#analog hall effect sensors

Explore tagged Tumblr posts

Text

Modular Hall Effect Sensors Market: Future Growth of the Semiconductor Sector, 2025–2032

MARKET INSIGHTS

The global Modular Hall Effect Sensors Market size was valued at US$ 834 million in 2024 and is projected to reach US$ 1.34 billion by 2032, at a CAGR of 7.1% during the forecast period 2025-2032. The U.S. market accounted for 32% of global revenue in 2024, while China is expected to witness the highest growth rate at 7.8% CAGR through 2032.

Modular Hall Effect sensors are compact, overmolded devices that detect magnetic fields with IP67-rated protection. These sensors separate the magnetic target from enclosed electronics, enabling space-efficient installations in demanding environments. They offer both analog and digital output options, making them versatile for position sensing, speed detection, and current measurement applications across industries.

The market growth is driven by increasing automation in manufacturing and rising electric vehicle production, where these sensors enable precise motor control. Furthermore, advancements in Industry 4.0 technologies and growing adoption in consumer electronics for touchless interfaces are expanding application horizons. Key players like Allegro MicroSystems and Texas Instruments are introducing energy-efficient variants with integrated signal conditioning, addressing the need for smarter IoT-enabled solutions.

MARKET DYNAMICS

MARKET DRIVERS

Growing Adoption in Automotive Applications Fuels Market Expansion

The automotive industry’s increasing reliance on modular Hall effect sensors is a primary driver for market growth. These sensors are critical for position sensing in throttle control, gear shift detection, and braking systems in modern vehicles. With the automotive sector accounting for over 35% of global Hall effect sensor demand, the transition toward electric vehicles (EVs) and advanced driver-assistance systems (ADAS) creates substantial opportunities. The integration of these sensors in brushless DC motors for EV powertrains, where they offer high reliability in harsh environments, is particularly noteworthy. Recent technological advancements have enhanced their ability to operate in temperature ranges from -40°C to 150°C, making them indispensable for automotive applications.

Industrial Automation Boom Accelerates Demand

Industrial automation represents another significant growth avenue, with modular Hall effect sensors finding extensive use in motor controls, robotics, and conveyor systems. The global industrial automation market is projected to grow at nearly 9% CAGR through 2030, creating parallel demand for precision sensing solutions. These sensors enable non-contact position detection in harsh industrial environments where traditional mechanical switches fail. Their modular design with IP67-rated housings provides robust protection against dust and moisture, a critical requirement in manufacturing facilities. Furthermore, Industry 4.0 initiatives are driving the adoption of smart sensors with digital outputs that can interface directly with IoT systems, creating new integration possibilities.

➤ An analysis of production data shows that industrial applications now account for approximately 28% of modular Hall effect sensor deployments, with particularly strong uptake in packaging machinery and CNC equipment.

The trend toward miniaturization in consumer electronics also presents significant growth potential. As devices become smaller, modular Hall effect sensors offer compact solutions for lid position detection in laptops and foldable smartphones, with some models now measuring less than 2mm x 2mm.

MARKET CHALLENGES

Intense Price Competition from Alternative Technologies

While modular Hall effect sensors offer distinct advantages, they face mounting competition from alternative sensing technologies like magnetoresistive (MR) and giant magnetoresistive (GMR) sensors. These alternatives often provide higher sensitivity and better signal-to-noise ratios in certain applications, putting pressure on Hall sensor manufacturers to differentiate their offerings. In price-sensitive markets such as consumer electronics, this competition frequently leads to margin erosion, with some sensor prices declining by approximately 15% over the past three years. Maintaining profitability while meeting the demand for cost reductions remains an ongoing challenge for major players.

Other Challenges

Supply Chain Vulnerabilities The semiconductor shortage impacts have revealed vulnerabilities in the sensor supply chain, particularly for specialized packaging materials. Lead times for certain sensor components have extended to 26 weeks in some cases, disrupting production schedules.

Technical Limitations Achieving sub-micron position resolution remains technically challenging for standard Hall effect designs, limiting their adoption in ultra-high precision applications compared to optical encoders.

MARKET RESTRAINTS

Design Complexity in High-Temperature Applications

While modular Hall effect sensors perform well in standard industrial environments, their application in extreme conditions presents design challenges. Operation above 150°C requires specialized materials and packaging techniques that can increase unit costs by 30-40%. This temperature limitation restricts their use in certain aerospace and oil/gas applications where environments routinely exceed these thresholds. The thermal drift characteristics of Hall elements also necessitate sophisticated compensation circuits, adding to system complexity and BOM costs.

Additionally, the need for precise magnetic field calibration in production creates yield challenges, with typical manufacturing tolerances requiring adjustments to ±1% or better for critical applications. These factors collectively restrain broader market adoption in some specialized segments.

MARKET OPPORTUNITIES

Emerging Medical Applications Present Significant Growth Potential

The medical device sector represents a high-growth opportunity, with modular Hall effect sensors finding new applications in surgical robotics, drug delivery systems, and implantable devices. The medical sensors market is projected to exceed $20 billion by 2027, creating substantial demand for reliable position sensing solutions. Recent innovations include contactless sensing for MRI-compatible equipment and miniature sensors for insulin pump mechanisms. The sterilization compatibility of properly packaged modular sensors makes them particularly attractive for single-use medical devices.

Furthermore, the development of ultra-low power Hall sensors consuming less than 10μA enables new battery-powered wearable applications with multi-year operational life, opening additional market segments. Strategic partnerships between sensor manufacturers and medical OEMs are accelerating the development of application-specific solutions.

MODULAR HALL EFFECT SENSORS MARKET TRENDS

Shift Towards Compact, High-Performance Sensing Solutions Drives Market Growth

The global Modular Hall Effect Sensors market, valued at $XX million in 2024, is experiencing robust expansion due to increasing demand for compact and reliable sensing solutions in industrial and automotive applications. These sensors, known for their IP67-rated durability and separation of magnetic targets from enclosed electronics, offer significant advantages in space-constrained installations. The automotive sector alone accounts for over 30% of total sensor demand, driven by the need for precise position detection in electric power steering and transmission systems. As industries continue miniaturizing components while requiring higher precision, modular Hall effect sensors are becoming the technology of choice for engineers worldwide.

Other Trends

Industrial Automation Revolution

The fourth industrial revolution is accelerating adoption across manufacturing sectors, with modular Hall effect sensors playing a critical role in Industry 4.0 implementations. These contactless sensors enable precise speed measurement in conveyor systems with an accuracy margin of ±1%, while their modular design allows easy integration into existing automated workflows. The global industrial automation market’s projected CAGR of 9.3% through 2032 directly correlates with increasing sensor deployments in robotic assembly lines and smart factory environments.

Advancements in Material Science and Chip Design

Recent breakthroughs in semiconductor materials and 3D packaging technologies are enabling sensor manufacturers to develop products with 30% higher sensitivity compared to previous generations. Leading manufacturers are now incorporating graphene-based elements and advanced ferromagnetic alloys that maintain stability across extreme temperature ranges from -40°C to 150°C. These innovations are particularly crucial for aerospace applications where sensors must perform reliably in both stratospheric cold and engine compartment heat. Digital output variants now dominate new product launches, representing 58% of 2024 modular Hall sensor introductions due to their compatibility with modern IoT ecosystems.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Strategic Expansion Drive Market Leadership

The global modular Hall Effect sensors market exhibits a moderately consolidated competition structure, where established electronic component manufacturers compete with specialized sensor providers. Sensata Technologies leads the segment with an estimated 18% revenue share in 2024, leveraging its diversified industrial sensor portfolio and strong OEM relationships in the automotive sector.

