#Transmitter and manifold integration

Explore tagged Tumblr posts

Text

Transmitter and manifold integration , Hydrotesting services in Dubai - TotalCal

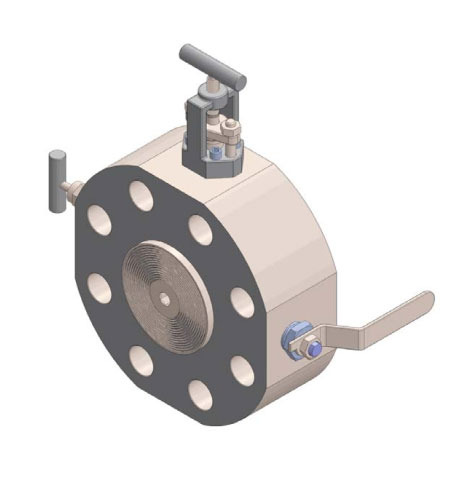

Enhancing Efficiency Through Transmitter and Manifold Integration

In today's fast-paced industrial environment, accuracy and reliability are critical. One of the most effective ways to ensure seamless operations in process industries is through transmitter and manifold integration. This integration is not just a trend—it’s a necessity for achieving optimal performance in pressure and flow measurement systems.

At TotalCal, we understand the importance of integrating transmitters and manifolds to reduce installation time, minimize potential leak points, and ensure accurate readings. Our team is experienced in providing custom integration solutions tailored to client-specific requirements, whether it’s for oil and gas, manufacturing, or water treatment industries.

Transmitter and manifold integration streamlines the instrumentation setup by directly connecting the pressure transmitter to a multi-valve manifold. This not only reduces the number of required fittings and tubing but also lowers the overall cost of maintenance. The integrated design allows for better control, increased safety, and efficient calibration, especially in critical applications where precision is non-negotiable.

TotalCal's Expertise in Hydrotesting Services in Dubai

Another crucial service offered by TotalCal is hydrotesting services in Dubai. Hydrotesting is an essential process for verifying the integrity of pressure vessels, pipelines, and other critical equipment. By filling the system with water and pressurizing it beyond its normal operating level, hydrotesting identifies any potential weaknesses or leaks before they can cause real problems.

At TotalCal, our hydrotesting services are designed to meet international standards while also complying with local safety regulations. We utilize advanced equipment and techniques to deliver high-pressure testing solutions across multiple sectors including oil and gas, petrochemical, and construction. Our technicians are trained to perform tests with precision, ensuring the safety and reliability of your systems.

Whether you are commissioning new equipment or performing routine maintenance checks, hydrotesting is a vital step in your quality assurance process. Our commitment to quality and safety makes us one of the most trusted names in hydrotesting services in Dubai.

Why Choose TotalCal?

TotalCal is more than just a service provider—we are a partner in ensuring the success and safety of your operations. Our integrated solutions for transmitter and manifold integration are designed to increase efficiency and reduce system complexity. When combined with our specialized hydrotesting services in Dubai, we offer a comprehensive approach to industrial instrumentation and testing.

Our services are backed by years of expertise, a commitment to excellence, and a passion for delivering reliable solutions that meet the highest industry standards. We work closely with clients to understand their specific needs and deliver tailored solutions that exceed expectations.

Conclusion

Whether you're upgrading existing systems or starting a new project, integrating your transmitters and manifolds can lead to long-term operational benefits. Coupled with professional hydrotesting services, TotalCal ensures that your systems are both accurate and safe. Trust TotalCal to deliver precision, safety, and performance—every step of the way.

0 notes

Text

How ICCL Mono Flange Valves Improve Safety in Offshore Platforms

In the challenging and high-stakes environment of offshore oil and gas platforms, safety and performance are absolutely essential. One key player in maintaining system integrity in these settings is the Mono Flange Valve. These valves are designed to simplify instrumentation, minimize leak paths, and enhance accessibility, making them the go-to choice for offshore installations.

Among the top manufacturers in this field, ICCL (Instrumentation Control Components Ltd.) has established itself as a reliable name for high-performance Mono Flange Valves, particularly in critical offshore and subsea applications.

In this blog, we’ll dive into how ICCL Mono Flange Valves boost safety on offshore platforms and why engineers and procurement teams worldwide trust ICCL for their valve requirements.

What is a Mono Flange Valve?

A Mono Flange Valve is a sleek, one-piece valve solution that combines isolation (block) and bleed functions into a single unit. Unlike traditional setups that rely on multiple valves, fittings, and connections, mono flanges streamline the entire operation—resulting in a smaller size, lighter weight, and, most importantly, reduced leak potential.

Key Safety Challenges in Offshore Platforms

Offshore oil and gas rigs face extreme conditions, including:

- High pressure (up to 10,000 psi or more)

- Corrosive seawater environments

- Limited installation space

- Risk of gas or fluid leaks

- Significant temperature fluctuations

- Compliance with strict industry standards (e.g., API, ASME, NACE)

Every extra connection in a piping system raises the risk of failure or leakage, making it vital to use compact and leak-proof components like ICCL’s MonoFlange valves.

How ICCL Mono Flange Valves Enhance Safety

Reduced Leak Paths

ICCL Mono Flange Valves replace multiple components (ball valve + needle valve + fittings + flanges) with a single forged body. This change can eliminate up to 70% of potential leak points, which is crucial for preventing dangerous leaks, especially when dealing with volatile fluids or gases.

Fire-Safe and Pressure-Tested Design

Every ICCL Mono Flange Valve undergoes thorough testing for fire safety, hydrostatic pressure, and helium leakage. They’re built to comply with API 6FA and ISO fire-safe standards, ensuring they perform reliably when it matters most.

Compact and Lightweight

Space can be a real challenge on offshore platforms. That’s why ICCL’s Mono Flange design is all about reducing the size and weight of valve installations. This makes installation in tight or elevated spaces not just easier, but also safer for everyone involved. Plus, it helps keep maintenance personnel safe by limiting their exposure.

Corrosion-Resistant Materials

ICCL is committed to using top-notch materials like SS316, Duplex, Super Duplex, Inconel, and Hastelloy. These materials provide excellent corrosion resistance in marine environments, which means a longer lifespan and a lower risk of failure due to material wear and tear.

Double Block & Bleed Capability

Many of the ICCL Mono Flange models come with a DBB (Double Block and Bleed) configuration. This feature guarantees complete isolation of pressure in both upstream and downstream directions, which is crucial for safety during maintenance, calibration, or shutdowns.

Compliance with Offshore Standards

ICCL Mono Flange Valves are designed to meet several important standards:

NACE MR0175 / ISO 15156 (for sour service)

API 6A / 6D (for pressure containment)

PED 2014/68/EU (European compliance)

This ensures they are reliable and accepted worldwide.

Applications in Offshore Environments

ICCL Mono Flange Valves are widely used in:

Pressure transmitter connections

Chemical injection skids

Wellhead control panels

Subsea pipeline monitoring

Manifold and riser systems

FPSO vessels and topside facilities

In these situations, safety isn’t just a priority—it’s essential. ICCL valves guarantee zero leakage, require minimal maintenance, and ensure safe operation, even in the toughest environments.

ICCL: A Trusted Name in Instrumentation Valves

Based in Saudi Arabia with a global reach, ICCL is recognized for:

Precision-engineered valves and fittings

Customizable valve configurations

Quick lead times and worldwide distribution

Customizable valve configurations

Quick lead times and worldwide support

Dedicated to ISO, CE, and international certifications

Their committed engineering team collaborates closely with EPCs, plant operators, and procurement teams to provide customized valve solutions for both onshore and offshore projects.

In the world of offshore oil and gas operations, you need components that can handle the pressure—both in terms of performance and reliability. ICCL’s Mono Flange Valves are built to tackle these challenges, offering safety, dependability, and efficiency all in one compact design.

Whether you're looking to upgrade an existing system or design a new offshore platform, think about the long-term safety, reliability, and performance advantages of choosing ICCL Mono Flange Valves.

