#cmm inspection services

Text

Dimensional Inspection: The Key to Perfecting Precision in Modern Manufacturing

In the world of modern manufacturing, precision is not just a goal—it's a necessity. As industries such as aerospace, automotive, medical devices, and consumer goods evolve, their requirements for accuracy and quality have surged. Meeting these demands involves more than just ensuring that parts fit together; it's about adhering to strict tolerances, avoiding costly mistakes, and complying with industry standards. This is where dimensional inspection comes into play.

Dimensional inspection is a critical process in manufacturing that ensures parts are built exactly to specification. From the earliest stages of development to final product approval, dimensional inspection offers detailed measurement data, reducing errors, enhancing quality control, and speeding up the production process. Whether you're producing prototypes or scaling to mass production, precision inspection is the linchpin that keeps projects on track.

What Is Dimensional Inspection?

Dimensional inspection involves measuring the physical dimensions of a manufactured part to ensure it meets specific tolerances. This isn't just about checking the length, width, and height. Advanced dimensional inspection covers intricate measurements such as angles, curvature, thickness, and surface texture.

Dimensional inspection techniques can be applied to products in various stages of manufacturing, such as:

First Article Inspection (FAI): The first prototype is thoroughly inspected to verify that it matches design specifications.

Ongoing Quality Control: During the production process, routine inspections are carried out to ensure consistency.

Final Product Inspection: Before the product is delivered to the market, a final check guarantees all dimensions are within acceptable tolerance levels.

Dimensional inspection services often use sophisticated tools and technologies like Coordinate Measuring Machines (CMM), laser scanners, and computed tomography (CT) scanning to capture detailed, highly accurate data.

Why Is Dimensional Inspection Critical for Manufacturers?

1. Avoid Costly Errors:

Manufacturing errors are not only expensive but can lead to significant delays. Errors that go undetected in the design or prototyping phase can multiply during mass production, leading to faulty products, expensive recalls, or even legal ramifications. Dimensional inspection mitigates this by catching errors early.

For example, a company producing medical devices must meet stringent regulatory requirements. Dimensional inspection allows manufacturers to verify each component's accuracy before moving forward with production, preventing potential non-compliance issues.

2. Ensure Product Functionality:

Parts that don’t meet required dimensions can cause products to malfunction or fail entirely. Dimensional inspection provides engineers and manufacturers with accurate measurements to ensure parts function as intended, improving product safety and performance.

In industries like automotive and aerospace, where precision is vital to safety, dimensional inspection ensures that parts like engine components or turbine blades meet exact specifications for both form and function.

3. Streamline Product Development:

Dimensional inspection accelerates the product development process by offering precise data quickly. This allows engineers to adjust designs on the fly, reducing time spent on trial and error. With advanced tools like 3D scanning and CT scanning, inspection reports are delivered within days instead of weeks, helping companies hit production milestones without unnecessary delays.

Key Tools Used in Dimensional Inspection

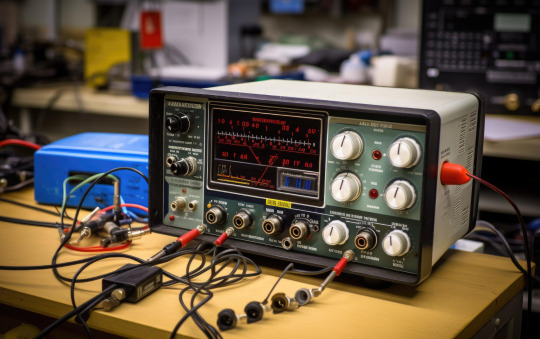

1. Coordinate Measuring Machines (CMM):

CMMs are used to measure the exact geometry of objects by sensing discrete points on the surface with a probe. The machine then calculates the coordinates and checks them against the intended design.

2. 3D Scanning:

3D scanners are commonly used for capturing the exact shape and surface detail of a part. Technologies such as blue-light laser scanners can generate accurate digital representations of objects, allowing for in-depth analysis and comparisons with CAD models.

3. Industrial CT Scanning:

Computed tomography (CT) scanning is increasingly being used for dimensional inspection, especially for complex or internal features that are hard to measure with traditional tools. CT scanning provides a 3D image of the part's internal and external structures, enabling precise inspection without disassembling or damaging the part.

Applications Across Industries

Dimensional inspection services cater to a wide variety of industries:

Medical Devices:

Dimensional inspection is crucial for ensuring that medical components like implants, drug delivery systems, and surgical instruments are produced to exact specifications, preventing patient harm.

Automotive:

In the automotive sector, precision is vital for the performance of components like engines, transmissions, and safety systems. Dimensional inspection ensures these parts are made to the highest standards.

Aerospace:

Aerospace components must meet stringent tolerances to guarantee safety and performance at high altitudes and extreme conditions. Dimensional inspection provides the necessary accuracy to meet these demands.

Consumer Products:

Whether it's packaging, electronics, or sporting goods, dimensional inspection helps ensure that products are manufactured consistently and meet consumer expectations.

The Role of Accreditation in Dimensional Inspection

When outsourcing dimensional inspection, choosing a laboratory accredited to international standards like ISO/IEC 17025 is critical. This accreditation ensures that the lab operates competently, consistently producing valid results. Accredited labs follow strict procedures and maintain equipment that is regularly calibrated to meet global standards of precision.

