#autonomous mobile robot demand

Explore tagged Tumblr posts

Text

The Role of AI in Enhancing Autonomous Mobile Robot Capabilities

An autonomous mobile robot (AMR) is a multipurpose, self-contained robot that can move around and carry out activities in dynamic surroundings without assistance from a human. AMRs can map their environment, make judgments in real time, and adjust to changing situations since they are outfitted with sophisticated sensors, cameras, and artificial intelligence. These autonomous mobile robots are commonly utilized for duties like material handling, inventory management, and patient care in sectors including manufacturing, logistics, and healthcare. Their independence boosts productivity, lowers personnel expenses, and increases security in intricate settings.

#autonomous mobile robot demand#autonomous mobile robot share#autonomous mobile robot trend#autonomous mobile robot size

0 notes

Text

Autonomous Mobile Robots (AMRs) Market Size, Revenue Share, Drivers & Trends Analysis, 2024–2030

The Autonomous Mobile Robots Market was valued at USD 1.7 billion in 2023 and will surpass USD 5.2 billion by 2030; growing at a CAGR of 16.9% during 2024 – 2030. the Autonomous Mobile Robots (AMRs) market has seen significant growth, driven by advancements in robotics, artificial intelligence (AI), and machine learning. AMRs, which can navigate and perform tasks without direct human intervention, are transforming industries by enhancing efficiency, reducing costs, and improving safety. This blog explores the current state of the AMRs market, key trends, and future prospects.

Autonomous Mobile Robots are a type of robot that can perform various tasks in diverse environments, from warehouses and manufacturing floors to hospitals and retail spaces. Unlike traditional automated guided vehicles (AGVs), which require predefined paths and external guidance, AMRs use sensors, cameras, and AI to understand their surroundings, make decisions in real-time, and navigate dynamically within a space.

Read More about Sample Report: https://www.intentmarketresearch.com/request-sample/autonomous-mobile-robots-amrs-market-3605.html

Market Growth and Drivers

The AMRs market is experiencing rapid expansion, with a compound annual growth rate (CAGR) expected to exceed 20% over the next few years. Several factors contribute to this growth:

E-commerce Boom: The rise of e-commerce has led to an increased demand for efficient and flexible logistics solutions. AMRs help in automating warehouse operations, handling goods, and optimizing supply chains, making them indispensable in the fast-paced world of online retail.

Labor Shortages and Rising Costs: In many industries, labor shortages and rising wages are pushing companies to seek automated solutions. AMRs offer a viable alternative, performing repetitive tasks like material handling, inventory management, and transportation more cost-effectively than human labor.

Technological Advancements: Continuous improvements in AI, machine learning, and sensor technologies are enhancing the capabilities of AMRs. These advancements allow robots to operate in increasingly complex environments, boosting their adoption across various sectors.

Safety and Compliance: AMRs are designed to work alongside humans safely, reducing the risk of workplace accidents. In environments like healthcare, where precision and hygiene are critical, AMRs can perform tasks such as disinfection and delivery, minimizing human contact and contamination risks.

Key Trends Shaping the AMRs Market

Industry-Specific Solutions: As the AMRs market matures, we are witnessing the development of industry-specific solutions. For instance, in healthcare, AMRs are used for patient monitoring, medication delivery, and even surgical assistance. In manufacturing, they are employed for assembly line automation and quality control.

Integration with IoT and Big Data: The integration of AMRs with Internet of Things (IoT) devices and big data analytics is creating smarter, more connected environments. By collecting and analyzing data from their surroundings, AMRs can optimize their operations, predict maintenance needs, and adapt to changing conditions in real-time.

Collaborative Robots (Cobots): The rise of collaborative robots, or cobots, is another significant trend. Cobots are designed to work alongside human workers, assisting with tasks that require precision, strength, or endurance. This collaboration not only enhances productivity but also reduces the workload on human employees.

Expansion into New Markets: While logistics and manufacturing have been the primary markets for AMRs, their application is expanding into new areas such as agriculture, hospitality, and defense. In agriculture, for example, AMRs are used for tasks like crop monitoring, harvesting, and soil analysis.

Ask for Customization Report: https://www.intentmarketresearch.com/ask-for-customization/autonomous-mobile-robots-amrs-market-3605.html

Challenges and Future Outlook

Despite the promising growth, the AMRs market faces challenges, including high initial investment costs, regulatory hurdles, and the need for ongoing technological development. Ensuring that AMRs can operate safely and efficiently in diverse environments, particularly in industries with stringent regulations, remains a critical challenge.

Looking ahead, the future of the AMRs market is bright. As technology continues to advance, we can expect to see more sophisticated and versatile AMRs that can handle increasingly complex tasks. The integration of AMRs with other emerging technologies like 5G, edge computing, and autonomous vehicles will further propel the market forward.

Conclusion

The Autonomous Mobile Robots market is at the forefront of a technological revolution, reshaping how industries operate. From enhancing efficiency in warehouses to improving patient care in hospitals, AMRs are proving to be invaluable assets in the modern world. As the market continues to grow, driven by innovation and the need for automation, AMRs will play an increasingly important role in the future of work.

#Autonomous Mobile Robots#Autonomous Mobile Robots Size#Autonomous Mobile Robots Growth#Autonomous Mobile Robots Demand

0 notes

Text

Autonomous Mobile Robots Market Estimated To Witness Growth Due To Rising Demand From Logistics And Warehousing Industries

The global autonomous mobile robots market is estimated to be valued at US$ 3.41 Bn in 2024 and is expected to exhibit a CAGR of 3.1% over the forecast period 2024 to 2031, as highlighted in a new report published by Coherent Market Insights. Market Dynamics: The key driver explained from the heading is the rising demand from logistics and warehousing industries. The growing e-commerce sector has placed significant pressure on logistics and warehousing companies to expedite and streamline operations. Autonomous mobile robots help in automating material handling tasks which reduces operational costs and improves productivity for warehouse and logistics companies. Additionally, AMRs ensure safer working environments by eliminating risks associated with manual material handling. This factor is further driving their adoption across industries. Furthermore, continuous technological advancements are making AMRs more affordable and efficient. Emergence of IoT and AI-enabled AMR solutions is also fueling market growth over the forecast period. SWOT Analysis Strength: Autonomous mobile robots are highly efficient as they can operate 24/7 without breaks. They perform repetitive and routine tasks with high accuracy reducing the scope of human errors. Their programming makes them consistent in task performance. Weakness: High initial investment costs are required for deployment of autonomous mobile robots. Technical glitches and system failures can disrupt workflow. Lack of dexterity and adaptability are limitations as they cannot handle unpredictable situations or tasks requiring human judgment. Opportunity: Increased labor costs and shortage of labor is driving many industries to adopt robotics solutions. The logistics and warehousing sector offers huge growth opportunity for autonomous mobile robots for applications like transportation and sorting. Growth of e-commerce will further boost demand. Threats: Concerns around job losses can increase resistance from labor unions. Delay in development of technologies like advanced sensing, AI and 5G networks can hamper full potential of autonomous mobile robots. Changes in government regulations regarding robotics can affect adoption plans of some companies. Key Takeaways The global autonomous mobile robots market growth is expected to witness high growth over the forecast period owing to benefits like improved efficiency and reduced costs. The market size is estimated to reach US$ 3.41 Mn in 2024 from US$ 1.23 Mn in 2019, indicating a CAGR of around 3.1% during the period. Regional analysis:

North America currently dominates the market attributed to rapid technological advancement and increasing investments by prominent players in the region. Asia Pacific is anticipated to be the fastest growing market led by countries like China, Japan and India. With growing industrialization and manufacturing hub status, the APAC autonomous mobile robots market is projected to witness a CAGR of over 4% during the forecast period. Key players:

Key players operating in the autonomous mobile robots market are Sanofi, Pfizer, Inc., Novartis AG., B. Braun Melsungen AG, Fresenius Medical Care, Medtronic, Preservation Solution Inc., TransMedics, Inc., Organ Recovery Systems, and Transonic Systems Inc. These key players are focused on new product launches and partnerships to strengthen their market position.