0 notes

Text

Stainless Steel 321 Condensate Pot Manufacturer, Exporter, Supplier in Malaysia – Mcneil Saudi Arabia

Introduction to Stainless Steel 321 Condensate Pots

Condensate pots are essential components in modern industrial systems, particularly when it comes to maintaining the integrity of instrumentation lines. These pots serve a critical function by collecting condensate, sludge, or foreign particles that could otherwise enter sensitive instruments like pressure gauges or transmitters. By preventing this intrusion, condensate pots help maintain accurate readings and extend the life of downstream devices. One of the most reliable materials used in the fabrication of these pots is Stainless Steel 321 (SS 321).

SS 321 is a titanium-stabilized austenitic stainless steel that resists intergranular corrosion and performs excellently at elevated temperatures. This makes it ideal for condensate applications, especially in high-temperature steam and gas systems. An ss 321 Condensate Pot is designed to withstand fluctuating pressure conditions and corrosive media, ensuring long-term stability in harsh environments.

These condensate pots are widely used in industries where thermal and mechanical stresses are common. From offshore rigs to power stations, SS 321 proves to be an ideal choice due to its robust chemical composition and low-maintenance characteristics. For organizations aiming to buy 321 Condensate Pot at best price in Malaysia, the material’s resilience and lifespan offer unmatched value.

About Mcneil Saudi Arabia

Mcneil Saudi Arabia is a reputed and established player in the field of industrial piping and instrumentation equipment. Headquartered in the SAIF-Zone, Sharjah, UAE, Mcneil offers a vast range of high-performance products designed for reliability and safety in complex systems. Their specialties include pipe fittings, flanges, manifolds, and condensate pots, manufactured using premium stainless steels and exotic alloys.

With a reputation built on quality, innovation, and customer satisfaction, Mcneil is a preferred ss 321 Condensate Pot manufacturer in Malaysia. The company combines global standards with regional expertise, allowing it to cater effectively to the needs of the Malaysian market.

Contact Information: 📞 Phone: +971 9870883613 📧 Email: [email protected] 📍 Address: SAIF-Zone, P.O. Box. 120345, Sharjah, UAE 🌐 Website: Mcneil Saudi Arabia

Manufacturing Expertise in SS 321 Condensate Pots

Mcneil Saudi Arabia brings decades of engineering experience and innovation to the manufacturing of SS 321 condensate pots. Their production facility is outfitted with state-of-the-art machinery and tools, allowing them to consistently meet and exceed international standards such as ASME, ASTM, and ISO. From the very beginning of the fabrication process, quality is built into each unit. Mcneil uses only premium, traceable raw materials sourced from certified mills, ensuring every condensate pot begins with high-grade Stainless Steel 321, known for its exceptional strength and corrosion resistance.

Once the raw material is approved, it is processed through CNC machining for precise cutting and shaping. This is followed by TIG or argon arc welding, which provides smooth, clean welds with superior penetration—essential for high-pressure applications where any flaw could compromise performance. Polishing and finishing are carried out meticulously, not only for aesthetic appeal but also to ensure a smooth internal surface that minimizes pressure drop and facilitates effective condensate drainage.

As a trusted manufacturer of ss 321 Condensate Pot, Mcneil offers full customization based on client needs. Whether it’s a vertical or horizontal pot, varying connection types like NPT or flanged ends, or specific wall thicknesses, Mcneil’s design engineers provide thorough support. CAD drawings and 3D models are developed to validate the design before production, ensuring compatibility with existing systems and instrumentation.

Quality assurance is embedded in every stage of production. Each unit undergoes stringent testing protocols including hydrostatic pressure testing—where pots are subjected to pressures well above operating levels to confirm durability—and pneumatic testing, which checks for leakage and weld integrity. Additionally, every condensate pot is visually and dimensionally inspected before it’s packed and shipped. The attention to detail in both fabrication and inspection underscores Mcneil’s commitment to delivering reliable, long-lasting products suitable for the most demanding industrial environments.

Export Capabilities to Malaysia

Mcneil’s strength lies not only in manufacturing but also in its efficient export operations. Malaysia, with its booming oil & gas and manufacturing sectors, demands quality-assured, certified equipment. Mcneil has developed a robust logistics network that ensures fast and secure delivery to clients across Kuala Lumpur, Johor Bahru, and Bintulu.

As recognized compressor ss 321 Condensate Pot exporters in Malaysia, the company provides all necessary documentation, including test reports, material traceability, and shipping certificates. The ability to meet tight project deadlines without compromising on product integrity has made Mcneil a preferred supplier across the region.

Product Specifications and Customization Options

Every condensate pot produced by Mcneil adheres to global industry standards such as ASME, ASTM, and ISO. Their SS 321 models are available in multiple configurations, including:

Sizes: The condensate pots are available in diameters ranging from 2 inches to 6 inches, making them suitable for both compact and large-scale installations. This size range ensures flexibility across different flow capacities and connection needs, accommodating both low and high-volume condensate collection.

Pressure Ratings: Built to withstand intense operational demands, Mcneil’s condensate pots support pressure ratings up to 6000 PSI. This high-pressure capacity makes them ideal for applications in steam and gas lines, especially in sectors like petrochemicals, offshore drilling, and power generation where pressure stability is critical.

End Connections: To provide maximum adaptability, the pots are manufactured with a variety of end connection types. These include NPT (National Pipe Thread), BSP (British Standard Pipe), flanged, and butt-weld ends. This ensures compatibility with various pipeline standards and allows easy integration with existing infrastructure.

Orientation: Based on system design and installation space, Mcneil offers both vertical and horizontal configurations. Vertical pots are commonly used when space is limited or when vertical drainage is essential, while horizontal pots may be preferred in setups requiring inline integration.

Capacity: The internal volume of the pots ranges from 500 milliliters to 5 liters, providing options for small-scale instrument protection as well as large-scale condensate accumulation. These variations help ensure that each unit is neither underutilized nor overwhelmed, contributing to optimal instrument performance and safety.

This range of technical options allows Mcneil to serve clients across various disciplines. Customization extends to specialized coatings, insulation options, and bracket arrangements for ease of installation. These capabilities position Mcneil among the top ss 321 Condensate Pot suppliers in Southeast Asia.

Industries We Serve with SS 321 Condensate Pots

Oil & Gas Sector: In upstream and downstream applications, condensate pots are used to isolate liquid slugs from instrumentation. SS 321's corrosion resistance is a crucial advantage in salty offshore environments.

Petrochemical and Chemical Industries: These industries often handle highly reactive substances. The chemical stability of SS 321 makes it suitable for collecting condensate without risking contamination or damage.

Marine and Offshore Installations: Maritime applications expose equipment to aggressive marine environments. The anti-corrosion and high-temperature resistance of SS 321 enhance safety and operational continuity.

These examples illustrate why Mcneil is considered one of the leading exporters of ss 321 Condensate Pot in Malaysia, capable of fulfilling both standard and high-spec requirements.

Benefits of Choosing SS 321 for Condensate Applications

SS 321 stands out due to its titanium-stabilized structure, which enhances its resistance to intergranular corrosion—a common issue in high-temperature environments. This makes it ideal for use in steam and gas lines, where temperatures regularly exceed 800°C.

The material also resists scaling and pitting, ensuring a longer service life compared to conventional grades like SS 304. The smooth internal surface of an instrumentation ss 321 Condensate Pot also reduces pressure drop and facilitates better drainage of condensate, improving system efficiency.

When considering long-term investments in instrumentation systems, SS 321 provides durability, operational safety, and lower total cost of ownership.

Quality Certifications and Testing Procedures

Mcneil ensures that each SS 321 condensate pot is manufactured in compliance with international quality benchmarks. Tests conducted include:

Hydrostatic testing at 1.5 times the design pressure

Pneumatic leak testing with soap solution

PMI (Positive Material Identification)

Radiographic and ultrasonic inspection (on request)

Clients receive full documentation packages, including MTCs, compliance statements, and dimensional drawings. Mcneil’s products are eligible for third-party inspections by agencies like BV, Lloyd’s, and TUV upon client request. This makes them a reliable ss 321 Condensate Pot exporter for projects with stringent QA/QC requirements.

