#automatic seed packing machine

Video

youtube

automatic bag filling and sealing machine price|automatic packaging machine

Raw material: Snacks, candy, nuts, potato chips, french fries etc.

Capacity:50kg/h-500kg/h

https://www.cnyazhong.com/products/Snacks-packaging-machine.html

Wechat/whatsapp:8613213203466

#automatic dry fruits packing machine

#automatic seed packing machine

#automatic dal packing machine

#automatic vegetable packing machine

#automatic snacks packing machine

#food packing machine automatic

#automatic food packaging machine

#automatic candy wrapping machine

#automatic popcorn packing machine

#automatic dry fruits packing machine#automatic seed packing machine#automatic vegetable packing machine#food packing machine automatic#automatic food packaging machine#automatic popcorn packing machine#automatic packaging machine#automatic bag filling and sealing machine price

0 notes

Text

Enhanced Shelf Life and Preservation Techniques in Grain and Pulses Packaging

Grains and pulses are staple food items worldwide, making their preservation and packaging essential for maintaining quality and extending shelf life. With the advent of automatic packaging machines, the industry has seen significant improvements in how these products are stored and distributed. Let us explore how our state-of-the-art machines, such as the automatic packaging machine, grain filling machine, sachet filling machine are revolutionizing grain and pulse packaging.

Importance of Effective Packaging

It is important to deliver your products with the right packaging. It plays a crucial role in preserving the freshness, nutritional value, and overall quality of grains and pulses. But it also keeps the trust of your consumers. A poor packaging can lead to moisture ingress, pest infestation, and oxidation, resulting in spoilage and wastage of the valuable product. To combat these challenges, we design new age packaging machines that ensure the right packaging and here is how our machines make the difference.

How Nichrome’s grain packaging machines make a difference

1. Modified Atmosphere Packaging (MAP)

Our machines are high end-tech machines that ensure Modified Atmosphere Packaging that involves altering the atmospheric composition inside the packaging to extend the shelf life of your products. By reducing oxygen levels and increasing nitrogen or carbon dioxide, MAP technology inhibits the growth of aerobic bacteria and fungi, preserving the quality of grains and pulses.

2. Vacuum Packaging

Vacuum packaging removes air from the package before sealing, creating a vacuum that significantly reduces the risk of oxidation and spoilage. This technique is particularly effective for extending the shelf life of pulses and high-fat grains prone to rancidity.

3. High-Barrier Films

High-barrier films are specialized materials designed to prevent moisture, oxygen, and light from penetrating the packaging. Our machines use best quality films which are essential for protecting grains and pulses from environmental factors that can degrade their quality.

4. Sealing and Lamination

Advanced sealing and laminating technologies ensure that packaging is airtight and durable. These techniques prevent contamination and enhance the overall integrity of the packaging.

Grain Packaging Machines by Nichrome

1. Excel 400 Plus Intelligent Electronic Weigh Filler: The EXCEL PLUS series comes with a plus advantage of automation equipped with CE marked PLC Controller and touch screen HMI. Key features include print mark scanners, servo motor driven bag length control system, and adjustable stroke of cross sealing jaws for optimum performance. It is designed as per stringent quality standards, and can be easily integrated to upstream or downstream machines/systems.

It has a bagger speed up to 80 packs per minute and can pack up to 10 kgs depending on product’s bulk density. The machine comes with a range of fillers to make this grain packaging machine a versatile packaging solution for all kinds of grains and pulses.

Conclusion

Effective packaging is vital for preserving the quality and extending the shelf life of grains and pulses. Our wide range of automatic grain packaging machines, including the automatic packaging machine, grains filling machine, and automatic pouch packing machine, provide robust solutions for the grain and pulse industry. By acquiring our packaging machines, your business can ensure product integrity, reduce waste, and deliver high-quality products to consumers. Investing in Nichrome's innovative packaging solutions is a step towards sustainable and efficient packaging practices, ultimately benefiting both the industry and consumers

#integrated packaging solutions#packaging machine manufacturers#innovative packaging solutions#automatic packaging machine#grain packaging machines#seed packaging machine#automated packaging machines#pulses packing machine

0 notes

Text

Best Automatic Pouch Packing Machine - Indian Trade Bird

Best Automatic Pouch Packing Machine - Indian Trade Bird

Indian Trade Bird specializes in connecting clients with a network of top manufacturers, suppliers, and exporters of Automatic Pouch Packing Machines. Our offerings include a wide range of high-quality machines that are meticulously designed to meet diverse customer requirements. These machines are renowned for their reliability, efficiency, and cost-effectiveness, making them an excellent investment for businesses looking to enhance their packaging processes. Whether you are looking to package food products, pharmaceuticals, or other goods, our Automatic Pouch Packing Machines ensure precision and speed, thereby optimizing productivity. With a strong focus on customer satisfaction, Indian Trade Bird ensures that all machines meet stringent quality standards, providing robust solutions that help streamline operations and reduce downtime.

Uses Of Automatic Pouch Packing Machine

Food and Beverage Industry: These machines are crucial for packaging items such as snacks, spices, coffee, tea, sauces, ready-to-eat meals, and beverages. They help preserve product freshness, ensure hygiene, and prolong shelf life.

Pharmaceuticals: Automatic Pouch Packing Machines are utilized for packaging medicines, powders, tablets, and other medical products. They provide accurate dosing, tamper-evident packaging, and adherence to regulatory standards.

Cosmetics and Personal Care: These machines are used to package products like creams, lotions, shampoos, conditioners, and other personal care items. They offer attractive and practical packaging that maintains the products' integrity.

