#Types of Fabric Inspection Machine

Explore tagged Tumblr posts

Text

BEFORE YOU NOTICED — CHAPTER ONE

WARNINGS — chronic illness, psychological distress, emotional neglect, power imbalance, themes of isolation, and blood

you wake to the taste of rust. it’s faint, like a penny left too long in your mouth, but it’s there when you swallow. your tongue probes the back of your teeth, searching for a cut, a reason. nothing. you roll over, and the pillowcase crinkles under your cheek. there’s a stain, it’s small and red, almost like a crushed petal. your breath catches. you tug the case off before rafe stirs, his arm heavy across the sheets, his face still slack with sleep. you ball the fabric in your fist and slip from the bed, bare feet cold on the hardwood.

the washing machine hums in the laundry room, a low drone that fills the glass mansion rafe built for you both. you toss the pillowcase in with the towels, pour too much detergent, and watch the water churn. it’s fine. it’s nothing. a nosebleed, maybe. you’ve been stressed, haven’t you? the city’s too loud, the air too dry. you press your knuckles to your lips and tell yourself it’s fine.

in the bathroom, you stand at the sink, the one with the gold faucet rafe insisted on because it looked “timeless.” you brush your teeth, the mint sharp enough to burn. when you spit, the foam is pink. your stomach lurches, but you lean closer to the mirror, inspecting your reflection. your hair’s still perfect, smoothed from last night’s blowout. your skin is dull, but it always is this early. you’re still pretty. you have to be. you rinse the sink until the porcelain gleams, until there’s no trace of red.

you google it on your phone, fingers trembling as you type “blood in spit causes.” the results load slowly, the wi-fi flickering in this high-rise cage. stress. allergies. dehydration. you skim the benign ones, the ones that let you breathe. you don’t click on the others, the ones with words like “chronic” or “terminal.” you close the tabs, delete the search history, and set the phone face-down on the counter. it’s nothing. you’re fine. right?

rafe’s gone by the time you return to the bedroom, his side of the bed already cooling. a note on the nightstand, scrawled in his sharp handwriting: late meeting. don’t wait up. you trace the letters with your fingertip, the paper crisp under your touch. you fold it neatly, tuck it into the drawer with the others. he’s always late now, always chasing something bigger—deals, status, a version of himself he hasn’t caught yet. you don’t mind. at least you tell yourself you don’t mind.

you spend the morning in the garden, the one you planted when you first moved in. it’s tucked against the glass walls of the mansion, a small rebellion against the sterile lines of rafe’s world. the forget-me-nots are wilting, their blue petals curling at the edges. you kneel in the dirt, your silk robe—the one he bought, still tagged—slipping off one shoulder. you water the flowers, your hands steady even as your chest aches. it’s just a cough, you think, when it comes again, sharp and wet. you cover your mouth with your sleeve, and when you pull it away, there’s a speck of red. you fold the fabric over, hide it in the folds of the robe. no one’s here to see. not anymore at least.

you shower after, the water is scalding, as if you your trying to burn the rust from your lungs. you scrub until your skin’s raw, until the mirror fogs and you can’t see yourself anymore. you wrap your hair in a towel, paint your nails coral—the shade rafe mentioned once, three years ago, when you were still new to each other. you sit on the edge of the tub, blowing on your fingertips, watching the polish dry. it’s chipped already, a tiny flaw at the edge of your thumb. you’ll fix it later. you always fix it.

the day stretches, empty and gleaming. you wander the mansion, your footsteps echoing on the marble. the rooms are too big, the furniture too sharp, everything chosen by a designer rafe hired because he wanted it “perfect.” you touch the back of a chair, the leather cool under your palm. you wonder if he’d notice if you moved it, just an inch. but you don’t try.

you cook dinner, something simple—herb-roasted chicken, rafe’s favorite. you set the table for two, the plates, the wine glasses catching the city lights through the floor-to-ceiling windows. you light an old candle, the flame flickering through the light. you sit down and wait. the clock ticks past eight, then nine, and suddenly your stomach twists, but you don’t eat. you just sip on water, your throat tight, and tell yourself it’s fine. he’s busy. he’s always busy.

at ten, you cough again, harder this time. you stumble to the sink, gripping the counter as your body shakes. the blood’s thicker now, a clot that stains your palm. you stare at it, your breath shallow, your pulse loud in your ears. you turn on the faucet, watch the red swirl down the drain. you scrub your hands until they’re pink, until the water runs clear. you dry them on a towel, fold it carefully, and tuck it into the laundry basket. no one will know.

you sit by the window, the city sprawling below, a glittering maze of lights and noise. you’re high above it all, untouchable, the wife everyone envies. your hair’s still perfect, your nails are done, your smile quiet when you practice it in the reflection. you’re still pretty, even when you bleed. you have to be.

rafe comes home at 11:47 pm. you hear the door, the jangle of his keys, the heavy tread of his shoes. you stand, smoothing your dress, the one you wore for him last month when he said you looked “nice.” he’s in the kitchen, loosening his tie, his jaw tight from whatever meeting kept him. you step into the light, your heart stuttering as he glances up.

“you’re still up,” he says, not a question. his eyes skim over you, quick, like he’s checking a box. “you look tired.”

you smile, the one you’ve practiced, the one that doesn’t waver. “just a long day,” you say, your voice soft, the way he likes it.

he kisses your cheek, quick, mechanical, like he’s clocking in. his lips are cold, and you smell the city on him—smoke, cologne, something sharper you can’t name. he moves past you, already pulling out his phone, scrolling through messages you’ll never see. “food’s cold,” he says, glancing at the table. he doesn’t sit.

“i can heat it,” you offer, but he’s already shaking his head, heading for the stairs.

“not hungry. long day.” he pauses, half-turns, his profile sharp against the city glow. “you should sleep. you don’t look good.”

you nod, your throat tight, your hands clasped to hide the tremor. “okay.”

he’s gone before you can say more, his footsteps fading up the stairs. you stand there, the candle still burning, the chicken untouched, the wine glasses empty. you blow out the flame, the smoke curling like a ghost. you clear the table, wrap the food, wipe the counter until it shines. you cough once, softly, and check your palm. it’s clean. for now.

you climb the stairs, the mansion too quiet, the air too heavy. you pass the bedroom door, rafe’s already asleep, his phone glowing on the nightstand. you slip into the bathroom, open your makeup drawer, and pull out the bottle of pills you hid last week. you don’t take one. you just hold it, the plastic cool against your skin. you’ll call the doctor tomorrow. or the day after. there’s time. there has to be.

you slide into bed, the sheets crisp and cold. you curl onto your side, away from rafe, your knees tucked to your chest. you think of the garden, the forget-me-nots, the way they droop under the weight of their own petals. you think of the silk robe, folded in the closet, waiting for a day he’ll notice. you think of the blood, hidden in sinks and sleeves and pillowcases.

you close your eyes, your breath shallow, your heart a quiet drum. you’re still pretty, you tell yourself. you’re still the wife worth coming home to.

you dream of red petals, falling.

#cameronsbabydoll ⋆. 𐙚 ˚#rafe cameron#rafe cameron headcanons#rafe cameron fluff#rafe cameron x yn#rafe cameron x reader#rafe cameron blurb#rafe cameron fanfic#rafe obx#rafe cameron series#rafe cameron angst#outerbanks angst#angst fic#rafe cameron fic#rafe cameron fanfiction#rafe cameron obx#rafe cameron smut#rafe cameron imagine#rafe cameron x you#rafe cameron prompt#rafe cameron x female reader#husband rafe cameron#husband!rafe#outerbanks#drew starkey fic#drew starkey angst#drew starkey x reader#drew starkey

743 notes

·

View notes

Text

Top Tips for Fast and Safe Panel Assembly

Panel assembly is a critical process in the electrical industry that directly impacts safety, performance, and efficiency. Whether you’re building distribution panels, control boards, or switchgear systems, the goal is to assemble panels quickly without compromising safety or quality. In this post, we’ll explore proven tips to help electricians, technicians, and panel builders streamline their workflow while ensuring compliance with safety standards.

1. Plan Thoroughly Before Assembly

Efficiency starts with preparation. Before you begin, study the layout drawings and electrical schematics carefully. Make a checklist of all the required components — circuit breakers, relays, terminal blocks, wire ducts, and enclosures.

