials.

Bonding Materials

Diamonds are bonded to the drill bit using various materials, including metal bonds and resins. These bonds help secure the diamonds in place and enhance the bit's durability and performance.

Design and Structure

Components of a Diamond Drill Bit

A typical diamond drill bit consists of a shank, which is the part that fits into the drill, and a cutting end embedded with diamonds. The design ensures efficient cutting and durability.

Shapes and Sizes

Diamond drill bits come in various shapes and sizes to suit different drilling needs. From small, precise bits for detailed work to large core bits for heavy-duty drilling, the variety ensures that there is a diamond drill bit for every application.

Manufacturing Process

Diamond Sintering

Diamond sintering involves embedding diamonds into a metal matrix at high temperatures and pressures, creating a strong bond. This process ensures that the diamonds stay in place during drilling.

Electroplating Diamonds

In electroplating, diamonds are coated onto the drill bit's surface using an electrochemical process. This method is commonly used for producing smaller, precision bits.

How Diamond Drill Bits Work

Cutting Mechanism

Diamond drill bits cut through materials by grinding rather than tearing. The hardness of the diamonds allows them to abrade the material, creating a smooth hole without causing cracks or damage.

Drilling Techniques

Effective drilling with diamond bits requires techniques such as applying steady pressure, using cooling fluids to prevent overheating, and drilling at appropriate speeds to maximize efficiency and bit life.

Applications of Diamond Drill Bits

Industrial Uses

In industries like construction, mining, and manufacturing, diamond drill bits are indispensable for drilling hard materials. They are used to create holes in concrete, stone, and other tough substrates.

DIY and Home Improvement

For home improvement enthusiasts, diamond drill bits are valuable tools for tasks like installing glass fixtures, cutting tiles, and creating holes in ceramics. Their precision and durability make them ideal for various DIY projects.

Advantages of Using Diamond Drill Bits

Durability

Diamond drill bits are known for their long lifespan and resistance to wear, making them cost-effective over time despite their higher initial cost.

Precision

The ability to create clean, precise holes without causing damage to the surrounding material is a significant advantage of diamond drill bits, particularly for delicate or high-value materials.

Disadvantages of Diamond Drill Bits

Cost

The high cost of diamond drill bits can be a deterrent for some users, especially for occasional use. However, their durability and performance often justify the investment.

Maintenance

Proper maintenance is crucial to keep diamond drill bits in good condition. This includes regular cleaning, appropriate storage, and using the bits according to manufacturer recommendations to prevent damage.

Choosing the Right Diamond Drill Bit

Factors to Consider

When selecting a diamond drill bit, consider factors such as the material to be drilled, the size and depth of the hole, and the specific application. Ensuring the bit matches the task at hand will enhance performance and longevity.

Tips for Selection

Material Compatibility: Ensure the bit is suitable for the material you are drilling.

Bit Size: Choose the correct diameter and length for the job.

Quality: Invest in high-quality bits for better performance and durability.

How to Use a Diamond Drill Bit

Safety Precautions

Using diamond drill bits safely involves wearing protective gear, securing the workpiece, and using appropriate drilling speeds. Cooling fluids should be used to prevent overheating and prolong bit life.

Step-by-Step Guide

Mark the Drilling Area: Clearly mark where the hole is needed.

Secure the Material: Clamp the material to prevent movement.

Start Drilling: Begin at a low speed to establish the hole, then gradually increase the speed.

Use Coolant: Apply water or another coolant to keep the bit cool.

Finish the Hole: Reduce speed as you approach the end to avoid chipping.

Maintenance and Care

Cleaning Tips

Regularly clean diamond drill bits with a soft brush to remove debris and prevent clogging. This helps maintain cutting efficiency and prolongs the bit's life.

Storage Advice

Store diamond drill bits in a dry, cool place to prevent corrosion. Keeping them organized and protected from physical damage ensures they remain in good condition for future use.