Chemical Industry: The machines are employed to package chemicals, fertilizers, and detergents. They ensure secure and safe packaging, preventing spills and contamination.

Agricultural Products: Seeds, pesticides, and other agricultural products are efficiently packaged using these machines, keeping them uncontaminated and effective.

Household Products: Automatic Pouch Packing Machines are also used to package household items such as cleaning agents, pet food, and other consumer goods, ensuring user convenience and ease of use.

Advantages Of Automatic Pouch Packing Machine

Enhanced Efficiency: These machines greatly accelerate the packaging process, facilitating high-speed operations and boosting productivity.

Consistency and Precision: They deliver uniform packaging with precise measurements, ensuring each pouch is accurately and consistently filled.

Cost-Effective: By decreasing manual labor and reducing material waste, these machines help to lower overall production costs.

Product Freshness and Hygiene: Automatic Pouch Packing Machines guarantee that products are sealed correctly, preserving their freshness and hygiene.

Versatility: They are capable of handling a wide variety of products and pouch sizes, making them suitable for diverse industry applications.

Improved Shelf Life: Effective sealing and packaging protect products from environmental factors, thereby extending their shelf life.

Reduced Contamination Risk: Automated systems reduce human contact, lowering the risk of contamination and ensuring a safer product.

Customization: These machines can be customized to meet specific packaging needs, including unique designs, sizes, and features.

User-Friendly Operation: Modern machines are designed with intuitive interfaces and easy-to-use controls, making them accessible to operators.

Regulatory Compliance: They assist in complying with industry standards and regulations, which is especially crucial in the pharmaceutical and food sectors.

Enhanced Product Presentation: The machines produce neat and professional packaging, enhancing the product's market appeal.

0 notes

Text

Form Fill Seal machine | Indian Trade Bird

Introduction Of Form Fill Seal Machine

These days, form fill seal (FFS) packaging machines are used in almost every industry. Furthermore, why not? These pouch packing machines automatically increase productivity and profitability since they are quick, precise, affordable, and adaptable solutions.

Enhanced speed and adaptability are the primary advantages of File Transfer Systems. Snack manufacturers, for instance, require systems with the adaptability to package various goods and enable quick switching between a wide variety of packaging designs.

Allow us to demonstrate form fill seal packaging machines and go over their operation with you.

What Are Form Fill Seal Machine?

create fill seal packaging machines are exactly what their name implies: they automatically create the package, fill it with a wet or dry product, and then seal it shut. The principal packaging, which is a pouch or bag, is mostly formed with flexible film; however, aseptic cartons are also made using FFS technology.

Form fill seal packaging machines work with a reel of flexible material (paper, film, or foil laminates) that is either formed into a tube and sealed and filled at predetermined intervals, or it is folded lengthwise and sealed at an angle to the fold to create a series of filled and sealed pockets.

Types Of Form Fill Seal Machine?

Vertical Form Fill Seal Machine wherein the material is formed over a forming collar into a circular section tube.

Horizontal Form Fill Seal Machine wherein a forming box is used to shape the material into a rectangular section tube. Additionally, horizontal variants of blister pack machines, thermoform fill and seal machines, four side seal machines, and sachet packaging machines are covered by HFFS.

Advantages Of Form Fill Seal Machine

Quick and steady packing rate

Cost-effective since the produced bags are less costly than pre-made ones

increases production rate to enable you to work less shifts

Clearing out between production batches is simple and quick.

Product information and readable bar codes are offered by online film printing.

Reduced moving parts, particularly in VFFS

Application Of FFS

FFS packaging machines have countless applications. These devices can package almost any product that can be packaged and sold in flexible pouches. Food, pharmaceutical, and other products can be packed using FFS machines in a wide range of capacities, from

Food Industry FFS machines are extensively used in the food industry for packaging items such as snacks, candies, frozen foods, grains, coffee, spices, and powdered products like flour and sugar.

Pharmaceutical Industry FFS machines are used to package pharmaceutical products like tablets, capsules, powders, and liquids in blister packs, sachets, or pouches, ensuring hygiene and accuracy in dosage.

Chemical Industry FFS machines package chemicals, fertilizers, detergents, and other similar products in pouches or bags, ensuring safety and preventing leakage.

Agricultural Industry FFS machines are used for packaging agricultural products like seeds, fertilizers, pesticides, and animal feed, ensuring proper handling and storage.

Hardware Industry These machines package hardware items such as screws, nuts, bolts, and small tools in pouches or bags, facilitating easy storage and transportation.

Follow For More Detail Visit Our Web Site

0 notes

Text

Challenges and Solutions in the Grain and Pulses Packaging Industry

The grain and pulses packaging industry is essential for ensuring that these staple foods reach consumers in optimal condition. However, the sector faces numerous challenges that can impact the quality, safety, and shelf life of the products. In this blog, we'll explore these challenges and discuss the innovative solutions Nichrome offers, including their advanced grains & seeds packaging machines, sachet packaging machines, and other cutting-edge equipment.

Key Challenges in Grain and Pulses Packaging

1. Maintaining Product Freshness

One of the primary challenges in grain and pulses packaging is maintaining the freshness and nutritional value of the products. Exposure to air, moisture, and light can lead to spoilage, degradation of nutritional content, and pest infestation.

2. Ensuring Consistent Quality

Consistency in packaging quality is crucial to prevent contamination and ensure consumer safety. Variability in packaging materials and techniques can result in compromised product integrity and consumer dissatisfaction.