Get more insights on this topic: https://www.newsstatix.com/the-autonomous-mobile-robots-market-growth-is-propelled-by-increasing-demand-for-automation-in-warehouses/

#Autonomous Mobile Robots#Autonomous Mobile Robots Market#Autonomous Mobile Robots Market size#Autonomous Mobile Robots Market share#Autonomous Mobile Robots Market demand#Autonomous Mobile Robots Market analysis

0 notes

Text

Breaking Down the Sectors Leading the top 10 nasdaq stocks

The Nasdaq Composite is home to some of the world’s most transformative companies—those that define sectors, influence technology adoption, and shape enterprise behavior across the globe. While the index includes thousands of publicly listed firms, the top 10 nasdaq stocks stand out for their leadership, operational scale, and foundational role in the digital economy.

These entities span a range of domains, from artificial intelligence and cloud computing to e-commerce, semiconductors, and biotechnology. Their influence extends beyond markets, deeply embedded in consumer lives, infrastructure, and cross-border commerce.

Technology Giants Driving Structural Shifts

Technology dominates the upper tier of Nasdaq. The top 10 nasdaq stocks feature companies that deliver infrastructure for cloud operations, productivity software, and data-driven services. These platforms enable enterprises to operate flexibly, scale on demand, and analyze vast datasets for strategic decision-making.

The focus areas include edge computing, AI model deployment, collaborative ecosystems, and real-time communication. Such platforms power workflows across industries—logistics, healthcare, education, and manufacturing alike.

Semiconductor Ecosystems and High-Performance Processing

Semiconductors are the engine behind almost every modern device. The top 10 nasdaq stocks include major chip manufacturers specializing in logic processors, GPUs, and memory technologies. These chips support a range of devices from smartphones to autonomous vehicles, and critical infrastructure such as AI training servers and IoT applications.

Their role is especially important in enabling advancements in robotics, quantum computing, and 5G integration. As demand for efficiency, speed, and computing scale increases, these hardware companies continue to evolve with new manufacturing processes and power-saving architectures.

Biotech Leaders Transforming Health Sciences

Several biotechnology and pharmaceutical companies are among the top 10 nasdaq stocks, recognized for their innovation in genomics, molecular diagnostics, and personalized therapy development. These firms focus on treatments that tackle complex diseases and contribute to advancements in healthcare delivery.

Their research efforts are driven by AI-assisted modeling, automated lab testing, and cloud-based trial management systems. By merging biology and data, these organizations are playing a key role in the evolution of modern medicine.

E-Commerce and Global Consumer Platforms

Digital retail has become an integral part of global commerce, with firms in the top 10 nasdaq stocks leading in logistics integration, virtual storefront management, and behavioral analytics. These platforms facilitate real-time inventory tracking, user-based customization, and high-speed fulfillment systems.

Their operations support vast product ecosystems and provide infrastructure that connects manufacturers, sellers, and buyers across multiple regions.

Fintech and Scalable Payment Systems

Several companies within the top 10 nasdaq stocks operate at the intersection of finance and technology, offering mobile payments, e-commerce checkout tools, and financial infrastructure APIs. These firms enable seamless global transactions and scalable platforms for businesses of all sizes.

Through security enhancements, intuitive interfaces, and backend automation, fintech platforms are streamlining user experience while expanding access to digital commerce solutions.

Cybersecurity and Data Resilience

With increased digital activity comes a greater need for cybersecurity. The top 10 nasdaq stocks include organizations that offer identity protection, intrusion prevention systems, and compliance monitoring tools. These services are critical for securing enterprise networks, hybrid cloud deployments, and endpoint devices.

Cyber platforms today are built to address adaptive threats using machine learning, behavioral analysis, and decentralized access control. Their services support the operational continuity of corporations, institutions, and governments alike.

Clean Energy and Electrification Technology

Environmental innovation is making its mark on the Nasdaq, with some of the top 10 nasdaq stocks focused on clean energy production, storage solutions, and smart grid capabilities. These firms are helping reshape energy use across industrial and residential landscapes through solar hardware, EV battery advancements, and real-time energy analytics.

Their platforms align with long-term global objectives centered around emission reduction, energy efficiency, and infrastructure modernization.

Artificial Intelligence and Data Platforms

AI continues to gain traction across sectors, and firms within the top 10 nasdaq stocks develop tools that analyze patterns, automate processes, and support predictive operations. These platforms are used in retail, healthcare, logistics, and more—delivering insights that optimize everything from inventory flow to patient outcomes.

The integration of natural language processing, image recognition, and machine learning modules further enhances decision-making across enterprise layers.

Streaming Services and Content Ecosystems

Digital entertainment continues to evolve through streaming platforms that offer global access to video, music, and interactive content. Several firms in the top 10 nasdaq stocks lead in content delivery, subscription systems, and personalized user interfaces.

These platforms use advanced algorithms to recommend content, monitor engagement, and optimize experience across smart devices and mobile ecosystems.

Automation and Smart Logistics Infrastructure

The rise of automation is visible in companies that focus on industrial logistics, robotics, and smart supply chains. The top 10 nasdaq stocks in this category build systems that enhance speed, reduce errors, and enable autonomous decision-making in physical operations.

Their tools are used in warehousing, shipping, manufacturing, and urban mobility—shaping the future of efficiency in physical commerce.

0 notes

Text

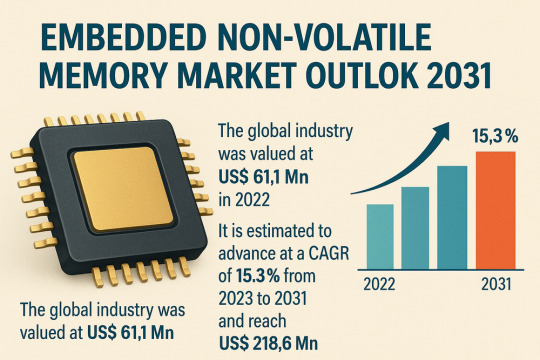

Embedded Non-volatile Memory Market to Hit $218.6 Million by 2031: What's Driving the Growth?

The global Embedded Non-volatile Memory (eNVM) market was valued at USD 61.1 million in 2022 and is projected to expand at a CAGR of 15.3% between 2023 and 2031, reaching USD 218.6 million by the end of 2031. Embedded NVM refers to non-volatile storage integrated directly into semiconductor chips, retaining data even when the system is powered off. Its core applications include firmware storage, calibration data retention, and secure configuration storage in microcontrollers, digital signal processors, and a wide array of embedded systems.

