#a yard a minute on my faster spindles

Text

Wanted to know how much faster spinning on my wheel is compared to spinning on a supported spindle--specifically, I wanted to compare the yardage I could produce on each tool within a given amount of time. I chose to use my russian supported spindle because it was next to me and empty, and spun on a 13.5:1 drive ratio (the medium whorl) since thats what my wheel was already set to (and to be fair, i rarely use another ratio). I spun some nice gray roving because i didnt want to use hand prepped fiber for it.

The experiment was thus: I set up my spindle/wheel (attaching fiber and spinning just enough to get started, then marked my place with some scrap fiber), set a timer for 20 minutes, and spun continuously until the timer ran out. I chose not to include the set up in my timing because that only happens at the beginning, and in a test this short i was pretty sure it would skew the results a little. I also never paused the timer when the fiber broke and i had to reattach it, since that can happen repeatedly while spinning and realistically does affect how fast one can spin.

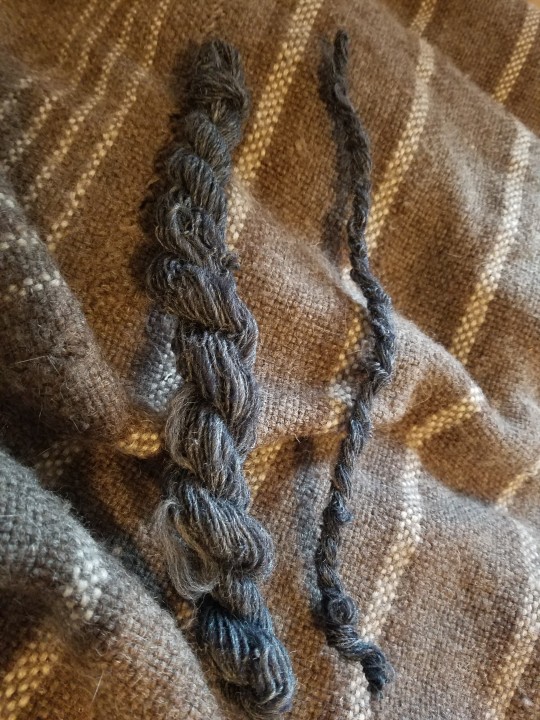

After 40 minutes of spinning, i had these two singles, shown on the bobbin/spindle and then skeined up.

No surprise there--obviously i spun more on the wheel. The pictures are actually pretty deceptive though, since i was not aiming for a particular weight and just spun what came naturally. On the wheel its much much thicker than on a supported spindle--a heavy fingering weight singles compared maybe a heavy cobweb singles. But the purpose of this experiment was to see the yardage specifically, and--

On my wheel, I spun 54 yards/49.3 meters in twenty minutes

On my spindle, I spun 17 yards/15.5 meters in twenty minutes

Which is just over 3 times faster on my wheel. I'm actually pretty shocked by that--I was predicting AT LEAST 5 times faster on my wheel, and I honestly wouldnt have been surprised if it was closer to 10. But nope, a measly 3.

Which is pretty cool to know. Before this experiment, if I had to spin something on a deadline, I would always have picked my wheel to spin it on. But now im actually thinking it may be a draw, maybe weighted just slightly in favor of the spindle for a few reasons--i have limited ability to spin on my wheel since it's more painful by far, but also my spindles are way more portable. So if, for some reason, i had to spin a hat's worth of laceweight singles ASAP, doing it on spindles that i can use in the car/on the train, at work, in bed, etc, would probably be a more efficient way of doing it than sitting at my wheel for two hours, ending up in quite a bit of pain and potentially triggering a flare up.

