#DIYRepair

Explore tagged Tumblr posts

Text

youtube

Desk of Ladyada - Kiddo Kart Repair 🔋👶

BabyAda's bumper car toy stopped working after overnight charging - turns out 24V charger + 12V battery = problems. Quick fix: replaced battery with correct one from DigiKey. Pro tip -Always check voltage compatibility!

#electronicsrepair#bumpercar#toyrecovery#fixit#diyrepair#12v#leadacidbattery#kidstoys#batteryreplacement#makersgonnamake#hardwarehacking#techfix#engineeringfun#stemtoys#babyada#toyhacking#fixingthings#techdiy#recycleelectronics#chargingmistake#voltagemismatch#digikey#hardwaredebugging#electronicfix#powerup#tinkerers#handsonlearning#makersmovement#repairculture#Youtube

4 notes

·

View notes

Text

0 notes

Text

Is Your Refrigerator Running Efficiently? Here’s How to Tell!

Your refrigerator operates 24/7 and is one of the most energy-hungry appliances in your house. If it's not operating efficiently, it may be quietly blowing up your electricity bill. Most homeowners look for fridge repair near me when they experience increasing costs or uneven cooling. But before issues occur, there are indicators to check that determine if your refrigerator is operating at optimal performance.

Check the Internal Temperature

A quick way to assess efficiency is by monitoring the internal temperature. Your fridge should stay between 37°F and 40°F, while the freezer should be at 0°F. If the appliance struggles to maintain these temperatures, it may be overworking and wasting energy, possibly due to dirty coils or a failing thermostat.

Listen for Strange Noises

While a soft hum is to be expected, clanking, buzzing, or clicking sounds loudly are cause for concern. These noises may indicate compressor problems or a faulty motor, both of which decrease efficiency and need to be addressed right away.

Check Door Seals

Dirty or worn-out door gaskets will allow cold air to leak out, and the fridge will have to work harder to remain cool. Shut the door on a sheet of paper—if it can slide all the way through without a struggle, your seal is due for replacement. Good sealing is crucial to energy efficiency.

Feel the Exterior Heat

It is to be expected that the back of your fridge will be warm, but if the sides or front are overly hot, this may be an indication that your compressor is overheating or that the air flow around the unit is poor. This is usually a subtle reason for high energy consumption.

Check the Energy Bill

A sudden increase in your power bill without any other added appliances can be a sign that your fridge is the offender. An inefficient refrigerator draws more power than normal to perform the same task—obviously a sign it needs maintenance or repair.

Conclusion

Capturing early indications of inefficiency avoids larger, more expensive problems down the road. If you're experiencing any of these symptoms and are looking for reliable fridge repair near me, Fixail provides professional and affordable refrigerator repair services. Their skilled technicians keep your fridge running efficiently, saving you money and preserving your food.

#RefrigeratorRepair#ApplianceMaintenance#HomeRepair#DIYRepair#RefrigerationServices#ApplianceRepair#HomeImprovement#KitchenAppliances#RepairTips#EnergyEfficiency

0 notes

Text

How to Fix a Sticking Garage Door

Is your garage door getting stuck halfway through? Here's a quick fix to get it running smoothly again:

Step 1: Check for debris or obstacles blocking the tracks. Step 2: Lubricate the rollers and tracks with a silicone-based spray. Step 3: Tighten any loose bolts and screws on the door’s hardware.

👉 Need more tips? https://artexoverheaddoor.com/ 👉 Not feeling up for repairs? https://artexoverheaddoor.com/contact-artex-overhead-door-company/

#DIYGarageDoor#GarageDoorRepair#HomeImprovement#GarageDoorTips#DIYRepair#HomeRepairs#FixItYourself#GarageDoorFix#GarageMaintenance#DIYProjects

1 note

·

View note

Text

A Dead Hoverboard On a Monday

So there I was, ready for my morning commute, when my trusty hoverboard decided to pull a total ghost mode on me. You know that feeling when you hit the power button and… nothing? Yeah, that was my Monday morning surprise.

At first I tried all the usual tricks - holding the power button longer (like that ever fixes anything), checking if the charger was properly plugged in, and doing that weird little shake that somehow makes us feel better even though it never helps. No dice.

After some frantic Googling and a deep dive into hoverboard forums (yes, those exist!), I started noticing a pattern. Turns out, these batteries typically last about 1-2 years with regular use, so I must have treated mine like the lovechild it is surviving for this long. The symptoms matched perfectly: no response to the power button, no lights, and that sad little silence when you know your favorite tech has given up the ghost.