3. Efficient Handling of Bulk Quantities

Packaging large quantities of grains and pulses efficiently and accurately is another significant challenge. Manual packaging processes are labor-intensive and prone to errors, leading to wastage and increased operational costs.

4. Meeting Regulatory Standards

Adhering to stringent regulatory standards for food safety and packaging is vital. Compliance with these standards requires advanced packaging technologies and meticulous quality control measures.

5. Sustainability Concerns

The increasing demand for sustainable packaging solutions adds another layer of complexity. Balancing the need for durable packaging with environmental sustainability is a key consideration for the industry.

Nichrome's Innovative Solutions

Nichrome, a leader in packaging technology, offers a range of solutions designed to address these challenges effectively. Here’s how Nichrome’s automatic packaging machines are a game changer for industries:

1. Preserving Freshness

Nichrome's seeds & grains packaging machine is designed to preserve the freshness and quality of grains and seeds. These machines utilize advanced sealing technologies and high-barrier materials to protect against environmental factors, ensuring longer shelf life and maintaining nutritional value.

2. Precision & Efficiency

For packaging smaller quantities, Nichrome’s sachet packaging machine offers precision and efficiency. Ideal for pulses and seeds, these machines ensure consistent quality and reduce the risk of contamination by providing secure and airtight packaging.

3. Minimizes Errors & Wastage

The automatic grain packing machine from Nichrome automates the packaging process, enhancing efficiency and accuracy. By reducing manual intervention, these machines minimize errors and ensure consistent packaging quality, significantly reducing operational costs and wastage.

4. Versatile Packaging for Diverse Market

As a leading pouch filling machine manufacturer, Nichrome provides versatile solutions for different packaging formats. Their machines are designed to handle a variety of pouch types, ensuring secure sealing and optimal product protection. This flexibility is crucial for meeting diverse market demands and regulatory requirements.

Vertical Form Fill Seal Machines by Nichrome

Nichrome’s vertical form fill seal machines offer an integrated solution for high-speed packaging. These machines are capable of handling bulk quantities efficiently, making them ideal for large-scale grain and pulses packaging operations. The vertical form fill seal technology ensures precise filling and secure sealing, enhancing overall productivity and product safety.

Nichrome manufacturers some of the best grain packaging machines including the Excel 400 Plus Intelligent Electronic Weigh Filler, Excel 400 Plus Cup Filler, Excel Vertipack 320 and many more.

Addressing Sustainability

Nichrome is committed to sustainability and offers eco-friendly packaging solutions that do not compromise on durability and product protection. By utilizing recyclable materials and energy-efficient technologies, Nichrome helps businesses meet their sustainability goals while maintaining high packaging standards.

Conclusion

The grain and pulses packaging industry faces several challenges, from maintaining product freshness to ensuring compliance with regulatory standards. Nichrome's innovative solutions, including grains & seeds packaging machines, sachet packaging machines, and vertical form fill seal machines, provide the necessary technology to overcome these challenges. By leveraging Nichrome's advanced equipment, businesses can enhance efficiency, reduce waste, and deliver high-quality products to consumers.

Nichrome's commitment to innovation and sustainability positions it as a leader in the packaging industry, helping businesses navigate the complexities of grain and pulses packaging with confidence. Investing in Nichrome's state-of-the-art packaging solutions is a strategic move towards achieving operational excellence and long-term success in the market.

0 notes

Text

Ensuring Seed Quality in Bangladesh with Nichrome's Advanced Packaging Technology

In the vibrant agricultural landscape of Bangladesh, the quality of seeds plays a crucial role in determining the success of crops. High-quality seeds lead to better germination rates, robust plants, and bountiful harvests. Recognizing the critical importance of seed quality. As a leading packaging manufacturer in Bangladesh, we design seed packaging machines to preserve and enhance seed integrity from the moment they are packed until they are sown.

Nichrome's Advanced Seed Packaging Technology: Unique Features

Our seed packaging machines with cutting-edge technology are tailored to meet the specific needs of seed preservation. Here are some unique features of our filling and packaging machines that ensure seed integrity and quality:

Hermetic Sealing: Our automatic sachet packaging machines provide airtight sealing to protect seeds from moisture, pests, and contaminants. This feature is crucial in Bangladesh's humid climate, where moisture can quickly degrade seed quality.

Controlled Atmosphere Packaging: To further safeguard seed viability, our vertical form fill seal machines can modify the packaging atmosphere, reducing oxygen levels and maintaining a low moisture environment. This helps in extending the shelf life of seeds.

Accuracy in Filling: Ensuring that each packet contains the exact amount of seeds with minimal variation is essential for maintaining uniformity and quality. Our automatic filling and packaging machines ensure precision that guarantees accurate seed count and weight.

Robust Packaging Materials: We use high-quality, durable materials for seed packaging that offer excellent barrier properties against environmental factors. These materials are also resistant to punctures and tears, ensuring the seeds remain protected throughout their journey.

Automated Quality Checks: Nichrome’s machines are integrated with advanced sensors and automated quality control systems to detect and reject any defective packages. This ensures that only the best quality seeds reach the farmers.

User-Friendly Interface: Our small packaging machines feature an intuitive interface that simplifies operation and maintenance. This ensures that even operators with minimal technical expertise can manage the packaging process efficiently.

Benefits of Maintaining Seed Quality from Packaging to Planting

Enhanced Germination Rates: High-quality seeds with intact germination capabilities lead to higher germination rates, ensuring that more plants grow successfully, maximizing crop yield.