The chief slowdown of the spindles is the logistics of the temporary cop, since it means that for every length of yarn you produce, you are winding it by hand three times--the first time onto the temporary cop, the second time onto your hand once the temporary cop is full, and then the third time onto the actual cop at the base/middle of the spindle. This is kinda unavoidable--you dont need a temporary cop for drop spindles, for example, because youre spinning much longer lengths of yarn at a time, so for each time that you have to wind it up the spindle stick to get to the tip, youve spun at least an armspan of yarn, potentially up to 2. Whereas on a supported spindle, much less (anywhere between 3 inches/7.5 cm to 12 inches /30.5 cm depending on what I'm spinning). I dont know exactly how much slower it is to forego a temporary cop, but i highly suspect its far more than the slowdown of winding thrice. Maybe ill check at some point, but i dont really want to (ive tried it, and its extremely tedious).

Anyway, suprising but heartening results ! Would be very interested to hear the results of others if anyone else wanted to give it a go for their own edification. (Im actually really curious what other spinners speed is ! And would be interested to hear drop spindle or other hand spindle speeds even without a comparison to another tool !)

#im also pretty pleased to learn that i spin close to a yard a minute on my spindles#and bear in mind that russian spindle is not among the fastest spindles that i have. pretty sure with a full cop im easily spinning#a yard a minute on my faster spindles#long post#yarn experimentation#handspun yarn#spinning#supported spindle#spinning wheel

54 notes

·

View notes

Text

Reviews of Top 3 Best Finish Mowers On The Market 2020

Common machines such as push mowers or riding mowers are unable to cut a large lawn. So, what to do now? My advice for you is to get the best finish mower on the market. This type of device can trim all the grasses fastly and effortlessly, which is ideal for mowing any large garden.

After testing plenty of good products on the market, I have found out the top 3 most functional finish mowers. And in this article, I will share my experience using them with you!

Top 3 Best Finish Mowers 2020

Product Image Product Name Our Rating Price King Kutter Rear Discharge Finish Mower - RFM-60 4.9 See latest Price Swisher FC14560BS 14.5 HP 60-Inch Electric Finish Cut Mower 4.8 See latest Price Swisher FC10544CL Classic 44" 10.5 HP Finish Cut Trail Mower 4.8 See latest Price

In-depth 3 Best Rated Finish Mowers Reviews

Right under below are the 3 mowers that please me most. Each device has its own best point. So read all of my reviews, and you will find out the best finish mower to buy!

#1: King Kutter RFM-60 – Best PTO Finish Mower For Tractors

Check Latest Price on Amazon.com

Specs:

Cutting Width: 60 inches

Cutting Height: 1 – 4.5 inches

Blade Length: 20 inches

Tractor HP requirements: 20 HP

Weight: 660 LBS

On my list of the top 3 products, this King Kutter RPM-60 is the best finish mower for a tractor, and also the best PTO finish mower.

In fact, I have started my experience using finish mowers with this King Kutter RFM-60. At the very beginning, my only need was to find a really powerful cutter. And luckily, this RFM-60 model has met my needs.

Having a tractor that runs at 20 Horse Power, this device has pleased me really much, as it provides a smooth and good looking cut on my large garden. To be honest, my lawn is quite uneven. So for a beautiful result like that, I have nothing to say but compliment the machine.

Pros: Cons:

Strong tractor

Anti-scalp roller

Low cutting height

60 inches of cutting width

Heavyweight

#2: Swisher FC14560BS – Best For Starting

Check Latest Price on Amazon.com

Specs:

Cutting Width: 60 inches

Cutting Height: 2 – 5.5 inches

Blade Length: 20 inches

Tractor HP requirements: 14.5 HP

Weight: 371 LBS

Starting a mower is such a difficult task. Therefore, I have moved on to find another product that has an easy-open feature. And at the end, this Swisher FC14560BS has attracted me.

You may wonder what makes this device simple to fire up, right? Just have a look at its yellow key starter. By turning this 12-volt electric key, you can bring the machine into work quickly and effortlessly.

On the other hand, when you need to shut down the machine, the key will also help! In fact, I have lost control one time because the machine was running too fast. And thanks to the key, I could stop the machine and restart my work. No injury has been made!