Accredited labs also provide traceability, ensuring that all measurements can be traced back to a recognized standard. This is particularly important for industries like medical devices and aerospace, where regulatory compliance is essential.

Conclusion: The Future of Dimensional Inspection

As manufacturing continues to evolve with new technologies and materials, the demand for dimensional inspection services will only grow. Tools like CT scanning, 3D metrology, and CMM systems allow for faster, more accurate inspections, giving manufacturers a competitive edge. Whether for small-scale prototyping or large-scale production, precision measurement plays a pivotal role in ensuring product quality, safety, and compliance.

With its ability to prevent costly errors, streamline product development, and ensure functionality, dimensional inspection is a cornerstone of modern manufacturing excellence.

For more information on how dimensional inspection can improve your manufacturing processes, visit Nel PreTech's Dimensional Inspection Services.

ChatGPT can make mistakes. Check important info.

0 notes

Text

SolidWorks Training in Gujarat | The SUNCAD Training & Designers

Suncad offers the best SolidWorks Training in Gujarat. For more information visit on : https://suncad.in/product/solidworks-3d-cad/ or call us on : +91-9925023229

#Solid Edge Training in Gujarat#3D Printing Services in Gujarat#CNC / VMC Machine Operating in Gujarat#3D Inspection Services in Gujarat#Laser Tracker Service in Gujarat#3D Lidar Scanning / 3D Terrestrial Scanning Services#Heritage Scanning Services#3D Scanning in Gujarat#CMM Inspection Services#Reverse Engineering in Gujarat#BIM Modeling and Scanning Service in Gujarat

0 notes

Text

CMM (Coordinate Measuring Machine) inspection services refer to the process of using specialized equipment to measure the physical characteristics of an object, such as its size, shape, and position, in order to ensure that it meets the required specifications and tolerances. CMMs use a probe to make contact with the object being measured, and the resulting data is then analyzed to determine whether the object is within the required parameters.

0 notes

Text

Digital Scan 3D specializes in 3D Scanning and applications. Apart from providing some of the best scanners and software in the world,

Some of our 3D Scanners capture color at the highest resolution of up to 10 microns (0.0003”). We will recommend the best 3D scanning solutions for your application.

Website: https://digitalscan3d.com/

#Inspection and CMM services in Oregon#USA#Kreon 3D Scanner#Polyworks inspector in Oregon#Kreon 3D Scanner in USA

0 notes

Text

Exploring Nearby CMM Inspection Services: Precision Measurement at Your Doorstep

In today's fast-paced manufacturing landscape, precision is paramount. To ensure products meet exacting standards and tolerances, Coordinate Measuring Machine (CMM) inspection services have become a critical component of the quality control process. This article delves into the world of CMM inspection services, highlighting their significance, benefits, and how they bring precision measurement right to your doorstep.

Table of Contents

Introduction

What are CMM Inspection Services?

The Importance of Precise Measurements

Benefits of Nearby CMM Inspection Services

How CMM Inspection Services Work

Advanced Technology in CMM Inspection

Industries That Rely on CMM Inspection

Choosing the Right CMM Inspection Provider

Ensuring Accuracy in Manufacturing

Increasing Efficiency Through CMM Inspection

Future Trends in CMM Technology

Common Misconceptions about CMM Inspection

The Cost-Effectiveness of CMM Inspection

Frequently Asked Questions (FAQs)

Introduction

In the world of manufacturing, where tolerances are often measured in micrometers, even the slightest deviation can lead to costly defects and recalls. This is where CMM inspection services step in to save the day.

What are CMM Inspection Services?

Coordinate Measuring Machine (CMM) inspection services involve the use of advanced measuring instruments to assess the dimensions and geometric attributes of various objects. These services utilize precision tools to ensure that components meet design specifications with utmost accuracy.

The Importance of Precise Measurements

Precise measurements are the cornerstone of quality manufacturing. Even a minuscule error can compromise the functionality and safety of a product. CMM inspection services play a pivotal role in verifying the dimensional accuracy of intricate parts, guaranteeing that they adhere to required specifications.

Benefits of Nearby CMM Inspection Services

Time Efficiency: Having CMM inspection services nearby accelerates the production process, as measurements can be taken promptly, minimizing downtime.

Cost Savings: Local services translate to reduced shipping costs and shorter lead times, contributing to overall cost savings.

Real-time Analysis: Nearby services allow for real-time analysis of measurements, enabling quicker decision-making.

How CMM Inspection Services Work

CMM inspection involves the use of specialized machines equipped with touch probes and optical systems. These machines scan the object's surface, collecting data points that are then analyzed to determine dimensional accuracy.

Advanced Technology in CMM Inspection

Modern CMM inspection services incorporate cutting-edge technology, such as laser scanning and non-contact measurement techniques. These advancements enhance measurement speed and accuracy.

Industries That Rely on CMM Inspection

CMM inspection services cater to a wide array of industries, including aerospace, automotive, medical devices, and electronics. Any sector that requires precision components benefits from CMM technology.

Choosing the Right CMM Inspection Provider

When selecting a CMM inspection provider, consider factors like their experience, range of services, technology used, and reputation within the industry.

Ensuring Accuracy in Manufacturing

CMM inspection significantly reduces the likelihood of defective products reaching consumers, maintaining brand reputation and customer trust.

