#feed processing machine

Explore tagged Tumblr posts

Text

3-4T/H Chicken Feed Mill Plant for Our United Arab Emirates Customer

The poultry industry in the United Arab Emirates (UAE) holds significant importance within the country's livestock sector, primarily aimed at meeting the domestic demand for chicken meat and eggs. Poultry farming is typically categorized into two main types: broiler farming and egg-laying chicken farming.

In terms of broiler farming, chicken meat production in the UAE heavily relies on poultry farms equipped with modern facilities and management systems to ensure the growth and health of chickens. These farms vary in scale, ranging from small to large operations, and utilize various farming methods, including free-range and cage systems.

Regarding egg-laying chicken farming, the UAE also boasts a considerable number of egg production farms. These farms are dedicated to producing high-quality eggs to meet the domestic demand for egg products. Similar to chicken meat production, these farms often employ modern farming equipment and management techniques to enhance both yield and quality.

youtube

It's worth noting that the poultry industry in the UAE faces challenges due to the country's climate conditions and limited water resources. Challenges include the impact of high temperatures and arid environments on chicken growth, as well as issues related to feed and water supply. Therefore, the government and poultry industry stakeholders typically implement measures such as providing technical support, improving feed formulations, and enhancing water resource management to promote the sustainable development of the poultry industry.

In 2023, we established a close cooperation with a prestigious client from the United Arab Emirates (UAE), marking a significant milestone for our factory. This partnership brought forth an important order: the construction of a chicken feed production line with a capacity of 3-4T/H. The client showed keen interest in our products and presented a series of stringent requirements for their feed production line, posing both a challenge and a valuable opportunity for us. The client demanded exceptional quality in their feed products, necessitating comprehensive preparation and careful selection of high-quality equipment to ensure the line's efficiency, stability, and product quality.

Firstly, we opted for a high-performance feed grinder. This equipment efficiently grinds raw material particles into the desired powdered form, ensuring uniformity and digestibility of the feed. Subsequently, we introduced an advanced feed mixer capable of thoroughly blending different types and proportions of raw materials, ensuring nutritional balance and consistency in the feed. Additionally, we selected an efficient feed pelletizer capable of compressing the blended feed materials into uniform, visually appealing pellets, thereby enhancing the quality and stability of the feed.

To safeguard the quality of the feed pellets, we specifically chose an integrated feed cooling and sieving device. This equipment effectively cools and sifts the feed pellets during the production process, ensuring that they meet standardized appearance and texture requirements. Furthermore, to facilitate the client's sales and storage processes, we equipped the production line with an efficient feed packaging machine capable of packaging the feed pellets according to customer specifications, enhancing the overall efficiency of the production line.

In addition to the primary equipment, we provided the client with a range of auxiliary equipment, including electrical control panels, boilers, air compressors, and storage silos, to ensure the smooth operation of the entire production process. During the shipping phase, we implemented stringent quality control measures to ensure that all equipment was dispatched in optimal condition. To maximize cargo protection, we custom-designed packaging and protection measures suitable for container shipping, minimizing the risk of damage or loss during transit.

We are delighted to learn that the client has successfully received all goods and has expressed exceptionally high praise for the quality, performance, and reliability of our equipment. Their endorsement has earned our factory immense trust and acclaim. We remain committed to maintaining a close partnership with the client, continually optimizing our products and services, and making a greater contribution to the development of the feed production industry.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now! Welcome Contact Us! Henan Herm Machinery Co., Ltd Email: [email protected] Phone/Whatsapp: 86-18037508651

0 notes

Text

Introducing the Future of Livestock Nutrition: The Feed Processing Machine Revolutionizes Animal Agriculture

In the rapidly evolving world of animal agriculture, advancements in technology have revolutionized various aspects of the industry. Among these groundbreaking innovations is the feed processing machine, which promises to reshape how livestock nutrition is managed and delivered. This state-of-the-art equipment streamlines the feed production process, optimizing animal health, and ultimately enhancing overall farm productivity.

Traditionally, feed processing involved several labor-intensive steps, such as grinding, mixing, and pelleting, which often required multiple machines and resources. However, with the advent of the feed processing machine, farmers can now enjoy improved efficiency and cost-effectiveness. This cutting-edge technology combines all these essential functions into a single, automated system, enabling streamlined operations with minimal human intervention.