Here's the kicker - replacing the battery was actually way easier than I expected. After finding a compatible 36V lithium-ion battery (make sure to match your board's specs!), it was just a matter of:

Unscrewing the bottom panel

Disconnecting the old battery

Swapping in the new one

Closing it all up

The whole operation took about 20 minutes, cost me $45 for a new battery, and now my board's running like it's fresh out of the box. Pro tip: keep those battery connector wires organized - future you will thank past you when it's time for the next replacement.

Not gonna lie, there's something satisfying about fixing your own stuff instead of tossing it. Plus, I saved like $200 compared to buying a new board! Anyone else deal with hoverboard battery drama?

Drop your repair stories below!

0 notes

Text

Cracked iPhone? Phone Parts and Accessories NZ Saves the Day!

Looking for top-quality Apple phone parts & accessories in New Zealand? Look no further than Phone Parts and Accessories! We offer a wide range of screens, batteries, cases & more! Get yours fast and fix your phone yourself.

0 notes

Text

Troubleshooting a Milwaukee Transfer Pump

Introduction

Milwaukee transfer pumps are reliable tools used in various applications, from dewatering to transferring water and other fluids. However, like any mechanical device, they can encounter issues that may hinder their performance. Understanding how to troubleshoot these problems can save time, reduce downtime, and extend the life of your pump. This guide will provide a detailed troubleshooting approach, covering common issues, diagnostics, and solutions.

Understanding the Milwaukee Transfer Pump

Milwaukee transfer pumps are designed to move water and other fluids efficiently. They are commonly used in construction, plumbing, and emergency dewatering scenarios. These pumps feature durable construction and battery-powered operation, making them portable and convenient.

Common Issues with Milwaukee Transfer Pumps

No Power

One of the most common issues is the pump not turning on. This can be due to battery problems, faulty switches, or electrical connections.

Low Suction

Low suction can hinder the pump's performance, often caused by clogged filters, air leaks, or impeller issues.

Overheating

Overheating can damage the pump and is usually due to overuse, blocked cooling mechanisms, or operating in high-temperature environments.

Leaks

Leaks can occur in hoses, seals, or the pump housing, leading to reduced efficiency and potential damage to the surrounding area.

Initial Diagnostics

Visual Inspection

Begin by visually inspecting the pump for obvious signs of damage or wear. Look for loose connections, worn seals, or any visible cracks.

Basic Checks

Perform basic checks such as ensuring the battery is fully charged, the pump is properly assembled, and all connections are secure.

Tool Requirements

Have the necessary tools ready, including screwdrivers, wrenches, and a multimeter for electrical testing.

No Power Troubleshooting

Battery Issues

Check if the battery is properly charged and seated. Swap with a known good battery to rule out battery failure.

Electrical Connections

Inspect all electrical connections for corrosion or loose wires. Tighten or clean as necessary.

Switch Problems

Test the power switch for continuity using a multimeter. Replace the switch if it is faulty.

Low Suction Troubleshooting

Clogged Filters

Remove and clean the inlet and outlet filters. Replace them if they are damaged.

Air Leaks

Check all hose connections for tightness. Apply sealant or replace hoses if air leaks are detected.

Impeller Problems

Inspect the impeller for damage or obstructions. Clean or replace the impeller as needed.

Overheating Troubleshooting

Cooling Mechanisms

Ensure that the cooling vents are not blocked. Clean any debris from the vents.

Usage Limits

Do not operate the pump continuously for longer than recommended. Allow the pump to cool down if it overheats.

Environmental Factors

Avoid using the pump in extremely hot conditions. Provide shade or ventilation if necessary.

Leak Troubleshooting

Seal Inspections

Inspect all seals for wear or damage. Replace any faulty seals to prevent leaks.

Hose Connections

Ensure that all hose connections are tight and secure. Use hose clamps if necessary.

Housing Cracks

Check the pump housing for cracks or damage. Repair or replace the housing if needed.

Motor Issues

Motor Noise

Unusual noises from the motor can indicate wear or damage. Inspect the motor and lubricate or replace parts as needed.

Stalling

If the motor stalls, check for blockages in the impeller or hoses. Ensure the power supply is consistent.