Increasing Efficiency Through CMM Inspection

By identifying discrepancies early in the manufacturing process, CMM inspection helps streamline production, reduces waste, and minimizes rework.

Future Trends in CMM Technology

The future of CMM inspection points toward even faster, more accurate measurements through artificial intelligence integration and automation.

Common Misconceptions about CMM Inspection

Contrary to misconceptions, CMM inspection is not only for large-scale production but is also relevant for small-batch and custom manufacturing.

The Cost-Effectiveness of CMM Inspection

Despite initial investment costs, CMM inspection services ultimately lead to significant cost savings by preventing defects and reducing rework expenses.

Frequently Asked Questions (FAQs)

What is the role of CMM technology in aerospace manufacturing?

CMM technology ensures precise measurements of aerospace components, vital for flight safety.

Can CMM inspection be performed on-site?

Yes, many CMM inspection providers offer on-site services for added convenience.

Is CMM inspection suitable for complex, non-standard parts?

Absolutely, CMM technology excels at inspecting intricate and custom parts.

How does CMM inspection contribute to quality control?

CMM inspection identifies deviations from design specifications, maintaining high-quality standards.

Are CMM inspection services only for large corporations?

No, businesses of all sizes benefit from CMM inspection, given its role in precision manufacturing.

In conclusion, CMM inspection services play a pivotal role in maintaining the integrity and precision of modern manufacturing processes. With advanced technology and local accessibility, businesses can ensure their products meet the highest quality standards. By embracing CMM inspection, industries pave the way for innovation, efficiency, and a future marked by accurate measurements and impeccable products.

#CMM Inspection services near me#Accredited CMM Lab#Third Party CMM Inspection#Dimensional Measurement#First article Inspection Canada

0 notes

Text

Enhancing Vehicle Quality with Automotive Parts Sorting & Inspection Services

In the automotive industry, ensuring that every component meets high standards of quality is critical for the safety, performance, and longevity of vehicles. Automotive parts sorting & inspection services are key to this quality assurance process, playing a vital role in identifying defects and ensuring that only the best parts are used in vehicle assembly. By implementing rigorous Inspection Services, manufacturers can enhance their production processes, minimize defects, and ultimately deliver safer, more reliable vehicles to consumers.

The Role of Automotive Parts Sorting & Inspection Services

Automotive Parts Sorting & Inspection Services are designed to detect and address defects before parts are incorporated into the final vehicle assembly. This process is essential for maintaining the integrity of the production line and ensuring that every component meets strict quality standards. The services involve sorting parts based on their quality and performing detailed inspections to confirm that they adhere to the required specifications.

During the sorting phase, parts are categorized into compliant and non-compliant groups. Defective parts are removed from the production line, ensuring that only those meeting quality standards proceed further. This process is crucial for preventing defective components from impacting the overall vehicle performance.

Types of Inspection Services

Various Inspection Services are employed to ensure that automotive parts meet the necessary quality and performance criteria. Each type of inspection serves a specific purpose in the quality control process:

Visual Inspection: This fundamental form of inspection involves examining parts for visible defects, such as scratches, cracks, or surface imperfections. Although it may seem basic, visual inspection is effective for detecting obvious flaws that could affect the part's functionality or aesthetic quality.

Dimensional Inspection: Precision is critical in automotive manufacturing. Dimensional Inspection Services use tools such as calipers, micrometers, and coordinate measuring machines (CMM) to measure parts and verify that they meet exact dimensional specifications. This type of inspection ensures that components fit together properly during assembly, reducing the risk of operational issues.

Non-Destructive Testing (NDT): Some defects, such as internal cracks or structural weaknesses, are not detectable through visual inspection alone. Non-Destructive Inspection Services employ advanced techniques like ultrasonic testing, X-rays, and magnetic particle testing to identify hidden flaws without damaging the parts. NDT is particularly important for critical components that experience significant stress, such as engine parts and suspension systems.

Functional Testing: For certain components, it is essential to perform functional testing to ensure they operate correctly under real-world conditions. This type of testing verifies that parts like brakes, sensors, and electronic systems perform as expected and meet safety and performance standards.

Benefits of Outsourcing Automotive Parts Sorting & Inspection Services

Outsourcing Automotive Parts Sorting & Inspection Services to specialized third-party providers offers several advantages for manufacturers:

Expertise: Specialized inspection companies bring extensive experience and knowledge in quality control. Their expertise ensures thorough and accurate inspections, using advanced technologies and methodologies to detect even the smallest defects.

Cost Efficiency: Outsourcing Inspection Services helps manufacturers avoid the expense of purchasing and maintaining inspection equipment and training staff. This can lead to significant cost savings while still ensuring high-quality standards.

Scalability: Outsourced inspection services offer flexibility, allowing manufacturers to adjust inspection levels based on production volume and demand. This scalability is particularly useful during periods of increased production or when launching new models.

Enhanced Accuracy: Third-party providers often use cutting-edge technologies, such as automated sorting systems and AI-driven inspection tools, to improve the accuracy of inspections. These advancements help identify defects that might be missed during manual inspections.