Pros Cons

Easy to fire the mower up

Large fuel tank

Anti-scalp rollers

Powerful operating

No rubber washers included

#3: Swisher FC10544CL – Best Pull Behind Finish Mower

Check Latest Price on Amazon.com

Specs:

Cutting Width: 44 inches

Cutting Height: 1.5 – 4.5 inches

Blade Length: 20 inches

Tractor HP requirements: 10.5 HP

Weight: 350 LBS

Since the FC14560BS has made me satisfied a lot, I decided to try another product that is also made by the Swisher company. And you know what? I have fallen in love with the Swisher FC10544CL! For me, this is the best pulled-behind finish mower.

Compared to 2 other products on my list, this FC10544CL is the easiest to control device. Having a steel structure and large tires, the mower can run stably and provide a good flotation.

Normally, I have to do the mowing job really carefully, or else I will cut my trees and shrubs by accident. But now, I can comfortably do my job without worrying about anything. That is all thanks to the bumper rollers equipped to the machine. These bumper rollers can prevent itself from damaging all the trees and shrubs, while still trimming all the grasses efficiently and smoothly. Isn’t it great?

Pros Cons

Sturdy construction

Large tires

Bumper rollers

G6 mulching blades

No battery included

Things to consider when choosing a finish mower

1. Power

This feature directly involves the cutting power of the machine. However, a finish mower actually gets the strength of cutting from 2 things: the tractor, and its engine. Therefore, if the tractor is not strong enough, the mower’s strength will also be affected.

If you are searching for a finish mower with no external assistance, the gas-powered machines might be your potential choice. This type of mower can be pulled by almost any type of vehicle. The only minus point is that it can be a bit costly and need proper maintenance to work correctly.

If you don’t mind the external assistance, then you can consider a PTO (Power Take-Off) finish mower. This type gets energy transferred from a tractor, so it is usually more powerful and mobile. There are mechanical and electrical PTO for you to choose, but the electronic PTOs are generally more convenient.

2. Blades

Most finish mowers have from 3 to 5 blades. Some mowers can have more blades which are larger and more expensive. For me, the number of blades is not a factor for consideration of selecting a finish mower unless you have a very large yard needed to mow.

The thing to consider here is the material and the scalping protection of the blades. For example, steel blades are lighter, stronger, and can be sharpened easily. The scalping protection feature can keep the blades elevated from the ground, which prevents getting damaged during the mowing process.

3. Width

This is also an important factor to look at. Indeed, if a finish mower comes with a wide cutting width, you can finish your task quickly.

A wide cutting width may cost you more. So, if your yard is small, you may choose a smaller cutting width mower.

4. Horsepower

When choosing a finish mower, you have to make sure that mower can work well with your tractor. This means you should consider the horsepower of both the tractor and the mower. For example, if the mower has a horsepower of 45, it can’t be pulled by a 30 HP tractor.

Besides, this feature relates to cutting power. The more horsepower the mower has, the more cutting power it can produce.

5. Speed

This factor shows how fast the finish mower moves around the yard. If your yard is large, you can benefit more from a high-speed mower.

Different finish mowers can have different maximum speeds. If you try to cut faster than that maximum speed, your lawn might not be left as beautiful as you wish.

Although high-speed cutting can save your time, it is said that a finish mower tends to last longer if being pulled at a lower speed.

6. Acreage

As the finish mower is pulled behind a tractor, it usually needs larger acreage than your normal yard.

Although knowing which acreage of yard suitable for a finish mower is important, sadly many manufactures do not include this measurement in their product advertising (as this can lead to different results).

7. Cost and warranty

The price of a finish mower is abundant depending on its type. Normally, a new finish mower can cost you about $2,000 to $3,000 which is not a small amount of money. So, you should consider it carefully before buying it.

Also, the warranty comes with it should be at least one year. However, it will be ideal if the warranty is 5-year or 10-year. As you know, if anything happens within the warranty period, you don’t have to pay extravagant money for repairs.