Market Drivers & Trends

Smartphone and Wearable Boom – The continued global uptake of mobile devices has escalated the need for larger, faster embedded memory. Users demand lightning-fast boot times and seamless multitasking, driving OEMs to integrate high-performance flash memory and emerging NVM technologies directly into system-on-chips (SoCs). – Wearables, smart speakers, and IoT gadgets prioritize low-density but highly efficient memory. 3D NAND flash has emerged as the preferred technology, offering high storage capacity in a minimal footprint. Samsung and SK Hynix have ramped up mass production of advanced 3D NAND modules tailored for connected device ecosystems.

Low-Power, High-Speed Requirements – Battery-powered devices mandate memory that combines rapid data access with minimal energy draw. Next-generation embedded NVMs—such as STT-MRAM and ReRAM—offer sub-microsecond access times and ultra-low standby currents, extending device lifespans and enhancing user experience. – System-in-Package (SiP) and Package-on-Package (PoP) solutions are gaining traction, integrating multiple memory dies and logic blocks into single compact modules, thereby reducing interconnect power losses and boosting overall throughput.

Security and Reliability – As embedded systems permeate mission-critical sectors (automotive ADAS, industrial controls, medical devices), secure and tamper-resistant memory is non-negotiable. Embedded flash and MRAM provide inherent read/write protections, while emerging PUF-based authentication schemes leverage intrinsic chip variability to safeguard cryptographic keys.

Latest Market Trends

3D XPoint and Beyond: Following its debut in enterprise SSDs, 3D XPoint is being miniaturized for embedded applications, promising DRAM-like speeds with non-volatility, ideal for real-time control systems.

Embedded MRAM/STT-MRAM: Gaining traction in safety-critical automotive and industrial sectors, MRAM offers unlimited endurance cycles and high radiation tolerance.

Embedded Ferroelectric RAM (FRAM): With nanosecond write speeds and high write endurance, FRAM is carving out niches in smart cards, metering, and medical devices.

Key Players and Industry Leaders The eNVM market is highly consolidated, with major semiconductor manufacturers and specialty memory providers driving innovation and capacity expansion:

eMemory Technology Inc.

Floadia Corporation

GlobalFoundries Inc.

Infineon Technologies AG

Japan Semiconductor Corporation

Kilopass Technology, Inc.

SK HYNIX INC.

SMIC

Texas Instruments Incorporated

Toshiba Electronic Devices & Storage Corporation

Download now to explore primary insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=24953

Recent Developments

March 2023 – ANAFLASH Commercialization U.S. startup ANAFLASH unveiled an energy-efficient embedded NVM solution tailored for battery-powered wireless sensors, medical wearables, and autonomous robots, promising up to 30% lower power consumption versus incumbent flash technologies.

February 2023 – GlobalFoundries Acquisition GlobalFoundries acquired Renesas Electronics’ resistive RAM patents and manufacturing know-how, aiming to integrate low-power ReRAM into next-generation SoCs for smart home and mobile applications.

May 2022 – Automotive Platform Collaboration Japan Semiconductor Corporation and Toshiba Electronic Devices partnered to develop a 0.13-micron analog IC platform with embedded flash, targeting advanced automotive applications such as in-vehicle networking and sensor fusion modules.

Market Opportunities

5G and IoT Rollout: The proliferation of 5G networks and edge computing devices demands local data storage and analytics, presenting growth avenues for low-latency embedded memory.

Automotive Electrification: Electric and autonomous vehicles require robust memory for ADAS, telematics, and battery management systems, creating new application segments.

Healthcare Wearables: Demand for continuous health monitoring fosters embedded memory integration in smart patches and implantable devices, where size and power constraints are paramount.

Future Outlook Analysts project that by 2031, the Embedded NVM market will surpass US$ 218 million, driven by sustained R&D investments and product diversification into emerging NVM technologies. The maturation of foundry support for STT-MRAM, ReRAM, and 3D XPoint, coupled with advanced packaging breakthroughs, will accelerate adoption across consumer, automotive, and industrial domains. Security-driven regulations and functional safety standards will further cement embedded memory’s role in next-generation electronic systems.

Market Segmentation

By Type

Flash Memory (dominant share in 2022)

EEPROM

nvSRAM

EPROM

3D NAND

MRAM/STT-MRAM

FRAM

Others (PCM, NRAM)

By End-Use Industry

Consumer Electronics (2022 market leader)

Automotive

IT & Telecommunication

Media & Entertainment

Aerospace & Defense

Others (Industrial, Healthcare)

By Region

North America

Europe

Asia Pacific (2022 market leader)

Middle East & Africa

South America

Buy this Premium Research Report for a detailed exploration of industry insights - https://www.transparencymarketresearch.com/checkout.php?rep_id=24953<ype=S

Regional Insights

Asia Pacific: Commanded the largest share in 2022, fueled by semiconductor R&D hubs in China, Japan, Taiwan, and South Korea, and robust electronics manufacturing ecosystems.

North America: Home to major foundries and design houses; 5G and IoT device adoption is expected to drive eNVM demand through 2031.

Europe: Automotive electrification and Industry 4.0 initiatives will underpin growth, with Germany and France leading demand.

MEA & Latin America: Emerging markets are gradually adopting consumer electronics and automotive technologies, presenting long-term opportunities.

Frequently Asked Questions

What is embedded non-volatile memory? Embedded NVM is memory integrated into semiconductor chips that retains data without power. It is used for firmware, configuration data, and security keys.

Which eNVM type holds the largest market share? Flash memory led the market in 2022 due to its balance of speed, density, and cost-effectiveness, particularly in consumer electronics and IoT devices.

What industries drive eNVM demand? Consumer electronics, automotive (ADAS, electrification), IT & telecom (5G equipment), aerospace & defense, healthcare wearables, and industrial automation.

How will emerging technologies impact the market? STT-MRAM, ReRAM, and 3D XPoint will offer faster speeds, higher endurance, and lower power profiles, expanding applications in safety-critical and high-performance systems.

Which regions offer the best growth prospects? Asia Pacific remains the leader due to manufacturing scale and R&D. North America and Europe follow, driven by advanced automotive and IoT deployments.

What factors may restrain market growth? High development costs for new NVM technologies, integration complexity, and supply chain disruptions in semiconductor fabrication could pose challenges.

Why is this report important for stakeholders? It equips semiconductor vendors, system integrators, and strategic investors with the insights needed to navigate technological shifts and seize emerging market opportunities in embedded memory.

Explore Latest Research Reports by Transparency Market Research:

Power Meter Market: https://www.transparencymarketresearch.com/power-meter-market.html

Radiation Hardened Electronics Market: https://www.transparencymarketresearch.com/radiation-hardened-electronics-semiconductor-market.html

AC-DC Power Supply Adapter Market: https://www.transparencymarketresearch.com/ac-dc-power-supply-adapter-market.html

5G PCB Market: https://www.transparencymarketresearch.com/5g-pcb-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Agriculture Automation and Control Systems Market: A Comprehensive Analysis

The agriculture automation and control systems market Analysis is undergoing rapid transformation as the industry increasingly adopts cutting-edge technologies to boost productivity and meet the demands of a growing global population. This blog offers a detailed analysis of the market, covering its current status, forecast, trends, segmentation, regional performance, key players, and future outlook.

Market Overview and Estimation

As of 2022, the global agriculture automation and control systems market was valued at USD 4.3 billion. It is expected to reach USD 6.69 billion by 2031, growing at a CAGR of 5.71% over the forecast period (2024–2031). This growth trajectory is primarily attributed to the rising need for efficiency in farming, labor shortages, and increasing awareness about sustainable agricultural practices. Technologies such as IoT (Internet of Things), artificial intelligence, and robotics are being increasingly integrated into agricultural operations to streamline processes, optimize input use, and enhance crop yields.

