#chlor alkali process

Text

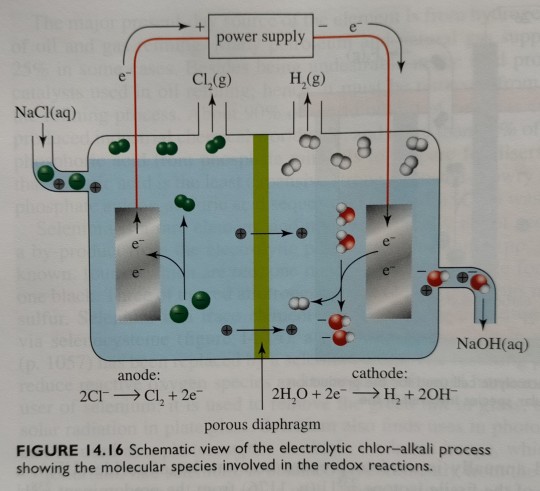

This is carried out on an industrial scale using the chlor-alkali process, which is shown schematically in figure 14.16.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#chlor alkali process#chlorine#redox#reduction#oxidation#schematic

1 note

·

View note

Text

Sodium Hypochlorite Prices Trend, Pricing, Database, Index, News, Chart, Forecast

Sodium Hypochlorite Prices a widely used chemical compound with significant applications in water treatment, disinfection, and bleaching, has experienced fluctuating prices influenced by various factors. The market for sodium hypochlorite, commonly known as bleach, is primarily driven by demand from the municipal water treatment sector, the healthcare industry, and household cleaning products. Over the years, the price dynamics of sodium hypochlorite have been affected by raw material costs, production processes, regulatory changes, and global economic conditions.

The production of sodium hypochlorite typically involves the reaction of chlorine with sodium hydroxide, both of which are derived from salt through the chlor-alkali process. Therefore, any changes in the prices of these raw materials directly impact the cost of producing sodium hypochlorite. For instance, fluctuations in the price of chlorine and caustic soda can lead to corresponding changes in sodium hypochlorite prices. Additionally, energy costs play a significant role, as the chlor-alkali process is energy-intensive. As energy prices rise, so too does the cost of production, ultimately affecting market prices.

In recent years, regulatory changes aimed at reducing environmental impact and improving safety standards have also influenced sodium hypochlorite prices. Stricter regulations often necessitate the adoption of advanced technologies and more robust safety measures, which can increase production costs. These additional costs are typically passed on to consumers in the form of higher prices. Moreover, regulatory requirements can vary by region, leading to price disparities in different parts of the world.

Get Real Time Prices of Sodium Hypochlorite: https://www.chemanalyst.com/Pricing-data/sodium-hypochlorite-1560

The global economic environment significantly impacts sodium hypochlorite prices. Economic downturns, such as the recession caused by the COVID-19 pandemic, can lead to reduced industrial activity and lower demand for sodium hypochlorite. Conversely, economic recovery and industrial growth spur increased demand, driving prices higher. During the COVID-19 pandemic, the demand for sodium hypochlorite surged due to its essential role in disinfection and sanitization. This increased demand led to a temporary spike in prices, as manufacturers struggled to keep up with the sudden surge.

Supply chain disruptions have also played a role in shaping sodium hypochlorite prices. Natural disasters, geopolitical tensions, and logistical challenges can interrupt the supply of raw materials and finished products. For example, hurricanes in key production regions can damage infrastructure and halt production, leading to shortages and price hikes. Similarly, geopolitical issues can affect the availability of chlorine and caustic soda, further influencing sodium hypochlorite prices.

The market structure and competitive landscape of the sodium hypochlorite industry also affect prices. The presence of numerous small and large manufacturers leads to varying pricing strategies and market competition. Large manufacturers with significant production capacities can often leverage economies of scale to offer competitive prices. In contrast, smaller manufacturers might face higher production costs, leading to higher prices. Additionally, market consolidation and mergers and acquisitions can alter the competitive dynamics, potentially impacting prices.

Technological advancements in the production process can lead to cost efficiencies and affect sodium hypochlorite prices. Innovations that improve yield, reduce energy consumption, or enhance safety can lower production costs, which may be reflected in market prices. For example, improvements in membrane cell technology in the chlor-alkali process have contributed to more efficient and environmentally friendly production, potentially stabilizing prices.

Seasonal variations can also influence sodium hypochlorite prices. For instance, the demand for sodium hypochlorite typically increases during the summer months when water usage is higher, leading to greater demand for water treatment chemicals. This seasonal demand can create temporary price fluctuations. Furthermore, the agricultural sector's demand for sodium hypochlorite for crop protection and irrigation purposes can vary seasonally, adding another layer of complexity to pricing dynamics.

In conclusion, the prices of sodium hypochlorite are shaped by a multitude of factors, including raw material costs, regulatory changes, global economic conditions, supply chain disruptions, market competition, technological advancements, and seasonal variations. Understanding these factors is crucial for stakeholders in the sodium hypochlorite market, including manufacturers, distributors, and consumers, as they navigate the complexities of pricing and ensure a steady supply of this essential chemical compound. As the market continues to evolve, staying informed about these influencing factors will be key to anticipating and managing price changes in the sodium hypochlorite industry.