· Pre-arrange tools and materials

· Verify component compatibility with design

· Identify high-priority tasks and dependencies

A well-organized plan saves time and avoids costly errors during installation.

2. Use Modular and Pre-Fabricated Components

Using modular devices like DIN-rail mountable circuit breakers or pre-assembled terminal blocks can reduce build time significantly.

Benefits:

· Faster mounting and wiring

· Easier upgrades and replacements

· Reduced wiring complexity

Where possible, opt for plug-and-play components or pre-terminated wiring kits.

3. Maintain a Clean and Organized Work Area

A tidy workstation boosts productivity and prevents mistakes. Use labeled bins, trays, and tool organizers to keep everything accessible.

· Segregate power, control, and signal cables

· Keep fasteners and tools sorted by size/type

· Remove scrap materials and wire offcuts regularly

A clean work area also improves safety and reduces trip hazards.

4. Label Components and Wiring Clearly

Proper labeling speeds up installation and future maintenance. Use heat-resistant wire markers or automated labeling machines for consistency.

Label:

· All wires at both ends

· Control devices (relays, contactors, timers)

· Terminal blocks and busbars

Clear identification is essential for testing, fault isolation, and panel certification.

5. Use the Right Torque Tools

Over- or under-tightened terminals can cause failures or fire risks. Always use torque screwdrivers or wrenches calibrated to the manufacturer’s specifications.

· Ensure solid mechanical and electrical contact

· Reduce the risk of arcing or overheating

· Document torque settings for quality records

Following torque guidelines is a best practice for long-term reliability.

6. Apply Effective Cable Management

Good cable routing isn’t just about aesthetics — it enhances performance and safety.

· Use wire ducts, cable ties, and strain reliefs

· Maintain minimum bend radii, especially for data cables

· Separate AC power and control wiring to avoid interference

Neatly routed cables simplify inspections and future modifications.

7. Conduct Final Visual and Electrical Inspection

Before energizing the panel:

· Inspect all terminations and mounting

· Check for exposed conductors or loose parts

· Test insulation resistance and continuity

· Verify grounding and bonding paths

A comprehensive inspection reduces commissioning delays and ensures compliance with safety standards.

8. Document As-Built Changes

If any field modifications were made during assembly, update the panel drawings and documentation to reflect those changes.

Include:

· Wiring diagrams

· Component serial numbers

· Torque test records

· Electrical test results

Accurate documentation is essential for maintenance, certification, and future upgrades.

9. Train Your Assembly Team

Skilled workers build faster and safer panels. Provide regular training on:

· Electrical safety and lockout/tagout

· Schematic interpretation

· Safe use of hand and power tools

· Latest panel-building standards (e.g., IEC, UL, NEC)

An informed and competent team minimizes rework and enhances build quality.

Final Thoughts

Fast panel assembly doesn’t mean cutting corners. By following structured processes, using the right tools, and prioritizing safety, you can consistently deliver high-quality panels — on time and within budget.

Looking for top-tier switchgear accessories and panel-building solutions? Contact us today to explore how we can support your projects with reliable, efficient, and cost-effective products.

5 notes

·

View notes

Text

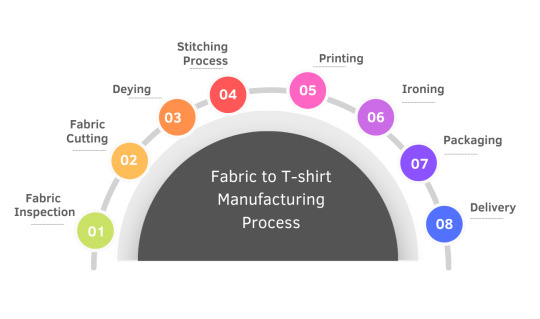

Have you wonder how a t-shirt is manufactured? Learn about t-shirt manufacturing process

The first t-shirt was manufactured in 1920. There are a huge variety of t-shirts manufactured all around the world starting with different types of neckband such as crew neck, V-neck, scoop neck and tank top. There are variations in sleeves such as full sleeves, half sleeves, capped, raglan and yoked. Raw materials used in the t-shirt manufacturing process are cotton and polyester. The neckband is made with a fabric named twill. A particular thread is used for stitching and sewing.

T-shirt Manufacturing Process

Cotton Farming: T-shirt manufacturing process starts from procuring cottons from farmers. Cottons are then converted into bales and transported to Ginning mills.

Ginning Mill: This is the place where cotton fiber and cotton seeds are separated. The cotton fiber is then used in manufacturing garments and cotton seeds are used in manufacturing vegetable oil.

Spinning : The cotton fibers are now separated and in this unit they are cleaned and cotton yarns are made out of it. Spinning unit involves many steps starting with Blow room → Combing → Carding → Drawing → Roving → Spinning.

Dyeing: The yarn is dyed using three dyeing processes: package dyeing, hank dyeing and warp dyeing. Package dyeing is the most popular dyeing process where yarn rolls are heated together with dye inorder to dye the yarn.

Knitting: Yarn enters the knitting machine as a raw material. There are various yarn inserted into the circular knitting machine, various yarn are intertwined together to make a sheet of fabric.

Inspection: Once the fabric is purchased by a garment manufacturer it is inspected by them in order to check any defectiveness or to check any shade variation. If the shade variation is found the cutting process is done accordingly.

Cutting: Many layers of the fabric are stacked together in this process and then using a bend knife cutting machine they are cut into different dimensions like front, back, sleeves, neckband and pocket if any.

Stitching: Different dimensions of fabric are stitched in this step using 2 methods of stitching overlock and superimposed. First front and back part are stitched then sleeves then neckband and at last the hem of the t-shirt.

Printing: Printing is done to the t-shirt to make it stylish. There are several types of printing. Screen-printing, digital printing, heat embossing and spray printing. Then these bulk printed t-shirts are transferred to the stitching department.

Finishing: This process is divided into 2 parts. Firstly, t-shirts are ironed in order to give it a finishing and appealing look and secondly, the tagging and packaging takes place. Then wholesalers and retailers offered to buy t-shirts in bulk.

#textile#textiles#dyeing#pattern#fiber art#fiber#fabric#knitting#sewing#patterns#business#clothing#manufacturing

2 notes

·

View notes

Text

Advanced Implant Compatibility with Multi-Unit Screws | MEDIDEN

MEDIDEN provides a comprehensive range of precision-engineered dental implant accessories and components, ensuring optimal compatibility, durability, and efficiency in clinical and laboratory settings. Multi-unit screws are specialized dental implant abutment systems used to secure prosthetic restorations onto multi-unit abutments, particularly in full-arch or All-on-X implant restorations, ensuring secure attachment.

Accessories for Implant Accuracy and Longevity:

The company accessories play a vital role in achieving precise implant positioning and long-lasting restorations. With high-performance tools like scan bodies, torque drivers, and analogues, they ensure seamless integration and durable clinical outcomes.

Adapter

Adapters for milling machines are crucial for securely holding pre-mill abutments during CAD/CAM milling, ensuring precise shaping and customization of dental components. They reduce movement during milling and are compatible with various Roland DWX series models.

Driver Kit

Driver kits are crucial tools for tightening abutments and prosthetic components, offering high Brinell hardness (55) durability, long-lasting use, color-coded heads for driver identification, support for various implant interfaces, and a boost in clinical and lab efficiency and organization.

Lab Driver Set

The lab driver set simplifies workflow in dental labs by providing color identification, extending tool life with heat-treated materials, reducing tool replacements, and improving lab productivity and workflow consistency.

Scanbody System Short Type

The short type Scanbody system is crucial for modern prosthetic design, ensuring accurate 3D scanning and implant positioning, improving alignment and fit in digital workflows, and being compatible with various implant systems worldwide.

Refill Torque Driver

Torque driver and refill tips provide consistent torque for implant component installation, offering economical refill ability, heat-treated strength, and easy tip replacement, extending tool life.

Polishing Handle

The polishing handle is crucial for fine finishing custom abutments without damaging components, preventing damage to implant-coupling surfaces, reducing polishing time, being available in various sizes, and improving final product quality.