Uniform Crop Growth: Consistent seed quality results in uniform plant growth, which is vital for efficient field management and harvesting processes.

Pest and Disease Resistance: Seeds that are well-preserved and protected during packaging are less likely to carry pests or diseases, reducing the risk of crop failure and the need for chemical treatments.

Economic Gains for Farmers: Quality seeds contribute to higher crop yields and better-quality produce, which can command higher prices in the market, leading to improved economic stability for farmers.

Seed Longevity: Proper packaging extends the shelf life of seeds, allowing farmers to store seeds for longer periods without compromising quality. This is particularly beneficial in managing planting schedules and preparing for adverse weather conditions.

Conclusion

In conclusion, maintaining seed quality from packaging to planting is essential for the prosperity of Bangladesh's agriculture. Our advanced packaging technology offers a comprehensive solution to preserve seed integrity, contributing to higher crop yields, better farmer incomes, and sustainable farming practices.

Partner with Nichrome and invest in the future of agriculture in Bangladesh!

#sugar packaging machines#automatic sugar packaging machines#Vertical Form fill seal machine#sachet filling machines#pouch filling machines#VFFS machine#automatic sugar filling machines#packaging machines in Kenya#commercial food packaging machine#automatic packaging machines

0 notes

Text

Top Packaging Machines

Pouch packaging is gentle, versatile, durable, transportable, sustainable, and easy to customize, appropriate for filling with solids, liquids, powders, and pastes. On the other hand, if you need to automatize your sugar packaging course an automated bagging machine is the best solution. The manual or semi-automatic packing machines could be designed in the web weight or gross weight model. Some examples of merchandise that could be packed with this machine are Potting soil, seeds, feed, plastic granules, Pet Food, and low-density merchandise of assorted grain sizes. The baggage that this packaging machine can pack is a minimum dimension of mm and a maximum size - sealer vacuum packaging machine.

Ideal for food products, it makes double square bottom bags that are compact, airless, and completely sq. in form. The baggage that this packaging machine can make is a minimum size of a hundred and twenty x one hundred mm and a maximum size. A vertical packaging machine is a machine for packaging bulk merchandise in luggage. When you choose a packaging machinery supplier that is close by you'll be saving yourself on a lot of unnecessary problems. Having a close provider will mean when there is a need for repairs or emergency service on your tools, the technicians be capable of getting to you faster to solve the issue - seal machine for food.

When pallet wrapping it is suggested to make use of semi-automatic or automated machines as it will make the process much less time-consuming while also saving film being wasted from excess or inadequate wrapping. The difference between using machine wrap and hand wrap could be seen in this video. When shopping for sealing machines, you should contemplate their features and advantages. You can use this article as information to select the most effective sealing machine for your business. To help you find one of the best vacuum sealers for your kitchen, we’ve extensively researched the highest makes and models on the market, scrutinizing experts’ suggestions, bestseller lists, and genuine client reviews. If you're in search of more data on how our products can profit your corporation. For more information, please visit our site https://packagingmachinesusa.com/

0 notes

Text

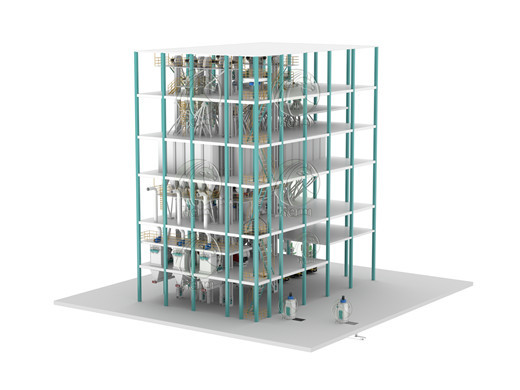

30-35T/H Feed Pellet Line

What is The 30-35T/H Feed Pellet Line ?

Large scale high quality 30-35t/h feed pellet plant is suitable for processing various animal feeds, such as chicken feed, poultry feed, livestock feed, bird feed, duck feed, goose feed, cattle feed, sheep feed, camel feed, horse feed, pig feed, rabbit feed, fish feed, shrimp feed, crab feed, aquatic feed, etc.

youtube

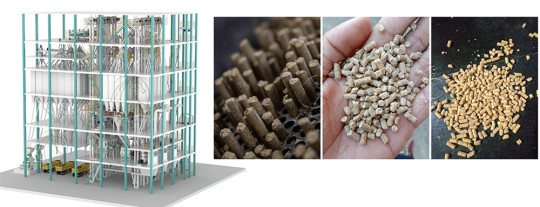

The main equipment of a complete 30-35T/H animal feed pellet mill machine includes an animal feed grinder and feed mixer, feed pellet machine, counter-flow feed pellet cooler, pellet crumbler machine, box cylinder pulse dust remover, vibrating screen classifier, bucket elevator, automatic bagging system, electric control cabinet, etc. This complete feed pellet plant can accomplish raw material mixing, transmission, feeding, and pelletizing. After the raw materials become feed pellets, the following equipment can cool them down and pack them into bags.

The animal-feed pellet plant has good raw material versatility and can be used for the granulation of various raw materials such as corn, sorghum, wheat, beans, and oilseed meal. At the same time, the animal feed production plant has the characteristics of low energy consumption, high production efficiency, and large profits. It is especially suitable for large feed mills, breeding farms, large farms, etc. At the same time, we provide free installation, training, factory design, and timely after-sales service.

Some Questions About the 30-35T/H Feed Pellet Line

1. Who is suitable for this 30-35t/h feed pellet production line?

This animal feed production line is specially designed for large farmers, large animal farm plants, animal feed suppliers, etc.