Packaging and Delivery Process for Malaysia

Mcneil uses export-grade packaging that includes anti-corrosive wrapping, foam padding, and heat-number labeling. All shipments are packed in fumigated wooden crates with clear identification tags for easy handling and installation.

The company collaborates with reliable logistics providers to ensure that all consignments reach clients in Malaysia damage-free and on time. Whether shipped by air or sea, each order includes a packing list, invoice, and bill of lading to streamline customs clearance.

Why Choose Mcneil in Malaysia?

Mcneil’s competitive edge lies in its blend of technical expertise, manufacturing capability, and customer support. Clients benefit from:

Quick response times for inquiries and quotes

Design customization to fit unique system layouts

Competitive pricing without compromising quality

Strong after-sales service and on-site guidance when needed

As a ss 321 Condensate Pot supplier with a consistent track record, Mcneil fosters long-term relationships with its clients. Many Malaysian clients opt for recurring purchase agreements due to the trust and consistency Mcneil offers.

Frequently Asked Questions (FAQs)

What Certifications Are Included? All condensate pots are supplied with MTCs, pressure test certificates, and compliance declarations. Optional TPI certificates are available upon request.

Can Mcneil Handle Large Orders? Yes. Mcneil’s scalable production facilities and global logistics network make them capable of fulfilling large and urgent orders efficiently.

What Makes SS 321 Better Than Other Grades? SS 321 offers superior high-temperature resistance and corrosion protection, especially in oxidizing environments. It is a preferred material for steam and gas service where SS 304 may fall short.

Conclusion

Choosing the right supplier for condensate pots can significantly impact system performance and project timelines. Mcneil Saudi Arabia stands out as a trusted ss 321 Condensate Pot manufacturer in Malaysia, offering top-quality products backed by engineering support and timely delivery. Whether your project involves high-temperature steam lines or sensitive instrumentation systems, Mcneil delivers reliability you can count on.

0 notes

Text

Stainless Steel 321 Condensate Pot Manufacturer, Exporter, Supplier in Malaysia – Mcneil Steel & Alloys FZE

Introduction to Stainless Steel 321 Condensate Pots

Condensate pots are essential components in modern industrial systems, particularly when it comes to maintaining the integrity of instrumentation lines. These pots serve a critical function by collecting condensate, sludge, or foreign particles that could otherwise enter sensitive instruments like pressure gauges or transmitters. By preventing this intrusion, condensate pots help maintain accurate readings and extend the life of downstream devices. One of the most reliable materials used in the fabrication of these pots is Stainless Steel 321 (SS 321).

SS 321 is a titanium-stabilized austenitic stainless steel that resists intergranular corrosion and performs excellently at elevated temperatures. This makes it ideal for condensate applications, especially in high-temperature steam and gas systems. An ss 321 Condensate Pot is designed to withstand fluctuating pressure conditions and corrosive media, ensuring long-term stability in harsh environments.

These condensate pots are widely used in industries where thermal and mechanical stresses are common. From offshore rigs to power stations, SS 321 proves to be an ideal choice due to its robust chemical composition and low-maintenance characteristics. For organizations aiming to buy 321 Condensate Pot at best price in Malaysia, the material’s resilience and lifespan offer unmatched value.

About Mcneil Steel & Alloys FZE

Mcneil Steel & Alloys FZE is a reputed and established player in the field of industrial piping and instrumentation equipment. Headquartered in the SAIF-Zone, Sharjah, UAE, Mcneil offers a vast range of high-performance products designed for reliability and safety in complex systems. Their specialties include pipe fittings, flanges, manifolds, and condensate pots, manufactured using premium stainless steels and exotic alloys.

With a reputation built on quality, innovation, and customer satisfaction, Mcneil is a preferred ss 321 Condensate Pot manufacturer in Malaysia. The company combines global standards with regional expertise, allowing it to cater effectively to the needs of the Malaysian market.

Contact Information: 📞 Phone: +971 9870883613 📧 Email: [email protected] 📍 Address: SAIF-Zone, P.O. Box. 120345, Sharjah, UAE 🌐 Website: Mcneil Steel & Alloys FZE

Manufacturing Expertise in SS 321 Condensate Pots

Mcneil Steel & Alloys FZE brings decades of engineering experience and innovation to the manufacturing of SS 321 condensate pots. Their production facility is outfitted with state-of-the-art machinery and tools, allowing them to consistently meet and exceed international standards such as ASME, ASTM, and ISO. From the very beginning of the fabrication process, quality is built into each unit. Mcneil uses only premium, traceable raw materials sourced from certified mills, ensuring every condensate pot begins with high-grade Stainless Steel 321, known for its exceptional strength and corrosion resistance.

Once the raw material is approved, it is processed through CNC machining for precise cutting and shaping. This is followed by TIG or argon arc welding, which provides smooth, clean welds with superior penetration—essential for high-pressure applications where any flaw could compromise performance. Polishing and finishing are carried out meticulously, not only for aesthetic appeal but also to ensure a smooth internal surface that minimizes pressure drop and facilitates effective condensate drainage.

As a trusted manufacturer of ss 321 Condensate Pot, Mcneil offers full customization based on client needs. Whether it’s a vertical or horizontal pot, varying connection types like NPT or flanged ends, or specific wall thicknesses, Mcneil’s design engineers provide thorough support. CAD drawings and 3D models are developed to validate the design before production, ensuring compatibility with existing systems and instrumentation.

Quality assurance is embedded in every stage of production. Each unit undergoes stringent testing protocols including hydrostatic pressure testing—where pots are subjected to pressures well above operating levels to confirm durability—and pneumatic testing, which checks for leakage and weld integrity. Additionally, every condensate pot is visually and dimensionally inspected before it’s packed and shipped. The attention to detail in both fabrication and inspection underscores Mcneil’s commitment to delivering reliable, long-lasting products suitable for the most demanding industrial environments.

Export Capabilities to Malaysia

Mcneil’s strength lies not only in manufacturing but also in its efficient export operations. Malaysia, with its booming oil & gas and manufacturing sectors, demands quality-assured, certified equipment. Mcneil has developed a robust logistics network that ensures fast and secure delivery to clients across Kuala Lumpur, Johor Bahru, and Bintulu.

As recognized compressor ss 321 Condensate Pot exporters in Malaysia, the company provides all necessary documentation, including test reports, material traceability, and shipping certificates. The ability to meet tight project deadlines without compromising on product integrity has made Mcneil a preferred supplier across the region.

Product Specifications and Customization Options

Every condensate pot produced by Mcneil adheres to global industry standards such as ASME, ASTM, and ISO. Their SS 321 models are available in multiple configurations, including:

Sizes: The condensate pots are available in diameters ranging from 2 inches to 6 inches, making them suitable for both compact and large-scale installations. This size range ensures flexibility across different flow capacities and connection needs, accommodating both low and high-volume condensate collection.

Pressure Ratings: Built to withstand intense operational demands, Mcneil’s condensate pots support pressure ratings up to 6000 PSI. This high-pressure capacity makes them ideal for applications in steam and gas lines, especially in sectors like petrochemicals, offshore drilling, and power generation where pressure stability is critical.

End Connections: To provide maximum adaptability, the pots are manufactured with a variety of end connection types. These include NPT (National Pipe Thread), BSP (British Standard Pipe), flanged, and butt-weld ends. This ensures compatibility with various pipeline standards and allows easy integration with existing infrastructure.

Orientation: Based on system design and installation space, Mcneil offers both vertical and horizontal configurations. Vertical pots are commonly used when space is limited or when vertical drainage is essential, while horizontal pots may be preferred in setups requiring inline integration.

Capacity: The internal volume of the pots ranges from 500 milliliters to 5 liters, providing options for small-scale instrument protection as well as large-scale condensate accumulation. These variations help ensure that each unit is neither underutilized nor overwhelmed, contributing to optimal instrument performance and safety.