Why and when you buy a finish mower?

Why buy?

A finish mower provides great benefits with its special features.

For me, the best benefit of a finish mower is great productivity within lesser time. And, I don’t have to do much labor work when just sitting on a tractor, maneuver it and eventually have a nicely-cut lawn.

A bush mower or a riding mower is handy for small yards but wasteful of time and labor for larger ones. Finish mowers are greatly efficient due to their following capabilities:

The cutting width is from 60 to 260 inches

Mowing height can range from 0.5 to 6 inches

Cutting modes are fine and coarse

There are 3 to 5 blades in a small machine

For the industry-grade machine, there are about 100 blades per head

The average cutting speed is from 15,000 to 18,000 feet per minute

Mowing 18,000 feet of lawn in a minute is definitely amazing, right? Feel like it is polishing your lawn in a breeze.

When to buy?

To know when you need one, there is a list of questions for you to check. If your answers are mostly “Yes”, then a finish mower might be your choice.

1. How big is your lawn? Is it larger than 0.5 acre?

If your lawn is smaller than 0.5 acre, getting a push mower will be better (although you might do a bit of cardio).

If you have lots of estate ground, or your lawn is larger than 0.5 acres, then a finish mower will be ideal.

Other fields definitely need a finish mower such as estates, school grounds, golf courses, sports fields, parks, sod farms, and so on. These are vast lawn which is impossible for a bush or riding mower.

2. Is your lawn flat and having no obstacle?

Remember a finish mower can work well on quite even surface with no tall bushes or trees. Otherwise, it will be hard to get things done.

3. Do you have a riding mower, ATV, or tractor?

A finish mower can be pulled behind these machines. Remember to check the right size for the machine.

How to keep finish mowers for longer use?

Here are some tips to keep your finish mower for longer use.

1. Maintenance before each use

Check tractor tire air pressure.

Check blades and spindles to ensure nothing is strapped.

Check blade bolts for tightness.

Inspect wheels for damage and replace them if necessary.

Lubricate before each use.

During operation, listen to abnormal sounds which might indicate loose parts, damaged bearings, or other damage.

2. Maintenance after each use

Clean all debris from the finish mower especially the underside of the deck.

When cleaning the underside of the deck, securely block the machine into position.

FAQs about Finish Mowers

1. What is a finish mower?

A finish mower is a type of mower that is attached to a tractor to create a nice cut for your lawn when the tractor moves around. Usually, it is used for large and even yards/lawns.

Unlike other types of mower, a finish mower can complete the cutting in a very short period of time with precise and clean trim.

2. What is the difference between a brush mower and a finish mower?

The difference is in their general usage. The former is often used to cut tall grass, dense shrubs, or small trees. Meanwhile, the latter is for an already landscaped lawn. A finish mower cannot cut brush or dense vegetation.

3. How tall and low of grass can a finish mower cut?

Finish mowers have adjustable rear gage that will allow you to cut grass from a range of height. Normally, the range is from 0.5 inches to 6 inches.

If you want to cut grass which is taller than 6”, a brush mower will be more suitable.

4. How often should you sharpen lawn mower blades?

If mowing a lawn needs about 45 minutes to finish, the mower blades should be sharpened every 26 to 33 mowing sessions.

Otherwise, you should sharpen the blades every 20 to 25 minutes for most rotary mowers. This will ensure you are not causing undue damage to your lawn every time you mow it.

Conclusion

Have you found a suitable product to buy? If not yet, I recommend you get the Swisher FC10544CL. With durable construction and many cool features, surely this model will be the best finish mower for the money you pay for. Also, it is easy to use. Thus, you do not need to be an expert to do the mowing work.

And now, I will end my writing here. Many thanks to you for having read!