One of the primary advantages of the feed processing machine is its ability to precisely control the particle size of animal feed. Different livestock species require varying feed composition, and the machine allows farmers to achieve the ideal particle size that optimizes both nutrient absorption and digestibility. This precision results in better feed conversion rates, reduced wastage, and improved animal growth, leading to healthier livestock and increased profits for farmers.

Furthermore, the feed processing machine offers unparalleled flexibility in terms of feed formulation. Farmers can customize the recipe according to specific nutritional requirements dictated by different stages of animal growth or specific objectives, such as weight gain or milk production. This versatility ensures that livestock receive a balanced and tailored diet throughout their lifecycle, maximizing their performance and overall health.

In addition to optimizing nutrition, the feed processing machine also improves feed hygiene and safety. By incorporating high-temperature processing techniques, it eliminates potential pathogens, parasites, and other harmful microorganisms commonly found in raw ingredients. Additionally, the machine's automated cleaning and sterilization processes minimize cross-contamination risks, ensuring that the feed is safe for consumption by the animals, ultimately reducing the risk of disease outbreaks.

The advantages of the feed processing machine extend beyond the farm gate. With the ability to produce high-quality feed efficiently, this technology contributes to sustainable agriculture by reducing feed waste and lowering the environmental impact associated with traditional feed processing methods. Additionally, the streamlined process ensures consistent feed quality, leading to healthier and more productive livestock, addressing global concerns about food security.

As with any technological advancement, the adoption of feed processing machines may require initial investment. However, the long-term benefits far outweigh the costs, as farmers experience increased operational efficiency and improved profitability. Moreover, with the potential to reduce feed costs and boost animal performance, this revolutionary technology offers a promising solution for farmers in an increasingly competitive market.

In summary, the feed processing machine represents a significant breakthrough in livestock nutrition management. Its multifunctionality, precision, and adaptability allow farmers to optimize feed production, enhance animal health, and ultimately drive the success of their farming operations. By embracing this cutting-edge technology, the future of animal agriculture is set to become more efficient, sustainable, and profitable than ever before.

1 note

·

View note

Text

hate when someone brings up generative ai at the function and i have to bite my tongue and hide what a crazy bitch i really am

#personally.#as an artist and a writer and a human being i abhor generative ai in all situations#no exceptions#if you're asking my true and honest opinion no not even to take notes. not even to create outlines#maybe this is just like my moral issues talking sometimes i have difficulty seeing gray area#because a. you're still feeding a machine and b. it's about the principle#doing that work yourself enhances not just your understanding of a subject but your work ethnic as well#working through difficult things is how you grow#but no one wants to hear that#so just yeah it's so cool and awesome and fun you use generative ai to skip important parts of your writing and thinking process :DDD#don't come across as pedantic#can't do that#like esp in college you're paying so much fucking money to be here and you're writing your papers with ai??? what

19 notes

·

View notes

Text

it's my solemn duty to introduce new characters and/or important plot details via oc memes instead of through normal or rational methods. this is Lola Erik she's one of Dr. Maverick's coworkers. she's about as normal anyone intentionally associated with a Maverick can be. which is to say: questionably.

#btw if youre wondering wtf dr. maverick is thinking about : its the delphi-4 facsimile machine.#i should clarify she is NOT thinking about tasting a clone LMFAO. she's thinking of the machine 'tasting' /her/. some of the verbage for#referring to fax machine stuff is eating-related ('feeding' it. some ppl refer to it processing DNA samples as it 'chewing' since it moves)#oc#mvrck#the template maverick#lola erik

7 notes

·

View notes

Text

HELP???

#melonposting#this is all so incredibly interesting to me. by the way. madoka magica always delivers#we want to increase the entropy of the universe... we want to turn the universe into a perpetual motion machine...#we need a source of energy that increases from input to output... and human emotions serve that purpose#especially the emotions of girls undergoing puberty#<- it doesn't explicitly state why pubescent girls have the most emotional energy. however...#i'm sure it has something to do with the prevailing gender ideology and how that affects girls' perception of puberty#in that it's both liberating and terrifying and burdensome and so many other things given society's roles for women#as in... you are becoming a woman as evidenced by the development of your secondary sex characteristics#so now you have to deal with all of that#(and of course boys deal with some of that too but it's different. because. well. sexism)#and the roles of womanhood have been a theme thus far... what with madoka's mom and teacher#you start a magical girl and turn into a witch. that process releases emotional energy#there's a certain cynicism about it all#where witches are exclusively arbiters of violence#and the supposedly heroic magical girls inevitably turn into them...#...by using up the magic needed to kill them#they sustain themselves as magical girls only by 'feeding' on the grief seeds left by the witches they've killed as 'reward'#and magical girls who only seek to kill witches for good end up being worn down by the system they're in. they turn into witches faster#i've yet to parse through all of the allegorical layers behind the relationship between magical girls and witches...#...but madoka magica is proving to be incredibly meaningful. and feminist