Analog Type

Analog components are crucial in lab models for replicating implant positions during prosthetic design, compatible with various implant brands, facilitating accurate fabrication, and backed by strong material quality for long-term use.

Fix-Pen

Fix-pen simplifies lab workflows, reduces damage risks to analogues, and is ergonomically designed for smooth, controlled use.

Screw

Screw components are crucial for securing abutments and prosthetics, made from biocompatible, USA-sourced Ti6Al-4V ELI, and manually inspected for perfect fit and safety, offering mechanical stability and long-term performance.

Overall, products support dental workflow stages from scanning to fabrication and are versatile for most implant systems. They use high-grade materials and are inspected for long-lasting performance. They are durable and easy to use, enhancing efficiency and comfort for dental professionals.

If you are looking for implant systems, you can find them at MEDIDEN.

Click here if you are interested in MEDIDEN dental products.

View more: Advanced Implant Compatibility with Multi-Unit Screws.

0 notes

Text

How Indian Industrial Valve Manufacturers Are Shaping Global Supply Chains

Industrial valves play a critical role in controlling the flow of liquids, gases, and slurries in pipelines and machinery. They are used in almost every major industry—from oil and gas to water treatment, power plants, pharmaceuticals, chemicals, and food processing. Over the years, Industrial Valves Manufacturers in India have made a significant mark globally due to their consistent quality, competitive pricing, and technological improvements.

Let’s explore how India evolved from being a domestic supplier to becoming a global hub for industrial valve manufacturing.

1. Growing Demand from Indian Industries

India has seen rapid industrial development in the last two decades. Industries like oil & gas, petrochemicals, fertilizers, steel, power generation, and water treatment require a constant supply of industrial valves to manage pressure, flow, and safety within pipelines and systems.

This large-scale demand pushed Indian companies to start manufacturing a wide range of valves such as:

Gate valves

Globe valves

Check valves

Ball valves

Butterfly valves

Safety relief valves

Control valves

As a result, Indian manufacturers gained extensive knowledge and experience, allowing them to meet both domestic and international standards.

2. Skilled Workforce and Engineering Expertise

One of India's biggest strengths is its large pool of talented engineers and technicians. This skilled workforce enables Industrial Valves Manufacturers in India to:

Design technically accurate products

Maintain high quality control

Innovate with better materials and production techniques

Provide customized valve solutions

Many companies invest in training, research & development, and testing to improve the efficiency and durability of their valve products.

3. Cost-Effective Production and Competitive Pricing

Another major advantage India has is its cost-effective manufacturing ecosystem. The availability of:

Local raw materials

Affordable labor

Modern machining and foundry setups

...allows Indian manufacturers to offer top-quality valves at lower prices compared to European or American counterparts—without compromising on performance. This makes Indian valves highly attractive for international buyers.

4. Adoption of International Standards and Certifications

To compete globally, Indian manufacturers began adopting key certifications such as:

ISO (International Organization for Standardization)

API (American Petroleum Institute)

CE (European Conformity)

BIS (Bureau of Indian Standards)

These certifications assure customers that the products meet safety, quality, and environmental standards. Many Indian companies also conduct third-party inspections and rigorous in-house testing before shipping valves to overseas clients.

5. Government Support and Export Promotion

Government initiatives like ‘Make in India’ and Production-Linked Incentive (PLI) Schemes have played a major role in encouraging manufacturing growth. Financial assistance, simplified tax policies, and export incentives have helped valve manufacturers grow their operations and reach global customers.

Moreover, India’s participation in trade expos and industrial exhibitions worldwide has helped showcase the quality of Indian-made valves on international platforms.

6. Well-Developed Industrial Clusters and Supply Chains

Industrial valves are manufactured in key regions such as:

Pune and Mumbai (Maharashtra)

Ahmedabad and Vadodara (Gujarat)

Coimbatore and Chennai (Tamil Nadu)

Hyderabad (Telangana)

These clusters are equipped with foundries, fabrication shops, testing facilities, skilled labor, and logistics support. Proximity to seaports and airports allows easy and timely export to countries in the Middle East, Europe, Asia, and the Americas.

7. Ability to Provide Customized Valve Solutions

Not every project or application needs the same type of valve. Some require corrosion resistance, high-pressure handling, or compact sizes. Indian manufacturers are known for their flexibility and customization, which gives them an edge over bulk producers in other countries.

Whether it’s valves for marine use, cryogenic applications, or hazardous chemicals, Indian manufacturers can develop specialized solutions based on customer needs.

8. Focus on Innovation and Modern Technologies

Today’s Industrial Valves Manufacturers in India are not just focused on production but also on innovation. They use:

Computer-aided design (CAD)

CNC machining

Simulation software

Automated testing units

This helps improve precision, reduce product failure, and offer valves with better lifecycle performance. Some companies are also investing in smart and IoT-enabled valves for Industry 4.0 applications.

9. Strong Global Presence and Partnerships

Many Indian valve companies have expanded their footprint by:

Exporting to over 50+ countries

Partnering with EPC (Engineering, Procurement, and Construction) firms

Setting up offices or distributors abroad

Working with global oil & gas and power companies

These collaborations have helped Indian valve manufacturers better understand global market needs and improve their product offerings.

Conclusion

India's journey toward becoming a global hub for industrial valve manufacturing is the result of strategic growth, technical excellence, cost competitiveness, and government support. Today, Industrial Valves Manufacturers in India are known for their quality, reliability, and global standards.

Whether you are looking for standard valve solutions or custom-engineered products, Indian manufacturers have proven their ability to deliver with precision, performance, and professionalism.

1 note

·

View note

Text

Carpet Cleaning Services in Dubai That Feel Like Magic Under Your Feet

In Dubai, elegance and cleanliness matter. Keeping carpets spotless is key to making your home or office feel fresh and inviting. The hot, sandy climate means carpets get dusty and stained more quickly than you'd like. Carpet cleaning is important in Dubai. Experts like Maids in Dubai make a big difference. They make your floors feel brand new with every step.

Why Carpet Cleaning Matters More in Dubai:

Dubai’s desert environment causes dust and fine sand to build up in your carpets. Regular vacuuming can help a bit, but it won’t get rid of the embedded dirt, allergens, or stubborn stains. Over time, this not only damages the carpet fibers but also impacts the air quality in your home or office. That’s why professional carpet cleaning isn’t just a luxury — it’s a necessity here.

The Magic Touch of Maids in Dubai:

When you choose Maids in Dubai for your carpet cleaning Dubai needs, you get more than just a surface clean. Their team uses special machines and eco-friendly solutions to clean your carpet thoroughly. They can manage all types of flooring. This includes Persian rugs, wall-to-wall carpets, and office mats. They can manage different textures, stains, and fabric types. You’ll feel the magic the moment you step onto your fresh, fluffy, and spotless carpet.

Call Maids in Dubai at 045490505 and see the transformation yourself.

How Professional Carpet Cleaning Works:

Here’s what happens when you hire professionals:

Inspection: They check the carpet type, stain level, and material. This helps them pick the best cleaning method.

Vacuuming: All loose dirt and dust is removed before deep cleaning starts.

Stain Treatment: We focus on tough stains, such as coffee, wine, and pet accidents.

Deep Cleaning: Steam or shampooing methods are used to deep-clean the carpet fibers.

Drying: High-speed dryers help carpets dry quickly without any odor or mold growth.

Final Touch: A deodorizing spray leaves your carpet smelling as fresh as it looks.

Benefits of Regular Carpet Cleaning:

Longer Carpet Life: Deep cleaning extends the life of your expensive carpets.

Healthier Home Environment: Removes allergens, bacteria, and dust mites.

Odor Removal: No more musty or dusty smell in your rooms.

Enhanced Appearance: Brightens up your interiors instantly.

Stain Prevention: Protective solutions can be applied to resist future stains.

Ideal for Homes and Offices:

Whether you're a homeowner or a business manager, clean carpets make a difference. In homes, they create a healthy environment for children and pets. In offices, they leave a positive impression on clients and staff. Maids in Dubai offers carpet cleaning for homes and businesses. They provide flexible scheduling and reliable service.

When Should You Get Your Carpets Cleaned?