Get Real Time Prices of Sodium Hypochlorite: https://www.chemanalyst.com/Pricing-data/sodium-hypochlorite-1560

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

liquid chlorine Prices Trend, Monitor, News & Forecast | ChemAnalyst

Liquid chlorine prices have experienced fluctuations influenced by various factors, including global market dynamics, industrial demand, and production costs. Understanding these price movements requires a comprehensive analysis of supply and demand dynamics, regulatory changes, and macroeconomic indicators.

The pricing of liquid chlorine is significantly impacted by the balance between supply and demand within the chemical and water treatment industries. Liquid chlorine, a chemical compound widely used for water disinfection, bleaching, and chemical synthesis, finds applications across diverse sectors. Disruptions in the supply chain, such as fluctuations in chlorine gas availability, manufacturing capacity, or transportation logistics, can affect the availability and cost of liquid chlorine, thereby influencing its market price.

Industrial demand plays a pivotal role in determining liquid chlorine prices. Industries such as water treatment, pulp and paper manufacturing, and chemical synthesis rely heavily on liquid chlorine for its disinfection and bleaching properties. Fluctuations in demand from these sectors, influenced by factors such as seasonal variations, regulatory requirements, and economic conditions, can lead to price volatility for liquid chlorine.

Get Real-Time liquid chlorine Prices : https://www.chemanalyst.com/Pricing-data/liquid-chlorine-45

Raw material costs significantly influence liquid chlorine prices. The price of raw materials such as salt and electricity, which are used in chlorine production via the chlor-alkali process, can fluctuate due to changes in global supply and demand dynamics, energy costs, and mining conditions. Any significant increase in raw material costs can translate into higher production costs for liquid chlorine manufacturers, thereby exerting upward pressure on prices.

Macroeconomic indicators, such as GDP growth, industrial output, and infrastructure investments, can indirectly impact liquid chlorine prices by affecting overall industrial activity and demand for water treatment and bleaching products. Economic downturns or slowdowns in major manufacturing regions may lead to decreased demand and downward pressure on prices. Conversely, robust economic growth and increased infrastructure spending can support higher prices for liquid chlorine by stimulating demand for water treatment chemicals.

Regulatory changes and quality standards also play a role in shaping liquid chlorine prices. Government regulations on water quality standards, environmental protection, and chemical safety can impact production costs and market access for liquid chlorine manufacturers. Compliance with these regulations may require investments in technology and process improvements, which could influence pricing dynamics.

Looking ahead, several factors are expected to continue influencing liquid chlorine prices. Continued growth in sectors such as water treatment, pulp and paper manufacturing, and chemical synthesis, coupled with increasing demand for disinfection and bleaching products, is likely to drive sustained demand for liquid chlorine. Moreover, advancements in manufacturing technologies and the development of new applications could lead to changes in market dynamics and price levels for liquid chlorine.

In conclusion, liquid chlorine prices are subject to a complex interplay of factors including supply and demand dynamics, industrial trends, raw material costs, regulatory changes, and macroeconomic indicators. Stakeholders in the chemical, water treatment, and manufacturing industries must closely monitor these factors to anticipate price movements and make informed decisions. As industries evolve and consumer preferences change, navigating the dynamic landscape of liquid chlorine pricing will remain a key challenge for industry participants.

Get Real-Time liquid chlorine Prices : https://www.chemanalyst.com/Pricing-data/liquid-chlorine-45

ChemAnalyst

GmbH — S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49–221–6505–8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Qingdao Tianya Chemical Co., Ltd

Qingdao Tianya Chemical Co., Ltd is the leading Sodium Metabisulfite China manufacturer and supplier, we produce and supply excellent quality China Sodium Metabisulfite products, our Sodium Metabisulfite products includes Sodium Metabisulfite Food Grade and Sodium Metabisulfite Industrial Grade (Technical Grade), and we also produce other a range of water treatment chemicals, including Sodium Bicarbonate, Polyaluminium Chloride (PAC) and Caustic Soda (Sodium Hydroxide), etc.. Our factory is located in Weifang of China, China’s biggest sea salt, soda ash, bromine, and refinery bases, and Asia’s biggest chlor-alkali base, which owns comprehensive chemical product production chain. Tianya Chemical owns an independent product R&D team, provides technical support for the company products development, which maintains the latest product production processes, and keep the company at the leading position of the industry.

Relying on advanced production equipment and processes, a sound management system, and unique geographical advantages, our products own quality and production capacity advantages. Until now, the annual production capacity of Sodium Metabisulfite reaches 300,000 tons, Sodium Bicarbonate with annual production capacity of 240,000 tons, Polyaluminium Chloride (PAC) with annual production capacity of 300,000 tons, and Caustic Soda (Sodium Hydroxide) with annual production capacity of 240,000 tons. The application fileds of our products cover water treatment, food industry, mining, garment, paper making industry, etc.. The products are supplied to domestic and international markets with large quantity. We have complete qualifications, ISO, Halal, Kosher, and food production licensing, etc.. The products are exported to over 100 countries and areas.

As the leading manufacturer of Sodium Metabisulfite and other water treatment chemicals in China, Tianya Chemical keeps supplying excellent quality products and satisfactory service to customers, we are willing to witness common success with our clients.

-"Sodium Metabisulfite China manufacturer"

1 note

·

View note

Text

Sodium Hydroxide Market Forecast 2024 to 2032

Sodium hydroxide, commonly known as caustic soda or lye, is a strong and highly caustic compound with the chemical formula NaOH. It is an inorganic base and alkali that is widely used in various industrial, commercial, and laboratory applications. Sodium hydroxide is produced through the chemical reaction of sodium carbonate (soda ash) with calcium hydroxide (slaked lime) or through the electrolysis of sodium chloride (table salt) in a process called the chlor-alkali process.