Comparing Diamond Drill Bits with Other Drill Bits

Diamond vs. Carbide

Diamond drill bits are superior for hard materials due to their durability and precision. Carbide bits, while cheaper, wear out faster and are less effective on very hard substrates.

Diamond vs. High-Speed Steel

High-speed steel bits are suitable for softer materials and are less expensive, but they lack the hardness and longevity of diamond bits, making them less effective for tough drilling tasks.

Innovations in Diamond Drill Bits

Latest Technological Advances

Recent advances in diamond drill bit technology include improved bonding methods, enhanced diamond quality, and innovative designs that increase efficiency and performance.

Future Trends

Future trends in diamond drill bits focus on increasing durability, reducing costs, and developing eco-friendly manufacturing processes. These innovations aim to make diamond drill bits more accessible and effective for a wider range of applications.

Frequently Asked Questions About Diamond Drill Bits

Q. What materials can diamond drill bits cut?

A. Diamond drill bits can cut through hard materials such as concrete, stone, glass, ceramics, and some metals.

Q. How long do diamond drill bits last?

A. The lifespan of a diamond drill bit depends on the quality of the bit, the material being drilled, and the usage conditions. High-quality bits can last significantly longer with proper care.

Q. Can diamond drill bits be sharpened?

A. While it is challenging to sharpen diamond drill bits, they can be refurbished by professionals to extend their life.

Q. Are diamond drill bits safe to use?

A. Yes, diamond drill bits are safe to use when proper safety precautions are followed, including wearing protective gear and using the bits as directed.

Q. How to prevent diamond drill bits from overheating?

A. To prevent overheating, use cooling fluids such as water, drill at appropriate speeds, and avoid applying excessive pressure.

Q. What are the signs of a worn-out diamond drill bit?

A. Signs of a worn-out diamond drill bit include reduced cutting efficiency, visible wear on the diamond edges, and increased drilling time.

Conclusion

Diamond drill bits are invaluable tools for drilling through hard materials with precision and durability. Understanding their design, types, and applications can help users make informed choices and achieve the best results in their projects. With proper care and usage, diamond drill bits can provide exceptional performance and long-lasting service.

#DiamondDrillBit#DrillMaster#PrecisionDrilling#ToolTech#DiamondTools#IndustrialTools#CuttingEdgeTech#DIYTools#DrillInnovation#EngineeringExcellence#ConstructionGear#DrillItRight#DiamondTip#HighPerformanceTools#ToolTalk#DiamondDrilling#ProTools#ConstructionLife#ToolTime#PrecisionTools

0 notes

Video

Wow, i love this tool.🆒🆒🆒😘 - - Repost @techpopular - credit @rrbuildings - #techpopular #tool #gardentool #gardentools #tooltech #technologymonth #tech #electronicsidea #chainsaw #chainsawcarving (at Galaxy Circle) https://www.instagram.com/p/B8tBzQogtln/?igshid=fr3y0o2ntbz

#techpopular#tool#gardentool#gardentools#tooltech#technologymonth#tech#electronicsidea#chainsaw#chainsawcarving

0 notes

Video

youtube

Precision Meets Protection ⚙️ Upgrade your accuracy with the iGaging Waterproof Digital Caliper! 💧 Engineered to withstand water, dust, and coolant, thanks to its **IP67 protective rating**. Whether in the toughest environments or the finest tasks, this caliper delivers precise measurements with ease. 🔥 ✨ Features include: ✅ Water & Coolant Proof ✅ High Contrast LCD Display ✅ Durable Stainless Steel Frame ✅ Protective Case for On-the-Go ✅ Powered by a 3V CR2032 Battery for lasting performance Perfect for machinists, DIYers, and professionals alike! Get yours today and never worry about conditions holding you back. 🛠️ #MachinistLife #PrecisionTools #WaterproofTools #Caliper #ToolOfTheDay #AccuracyMatters #ToolTech https://www.penntoolco.com/igaging-ip67-coolant-cal-x-large-digital-display-caliper-6-100-800-06/

0 notes