Motor Replacement

If the motor is beyond repair, refer to the manufacturer’s guidelines for replacing the motor.

Electrical Problems

Wiring Checks

Inspect all wiring for wear, damage, or corrosion. Replace any faulty wiring.

Fuse Replacement

Check and replace any blown fuses. Ensure the correct fuse rating is used.

Circuit Testing

Use a multimeter to test the electrical circuit for continuity and proper voltage.

Impeller Maintenance

Cleaning

Regularly clean the impeller to remove debris and prevent clogs.

Replacement

Replace the impeller if it shows signs of wear or damage.

Performance Testing

Test the pump's performance after cleaning or replacing the impeller to ensure proper operation.

Battery Maintenance and Replacement

Battery Life

Monitor the battery life and replace it when it no longer holds a charge.

Charging Practices

Follow the manufacturer's guidelines for charging to extend battery life.

Replacement Guidelines

Use only recommended batteries to ensure compatibility and performance.

Filter Cleaning and Replacement

Types of Filters

Familiarize yourself with the types of filters used in your pump model.

Cleaning Process

Clean filters regularly to maintain optimal performance.

Replacement Steps

Replace filters according to the manufacturer's instructions.

Pump Assembly and Disassembly

Step-by-Step Guide

Follow a detailed guide to disassemble and reassemble the pump safely.

Tool Requirements

Ensure you have all necessary tools before beginning.

Safety Tips

Always disconnect the power source before performing maintenance.

Usage Best Practices

Correct Operation

Operate the pump within its specified parameters to avoid damage.

Preventive Measures

Implement preventive measures such as regular maintenance and proper storage.

Storage Tips

Store the pump in a cool, dry place when not in use to prevent damage.

Regular Maintenance Routines

Scheduled Checks

Perform regular checks to identify and address issues early.

Parts Replacement

Replace worn parts to prevent breakdowns.

Lubrication

Lubricate moving parts to reduce friction and wear.

Signs of Wear and Tear

Identifying Issues Early

Look for signs of wear such as reduced performance or unusual noises.

Impact on Performance

Address wear and tear promptly to maintain pump efficiency.

When to Call a Professional

Major Repairs

For complex issues, seek professional repair services.

Warranty Issues

Contact the manufacturer if the pump is under warranty.

Expert Services

Utilize expert services for thorough inspections and repairs.

Frequently Asked Questions About Milwaukee Transfer Pump

Q. Why is my Milwaukee transfer pump not turning on?

A. Check the battery, power switch, and electrical connections.

Q. How can I improve the suction of my transfer pump?

A. Clean the filters, check for air leaks, and inspect the impeller.

Q. What should I do if my pump overheats?

A. Allow the pump to cool, clean the cooling vents, and avoid using it in high temperatures.

Q. How do I fix a leak in my transfer pump?

A. Inspect and replace seals, tighten hose connections, and check for housing cracks.

Q. What causes unusual noises in the pump motor?

A. Noises can indicate motor wear or damage. Lubricate or replace motor parts as needed.

Q. When should I replace the battery of my pump?

A. Replace the battery when it no longer holds a charge or fails to power the pump adequately.

Conclusion

Maintaining and troubleshooting a Milwaukee transfer pump involves regular inspections, timely repairs, and understanding the common issues that can arise. By following the guidelines outlined in this article, you can ensure your pump operates efficiently and reliably, minimizing downtime and extending its lifespan.

#MilwaukeeTransferPump#PumpTroubleshooting#MilwaukeeTools#TransferPump#ToolRepair#MilwaukeePower#WorkshopTools#PumpMaintenance#DIYRepair#PumpEfficiency#MilwaukeeEquipment#PowerTools#ToolTech#PumpPerformance#ReliableTools

0 notes

Text

What Size Wrench for O2 Sensor

Wondering what size wrench you need for an O2 sensor? Most O2 sensors require a 7/8 inch or 22mm wrench. Using the right tool makes the replacement process smooth and easy. Make sure you have the correct wrench to keep your car running efficiently!

0 notes

Text

Locked out? Learn how to cut a bike lock safely and efficiently with these expert tips! Whether you've lost your key or need to remove a forgotten lock, we've got you covered. Discover the right tools and techniques to unlock freedom and get back on the road. Say goodbye to bike lock woes and hello to hassle-free rides!