2. What raw material can be used in the 30-35t/h feed pellet production line?

Animal feed pellet production line raw materials include corn/maize, wheat, grass, alfalfa, oil seed meal & cakes, pasture, bone meal, microelements, etc., and other kinds of raw materials, such as premix, vitamins, wheat bran, salt and other. Different formulations can be made according to different formulas and the needs of the animals being farmed.

3. Why Choose Our Animal Feed Production Line?

Widely Applications: This animal feed pellet mill plant can make feeds for poultry, livestock, sheep, pig, cattle, chicken, duck, fish, shrimp, crab, aquatic, and other animals, it makes pellets of 1-12mm in diameter, and the pellet size can be changed with our feed pellet machine by adjust die. It also can produce mash and crumble.

Small Investment: the compact design of this small feed mill plant can reduce the investment in workshops, etc.

Low Installation Cost: Our feed production line comes with detailed installation and commissioning instructions, it is easy to install the machine, and you can use it immediately after the machine is installed.

Low Production Cost: The animal feed factory only needs 1-2 production workers to complete the production operation. With less labor and lower production costs, your profits will increase.

4. What kind of animal feed pellet production line produce?

This feed pellet production line can produce feed for meat chicken, broilers, laying hens, small baby chicken feed, cattle feed, pig feed, duck feed, sheep feed, poultry feed, livestock feed, goat feed, fish feed, shrimp feed, crab feed, aquatic feed, etc. Such as 2-4mm diameter chick feed pellets and pig feed pellets. 2-5mm rabbit feed pellets, 4-8mm cattle or sheep feed pellets.

This feed pellet mill with a ring die, makes pellets of 1-12mm in diameter, the pellet size can be changed with our feed pellet machine by adjusting the die. It also can produce mash and crumble.

5. What we can do for you?

We can provide the project design, flow chart, feed-making machine manufacturer, project installation and commission, your staff training, after-sales service, etc. Also, our professional install team will serve you if you need it.

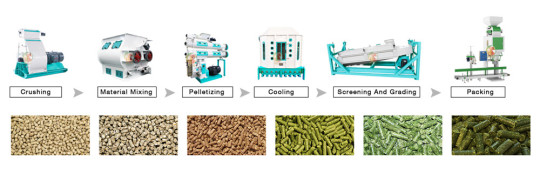

What is The Complete Animal Feed Pellet Production Line Working Process?

Feed Pellets Processing Technology

Raw Material → Feed Grinding → Feed Mixing → Feed Pelletizing → Pellet Cooling → Pellet Crushing → Screening & Grading → Pellet Packing

1. Storage of the raw materials

There are many different raw materials and materials in the feed, so various types of silos must be used. There are three types of silo that can be used in the feed pellet line, such as hopper silo, flat bottom silo, and galvanized silo.

2. Cleaning of raw materials

Impurities in feed raw materials not only affect the quality of feed products but also directly affect the use of feed processing equipment and the personal safety of staff. In severe cases, the entire equipment will be damaged and the smooth progress of feed production will be affected. Therefore, impurities in the feed raw materials should be removed in time.

3. Crushing of raw materials

The technological process of feed crushing is determined according to the required particle size, feed variety, and other conditions. According to the number of raw material crushing, it can be divided into primary crushing process and circulating crushing process or secondary crushing process. The combination with the batching process can be divided into the first batching and then crushing process and the first crushing and then batching process.

4. Batching process

The rational design of the batching process is to correctly select the specifications and quantities of the batching metering device so that it is fully coordinated with the combination of batching feeding equipment, mixing units, and other equipment.

5. Mixing process

The mixing process refers to the technological method and process of weighing the ingredients in the feed formula and then entering the mixer for uniform mixing. The mixing section requires a short mixing cycle, high mixing quality, fast discharge, low residual rate, good air tightness, and no dust spillage.

6. Pelleting process

The pelleted feed obtained by compacting and extruding a single raw material or compound mixture by mechanical action is called feed pelleting. The purpose of pelleting is to use the heat, moisture, and pressure in the pelleting process to pelletize the feed that is finely divided, easily dusty, poorly palatable, and difficult to transport.

7. Cooling process

During the pelleting process, when the pellet feed comes out of the feed pellet machine, the water content reaches 16%-18%, and the temperature is as high as 75°C-85°C. It will also cause adhesion and mildew during storage. The moisture must be reduced to below 14%, the temperature must be below 8°C higher than the air temperature, and cooling is required.

8. Crumbling process

In the production process of the feed pellet mill, in order to save electricity, increase production and improve quality, the material is often made into a certain size of pellets, and then crushed into qualified products according to the size of the feed pellets.

9. Screening process

After the pellet feed is processed by the crushing process, some unqualified materials such as powder will be produced. Therefore, the crushed pellet feed needs to be sieved into a product with neat particles and uniform size.

10. Packaging process

After weighing, put the finished product into the packing scale and pack it. During this process, the package should be calibrated until the package weight standard is met.

0 notes

Text

From Orchard to Market: Navigating the Cashew Processing Business

Introduction:

Cashew nuts, known for their creamy texture and distinct flavor, have become a global favorite, finding their way into various culinary delights and snack options. Behind the scenes, a sophisticated and intricate process unfolds to bring these delicious nuts from the orchard to your table. In this blog post, we'll explore the fascinating world of cashew processing Machine businesses, delving into the journey that transforms raw cashews into the premium product we enjoy.