This range of technical options allows Mcneil to serve clients across various disciplines. Customization extends to specialized coatings, insulation options, and bracket arrangements for ease of installation. These capabilities position Mcneil among the top ss 321 Condensate Pot suppliers in Southeast Asia.

Industries We Serve with SS 321 Condensate Pots

Oil & Gas Sector: In upstream and downstream applications, condensate pots are used to isolate liquid slugs from instrumentation. SS 321's corrosion resistance is a crucial advantage in salty offshore environments.

Petrochemical and Chemical Industries: These industries often handle highly reactive substances. The chemical stability of SS 321 makes it suitable for collecting condensate without risking contamination or damage.

Marine and Offshore Installations: Maritime applications expose equipment to aggressive marine environments. The anti-corrosion and high-temperature resistance of SS 321 enhance safety and operational continuity.

These examples illustrate why Mcneil is considered one of the leading exporters of ss 321 Condensate Pot in Malaysia, capable of fulfilling both standard and high-spec requirements.

Benefits of Choosing SS 321 for Condensate Applications

SS 321 stands out due to its titanium-stabilized structure, which enhances its resistance to intergranular corrosion—a common issue in high-temperature environments. This makes it ideal for use in steam and gas lines, where temperatures regularly exceed 800°C.

The material also resists scaling and pitting, ensuring a longer service life compared to conventional grades like SS 304. The smooth internal surface of an instrumentation ss 321 Condensate Pot also reduces pressure drop and facilitates better drainage of condensate, improving system efficiency.

When considering long-term investments in instrumentation systems, SS 321 provides durability, operational safety, and lower total cost of ownership.

Quality Certifications and Testing Procedures

Mcneil ensures that each SS 321 condensate pot is manufactured in compliance with international quality benchmarks. Tests conducted include:

Hydrostatic testing at 1.5 times the design pressure

Pneumatic leak testing with soap solution

PMI (Positive Material Identification)

Radiographic and ultrasonic inspection (on request)

Clients receive full documentation packages, including MTCs, compliance statements, and dimensional drawings. Mcneil’s products are eligible for third-party inspections by agencies like BV, Lloyd’s, and TUV upon client request. This makes them a reliable ss 321 Condensate Pot exporter for projects with stringent QA/QC requirements.

Packaging and Delivery Process for Malaysia

Mcneil uses export-grade packaging that includes anti-corrosive wrapping, foam padding, and heat-number labeling. All shipments are packed in fumigated wooden crates with clear identification tags for easy handling and installation.

The company collaborates with reliable logistics providers to ensure that all consignments reach clients in Malaysia damage-free and on time. Whether shipped by air or sea, each order includes a packing list, invoice, and bill of lading to streamline customs clearance.

Why Choose Mcneil in Malaysia?

Mcneil’s competitive edge lies in its blend of technical expertise, manufacturing capability, and customer support. Clients benefit from:

Quick response times for inquiries and quotes

Design customization to fit unique system layouts

Competitive pricing without compromising quality

Strong after-sales service and on-site guidance when needed

As a ss 321 Condensate Pot supplier with a consistent track record, Mcneil fosters long-term relationships with its clients. Many Malaysian clients opt for recurring purchase agreements due to the trust and consistency Mcneil offers.

Frequently Asked Questions (FAQs)

What Certifications Are Included? All condensate pots are supplied with MTCs, pressure test certificates, and compliance declarations. Optional TPI certificates are available upon request.

Can Mcneil Handle Large Orders? Yes. Mcneil’s scalable production facilities and global logistics network make them capable of fulfilling large and urgent orders efficiently.

What Makes SS 321 Better Than Other Grades? SS 321 offers superior high-temperature resistance and corrosion protection, especially in oxidizing environments. It is a preferred material for steam and gas service where SS 304 may fall short.

Conclusion

Choosing the right supplier for condensate pots can significantly impact system performance and project timelines. Mcneil Steel & Alloys FZE stands out as a trusted ss 321 Condensate Pot manufacturer in Malaysia, offering top-quality products backed by engineering support and timely delivery. Whether your project involves high-temperature steam lines or sensitive instrumentation systems, Mcneil delivers reliability you can count on.

0 notes

Text

What Is a Stainless Steel Manifold Valve and How Does It Work?

An essential part of fluid and gas management systems, a stainless steel manifold valve is made to distribute, isolate, and control flow in industrial settings. Because of their robustness, resistance to corrosion, and capacity to function in high-pressure settings, these valves are extensively utilized in a variety of industries, including petrochemicals, instrumentation, power generation, and oil and gas.

Structure and Components

A stainless steel manifold valve typically consists of multiple valves integrated into a single block or unit. The primary types include:

Two-Valve Manifold: Used for simple isolation and equalization in pressure measurement applications.

Three-Valve Manifold: Commonly used with differential pressure transmitters, incorporating two isolation valves and an equalization valve.

Five-Valve Manifold: Includes additional vent or test valves, offering more functionality in complex systems.

These manifold valves feature key components such as isolation valves, equalization valves, vent valves, and mounting flanges, all made from stainless steel to ensure longevity and resistance to extreme conditions.

How It Works

The function of a stainless steel manifold valve depends on its configuration and application:

Isolation: The isolation valves allow operators to cut off fluid or gas flow to perform maintenance or calibration on instruments without shutting down the entire system.

Equalization: In three- and five-valve manifolds, the equalization valve balances pressure between the high and low sides of a differential pressure transmitter, ensuring accurate readings.

Bleeding and Venting: Some manifolds include vent valves to release trapped air, remove excess pressure, or facilitate system testing.

Flow Regulation: By controlling the opening and closing of valves, operators can precisely regulate the flow rate and pressure within the system.

Benefits of Stainless Steel Manifold Valves

Corrosion Resistance: Stainless steel construction prevents rust and degradation, even in harsh environments.

High Pressure and Temperature Tolerance: Suitable for extreme industrial applications.

Compact Design: Reduces the need for multiple separate valves, minimizing space and connection points.

Enhanced Safety: Reduces leak points, improving overall system integrity.

0 notes

Text

Industrial Manifold Valves Manufacturer in India

India has become a hub for high quality industrial equipment manufacturing, and manifold valves play a critical role in industrial applications across multiple sectors. As a leading manifold valves manufacturer in Mumbai, Chennai, Ahmedabad, Vadodara, Bengalore, Gujarat, Rajasthan, Ghaziabad and Delhi in India, Pedlock has carved a niche in providing reliable, durable, and precision engineered solutions.

Manifold valves are essential components in fluid control systems. These devices consolidate multiple functions into a single compact unit, allowing for easier installation, maintenance, and operation. Their versatility makes them indispensable in industries like oil and gas, petrochemicals, power generation, and pharmaceuticals.

Key Features of Manifold Valves

Precision Engineering: Manifold valves are crafted to ensure leak-proof performance and seamless operation under high pressure and temperature.

Corrosion Resistance: With materials like stainless steel and exotic alloys, they resist harsh environmental conditions.

Compact Design: Space-saving designs ensure easy integration into complex systems.

Long Lifespan: Engineered for durability, these valves withstand rigorous usage.

A Trusted Name in Manifold Valves Manufacturer in Across India

Why Choose Pedlock?

Pedlock is synonymous with excellence in manifold valves manufacturer in Delhi, Ahmedabad, Gujarat, Chennai, Bengalore, Mumbai, Rajasthan, Vadodara and Ghaziabad, India. Here are the reasons why industries trust:

Superior Quality Control: Our Company ensures every valve meets stringent quality standards through rigorous testing.

Innovative Design: The Company’s engineering team focuses on creating innovative solutions tailored to client needs.

Global Standards Compliance: Pedlock’s valves adhere to international standards like ISO, ASME, and ASTM.

Wide Product Range: From simple two-valve manifolds to complex five-valve manifolds, our company offers it all.

Types of Instrument Manifold Valves

1. Two Valves Manifolds

Two valve manifolds are used for isolating and bleeding applications. They typically consist of an isolation valve and a bleed valve.