Conclusion

In the automotive industry, the quality of every component directly impacts the safety and performance of the final vehicle. Automotive Parts Sorting & Inspection Services are essential for identifying and addressing defects before parts are used in assembly. Through various inspection services, including visual, dimensional, non-destructive testing, and functional testing, manufacturers can maintain high standards and ensure that only the best parts are used in vehicle production. Outsourcing these services offers additional benefits such as cost savings, expertise, and scalability, ultimately contributing to the production of high-quality, reliable vehicles.

1 note

·

View note

Text

Facilities Management: A Step-by-Step Guide

Facilities management is a critical function within any organization, encompassing a wide range of services and responsibilities aimed at ensuring the smooth operation of physical spaces. From maintaining buildings and infrastructure to managing resources and ensuring safety, effective facilities management is key to creating a productive and safe environment for employees, customers, and visitors. This step-by-step guide provides an in-depth look at the essential components of facilities management, offering practical tips and strategies to help organizations optimize their facilities and support their broader business goals.

1. Understanding Facilities Management

Before diving into the specifics, it’s important to understand what facilities management entails. It is a multidisciplinary field that integrates people, places, processes, and technology to ensure the functionality, comfort, safety, and efficiency of the built environment. Facilities management covers various areas including building maintenance, energy management, space planning, security, and compliance with health and safety regulations.

Key Responsibilities: Maintenance of HVAC systems, plumbing, electrical systems, landscaping, janitorial services, space utilization, waste management, and emergency preparedness.

2. Developing a Facilities Management Strategy

The foundation of effective facilities management is a well-defined strategy that aligns with the organization’s goals and objectives. This strategy should consider both short-term needs and long-term goals, ensuring that facilities support the overall mission of the organization.

Strategic Planning: Start by conducting a thorough assessment of your current facilities, identifying strengths, weaknesses, opportunities, and threats (SWOT analysis). Define your goals, whether they include improving energy efficiency, enhancing employee comfort, or optimizing space utilization. Develop a roadmap outlining the steps needed to achieve these goals, along with timelines and key performance indicators (KPIs) to measure progress.

3. Implementing Preventative Maintenance

Preventative maintenance is one of the most critical aspects of facilities management. By regularly inspecting and maintaining equipment and systems, you can prevent costly breakdowns, extend the lifespan of assets, and ensure a safe and comfortable environment for building occupants.

Best Practices: Create a preventative maintenance schedule that covers all critical systems, including HVAC, electrical, plumbing, and elevators. Use computerized maintenance management systems (CMMS) to track maintenance tasks, schedules, and work orders. Ensure that maintenance staff are trained and equipped to perform necessary tasks, and consider outsourcing specialized maintenance tasks to qualified contractors.

4. Optimizing Space Utilization

Efficient space utilization is key to maximizing the value of your facilities. This involves analyzing how space is used within your organization and making adjustments to improve efficiency, productivity, and employee satisfaction.

Space Planning: Conduct a space audit to determine how different areas of your facility are being used. Identify underutilized spaces and consider reconfiguring them to better meet the needs of your organization. Implement flexible workspaces, such as hot-desking or shared offices, to accommodate changing workforce needs. Use space management software to track space usage and make data-driven decisions about space allocation.

5. Enhancing Energy Management

Energy management is not only about reducing costs but also about supporting sustainability goals. Effective energy management involves monitoring and controlling energy use to improve efficiency and reduce the environmental impact of your facilities.

Energy Efficiency Measures: Conduct an energy audit to identify areas where energy is being wasted. Implement energy-saving measures such as upgrading to LED lighting, installing energy-efficient HVAC systems, and improving insulation. Use energy management systems (EMS) to monitor and control energy use in real time. Engage employees in energy-saving initiatives by promoting awareness and encouraging behavior changes.

6. Ensuring Health and Safety Compliance

Health and safety are paramount in facilities management. Organizations must comply with various regulations and standards to ensure the safety of employees, visitors, and contractors.

Compliance Checklist: Familiarize yourself with local, state, and federal regulations related to health and safety in the workplace. Conduct regular safety inspections and audits to identify potential hazards. Implement safety protocols and emergency procedures, such as fire drills, evacuation plans, and first aid training. Ensure that all safety equipment, such as fire extinguishers, smoke detectors, and emergency lighting, is properly maintained and accessible.

7. Managing Vendors and Contracts

Facilities management often involves working with external vendors for services such as cleaning, landscaping, security, and maintenance. Effective vendor management is crucial for ensuring that services are delivered on time, within budget, and to the required standards.

Vendor Management Tips: Develop clear contracts with detailed service level agreements (SLAs) that outline expectations, responsibilities, and performance metrics. Regularly review vendor performance and address any issues promptly. Maintain open communication with vendors to ensure alignment with your facilities management goals. Consider using a vendor management system (VMS) to track contracts, schedules, and payments.

8. Leveraging Technology in Facilities Management

Technology plays a vital role in modern facilities management, providing tools to automate tasks, monitor performance, and manage resources more efficiently.

Technological Tools: Implement a computerized maintenance management system (CMMS) to streamline maintenance operations, track work orders, and manage inventory. Use building management systems (BMS) to control and monitor building systems, such as HVAC, lighting, and security, from a central location. Explore the use of smart technologies, such as IoT sensors, to gather real-time data on energy use, occupancy, and environmental conditions.

9. Sustainability and Environmental Responsibility

Sustainability is becoming increasingly important in facilities management, as organizations seek to reduce their environmental footprint and comply with green building standards.