The Cashew Tree and Harvesting:

The journey begins in the tropical regions where cashew trees thrive. Native to Brazil, cashew trees now grow in various parts of the world, including India, Vietnam, Nigeria, and Ivory Coast. The cashew nut, which is actually a seed, is encased in a hard shell attached to the cashew apple. Harvesting involves carefully plucking the cashew apples and extracting the nuts.

Processing the Raw Cashews:

Once harvested, the cashews undergo a series of processing steps to make them market-ready. The first step involves removing the outer shell with the help of Automatic Shelling machine, which is toxic and can cause skin irritation. This delicate process is typically done manually to ensure the nuts remain intact.

Drying and Curing:

After the outer shell is removed, the cashews are spread out for drying in Cashew Dryer. Proper drying is crucial to prevent mold and ensure a longer shelf life. The dried cashews then undergo a curing process to enhance flavor and reduce the risk of spoilage. This step is critical in maintaining the quality of the final product.

Grading and Sorting:

Once cured, the cashews are graded based on size, color, and quality. Sorting ensures that only premium nuts make it to the next stages of processing, guaranteeing a uniform and high-quality end product. Advanced machinery is often employed to streamline this process, increasing efficiency and accuracy.

Roasting and Packaging:

Roasting is a key step in developing the rich, nutty flavor that cashews are known for. The nuts are carefully roasted at controlled temperatures to achieve the desired taste profile. Following roasting, the cashews are packaged in various sizes vacuum packing machine and formats for distribution to consumers, retailers, and food manufacturers.

Market Trends and Challenges:

The cashew processing industry is not without its challenges. Fluctuating weather conditions, price volatility, and supply chain disruptions can impact the industry. Moreover, market trends, such as the increasing demand for organic and sustainably sourced products, play a significant role in shaping the business strategies of cashew processors.

Global Impact and Economic Contributions:

Cashew processing is not just a culinary journey but also an economic one. Many countries rely heavily on cashew production and processing as a major source of income. The industry provides employment opportunities and contributes to the economic development of regions where cashews are cultivated.

The Future of Cashew Processing:

As consumer preferences evolve, the cashew processing Machine industry continues to innovate. From introducing new flavors to exploring sustainable and eco-friendly practices, businesses in this sector are adapting to meet the demands of a dynamic market.

Conclusion:

The journey from cashew orchard to kitchen table is a testament to the intricate process that transforms raw nuts into the delectable snack we all enjoy. Cashew processing businesses play a crucial role in delivering quality products to consumers while contributing to the economic development of regions where cashews are cultivated. As the industry navigates challenges and embraces innovation, the future holds exciting possibilities for both producers and consumers in the world of cashew processing.

#cashew#cashew machine#cashew nut machine#automatic shelling machine#cashew processing machine#automatic cashew shelling machine#raw cashew nut shelling machine#automatic cashew peeling machines#cashew boilers#automatic raw cashew grader

0 notes

Text

1-100G Fully Automatic Tea Coffee Filter Paper Packaging Machine Sugar Salt Seed Herb Particle Granule Packing Machine

0 notes

Video

youtube

food packaging machine|food packaging machin pricee#automatic dry fruits packaging machine

Raw material: Snacks, candy, nuts, potato chips, french fries etc. Capacity:50kg/h-500kg/h https://hnjoyshine.com/products/Granule-Packaging-Machine.html Wechat/whatsapp:8613213203466 #automatic dry fruits packing machine #automatic seed packing machine #automatic dal packing machine #automatic vegetable packing machine #automatic snacks packing machine #food packing machine automatic #automatic food packaging machine #automatic candy wrapping machine #automatic popcorn packing machine

0 notes

Text

Challenges and Solutions in the Grain and Pulses Packaging Industry

The grain and pulses packaging industry is essential for ensuring that these staple foods reach consumers in optimal condition. However, the sector faces numerous challenges that can impact the quality, safety, and shelf life of the products. In this blog, we'll explore these challenges and discuss the innovative solutions Nichrome offers, including their advanced grains & seeds packaging machines, sachet packaging machines, and other cutting-edge equipment.

Key Challenges in Grain and Pulses Packaging

1. Maintaining Product Freshness

One of the primary challenges in grain and pulses packaging is maintaining the freshness and nutritional value of the products. Exposure to air, moisture, and light can lead to spoilage, degradation of nutritional content, and pest infestation.

2. Ensuring Consistent Quality

Consistency in packaging quality is crucial to prevent contamination and ensure consumer safety. Variability in packaging materials and techniques can result in compromised product integrity and consumer dissatisfaction.

3. Efficient Handling of Bulk Quantities

Packaging large quantities of grains and pulses efficiently and accurately is another significant challenge. Manual packaging processes are labor-intensive and prone to errors, leading to wastage and increased operational costs.

4. Meeting Regulatory Standards

Adhering to stringent regulatory standards for food safety and packaging is vital. Compliance with these standards requires advanced packaging technologies and meticulous quality control measures.

5. Sustainability Concerns

The increasing demand for sustainable packaging solutions adds another layer of complexity. Balancing the need for durable packaging with environmental sustainability is a key consideration for the industry.

Nichrome's Innovative Solutions

Nichrome, a leader in packaging technology, offers a range of solutions designed to address these challenges effectively. Here’s how Nichrome’s automatic packaging machines are a game changer for industries:

1. Preserving Freshness

Nichrome's seeds & grains packaging machine is designed to preserve the freshness and quality of grains and seeds. These machines utilize advanced sealing technologies and high-barrier materials to protect against environmental factors, ensuring longer shelf life and maintaining nutritional value.