Latest News and out look

Recent developments in the market reflect the industry's move toward complete digitization and automation:

Internet of Things (IoT): Farmers are adopting IoT-enabled sensors and monitoring systems to track real-time data on soil moisture, nutrient levels, and climate conditions. This not only improves decision-making but also significantly reduces waste.

Autonomous Farm Equipment: Companies are designing unmanned aerial vehicles (UAVs), self-driving tractors, and robotic harvesters to automate labor-intensive processes like planting, spraying, and harvesting.

Artificial Intelligence (AI): AI algorithms are now being used to predict pest infestations, monitor crop health, and manage irrigation, enabling precision agriculture at scale.

Smart Greenhouses and Vertical Farming: With urbanization on the rise, smart greenhouses and controlled environment agriculture are gaining traction, especially in countries facing arable land scarcity.

Startups and Collaborations: Startups focusing on agritech are receiving significant investments. Established companies are collaborating with technology firms to develop innovative, scalable solutions for commercial agriculture.

Sample Link

Market Segmentation

The agriculture automation and control systems market is segmented by type and application.

By Type, the market encompasses several core technologies:

Yield Monitoring: Utilized primarily for mapping field variability and optimizing crop yields, yield monitoring systems are a critical component of precision farming. These systems help farmers collect and analyze crop data in real-time.

Irrigation Management: Automated irrigation systems manage water usage based on weather forecasts and soil moisture levels. This minimizes water waste and boosts crop health.

Field Mapping: Through GPS and sensor-based technologies, field mapping solutions provide detailed data on field conditions, soil types, and nutrient availability.

Weather Tracking and Forecasting: These systems gather meteorological data to help farmers plan their field activities, such as planting and harvesting.

Crop Scouting and Health Monitoring: UAVs and remote sensors help in monitoring plant health and detecting diseases or pests early, allowing for timely interventions.

Farm Labor and Inventory Management: Automation reduces dependence on manual labor, improves scheduling, and streamlines the supply chain from seed to market.

By Application, the market is divided into:

Commercial Farming: This segment dominates the market, accounting for over 70% of the global share. Large-scale operations adopt comprehensive automation systems for end-to-end efficiency.

Personal or Small-Scale Farming: While adoption is slower, small farms are increasingly integrating affordable, scalable solutions like mobile-based farm management apps and low-cost sensors.

Regional Analysis

United States: The U.S. leads in both adoption and innovation of agricultural automation systems. The market is bolstered by strong infrastructure, investment in agritech R&D, and favorable government initiatives such as subsidies for precision farming tools. U.S. farms widely use GPS-guided tractors, smart irrigation systems, and AI-driven crop monitoring. The country accounts for a significant share of the global market and continues to see steady growth supported by technological integration and sustainability goals.

Japan: Japan is emerging as a technological leader in smart farming, especially due to its aging farmer population and limited agricultural labor. The Japanese smart agriculture market is forecast to grow from 15.87 billion JPY in 2019 to 44.28 billion JPY by 2025, reflecting a robust CAGR of 11.8%. Government support, such as equipment subsidies and regulatory frameworks encouraging innovation, is instrumental in driving this growth. Japan is also seeing the adoption of automated tractors, drone-based monitoring systems, and AI for crop management in both open-field and indoor farming systems.

Key Highlights from the Market

AI and Data Analytics are becoming central to automated farming, enabling predictive maintenance of equipment, yield forecasting, and risk mitigation.

Hydroponics and Controlled Environment Agriculture are gaining popularity, especially in urban areas and countries facing land scarcity.

Collaborations and Technological Integration between agricultural equipment manufacturers and tech firms are creating more integrated, user-friendly systems.

Sustainability Initiatives are encouraging the use of automation to reduce water usage, greenhouse gas emissions, and chemical inputs.

Key Players and Competitive Landscape

Several companies are dominating the agriculture automation space with extensive product portfolios and strategic investments. The five major players with the largest market share include:

John Deere – A pioneer in autonomous tractors and precision agriculture solutions. Their focus on smart machinery places them at the top of the market.

AGCO Corporation – Known for brands like Fendt and Massey Ferguson, AGCO is aggressively expanding its automation capabilities through acquisitions and innovations.

Emerson Electric Co. – Offers a range of automation and control solutions tailored for agricultural use, contributing to more efficient farm operations.

Schneider Electric – Focuses on energy-efficient automation and digital transformation, helping farms optimize resource use.

Bonsai Robotics – A rapidly emerging player developing robotic solutions for harvesting and field operations, addressing labor shortages in agriculture.

These players continue to invest in R&D, expand their global footprint, and form strategic alliances to maintain competitive advantage.

Conclusion

The agriculture automation and control systems market is on an upward trajectory, fueled by a combination of necessity and innovation. As challenges like climate change, food security, and labor shortages intensify, the role of automation in agriculture becomes increasingly vital. Countries like the U.S. and Japan are setting benchmarks through their adoption of smart technologies and supportive policies. With robust growth forecasts and active participation from both tech giants and startups, the future of farming is undeniably digital. Embracing automation not only ensures sustainable food production but also opens new avenues for economic and environmental progress in agriculture.

0 notes

Text

WMS and Automation: Transforming Warehouse Operations

In today’s highly competitive and fast-paced business environment, efficiency, accuracy, and speed are no longer optional—they’re essential. For warehouse and logistics managers, the pressure to optimize operations while reducing costs is greater than ever. This is where the integration of Warehouse Management Systems (WMS) and automation technologies comes into play, creating a powerful combination that is revolutionizing warehouse operations across industries.

What is a Warehouse Management System (WMS)?

A Warehouse Management System is a software solution that provides visibility into a company’s inventory and manages supply chain fulfillment operations from the distribution center to the store shelf. A robust WMS optimizes picking, packing, shipping, and inventory management, making warehouse operations more efficient and less prone to human error.

The Role of Automation in Warehousing

Warehouse automation involves the use of technology—including robotics, conveyor systems, barcode scanners, RFID, and AI-powered machines—to automate repetitive tasks within the warehouse. These technologies reduce manual labor, improve accuracy, and speed up overall operations.

How WMS and Automation Work Together

Integrating automation tools with a WMS unlocks the full potential of both systems. Here's how:

1. Optimized Inventory Management

Automated systems continuously update inventory levels in real time through barcode scanning and RFID tracking. When integrated with a WMS, this provides warehouse managers with up-to-the-minute data, enabling smarter stock decisions and reducing the risk of overstocking or stockouts.

2. Faster Order Fulfillment

Automation speeds up the picking and packing process. A WMS can direct automated guided vehicles (AGVs) or robotic arms to specific storage areas, allowing for faster and more accurate order fulfillment with minimal human intervention.

3. Reduced Errors and Increased Accuracy

Manual data entry and handling often lead to errors. Automated systems reduce these risks, and a WMS ensures accurate tracking of every item, from the moment it enters the warehouse until it leaves.

4. Improved Labor Efficiency

With automation handling repetitive and labor-intensive tasks, human workers can focus on more strategic roles. A WMS can assign tasks more intelligently, balancing workloads and improving overall labor productivity.

5. Real-Time Data and Analytics

An automated warehouse equipped with WMS delivers actionable insights through real-time dashboards and reports. This allows managers to make informed decisions, anticipate demand, and continually refine operations.