Features

Compact and lightweight design

Suitable for pressure instruments

High-pressure rating compatibility

2. Three Valves Manifolds

Three valve manifolds are widely used in differential pressure transmitters. They include two isolation valves and one equalizing valve.

Applications

Differential pressure measurement in process systems

Minimizing pressure fluctuations during maintenance

3. Five Valves Manifolds

These advanced manifolds are ideal for applications requiring high accuracy and reliability.

Advantages

Enhanced functionality with two isolation valves, two equalizing valves, and a vent valve

Designed for high-pressure and high-temperature environments

4. Instrument Manifolds Valves

Instrument manifolds valves integrate multiple connections, ensuring efficient monitoring and control.

Industries Served

Oil and gas exploration

Petrochemical processing

Power plants

Applications of Manifold Valves

Manifold valves serve diverse industries and applications, including:

Oil and Gas: Used in upstream, midstream, and downstream operations for pressure and flow control.

Petrochemicals: Ensure precise control and measurement in chemical processing units.

Power Generation: Monitor and manage steam and gas flows in power plants.

Pharmaceuticals: Enable sterile and controlled environments for drug manufacturing.

Water Treatment: Facilitate efficient flow management in desalination and purification plants.

Advantages of Choosing Pedlock’s Manifold Valves

Customization Options: our company offers customized solutions to meet specific industrial requirements.

Durability: High-quality materials ensure longevity and reliability even in challenging environments.

Cost-Effectiveness: Competitive pricing without compromising on quality.

Quick Delivery: An extensive distribution network ensures timely delivery.

Expert Support: Dedicated customer support for pre-sales and post-sales queries.

Our Commitment to Sustainability

Our company not only focuses on delivering top manifold valves but also emphasizes sustainability. The company employs eco-friendly practices in its manufacturing processes, reducing its carbon footprint while ensuring high product quality.

Conclusion

Pedlock stands out as a premier manifold valves manufacturer in Chennai, Ahmedabad, Gujarat, Vadodara, Delhi, Mumbai, Rajasthan, Ghaziabad and Bengalore, India, offering unparalleled quality, a wide range of products, and exceptional customer service. Whether you need two-valve, three-valve, or five-valve manifolds, our company has the expertise and resources to deliver tailored solutions.

#manifold valves manufacturer#manifold valves manufacturer in Mumbai#manifold valves manufacturer in Chennai#manifold valves manufacturer in Ahmedabad#manifold valves manufacturer in Gujarat#manifold valves manufacturer in Bengalore#manifold valves manufacturer in Rajasthan#manifold valves manufacturer in Delhi#manifold valves manufacturer in Ghaziabad#manifold valves manufacturer in Vadodara

1 note

·

View note

Text

Selecting the Right Manifold Valves for Your Pressure Gauge

When running with pressure gauges in commercial and instrumentation structures, manifold valves are important components that make protection, performance, and reliability. A carefully selected manifold valve guarantees accurate strain readings, prevents leaks, and extends the lifespan of the stress gauge. But how do you pick out the right manifold valves for your unique wishes? This blog will guide you through the essential elements to bear in mind while deciding on manifold valves, ensuring your strain gauge operates successfully.

Understanding Manifold Valves

Manifold valves are specialized gadgets that connect strain gauges, transmitters, or switches to the method line. They perform essential functions like separating the gauge, bleeding off trapped stress, and equalizing strain in differential stress gauges. These valves are integral in industries together with oil and gas, petrochemicals, prescribed drugs, and energy technology.

Manifold valves are to be had in various configurations, together with 2-valve, 3-valve, and 5-valve assemblies, each serving unique applications. Choosing the appropriate configuration depends on the sort of stress gauge and the character of the software.

Factors to Consider When Choosing Manifold Valves

Application Requirements

The first step in deciding on the proper manifold valve is knowing the software. Determine the type of strain gauge being used, the working pressure range, and the system fluid. Manifold valves have to be compatible with the running conditions, which include temperature and strain, as well as fluid properties like corrosiveness or viscosity.

Valve Material

Material choice is important for ensuring the durability and reliability of the manifold valves. Common substances include stainless steel, carbon steel, and excessive-overall performance alloys. For corrosive environments, stainless steel or specialized alloys are best. Ensure the material aligns with your procedure conditions to save you an untimely failure or leakage.

Valve Configuration

Choose the manifold valve configuration based totally on the functionality required:

2-Valve Manifold Valves: Suitable for static strain and liquid level packages. They normally encompass isolation and vent valves.

3-Valve Manifold Valves: Commonly used for differential pressure size, those valves encompass two isolation valves and one equalizing valve.

5-Valve Manifold Valves: Ideal for superior applications, they consist of isolation valves, two equalizing valves, and one vent valve.

Pressure and Temperature Ratings

Ensure the manifold valves can manage the strain and temperature of your utility. Exceeding the valve’s rated limits can lead to dangerous screw-ups. Always talk over the producer’s specs to match the valve’s rankings along with your system's necessities.

Ease of Installation and Maintenance

Look for manifold valves which can be cleaned to put in and keep. Compact designs and user-pleasant features can reduce downtime and labor fees. For instance, Instrumxx Industries gives manifold valves with ergonomic designs that ensure smooth operation and trouble-free protection.

Leak Prevention

Leaks in instrumentation systems can result in inaccuracies and capability dangers. High-quality manifold valves with precision engineering and durable sealing mechanisms decrease the hazard of leaks. Selecting a reputable manifold valve provider guarantees product reliability.

Why Quality Matters in Manifold Valves

Investing in terrific manifold valves may additionally contain better advance charges, but it will pay off in terms of overall performance and durability. Poor exceptional valves can bring about common preservation, sudden downtime, and safety dangers. Instrumxx Industries, an ISO-licensed manufacturer, emphasizes "Xtra Quality Xtra Endurance," ensuring that their manifold valves deliver constant and dependable overall performance in traumatic environments.

Benefits of Choosing Instrumxx Industries for Manifold Valves

Instrumxx Industries, hooked up in 2021, has quickly ended up dependent on manifold valve suppliers below the brand name ‘IXX.’ Here’s what sets them apart:

ISO Certification: Ensures compliance with global quality requirements.

Comprehensive Product Range: From manifold valves to fittings and condensate pots, they may be a one-stop solution for instrumentation merchandise.

Custom Solutions: They provide tailor-made manifold valves to satisfy precise industry necessities.

Durability and Precision: Their merchandise is designed to offer unequaled patience and precision, making them a preferred preference across industries.

Steps to Ensure the Right Selection

Evaluate Your System: Analyze your stress gauge setup and operational situations.

Consult with Experts: Collaborate with a dependable manifold valve supplier to pick out the nice product for your utility.

Review Specifications: Always affirm the valve’s material, configuration, and ratings against your application desires.

Test for Compatibility: Ensure the manifold valve integrates seamlessly with your pressure gauge and method line.

Applications of Manifold Valves

Manifold valves are flexible and discover packages in a huge range of industries:

Oil and Gas: For stress dimension in pipelines and refining approaches.

Power Generation: To display boiler and turbine pressures.

Chemical Processing: For coping with corrosive and dangerous fluids.

Pharmaceuticals: To make certain precision in sterile environments.

Conclusion

Selecting the proper manifold valves in your strain gauge is an important decision that affects the overall performance and protection of your system. By thinking about factors like application requirements, valve fabric, configuration, and stress rankings, you could make a knowledgeable choice. Partnering with a reputable manifold valve provider ensures incredible products that meet the demands of cutting-edge commercial packages.

Instrumxx Industries, with its commitment to "Xtra Quality Xtra Endurance," provides dependable manifold valves and different instrumentation merchandise below the emblem called 'IXX.' Whether you're searching out preferred or customized answers, we are your trusted companion for instrumentation hardware.

0 notes

Text

How to Pick a Reliable Manifold Valve

Manifold valves are essential components in diverse commercial structures that control the drift of fluids and gases. Whether it's for oil and gasoline, chemical processing, or energy generation, selecting the right manifold valve can appreciably affect the efficiency, protection, and performance of your operations.