2. Precision & Efficiency

For packaging smaller quantities, Nichrome’s sachet packaging machine offers precision and efficiency. Ideal for pulses and seeds, these machines ensure consistent quality and reduce the risk of contamination by providing secure and airtight packaging.

3. Minimizes Errors & Wastage

The automatic grain packing machine from Nichrome automates the packaging process, enhancing efficiency and accuracy. By reducing manual intervention, these machines minimize errors and ensure consistent packaging quality, significantly reducing operational costs and wastage.

4. Versatile Packaging for Diverse Market

As a leading pouch filling machine manufacturer, Nichrome provides versatile solutions for different packaging formats. Their machines are designed to handle a variety of pouch types, ensuring secure sealing and optimal product protection. This flexibility is crucial for meeting diverse market demands and regulatory requirements.

Vertical Form Fill Seal Machines by Nichrome

Nichrome’s vertical form fill seal machines offer an integrated solution for high-speed packaging. These machines are capable of handling bulk quantities efficiently, making them ideal for large-scale grain and pulses packaging operations. The vertical form fill seal technology ensures precise filling and secure sealing, enhancing overall productivity and product safety.

Nichrome manufacturers some of the best grain packaging machines including the Excel 400 Plus Intelligent Electronic Weigh Filler, Excel 400 Plus Cup Filler, Excel Vertipack 320 and many more.

Addressing Sustainability

Nichrome is committed to sustainability and offers eco-friendly packaging solutions that do not compromise on durability and product protection. By utilizing recyclable materials and energy-efficient technologies, Nichrome helps businesses meet their sustainability goals while maintaining high packaging standards.

Conclusion

The grain and pulses packaging industry faces several challenges, from maintaining product freshness to ensuring compliance with regulatory standards. Nichrome's innovative solutions, including grains & seeds packaging machines, sachet packaging machines, and vertical form fill seal machines, provide the necessary technology to overcome these challenges. By leveraging Nichrome's advanced equipment, businesses can enhance efficiency, reduce waste, and deliver high-quality products to consumers.

Nichrome's commitment to innovation and sustainability positions it as a leader in the packaging industry, helping businesses navigate the complexities of grain and pulses packaging with confidence. Investing in Nichrome's state-of-the-art packaging solutions is a strategic move towards achieving operational excellence and long-term success in the market.

0 notes

Video

youtube

food packaging machine|#automatic dry fruits packing machine#automatic snacks packing machine

Raw material: Snacks, candy, nuts, potato chips, french fries etc. Capacity:50kg/h-500kg/h https://hnjoyshine.com/products/Granule-Packaging-Machine.html Wechat/whatsapp:8613213203466 #automatic dry fruits packing machine #automatic seed packing machine #automatic dal packing machine #automatic vegetable packing machine #automatic snacks packing machine #food packing machine automatic #automatic food packaging machine #automatic candy wrapping machine #automatic popcorn packing machine

#food packaging machine#automatic dry fruits packing machine#automatic snacks packing machine#puff food packaging machine#potato chips packaging machine#french fries packaging machine

0 notes

Video

youtube

automatic bag filling and sealing machine price|automatic packaging machine

Raw material: Snacks, candy, nuts, potato chips, french fries etc. Capacity:50kg/h-500kg/h https://www.cnyazhong.com/products/Snacks-packaging-machine.html Wechat/whatsapp:8613213203466 #automatic dry fruits packing machine #automatic seed packing machine #automatic dal packing machine #automatic vegetable packing machine #automatic snacks packing machine #food packing machine automatic #automatic food packaging machine #automatic candy wrapping machine #automatic popcorn packing machine

#automatic bag filling and sealing machine price#automatic packaging machine#snacks packaging machine#snack packing machine

0 notes

Text

Beer Liquid Bottle Filling Machine Household Manual

While initially constructed for filling gels, lotions, and creams, these fillers also accommodate water heavy and thin paste products. In March 2021, Scholle IPN, a US-based firm that manufactures bag-in-box packaging products, completed the acquisition of Bossar Packaging Pvt. This acquisition will leverage the combined manual food filling machines capabilities of both businesses to supply one-stop shopping for vertically built-in, sustainable options for the global filling machine market. Ltd. is a US-based firm that gives HFFS machines and filling machines for pre-made pouches.

Depending on the volume, electrical necessities, location on the road and machinery weight, some early planning is a significant dynamic of this procedure. There is an absolute multitude of issues when selecting packaging machinery and supplies are a few of the most essential things to consider. The equipment is loaded with a continuing flat plastic movie roll, which has had labeling and art work on the interior or exterior of the film. For other merchandise the movie might first be put by way of a sterilizing chemical wash and drying earlier than utilizing in the packaging system. "Machinery" and "tools" are used interchangeably when it comes to packaging. In this text when discussing varieties, "equipment" will refer to machines which do the actual packaging and "gear" will refer to machines or materials which are part of the packaging line.

Suited for decrease velocity production traces, pilot plant operations, analysis, and growth laboratories. The product is loaded into the top pan and manually fed into the filling tube by an operator. From Multi-Fill can deposit some foods at speeds as a lot as 120 containers per minute while sustaining product look and integrity? The machine speed varies by mannequin, structure manual food filling machines, product, and container type, but with our expertise, your buyer is eating their green olives sooner somewhat than later. GEA’s massive bag fillers are designed to pack a extensive variety of powdered merchandise into versatile luggage . We have three types of big bag fillers — BF-300, BBS-S and BBS-D — with numerous options for both ...