The Sodium Hydroxide Market was valued at USD 34.36 Billion in 2022 and is expected to register a CAGR of 5.1% by 2032.

Sodium hydroxide is a fundamental chemical used in the production of a wide range of products, including detergents, soaps, textiles, plastics, and various chemical compounds. The growth of these industries drives the demand for sodium hydroxide as a key raw material.

Get PDF Sample Report: https://www.xcellentinsights.com/enquiry/sample/501192

Key companies:

• BASF SE

• Dow Chemical Company

• Shin-Etsu Chemical Co Ltd

• Westlake Chemical Corporation

• Tosoh Corporation

• FMC Corporation

• Olin Corporation

• Formosa Plastics Corporation

• Covestro AG

• Solvay S.A.

• Gujarat Alkalies and Chemicals Limited

• Occidental Petrochemical Corporation

• Tata Chemicals Ltd.

• Xinjiang Zhongtai Chemical Co. Ltd.

• Vynova Group

• Other Prominent Players

Sodium Hydroxide Market Segments

• By Product Type

o Flakes

o Caustic Lye

• By Application

o Cleaning Agent

o Catalyst

o Additive

• By End Use

o Pulp and Paper

o Personal Care

o Pharmaceutical

o Textile

o Food & Beverages Industry

o Oil & Gas Industry

o Aluminum

Get Full report + Tables + Graphs: https://www.xcellentinsights.com/reports/sodium-hydroxide-market-501192

About Us:

Xcellent Insights is a market intelligence provider and consulting firm. We offer data-driven research services based on multiple analysis frameworks which helps businesses across the globe to understand current market scenario and align their strategic initiatives.

We offer syndicated research reports, customized research reports, consulting services and datasets which are mapped across multiple datapoints.

We provide research reports for all the industry sectors like Consumer Goods, Packaging, Chemicals and Materials, Healthcare, Pharmaceuticals, Medical Devices, Agriculture, Food and Beverages, Automobile and transportation, Electronics and Semiconductors, IT and Communication, Energy and Power, Machinery and Equipment.

Contact Us:

Name: Willie J

Phone: US: +1 4086277717

UK: +44 2086386439

Email: [email protected]

0 notes

Text

Brazil’s chlor-alkali producers target green hydrogen

Chlor-alkali producers in Brazil are hoping to tap into the expected growing demand for renewable hydrogen, according to industry association Abiclor.

Abiclor has included the prospects for renewable hydrogen in its strategic roadmap to 2035.

Hydrogen is a by-product of chlorine alkali production and, while for much of the world using a electrolyser to obtain hydrogen is a novel concept, "our industry has been producing hydrogen through electrolysis for 50 years," Abiclor president Milton Rego told Argus.

The Brazilian chlor-alkali sector currently produces 40,000 t/yr of hydrogen from 3.2mn t/yr of chlor-alkali output — some of which is used by the companies for their own processes, while some is sold as feedstock to other chemical and industrial gas companies.

Continue reading.

#brazil#politics#economy#environmentalism#brazilian politics#renewables#mod nise da silveira#image description in alt

0 notes

Text

Bellow Seal Valves: Ensuring Superior Performance and Safety in Industrial Applications

In the ever-evolving landscape of industrial processes, safety, efficiency, and environmental compliance remain top priorities for operators and engineers. In critical applications involving hazardous or corrosive fluids, leakage prevention and reliable valve performance are of utmost importance. Enter bellow seal valves, an innovative solution designed to address these challenges. In this article, we will delve into the key features, benefits, and applications of bellow seal valves, showcasing their crucial role in ensuring superior performance and safety across diverse industries.

1. Understanding Bellow Seal Valves:

Bellow seal valves are a specialized type of globe valve that features an external metal bellows assembly, which acts as a dynamic seal between the stem and the bonnet. Unlike traditional globe valves, bellow seal valves eliminate the need for packing, reducing the risk of stem leakage and fugitive emissions. The bellows, typically made of stainless steel or other corrosion-resistant materials, expand and contract with the stem's movement, providing a reliable and leak-free seal.

Types of Bellow Seal Valves

Bellow seal valves come in different types based on their design and application. The main types of bellow seal valves include:

Bellow Seal Globe Valve:

The most common type of bellow seal valve, it features a globe valve design with an external bellow assembly to provide a leak-free seal between the stem and the bonnet. These valves are versatile and widely used in various industries.

Bellow Seal Gate Valve:

These valves have a gate-like disc that moves up and down to control flow. The bellow assembly ensures a tight seal, making them suitable for high-pressure applications where a positive shut-off is required.

Bellow seal Euro-Chlor Valve:

The Bellow Seal Euro-Chlor Valve is a specialized type of bellow seal globe valve designed specifically for applications in the chlor-alkali industry. It is used in processes involving the production of chlorine and other caustic chemicals.

Bellow Seal Control Valve:

A Bellow Seal Control Valve is a type of control valve that features a bellow seal to provide a hermetic and leak-free sealing between the valve stem and the bonnet. Control valves are widely used in industrial processes to regulate the flow, pressure, or level of fluids in a system, and the addition of a bellow seal enhances their safety and reliability, making them suitable for critical applications.

Each type of bellow seal valve serves specific purposes and offers advantages in different applications. The choice of valve type depends on the nature of the fluid, the operating conditions, and the specific requirements of the industrial process.