Texas Instruments and Allegro MicroSystems collectively hold approximately 25% market share, driven by their advanced semiconductor expertise and vertically integrated production capabilities. These companies continue to dominate due to their ability to offer customized solutions for high-growth applications such as electric vehicles and Industry 4.0 automation systems.

While traditional players maintain strong positions, emerging competitors like Melexis are disrupting the market through innovative packaging technologies and miniaturized sensor designs. The Belgium-based company recently launched its third-generation Hall Effect ICs, specifically optimized for space-constrained medical devices and wearables.

The supplier ecosystem is witnessing increased M&A activity as manufacturers seek to consolidate expertise. Littelfuse’s 2023 acquisition of C&K Components exemplifies this trend, enhancing their position in ruggedized industrial sensors. Similarly, Rohm Semiconductor expanded its European footprint through strategic partnerships with automotive Tier 1 suppliers.

List of Key Modular Hall Effect Sensor Companies Profiled

Sensata Technologies (U.S.)

Texas Instruments (U.S.)

Rohm Semiconductor (Japan)

Littelfuse (U.S.)

ZF Switches & Sensors (Germany)

Marposs (Italy)

Allegro MicroSystems (U.S.)

Lake Shore Cryotronics (U.S.)

Regal Components (Sweden)

Silicon Labs (U.S.)

Melexis (Belgium)

Segment Analysis:

By Type

Hall Switch Segment Leads the Market with Extensive Use in Position Sensing and Switching Applications

The market is segmented based on type into:

Hall Switch

Subtypes: Unipolar, Bipolar, and Omnipolar

Linear Hall Sensor

Subtypes: Analog Output and Digital Output

Others

By Application

Automotive Segment Dominates Due to Increasing Adoption in Position Detection and Current Sensing Applications

The market is segmented based on application into:

Consumer Electronics

Automotive

Aerospace

Medical

Industrial

By Functionality

Position Sensing Segment Holds Major Share with Growing Demand Across Industries

The market is segmented based on functionality into:

Position Sensing

Current Sensing

Speed Detection

Others

By Output

Analog Output Segment Maintains Strong Position in Various Measurement Applications

The market is segmented based on output into:

Analog Output

Digital Output

Subtypes: Pulse Width Modulation (PWM), I2C, and SPI

Others

Regional Analysis: Modular Hall Effect Sensors Market

North America The North American market remains a key revenue generator for modular Hall effect sensors, driven by strong automotive and industrial automation demand. The U.S. accounts for over 60% of the regional market value, benefiting from heavy investments in electric vehicle manufacturing and smart factory initiatives. Recent technological advancements by market leaders like Allegro MicroSystems and Texas Instruments have strengthened product offerings in high-temperature and high-precision applications. However, pricing pressures from Asian manufacturers pose a challenge to domestic producers. The Canadian market shows steady growth, particularly in aerospace and medical equipment segments where reliability is paramount.

Europe Europe’s market is characterized by stringent quality standards and innovation-driven demand, particularly in automotive and industrial sectors. Germany leads adoption with its robust manufacturing base, while Nordic countries demonstrate increasing usage in renewable energy systems. The Hall Switch segment dominates due to its prevalence in automotive position sensing applications. European OEMs emphasize miniaturization and energy efficiency, creating opportunities for modular sensors with integrated signal processing. However, the transition to electric vehicles has temporarily disrupted traditional supply chains, causing suppliers to realign production capacities toward EV-specific sensor solutions.

Asia-Pacific Asia-Pacific represents the fastest-growing regional market, projected to capture over 45% of global demand by 2032. China’s dominance stems from massive electronics production and government-backed Industry 4.0 initiatives fueling industrial automation. Japanese manufacturers lead in high-precision applications like robotics, while South Korea sees strong demand from consumer electronics giants. The region witnesses intense price competition, with local players like ROHM Semiconductor gaining market share through cost-effective solutions. India emerges as a promising market with expanding automotive manufacturing and infrastructure modernization programs, though quality consistency remains a concern among buyers.

South America Market growth in South America remains moderate, constrained by economic instability and limited local manufacturing capabilities. Brazil accounts for nearly half the regional demand, primarily serving automotive and appliance industries. Cost sensitivity drives preference for basic Hall Switch models over advanced linear sensors. While foreign investments in Argentina’s industrial sector show potential, currency volatility discourages long-term commitments from major sensor suppliers. The aftermarket for sensor replacements presents steady opportunities, particularly in aging industrial equipment maintenance across the continent.

Middle East & Africa This region demonstrates uneven growth patterns, with Gulf Cooperation Council countries leading adoption in oil/gas and building automation applications. Israel’s thriving medical technology sector drives specialist demand for high-reliability sensors. South Africa serves as an industrial hub for sub-Saharan Africa, though infrastructure limitations hinder widespread sensor integration. The market sees increasing Chinese imports due to competitive pricing, while European suppliers maintain dominance in high-value industrial projects. Government initiatives to diversify economies toward manufacturing create long-term growth potential, albeit from a comparatively small base.

Report Scope

This market research report provides a comprehensive analysis of the global Modular Hall Effect Sensors market, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global market was valued at USD million in 2024 and is projected to reach USD million by 2032.

Segmentation Analysis: Detailed breakdown by product type (Hall Switch, Linear Hall Sensor), application (Consumer Electronics, Automotive, Aerospace, Medical, Industrial), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America (USD million market size in U.S.), Europe, Asia-Pacific (China projected at USD million), Latin America, and Middle East & Africa.

Competitive Landscape: Profiles of leading market participants including Sensata Technologies, Texas Instruments, Allegro MicroSystems, and others holding approximately % market share in 2024.

Technology Trends & Innovation: Assessment of emerging sensor technologies, integration with IoT systems, and evolving industry standards for magnetic sensing applications.

Market Drivers & Restraints: Evaluation of factors including automotive electrification, industrial automation demand, along with supply chain constraints and material cost challenges.

Stakeholder Analysis: Strategic insights for sensor manufacturers, OEMs, system integrators, and investors regarding market opportunities and competitive positioning.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/global-video-sync-separator-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silicon-rings-and-silicon-electrodes_17.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ceramic-bonding-tool-market-investments.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/coaxial-panels-market-challenges.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/oled-and-led-automotive-light-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/gas-cell-market-demand-for-ai-chips-in.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digital-demodulator-ic-market-packaging.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/nano-micro-connector-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/single-mode-laser-diode-market-growth.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silicon-rings-and-silicon-electrodes.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/battery-management-system-chip-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/scanning-slit-beam-profiler-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/atomic-oscillator-market-electronics.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/plastic-encapsulated-thermistor-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ceramic-bonding-tool-market-policy.html

0 notes

Text

QMK Projects

Hello QMK Community,

I've been an amateur mechanical keyboard user for years and an even more amateur electrician for even longer. I had learned about the existence of a Dactyl Manuform keyboard and had to make one for myself. With a few trials and helpful guides I eventually made two pairs, one for work and one for home. I named them Enki and Namma after the Sumerian creation gods. They were made with Gatreon Green and Kaith White switches respectively.

Pictured: Wiring process top, Enki left, Namma right

I even went so far to make my own keyboard layout combining the "Workman" layout and the "M-system" layout to make a keyboard optimized for English and Japanese typing.