Source: Reviews of Top 3 Best Finish Mowers On The Market 2020

source https://sandcreekfarm.net/best-finish-mowers-on-the-market-reviews/

0 notes

Text

This 1973 Heidts-Equipped Camaro Will Have You Green with Envy

In a world chock-full of Camaros, this one will have other F-body owners green with envy. If not from the stomach churning g-force it’s capable of pulling, then from the radical green paint scheme. Owned and driven by Ken Thwaits, this 1973 Camaro was a staunch competitor at the 2017 Classic Industries Super Chevy Muscle Car Challenge presented by Falken Tires.

Originally built by Randy Johnson of D&Z Customs in Kewaskum, Wisconsin, the Camaro has a long history of competing in the Optima Ultimate Street Car series. Johnson campaigned it there during the inaugural season of the series where it caught Thwaits’ eye. “I was racing a fifth-gen Camaro at Optima, but really liked Randy’s Camaro,” said Thwaits. “[Randy] called me and asked if I wanted to buy it at the end of the season, and we struck up a deal. I told him, ‘If you crash the car, the deal’s off!’ You never saw a guy so nervous when he’s racing,” laughed Thwaits.

Under the hood of the Camaro—affectionately named Envy, due to its vibrant hue–beats a Wegner Motorsports–built LS7 that pumps out an asphalt-melting 680 horsepower. “[The engine] is very powerful,” said Thwaits. “It sounds awesome and the public loves it!” Wiseco 11:1-compression pistons and Callies connecting rods and crankshaft comprise the rotating assembly, while Comp pushrods, roller lifters, and custom-grind cam; FAST LSXR intake; and RHS LS7 heads make up the top end. Connected to the engine is a TREMEC Magnum six-speed transmission and a Centerforce DYAD dual-disc clutch that feeds power through a Dynotech 3.5-inch steel driveshaft to a Heidts Pro-G rearend.

While the Camaro is a looker, and a beast in the horsepower department, under the skin works a functional and track-focused Heidts Pro-G suspension system. Heidts’ approach to suspension design is twofold: make it simple and make it work. “We moved heavily to bolt-in parts to allow the average Joe to get in there and compete,” said Heidts owner Wallace Leyshon. “Guys like Danny Popp and Ken Thwaits have discovered that we make good stuff.”

The fore end of the car is loaded with a Heidts Pro-G front subframe. It’s a bolt-on suspension system that replaces the outdated, GM-issued front clip. While the subframe, control arms, and spindles are all over the counter pieces available from Heidts, the shock setup is a prototype cantilever design that uses control arm–mounted pushrods to articulate the three-way adjustable RideTech coilovers. “We try to make our stuff handle well on the street as well as for Pro Touring drivers, like Ken,” said Todd Westberg of Heidts. “The front end has a splined sway bar, which is for cars that perform at this level, but we also have other sway bars.” “As a driver and tuner, it’s really easy to get to the suspension pieces to make changes and adjustments,” added Thwaits.

At the rear, a Heidts Pro-G IRS replaced the factory live axle in favor of more modern hardware. The 9-inch-style differential housing is completely independent, allowing the rear wheels to move of their own volition and to have camber gain curves—not possible with a solid rearend. This setup keeps the tires more firmly in contact with the pavement as the body rolls and the suspension articulates during cornering. “We really feel the bolt-in IRS is extremely affordable for the value and ease of installation,” said Westberg. “It’s professional grade suspension the average enthusiast can install at home in their garage, with no fabrication or welding needed. The saddles are custom fit right into the framerails.”

Bringing the LS engine’s hefty horses to a slow are a set of Wilwood W6A six-piston calipers and 14-inch GT slotted rotors on the front, and Wilwood DynaPro four-piston calipers and 10.25-inch rotors on the rear—a setup focused on outright domination on the track. On the Heidts Pro-G rear suspension, the rotors are mounted inboard of the control arms, near the pumpkin, helping to reduce unsprung weight on the suspension. This trick makes the car more responsive and nimble.