8 notes

·

View notes

Text

i hate gen AI so much i wish crab raves upon it

#genuinely this shit is like downfall of humanity to me#what do you mean you have a compsci degree and are having chatgpt write basic code for you#what do you mean you are using it to come up with recipes#what do you mean you are talking to it 24/7 like it’s your friend#what do you mean you are RPing with it#what do you mean you use it instead of researching anything for yourself#what do you mean you’re using it to write your essays instead of just writing your essays#i feel crazy i feel insane on god on GOD#i would have gotten a different degree if i knew that half the jobs that exist now for my degree are all feeding into the fucking gen AI#slop machine#what’s worse is my work experience is very much ‘automation engineering’ which is NOT AI but#using coding/technology/databases to improve existing processes and make them easier and less tedious for people#to free them up to do things that involve more brainpower than tedious data entry/etc#SO ESPECIALLY so many of the jobs i would have been able to take with my work experience is now very gen AI shit and i just refuse to fuckin#do that shit?????

2 notes

·

View notes

Text

every day I open my phone to see the continuing erosion of everything that was remotely even semi-enjoyable about life and I just kind of despair for the future tbh

#The ai ghibli stuff that’s just everywhere is only the latest thing making me foam at the mouth#god just. If you have the means just pay an artist or try to see if you can redraw your family photos in that style yourself#the process is the Point. The end result might be bad if you’ve never tried it before but the point is you dared to try#maybe it turned out better than you thought it would and suddenly you’ve found a new hobby to indulge in and a new skill to cultivate#just. For the love of god make your own art. Even if it’s bad. Especially if it’s bad. Just. Let it be Human#and not just a cold imitation fed off the hard work and countless hours of growth real ppl put in to do it with their own hands#long before you thought up some lazy prompt to feed into some machine#that’s gonna guzzle up water and energy to create something quickly just for some heartless gratification#that you think you get from saying I made this! You didn’t make it! The machine shat it out from a slurry of other ppls hard work

6 notes

·

View notes

Text

"AI generated quests" "AI generated dialogue" – so these people are admitting that they see story and narratives as filler meant to inflate the size of a game, instead of enriching the world it's meant to portray? If a character only talks about some meaningless bullshit when I interact with them because their story has been automated by an artificial mimicry datascraper tool and that the devs might not even be aware about what it talks about, they can honestly just stay silent. You are wasting people's time! Unethical AI is pure quantity over quality, instead of a single well designed thing you'll just get 50 turds with a randomised shape. We're gonna get flooded with so much unnecessary crap in the next years. There will be so much inflated content and time-wasters, so much noise just to trick you into losing even more time and money. We ought to come up with clever review techniques to sort out the trash efficiently.

#i talk sometimes#i understand if AI starts getting used primarily as a tool to ethically streamline a process that is still 100% controlled by the person#but using AI as a creation machine is utter bullshit#and also real questionable if you don't feed it with your own data. it's baffling how people suddenly don't care for copyright anymore lol#disney won't be the one stolen from but small creators nobody cares for everybody needs to understand that

4 notes

·

View notes

Text

10T/H Chicken Feed Pellet Making Machine for Kazakhstan Client

Successful Collaboration with Kazakhstan Client: Establishing an Efficient Chicken Feed Pellet Production Line

Recently, our company successfully collaborated with a client from Kazakhstan to design and produce a 10-ton-per-hour chicken feed pellet production line. This project not only demonstrates the high quality and efficiency of our products but also reflects our excellent customer service and technical support.

youtube

Customer Needs and Initial Contact

The client from Kazakhstan reached out to us after extensive research and comparisons online. They expressed a clear need for a production line capable of producing 4mm diameter chicken feed pellets. Initial discussions revealed that the client already had a powder feed production line and aimed to start producing pellet feed to meet their farming needs.