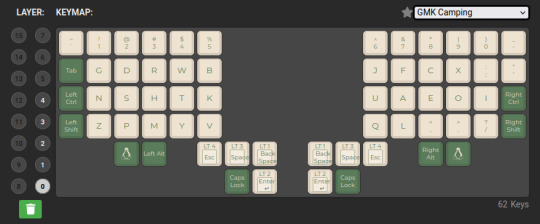

Pictured: Workman / M-system Hybrid Layout

All of these projects above would not be possible without QMK (Quantum Mechanical Keyboard) an open source firmware used in hobbyist mechanical keyboards. Despite all of that, QMK currently has no support for my next ambitions. There are two primary features I am looking for: -Analog Hall Effect Switches -PS/2 Support

The first feature I would like to implement is analog hall effect switch support. Hall effect switches are switches that utilize the "Hall effect". Basically, they are a sensor that can detect when a magnet is moving over them. In keyboards, this means you can create a switch that is literally just a magnet on a spring. This simplicity makes the switch very durable. These switches can even be analog meaning they can detect the intensity of a key press and be adjusted in software. The one downside for most consumers is that they are only offered as linear switches, in other words, switches with little or no click. Personally, this is not a downside because I'm looking to move to linear switches anyway.

Pictured: Hall effect sensor left, Hall effect process right

Hall effect switches already have support to a certain extent. Hall effect sensors can be digital instead of analog, meaning the switch can be used as a normal switch plugged in the normal way. I see this as wasted potential and will not be using these for my project. Only one analog Hall effect QMK keyboard exists to my knowledge, the Keychron Q1 HE. I do not intend to buy this keyboard but may reach out to Keychron to see how they pulled this off.

Pictured: Keychron Q1 HE

The second feature I want to implement is PS/2 support. I imagine very few of you know what I'm talking about, some of you think I'm trying to make a keyboard compatible with a 25 year old games console, and the ones who do know what I'm talking about probably think I'm crazy.

Pictured: PS/2 Port

Above is a PS/2 port, a standard introduced by IBM in 1987. Now I suspect the entire audience is on the same page of thinking I am nuts. Hear me out, there is a reason you can still find computer's made with this port today. When using this port with a keyboard or mouse, the device interfaces directly with the hardware of the machine. USB devices have a polling rate, they effectively send their data by waiting for the bus. With a PS/2 port, there is no waiting so the speed of data is dramatically increased. There are several other features exclusive to PS/2 but the latency decrease is my primary objective

Pictured: Passive PS/2 Adapter

Some of you may find a device like the one pictured above and think there is no need for this direct support, you can just plug the keyboard into this adapter and it will just work. You are wrong. Only certain keyboards play well with these adapters. There is a protocol built into a normal keyboard's firmware that can detect if it's plugged into an adapter like this. This protocol does not currently exist in QMK to my knowledge. My intention is to introduce this protocol into QMK's firmware for use with these passive adapters. This way, I don't need to introduce a new port to my existing keyboards or get PS/2 wires and plugs.

I'm intending to make another two keyboards with both of these new features named Gilgamesh and Enkidu because what good is a theme if you don't stick to it? I'll post updates as I continue along this journey and hope you are interested in how this project develops. If you have any insights or knowledge please feel free to reach out.

#qmk#mechanical keyboard#keyboard#hall effect#ps/2#diy projects#diy#hall effect keyboard#electronics

0 notes

Text

Global Magnetic Sensors Market to Grow at 4.2% CAGR Through 2031

The global magnetic sensors market was valued at USD 5.6 Bn in 2022 and is poised to reach USD 8.2 Bn by 2031, expanding at a CAGR of 4.2% from 2023 to 2031. The market is witnessing robust growth fueled by the rising adoption of smart consumer electronics, automotive advancements, and increasing demand across industrial automation and healthcare sectors. Magnetic sensors, which detect and convert magnetic fields into electrical signals, are evolving with new technologies such as Hall effect, Anisotropic Magneto Resistance (AMR), Giant Magneto Resistance (GMR), and Tunnel Magneto Resistance (TMR), driving performance, precision, and reliability across multiple applications.

Market Drivers & Trends

One of the key factors propelling market expansion is the growth in the automotive sector, particularly the integration of Advanced Driver Assistance Systems (ADAS), which heavily rely on magnetic position and speed sensors. These components are essential for measuring motion, position, and speed, playing a pivotal role in features such as automatic transmissions, antilock braking systems, and parking assist technologies.

Additionally, the increased adoption of consumer electronics, including smartphones, tablets, and digital cameras, has augmented demand for Hall effect sensors that enable screen rotation, compass functionality, and motion detection. The rise in investment in industrial automation, including robotics and precision machinery, is another significant driver. Sensors are increasingly used for applications such as robotic arm positioning, conveyor belt monitoring, and machine tooling control.

Latest Market Trends

Recent trends indicate a growing focus on miniaturization and precision engineering. Manufacturers are innovating compact magnetic micro-actuators and sensors that enable advanced functionalities in constrained environments. This trend is particularly relevant in medical devices and portable electronics.

Moreover, there is an increasing shift toward non-contact magnetic sensor technology, which enhances sensor durability and performance while reducing maintenance costs. Developments in Tunnel Magneto Resistance (TMR) sensors are also gaining attention for their ultra-low power consumption and high sensitivity, ideal for wearable and IoT applications.

Key Players and Industry Leaders

The global magnetic sensors market is marked by the presence of several established players that continuously invest in research and development. Major companies include:

Infineon Technologies AG

Honeywell International, Inc.

NXP Semiconductors

Alps Electric Co., Ltd.

Asahi Kasei Microdevices Corporation

Analog Devices, Inc.

TE Connectivity Corporation

Elmos Semiconductor AG

Magnetic Sensors Corporation

Allegro Microsystems, Inc.

Other Prominent Players

These companies are competing on the basis of product innovation, sensor accuracy, and energy efficiency. Key players are also forming strategic alliances and partnerships to extend their global reach and penetrate new markets.

Explore the highlights and essential data from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=289

Recent Developments

The market has seen several noteworthy advancements in recent months:

In October 2023, Renesas Electronics Corp. unveiled a new inductive position sensor (IPS) technology aimed at robotics, industrial, and medical applications.

In April 2023, TDK Corporation announced a major expansion of its TDK Asama Techno Factory in Japan to increase TMR magnetic sensor production, responding to rising demand in automotive and industrial sectors.

In July 2023, MultiDimension Technology Co., Ltd. introduced new TMR switch sensors targeting medical, industrial, and automotive applications.

These developments underscore the industry’s emphasis on technological innovation and application-specific customization.

Market Opportunities

Emerging applications in healthcare and the Internet of Things (IoT) offer significant growth avenues. Magnetic sensors are increasingly used in non-invasive medical diagnostics, such as magnetic field imaging and implantable device monitoring. The rising trend of smart homes and connected devices also contributes to higher adoption of sensors for automation and security functions.

Furthermore, industries are transitioning toward Industry 4.0, which places magnetic sensors at the center of intelligent manufacturing and predictive maintenance ecosystems.

Future Outlook

Looking ahead, the magnetic sensors market is expected to grow steadily, driven by:

Continuous innovation in TMR and GMR technologies

Expansion in electric and autonomous vehicle production

Integration of sensors in wearable technologies

Increased demand for energy-efficient industrial automation

North America is likely to dominate in terms of revenue share, followed by Asia Pacific, due to rapid industrialization and technological adoption. Asia Pacific, particularly China, Japan, and India, is expected to witness the fastest growth due to local electronics manufacturing and automotive production surges.

Market Segmentation

The magnetic sensors market can be segmented by technology and application:

By Technology:

Hall Effect

Anisotropic Magneto Resistance (AMR)

Giant Magneto Resistance (GMR)

Tunnel Magneto Resistance (TMR)

Others

By Application:

Automotive

Consumer Electronics

Industrial

Others (including medical devices, aerospace, etc.)

Regional Insights

North America: Leading region due to strong industrial automation, growing medical technology applications, and R&D investments.

Europe: Significant automotive production base, with high integration of magnetic sensors in vehicle safety and performance systems.

Asia Pacific: Fastest-growing region owing to the rise in electronics manufacturing, smart city initiatives, and expanding automotive industry.

Latin America and Middle East & Africa: Emerging regions with growing industrial automation and energy sector demands.