Every 6-12 months for regular maintenance

After a party or gathering

When stains or odors become noticeable

Before moving into a new space

After a renovation or repair project

Why Choose Maids in Dubai?

With so many cleaning companies in Dubai, why go with Maids in Dubai?

Trusted by hundreds of happy customers

Use of modern equipment and safe cleaning solutions

Experienced team that treats every carpet with care

On-time, hassle-free bookings

Available at 045490505 for quick assistance

Final Thoughts:

Carpet cleaning in Dubai doesn’t have to be stressful. With Maids in Dubai, it feels like magic — your carpets go from dusty and dull to fresh and fabulous. One call can transform your living space or get your office ready for guests. Dial 045490505 today and bring the magic under your feet!

0 notes

Text

What Sets a Wholesale Wheelchair Manufacturer Apart

Across the international healthcare and rehabilitation sectors, the search for a dependable Wholesale Wheelchair Manufacturer has become a critical component of meeting mobility demands in hospitals, clinics, and elder care environments. In the center of this expanding market, Suzhou Xinxin Vehicle Science and Technology Co., Ltd.—known globally as Sweetrich—has established itself as a trusted production base that delivers durability, safety, and customized functionality to partners worldwide.

Located in Suzhou, China, Sweetrich integrates advanced manufacturing with responsive customer support, giving wholesale buyers access to a variety of wheelchair models ranging from manual and lightweight designs to electric, foldable units for long-term mobility use. The company operates an intelligent production system that includes CNC processing, aluminum alloy welding, electronic component assembly, and multiple inspection points—all designed to ensure stability and comfort for end users.

What makes Sweetrich stand out is its attention to ergonomics and long-use practicality. Every wheelchair model is designed with patient and caregiver needs in mind. From adjustable footrests and anti-slip hand rims to breathable back cushions and puncture-resistant tires, the details are refined to deliver optimal support in home care, hospital, and institutional settings. The engineering team frequently collaborates with physical therapists and international clients to adjust seating angles, frame weight, and mobility accessories.

As a Wholesale Wheelchair Manufacturer, Sweetrich places great emphasis on OEM and ODM flexibility. Bulk buyers have the ability to select features such as seat width, wheel size, controller type, and even upholstery patterns. Products can also be co-branded, labeled for specific retail chains, or adapted to meet country-specific regulations like CE, ISO 13485, or FDA standards. Each unit comes with technical documentation, multi-language manuals, and after-sales support information for quick integration into local markets.

Sweetrich’s electric wheelchair lines are designed with modern control systems and extended battery range. Intelligent braking, joystick interfaces, electromagnetic motors, and foldable structures enable them to be used both indoors and outdoors with confidence. For manual designs, the factory uses ultra-light yet reinforced aluminum frames to maintain maneuverability without compromising weight capacity.

The company also leads in logistics coordination. Its global export team offers tailored shipping schedules, container optimization, and documentation services. Whether a client is managing private label distribution or fulfilling public procurement contracts, Sweetrich supports streamlined fulfillment, including pre-assembled units and spare part supply guarantees.

In response to increasing demand for mobility devices in emerging markets, Sweetrich has ramped up its monthly production output and upgraded testing facilities. Each wheelchair undergoes endurance testing for stress, vibration, and corrosion resistance. Frame fatigue is tested using dynamic load machines, while braking systems and motor response are inspected under simulated user conditions.

Beyond production, Sweetrich maintains technical training channels and a multilingual customer service portal. Wholesale clients are provided with ongoing product updates, maintenance tips, and remote diagnostics for electric models. Support for warranty claims and spare parts dispatches are prioritized to minimize equipment downtime for local service providers.

Sweetrich continues to innovate in material sourcing and component integration. Lightweight magnesium alloys, sustainable fabrics, and lithium battery modules are now under review for upcoming models. The R&D team also explores smart add-ons such as app connectivity, voice control, and compact travel conversion kits for future market expansion.For more details on collaboration and product catalogs from a trusted Wholesale Wheelchair Manufacturer, please visit: https://www.sweetrichmobility.com/ .

0 notes

Text

Precision, Clarity, and Coordination: Advantage Engineering Technologies, PLLC Leads the Way in Construction Drawing Solutions

In the modern construction and engineering landscape, the success of a project often hinges on the clarity and accuracy of its technical documentation. As buildings grow in complexity and collaboration between trades becomes more critical, the need for precise, discipline-specific drawings has never been greater. That’s where Advantage Engineering Technologies, PLLC stands out—offering expertly crafted construction coordination drawings, mechanical shop drawings, ductwork fabrication drawings, and HVAC shop drawings that ensure every stakeholder works from the same blueprint.

The Foundation of Project Success: Construction Coordination Drawings

At the core of Advantage Engineering Technologies’ offerings is its robust expertise in construction coordination drawings. These drawings are vital in aligning the plans of architects, structural engineers, MEP trades, and fabricators to eliminate clashes and optimize the constructability of the project.

By integrating input from all major trades and developing composite coordination drawings, the firm ensures that every pipe, duct, beam, and cable is accounted for before construction begins. This minimizes costly field rework, delays, and change orders, helping projects run more smoothly and profitably.

Advantage Engineering Technologies uses advanced 3D modeling tools like Autodesk Revit and Navisworks to detect and resolve conflicts before they happen in the field. These tools allow their team to visualize how systems interact spatially and functionally, a level of detail that 2D drawings alone cannot provide.

“Coordination is more than just checking for clashes—it’s about ensuring buildability,” explains one of the company’s lead project engineers. “Our construction coordination drawings give everyone on-site a clear roadmap to follow.”

Precision Engineering with Mechanical Shop Drawings

For mechanical contractors, accurate and detailed mechanical shop drawings are essential to ensure that equipment, piping, and mechanical systems are fabricated and installed exactly as intended. Advantage Engineering Technologies delivers shop drawings that go beyond general layouts by including fabrication-level detail, installation notes, and material specifications.

Whether the scope includes plumbing, fire protection, or hydronic systems, these mechanical shop drawings are tailored to meet both project and industry standards. The firm works closely with mechanical engineers and fabricators to ensure every drawing is accurate, code-compliant, and construction-ready.

The result is not only improved field installation but also easier inspection, faster procurement, and reduced ambiguity for subcontractors.

“Our mechanical shop drawings are developed with the installer in mind,” says a senior drafter at the firm. “We make sure everything fits, flows, and functions in the real world—not just on paper.”

Streamlined Fabrication with Ductwork Fabrication Drawings

Fabricators and sheet metal contractors rely heavily on well-prepared ductwork fabrication drawings to produce and install HVAC systems with precision and efficiency. Advantage Engineering Technologies understands this critical link in the construction chain and delivers shop drawings that are highly accurate, logically laid out, and optimized for fabrication.

These drawings include essential information such as duct sizes, transitions, material types, reinforcement details, and flange requirements. The team also prepares files that can be used directly by CNC cutting machines, streamlining the production process and minimizing material waste.

By integrating duct design with the firm’s broader BIM coordination models, every elbow, damper, and support is precisely located and accounted for. The result? Faster fabrication, cleaner installations, and fewer on-site adjustments.

“Our ductwork fabrication drawings are more than just documents—they’re production tools,” explains a fabrication support specialist at Advantage Engineering Technologies. “They help our clients work smarter and reduce costly errors.”

Complete HVAC Shop Drawings for Accurate System Installation

HVAC systems are among the most complex in any building, involving intricate routing, space constraints, and coordination with structural and architectural elements. Advantage Engineering Technologies provides comprehensive HVAC shop drawings that make this complexity manageable.

These detailed documents include layout plans, sections, elevations, and 3D views that illustrate how all HVAC components will be installed. From air handling units and duct runs to diffusers and VAV boxes, every piece of the puzzle is clearly documented for the installing contractor.

The firm's HVAC shop drawing services also support coordination efforts by ensuring mechanical systems do not conflict with other building systems. This integrated approach reduces change orders, shortens the construction timeline, and improves the overall quality of the HVAC installation.

“Our HVAC shop drawings serve as a bridge between design intent and physical construction,” says a lead HVAC designer at the company. “They ensure that what’s installed is exactly what was envisioned.”