Benefits of WMS-Driven Automation

Cost savings over time through reduced labor and improved efficiency

Better space utilization via intelligent storage and retrieval systems

Enhanced customer satisfaction due to quicker and more accurate deliveries

Scalability to support future growth without a proportional increase in workforce

The Future of Warehouse Automation

As technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and Machine Learning continue to evolve, warehouses are becoming smarter and more autonomous. Predictive analytics, voice-picking systems, and autonomous mobile robots are no longer concepts of the future—they’re happening now.

Businesses that adopt WMS-integrated automation early are setting themselves up for long-term success, improved ROI, and a competitive edge in an increasingly demanding market.

Conclusion

The combination of Warehouse Management System and automation is not just a technological upgrade—it’s a strategic move that transforms how warehouses operate. By streamlining processes, reducing errors, and enhancing scalability, this powerful duo paves the way for smarter, faster, and more efficient warehouse operations.

0 notes

Text

How Camera Technology is Shaping the Smart Service Robots of Tomorrow

Service robots are no longer just a futuristic concept; they are already transforming industries such as hospitality, healthcare, construction, retail, and even our homes. As these robots evolve to carry out more complex and human-like tasks, embedded camera technology is proving to be one of the most critical enablers in their success.

At Silicon Signals, we explore how embedded vision is reshaping the landscape of service robotics, making machines smarter, safer, and more autonomous than ever before.

What Are Service Robots and Where Are They Used?

According to ISO standards, a service robot is defined as "a robot that performs useful tasks for humans or equipment excluding industrial automation applications." These robots are widely used in non-industrial settings such as:

Hotels and Restaurants

Office Buildings

Hospitals and Clinics

Retail Stores

Construction Sites

Households

Unlike traditional industrial robots, service robots are built to interact with people and perform tasks that require a combination of mobility, perception, and decision-making.

The Role of Embedded Cameras in Smart Decision Making

Embedded cameras act as the eyes of the robot. Whether it's navigating tight spaces or recognizing faces, the intelligence of service robots depends largely on the quality and integration of their camera systems.

Here’s how cameras are enabling smarter robots across various sectors:

1. Hotels and Restaurants

Robots here perform tasks like guiding guests, delivering food, providing information, and enabling telepresence. Cameras help them by:

Using 3D depth cameras for path planning and navigation

Detecting obstacles with 2D vision sensors

Performing optical character recognition (OCR) to read door signs or labels

2. Office Buildings

Service robots in office spaces offer navigation, material delivery, and even social interaction. Embedded vision enables:

Object detection and face recognition

People counting using AI-powered image analysis

Collecting environmental data for reporting

3. Hospitals and Clinics

Medical service robots are now part of everyday operations—from disinfection to delivering medicine. Vision technology helps them by:

Mapping hospital layouts in real-time

Planning routes with SLAM (Simultaneous Localization and Mapping)

Detecting humans or objects in critical zones

4. Retail Stores

Retail robots assist customers, track inventory, and even personalize shopping experiences. Embedded cameras enable them to:

Identify and locate products

Guide shoppers to specific aisles

Avoid collisions in crowded spaces

5. Construction Sites

In rugged and dynamic environments, service robots take on tasks like inspection, maintenance, and material transport. Cameras help with:

Measuring distances to objects and walls

Spotting defects or anomalies

Capturing real-time footage for safety audits

6. Households

From cleaning robots to food-serving assistants, service robots are entering our homes. Embedded vision supports them in:

Avoiding pets or furniture

Performing gardening tasks

Ensuring safety while handling objects

Why Choose Silicon Signals for Camera Integration?

At Silicon Signals, we specialize in integrating robust, reliable, and customized embedded vision solutions for service robots. Our offerings include:

High-Performance Global & Rolling Shutter Cameras for accurate imaging

3D Depth Cameras for precision depth sensing

Low Light & NIR Cameras for performance in dark environments

End-to-End Customization including optics, firmware, interfaces, and form factors

We understand that every robot has a unique use case. That’s why we work closely with our clients to deliver tailored camera solutions that perfectly align with the robot’s application and environment.

Powering the Future of Robotics

As the demand for intelligent service robots increases, embedded vision will be at the forefront of innovation. With expertise in embedded hardware and software design, Silicon Signals is committed to empowering next-gen robotics through custom camera solutions that are efficient, scalable, and future-ready.

If you're building the next groundbreaking service robot and need help with camera integration, reach out to our experts at [email protected].

Let’s create a smarter future, together.

#embeddedtechnology#embeddedsoftware#embeddedsystems#linuxdebugging#cameradesign#camera#embeddedcamerasystems#cctv

0 notes

Text

Driving the Future: How Automated Guided Vehicles Are Powering Warehouse Automation

In the world of logistics and supply chain management, speed, precision, and adaptability are everything. As customer expectations grow and same-day delivery becomes the norm, businesses are under constant pressure to move goods faster, more efficiently, and with fewer errors. One of the standout technologies stepping up to meet this demand is the automated guided vehicle (AGV). These intelligent, self-navigating machines are reshaping the future of warehouse automation, bringing in a new era of smart logistics.

What Is an Automated Guided Vehicle?

An automated guided vehicle is a mobile robot that follows predefined paths or navigates using advanced sensors and software to transport materials within a facility. They are typically used in warehouses, manufacturing plants, and distribution centers to move pallets, racks, or carts with minimal human intervention.

Unlike traditional forklifts or conveyor systems, AGVs can operate autonomously, making them ideal for repetitive, time-sensitive, and high-volume tasks. They come in various forms—tugger AGVs, unit load carriers, pallet trucks, and even customized bots tailored for specific industries.

The Rise of Warehouse Automation

Warehouse automation is no longer a futuristic concept, it’s happening right now. Businesses across the globe are investing in technologies that minimize manual labor, reduce errors, and optimize space. Automation helps reduce operational costs while maximizing output and ensuring consistent performance.

From automated storage and retrieval systems (ASRS) to robotic picking arms, the landscape of warehousing is transforming rapidly. But among all the technologies, the automated guided vehicle stands out for its flexibility, scalability, and cost-effectiveness.

Why AGVs Are a Game-Changer in Warehouse Automation

1. Labor Optimization

One of the most significant benefits of using automated guided vehicles is the reduction in dependency on manual labor. With increasing labor shortages and rising wages, AGVs offer a long-term solution to manpower constraints. They can work 24/7, don’t require breaks, and can be reprogrammed as operational needs change.

This allows human workers to focus on more complex, decision-based tasks, like inventory analysis, customer support, and quality control, while AGVs take care of the heavy lifting, literally and figuratively.

2. Enhanced Safety and Accuracy

Warehouses can be hazardous places, especially when there’s a high volume of forklifts and human operators working simultaneously. AGVs reduce the risk of workplace injuries by following strict safety protocols and moving along controlled paths.

Thanks to advanced sensors and real-time navigation systems, these machines can detect obstacles, avoid collisions, and stop immediately if something unexpected appears in their path. This makes them a safer and more accurate alternative in the automation journey.

3. Scalability and Flexibility

One of the biggest advantages of warehouse automation using AGVs is scalability. Whether you're operating a small facility or a sprawling distribution center, AGV fleets can grow with your business. You can start small, test their performance, and gradually expand the system as your operations scale.

Additionally, AGVs can be reprogrammed to adapt to layout changes, new workflows, or seasonal demands, giving businesses more flexibility than fixed conveyors or static systems.