Why Buy This Report?

In-depth industry analysis with historical data and future forecasts

Detailed segmentation by technology, application, and region

Profiles of top market players, highlighting their strategies, product portfolios, and financials

Recent developments and innovations in the global market

Insights into emerging opportunities and investment areas

Analysis of key market trends and competitive landscape

Access to customized PDF and Excel data formats

Explore Latest Research Reports by Transparency Market Research: Interactive Display Market: https://www.transparencymarketresearch.com/interactive-display-market.html

GaN Epitaxial Wafers Market: https://www.transparencymarketresearch.com/gan-epitaxial-wafers-market.html

Micro Switch Market: https://www.transparencymarketresearch.com/micro-switch-market.html

GaAs Photodiode Market: https://www.transparencymarketresearch.com/gaas-photodiodes-market.html About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

⚡ Tiny Sensors, Huge Growth: Current Sensor Market to Reach $7.8B by 2034

Current Sensor Market is on an impressive upward trajectory, expected to surge from $3.1 billion in 2024 to $7.8 billion by 2034, growing at a strong CAGR of 9.7%. This growth mirrors the increasing demand for current measurement in smart technologies, electric vehicles, renewable energy systems, and advanced industrial machinery. Current sensors play a crucial role in monitoring and regulating electric currents to enhance system efficiency, safety, and energy savings. From managing battery systems in electric cars to powering smart grid infrastructure, their role is more vital than ever.

Market Dynamics

The market is being driven by a combination of technological innovations, rising renewable energy adoption, and the global transition to electric mobility. The demand for Hall Effect sensors, due to their reliability and cost-effectiveness, remains dominant across several sectors. Shunt-based sensors, gaining ground due to their versatility, are widely used in energy management and automation.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS20825

On the flip side, challenges such as the rising cost of raw materials, integration complexities with IoT, and regulatory compliance across geographies could hinder short-term growth. Yet, the ongoing miniaturization of sensors and increased investment in AI-driven monitoring systems are expected to unlock new opportunities.

Key Players Analysis

Some of the major players steering the current sensor industry include Allegro MicroSystems, Infineon Technologies, Honeywell International, LEM Holding, and Melexis NV. These companies are setting benchmarks through innovation, mergers, and partnerships aimed at improving sensor accuracy, energy efficiency, and real-time data capabilities. Emerging names like Volt Guard, Sense Stream, and Electra Sense are also entering the competitive arena, bringing niche innovations and disrupting traditional sensor models. Strategic moves by these players — especially toward sustainable manufacturing and smart applications — are reshaping the competitive landscape.

Regional Analysis

The Asia-Pacific region continues to lead the current sensor market, driven by rapid industrial growth and tech innovation in countries like China, Japan, and India. Smart city initiatives and the boom in EV adoption have further accelerated sensor deployment. North America follows closely, where focus on IoT, energy-efficient infrastructure, and robust automotive markets — especially in the United States — are fueling demand. Europe, led by Germany and France, maintains strong growth through regulatory pushes for sustainability and automation. Meanwhile, Latin America, the Middle East, and Africa are emerging as high-potential markets, thanks to infrastructure development and increasing renewable energy projects.

Recent News & Developments

Recent years have seen an evolution in sensor pricing and design, with costs ranging from $1 to $50 per unit, depending on type and functionality. Innovations like wireless current sensors, non-invasive technologies, and AI-integrated systems are redefining application scopes. Companies such as Aceinna and Analog Devices have introduced advanced sensor models supporting real-time analytics and predictive maintenance. Moreover, global supply chain challenges and trade policy shifts are prompting businesses to invest in localized manufacturing and sustainable sourcing. Regulatory developments, especially around energy efficiency and data security, are also shaping R&D focus.

Browse Full Report : https://www.globalinsightservices.com/reports/current-sensor-market/

Scope of the Report

This report offers a detailed snapshot of the current sensor industry, spanning segmentation by type, technology, material, and application. It analyzes both quantitative trends — such as unit sales and CAGR — and qualitative dynamics, including SWOT, PESTLE, and competitive strategies. It highlights regional performance, emerging market entrants, and key development strategies like partnerships, acquisitions, and R&D investment. From OEMs to aftermarket trends, and from analog to digital sensor tech, the report lays out a comprehensive roadmap for stakeholders. With detailed insights into cross-segmental opportunities, demand-supply analysis, and local regulatory landscapes, it empowers strategic decision-making for sustainable and profitable growth in this evolving market.

Discover Additional Market Insights from Global Insight Services:

Asset Integrity Management Market : https://www.globalinsightservices.com/reports/asset-integrity-management-market/

Printed Circuit Board Market : https://www.globalinsightservices.com/reports/printed-circuit-board-market/

Medical Sensors Market : https://www.globalinsightservices.com/reports/medical-sensors-market/

Fiber Optic Cables Market : https://www.globalinsightservices.com/reports/fiber-optic-cables-market/

Smart Factory Market : https://www.globalinsightservices.com/reports/smart-factory-market/

#currentmarkettrends #currentsensormarket #iotdevices #energyefficiency #automotivesensors #smartgridtech #hallfx #digitalsensors #industryautomation #techdriven #renewableenergygrowth #electricvehicles #embeddedtech #standaloneelectronics #asiapacificgrowth #europetechmarket #northamericainnovation #industrialsolutions #automotiveinnovation #sensorfusion #smartdevices #powersystems #futuretech #sensorinnovation #aiintegration #minisensors #costefficienttech #energymanagement #techtrends2025 #sensorrevolution #microelectronics #semiconductortechnology #globaltechmarket #batterymanagement #cleantech #sustainablesolutions #iotintegration #powersensing #currentmeasurement #smartmobility

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

The Science Behind Hollow Shaft Rotary Encoders: Torque, Speed, and Accuracy

In the landscape of modern automation, sensors and feedback mechanisms are crucial for maintaining the precision and efficiency of machinery. One of the most indispensable devices in this category is the rotary encoder, especially the hollow shaft rotary encoder. These devices provide real-time data on angular position, velocity, and direction, enabling refined control over dynamic systems. Their unique hollow shaft design offers numerous advantages, particularly when integrating with rotating shafts and assemblies in compact or sensitive environments. This article delves into the scientific underpinnings of these encoders, examining how they measure torque, speed, and accuracy in industrial and robotic applications.

Basics of Rotary Encoders

Rotary encoders translate rotational motion into digital signals. They are broadly categorized into absolute and incremental types. Absolute encoders deliver a unique position value, whereas incremental encoders provide relative motion data. Hollow shaft rotary encoders, a sub-type of these devices, allow the shaft of the motor or machinery to pass through the encoder. This design minimizes axial load, reduces mechanical complexity, and facilitates easier installation. The hollow shaft construction is particularly beneficial in applications where space is limited or where quick replacement and alignment are essential. These encoders are primarily used in robotics, CNC machinery, elevators, and energy sector equipment.

Working Principle of Hollow Shaft Rotary Encoders

Hollow shaft rotary encoders typically use optical, magnetic, or capacitive sensing methods. Optical encoders employ a light source and photodetector array to read patterns on a rotating disk. Magnetic encoders detect changes in magnetic fields using Hall-effect sensors or magnetoresistive elements. Capacitive encoders utilize variations in capacitance caused by changes in geometry as the shaft rotates. Each method has its advantages in terms of resolution, durability, and environmental robustness. The hollow shaft design does not alter the fundamental sensing mechanism but allows the encoder to be mounted directly over a rotating shaft without additional couplings. This direct interface helps reduce backlash and enhances accuracy.