Why Clients Trust Advantage Engineering Technologies, PLLC

Advantage Engineering Technologies has built a reputation for accuracy, responsiveness, and technical excellence. Their team of engineers, modelers, and drafting professionals brings decades of combined experience across commercial, healthcare, industrial, and institutional projects.

Here’s what sets them apart:

Detail-Oriented Deliverables – Every drawing is reviewed for accuracy, constructability, and compliance.

Trade-Specific Expertise – Services are tailored to meet the unique needs of mechanical, electrical, plumbing, and HVAC contractors.

Fast Turnaround – Projects move quickly, with flexible delivery options and prompt client communication.

Cutting-Edge Tools – The firm leverages the latest BIM, CAD, and fabrication software to ensure industry-best results.

Client-Focused Approach – They treat each project as a partnership, working closely with clients to meet tight deadlines and evolving scopes.

Building Smarter with Every Project

As the construction industry continues to adopt digital workflows and integrated design practices, having a reliable partner like Advantage Engineering Technologies, PLLC is more important than ever. Their high-quality construction coordination drawings, mechanical shop drawings, ductwork fabrication drawings, and HVAC shop drawings form the blueprint for efficient, accurate, and cost-effective construction.

Whether you're managing a hospital expansion, a commercial high-rise, or a new data center, Advantage Engineering Technologies delivers the drawing solutions that make complex builds possible—on time and on budget.

0 notes

Text

Sofa Cleaning Services Abu Dhabi

Does your sofa look dull and lifeless? Revive it with Sofa Cleaning Services in Abu Dhabi! Our professional team of cleaners will make sure your sofa looks brand new, with deep cleaning and sanitization that removes dirt and dust from the deepest corners. Enjoy a clean, safe, and fresh-smelling home with Sofa Cleaning Services in Abu Dhabi!

The sofa you love to relax in can easily become dirty and become the cause of allergic reactions such as sneezing, and eye-watering. It is critical to ensure the cleanliness and hygiene of your sofas and it can not be achieved with a simple dusting or vacuum. In order to deal with this situation, you can either purchase an upholstery cleaning machine to keep your sofa clean or hire a professional for sofa cleaning services. Cleaning your sofas regularly improves hygiene and preserves the value of your furniture. It is always a good idea to have your sofa shampooed regularly to improve the health of your family.

At Citi Maids, we understand your cleaning needs and help contribute to the journey to provide a clean and tidy home with long-lasting furniture. We provide Professional and reliable sofa cleaning services in Abu Dhabi for homes, offices, hotels, and commercial spaces at affordable rates. Our Sofa Cleaning Service Experts in Abu Dhabi will come and clean your sofa and upholstery, no matter what the conditions are.

FREE CLEANING QUOTE

Book expert cleaning Services

Service that can make you feel extremely satisfied

Is your sofa looking tired and worn out? Revive it with Sofa Cleaning Services in Abu Dhabi! Our professional cleaners use the latest techniques and products to quickly and effectively remove dirt, dust, and grime from all types of sofas. We guarantee a deep clean that will leave your furniture looking like new again. Get the sofa cleaning services you need for a sparkling clean at an affordable price.Our upholstery cleaning service begins with a thorough inspection of your furniture by our technicians. They consider the fabric type, color, and age to determine the best approach. Next, they spot-treat any areas that require extra attention on your couches, chairs, mattresses, or other upholstered items.

#Our Services#Home Cleaning#Office Cleaning#Apartment Cleaning#Villa Cleaning#Move In & Move Out Cleaning#General Cleaning#Deep Cleaning Services#Carpet Cleaning Services#Sofa Cleaning#Window Cleaning#Ironing & Baby Setting#Baby & Pet Setting#Glass Cleaning#Building Cleaning#home cleaning abu dhabi#deep cleaning services abu dhabi#building cleaning services#commercial cleaning

0 notes

Text

How CNC Machining Services Work: An Overview

CNC machining is a cornerstone of modern manufacturing, offering high precision, speed, and flexibility for producing intricate parts and components. From aerospace to automotive, electronics to industrial machinery, CNC machining services are critical in fabricating parts that meet exact specifications. Whether you're a product designer or a manufacturing engineer, understanding how CNC machining works can help you leverage its benefits effectively.

What Is CNC Machining?

CNC machining is a subtractive manufacturing process where material is removed from a solid block—known as a blank or workpiece—using a variety of cutting tools. The process is controlled by pre-programmed computer software that dictates the movement of machines such as mills, lathes, routers, and grinders. Unlike manual machining, CNC systems operate with extraordinary precision and repeatability, making them ideal for high-tolerance, complex parts.

Key Components of CNC Machining Systems

Computer-Aided Design (CAD): Everything starts with a 3D model or a technical drawing of the desired part. Engineers or designers use CAD software to define dimensions, geometries, and tolerances.

Computer-Aided Manufacturing (CAM): The CAD file is then imported into CAM software, which generates a toolpath and converts the design into G-code—a programming language that CNC machines understand.

CNC Machine: The G-code is uploaded to the CNC machine, which follows the programmed instructions to execute precise movements and tool changes. Machines may be 3-axis, 4-axis, or even 5-axis, depending on the complexity of the part and the number of simultaneous movements required.

Cutting Tools: Depending on the material and design, different cutting tools are used, such as end mills, drills, or turning tools. The choice of tool affects surface finish, cutting speed, and overall efficiency.

Workholding: Fixtures and vises secure the workpiece in place during machining, ensuring stability and accuracy.

The CNC Machining Workflow

Here’s a simplified breakdown of the typical CNC machining process:

1. Design & Planning

The journey of custom CNC machined parts begins with a detailed design. Engineers define all technical requirements, including geometry, material selection, surface finish, and tolerance. This stage is crucial because the CAD model directly influences machining feasibility and cost.

2. Programming

CAM software interprets the CAD model to produce G-code. This code tells the CNC machine what actions to perform—movements along the X, Y, and Z axes, spindle speeds, feed rates, tool changes, and more.

3. Setup

A technician sets up the machine by loading the workpiece, installing the required tools, and configuring the machine based on the program. This step may also involve calibrating the tool offsets and checking initial positions.

4. Machining

Once everything is set up, the machine starts removing material as per the G-code instructions. The process could involve multiple operations such as drilling, milling, turning, or tapping. Multi-axis machines can produce complex geometries in a single setup, reducing lead time and improving precision.

5. Inspection & Quality Control

After machining, the part is inspected using precision measurement tools such as calipers, micrometers, or Coordinate Measuring Machines (CMM). This step ensures that the final product meets all specified dimensions and tolerances.

6. Finishing Operations

Depending on the application, post-machining processes like deburring, anodizing, or powder coating may be applied. These finishing steps enhance durability, corrosion resistance, or aesthetics.

Types of CNC Machining

There are several types of CNC machining processes, each suited for specific applications:

Milling: A rotating cutting tool moves along multiple axes to remove material.

Turning: The workpiece rotates while a stationary cutting tool shapes its exterior or interior.

Drilling: Straight holes are created using a rotating drill bit.

EDM (Electrical Discharge Machining): Material is removed using electrical sparks—ideal for hard materials or intricate cavities.

Grinding: A rotating wheel removes material to achieve high surface finish and tight tolerances.

Advantages of CNC Machining

Precision: CNC machines can achieve tolerances as tight as ±0.001 inches, ideal for high-performance industries.

Repeatability: Once programmed, the machine can produce thousands of identical parts with minimal variation.

Flexibility: CNC services can handle one-off prototypes or high-volume production runs.

Efficiency: Faster turnaround times and reduced manual labor.

Material Versatility: Supports a wide range of materials including metals (aluminum, steel, titanium), plastics (nylon, ABS, PEEK), and composites.

Applications of Custom CNC Machined Parts

Custom CNC machined parts are essential in industries where performance and reliability are non-negotiable:

Aerospace: Complex components such as turbine blades, housings, and brackets.

Medical Devices: Surgical instruments, prosthetics, and diagnostic equipment.

Automotive: Engine components, transmission parts, and custom performance mods.

Robotics & Automation: Gears, end-effectors, and structural parts.

Consumer Electronics: Housings, frames, and connectors.