Initially, the client only inquired about the prices of our single machines, including the 420 ring die pellet mill, counter-flow feed cooler, and rotary grading sieve, stating that they would discuss other auxiliary equipment later. After we showcased some real-life videos of high-capacity cases, the client was highly impressed with our production capacity and quality.

Technical Proposal and Dimension Confirmation

Based on the client’s requirements, we provided the corresponding single-machine prices. After comparing various options, the client initially chose our products. To ensure that the new equipment would seamlessly integrate with the client's existing production line, we requested precise measurements. The client measured and provided detailed dimensions as per our request. Our technical team then began designing the process flow diagram to ensure feasibility and accuracy.

Additional Requirements and On-Site Measurement

Following the New Year celebrations in Kazakhstan, the client resumed communication with us, adding the need for a crumbler and a fat addition system. We revised the quotation to include these new components. After a thorough review, the client decided to move forward with us. To ensure the production process's accuracy, the client requested our technical personnel to conduct on-site measurements.

Understanding the client’s situation, our technical team promptly traveled to Kazakhstan, where they were warmly received by the client. After two days of on-site measurements and inspections, our team designed three different solutions based on the client’s existing facilities and space constraints. After multiple discussions and confirmations, the client selected the most satisfactory solution and signed a purchase contract with us.

Production Preparation and Client Inspection

Following the detailed planning and contract signing, our company immediately commenced the production of the required equipment. After two months of preparation, all equipment was successfully manufactured. The client dispatched staff to our factory for an inspection visit. They witnessed the manufacturing process and inspected the final products. Satisfied with the quality and production process, the client further affirmed the wisdom of choosing to collaborate with our company.

youtube

Summary and Outlook

This cooperation provided the client with an efficient and cost-effective chicken feed pellet production solution, showcasing our professional technology and excellent service in the feed machinery industry. From initial communication, and solution design, to final production and inspection, we meticulously managed every step to ensure the client's needs were optimally met.

Looking forward, we are committed to providing the highest quality products and services to clients worldwide, helping them achieve efficient production and jointly advancing the development of the feed machinery industry.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now! Welcome Contact Us! Henan Herm Machinery Co., Ltd Email: [email protected] Phone/Whatsapp: 86-18037508651

#pellet feed making machine#feed production line#feed processing machine#pellet mill machine#feed pellet mills#Youtube

0 notes

Text

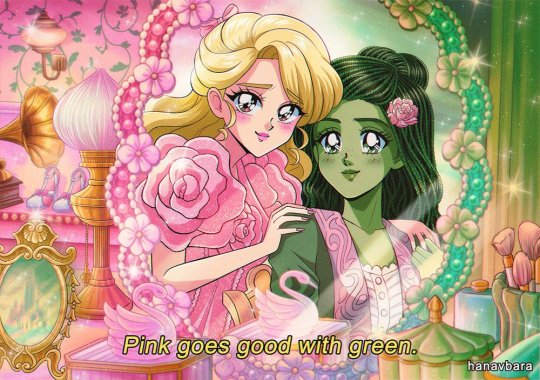

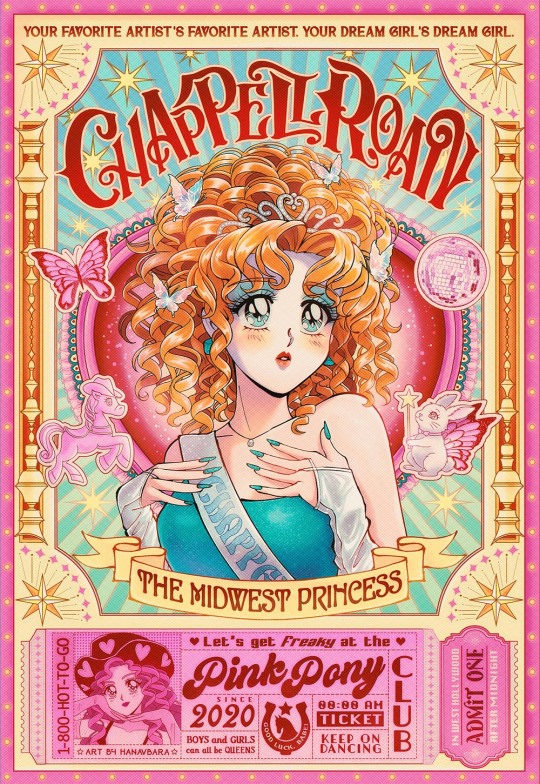

support HUMAN artists, not AI‼️

AI generated images are NOT art. art is CREATED, not GENERATED.