Measuring Torque with Hollow Shaft Rotary Encoders

Torque is the rotational analog of linear force. Although rotary encoders are not traditionally used as torque sensors, they play a significant role in torque estimation. By precisely measuring angular displacement and speed, and knowing the system's moment of inertia, torque can be inferred. In applications where torque sensors are either too bulky or expensive, high-resolution encoders serve as a cost-effective alternative. The key lies in correlating the angular velocity and acceleration data provided by the encoder with the mechanical characteristics of the system. For dynamic torque measurement, especially in systems with varying load conditions, encoders offer real-time feedback that can be analyzed via control algorithms to maintain performance consistency.

Speed Detection in Dynamic Systems

Speed detection is a primary function of rotary encoders. Incremental hollow shaft rotary encoders are particularly adept at delivering high-fidelity speed data. They generate pulses for every increment of rotation, which are counted over time to calculate speed. Higher pulse counts per revolution (PPR) mean greater resolution and more accurate speed readings. In applications like conveyor systems, turbines, or robotic joints, this level of speed precision ensures smoother operation and reduces wear and tear. Encoders are also favored for their minimal latency, allowing near-instantaneous speed adjustments. Furthermore, their digital output can be seamlessly integrated into programmable logic controllers (PLCs) or microcontrollers for real-time processing and control.

Ensuring Accuracy and Resolution

Accuracy in rotary encoders refers to the degree to which the measured position matches the actual position. Resolution, on the other hand, is the smallest change in position that the encoder can detect. High-resolution encoders are essential for systems requiring fine control, such as semiconductor manufacturing or surgical robotics. Hollow shaft rotary encoders often offer both high resolution and excellent accuracy due to their ability to directly interface with the rotating element. This reduces mechanical errors associated with couplings or misalignment. Optical encoders typically offer the highest resolution, while magnetic and capacitive types provide better resilience in harsh environments. Calibration and alignment during installation also play critical roles in maintaining accuracy.

The Importance of Zero Backlash

Backlash is the slight movement that occurs when direction is reversed in a mechanical system. This can cause significant errors in position sensing. Hollow shaft encoders help minimize backlash by allowing direct mounting onto the shaft, thereby eliminating intermediate couplings or gears that can introduce slack. Zero backlash is particularly critical in high-precision applications like robotics and CNC machining, where even minor errors can lead to defective outcomes. By integrating the encoder directly onto the shaft, manufacturers can achieve tighter control loops, reduced error margins, and more reliable performance. This direct integration also facilitates better synchronization between motor movement and feedback, enhancing overall system stability.

Environmental and Structural Considerations

Industrial environments often expose equipment to dust, moisture, temperature fluctuations, and vibrations. Hollow shaft rotary encoders are designed to withstand these conditions through robust housing, sealed bearings, and non-contact sensing technologies. Magnetic and capacitive encoders are particularly well-suited for such environments due to their resistance to contaminants and mechanical wear. Structural considerations also include the material of the encoder’s housing and shaft, which must align with the application’s requirements for durability and weight. The hollow shaft itself can be designed to accommodate different shaft diameters, increasing its adaptability across multiple systems. Proper installation and maintenance further ensure the encoder's longevity and consistent performance.

Integration into Closed-Loop Systems

Hollow shaft rotary encoders play a pivotal role in closed-loop control systems, where feedback is used to adjust and correct motion in real time. These systems require high-resolution and low-latency feedback to maintain accuracy and efficiency. The encoder sends position and speed data to a controller, which then adjusts the motor’s operation accordingly. This continuous feedback loop allows for precise control even in variable load conditions. Integration into such systems requires compatibility with control hardware, appropriate signal output formats, and real-time data processing capabilities. Encoders that support multiple output protocols, such as quadrature, SSI, or BiSS, offer greater flexibility in system design.

Case Study: Hollow Shaft Encoders in Robotic Arms

Robotic arms require exceptional precision and agility, often functioning in environments that demand both speed and safety. Hollow shaft rotary encoders enable these capabilities by offering accurate position and velocity feedback without adding bulk to the joints. Their compact design fits seamlessly into tight spaces, while their direct shaft interface ensures minimal mechanical error. For example, in medical robotics, where minute movements can have significant consequences, the encoder's resolution and accuracy become critical. Additionally, their ability to function reliably in varying environmental conditions makes them suitable for both cleanrooms and industrial settings. This case study illustrates how the theoretical benefits of hollow shaft encoders translate into practical performance gains.

Comparing Hollow Shaft and Solid Shaft Encoders

Solid shaft encoders require couplings or adapters for installation, which can introduce alignment issues and mechanical play. Hollow shaft encoders bypass these challenges by mounting directly onto the shaft, thereby reducing complexity and improving measurement fidelity. While solid shaft designs may offer slightly more mechanical robustness, they often necessitate more space and careful alignment. Hollow shaft encoders, by contrast, are easier to install and replace, which is beneficial in systems where downtime must be minimized. The choice between the two often comes down to the specific application requirements, including available space, desired precision, and environmental factors. Ultimately, hollow shaft models offer a compelling mix of convenience and performance.

Market Trends and Future Outlook

The market for rotary encoders is evolving rapidly, driven by advancements in automation, robotics, and smart manufacturing. Hollow shaft rotary encoders are gaining traction due to their compact design and enhanced integration capabilities. Innovations such as wireless data transmission, miniaturization, and improved environmental resistance are expanding their application scope. Additionally, the incorporation of edge computing and AI into encoder systems is enabling predictive maintenance and smarter feedback mechanisms. As industries continue to push for higher efficiency and precision, the demand for reliable and versatile encoders will only increase. In this context, the hollow shaft encoder emerges as a key component in future-ready systems.

Conclusion

The science behind hollow shaft rotary encoders encompasses a multidisciplinary understanding of mechanics, electronics, and systems engineering. Their ability to provide accurate, real-time data on torque, speed, and position makes them invaluable in a wide array of industrial and robotic applications. Their unique hollow design simplifies installation and enhances performance by reducing mechanical errors. From aiding in torque estimation to ensuring zero backlash and high-resolution feedback, these encoders are tailored for precision-driven environments. As technological advancements continue to refine their capabilities, the hollow shaft rotary encoder is poised to remain a cornerstone of intelligent motion control systems across industries.

0 notes

Text

📢 MT9105ET Board Mount Motion & Position Sensor – Now Available at Xon Electronics! 🔥 🚀 Precision in Motion & Position Sensing! The MT9105ET by MagnTek is a compact, high-performance Hall-effect sensor designed for linear & angular position sensing in industrial and automation applications. 🔹 📌 Specifications: ✔ Package: SOT-23 ✔ Supply Voltage: 3.0V – 5.5V ✔ Output: Analog (Ratiometric) ✔ Power Consumption: Ultra-low (~1.5mA) ✔ Compliance: RoHS 💡 ✨ Key Features: ✅ High precision & reliability ✅ Compact SOT-23 design for space-saving applications ✅ RoHS compliant & eco-friendly ✅ Low power consumption – ideal for battery-operated devices 🏭 🔧 Applications: 🔸 Industrial automation & robotics 🔸 Proximity & current sensing 🔸 Motor & angle position measurement 🔸 Conveyor belt tracking 🛒 Order Now at Xon Electronics! 🌍 Available in USA, India, Australia, Europe & more! 📥 Download the MT9105ET Datasheet (PDF) Now! Visit Now: https://www.xonelec.com/mpn/magntek/mt9105et MT9105ET #MagnTek #PositionSensor #MotionSensor #HallEffectSensor #XonElectronics #Automation #IndustrialTech #Sensors #PCBDesign #ElectronicComponents #Electronics

0 notes

Text

Hall Effect Sensor Market to Observe Strong Growth to Generate Massive Revenue in Coming Years

Hall Effect Sensor market is expected to mark significant growth over forecasted period owing to increasing applications in industries such as automotive, healthcare, consumer electronics, and defense and aerospace, anti-lock braking systems& tachometers and high speed gaming applications and technological advancement. Hall Effect Sensor allows users to generates a query, analyze spatial information, map data and provide output in magneto-resistance-based sensors or fluxgate magnetometers. The major companies are adding more proven technologies systematically and strategically in Asia-Pacific countries as these countries are focused on fastest-growing verticals in the automation, infrastructure/building sector.