At MS Machining, our team specializes in producing high-quality custom CNC machined parts tailored to exact client specifications. Whether you need prototypes or full-scale production, MS Machining delivers consistent quality with fast lead times.

Why Choose MS Machining?

When it comes to custom CNC machined parts, choosing the right partner can make all the difference. Here's what sets MS Machining apart:

State-of-the-Art Equipment: We operate a fleet of advanced 3-, 4-, and 5-axis CNC machines.

Experienced Technicians: Our machinists have years of hands-on experience across multiple industries.

Fast Turnaround: We streamline production timelines without compromising quality.

Material Expertise: From exotic alloys to engineering plastics, we handle diverse materials with precision.

Quality Assurance: Every part undergoes rigorous inspection to ensure it meets or exceeds your requirements.

Whether you're a startup developing your first prototype or a large enterprise needing scalable production, MS Machining is your trusted source for dependable CNC machining services.

The Future of CNC Machining

CNC machining is constantly evolving, with emerging technologies like AI, machine learning, and automation pushing the boundaries further. Predictive maintenance, adaptive toolpath optimization, and real-time quality monitoring are enhancing productivity and reliability. As industries continue to demand higher performance and customization, CNC machining will remain a foundational technology for manufacturing innovation.

Final Thoughts

CNC machining is more than just a fabrication method—it's a bridge between concept and reality. With its unparalleled accuracy, versatility, and efficiency, it enables manufacturers to produce everything from simple fixtures to complex aerospace components. Companies like MS Machining are at the forefront, delivering precision-crafted custom CNC machined parts that help bring ambitious designs to life.

Whether you're exploring rapid prototyping or full-scale manufacturing, understanding how CNC machining services work empowers you to make informed decisions and achieve superior results.

0 notes

Text

Affordable CNC Milling India , Best Manufacturers & Suppliers

Need affordable CNC machining in India? Choose from leading CNC Milling Suppliers that offer quality work at competitive prices. Call us now.

CNC (Computer Numerical Control) machining is a manufacturing process that uses pre-programmed software to control machinery. It allows for precise cutting, drilling, and shaping of materials like metal, plastic, and wood. Imagine a robotic sculptor working with extreme accuracy—that’s CNC machining.

Why Choose CNC Machining in India?

India offers top-tier CNC machining services with a unique edge:

Lower operational costs

Highly skilled engineers

Advanced equipment

Faster project turnaround

That’s why global brands are outsourcing their CNC needs to Indian suppliers—it saves money without sacrificing quality.

Suppliers: Bridging Industries and InnovationEqually important to the CNC Milling Manufacturers chain are CNC Milling Suppliers, who connect industries with the right equipment and services. They offer a range of products, from compact desktop milling units to high-end industrial machines. These suppliers act as consultants, helping clients choose the most appropriate technology based on application, budget, and output requirements.

Modern suppliers provide value added services like installation, training, preventive maintenance, and troubleshooting. Their role is indispensable in sectors that demand minimal downtime and continuous productivity. They also facilitate customization, offering different table sizes, control units, and compatibility with CAD/CAM software systems.

Key Benefits of CNC Machining

High Precision: Ensures accuracy to within microns.

Consistency: Identical results even in large batches.

Efficiency: Faster production with less waste.

Complex Designs: Capable of producing intricate shapes and structures.

Whether you need a single prototype or thousands of units, CNC machining is up to the task.

Applications :

CNC machining is used everywhere, including:

Automotive: Engine parts, gear systems

Aerospace: Aircraft components

Medical Devices: Surgical tools, implants

Consumer Electronics: Device casings, connectors

Defense: Precision hardware

Indian CNC manufacturers cater to all these sectors and more.

How Indian CNC Suppliers Ensure Quality

Top suppliers in India use:

ISO-certified processes

CMM inspection tools

Real-time monitoring

Highly trained operators

They don’t just meet global standards—they exceed them.

Top CNC Machining Manufacturers in India

Some of the most reputable names include:

Deccanew

Ace Micromatic Group

Jyoti CNC Automation

LMW (Lakshmi Machine Works)

Micromatic Grinding Technologies

These companies have global reach, export capabilities, and strong quality control systems.

Factors That Affect CNC Machining Costs

CNC machining is affordable in India, but prices vary based on:

Material type

Part complexity

Volume (single or batch production)

Surface finishing

Machine run time

India’s lower labor and energy costs make even complex jobs more budget-friendly.

CNC Milling India Is Gaining Momentum

India offers a blend of affordability, engineering talent, and high-precision outputs. Many global and local manufacturers are tapping into CNC services in India for prototype development, mass production, and custom fabrication. By investing in CNC milling, industries are reducing human error, minimizing waste, and significantly improving operational efficiency. CNC machines are digitally programmed, allowing for consistent results with excellent repeatability.

How to Select the Right CNC Supplier

Here’s what to look for:

Experience in your industry

Custom capabilities

Certifications like ISO, AS9100

Prompt delivery records

After-sales support

It’s not just about cost—it’s about reliable performance.

Materials Commonly Used in CNC Machining

Indian CNC machining shops work with:

Metals: Aluminum, steel, brass, titanium

Plastics: Nylon, ABS, PEEK, acrylic

Composites: Carbon fiber, fiberglass

Make sure the supplier has experience with your specific material needs

Deccanew is one of India’s emerging leaders in CNC Milling India. They offer:

Custom CNC solutions

Fast delivery

Affordable pricing

Reliable customer service

From design to delivery, Deccanew combines technical precision with business-friendly pricing.

Trends in Indian CNC Machining Industry

Modern Indian CNC firms are embracing:

AI and machine learning

Smart factories (Industry 4.0)

Eco-friendly machining

Digital twins and cloud-based design

These trends ensure sustainability, efficiency, and innovation for future manufacturing.

Visit: https://www.deccanew.com/cnc-milling-manufacturers-suppliers-india.phpContact: +91 9657039991

0 notes

Text

Why Lola’s Laundry, LLC Cleaning Service Is a Local Favorite

Tired of laundry piling up or the clothes never quite smelling fresh after a wash? At Lola’s Laundry, LLC, located in Kentucky, they lace their craft into laundry sales. Hence, fittingly regarded as a go-to provider for laundry cleaning service needs, Lola’s Laundry, LLC is changing how busy families and working professionals approach their weekly bustle of wash. Merging the local feel with superior end-result, this brand is shifting requisites for laundry and cleaning service in and around your area.

What Makes Laundry Feel Like A Luxury At Lola’s?

At Lola's Laundry, LLC, each garment is cared for and not cleaned. This, coupled with their philosophy, ensures that actual cleaning goes hand in hand with nurturing care so your clothes return home as good as new. From delicates to business attire to everyday clothes, their washes are customized to meet fabric requirements and customer expectations. You are not just another laundry bag to them-you are a neighbor.

Is It Just Laundry Or A Full Cleaning Experience?

This is where the differences begin. At Lola, you don’t just throw your clothes into machines. They offer laundry and cleaning services that keep your stain treatments, fabric consultation, foldings so delicate that it feels hotel-grade. Their team of people is proud to work on your clothing and linens as they would their own. A few customers have reported fresher scents, softer textures, and brighter colors after just one service.

How Does Lola’s Stand Out From Other Dry Cleaners?

Some providers may have dry cleaning and laundry services, but Lola's Laundry, LLC emphasizes local ties and consistency. Their dry cleaning method is gentle on delicate fabrics yet tough on stains-that clothes really need-cleaning from suits to silk blouses. No outsourcing or handling outside of town-everything is done inside and supervised by their trusted team. With such care, customers feel the different results.

Can You Trust Lola’s With Your Most Delicate Items?

Absolutely! Lola's Laundry, LLC earned customer loyalty through a trust formed garment by garment. Whether it is the spot treatment of a wedding gown or the weekly cleaning of working uniforms, this company takes the time to understand fabric type and the process required. With careful handling and inspection of the garments, the customers have no surprises, just complete satisfaction.

Why Is This Local Kentucky Laundry Shop A Must-Try?

Convenience: Flexible drop-off and pick-up options

Precision: Advanced fabric care with expert handling

Affordability: Premium service without the premium cost

Eco-conscious: Efficient machines and eco-friendly detergents

Trustworthy: Family-run values that reflect in every service

Is It Time To Upgrade Your Laundry Routine?