Sustainability Strategies: Implement a waste management program that includes recycling, composting, and waste reduction initiatives. Consider pursuing green building certifications, such as LEED or BREEAM, to demonstrate your commitment to sustainability. Explore renewable energy options, such as solar panels or wind turbines, to reduce reliance on fossil fuels. Engage employees in sustainability efforts by promoting green practices and providing training on environmental responsibility.

10. Monitoring and Continuous Improvement

Facilities management is an ongoing process that requires continuous monitoring and improvement. By regularly reviewing performance and making adjustments, you can ensure that your facilities remain efficient, safe, and aligned with organizational goals.

Continuous Improvement: Establish key performance indicators (KPIs) to measure the success of your facilities management initiatives. Conduct regular reviews of maintenance schedules, energy use, space utilization, and vendor performance to identify areas for improvement. Stay informed about industry trends and best practices, and be open to adopting new technologies and strategies that can enhance your facilities management efforts.

Conclusion

Effective facilities management is essential for creating a safe, efficient, and productive environment. By following this step-by-step guide, organizations can develop a comprehensive facilities management strategy that aligns with their goals, optimizes resources, and supports long-term success. Whether you’re managing a single building or a large portfolio of properties, these principles will help you achieve excellence in facilities management, ensuring that your facilities are well-maintained, compliant, and capable of meeting the evolving needs of your organization.

0 notes

Text

Maintenance Repair & Operations (MRO) Procurement Intelligence 2024-2030: From Insights to Action

The maintenance repair & operations (MRO) category is expected to grow at a CAGR of 2.2% from 2024 to 2030. The increasing demand from the manufacturing industries, the high adoption of smart technologies, and the growing requirement to reduce equipment downtime are driving the category’s growth. Companies are increasingly using MRO services to manage their supply chain and inventory efficiently. It is mainly helpful when multiple materials are used in the production process and the absence of any particular material can have a significant impact on production. Robotics is one of the fastest-growing technologies in this category used for improving operational efficiency. It is widely implemented in the industrial, manufacturing, and aftermarket segments. The major applications include single-part repairs, carbon fiber manufacturing, and intricate inspection tasks using miniaturization, which enables robots to inspect components normally difficult for humans to access.

The category is fragmented with a mix of players ranging from spare parts suppliers to national and international-level distributors. MRO often involves a wide, fragmented network of suppliers providing anything from tools, safety equipment, and cleaning supplies. According to industry experts, there is a growth trajectory for aftermarket and maintenance, engineered and machined components suppliers in lower-tier (or, Tier 3) segments in fragmented markets. Companies are increasingly collaborating or collaborating with technology providers to improve their services or expand their product lines.

A few instances of recent developments include:

• In January 2024, Wurth’s division, “Wurth Electrical Wholesale Group” purchased a Poland-based company, TIM SA. The latter is one of the largest electrical materials distributors in Poland. The deal aims to expand and strengthen Wurth’s electrical wholesaling activities in Poland as TIM operates as the largest e-commerce platform in the nation, generating around 70% of revenue through online mediums. Post-purchase, both units under the acquiree-the wholesale and the logistics division-will continue to operate as independent companies.

• In September 2023, Applied Industrial Technologies (AIT) purchased two companies-Bearing Distributors and Cangro Industries. The acquisition will help AIT strengthen its local presence in South Carolina and New York and increase customer access. Both companies will benefit from expanded product lines as they get access to enhanced automation operations.

Order your copy of the Maintenance Repair & Operations (MRO) Procurement Intelligence Report, 2024 - 2030, published by Grand View Research, to get more details regarding day one, quick wins, portfolio analysis, key negotiation strategies of key suppliers, and low-cost/best-cost sourcing analysis

Labor, warehousing, rent and utilities, technology or IT infrastructure, and overheads. Other costs can include transportation, marketing, legal, or tax. Labor is the largest cost component. IT infrastructure is crucial as it includes elements like engineering systems, computerized maintenance management systems (CMMS), enterprise resource planning (ERP) software, and e-procurement systems that impact costs. A CMMS system allows firms to simplify maintenance operations by tracking equipment, inventory, and manpower. There are multiple pricing models in CMMS such as per-user per-month subscription model, tiered pricing models, and on-time perpetual licensing model. In 2024, CMMS software prices may range from as low as USD 30 per user per month to USD 350 per user per month for more complex capabilities. For a customized CMMS solution, the cost can range between USD 1,800 - USD 20,000. Mid-sized companies spend on average between USD 10,000 - USD 50,000 for a customized solution. Small companies can pay around USD 45 - USD 125 per month for a subscription-based model.

China is one of the most preferred countries for procuring industrial supplies and MRO services. While selecting the MRO service providers, clients should consider a number of factors, including product quality, service, and supplier reliability, years of experience and expertise in the target industry, shipping speed, and shipping costs. Other important considerations, under sourcing, include examining the seasonal patterns of MRO inventory demand and adjusting purchases accordingly.

Maintenance Repair & Operations (MRO) Sourcing Intelligence Highlights

• The maintenance repair & operations (MRO) category is fragmented. As a result of this fragmentation, the major challenges for vendors include high acquisition costs, poor visibility into demand, and duplication.

• The competitive rivalry is high among players due to low switching costs and industry fragmentation. One of the major barriers to entry among new entrants is information asymmetry as a result of information or data controls and manuals by manufacturers, OEMs, or vendors.