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/105213-global-hall-effect-sensor-market?utm_source=Organic&utm_medium=Vinay

Latest released the research study on Global Hall Effect Sensor Market, offers a detailed overview of the factors influencing the global business scope. Hall Effect Sensor Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Hall Effect Sensor The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are MEMSIC, Inc. (United States), Bartington Instruments Ltd (United Kingdom) , TE Connectivity Ltd (Switzerland), Analog Devices, Inc. (United States) , Honeywell International Inc. (United States) , Robert Bosch GmbH (Germany) , NXP Semiconductors N.V. (The Netherlands) , Ams AG (Austria) , The Micronas Group (Switzerland) ,

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

Contact Us:

Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

0 notes

Text

China made Sensor speed CS-1 G-065-05-1 for power plant

"China made Sensor speed CS-1 G-065-05-1 for power plant Deyang Dongfang Yoyik is a strong manufacture and trade company. We have a wide range of mechanical parts and components generator parts, electrical and electronic products processing, hydraulic machinery and components, hydroelectric generating units, coal-fired generating units, especially professional accessories for generator units. The goods are absolutely authentic, rest assured.

Yoyik can offer many spare parts for power plants as below:

DF-Sensor speed CS-1 G-065-05-1-DF

sensor lvdt ZD-5000TDB rtd temperature 4Q15244 sensor lvdt 1000TDZ-A Magnetic Speed Sensors CS-3-M10-L70 thermocouples extension lead wires TE-209 Analog Linear Displacement Sensor 700TD high temperature thermocouple TC03A2-KY-2B/S3 Magnetic Pick-up Speed Sensor 143.35.19 Resistance Temperature Detector WZPM2 3 wire rtd DZ3.1.2.7-1992 inductive displacement sensor LVDT-20-6 temperature gauge sensor WZPM2-08-040-M18-S lvdt linear position sensor A156.33.42.04 displacement sensor sany C9231118 Non-Contact Linear Displacement sensor TD-1-100 thermal resistance units WZPK2-380B φ8 platinum rhodium thermocouple wire WRNK2-331\φ6\K lvdt 0-300 ZDET700B Hall Effect RPM/Speed Sensor CS-3 thermocouple type k TC03A2-KY-2B/S17 lvdt-sensor TDZ-1 lvdt probe 191.36.09.02 thermistor TE-104 rpm meter digital speed HZQW-03A thermocouple range TE-305 lvdt probe 191.36.09.18 rtd WZPK2-238 LVDT sensor TDZ-1-24 displacement sensor 186.33.01.07 lvdt 20mm sensor A157.33.42.03 pt100 temperature controller WZPM2-08-040-M18-S rtd thermal resistance WZPM2-001 Φ5 displacement sensor 6000TDGN industrial displacement sensor 268.33.01.B Thermocouple Temperature Measurement WRNR-010 K φ5mm rpm sensor generator H1512-001 Sensor speed CS-1 G-065-05-1

Limit switch ZHS40-4-N-03 liquid level transmitter CEL-3596F/G lvdt 0-300 ZD-10000TDB output shaft speed sensor ZS-03 Platinum RTD Sensor WZP type k thermocouple TE-205 LVDT Displacement Transducer Sensors LVDT-50-3 heater cartridge 24v ZJ-14.5-400 lvdt transducer displacement 191.36.09.11 linear displacement sensor B151.36.09.04-007 speed sensor CS_1 D-088-02-01 LVDT Displacement Sensors ZDET300B vertical Pressure gauge Z1237973 lvdt-sensor DET600A capillary temperature gauge WSSP-481 LVDT Position Sensor TDZ-1-13 speed sensor cost PRA-BOX TE Temperature element WZPN2-002 Adjustable Bimetal Thermometer WSSP-481 lvdt displacement sensor inductive sensor LVDT-300-6 steam turbine bolt heater ZJ-20-13(R) Rotary Torque Sensor CS-3-M16-L140 Analog Linear Displacement Sensor HL-6-25-15 full form of lvdt FRD.WJA2.308 temperature probe sensor WZPK2-336 linear displacement sensor TDZ-1-02 Platinum Thermocouple Wire TE-106 thermowell TE-304 displacement transducer 7000TDG turbine speed sensor bme tcu 70085-1010-411 dual sensor rtd WZPK2-323 rpm sensor generator CS1 Bimetal Temperature Gauge WTY-402 flexible heating element JHG03 linear variable displacement transducer ZD-10000TDA Speed Sensor SZCB-01 Sensor speed CS-1 G-065-05-1

DFYLSYC-2024-6-11-A

"

0 notes

Text

I bought an 8BitDo Pro 2 controller a few months ago because I wanted something that would be a good match for playing retro games through emulation. The Pro 2 seemed like a good choice because it's got that Nintendo reversed button layout (BA/YX instead of AB/XY) and a proper D-pad. It took a little finagling in RetroArch, but it performs this task admirably. In fact this thing is just so damn good that it has replaced the XBox Series controller as the gamepad I reach for when playing any game where a controller is the optimal choice (e.g. FromSoft games).

The sticks are responsive and make use of hall effect sensors rather than potentiometers so there's no risk of stick drift over time, the R2 and L2 triggers are fully analog and adjustable, it's got programmable paddles on the bottom (I've got them set to R3 and L3), and the software allows for full programmability of the face buttons, dead zones for the analog sticks, and variable turbo settings, all of which can be saved to one of the three user profiles. The rechargeable battery lasts 20 hours, failing that you can swap it out for two AAs. The Bluetooth is rock solid and fast after a firmware update. It just feels solid too. The big thing for me is that it's just really comfortable to hold. I have large hands with very long fingers so the wider spacing between the analog sticks and the buttons means my hands are much less cramped with this controller. I'm not shaking out my hands and doing finger stretches every fifteen minutes because of cramping.

Oh and if you plug it in and set the input toggle over to Switch mode, YuZu reads it as a Switch Pro controller and the Pro 2's motion input works perfectly, which makes those dungeons in Breath of the Wild/Tears of the Kingdom where you need to move a ball through a maze a hell of a lot easier.

I grew up in the Nintendo 64/PlayStation era when a third party controller was something you forced on your little brother because it was a piece of shit. This is miles removed from that experience. Now don't get me wrong, the XBox Series controller is really nice, but it's the one I'm giving to be forcing onto any friend who comes over and wants to play Mario Kart 64.

7 notes

·

View notes

Text

Current Sensor Market Expected to Reach $2.61 Billion, Globally, by 2027 at 6.3% CAGR: Allied Market Research

As per the current sensor market trend, rise in adoption of power management system sin data centers for improved efficiency & speed with reduced power expenditure is anticipated to fuel the market demand. Current sensors integrated with backup power systems such as inverters and UPS systems enable protection of battery at the stage of charge and offer efficiency, increasing their demand in data centers. Moreover, stringent government regulations in relation to control of data center power consumption is also one of the major factors that influence the current sensor market growth.

Wilmington, Delaware

According to a recent report published by Allied Market Research, titled, “Current Sensor Market by Type, Current Sensing Technology, And End Use: Opportunity Analysis and Industry Forecast, 2020-2027,” the global current sensor industry size was valued at $1.65 billion in 2019, and is projected to reach $2.61 billion by 2027, growing at a CAGR of 6.3% from 2020 to 2027.