However, with many manufacturers and varieties to be had, it may be hard to select the most dependable manifold valve for your unique wishes. This weblog will guide you through the critical elements to consider whilst deciding on manifold valves.

Understanding Manifold Valves

Before diving into the selection manner, it’s important to understand what manifold valves are. In business settings, manifold valves are used to isolate, vent, or control the strain of fluid or gasoline in a pipeline or device. These valves are commonly used with strain units like transmitters, gauges, or strain switches. They are designed to connect multiple valves right into an unmarried unit, supplying greater manipulation over the fluid or gasoline glide and minimizing leakage dangers.

Choosing the right manifold valves in your software involves thinking about several technical and operational elements to make certain most overall performance and protection. Below, we talk about the important steps to selecting dependable manifold valves.

1. Understand Your Application Requirements

The first step in deciding on manifold valves is understanding the utility for which you want them. Different industries and procedures have specific necessities, so it’s important to perceive these earlier than making a decision.

Pressure Range: Consider the pressure ranges the manifold valve needs to withstand. Manifold valves are rated for unique stress capacities, normally starting from low to extraordinarily high pressures. Ensure the manifold valve you choose can handle the maximum strain on your system.

Temperature Conditions: Industrial environments regularly issue manifold valves to extreme temperatures. Choose valves that could function efficiently on your system’s temperature range without compromising their structural integrity.

Media Compatibility: The kind of fluid or gas that the valve will deal with is vital. Whether it’s a corrosive chemical or a standard gas, make certain the manifold valve fabric is well suited with the media to avoid corrosion or degradation through the years.

2. Material Selection

Choosing the right cloth for manifold valves is vital to their sturdiness and reliability. Manifold valves are to be had in a number of substances, which includes stainless-steel, carbon metallic, and high nickel alloys.

Stainless Steel: Stainless steel manifold valves are corrosion-resistant, making them ideal for corrosive environments and packages wherein hygiene is vital, along with meal processing and prescription drugs.

Carbon Steel: Carbon steel is powerful and appropriate for high-stress applications however may not be as corrosion-resistant as chrome steel.

High Nickel Alloys: For extraordinarily harsh environments, high nickel alloys together with Inconel or Monel offer superior resistance to corrosion and excessive temperatures. These alloys are normally used in industries like chemical processing and offshore oil and gas platforms.

When deciding on manifold valves, recall the working surroundings and make sure the fabric can withstand both the physical and chemical stresses it will come upon.

3. Valve Configuration

Manifold valves come in one-of-a-kind configurations relying on your utility wishes. The most not unusual types are:

2-Valve Manifold: Typically used for pressure units, this configuration permits isolation and calibration of the device.

3-Valve Manifold: This is usually used for differential pressure transmitters and enables zeroing calibration, and isolation capabilities.

5-Valve Manifold: Used in extra complex structures, the 5-valve manifold configuration gives additional alternatives for isolation, venting, and calibration.

Choosing the right valve configuration depends on the complexity of your system and the wide variety of strain points you want to control.

4. Seal Type and Design

Seals are a vital thing of manifold valves as they save you leaks and make certain the integrity of the device. When choosing a manifold valve, make certain the seal layout is strong and appropriate for the utility.

Metal-to-Metal Seals: These seals are usually used in high-strain and high-temperature environments. They offer tremendous sturdiness and are less susceptible to put on.

Soft Seals: Soft seals are more flexible and can offer a tighter seal for low-stress programs, but they'll put on out faster, specifically in extreme situations.

Also, take a look at whether or not the manifold valve layout provides a clean get-right of entry for maintenance and repairs. A well-designed valve should allow for short substitution of seals without disrupting the entire system.

5. Safety Features

When it comes to industrial applications, safety has to usually be a pinnacle priority. Manifold valves play an important role in preserving safe operation with the aid of controlling strain and separating critical equipment.

Look for safety functions like blow-out proof stems, which save you the stem from being ejected in case of inner pressure build-up. Additionally, take into account valves with anti-tamper features to keep away from unintentional adjustments.

6. Reliability and Certifications

Manifold valves are utilized in sensitive commercial techniques, in which failure can lead to substantial downtime, expensive repairs, and safety dangers. Therefore, selecting manifold valves from a good producer with an established track file is important.

Look for manifold valves that adhere to industry standards and certifications consisting of API, ISO, and ASME. Valves that comply with these standards ensure higher reliability and meet stringent safety necessities.

7. Testing and Quality Assurance

When choosing manifold valves, make certain that they undergo rigorous trying out before use. Reliable producers regularly test their manifold valves for stress, leakage, and material integrity.

Testing can encompass hydrostatic checking out, pneumatic checking out, and overall performance assessments below simulated working situations. Ask the manufacturer or provider for documentation that indicates the valve has surpassed all essential nice checks.

8. Cost Considerations

Cost is continually a component whilst choosing a business system, however it’s important to value stability with quality and reliability. While it is tempting to move for less expensive manifold valves, consider that low-best valves are more susceptible to failure, which could lead to higher renovation fees and capacity device shutdowns.

It’s higher to spend money on notable manifold valves from professional providers to make certain long-time period performance and value savings.

Conclusion

Picking a dependable manifold valve calls for careful attention to numerous factors, which includes software requirements, material compatibility, valve configuration, seal design, and protection capabilities. By informing the precise wishes of your system and deciding on the proper kind of manifold valve, you can ensure efficient, secure, and dependable operation on your business approaches.

For those seeking out pinnacle-satisfactory manifold valves, Bu-Lok is one of the leading and maximum prominent manufacturers, traders, and suppliers of stainless-steel, high nickel steel, alloy metallic, and carbon steel products in numerous paperwork, such as pipes, fittings, flanges, fasteners, plates, and round bars. Contact Bu-Lok today to discover their comprehensive range of manifold valves tailor-made to meet your particular commercial needs.

0 notes

Text

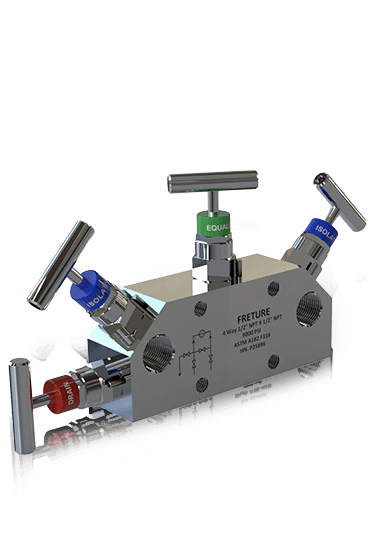

4 Way Manifold Valve: Key Applications and Benefits

A 4 Way Manifold Valve is a crucial component in many industrial systems, especially in the oil and gas, chemical, and pharmaceutical industries. These valves are designed to streamline pressure measurement processes, particularly when used with pressure transmitters and gauges. They ensure accurate readings, simplify maintenance, and improve overall system reliability.

In this article, we will explore the structure, function, and key advantages of 4 Valve Manifolds, along with a closer look at their applications in pressure transmitters and gauges.

What is a 4 Way Manifold Valve?

A 4 Way Manifold Valve is a multi-port valve designed to control the flow of fluids in a pipeline. It typically consists of four valves integrated into a single unit, allowing for the isolation, equalization, and venting of pressure instruments. This makes it highly versatile and suitable for pressure measurement systems.

The valve's four ports typically serve different purposes:

Isolation Valves (2 ports): These valves are used to isolate the pressure instrument (e.g., pressure transmitter or gauge) from the process fluid, ensuring safe removal or maintenance of the instrument without disrupting the entire system.

Equalizing Valve (1 port): This valve equalizes the pressure across both sides of the transmitter or gauge, ensuring accurate measurements.

Venting Valve (1 port): This valve allows for the safe venting of trapped pressure, preventing potential damage to the instrument or the system.