• Labor forms the largest component, accounting for a 40% - 50% share of the total cost structure.

• Some of the other preferred countries for procuring MRO services include Malaysia, Singapore, Turkey, and UAE (Dubai). These nations have consistently established themselves as reliable players in the APAC region. This is mainly due to the favorable government policies and tax incentives, the ability to create viable ecosystems, and the presence of cost-efficient skilled labor.

List of Key Suppliers

• Adolf Würth GmbH & Co. KG

• Air Liquide S.A.

• Applied Industrial Technologies, Inc.

• MSC Industrial Direct Co., Inc.

• Rubix Group International Limited

• Linde Engineering

• ERIKS Group

• Sonepar Group

• WESCO International, Inc.

• W. W. Grainger, Inc.

• RS Group (formerly Electrocomponents plc)

• Critica Infrastructure (Henkel)

Browse through Grand View Research’s collection of procurement intelligence studies:

• Meetings and Events Procurement Intelligence Report, 2024 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

• Facilities Management Services Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

Maintenance Repair & Operations (MRO) Procurement Intelligence Report Scope

• Maintenance Repair & Operations (MRO) Category Growth Rate: CAGR of 2.2% from 2024 to 2030

• Pricing Growth Outlook: 8% - 15% (Annually)

• Pricing Models: Cost Plus pricing, contract-based pricing model

• Supplier Selection Scope: Cost and pricing, past engagements, productivity, geographical presence

• Supplier Selection Criteria: By types of services and supplies (industrial and production equipment, construction and infrastructure repairs, material handling equipment, tools and supplies, etc.), operational and functional capabilities, quality measures, standards followed, certifications, regulations, and others

• Report Coverage: Revenue forecast, supplier ranking, supplier matrix, emerging technology, pricing models, cost structure, competitive landscape, growth factors, trends, engagement, and operating model

Brief about Pipeline by Grand View Research:

A smart and effective supply chain is essential for growth in any organization. Pipeline division at Grand View Research provides detailed insights on every aspect of supply chain, which helps in efficient procurement decisions.

Our services include (not limited to):

• Market Intelligence involving – market size and forecast, growth factors, and driving trends

• Price and Cost Intelligence – pricing models adopted for the category, total cost of ownerships

• Supplier Intelligence – rich insight on supplier landscape, and identifies suppliers who are dominating, emerging, lounging, and specializing

• Sourcing / Procurement Intelligence – best practices followed in the industry, identifying standard KPIs and SLAs, peer analysis, negotiation strategies to be utilized with the suppliers, and best suited countries for sourcing to minimize supply chain disruptions

#Maintenance Repair & Operations (MRO) Procurement Intelligence#Maintenance Repair & Operations (MRO) Procurement#Procurement Intelligence 2024-2030

0 notes

Text

Enhancing Operational Efficiency with Preventive Maintenance Software

In the realm of modern business operations, maintaining equipment and assets is not just about fixing things when they break down. It’s about proactive management to prevent issues before they occur, ensuring smooth operations and minimizing costly disruptions. This proactive approach is where preventive maintenance software plays a pivotal role.

What is Preventive Maintenance Software?

Preventive maintenance software is a sophisticated tool designed to streamline the process of managing and executing maintenance tasks. Unlike reactive maintenance, which addresses problems after they arise, preventive maintenance focuses on preemptive actions to keep equipment in optimal condition. The software enables organizations to schedule regular inspections, lubrications, repairs, and replacements based on time intervals, usage metrics, or predefined triggers.

Key Features and Benefits

Scheduled Maintenance: Perhaps the most fundamental feature, preventive maintenance software automates the scheduling of routine tasks. This ensures that critical equipment and assets receive timely inspections and servicing, reducing the likelihood of unexpected breakdowns.

Asset Management: The software maintains a detailed inventory of all assets, including their specifications, maintenance history, and current condition. This centralized database allows maintenance teams to prioritize tasks efficiently based on asset criticality and historical performance data.

Resource Optimization: Effective maintenance relies on the availability of resources such as spare parts and skilled labor. Preventive maintenance software helps optimize inventory levels, automate procurement processes, and allocate resources effectively, thereby reducing downtime and costs.

Data-Driven Insights: By capturing and analyzing maintenance data over time, the software provides actionable insights into equipment performance, reliability trends, and maintenance costs. These insights empower decision-makers to make informed choices, optimize maintenance strategies, and forecast budgetary needs more accurately.

Compliance and Documentation: Industries with stringent regulatory requirements benefit from preventive maintenance software’s ability to maintain detailed audit trails, compliance records, and documentation of maintenance activities. This ensures adherence to standards and facilitates inspections and certifications.

Industries and Applications

Preventive maintenance software is widely adopted across various industries where operational efficiency and asset reliability are critical. For instance:

Manufacturing: Minimizing downtime on production lines is essential for meeting production targets and maximizing output.

Healthcare: Ensuring the reliability of medical equipment is paramount for patient care and safety.

Hospitality: Maintaining facilities and amenities helps deliver exceptional guest experiences while minimizing disruptions.