4. Cost Efficiency in the Long Run

While the upfront cost of investing in an automated guided vehicle may seem high, the long-term ROI makes it worthwhile. Reduced labor costs, fewer workplace accidents, improved order accuracy, and minimized downtime all contribute to lower operational expenses.

AGVs also help extend the life of your warehouse infrastructure by reducing wear and tear on floors, shelves, and racking systems due to their precision movements and consistent handling.

5. Real-Time Data and Integration

Modern AGVs don’t just move materials, they also collect valuable data in real time. When integrated with warehouse management systems (WMS), AGVs can help track inventory, monitor productivity, and provide insights that inform business decisions.

This data-driven approach helps identify bottlenecks, predict maintenance needs, and ensure optimal performance across the entire warehouse automation ecosystem.

Industry Applications of AGVs

AGVs are used across a variety of industries, including:

E-commerce and Retail: To handle high order volumes and reduce picking times.

Pharmaceuticals: For precise and sterile material handling.

Automotive: To move heavy parts and components across the production floor.

Food and Beverage: For transporting items in temperature-controlled environments.

No matter the industry, the role of the automated guided vehicle is the same: improve efficiency, reduce costs, and support consistent, high-volume operations.

Are AGVs Right for Every Warehouse?

While an automated guided vehicle offers a wealth of benefits, they’re not a one-size-fits-all solution. Businesses need to assess their current layout, workflows, and automation goals. AGVs work best in facilities with predictable routes, consistent volumes, and clearly defined tasks.

However, as technology continues to evolve, new generations of AGVs with better navigation, faster speeds, and adaptive AI are making them more viable for even complex and dynamic environments.

As the demand for faster, more efficient logistics grows, warehouse automation is becoming not just a competitive edge, but a necessity. Automated guided vehicles represent one of the most impactful and accessible technologies in this space. They offer a perfect blend of precision, scalability, and cost savings that businesses of all sizes can benefit from.

If you're looking to modernize your operations, reduce manual workload, and future-proof your supply chain, investing in AGVs is a strategic move that pays dividends now and in the years to come.

0 notes

Text

Autonomous Mobile Robots Market: Driving Automation and Efficiency Across Multiple Industries Worldwide

The Autonomous Mobile Robots market is experiencing significant growth driven by several technological advancements and societal shifts. These robots, capable of performing tasks with minimal human intervention, are transforming industries such as logistics, manufacturing, healthcare, and agriculture. The market is poised to expand due to a combination of factors that include cost reduction, increased demand for automation, and advancements in artificial intelligence (AI) and sensor technologies. Below are the primary drivers of the Autonomous Mobile Robots market.

1. Rising Demand for Automation in Industrial Applications

One of the most prominent factors driving the growth of the AMR market is the growing demand for automation across industries. Automation in sectors like manufacturing, logistics, and warehousing helps improve productivity, reduce human error, and lower operational costs. Autonomous robots are particularly useful in environments where repetitive tasks are common, such as in sorting, packing, inventory management, and material handling. These robots can work 24/7 without breaks, thereby boosting operational efficiency and throughput. As companies seek to optimize their operations and stay competitive, they are increasingly adopting AMRs.

2. Cost Efficiency and Operational Savings

AMRs help businesses reduce labor costs, particularly in industries where labor shortages or high turnover rates exist. While the initial investment in AMRs can be high, the long-term savings outweigh the costs. AMRs can perform tasks faster and more efficiently than human workers, leading to a reduction in overtime pay, accidents, and operational delays. Additionally, the cost of manufacturing AMRs has been steadily declining due to advancements in technology and mass production, making them more accessible to small and medium-sized enterprises (SMEs). This affordability has contributed significantly to the adoption of AMRs across different industries.

3. Technological Advancements in Robotics and AI

The development of AI and machine learning technologies has significantly enhanced the capabilities of autonomous robots. AI algorithms allow robots to make decisions in real-time, optimize routes, and adapt to new environments. Machine learning enables AMRs to continuously improve their performance by learning from their experiences. Additionally, advancements in sensors, such as LiDAR (Light Detection and Ranging), cameras, and ultrasonic sensors, have improved the navigation and obstacle avoidance capabilities of AMRs, allowing them to work safely alongside humans in dynamic environments.

4. E-commerce and Retail Growth

The rapid expansion of e-commerce has led to an increased need for automation in warehouses and distribution centers. E-commerce companies, which need to manage a vast number of orders and maintain high service levels, are turning to AMRs for inventory management, order fulfillment, and last-mile delivery. AMRs enable these companies to meet the demand for faster delivery times and improve their overall supply chain efficiency. Retailers are also exploring autonomous robots for shelf scanning, restocking, and customer service, further driving the demand for AMRs in the retail sector.

5. Labor Shortages and Safety Concerns

Labor shortages, especially in sectors like manufacturing, logistics, and healthcare, are becoming a significant issue. Autonomous robots help fill this gap by performing tasks that would traditionally require human labor. This is particularly beneficial in industries experiencing high turnover rates or those in remote areas where labor is scarce. Additionally, AMRs improve safety by handling hazardous tasks in environments that may pose risks to human workers, such as lifting heavy objects, working in extreme conditions, or operating in high-risk environments like factories and warehouses.

6. Increased Focus on Supply Chain Optimization

Supply chain management is undergoing significant changes, and businesses are increasingly looking for ways to optimize their supply chains. AMRs play a key role in improving supply chain efficiency by automating tasks such as inventory tracking, sorting, and material handling. These robots can reduce the time it takes to move goods through a warehouse or distribution center, enhance stock visibility, and reduce the likelihood of inventory errors. As the global supply chain becomes more complex, companies are investing in AMRs to create more resilient and flexible systems.

7. Government Initiatives and Industry Regulations

Governments around the world are encouraging the development and deployment of AMRs through various initiatives, research funding, and industry regulations. The regulatory landscape is evolving to support the safe and effective use of autonomous robots in commercial settings. Policies that incentivize technological innovation and the adoption of automation technologies are propelling the market forward. Moreover, regulatory bodies are establishing safety standards to ensure that AMRs work in compliance with local laws, which enhances their adoption by enterprises looking for reliable and compliant automation solutions.

8. Global Expansion of Logistics and Freight Solutions

With the rise of global trade and international shipping, logistics companies are under pressure to improve efficiency and reduce delivery times. AMRs are increasingly being utilized in logistics centers to move goods efficiently, enabling faster sorting and distribution. Furthermore, AMRs are being employed in autonomous delivery systems, such as drones or ground-based robots, to optimize last-mile delivery. This trend is expected to grow as e-commerce giants continue to invest in autonomous solutions to meet the demands of their customers.

Conclusion

The Autonomous Mobile Robots market is poised for substantial growth driven by factors such as the rising demand for automation, cost efficiency, technological advancements, labor shortages, and a growing focus on supply chain optimization. As industries continue to embrace automation, AMRs are expected to play a central role in improving operational efficiency, safety, and productivity across a wide range of sectors. As technology evolves and the cost of adoption decreases, more businesses are likely to turn to AMRs to meet their automation needs.

0 notes

Text

Personal Mobility Devices Market Witnesses Innovation Boost from AI Integration and Sustainability Trends

The Personal Mobility Devices (PMDs) market has witnessed significant growth in recent years, driven by increasing awareness of mobility challenges, an aging population, and advances in assistive technologies. These devices—which include wheelchairs, mobility scooters, walkers, and canes—play a crucial role in enhancing the independence and quality of life for individuals with mobility impairments.