Download Research Report Sample & TOC: https://www.alliedmarketresearch.com/request-sample/8323 (We look forward to moving quickly to provide the Report Analysis needed for your Business Success) •114 – Tables •80 – Charts •227 – Pages

Current sensors, also commonly referred to as current transformers or CTs, are devices that measure current running through a wire by using magnetic field to detect the current and generate a proportional output. They are used with both AC and DC current. They are used in various applications such as motor driving circuits and inverter circuits. Current sensors are used in various industries such as automotive, consumer electronics, and telecommunication.

Prime determinants of growth:

Adoption of industrial robots and increase in trend of hybrid vehicles in the automotive industry drive the current sensor market growth. However, technical issues and high costs associated with current sensors across the globe hamper the market growth. On the contrary, rapid adoption of 5G technology increases demand for closed loop current sensors, which is expected to create lucrative opportunities for the current sensor market.

Report Coverage and Details:

Aspects

Details

By Type

Open loop

Closed loop

By Current Sensing Technology

Hall Effect

Current Transformer

Flux Gate

Rogowski Coil

By End Use

Automotive

Consumer Electronics

Industrial

Telecommunication

Others

COVID-19 Scenario:

The COVID-19 outbreak has currently restrained the research & development activities in the electronics & semiconductor industry and has led to shutdown of several manufacturing facilities globally. The shortage or unavailability of raw materials and components due to supply chain disruption has hindered the production capacity of sensor manufacturers. Further, decline in purchase capability among consumers due to uncertain economy and decrease in the adoption of electric vehicles will further hinder the market growth.

A current sensor is a device that detects electric current in a wire and generates a signal proportional to that current. The generated signal could be analog voltage or current or a digital output. These are categorized in open loop and closed loop and use technologies such as Hall-effect, Rogowski effect, and flux gate. Current sensors are used in various industries such as consumer electronics and automotive.

Inquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/8323

Leading Market Players:

LEM Group,

Eaton,

TDK Corporation,

Sensitec GmbH,

Infineon Technologies AG,

TAMURA CORPORATION,

TEXAS INSTRUMENTS,

ALLEGRO MICROSYSTEMS, INC.,

Honeywell International Inc.,

Pulse Electronics

The report provides a detailed analysis of these key players of the global current sensor market. These players have adopted different strategies such as product development and product launch to increase their market share and maintain dominant shares in different regions. The report is valuable in highlighting business performance, operating segments, product portfolio, and strategic moves of market players to showcase the competitive scenario.

Key Benefits for Stakeholders:

By type, the open loop segment held the highest revenue of $1,172.4 million in 2019, and contributed a major part in current sensor market share.

By current sensing technology, the Hall Effect segment held the highest revenue of $676.2 million in 2019.

By end use, the industrial segment held the highest revenue share of the market in 2019, generating $633.7 million as per the market analysis.

By region, Asia-Pacific is expected to dominate the market, garnering a major share during the forecast period.

By Region:

North America (U.S., Canada, and Mexico)

Europe (U.K., Germany, France, Italy, Spain, Russia, Netherlands, Belgium, Poland, and Rest of Europe)

Asia-Pacific (China, Japan, India, South Korea, Australia, Malaysia, Thailand, Philippines, Indonesia, and Rest of Asia-Pacific)

LAMEA (Latin America, Middle East and Africa)

Trending Reports in Semiconductor and Electronics Industry (Book Now with Up to 20% Discount + COVID-19 Scenario):

Antenna Market size is projected to reach $40.1 billion by 2032, growing at a CAGR of 9.1% from 2023 to 2032.

Image Sensor Market size is projected to reach $87.5 billion by 2032, growing at a CAGR of 12.9% from 2023 to 2032.

Superconductors Market share is projected to reach $17.4 billion by 2032, growing at a CAGR of 10% from 2023 to 2032.

Power Cable Market size is projected to reach $277.8 billion by 2031, growing at a CAGR of 6.4% from 2022 to 2031

Embedded Systems Market size is projected to reach $163.2 billion by 2031, growing at a CAGR of 6.5% from 2022 to 2031.

About Us:

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Wilmington, Delaware. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of "Market Research Reports Insights" and "Business Intelligence Solutions." AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

We are in professional corporate relations with various companies and this helps us in digging out market data that helps us generate accurate research data tables and confirms utmost accuracy in our market forecasting. Allied Market Research CEO Pawan Kumar is instrumental in inspiring and encouraging everyone associated with the company to maintain high quality of data and help clients in every way possible to achieve success. Each and every data presented in the reports published by us is extracted through primary interviews with top officials from leading companies of domain concerned. Our secondary data procurement methodology includes deep online and offline research and discussion with knowledgeable professionals and analysts in the industry.

Contact:

David Correa

1209 Orange Street, Corporation Trust Center, Wilmington, New Castle, Delaware 19801 USA.

Int'l: +1-503-894-6022 Toll Free: +1-800-792-5285

UK: +44-845-528-1300

India (Pune): +91-20-66346060 Fax: +1-800-792-5285 [email protected]

0 notes

Text

Sensor Cables What They Are and How to Use Them to Measure Velocity

In the world of modern technology, sensor cables play a crucial role in various applications. They are an integral part of systems designed to measure velocity accurately, and they offer a wide range of benefits. In this blog, we'll explore what sensor cables are and how to effectively use them to measure velocity.

What Are Sensor Cables?: These cables are specialized cables designed to connect sensors to data acquisition systems. They come in various types, including analog, digital, and serial sensor cables. These cables are engineered to transmit data signals from the sensor to the data processing unit with minimal interference, ensuring the accuracy of measurements.

Measuring Velocity with Sensor Cables: Velocity sensors are essential for various applications, from monitoring vehicle speed to measuring fluid flow rates. Sensor cables are used to connect these sensors to the data acquisition system. The process is simple: Choose a sensor that suits your application, such as a Doppler velocity sensor for fluid measurement or a Hall effect sensor for object velocity.

Connect the sensor cable to the sensor and ensure a secure connection. Ensure the sensor cable is routed safely to avoid interference or damage. Use cable clips or conduit as necessary. Connect the other end of the sensor cable to the data acquisition system, which can be a computer, controller, or data logger. Calibrate the sensor if required and analyze the data collected to measure velocity accurately.

Advantages of Using Sensor Cables: Using sensor cables offers numerous advantages, including: Sensor cables ensure reliable and accurate data transmission from the sensor to the data acquisition system. Properly shielded sensor cables minimize electromagnetic interference, ensuring precise measurements.

Choosing the right sensor cable and following proper installation techniques can make a significant difference in the accuracy and reliability of your velocity measurements. To explore a wide range of sensor cables suitable for your needs, visit our website. Our products are designed to meet the highest standards of quality and performance, ensuring the success of your velocity measurement projects.

0 notes

Text

TDK launches position sensor based on 3D HAL® technology with analog output and SENT interface.