Choosing the Right Software

When selecting preventive maintenance software, organizations should consider several factors. These include scalability to accommodate growth, integration capabilities with existing systems (such as ERP or CMMS), ease of use for technicians, mobile accessibility for field operations, and robust customer support. Customizable features and reporting capabilities tailored to specific needs further enhance the software's utility and effectiveness.

Conclusion

In conclusion, preventive maintenance software represents more than just a technological tool—it’s a strategic asset that empowers organizations to proactively manage their assets, enhance operational efficiency, and deliver consistent performance. By implementing robust preventive maintenance strategies supported by advanced software solutions, businesses can mitigate risks, reduce costs, and maintain a competitive edge in today's dynamic marketplace. Embrace preventive maintenance software today to safeguard your assets, optimize resource utilization, and pave the way for sustained success.

1 note

·

View note

Text

The global demand for Metrology Services was valued at USD 691.2 million in 2023 and is expected to reach USD 1177.7 million in 2032, growing at a CAGR of 6.10% between 2024 and 2032.The metrology services market, a critical segment of the industrial landscape, plays a pivotal role in ensuring the accuracy and quality of manufactured products across diverse industries. Metrology, the science of measurement, has evolved significantly over the years, encompassing various techniques and technologies to achieve precise measurements. This market is driven by the need for high-quality control in manufacturing processes, stringent regulatory standards, and advancements in measurement technologies. In this article, we explore the key drivers, challenges, and future prospects of the metrology services market.

Browse the full report at https://www.credenceresearch.com/report/metrology-services-market

Market Drivers

1. Growing Demand for Quality Control:

In an era of increasing competition and consumer expectations, manufacturers are under constant pressure to deliver products that meet high-quality standards. Metrology services provide the necessary precision in measurement to ensure that components and products meet specified tolerances. This demand is particularly pronounced in industries such as automotive, aerospace, electronics, and healthcare, where even minor deviations can lead to significant consequences.

2. Advancements in Technology:

The metrology services market has witnessed substantial technological advancements in recent years. Traditional measurement techniques are being complemented and, in some cases, replaced by cutting-edge technologies such as coordinate measuring machines (CMM), optical digitizers and scanners (ODS), and X-ray computed tomography (CT). These technologies offer higher accuracy, speed, and versatility, enabling manufacturers to achieve better quality control and reduce production costs.

3. Regulatory Compliance:

Stringent regulatory standards across various industries necessitate precise measurement and documentation. For instance, the aerospace and automotive sectors must adhere to rigorous safety and quality standards, which require meticulous measurement and inspection processes. Metrology services ensure compliance with these standards, minimizing the risk of product recalls and enhancing overall safety.

Market Challenges

1. High Initial Investment:

The adoption of advanced metrology equipment often involves significant initial investment. Small and medium-sized enterprises (SMEs) may find it challenging to allocate the necessary resources for acquiring and maintaining these high-tech instruments. This can be a barrier to entry for some companies, limiting the market's overall growth potential.

2. Skilled Workforce Shortage:

The effective utilization of advanced metrology technologies requires a skilled workforce capable of operating complex instruments and interpreting measurement data accurately. However, there is a shortage of qualified professionals in the field of metrology. This skills gap poses a challenge for the industry, as companies may struggle to find and retain personnel with the necessary expertise.

3. Integration with Manufacturing Processes:

Integrating metrology services seamlessly into existing manufacturing processes can be challenging. Ensuring that measurement data is accurately incorporated into production workflows without causing delays or disruptions requires careful planning and coordination. Overcoming these integration challenges is crucial for maximizing the benefits of metrology services.

Future Prospects

1. Industry 4.0 and Smart Manufacturing:

The advent of Industry 4.0 and smart manufacturing is expected to revolutionize the metrology services market. The integration of metrology with digital technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), will enable real-time monitoring and analysis of measurement data. This will lead to predictive maintenance, improved process control, and enhanced product quality.

2. Increasing Adoption of Non-Contact Measurement Techniques:

Non-contact measurement techniques, such as laser scanning and 3D imaging, are gaining popularity due to their ability to measure complex geometries and delicate surfaces without physical contact. These techniques offer higher speed and accuracy, making them ideal for industries like electronics and medical devices, where precision is paramount.

3. Expansion in Emerging Markets:

Emerging markets, particularly in Asia-Pacific and Latin America, are experiencing rapid industrialization and urbanization. As manufacturing activities increase in these regions, the demand for metrology services is expected to rise. Companies are expanding their presence in these markets to capitalize on the growing opportunities and cater to the evolving needs of local industries.

Key Players

Hexagon AB

Trescal SA

Optical Metrological Services

Carl Zeiss Corporation

Danish Micro Engineering A/S

Nikon Metrology Inc.

FARO Technologies, Inc.

Renishaw plc

Optical Gaging Products, Inc.

ZEISS Inc.