As global demographics shift, the demand for PMDs continues to grow. According to the World Health Organization (WHO), by 2050, one in six people in the world will be over the age of 65. This demographic change, particularly in developed nations, is one of the most influential factors boosting the PMDs market. Older adults are more likely to experience mobility limitations, necessitating the use of supportive equipment.

Technological innovation has been a major catalyst in reshaping the landscape of PMDs. Manufacturers are increasingly integrating smart features such as GPS tracking, automatic braking systems, foldable designs, and IoT-enabled diagnostics. These enhancements not only improve user safety but also attract a younger demographic of users recovering from injuries or managing chronic conditions.

In terms of product types, the market is broadly categorized into wheelchairs (manual and powered), mobility scooters, canes, crutches, and walkers. Among these, powered wheelchairs and scooters are gaining traction due to their ease of use and improved maneuverability. Meanwhile, traditional devices like walkers and canes remain essential for their affordability and simplicity.

The geographical spread of the PMDs market varies significantly. North America and Europe dominate due to well-established healthcare systems, government support, and high levels of public awareness. The United States, in particular, has seen a surge in demand due to the implementation of Medicare policies that cover many assistive devices. Europe’s aging population, especially in countries like Germany and Italy, also supports continued market expansion.

However, the Asia-Pacific region is emerging as the fastest-growing market, propelled by rising healthcare expenditure, improving infrastructure, and growing elderly populations in countries like Japan, China, and South Korea. Japan leads the way in terms of innovation and adoption, with a strong focus on robotics and autonomous mobility aids.

While the market offers promising opportunities, it also faces several challenges. High costs of advanced PMDs and limited reimbursement options in some countries can restrict access for lower-income individuals. Furthermore, the lack of standardized safety regulations across regions poses a risk to both users and manufacturers. Addressing these challenges requires collaboration between governments, healthcare providers, and manufacturers to develop inclusive policies and improve device affordability.

COVID-19 also impacted the PMDs market. Initially, there was a slowdown due to supply chain disruptions and limited access to healthcare services. However, the pandemic highlighted the importance of mobility and independence for vulnerable populations, ultimately renewing interest and investment in personal mobility technologies.

Looking ahead, the PMDs market is expected to continue expanding, driven by both demand-side and supply-side factors. From a demand perspective, increased life expectancy, prevalence of disabilities, and rising lifestyle-related conditions such as obesity and arthritis contribute to the growing need for mobility aids. From the supply side, advances in materials, electronics, and AI integration are opening new possibilities for personalization, automation, and comfort.

Sustainability is also becoming an important consideration in the design and production of PMDs. Companies are exploring eco-friendly materials and energy-efficient systems, especially for powered devices. Modular and recyclable components are being integrated to reduce environmental impact, aligning with global sustainability goals.

In conclusion, the Personal Mobility Devices market is evolving rapidly, fueled by demographic trends, technological innovation, and shifting consumer needs. With the right combination of affordability, accessibility, and innovation, PMDs can continue to transform the lives of millions of individuals around the world. As stakeholders work to overcome existing challenges, the market is well-positioned for sustained and inclusive growth.

0 notes

Text

Revolutionizing E-Commerce Logistics: How Amazon's Warehousing Innovations Are Shaping India's Future

Amazon's expansion in India has been nothing short of transformative, particularly in the realm of warehousing and logistics. With over 60 fulfillment centers across 15 states, Amazon has established a robust infrastructure that supports millions of sellers and caters to a vast customer base. This strategic network not only enhances delivery speeds but also creates significant employment opportunities, contributing to the local economy.

The Scale of Amazon's Fulfillment Network in India

Amazon's fulfillment centers (FCs) are the backbone of its operations in India. These state-of-the-art facilities are strategically located to ensure efficient storage and quick dispatch of products. For instance, the launch of a new FC in Gurugram, Haryana, added close to 2 million cubic feet of storage space, specializing in large appliances and furniture. This expansion increased Amazon's storage capacity in Haryana by more than 35%, benefiting over 45,000 sellers and creating numerous local jobs .

Similarly, Amazon's recent launch of three new FCs in Delhi NCR, Guwahati, and Patna, with a combined storage space of over 1.2 million cubic feet, underscores the company's commitment to enhancing its logistics network ahead of peak seasons like the Great Indian Festival .

Technological Advancements in Warehousing

Amazon's investment in technology is evident in its warehousing operations. The integration of robotics and automation has streamlined processes, reducing human error and increasing efficiency. The introduction of autonomous mobile robots (AMRs) like Proteus has further optimized the picking and sorting processes, enabling faster order fulfillment and improved safety for workers .

Addressing Challenges and Ensuring Compliance

While Amazon warehousing operations have been largely successful, they have not been without challenges. In March 2025, Indian authorities conducted raids on Amazon and Flipkart warehouses in Delhi, seizing products that lacked the necessary quality control certifications. This incident highlights the importance of adhering to local regulations and maintaining product quality standards .

Additionally, labor practices in Amazon's warehouses have come under scrutiny. Reports of harsh working conditions during heatwaves and demands for better wages have led to protests by workers in India. These concerns emphasize the need for companies to prioritize the well-being of their employees and ensure fair labor practices .

The Role of RGX Group in Enhancing Warehousing Solutions

In the evolving landscape of e-commerce logistics, companies like RGX Group play a pivotal role in providing innovative warehousing solutions. RGX Group's expertise in supply chain management and warehousing infrastructure supports businesses in optimizing their operations, ensuring timely deliveries, and maintaining high-quality standards. By partnering with RGX Group, companies can enhance their warehousing capabilities, contributing to the overall efficiency of the e-commerce ecosystem.

0 notes

Text

Can HDI PCBs Keep Up with AI Hardware Demands?

As the artificial intelligence (AI) revolution gains momentum, the need for smarter, faster, and more efficient hardware is at an all-time high. At the core of this evolution is the printed circuit board (PCB) — the silent workhorse behind every intelligent machine. Specifically, the HDI Printed Circuit Board (High-Density Interconnect PCB) is stepping into the spotlight, offering the compactness, speed, and capability modern AI systems require.

But with increasing complexity and power in AI algorithms, can HDI PCBs keep up with the pace of innovation? At Pcb-Togo Electronic, Inc., we specialize in crafting high-performance HDI Printed Circuit Board solutions designed to meet and exceed the ever-growing expectations of AI-driven hardware. In this post, we’ll explore how HDI PCBs are rising to the challenge and why they’re becoming indispensable in today’s AI landscape.

What Are HDI PCBs and Why Do They Matter?

HDI Printed Circuit Boards differ from traditional PCBs in both structure and capability. They utilize microvias, blind/buried vias, and high-density routing to accommodate more components in less space. This compact architecture reduces signal travel distance, minimizes losses, and allows for faster processing — all crucial elements for AI systems that operate at blistering speeds and demand impeccable accuracy.

The typical AI processor, whether in a data center or an autonomous vehicle, needs a reliable, dense interconnect system to maintain performance. HDI PCBs deliver that reliability in a smaller, lighter, and more efficient footprint.

Why AI Hardware Demands Are Escalating

AI workloads — from machine learning inference to real-time edge processing — require lightning-fast communication between components, robust data throughput, and efficient thermal handling. As AI systems become more embedded in mobile devices, wearables, and compact robotics, the pressure mounts on hardware designers to shrink board sizes without sacrificing performance.