2. Key Advantages of Bellow Seal Valves:

a. Zero Leakage Assurance: The primary advantage of bellow seal valves is their impeccable sealing capability, preventing fugitive emissions and eliminating the risk of process fluid leakage. This zero-leakage feature ensures compliance with environmental regulations and enhances safety for personnel and the surrounding environment.

b. Corrosion Resistance: Bellow seal valves are engineered with materials that offer exceptional corrosion resistance, making them suitable for handling aggressive and corrosive media. The external bellows protect the stem from direct contact with the fluid, further enhancing the valve's lifespan and reliability.

c. High Temperature and Pressure Handling: Bellow seal valves are designed to withstand high pressures and temperatures, making them a preferred choice for challenging applications in refining, petrochemical, and power generation industries.

d. Reduced Maintenance: By eliminating the need for traditional packing, bellow seal valves require less maintenance and have longer service intervals, reducing operational costs and downtime.

e. Improved Safety and Process Efficiency: The leak-free design of bellow seal valves contributes to improved safety in critical processes and enhances overall process efficiency by ensuring precise flow control.

3. Applications of Bellow Seal Valves:

Bellow seal valves find extensive use in a variety of industries and applications:

a. Chemical and Petrochemical: These valves are employed in handling aggressive chemicals, acids, and toxic substances where leak-free operation is crucial.

b. Oil and Gas: In upstream and downstream processes, bellow seal valves are essential for controlling the flow of various fluids and gases.

c. Pharmaceuticals: Bellow seal valves are preferred in pharmaceutical manufacturing to avoid contamination risks and ensure product purity.

d. Power Generation: These valves play a vital role in controlling steam, feedwater, and other fluids in power plants, ensuring safe and efficient operation.

e. Water and Wastewater Treatment: Bellow seal valves are utilized in water treatment facilities for precise flow control and to prevent leakage of chemicals.

4. Installation and Maintenance Considerations:

Proper installation and regular maintenance are crucial for maximizing the benefits of bellow seal valves. Following manufacturer guidelines, using compatible materials, and performing routine inspections ensure optimal performance and longevity.

Conclusion:

Bellow seal valves have emerged as an indispensable solution for achieving leak-free, reliable, and efficient operation in critical industrial processes. Their zero-leakage design, resistance to corrosion, and ability to handle extreme conditions make them a preferred choice for applications across multiple industries. As industrial processes become increasingly demanding, bellow seal valves continue to demonstrate their importance in ensuring safety, environmental compliance, and superior performance in the modern industrial landscape.

Freture Techno is a leading manufacturer, supplier, and exporter of high-quality bellow seal valves from India. With a strong commitment to engineering excellence and customer satisfaction, Freture Techno's bellow seal valves offer superior performance, zero-leakage assurance, and exceptional corrosion resistance. Their valves are meticulously crafted using top-grade materials and advanced manufacturing processes, ensuring reliability and longevity in critical industrial applications. As a trusted global supplier, Freture Techno caters to diverse industries worldwide, providing top-notch products, on-time deliveries, and responsive customer support. When it comes to bellow seal valves, Freture Techno stands at the forefront, empowering industries with innovative solutions for safety, efficiency, and environmental compliance.

#Bellow Seal Valves#Bellow Seal Globe Valve#Bellow Seal Gate Valve#Bellow Seal Euro-Chlore Valve#Exte. Stem Bellow Seal Valve#freture techno#mumbai#india

0 notes

Text

Main uses of magnesia chrome bricks

Magnesia chrome brick is a high-quality refractory material composed of magnesium oxide (MgO) and chromium trioxide (Cr2O3). It has excellent performance in high temperature environment and is widely used in many fields. The following are the main uses of magnesia chrome bricks:

1、Metallurgical industry: Magnesia-chrome bricks are widely used in high-temperature equipment in the metallurgical industry, such as steel converters, electric furnaces, and smelting furnaces. They can be used in areas such as linings, furnace floors, furnace walls and furnace roofs to provide refractory protection and withstand erosion and wear under high temperature conditions.

2、Chlor-alkali industry: Equipment such as electrolyzers and evaporators in the production process of the chlor-alkali industry need materials that can withstand high temperatures and corrosion. Magnesia-chrome bricks are widely used in these equipment, providing excellent fire resistance and corrosion resistance, ensuring long-term stable operation of the equipment.

3、Oil refining and chemical industry: In the oil refining and chemical industry, magnesia-chrome bricks are often used in high-temperature equipment such as catalytic cracking units, hydrogenation units, reforming units and furnaces. They withstand high temperatures, corrosive gases and chemicals and provide reliable fire protection.

4、Glass industry: Glass furnaces are the core equipment in the glass industry, which are required to withstand extremely high temperatures and chemical erosion. Magnesia-chrome bricks are widely used in the inner lining, cooling zone and melting area of glass furnaces to maintain stable refractory performance and long service life.

5、Power industry: In the power industry, magnesia-chrome bricks are often used in high-temperature equipment such as boilers, burners, chimneys and hot blast stoves. They can withstand high temperature and flue gas erosion, and provide effective fire protection to ensure the normal operation and safety performance of equipment.

6、Other industries: In addition, magnesia-chrome bricks are also widely used in cement kilns, ceramic kilns, welding furnaces, carbonization furnaces, aluminum electrolytic cells and other fields. Its excellent fire resistance and corrosion resistance make it an important high temperature refractory material.