Like it or not, doing the laundry is one of those never-ending jobs whose work is never quite finished. But with Lola's Laundry, LLC, the worst chore becomes easy. Say goodbye to missing pairs of socks, faded colors and hard towels. Their cleansing service is not only trustworthy but also rejuvenating.

Have the joy of having your clothes cleaned and neatly folded with a smile to greet you. Go to Lola's Laundry today and experience that local touch that keeps Kentucky fresh—one load at a time.

0 notes

Text

Elevating Safety Standards: A Comprehensive Guide to Abrasive Wheels Awareness

In the realm of industrial operations, construction, and fabrication, abrasive wheels are indispensable tools. From grinding and cutting to polishing and sharpening, these tools contribute significantly to operational efficiency and productivity. However, with their powerful performance comes the inherent risk of accidents and injuries, making Abrasive Wheels Awareness in the UK a crucial aspect of occupational safety and compliance.

This blog offers a deep dive into the importance of abrasive wheel awareness, UK regulations, risk factors, and best practices for ensuring safety in the workplace.

Understanding Abrasive Wheels

Abrasive wheels are powered grinding tools made of abrasive particles that are bonded together to cut, grind, or polish materials such as metal, stone, and concrete. They come in various types and sizes, including bench grinders, angle grinders, and cut-off wheels, each designed for specific applications.

Despite their utility, abrasive wheels pose significant hazards when mishandled. The high-speed rotation, combined with the potential for wheel breakage, flying particles, and physical injury, necessitates strict safety protocols and awareness.

Why Abrasive Wheels Awareness is Vital in the UK

The Health and Safety Executive (HSE) in the UK mandates strict guidelines for the use and handling of abrasive wheels. These guidelines are rooted in the Provision and Use of Work Equipment Regulations 1998 (PUWER), which emphasise the importance of proper training, equipment maintenance, and hazard control.

Failing to adhere to safety standards can result in severe injuries, including lacerations, eye damage, respiratory issues, and even fatalities. Therefore, Abrasive Wheels Awareness in the UK isn’t merely a recommendation—it is a regulatory necessity.

Key Hazards Associated with Abrasive Wheels

Understanding the potential risks associated with abrasive wheels is the first step toward mitigating them. Key hazards include:

Wheel Breakage: Due to improper mounting, misuse, or manufacturing flaws.

Entanglement: Loose clothing or accessories can get caught in the rotating wheel.

Eye Injuries: Flying debris and sparks can cause serious eye damage.

Inhalation Risks: Grinding certain materials releases harmful dust and particles.

Noise and Vibration: Prolonged exposure may lead to hearing loss or vibration-related injuries.

Addressing these risks through awareness and training significantly reduces workplace incidents.

Regulatory Requirements and Training

In the UK, employers are legally required to provide training to all workers who use or supervise the use of abrasive wheels. This includes understanding:

The features and potential hazards associated with various kinds of wheels

Methods of identifying and inspecting defective wheels

Correct procedures for mounting wheels

Usage of protective gear and machine guards

Emergency procedures and accident reporting

Training is not a one-off task. Regular refresher courses are recommended to ensure continuous compliance and safety awareness.

Best Practices for Abrasive Wheels Safety

To strengthen Abrasive Wheels Awareness in the UK, both employers and workers should commit to the following best practices:

1. Pre-Use Checks

Before using any abrasive wheel, operators should inspect it for cracks, wear, or defects. Check that the wheel is compatible with the machine and is securely mounted.

2. Use of Personal Protective Equipment (PPE)

Always wear appropriate PPE such as:

Safety goggles or face shields

Hearing protection

Dust masks or respirators

Gloves and flame-resistant clothing

3. Proper Mounting and Handling

Ensure that wheels are mounted using appropriate tools and following the manufacturer's guidelines. Only trained personnel should undertake this task to avoid misalignment or stress fractures.

4. Machine Guarding

Guards should be fitted and maintained on all abrasive wheels to protect against debris and accidental contact. Never remove or tamper with machine guards.

5. Safe Work Environment

Maintain a clean and organised workspace. Avoid distractions, and ensure there is adequate lighting and ventilation.

6. Ongoing Education

Encourage ongoing training and encourage reporting of near-misses to continually improve safety protocols.

Promoting a Culture of Safety

One of the most effective ways to enhance Abrasive Wheels Awareness in the UK is by fostering a strong culture of safety within the workplace. This includes:

Regular toolbox talks and safety briefings

Encouraging open communication about hazards

Empowering employees to take responsibility for their safety and that of their colleagues

By embedding safety into the work culture, businesses can significantly reduce the risk of abrasive wheel-related incidents.

Conclusion

In industries that rely heavily on abrasive wheels, awareness and education are the cornerstones of safety. Understanding the risks, complying with UK regulations, and committing to best practices are not just legal obligations—they are ethical ones.

Investing in Abrasive Wheels Awareness in the UK translates to safer work environments, fewer injuries, higher productivity, and improved employee morale. Whether you're an employer, supervisor, or operator, staying informed and vigilant is the key to elevating safety standards and ensuring that every worker returns home safely at the end of the day.

#Abrasive Wheels Awareness in UK#Abrasive Wheels#Construction Training Programs UK#education#courses#united kingdom#london

0 notes

Text

Unveiling the True Beauty of Your Home: Expert Carpet & Upholstery Cleaning in Perth

Your home is your sanctuary, a place where memories are made, and comfort is paramount. The carpets beneath your feet and the upholstery on your furniture play a significant role in creating that inviting atmosphere. However, over time, they accumulate a surprising amount of dust, allergens, dirt, and even microscopic organisms that can diminish their appearance and impact your indoor air quality. While regular vacuuming helps, it's the professional touch of expert carpet cleaning services and specialized upholstery cleaning Perth that truly revitalizes your living space. At HP Professional Cleaning, we believe in restoring the beauty and hygiene of your home, one fiber at a time.

More Than Just Dirt: The Hidden Truth About Your Carpets and Upholstery

It's easy to overlook what's lurking within your carpets and upholstered furniture. Beyond visible spills and tracked-in dirt, these fabrics act as filters, trapping:

Allergens: Dust mites, pollen, pet dander, and mold spores find refuge deep within carpet fibers and upholstery, triggering allergies and respiratory issues.

Bacteria and Viruses: Foot traffic and everyday use introduce a host of microorganisms that can thrive in damp or soiled areas.

Grime and Oils: Everyday oils from skin, cooking, and even air pollution can adhere to fibers, leading to discoloration and a sticky residue that attracts more dirt.

Pet Odors: Even the most well-behaved pets can leave behind dander and odors that permeate fabrics.

Invisible Residues: Cleaning products not properly rinsed can leave behind sticky residues that actually attract more dirt.

These hidden contaminants not only compromise the cleanliness of your home but can also significantly impact your family's health and well-being.

Why DIY Cleaning Falls Short

Many homeowners attempt to tackle carpet and upholstery cleaning themselves, often with rented machines or store-bought products. While these methods might offer a superficial improvement, they often come with drawbacks:

Incomplete Extraction: Rented machines often lack the powerful suction needed to extract all the water and loosened dirt, leading to prolonged drying times and the risk of mold growth.

Residue Build-up: Improperly used cleaning solutions can leave behind sticky residues that attract more dirt, causing your carpets and upholstery to get dirty faster.

Fabric Damage: Using the wrong cleaning agents or excessive scrubbing can damage delicate fibers, leading to discoloration, shrinkage, or matting.

Time and Effort: DIY cleaning is a time-consuming and labor-intensive task, often yielding subpar results compared to professional services.

Lack of Expertise: Different fabric types require specific cleaning methods. Without this knowledge, you risk permanent damage.

The HP Professional Cleaning Difference: Our Approach to Impeccable Cleanliness

At HP Professional Cleaning, our carpet cleaning services and upholstery cleaning Perth are designed to deliver a deep, thorough, and safe clean for all your fabric surfaces. We utilize industry-leading techniques and eco-friendly solutions to ensure exceptional results:

For Your Carpets:

Pre-Inspection and Spot Treatment: Our technicians begin by inspecting your carpet for problem areas, identifying fabric type, and pre-treating stubborn spots and heavy traffic areas.