These demands translate directly into challenges that the HDI Printed Circuit Board must solve:

Higher signal integrity

Greater heat dissipation

Denser component placement

Multi-layer interconnectivity

Reduced electromagnetic interference (EMI)

Traditional PCBs simply can’t keep up. HDI PCBs, on the other hand, are uniquely suited for the job — if designed and manufactured correctly.

How HDI PCBs Meet AI Hardware Needs

Let’s break down how HDI PCBs directly address the performance gaps AI hardware faces:

Miniaturization Without Compromise

AI-enabled devices are getting smaller. Smartphones, smartwatches, and drones are powerful yet compact. HDI PCBs offer multiple layers and stacked vias, enabling high functionality in limited space.

Signal Integrity

AI processors often run at high frequencies. HDI PCBs reduce signal path lengths and crosstalk, enhancing the signal integrity necessary for high-speed processing.

Thermal Management

Advanced AI chips generate a lot of heat. HDI PCBs incorporate thermal vias and advanced materials that effectively disperse heat, ensuring components don’t overheat or fail.

High-Speed Interconnects

With fine pitch components and narrow trace widths, HDI Printed Circuit Boards enable faster communication between AI subsystems — a must for tasks like neural network inference.

Increased Layer Count

Many AI applications require multilayer designs. HDI technology allows designers to stack more functionality into a compact footprint, which would be impossible with conventional PCBs.

Challenges and Considerations

Despite their advantages, HDI PCBs do come with engineering and production challenges. These include:

Higher manufacturing costs due to advanced fabrication methods

Complex design rules for impedance control and signal routing

Material selection issues, especially in high-temperature environments

However, the return on investment is clear for high-performance applications. At Pcb-Togo Electronic, Inc., our team collaborates closely with engineers to create optimized HDI PCB layouts that align with AI performance goals while staying within budget.

What's Next for HDI PCBs in AI?

The future of AI involves even more intensive computing — think quantum-inspired AI processors, real-time 3D object recognition, and edge inference with cloud synchronization. HDI Printed Circuit Boards will need to evolve as well, integrating embedded passive components, leveraging new materials like liquid crystal polymer (LCP), and incorporating optical interconnects.

Our R&D team at Pcb-Togo Electronic, Inc. is actively engaged in developing next-generation HDI solutions tailored for tomorrow’s AI. Whether you’re designing for a new wearable AI assistant or a smart factory sensor array, we’re ready to help you bring your innovation to life.

Why Choose Pcb-Togo Electronic, Inc.?

We don’t just build HDI PCBs — we engineer them for the future. With decades of expertise in PCB manufacturing and a deep understanding of AI hardware demands, we offer:

Precision fabrication of 4+ layer HDI boards

Advanced testing for signal and thermal performance

Fast turnaround and prototyping

Customized consultation from schematic to production

Final Thoughts

Can HDI PCBs keep up with AI hardware demands? Absolutely — if they’re built by a partner who understands both the challenges and opportunities ahead. The evolution of AI is not slowing down, and neither should your hardware. HDI Printed Circuit Boards, when engineered with foresight and precision, are not only keeping pace — they’re leading the charge.

To discover how our HDI PCB solutions can elevate your next AI project, Find Out More about our capabilities.

By partnering with Pcb-Togo Electronic, Inc., you ensure that your AI hardware infrastructure is as advanced, efficient, and reliable as the algorithms it supports. Let's build smarter systems together — starting from the circuit board up.

Original Link: https://pcbtogo.blogspot.com/2025/05/can-hdi-pcbs-keep-up-with-ai-hardware.html

0 notes

Text

The Future of Material Handling: Game-Changing Innovations Enhancing Industrial Efficiency

Material handling is rapidly evolving with the advent of smarter, safer, and more efficient technologies. As industries push the boundaries of productivity and sustainability, advanced solutions are redefining traditional methods. At the heart of this transformation is LeisterTech, an industry leader in innovative material handling systems. Their cutting-edge tools—ranging from lifting magnets to automated scrap transfer trolleys—are streamlining operations across manufacturing, construction, steel, and automotive sectors.

Smarter Lifting Solutions: The Rise of Electromagnetic Handling

Heavy industries rely heavily on safe and precise lifting equipment to handle metal sheets, billets, and scrap materials. LeisterTech’s lifting magnets offer a smarter, more efficient alternative to traditional lifting methods.

Key Features:

Enhanced Safety: Built-in sensors monitor load capacity and magnetic force to prevent accidents.

Energy Efficiency: Designed to deliver maximum lifting power with minimal energy consumption.

Automation-Ready: IoT-enabled systems allow remote control and real-time monitoring, reducing manual intervention and increasing throughput.

Whether for steel production or construction logistics, lifting magnets ensure operational continuity with enhanced precision and safety.

Scrap Handling Reimagined: Automation in Motion

Efficient scrap management is vital for reducing operational waste and promoting sustainability. LeisterTech’s scrap transfer trolleys are engineered to handle high volumes in the most demanding environments.

Highlights:

Speed & Precision: Smart trolleys equipped with automation technologies facilitate rapid and accurate scrap transport.

Industrial Durability: Constructed with rugged materials to ensure long-term performance.

Seamless Integration: Smart connectivity allows these trolleys to sync with other systems for streamlined workflows.

By incorporating these systems, facilities can dramatically reduce downtime and improve scrap recycling rates.

Unlocking Benefits Across the Board

1. Productivity Gains: Automated systems reduce cycle times, improve accuracy, and maintain continuous operation, even under heavy loads.

2. Safety Enhancements: From lifting magnets to stationary cranes, smart technology helps minimize human exposure to dangerous tasks. LeisterTech’s stationary cranes are another prime example of their commitment to worker safety and operational reliability.

3. Lower Operating Costs: Efficient energy use and less mechanical wear help reduce both energy bills and maintenance expenses.

4. Sustainability Impact: Smart material handling reduces scrap waste and supports closed-loop production processes—key components of modern sustainability strategies.

Technology at the Core of Transformation

IoT & Connectivity: Real-time tracking, performance monitoring, and predictive maintenance are now standard in next-gen material handling solutions.

AI-Driven Automation: AI algorithms optimize load distribution, navigation routes, and material flow, setting the stage for intelligent, self-optimizing facilities.

Sustainable Engineering: Eco-conscious designs in products like lifting magnets and electric trolleys contribute to energy conservation and lower emissions.

Real-World Applications Across Industries

https://leistertech.com/wp-content/uploads/2025/04/Applications-in-Modern-Manufacturing-1.png

Steel Manufacturing: Rapid billet and plate handling eliminates bottlenecks in processing lines.

Foundries: Heat-resistant equipment ensures safe and accurate movement of molten and solid materials.

Construction & Automotive: Precision handling tools aid in efficient material assembly, enhancing build quality and turnaround time.

Looking Ahead: Trends Shaping the Future

Autonomous Vehicles & Drones: Expect to see more mobile robots and aerial systems replacing human-led transport in confined industrial spaces.

Full Industry 4.0 Integration: The future lies in fully connected smart factories, where machinery communicates autonomously to manage workflows.

Eco-Innovations: Renewable-powered handling systems and recyclable components are set to become standard in environmentally responsible manufacturing.

Conclusion: Pioneering the Future of Industrial Handling

From intelligent lifting magnets to robust scrap transfer systems and reliable stationary cranes, LeisterTech is revolutionizing how industries approach material handling. Their innovative, tech-driven solutions enhance safety, boost productivity, and align perfectly with the global shift toward sustainable, automated manufacturing. For industries looking to future-proof their operations, LeisterTech provides the tools to make it happen.

0 notes