In conclusion, magnesia chrome bricks are widely used in several industries due to their high temperature resistance, erosion resistance and mechanical strength. Whether it is metallurgy, chlor-alkali, oil refining and chemical industry, glass or electric power and other fields, magnesia-chrome bricks can provide reliable fire-resistant protection to ensure long-term stable operation of equipment.

0 notes

Text

Chlor-Alkali Market: An Essential Component of Industrial Processes

The chlor-alkali market is a crucial sector of the chemical industry, encompassing the production and distribution of chlorine, sodium hydroxide (caustic soda), and hydrogen gas. These chemicals are essential for a wide range of industrial applications, including water treatment, pulp and paper manufacturing, textiles, plastics, and pharmaceuticals. The chlor-alkali market plays a vital role in supporting various industrial sectors and is driven by factors such as economic growth, population expansion, and technological advancements.

Market Overview:

The global chlor-alkali market has witnessed significant growth over the years and is expected to continue its upward trajectory in the foreseeable future. The market is primarily driven by the increasing demand for caustic soda and chlorine in several industries. The major market players are continually focusing on expanding their production capacities, optimizing manufacturing processes, and developing innovative solutions to meet the evolving customer requirements.

Key Products:

Chlorine: Chlorine is widely used as a disinfectant and bleaching agent in water treatment, wastewater treatment, and the production of various chemicals. It is also utilized in the manufacturing of PVC, solvents, pesticides, and pharmaceuticals.

Caustic Soda (Sodium Hydroxide): Caustic soda is a highly versatile chemical that finds applications in numerous industries. It is a key ingredient in the production of paper, textiles, soaps, detergents, and aluminum. Additionally, caustic soda is extensively used in the petroleum industry for refining petroleum products.

Hydrogen Gas: Hydrogen gas is a byproduct of the chlor-alkali industry and is utilized in various sectors, including oil refining, metal production, and the production of ammonia and methanol. Furthermore, hydrogen is gaining prominence as a potential clean energy source, with growing investments in hydrogen fuel cells and hydrogen-powered vehicles.

Market Drivers:

Increasing Demand from End-Use Industries: The growing population and rising urbanization have spurred the demand for chlor-alkali products in industries such as water treatment, pulp and paper, textiles, and pharmaceuticals. These sectors require chlorine and caustic soda for their manufacturing processes, thus driving market growth.

Technological Advancements: Continuous advancements in production technologies, including membrane cell technology and electrolysis processes, have improved the energy efficiency and environmental sustainability of chlor-alkali production. These technological developments have positively influenced market growth.

Government Regulations and Environmental Concerns: Stringent government regulations aimed at wastewater treatment, environmental protection, and product safety have propelled the demand for chlorine and caustic soda. Moreover, the increased focus on sustainable practices and eco-friendly chemicals has created opportunities for market expansion.

Regional Analysis:

The chlor-alkali market is geographically diverse, with key regions including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Asia Pacific holds the largest market share due to its robust industrial base, growing population, and expanding manufacturing sector. North America and Europe also contribute significantly to the market, driven by established industrial infrastructure and technological advancements.

Key Market Players:

Dow Chemical Company

Occidental Petroleum Corporation

Akzo Nobel N.V.

Formosa Plastics Corporation

Shin-Etsu Chemical Co., Ltd.

Hanwha Chemical Corporation

Olin Corporation

Tata Chemicals Limited

Xinjiang Zhongtai Chemical Co., Ltd.

Tosoh Corporation

Future Outlook:

The chlor-alkali market is expected to witness sustained growth in the coming years, driven by increasing industrialization, urbanization, and the need for sustainable solutions. The development of innovative production technologies and the rising demand for clean energy sources like hydrogen are anticipated to shape the future of the market. Additionally, strategic collaborations, mergers and acquisitions, and investments in research and development will play a vital role in the market's evolution.

Conclusion:

The chlor-alkali market is a critical component of the chemical industry, supplying essential chemicals like chlorine, caustic soda, and hydrogen gas to various sectors. With increasing industrialization, technological advancements, and environmental concerns, the market is poised for steady growth. Key market players are expected to focus on sustainable practices and innovative solutions to meet the evolving demands of end-use industries and drive the market forward.

0 notes

Text

Chlor-alkali Equipments Market Growing Popularity and Emerging Trends in the Industry

Latest study released by AMA Research on Global Chlor-alkali Equipments Market research focuses on latest market trend, opportunities and various future aspects so you can get a variety of ways to maximize your profits. Chlor-alkali Equipments Market predicted until 2027*.

Chlor-alkali equipment is defined as an equipment’s present in the plant needed for manufacturing and for other processes of Chlor-alkali. While Chlor alkali is defined as an industrial process for producing the caustic soda, chlorine, and other sodium and chlorine-based derivatives such as chlorinated paraffin, hydrochloric acid, bleaching powder, hydrogen gas, and sodium hypochlorite. Chorine is basic chemical for the plastics industry, as EDC/PVC is used in a large number of plastics.