Applications of 4 Way Manifold Valves

4 Valve Manifold for Pressure Transmitter Pressure transmitters are critical in monitoring and controlling industrial processes. The 4 valve manifold for pressure transmitter plays a key role in protecting the transmitter and ensuring accurate readings. These valves allow operators to isolate the transmitter from the process, equalize pressures, and safely vent any excess pressure before maintenance or calibration.

Isolation: By using the isolation valves, the pressure transmitter can be completely cut off from the process line, enabling safe removal or replacement without affecting the overall system operation.

Equalization: The equalizer valve balances pressure on both sides of the transmitter, preventing inaccurate readings due to differential pressures.

Venting: The venting valve allows for the controlled release of pressure before opening the transmitter, preventing system damage or hazards.

4 Valve Manifold for Pressure Gauge Pressure gauges provide essential data about system pressure. In high-pressure environments, a 4 valve manifold for pressure gauge ensures that the gauge can be isolated and serviced without halting operations. Like the pressure transmitter manifold, it offers isolation, equalization, and venting capabilities to ensure the gauge operates efficiently and safely.The manifold also protects the pressure gauge from pressure surges or process fluid contamination, ensuring longevity and accuracy. This is especially important in applications where continuous and precise pressure monitoring is critical, such as in oil and gas or pharmaceutical processing.

4 Way Valve Manifold for Pressure Transmitter In complex process systems, a 4 way valve manifold for pressure transmitter is essential for ensuring accurate pressure measurement and system safety. The four-port design allows for easy pressure balancing, maintenance, and venting, reducing the risk of inaccurate readings or system failures.This type of manifold is commonly used in critical industries such as chemical processing, where maintaining the integrity of pressure measurement devices is essential for both safety and operational efficiency.

Key Features and Benefits of 4 Way Manifold Valves

Compact Design One of the primary benefits of the 4 valve manifold is its compact design. By integrating multiple functions (isolation, equalization, and venting) into a single unit, these valves reduce the need for additional piping or components, saving space and simplifying installation.

Improved Safety The ability to isolate, equalize, and vent pressure instruments significantly enhances safety in industrial environments. Operators can safely remove or maintain pressure gauges and transmitters without risking exposure to high-pressure fluids or gases. Additionally, the venting function ensures that trapped pressure is safely released, preventing potential accidents.

Enhanced Accuracy Pressure measurement instruments rely on stable, equal pressures for accurate readings. The 4 way valve manifold for pressure transmitter and gauge ensures that pressure is properly equalized across both sides of the instrument, reducing the risk of measurement errors. This is especially important in industries where precise pressure monitoring is critical for product quality or safety.

Versatility These manifolds are highly versatile and can be used with a variety of pressure instruments, including transmitters, gauges, and switches. Whether you're working in an oil refinery or a pharmaceutical manufacturing plant, a manifold 4 valve will meet the demands of high-pressure environments.

Ease of Maintenance The integrated design of the 4 valve manifold allows for easy maintenance of pressure instruments without shutting down the entire system. Operators can isolate the instrument, vent any remaining pressure, and perform maintenance tasks with minimal disruption to operations. This reduces downtime and maintenance costs, improving overall system efficiency.

Corrosion Resistance Many 4 valve manifolds are constructed from high-quality materials such as stainless steel or carbon steel, making them resistant to corrosion and suitable for harsh environments. In industries where exposure to corrosive fluids or extreme temperatures is common, these manifolds ensure long-term reliability and performance.

How to Choose the Right 4 Way Manifold Valve

Selecting the appropriate 4 valve manifold for your system depends on several factors:

Pressure Rating Ensure that the manifold is rated for the maximum pressure in your system. Operating a manifold outside its pressure limits can lead to valve failure or system damage.

Material Compatibility Choose a manifold made from materials compatible with your process fluids. For instance, stainless steel manifolds are highly resistant to corrosion and suitable for a wide range of industrial applications, while carbon steel is typically used for lower-cost applications.

End Connections Consider the type of end connections you require, such as threaded or flanged connections. The connection type should match the specifications of your pressure instruments and piping system.

Operating Temperature Make sure the manifold is rated for the temperature range of your system. High-temperature applications may require specialized materials or seals to ensure long-term performance.

Application Finally, consider the specific application. Whether you're using the manifold with a pressure transmitter or gauge, ensure that it has the necessary isolation, equalization, and venting capabilities to meet your system's requirements.

Best Practices for Installation and Maintenance

Proper Installation Ensure that the 4 valve manifold is properly installed to prevent leaks or pressure drops. Check that all connections are secure and that the manifold is mounted in a position that allows easy access for maintenance.

Regular Maintenance Perform regular maintenance checks to ensure the manifold and pressure instruments are functioning correctly. This includes inspecting seals, checking for leaks, and testing the isolation, equalization, and venting functions.

Calibrate Instruments Periodically calibrate pressure transmitters and gauges to ensure accurate readings. The 4 valve manifold simplifies this process by allowing easy isolation and venting of the instrument.

Use in Clean Environments If used in industries with strict cleanliness requirements, such as pharmaceuticals, ensure that the manifold is regularly cleaned to prevent contamination. Manifolds designed for clean environments may include features such as smooth internal surfaces to minimize fluid retention.

A 4 Way Manifold Valve offers a reliable solution for managing pressure measurement in industrial systems. Its compact design, enhanced safety features, and ease of maintenance make it a popular choice across a wide range of industries. By ensuring accurate pressure readings, it helps improve system efficiency and reduces the risk of costly errors or accidents.

When selecting a 4 valve manifold, consider factors such as pressure rating, material compatibility, and end connections to ensure optimal performance in your specific application.

Buy 4 Way Manifold Valves from Freture Techno Pvt. Ltd., a trusted manufacturer of high-quality industrial valves and instrumentation. Their manifolds are designed to meet the demands of modern industrial processes, ensuring reliability, safety, and precision in pressure measurement systems.

#manifold valves#2 way manifold valves#3 way manifold valves#4 way manifold valves#5 way manifold valves#instrumentation valves#freture techno

0 notes

Text

Discover the Leading Five Valve Manifold Supplier in India

In the intricate world of industrial instrumentation and control, the role of precision-engineered components cannot be overstated. Among these, the five valve manifold stands out as a critical component, ensuring the smooth and efficient operation of pressure measurement systems. If you're in search of a reliable five valve manifold supplier in India, you need a partner who not only understands the importance of quality but also delivers unmatched performance.

Understanding the Importance of Five Valve Manifolds

A five valve manifold is a crucial device used in differential pressure measurement applications. It facilitates the isolation, calibration, and maintenance of pressure instruments, ensuring accuracy and reliability in process control systems. Typically, a five valve manifold includes two isolation valves, two equalizing valves, and one vent valve. These valves work together to protect the differential pressure transmitter from potential damage and to maintain the integrity of the measurement process.

Given the complexity and critical nature of these systems, choosing the right supplier is essential. A reliable five valve manifold supplier in India will provide products that meet stringent quality standards, ensuring durability, precision, and long-term reliability.

Why Choose the Leading Five Valve Manifold Supplier in India?

When it comes to selecting a five valve manifold supplier, several factors must be considered to ensure that you receive a product that meets your specific requirements. Here’s why choosing a leading supplier makes all the difference:

High-Quality Materials and Manufacturing ProcessesA top-tier supplier uses only the highest quality materials in the manufacturing process. This ensures that the five valve manifolds are resistant to corrosion, capable of withstanding high pressures, and durable enough to last in demanding industrial environments. The manufacturing process is also meticulously controlled to guarantee precision and consistency across all products.

Customization and VersatilityLeading suppliers understand that different industries have unique requirements. As such, they offer customizable solutions to meet the specific needs of various applications. Whether you require a standard configuration or a customized design, a reliable supplier will provide the flexibility you need to achieve optimal performance in your systems.

Compliance with Industry StandardsCompliance with national and international standards is a hallmark of a reputable supplier. This ensures that the five valve manifolds you receive are not only of high quality but also meet the safety and performance standards required in your industry.

Technical Support and After-Sales ServiceA trusted supplier offers more than just products—they provide comprehensive technical support and after-sales service. This includes assistance with installation, troubleshooting, and maintenance, ensuring that your systems operate smoothly and efficiently.