October 13, 2023 /SemiMedia/ — TDK Corporation announces the expansion of its Micronas direct-angle Hall effect sensor family product portfolio with the new HAL® 3927* sensor for automotive and industrial applications. HAL 3927 features a linear, ratiometric analog output with integrated wire-break detection as well as an SAE J2716 compliant SENT interface according to rev. 4. Samples are already…

View On WordPress

0 notes

Note

Doom anon here, bitching about modern controllers & modern joysticks

so about my difficulty readjusting to Doom with joysticks after playing the PlayStation Doom on PC with a mouse in the PsyDoom source port (great source port btw, the best way to play the PlayStation Doom & Final Doom ports imo)...

it didn't help that I was using a new controller because my Switch pro controller's joystick drifts, so I got this GuliKit KingKong 2 Pro or whatever... I have mixed opinions about it

like as a controller it's fine and as a Switch controller it's adequate, it's got gyro and it can wake the console from sleep and it even has NFC, all it's missing is HD rumble

but it's terribly unergonomic and idk why they gave it analog triggers when Switch can't use them (except it also has modes for Xinput, Dinput, and Android, so that's why), and the joysticks use Hall effect sensors so they won't drift (which is great, and its main selling point) but they're a little loose like on a controller that's been used for a decade, and I hate the face buttons and I'm not a fan of the shoulder buttons and the rumble is bad when playing on Switch (not on PC though, which makes me think it's an HD rumble mismatch since it's read as a pro controller by the Switch) and there's not an app for it so any configuration happens with button combos

it'd be a decent controller, but not at a $70 price tag. it's insane that it's $70, but I think they're exploiting the fact that the Switch pro controller is a $70 "premium" hunk of junk with the same type of cheap garbage potentiometers every modern joystick has been using, and people are more aware of joystick drift on Switch so even though the same cheap potentiometers are in the PS5 and Xbox Series controllers they bank on the higher profile Switch failures to sell this

8bitdo is doing the same thing now. they're copying off GuliKit to put Hall effect sensors in a controller for Switch to charge $70 with the promise that it won't drift -- "would you rather pay $70 for a drifting Nintendo controller or $70 for non-drifting?" is essentially the tactic. and it's so scummy. hilariously transparent too, since the new 8bitdo has 3 versions and only the Switch version is $70 and only it has Hall effect sensors, so it's pretty blatant why that is

obviously GuliKit weren't the first to use Hall effect sensors for joysticks, Sega did it back in the 90s, but no one else had done it since. and I'm sorry but Hall effect sensors aren't that terribly expensive to implement, they're charging more just because they can and they know people fed up with cheap potentiometers will cough up the dough

it's ridiculous. it's not even that potentiometers are inherently this terrible (though all will inevitably fail eventually and sooner than alternatives would since they're mechanical), it's that the ones being used are complete junk in an effort to shave off a tiny bit of cost per unit to increase profits. for them to then take decades old technology and pass it off as new and charge a premium is disgusting

that's not even getting into the fact that the way these Hall effect sensors are implemented is bad and stupid, if you look at a teardown of the GuliKit I bought and compare that to a teardown of the Dreamcast controller you can see how much worse the GuliKit design is

and, the GuliKit one still drifts! it's not the same type or extent of drift, but without a pretty sizeable and foolishly implemented deadzone active, the joysticks on the GuliKit controller don't go back to center, they drift like crazy in a very small area around the center. it's not always noticeable all the time in-game but in testing it is, and I wouldn't mind the dead zone except that instead of recalculating the values so that you keep a full range of input to be read by the console, all the lowest values are simply completely discarded, which depending on the game is quite noticeable actually and can be seen in testing apps and on the Switch's joystick calibration menu – the cursor will jump from the center to further away, which pro controller and joy-con won't

also, Switch pro controller has roughly circular input, but in Switch mode the GuliKit controller has pretty square input. people argue about circularity being super important, but frankly some older games that expect square input are near unplayable with circular input, whereas square input is just more of an inconvenience when a circular input range is expected. still, for Switch specifically, it should be circular – they fixed this for other modes with firmware updates, but not for the Switch mode. very strange

the 8bitdo one coming out will probably be better in some ways, but it's not gonna have NFC, and it's not gonna wake the Switch, and I despise the godawful D-pad people praise 8bitdo for, and the gyro is terrible in their $50 controller I got, and the software app for them is missing tons of features that were standard for cheap $20 controllers you could get 15 years ago…

anyway none of that relates to Doom but I am just incredibly frustrated with all these big companies making awful controllers and awful joysticks. I literally never had any drift until getting a Switch, and the joy-con and pro controller started drifting inside of 2 years. the springs in old controllers I own became super loose, but they still don't drift. New 3DS (unpopular opinion maybe but once I got used to it that circle pad became my favorite analog joystick), Wii U gamepad, Wii U pro controller, Wii nunchuk, Wii classic controller, GameCube controller, MadCatz GameCube controller that's gross and falling apart, N64 controller with a joystick so loose you can't use it, PS1 controller, cheap Logitech PC gamepad that was 20 bucks 15 years ago, nothing I owned drifted -- maybe other parts failed for other reasons (the flimsy plastic cap on my 3DS busted and I tore it off), but joysticks never drifted on me

speaking of N64, that wasn't a potentiometer or a Hall effect sensor, it was an optical sensor, which if you implemented it correctly would be a better idea than Hall effect sensors imo. but the N64 stick has other problems unrelated to the sensor

one last thing though, okay? so let's say for whatever reason, it's too hard to do optical sensors or Hall effect sensors, even though they had both for joysticks in the 1990s and those weren't expensive. okay I'll accept this false premise, it's too hard or it's too expensive, and also consumers shouldn't complain because everything will fail eventually (I have seen sooo many galaxy brained gaming youtubers say this). okay, so then why the fuck aren't joysticks all modular and easy to replace, with parts easy to buy? if you know it will fail, why is it not a priority to make it more replaceable for the consumer?

any child could disassemble and replace an N64 joystick easily enough, I know because I took apart my controller as a kid to try to figure out why the stick got so loose -- the N64 joystick's sensor wouldn't fail, but the other parts were still junk

you didn't need a special obscure screwdriver, you didn't need to worry about stripping cheap fragile screws designed to discourage user repair, and you didn't have to desolder anything either. the same was true of the Dreamcast controller, in fact its joystick is even easier to replace (but you'd probably never need to do it)

instead we now have in the Switch pro controller screws that strip incredibly easily and joysticks soldered to the board that you can't replace without desoldering them and then soldering the new one back on, so that you either have to send it for repairs (which they won't do if you tried to repair it yourself!) or buy an entire new $70 controller because the absolute cheapest part that would be incredibly easy to replace has failed through normal usage because the company that makes it has not made it to last long at all. that isn't the fault of the manufacturer of the potentiometers, it lasts as long as they say it will, it's the controller manufacturers making it intentionally difficult to replace who are to blame. at least there's no soldering to replace the joy-con joysticks, but it's still a royal pain and way harder than it needs to be tbh

but, you know... "capitalism breeds innovation!" that's why we went from the optical sensors and Hall effect sensors of the 1990s to the absolute cheapest junk sensors we could, only to come back to old technology decades later to market it as new and exciting and charge a premium for it

the only thing capitalism innovates is new ways of exploiting people, because that is its only goal, accumulate wealth by every means available to you. when your ideology values money above all else, it obviously isn't going to care about anything but money. why use a better technology when you could use a cheaper one? why make repairs easy when you can charge people for it instead?

anyway, sorry to make it political, but like... it literally objectively is a result of capitalism

also this is extremely tame compared to a lot of the atrocities done by capitalist ideology, in comparison to those things the joysticks don't matter even a little bit, but I can care about things big and small simultaneously, it isn't like it's mutually exclusive or anything

No you're 100% right to be annoyed about this. Especially when you KNOW that capitalism is ruining something you enjoy, but you alone can't do much to stop it. And yeah capitalism just recycles old shit while encouraging planned obsolescence. It happens with basically all technology nowadays (I see it with cellphones a lot cuz I like watching cellphone repair videos), so it's no surprise that it would be happening with Switch "Pro" controllers. And yeah companies fuck8ng HATE the idea of the consumer being able to repair their own products cuz then they can't suck people dry of all their money indefinitely. It's absolutely fucked and it doesn't matter if it's "insignificant" in the grand scheme of Fucked Up Shit Caused By Capitalism. It's another example of how -no matter big or small- capitalism will ruin everything.

#my answers#Kia's answers#and wrt cellphones an planned obsolescence that's why I don't genuinely subscribe to the brand wars people have over phones#cuz ALL of them fucking suck

4 notes

·

View notes

Text

World most advanced Radio Remote Control for Cranes