Some of Key Players included in Chlor-alkali Equipments Market are

thyssenkrupp Uhde Chlorine Engineers (Germany)

Asahi Kasei Corporation (Japan)

Bluestar (beijing) chemical machinery Co. LTD. (China)

Nuberg Engineering Limited (India)

Alfa Laval AB (Sweden)

Powell Fabrication & Manufacturing, LLC (United States)

3V Tech S.p.A. (Italy)

Titanium Tantalum products limited (India)

Nanjing Tangent Fluid Technology Co., Ltd. (China)

Boccard (France)

Drivers: Promising Growth of Chemical Industry in Emerging Markets

Rising Government Support

Rising R&D Investment

Challenges: High Cost of Installation and Operation

Regulatory Compliance and Traceability

Opportunities: The Increasing Plant Set-Ups among the Developing Countries

The titled segments and Market Data are Break Down by Type (Electrolytic Equipment {Membrane cell, Mercury cell, and Diaphragm cell}, Container Equipment, Others), Application (Chlor-alkali Industry, Metallurgical Engineering, Other Chemical Industry)

Presented By

AMA Research & Media LLP

0 notes

Text

Chlorine Market Size, Share, Demand, Growth & Trends by 2032

The global chlorine market is worth US$ 14.36 Billion as of now and expected to reach US$ 21.86 Billion by the year 2032 at a CAGR of 4.3% between 2022 and 2032.

The end-uses of chlorine and its derivatives include paints & coatings, adhesives, food processing, plastic, cosmetics, pharmaceuticals, water treatment, and likewise.

Chlorine acts as a raw material to produce a series of chemicals. For instance – it is vital regarding production of PVC (Polyvinyl Chloride). The applications of PVC include automotive, construction, composite manufacturing.

At the same time, it needs to be noted that handling as well as transporting chlorine comes with risks, as chlorine falls in the category of toxicological and inflammable substances. It also ends up enhancing the other materials’ combustion rate. Regulatory bodies like the US FDA, EPA, WHO, IARC, and likewise are imposing stern restrictions in the interest of safeguarding the environment.

For details on vendors and their offerings – Request a sample report: https://www.futuremarketinsights.com/reports/sample/rep-gb-591

Additionally, production of chlorine is energy-intensive, which adds to overheads. In the last few years, countries like China have over-produced chlorine. As such, the prices have come down drastically. This could be problematic to the manufacturers regarding the way they cover the overall costs. The demand won’t cease, as market is witnessing a shift to membrane technology from mercury cell technology.

Regions like India, Austria, Brazil, the UK, Sweden, the US, France, and Spain are heavily investing in the building & construction sector. This asks for an exorbitant demand for PVC. Thus, the chlorine market, in spite of the over-reactive nature of chlorine, is expected to go great guns going forward. Future Market Insights has highlighted these findings with future perspectives in its latest market study entitled ‘Chlorine Market’. It has its indigenous team of analysts and consultants to deploy a bottom-up approach in its primary, secondary, and tertiary modes of research.

“With agrochemical and pharmaceutical verticals witnessing an upsurge in EDC (ethylene dichloride) and PVC (polyvinyl chloride), the chlorine market is expected to grow remarkably in the near future”, says an analyst from Future Market Insights.

Key Takeaways from Chlorine Market

· North America holds close to 18% of the market share. This could be attributed to the US housing several primary manufacturers. Also, chlorine, along with its derivatives, are widely sold for producing prescription chemicals sold al across Canada and the US.

· Europe is expected to show steadiness in the chlorine market in the forecast period, especially amidst the economic slowdown faced by the UK.

· The Asia-Pacific is expected to witness a marked growth in chlorine market in the forecast period due to growing demand for caustic soda (which is by-product of chlorine production).

Browse Full Report: https://www.futuremarketinsights.com/reports/chlorine-market

Competitive Doorstep

· INOVYN, in January 2021, got selected by Koyuncu Group for supplying chlor-alkali technology at novel manufacturing facility in Konya, Turkey. BICHLOR bipolar electrolyzers would be provided by INOVYN for new facility for producing hydrochloric acid, chlorine, and sodium hypochlorite. Production began at the start of 2022 and claims to have manufacturing capacity of 50K tons every year.

· Potasse et Produits Chimiques SAS, in July 2019, did join Vynova Group. Site based out of Thann (France) has been rechristened to ‘Vynova PPC SAS’ and included under Vynova umbrella. It contains a membrane electrolysis plant and manufactures liquid potassium hydroxide (KOH) and chlorine.

· NX Filtration does develop hollow fiber modules and membranes for ultrafiltration and nanofiltration. The ultrafiltration membrane’s ‘Ultra’ range is based on modified PES (polyethersulfone) chemistry retaining yeast, microorganisms, and floating particles at the time of facilitating salts, proteins, and petite organic molecules. The membranes are known for having superlative tolerance to chlorine, with higher pH.

Unleashing the Macros of Chlorine Market

· The research study is based on application (isocyanates and oxygenates, EDC/PVC, inorganic chemicals, chloromethanes, solvents and electrolysis, pharmaceuticals, and electronics), and by end-use (pulp and paper, water treatment, chemicals, plastics, pesticide, and durable pipes).

· Growing demand for various chemical intermediates like acid chlorides, hydrochloric acid, metal chlorides, hypochloric acid, chloroform, and the other chlorine derivatives would certainly keep the cash registers ringing for chlorine market.

0 notes

Text

Sodium Hypochlorite Prices Trend, Database, Chart, Index, Forecast

Sodium Hypochlorite prices have experienced notable fluctuations in recent times, influenced by various factors within the chemical industry and global economic landscape. As a key component in disinfectants, bleaches, and water treatment solutions, sodium hypochlorite plays a crucial role in numerous sectors, including healthcare, sanitation, and municipal water treatment facilities. The pricing dynamics of sodium hypochlorite are closely tied to the cost of raw materials, primarily chlorine and caustic soda, which are used in its production through the chlor-alkali process. Fluctuations in the prices of these raw materials, driven by factors such as supply-demand dynamics, energy prices, and regulatory changes, directly impact the overall production cost of sodium hypochlorite.