All of your business’s food processing needs – beyond simply filling and closing – are lined underneath our one roof. Pacific provides manual, semi-automatic, and automatic fillers for 50-gallon drums to 500-gallon totes. These machines provide all manual food filling machines the identical advantages as their new counterparts, however at a extra mild worth. Browse our currently out there used machines and save on value without compromising your machinery’s quality.

With the perfect packaging machines, a smaller labor force will be required therefore paying out very fewer wages. Indeed, packaging machines may include a large price tag, but when whole value of possession of a packaging line is taken and compared to manual laborers, then machinery is the most sensible option. Food– ready-to-eat food, grains & seeds, milk & liquids, spice, espresso, sugar, oil packaging machine, salt, tea, bakery, beverage, candy/confections, dairy, beverage, and bakery. Running eco-friendly materials can be a significant consideration.

Nylon with TPE inside sealing gland and CR/ NBR outer sealing gland. Use caps and plugs to guard crucial profiles from damage during handling and transportation. You can even get an expert finish by using high-temperature masking for holes and get in touch with factors with easy-to-fit caps and plugs. You can regulate the filling volume by loosing the screw A1 and A2 to regulate the output. But the screw A3 must be tightened to the half above, or the deal with may be caught.

The sizzling filling equipment is stuffed at 83℃-95℃ to kill the microorganisms on the bundle and the top cowl, which meets the industrial aseptic conditions and is used for the packaging of liquid food, and so forth. Microbial proliferation testing of liquid foods packaged in aseptic packaging, sizzling filling and ultra-clean filling tools. Let us bottle and promote your best-tasting creation to the world-wide market! For over 20 years we’ve been pioneering within the beverage trade as one of many main providers of beverage machinery for food producers across the globe.

The food-grade material is anti-corrosion and wear-resistances, simple to clean and preserve. The strong base retains sturdy, provides a stable working surroundings. Moreover, some gamers are a worldwide provider for these equipments and contribute to the expansion of the market for this region. All of our food filling methods are constructed from 316SS and other FDA, USDA and Dairy 3A approved supplies. The filling machine is designed for Clean-in-Place washing and may be mixed with our exterior cleansing system to supply high levels of repeatable cleanliness. Versatile and flexible, Pacific’s viscous fillers are customized to accommodate a variety of filling techniques.

Alternatively, it could perform as a double-sided sealing frame for 2 totally different kinds of packs. Free-flowing simply refers to powdered products that can't keep its shape even when further strain is added. In distinction, non-free-flowing merchandise, corresponding to powdered milk and brown sugar, can be compressed and maintain their form.

Also, some of them have nozzles for pre-cleaning the container with a nitrogen flush. These machines are a boon and the future of the pharmaceutical business. The digital liquid filling machine works on the precept of gear pump filling, so the fluid is displaced or moved by a fixed volume within gears. This machine comes with an attached silicone pipe and uses the syringe to fill the liquid.

0 notes

Text

Price: [price_with_discount]

(as of [price_update_date] - Details)

[ad_1]

Enjoy the authentic flavors of India with Alco Chicken Masala! This blend of spices is crafted with age-old recipes to bring you a delightful taste experience. Aromatic, flavourful Alco chicken masala powder is a go-to for those seeking to take their chicken or meat dishes to the next level. Alco has crafted a tantalizing chicken Masala, thoughtfully combining tips and ideas from grandmothers. Whether at home or away, just a pinch of chicken masala powder can spell a delicious spell on all chicken-based food. Chicken nuggets, barbeque grills, Kerala chicken curry masala, chicken masala Kerala-based snacks - you can use this 100 gm organic pack to enhance the flavor of any chicken snacks. We are confident that once you have tried Alco chicken Masala, you will never hesitate to add it to your pantry; you can also find it easily through amazon fresh items online. Alco chicken masale powder is made from 100% pure, natural ingredients that are free from preservatives, artificial flavors, MSG, and soy. Alco applies an extraordinary slow-roasting approach to spices like cumin, cassia, mace, clove, black cardamom, fenugreek seed, and more. The convenient resealable zipper technology for chicken masala powder will preserve spices for longer. Additionally, the low grinding temperature ensures the preservation of all natural flavor notes. Whether you are a beginner or an experienced cook, our fresh spices are easy to use and enhance the flavor of chicken snacks. Alco chicken masala powder is highly versatile and can be used for multiple purposes, such as making chicken masala 65 powder, Kerela chicken curry masala, and other ready-to-eat chicken dishes. This chicken masala powder is an excellent addition to butter chicken masala, an iconic Indian recipe. All necessary grocery items are conveniently located in a zipper pack of chicken masala powder. Try Alco Chicken Masala today and savor India's most beloved dishes in the comfort of your own home!

Rich Taste and Aroma - We use fresh and unadulterated spices. Our Chicken Masala offer great aroma while cooking Chicken.

Natural Flavor Intact - Our Chicken masala powder has the natural flavor. We do not mix additives in Chicken masala powder.

Sourced From Best Farms - Spices used in chicken masala are sourced from best farms. Chicken masala to offer you only the best

Packed Without Human Touch - Products at Alco are packed in an entirely automatic plant with SS304 stainless steel machines.

Natural and Healthy - Our Chicken Masala Powder is gluten-free, has no preservatives, MSG, anti-caking agents and non-GMO.

Accessible to Store - Available in a 100 gms zipper pack which is easy to store and takes less space in kitchen pantry.

[ad_2]

0 notes