this is not just about taking jobs from artists (which is already a huge deal), it’s also about devaluing art itself, turning it into mass-produced, empty and soulless content. it’s heartbreaking to see AI stealing from real artists: from Studio Ghibli to smaller creators like us.

personally, we started our art journey by reinterpreting what we love: music, TV series, anime and transforming it into our vision inspired by the 90’s anime that we grew up with. when we create our illustrations, we try to capture the emotion and love we feel for the subject, aiming to tell a story with each drawing. ever since AI was created, we have had many people asking if our art is AI generated. honestly, it’s heartbreaking every single time. for us, art is a deeply human experience that we’ve been dedicating ourselves to for seven years. creating from nothing takes dedication, skill, and an emotional investment that, in our opinion, AI simply can’t capture.

you’ve probably seen your feed flooded with AI generated images in a “Studio Ghibli style”. trends like these reinforce the idea that art can be easily replicated and devalued. the future of artists is more uncertain than ever. we don’t know if in a few years we’ll still be able to make a living from this, since many companies are adopting the mindset of “why should i pay someone for their well-earned work when a machine can do it for free in an instant?” that mindset is the real problem: the way society is starting to perceive art.

art is essential to human life. many people realized this during the pandemic: what would we do without music, movies, books, that bring us comfort? art is more than just the final product. it’s about the process, struggles, and personal growth that comes with it. when you create, you grow, learn, and challenge yourself. AI erases that, replacing it with instant and shallow replication. real art brings people together, evoking emotions and reminding us of what it means to be human.

relying on AI to make art isn’t innovation, it’s avoiding the challenge of creating something meaningful. AI tools like these are being pushed as "the future," but what does that say about us? replacing human artistry with shallow, mass-produced content takes away humanity from art, do we really want to be part of a world where art is just another disposable product? what value do we place on creativity?

if you’ve made it this far, it means you care about these issues. let’s raise our voices together and speak up. don’t consume AI generated images. value and respect creativity. SUPPORT REAL HUMAN ARTISTS.

#artist#artists on tumblr#ai#anti ai#fuck ai#art#illustration#anime#digital art#artwork#creativity#chatgpt#studio ghibli#ghibli#artificial intelligence

8K notes

·

View notes

Text

How to Start a Profitable Chicken Feed Manufacturing Business

🐔 Ready to start your Poultry Feed Manufacturing Business? Learn the secrets to success and create high-quality chicken feed that boosts profits! 🚀 #PoultryFeedBusiness #ChickenFeedProductionFeedManufacturing #EntrepreneurJourney #ProfitableIdeas

Poultry products such as eggs and meat contribute to a significant percentage of the world’s food demand. Chicken feed generally refers to the food of chickens, ducks, pigeons, quails, and so on. Usually, when they are free, they arrange their own food. But when they are raised commercially, they need chicken feed as their food. Because, commercial chicken feed is rich in protein, minerals,…

#business ideas 2025#chicken farming business#chicken feed business#chicken feed business in india#chicken feed business plan#chicken feed machine#chicken feed making business#chicken feed manufacturing business#chicken feed pellets business#chicken feed processing business#how to build a chicken feed business#manufacturing business ideas#poultry farming#poultry farming business plan#poultry feed#start chicken feed farming business#startups

0 notes

Text

Performance comparison and selection guide of different types of feed pellet machines

Feed pellet machines are indispensable equipment in modern breeding industry, which are used to process raw materials into pellet feed. According to different processing requirements and raw material characteristics, there are many types of feed pellet machines on the market. Choosing a suitable pellet machine is crucial to improving feed production efficiency and reducing production costs. The following is a performance comparison and selection guide of several common feed pellet machine types:

Flat die pellet machine The working principle fish feed processing machine Suppliers of the flat die pellet machine is to extrude the raw materials into pellets through horizontally placed dies and rollers. Its advantages are simple structure, convenient maintenance, and suitable for small-scale and medium-scale production. It is suitable for processing some feeds with larger particle diameters, such as cattle and sheep feed, fish feed, etc. The disadvantage of the flat die pellet machine is low output, which is suitable for occasions with low requirements for pellets.