Furthermore, market demand and supply dynamics also influence sodium hypochlorite prices. The COVID-19 pandemic, for instance, led to a surge in demand for disinfectants and sanitizers, including those containing sodium hypochlorite, driving prices upward due to increased market demand. Conversely, periods of economic slowdown or reduced industrial activity can lead to a decrease in demand, consequently putting downward pressure on prices. Moreover, geopolitical factors, such as trade tensions and currency fluctuations, can further exacerbate price volatility in the sodium hypochlorite market by affecting the cost of imported raw materials and finished products.

Get Real Time Prices of Sodium Hypochlorite: https://www.chemanalyst.com/Pricing-data/sodium-hypochlorite-1560

Regulatory factors also play a significant role in shaping sodium hypochlorite prices. Environmental regulations, in particular, can impact production processes and input costs, as stringent regulations may require manufacturers to invest in cleaner production technologies or comply with stricter safety and environmental standards, leading to increased operational costs that may be passed on to consumers in the form of higher prices. Additionally, changes in regulatory frameworks governing the transportation, storage, and handling of sodium hypochlorite can impact supply chain costs and logistics, thereby influencing overall pricing dynamics.

In addition to these external factors, internal dynamics within the sodium hypochlorite industry, such as production capacity, market competition, and technological advancements, also contribute to price fluctuations. Capacity expansions or new entrants in the market can increase supply and intensify competition, putting downward pressure on prices. Conversely, disruptions in production due to maintenance shutdowns, accidents, or force majeure events can constrain supply and drive prices higher. Moreover, advancements in production technologies or manufacturing processes can improve efficiency and reduce production costs, potentially leading to price reductions over time.

Looking ahead, several trends are expected to shape the future pricing landscape of sodium hypochlorite. The ongoing transition towards sustainable and eco-friendly solutions is likely to drive investments in greener production technologies and alternative sources of raw materials, which could impact cost structures and pricing strategies within the industry. Moreover, the continued focus on hygiene and sanitation, particularly in light of the lessons learned from the COVID-19 pandemic, is expected to sustain demand for sodium hypochlorite-based disinfectants and sanitizers, albeit at potentially varying levels across different regions and sectors.

Overall, sodium hypochlorite prices are influenced by a complex interplay of factors, including raw material costs, market demand, regulatory requirements, industry dynamics, and macroeconomic trends. While short-term price fluctuations are inevitable due to the dynamic nature of these factors, long-term pricing trends are likely to be shaped by broader shifts towards sustainability, resilience, and innovation within the chemical industry and its downstream applications. As stakeholders navigate these evolving dynamics, a deep understanding of the various drivers and constraints impacting sodium hypochlorite prices will be essential for making informed decisions and managing risk effectively in the market.

Get Real Time Prices of Sodium Hypochlorite: https://www.chemanalyst.com/Pricing-data/sodium-hypochlorite-1560

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

China soda ash market

Introduction

Soda ash, also known as sodium carbonate, is an alkali chemical that is manufactured through three chemical technologies.

Raw materials:

sodium chloride, limestone

Chemical technology:

Combined alkali process, natural alkali and chlor-akali process

Application:

Soda ash dense is the main material for industrial-grade glass used in real estate and PV(photovoltaic)industries. It…

View On WordPress

0 notes

Text

Chlor-Alkali Market Share, Size, Growth, Key Vendors, Trends, Analysis, Segmentation, Forecast To 2022-2028

Global Chlor-Alkali Market was valued at USD 91.55 billion in 2021 and is expected to reach USD 118.86 billion by the year 2028, at a CAGR of 3.8%.

Chlor-alkali refers to the two chemicals such as chlorine and alkali which are concurrently manufactured as a result of the electrolysis of salt water. The most common chlor-alkali chemicals are chlorine and caustic soda (sodium hydroxide) but can include potassium hydroxide and muriatic acid. There are three types of electrolytic processes utilized in the production of chlorine and caustic soda such as the diaphragm cell process, the membrane cell process, and the mercury cell process. In the mercury cell process, chlorine and sodium hydroxide are manufactured all together by electrolyzing seawater (sodium salt water or brine) in a mercury cell.

Read More: -

The global Chlor-Alkali Market research investigates the market in-depth and offers a comprehensive analysis of the major growth determinants, Chlor-Alkali Market share, current trends, key players, and their future predictions. In addition, market demand and supply, each geographical region's growth rate, and market potential are all included in the Chlor-Alkali Market study. Raw materials, marketing channels, client surveys, industry trends and proposals, CAGR status, product scope, Chlor-Alkali Market trends, major leading countries/regions, market risk, and market driving force are all included in the market research. The market prediction was based on a thorough market investigation completed by several industry experts.

0 notes

Link

0 notes

Text

Chlor-Alkali Market Forecast to 2028 - Covid-19 Impact and Global Analysis - by Source; Function; Application and Geography

Global Chlor-Alkali Market was valued at USD 91.55 billion in 2021 and is expected to reach USD 118.86 billion by the year 2028, at a CAGR of 3.8%.