Powerful Hot Water Extraction (Steam Cleaning): This is the most effective method for deep cleaning carpets. Our powerful truck-mounted or portable units inject hot water and a specialized cleaning solution deep into the carpet fibers, agitating and loosening embedded dirt, allergens, and grime.

High-Powered Extraction: Simultaneously, powerful vacuums extract the dirty water, along with all the loosened contaminants, leaving your carpets significantly cleaner and drier.

Deodorization (Optional): We can apply professional-grade deodorizers to neutralize lingering odors, leaving your carpets smelling fresh and clean.

Protective Treatment (Optional): We offer stain protection treatments that create an invisible barrier around carpet fibers, making them more resistant to spills and stains in the future.

For Your Upholstery:

Fabric Identification and Testing: Our experts meticulously identify the fabric type of your furniture (e.g., cotton, linen, silk, synthetic blends) and perform a small patch test to ensure the cleaning solution is safe and effective.

Vacuuming and Pre-Treatment: We thoroughly vacuum the upholstery to remove loose dirt and debris, followed by targeted pre-treatment of soiled areas and stains.

Gentle Yet Effective Cleaning: Depending on the fabric, we utilize specialized upholstery cleaning techniques, such as low-moisture cleaning or hot water extraction with specialized attachments, to gently yet effectively lift dirt and refresh the fabric.

Spot Treatment and Stain Removal: We employ advanced stain removal techniques to tackle even the toughest stains, restoring the beauty of your furniture.

Fast Drying: Our efficient extraction methods minimize drying time, allowing you to enjoy your refreshed furniture sooner.

The Unmistakable Benefits of Professional Cleaning

Choosing HP Professional Cleaning for your carpet cleaning services and upholstery cleaning Perth offers a multitude of advantages:

Improved Indoor Air Quality: By removing trapped allergens and pollutants, professional cleaning significantly improves the air you breathe, benefiting those with allergies or respiratory sensitivities.

Extended Lifespan of Carpets and Upholstery: Regular deep cleaning prevents premature wear and tear caused by abrasive dirt particles, prolonging the life of your valuable investments.

Restored Appearance: Say goodbye to dull, dingy carpets and furniture. Our services bring back their original vibrancy and freshness, making your home look and feel cleaner.

Elimination of Odors: Professional cleaning neutralizes unpleasant odors from pets, spills, and everyday use, leaving your home smelling fresh and clean.

Effective Stain Removal: Our expert technicians have the knowledge and tools to tackle a wide range of stains that DIY methods often can't handle.

Enhanced Hygiene: By removing bacteria, viruses, and dust mites, professional cleaning creates a healthier and more hygienic living environment for your family.

Convenience and Time Savings: Let the professionals handle the hard work, freeing up your valuable time and ensuring a superior clean.

Don't underestimate the power of a truly clean home. Invest in the health and beauty of your living space with HP Professional Cleaning. Whether you need comprehensive carpet cleaning services or meticulous upholstery cleaning Perth, we are your trusted partners in maintaining a pristine and healthy environment. Contact us today for a free quote and discover the HP Professional Cleaning difference – where cleanliness meets excellence.

0 notes

Text

How The Clothing Clinic Transforms Everyday Laundry into Luxury Care

When it comes to laundry in Bray, The Clothing Clinic is more than a service — it is a standard of excellence. We redefine what laundry means by blending state-of-the-art techniques, eco-conscious processes, and exceptional garment care. Whether you search for “laundry services in Bray”, “laundry near me”, or “laundry Bray”, The Clothing Clinic stands at the top — where everyday laundry becomes a luxury experience.

Why Luxury Laundry Begins with The Clothing Clinic

At The Clothing Clinic, we do not just clean clothes — we restore them, rejuvenate them, and extend their life. With our experience, attention to detail, and use of premium cleaning technologies, we ensure that your wardrobe receives the care it truly deserves.

Premium Fabric Care with Precision

We understand that every piece of clothing has a story, a purpose, and a unique fabric composition. That’s why we tailor our approach for each item — whether it’s your delicate silk blouse, tailored suit, or casual cotton tee. Our fabric experts inspect every garment and select the optimal wash cycle, temperature, and detergent blend to preserve its integrity.

Unrivaled Laundry Services in Bray

We offer a broad spectrum of laundry services in Bray designed to suit every lifestyle and schedule. From busy professionals to active families, we cater to all with efficiency, discretion, and unmatched professionalism.

Complete Laundry & Ironing Packages

Our signature service includes washing, drying, folding, and pressing — all performed with meticulous care. Clothes return to you crisp, neatly packaged, and smelling fresh, making your daily routine easier.

Eco-Friendly Laundry Solutions

The Clothing Clinic is committed to sustainability. We use biodegradable detergents, low-energy machines, and water-saving technologies. Not only are your clothes treated with care, but so is the planet.

Same-Day and Express Laundry Services

Need a quick turnaround? Our express laundry Bray option ensures your clothes are ready within hours, not days — perfect for last-minute events or busy schedules.

From Drop-Off to Doorstep: A Seamless Experience

Our process is built around convenience and luxury. Whether you visit our Bray-based location or choose home pickup and delivery, we make laundry effortless.

Easy Drop-Off & Pick-Up

Our central location in Bray allows for easy, fast drop-offs, with trained staff ready to assist. Prefer to stay in? Use our pickup & delivery laundry service and enjoy luxury laundry without leaving your home.

Digital Booking & Tracking

With our modern booking platform, you can schedule pickups, track your orders, and communicate preferences — all at your fingertips.

Laundry Near Me? The Clothing Clinic Is Just Around the Corner

When you search for “laundry near me” in Bray, you deserve a service that goes beyond expectations. We are proud to be a trusted name in the community, providing not just clean clothes, but peace of mind, quality assurance, and genuine care.

Expert Stain Removal & Fabric Restoration

Accidents happen, but they don’t have to be permanent. Our trained technicians are experts in advanced stain removal techniques. From wine and grease to ink and makeup — we treat each garment with specialised solvents and gentle agitation that targets stains without harming the fabric.

We also offer fabric restoration for discoloured, pilled, or misshaped garments, breathing new life into your wardrobe.

Specialty Services for Every Fabric Type

Delicates & Designer Wear

Your high-end garments are safe in our hands. We offer luxury garment care for brands like Chanel, Armani, and Dior — ensuring fabric-safe cleaning, proper handling, and detailed inspection.

Bedding & Linen Services

Nothing compares to sleeping in freshly laundered linens. We provide hotel-quality laundry services for bedding, duvets, pillowcases, and more — perfect for homes, Airbnbs, and boutique hotels in Bray.

Curtains & Upholstery

Your curtains collect dust and allergens over time. We offer deep cleaning that refreshes the fabric without causing shrinkage, fading, or creasing. Our services ensure your home looks and feels immaculate.

Customer-Centric, Quality-Driven

We’re known not just for our quality, but for our service. Our friendly team is trained in customer-first practices, and we welcome your preferences — whether it’s a specific detergent, folding style, or return packaging.

Each order is double-checked for quality control, ensuring your garments meet our high standards before they return to you.

Affordable Luxury for Every Wardrobe

At The Clothing Clinic, luxury doesn’t mean overpriced. Our pricing is transparent, competitive, and fair — making premium laundry services in Bray accessible to all. We offer:

Flexible subscription plans

Pay-as-you-go options

Bulk wash discounts

Loyalty rewards

Why Bray Chooses The Clothing Clinic

✅ 5-Star Google Reviews from satisfied customers

✅ Same-day service availability

✅ Free collection & delivery in Bray

✅ Tailored care for every fabric and garment

✅ Sustainably conscious practices

Book Your Luxury Laundry Service in Bray Today

Luxury laundry care is not a dream — it’s just a booking away. Whether you’re preparing for a big event or managing everyday family needs, The Clothing Clinic is your go-to destination for top-tier laundry Bray solutions.

Join hundreds of satisfied customers in Bray who have made the switch to a smarter, more refined laundry experience.

Visit our Bray location, call us, or book online today — and transform how you care for your clothes.

0 notes

Text

🏭 How Udhhyog Ensures Quality in Every Puddle Flange We Manufacture