Ring die pellet machine The ring die pellet machine uses a vertically placed die, and the raw materials are extruded into pellets through the channels in the die. This pellet machine has a strong production capacity and is suitable for large-scale production. The pellet uniformity of the ring die pellet machine is high, which can effectively improve the digestibility of the feed. It is suitable for processing feed for pigs, poultry, etc. The disadvantages are high price, high energy consumption, and high maintenance requirements.

Twin-screw pellet machine Twin-screw pellet machine has higher processing capacity and can handle more kinds of materials, such as high-humidity and high-oil raw materials. It uses twin-screw extrusion to mix the materials evenly and form pellets. This pellet machine is usually used for high-end feed production, such as special feed with added drugs, vitamins and other ingredients. The advantage is high production efficiency, and the disadvantage is that it is expensive and requires high operating technology.

Single-screw pellet machine Single-screw pellet machine has a simple structure and is suitable for small and medium-sized feed processing. It uses a spiral device to extrude the material into pellets, which is suitable for some low-fat and low-humidity feeds. The cost of a single-screw pellet machine is lower, but the production efficiency and pellet quality are not as good as a twin-screw machine.

Selection Guide: Production requirements: For small-scale production, you can choose a flat die pellet machine or a single screw pellet machine; while large-scale production is more suitable for a ring die pellet machine or a twin-screw pellet machine. Raw material characteristics: If you need to process high-humidity, high-oil or difficult-to-form materials, a twin-screw pellet machine is the best choice; for ordinary feed, ring die pellet machines and single-screw pellet machines can also meet the needs. Budget considerations: Under limited budgets, single-screw pellet machines and flat die pellet machines are more cost-effective; if the budget is sufficient, you can consider investing in ring die or twin-screw pellet machines to improve production efficiency and pellet quality. In short, choosing a suitable feed pellet machine requires comprehensive consideration of factors such as production scale, raw material characteristics, equipment cost and maintenance requirements.

0 notes

Text

ive been using pinterest solely for haircut ideas and tattoo & piercing inspiration for years. the last time i used it was maybe 6 months ago and i just now opened it and realised how much there is AI generated images there :o

#these shitty ai photos will confuse the machine learning process#the quality of ai is as good as the material youre giving to it and oh my lord this shit will just keep feeding shit to itself

0 notes

Text

The circulating emulsification tank has the functions of automatic feeding, automatic stirring, emulsification, circulating emulsification, etc. It is suitable for food, medicine, scientific research experiments, and cosmetics processing. The equipment can be customized. Please contact us if you need it.

#machine#automatic stirring#The circulating emulsification tank has the functions of automatic feeding#emulsification#circulating emulsification#etc. It is suitable for food#medicine#scientific research experiments#and cosmetics processing. The equipment can be customized. Please contact us if you need it.

0 notes

Text

ya watch one (1) video out of bored curiosity and suddenly your recommendations are full of videos like that. i hate algorithms and i hate the internet. die

#i figured i should figure out what the boys is about at some point and looked it up#BAM half my feed is about the show now. i dont watch it and dont want to#for a time i thought it was the same show that cillian murphy is in for some reason?#i was actually very surprised the first time i learned it was about superheroes?#anyway. the machines better stop trying to psychoanalyze me. they WILL break in the process

1 note

·

View note

Text

going insane about haymitch the rebellion’s sacrificial lamb. they saw a kid honor the dead and make a mockery of snow in a public setting and knew he’d earned himself a death sentence. so they recruit him. ask him to do something that will only increase the target on his back. maybe it’s heartless but it’s for the greater good. they can achieve their aims of rebellion and let him make his death mean something in the process. it’s the best they can make of an unbearable situation

but then it doesn’t work. the arena doesn’t break and haymitch doesn’t die and the world and the games go on. and the personal consequences are dire.

fast forward twenty four years and now haymitch is the adult and he’s got the same kind of teenager on his hands and the same heartless choices in his lap. how much do you think it killed him to feed her to the same machine, when he knows intimately exactly how high the cost of failure can be?

#the hunger games#sunrise on the reaping#sunrise on the reaping spoilers#haymitch abernathy#i finished…lying down about it boys…#i always figured haymitch was the spark without tinder but god. the parallels. the proto-katniss of it all

6K notes

·

View notes