Chlor-alkali refers to the two chemicals such as chlorine and alkali which are concurrently manufactured as a result of the electrolysis of salt water. The most common chlor-alkali chemicals are chlorine and caustic soda (sodium hydroxide) but can include potassium hydroxide and muriatic acid. There are three types of electrolytic processes utilized in the production of chlorine and caustic soda such as the diaphragm cell process, the membrane cell process, and the mercury cell process. In the mercury cell process, chlorine and sodium hydroxide are manufactured all together by electrolyzing seawater (sodium salt water or brine) in a mercury cell. The chlor-alkali process makes usages of cation exchange membrane technology, which is the most advanced, very efficient, and the most environmentally friendly Chlor-alkali technology producing high-quality products meeting a wide range of demanding applications such as Soaps and Detergents, Paper and Pulp, Pharmaceuticals, Organic chemical, Inorganic chemical, Textiles, Alumina, Textile, Water Treatment, Chemical Processing, and Others.

The research covers factors impacting the top market participants as well as current technical breakthroughs. The study includes thorough statistical data to assist top organizations in better understanding the industry's operations. The report examines every major organization and actor involved in industrial growth, as well as providing a complete assessment of the competitive environment. In addition, the inquiry looks into market challenges, opportunities, constraints, development drivers, trends, and the company production network, among other things. It also provides information about each section's attractiveness, as well as its growth rate and market size, which aids in determining which segment to invest in or promote.

To learn more about this report, request a free sample copy:

https://introspectivemarketresearch.com/request/15933

Key Industry Players in the Chlor-Alkali Market:

· Olin Corporation(US)

· Westlake Chemical Corporation (US)

· Tata Chemicals Limited (India)

· Occidental Petroleum Corporation (US)

· Formosa Plastics Corporation (Taiwan)

· Solvay SA (Belgium)

· Tosoh Corporation (Japan)

· Hanwha Solutions Corporation (South Korea)

· Nirma Limited (India)

· AGC Inc. (Japan)

· Dow Inc. (US)

· Xinjiang Zhongtai Chemical Co. Ltd. (China)

· INOVYN (UK)

· Ciner Resources Corporation (US)

· Wanhua-Borsodchem (Hungary) and other major players.

Chlor-alkali products such as chlorine, caustic soda, and soda ash play a vital role in the chemical industry. These products are necessary raw materials in major bulk chemical industries and utilized in various industrial and manufacturing value chains. The products are used in different applications such as plastics, alumina, paper & pulp, and others and find applications in diverse end-use industries (construction, automotive, and others). Thus, rising chemical output and strong economic conditions in emerging countries are expected to drive the growth of the chlor-alkali market.

Segmentation Analysis Includes,

By Type:

· Caustic Soda

· Chlorine

· Soda Ash

· Others

By End Users:

· Soaps & Detergents

· Paper & Pulp

· Organic Chemical

· Water Treatment

· Others

By Distribution Channels:

· Direct Sales

· Specialty Stores

· Warehouses

· Online

· Others

By Region:

· North America (U.S., Canada, Mexico)

· Europe (Germany, U.K., France, Italy, Russia, Spain, Rest of Europe)

· Asia-Pacific (China, India, Japan, Singapore, Australia, New Zealand, Rest of APAC)

· Middle East & Africa (Turkey, Saudi Arabia, Iran, UAE, Africa, Rest of MEA)

· South America (Brazil, Argentina, Rest of SA)

Will you have any doubt about this report? Please contact us on:

https://introspectivemarketresearch.com/inquiry/15933

Table of Content:

Chapter 1: Introduction

Chapter 2: Executive Summary

Chapter 3: Growth Opportunities By Segment

Chapter 4: Market Landscape

Chapter 5: Chlor-Alkali Market by Type

Chapter 6: Chlor-Alkali Market by End Users

Chapter 7: Chlor-Alkali Market by Distribution Channels

Chapter 8: Company Profiles and Competitive Analysis

Chapter 9: Global Chlor-Alkali Market Analysis, Insights and Forecast, 2016-2028

Chapter 10: North America Chlor-Alkali Market Analysis, Insights and Forecast, 2016-2028

Chapter 11: Europe Chlor-Alkali Market Analysis, Insights and Forecast, 2016-2028

Chapter 12: Asia-Pacific Chlor-Alkali Market Analysis, Insights and Forecast, 2016-2028

Chapter 13: Middle East & Africa Chlor-Alkali Market Analysis, Insights and Forecast, 2016-2028

Chapter 14: South America Chlor-Alkali Market Analysis, Insights and Forecast, 2016-2028

Chapter 15 Investment Analysis

Chapter 16 Analyst Viewpoint and Conclusion

The outbreak of COVID-19 has impacted most industrial operations across the world. Disruptions in logistics & supplies, labor shortage, absence of end-users, and other restraints are major challenges faced by industries globally. During the initial phase of the outbreak, operation rates had fallen sharply, and some plants had to halt production for a few days. Further, the absence of end-users significantly reduces the demand for these products, particularly chlorine.

Purchase This Report: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=15933

The sudden emergence of the humanitarian crisis has inflicted a negative impact on the market’s growth. The low available workforce and the closure of production facilities during the initial days of the pandemic have affected the growth of the market. The disruptions in the supply chain networks have exacerbated the impact. Additionally, the reduced demand for chlorine by end-use industries further aggravated the situation.

Related Report: -

https://introspectivemarketresearch.com/reports/chlor-alkali-ion-exchange-membrane-market/

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyze extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1047

Linkedin| Twitter| Facebook

Email: [email protected]

0 notes