A car, as with any tool, is only as competent as its wielder, and Thwaits is no slouch in the driver’s seat of his surgical-instrument-grade Camaro. He competed in the Formula Mazda series between 1985 and 1987, and took home the championship in 1985. He then took a break from driving, marrying in 1992, and starting a family—but the fire never died.

“I saw the Optima series covered in Popular Hot Rodding years ago and thought, ‘that looks pretty cool.’” When his son hung up his baseball glove, subsequently did Thwaits his coach’s whistle. That meant there was time to return to the track. He entered a fifth-gen Camaro into the Optima series in 2014 and took home the points championship his first season. He continues to compete till this day and in Novemeber 2017 won the Optima Ultimate Street Car Invitational in his Mitsubishi EVO. He drives Envy at events like the Holley LS Fest in Bowling Green, Kentucky, and a few others to “shake out the moth balls.”

In addition to driving, Thwaits is an avid Camaro collector and enthusiast. “I have 24 Camaros in my collection, Showtime Motorsports, which includes 11 ’69 Camaros (with four of those being the rare JL8 four-wheel disc brake option), and a 1985 IROC third-gen found in a shipping container with under 10 miles on the odometer,” he said. Ken is a genuine Camaro lover; and, as the Muscle Car Challenge proved, an ace behind the wheel.

What Makes It Handle Engine: Type: Wegner Motorsports dry-sump 427-inch LS7 Components: Comp cam, ARP head studs, Wiseco forged pistons, Callies crank, FAST LSXR 102mm intake Power (at the crank): 680 hp and 570 lb-ft of torque Drivetrain: Transmission: TREMEC Magnum six-speed Clutch: Centerforce DYAD dual-disc Rearend: Heidts Pro-G IRS 9-inch-style with 3.89 gears Chassis/Suspension: Chassis: Modified stock Front Suspension: Heidts Pro-G replacement subframe Spindles: Heidts Pro-G 2-inch drop Shocks: RideTech triple-adjustable Sway Bar: Heidts adjustable, splined Brakes: Wilwood W6A six-piston calipers and 14-inch GT slotted rotors Rear Suspension: Heidts bolt-in Pro-G independent suspension (IRS) Shocks: RideTech triple-adjustable Sway Bar: Custom adjustable, splined Brakes: Wilwood DynaPro four-piston calipers and 10.25-inch rotors Wheels and Tires: Wheels: Forgeline DE3C 18×10 front, 18×12 rear) Tires: Falken Azenis RT615K 275/35ZR18 front, 315/30ZR18 rear Cost of Chassis/Suspension with shock upgrade and brakes $18,589 ($14,989 with standard shock and brake package) Weight (pounds): Total Without Driver: 3,387 LF: 853 RF: 904 LR: 816 RR: 814 Percentage F: 51.9% R: 48.1 %

How’d It Stack Up? Slalom Average Speed 420-ft 100 Yard Dash Road Course Lap Time Heidts Hot Rod Shop 1973 Camaro 44.2 mph 5.19 seconds 1:15.92 2017 Camaro SS 46.6 mph 5.41 seconds 1:22.15 The Heidts Hot Rod Shop 1973 Camaro showed its racing heritage rounding out a solid performance in a competitive pack. It flexed its LS-derived muscle in the 100-yard dash finishing in the Top 5 with a 5.19-second performance and took Top 3 honors on the road course with a highly impressive 1:15 minute lap, quite a bit faster than our 2017 Camaro baseline car. Thwaits struggled in our slalom challenge and couldn’t find his groove maneuvering through our 420-feet of pylons, taking them way too wide for a good score. Still, this Camaro proved that you can, in fact, teach an old dog new tricks. The Heidts suspension–equipped ’73 bested the 2017 Camaro baseline car in nearly every aspect of the challenge, including style.

The post This 1973 Heidts-Equipped Camaro Will Have You Green with Envy appeared first on Hot Rod Network.

from Hot Rod Network http://www.hotrod.com/articles/1973-heidts-equipped-camaro-will-green-envy/

via IFTTT

0 notes