Get Inspired, visit www.outsideace.com

#BikeLife#LockRemoval#DIYHacks#BikeSecurity#UnlockFreedom#CyclingTips#DIYRepair#BikeLocksmith#GetBackOnTheRoad#SafetyFirst#Outsideace#camping#backyard#hiking#travel blog#travel photography#outdoors#travel#traveling#hikingtips

0 notes

Text

For professional repairs, maintenance, and prompt assistance, visit the reputable Refrigerator Service Center in Calicut if you need a rapid fridge fix. Maintain the freshness of your food and the efficiency of your refrigerator!

#RefrigeratorRepair#ApplianceRepair#HomeMaintenance#DIYRepair#FridgeFix#ApplianceService#HomeAppliances#RepairTips#EnergyEfficiency

0 notes

Text

#DryerRepair#ApplianceRepair#DryerMaintenance#HomeAppliances#SearsDryer#SamsungDryer#DIYRepair#HomeMaintenance#FixItYourself#ProfessionalService

0 notes

Text

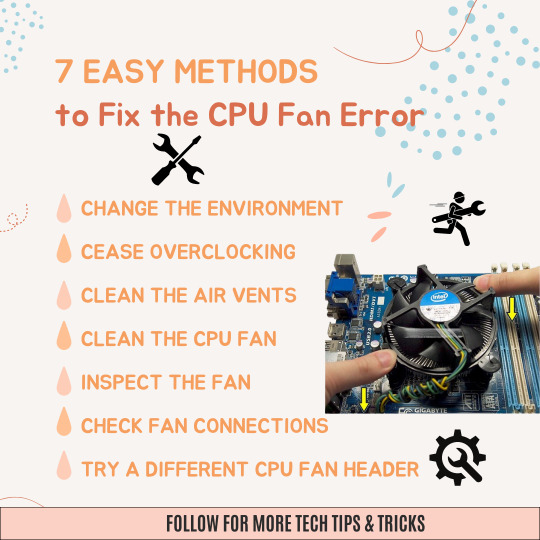

7 Easy Methods to Fix the CPU Fan Error

🔧😊Troubleshoot your CPU fan woes with these 7 simple solutions!🕖

💻❄️Keep your system running cool and smooth.☃️🚗

🔑🔥Prevent overheating and extend your hardware's lifespan.↔️🛠️Tackle the CPU fan error effortlessly.✨

🔍🎩Uncover the root cause and find the perfect fix.⚒️🪛🚀Optimize your PC's performance today!💪🦍

#computerhelp#techtips#pcrepair#diyrepair#pcgaming#pcmasterrace#cpu#cpucooler#overheating#pcmaintenance#techtutorial#fixityourself#savemoney#performanceboost#pcfix#computerrepair#howto#troubleshooting#cpuoverheating#pccooling#thermalpaste#pcproblems#savethepc#coolandquiet

0 notes

Text

Upgrade Your Samsung with Genuine Parts

Phone Parts NZ offers a comprehensive selection of genuine Samsung phone parts, including screens, batteries, charging ports, and more. Find everything you need to repair your Samsung phone and restore it to top condition. We offer fast shipping and competitive prices.

0 notes

Text

Top-Notch Amana Appliance Service in the USA

You can get in touch with an expert appliance repair person if your search for Amana repair near me on a search engine yields no good results. In their line of work, they enjoy a solid reputation. Please give the number listed a call if you need assistance right away. Please give us a call at +1-855-512-8222.Follow us on Facebook: @theappliancerepairprofessionals

#AmanaRepair#ApplianceRepair#HomeAppliance#FixItNow#AmanaService#HomeMaintenance#BrokenAppliance#DIYRepair#FixMyAmana#LocalRepair

0 notes

Text

Brake Bleeder Wrench Size - Brake Bleeding Guide

Choosing the right brake bleeder wrench size is crucial for effective brake maintenance. Most vehicles require a 10mm wrench, but always check your vehicle's manual for the exact size. Investing in quality tools ensures a safer and smoother DIY repair experience. Keep your brakes in top shape and drive safely!

0 notes

Text

Unlock the mystery of your Delta shower faucet! Learn how to easily identify its model with our expert guide, making repairs and upgrades a breeze.

Get Inspired, visit www.kitchenov.com

#DeltaFaucet#ShowerUpgrade#DIYRepair#Kitchenov#kitchen cabinets#kitchen decor#kitchen sink#homeimprovement#diyplumbing#dining room#kitchen appliances#kitchen#appliances

0 notes