Competitive Pricing and Timely DeliveryWhile quality is paramount, cost-effectiveness and timely delivery are also crucial factors in the selection of a supplier. Leading suppliers offer competitive pricing without compromising on quality and ensure that your orders are delivered on time to keep your projects on schedule.

Applications of Five Valve Manifolds

Five valve manifolds are used across a wide range of industries, including:

Oil and Gas: For accurate differential pressure measurement in exploration and processing operations.

Chemical and Petrochemical: To ensure precise control in complex chemical processing systems.

Power Generation: For monitoring and controlling pressure in power plants to ensure safety and efficiency.

Pharmaceuticals: To maintain strict control over pressure in manufacturing environments where precision is critical.

Partner with the Best Five Valve Manifold Supplier in India

When you partner with a leading five valve manifold supplier in India, you gain access to high-quality products, expert knowledge, and reliable support. This ensures that your pressure measurement systems are equipped with the best components, leading to increased efficiency, safety, and overall performance.

If you're looking to source top-of-the-line five valve manifolds, ensure you choose a supplier who meets all these criteria. With the right partner, you can trust that your instrumentation and control systems will operate at their best, delivering accurate results and long-term reliability.

In conclusion, selecting the right five valve manifold supplier in India is essential for the success of your industrial operations. Focus on quality, customization, compliance, and support to ensure you receive the best products and services available.

0 notes

Text

Air Header type and function application in instrument system

In the elaborate global of industrial automation, countless components paintings together to orchestrate complex approaches. While excessive-tech machinery and sophisticated control systems often take center stage, a much less glamorous but equally essential element perforan a important role – the air header. As a leading air header manufacturer and supplier we understand the importance of these unsung heroes. Today, we delve into the sector of air headers, exploring their kinds, functions, and programs in tool systems.

Demystifying the Air Header:

An air header, also known as an instrument air manifold, is basically a vital distribution factor for compressed air inside a device device. Imagine a sequence of pipes related collectively, with inlets for receiving compressed air and stores for channeling it to diverse contraptions and devices. This reputedly simple design offers a mess of benefits:

Centralized Control: The air header affords a single point of right of entry for controlling and regulating the compressed air supply. This simplifies device management and preservation for our clients.

Efficient Distribution: By putting off the need for personal air strains jogging to each tool, air headers ensure a green and uniform distribution of compressed air at some stage in the system. This translates to price savings and a streamlined design in your tool system.

Reduced Cost and Complexity: Air headers minimize the amount of piping required, leading to decrease set up and protection expenses. They also streamline the general system layout, an advantage we strive to deliver.

Safety Enhancement: Air headers can be prepared with safety capabilities like pressure remedy valves, supporting to shield the gadget from capability overpressure situations, presenting an extra layer of protection on your device gadget.

Types of Air Headers: Tailored Solutions from Instrumxx

We understand that a one-size-fits-all technique does not work. That's why we provide diverse air header configurations to cater to unique application necessities. Here's a breakdown of some not unusual types:

Simple Air Headers: These basic headers characterize a single inlet and a couple of outlets, supplying a trustworthy solution for distributing air to a limited number of instruments. Ideal for smaller structures.

Sectional Air Headers: These modular headers include interconnected sections, taking into consideration enlargement and customization as needed. This is ideal for structures with varying air needs or ability destiny increase, presenting flexibility for our customers.

Filtered Air Headers: These headers comprise filtration elements to get rid of contaminants from the compressed air circulation, protecting touchy devices from damage. Perfect for applications requiring easy air.

Regulated Air Headers: These state-of-the-art headers integrate strain regulators at each outlet, allowing unique management of the air pressure brought to individual instruments. Ideal for structures where instruments require varying stress degrees.

The Power of Application: Where Instrumxx Air Headers Shine

The air headers find software in an extensive range of tool systems throughout numerous industries. Here are a few distinguished examples:

Process Control Systems: In chemical processing plants, refineries, and other centers, the air headers supply compressed air to pneumatic actuators that function valves, dampers, and different control factors.

Instrumentation and Control Panels: Our air headers offer a dependable source of air for powering pressure gauges, transmitters, and other gadgets used for method monitoring and manipulation.

Pneumatic Tool Systems: Our air headers deliver compressed air for various pneumatic tools utilized in manufacturing, meeting strains, and protection programs.

Power Generation Plants: Our air headers play a function in powering managed structures and pneumatic instruments within energy plant life.

Choosing the Right Air Header: Expert Guidance from Us

Selecting the top-rated air header in your tool device requires careful consideration, we're here to assist. Here are a few factors to don't forget:

Flow Rate Requirements: Identify the full compressed air call for your devices to make sure the selected header has sufficient capability. Our crew can assist you with this calculation.

Operating Pressure: Match the air header's strain rating to the strain wishes of your instruments. We provide air headers for various strain tiers.

Number of Outlets: Choose a header with sufficient retailers to accommodate all of your units. We have an extensive range of options to fit your wishes.

Material Compatibility: Select an air header supplier appropriate for the kind of compressed air being used and the environment it'll function in. Our crew can advise on the most appropriate material.

Safety Features: Consider the need for pressure remedy valves or different safety features relying on your software. We offer air headers with diverse safety functions.

Conclusion: Instrumxx - Your Trusted Partner for Air Headers

By expertise in the types, features, and programs of air headers, you could admire their massive role in ensuring the smooth operation of your tool systems.

0 notes

Text

Elevating Precision in Fluid Dynamics: The Role of Stainless Steel

In the complex world of fluid management, the advent of stainless steel needle valves has been a game-changer, significantly enhancing precision in controlling flow rates. These valves, known for their robustness and durability, are pivotal in applications requiring meticulous control over fluid dynamics. The material’s resistance to corrosion and ability to withstand high temperatures make stainless steel needle valves indispensable in industries ranging from oil and gas to pharmaceuticals. Their precision in flow control ensures that operations are efficient and safe, minimizing risks associated with high-pressure systems.

The Keystone of Modern Industrial Measurement: Manifold Innovations

ᅠThe integration of pressure transmitter manifold systems has revolutionized the way industries measure and control process pressures. These manifold systems, designed to connect a pressure transmitter to a process line, are critical in ensuring accurate pressure readings while providing a safe and reliable method for isolating the transmitter for maintenance or calibration. The ability to manage pressure measurements with such precision underscores the manifold's importance in safeguarding the integrity of industrial processes, highlighting its role as a cornerstone of modern measurement technology.

Navigating the Highs and Lows: Stainless Steel's Impact

ᅠStainless steel needle valves stand at the forefront of managing high-pressure environments with unparalleled precision. Their design allows for fine adjustments in flow, making them ideal for various industrial applications. This capability is particularly crucial in sectors where controlling the flow rate accurately can mean the difference between operational excellence and failure. The resilience of stainless steel further ensures that these valves maintain their integrity even in the harshest of environments, proving them to be a resilient and reliable choice for industries worldwide.

Advancing Process Control with Manifold Technology

The pressure transmitter manifold represents a significant advancement in process control, offering a sophisticated solution for managing system pressures with accuracy and reliability. This technology enables seamless integration with pressure transmitters, facilitating precise control and monitoring of process pressures. The manifold's design, which typically includes isolation, equalization, and venting capabilities, ensures that maintenance and calibration tasks can be performed safely and efficiently, minimizing downtime and enhancing overall system reliability.

ᅠAs industries evolve, the demand for high-quality, reliable valve solutions becomes increasingly critical. In this landscape, techtubes.in emerges as a beacon of excellence, specializing in manufacturing and supplying manifold valves that meet the highest standards of quality and performance. With a product range that includes stainless steel needle valves and pressure transmitter manifold systems, techtubes.in is dedicated to providing solutions that enhance industrial operations' efficiency, safety, and reliability. Their commitment to innovation and quality makes techtubes.in is the go-to source for industries seeking the best furnishing manifold valves, driving forward the future of fluid and pressure management technology.