Segmentation

By Type of Service:

Coordinate Measuring Services (CMM)

3D Scanning Services

Reverse Engineering Services

Calibration Services

Dimensional Inspection Services

Form Measurement Services

Alignment Services

Others

By Product Type:

Hardware (Coordinate Measuring Machines, Optical Digitizers and Scanners)

Software

Services

By End-User:

Automotive

Aerospace

Manufacturing

Electronics

Medical

Energy and Power

Construction

Others

By Application:

Quality Control and Inspection

Reverse Engineering

Dimensional Analysis

Alignment

Material and Component Testing

Others

By Technology:

Coordinate Measuring Machines (CMM)

3D Scanners

Laser Trackers

Optical Digitizers

Portable Measuring Arms

X-ray and CT Scanning

Others

By Service Provider:

OEM (Original Equipment Manufacturer) Metrology Service Providers

Third-Party Metrology Service Providers

By Industry Standards:

ISO 9001

ISO/IEC 17025

ISO 13485

AS9100

Others

By Measurement Type:

3D Measurement

2D Measurement

4D Measurement

By Region

North America

The U.S.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Reverse Engineering Service CAD

Reverse engineering CAD (Computer-Aided Design) involves creating a digital 3D model of an existing physical object. This process is commonly used in various industries for product development, redesign, and quality control. Here’s a general overview of the steps involved in reverse engineering CAD:

Steps in Reverse Engineering CAD:

Data Acquisition:

3D Scanning: Use 3D scanners (laser, structured light, or photogrammetry) to capture the physical dimensions and surface geometry of the object. This process generates a point cloud or a mesh that represents the object’s surface.

Manual Measurement: In cases where 3D scanning is not feasible, manual measurement tools like calipers and micrometers can be used to capture dimensions.

Data Processing:

Point Cloud Processing: Clean and filter the point cloud data to remove noise and redundant points. This may involve aligning multiple scans to create a complete model of the object.

Mesh Generation: Convert the point cloud into a mesh, which is a collection of vertices, edges, and faces that define the shape of the object.

Model Creation:

Surface Reconstruction: Use CAD software to create a surface model from the mesh. This can involve fitting surfaces to the mesh data and creating a watertight (solid) model.

Solid Modeling: Convert the surface model into a solid model, which is a more detailed and structured representation used for engineering purposes. This step might involve creating parametric features (e.g., extrusions, fillets, holes) in CAD software.

Validation and Refinement:

Dimensional Inspection: Compare the reverse-engineered CAD model to the original physical object to ensure accuracy. This may involve dimensional checks using CMM (Coordinate Measuring Machine) or comparison tools within the CAD software.

Refinement: Adjust and refine the CAD model to correct any discrepancies and ensure it meets the desired specifications.

Documentation and Output:

Technical Drawings: Generate technical drawings and documentation from the CAD model for manufacturing, assembly, and quality control.

Export Files: Export the CAD model in various formats (e.g., STEP, IGES, STL) for use in downstream applications such as CAM (Computer-Aided Manufacturing) or FEA (Finite Element Analysis).

Tools and Software for Reverse Engineering CAD:

3D Scanners: Examples include Faro, Creaform, and Artec 3D scanners.

CAD Software: Common CAD software used in reverse engineering includes SolidWorks, Autodesk Inventor, Siemens NX, and PTC Creo.

Mesh Processing Software: Tools like Geomagic Design X, MeshLab, and Rapidform are used for processing and converting mesh data into CAD models.

Inspection Software: PolyWorks, Verisurf, and GOM Inspect are used for validating and inspecting the accuracy of the reverse-engineered models.

Applications of Reverse Engineering CAD:

Product Development: Reverse engineering helps in redesigning and improving existing products.

Legacy Parts: Creating digital models of obsolete parts for which no CAD data exists.

Quality Control: Ensuring that manufactured parts conform to design specifications.

Customization: Adapting existing designs to create customized products.

Reverse engineering CAD is a powerful technique that bridges the gap between physical objects and digital models, facilitating innovation and ensuring the accuracy and quality of manufactured products.

0 notes

Text

CMM Inspection Services

Nel Pretech Corporation offers precision CMM Inspection Services, ensuring the highest accuracy in measurement for quality control. Our expert team uses advanced CMM technology to meet your specific inspection needs, providing reliable data for product validation and manufacturing processes. Trust us to deliver precise results with unparalleled attention to detail.

0 notes

Text

Leica RTC 360 Scanning Service Provider in Gujarat | The SUNCAD Training & Designers

Suncad is Leica RTC 360 Scanning Service provider in Gujarat. For more information visit on : https://suncad.in/leica-plant-scanner/ or call us on : +91-9925023229

#BIM Modeling and Scanning Service#Reverse Engineering in Gujarat#CMM Inspection Services#3D Scanning in Gujarat#Heritage Scanning Services in Gujarat#3D Lidar Scanning / 3D Terrestrial Scanning Services#Laser Tracker Service in Gujarat#3D Inspection Services in Gujarat#CNC / VMC Machine Operating#3D Printing Services#Solid Edge Training in Gujarat#SolidWorks Training in Gujarat

0 notes

Text

Hire the Best CMM Programmers from India, DLA

In today’s competitive manufacturing landscape, precision and accuracy are paramount. At Diamond Lead Associates (DLA), we understand the importance of top-tier Coordinate Measuring Machine (CMM) programming in achieving excellence in quality control. As the leading HR consultancy in India, DLA offers exceptional CMM programmers to elevate your projects and ensure precise measurements every time.

Why Choose DLA for CMM Programming?

1. Unmatched Expertise: Our CMM programmers are proficient in using advanced software such as PC-DMIS and Calypso. With years of experience, they are skilled at developing accurate measurement programs tailored to your specific needs, ensuring high-quality inspections and precise results.

2. Customized Solutions: DLA’s approach is client-focused. We understand that each project has unique requirements and challenges. Our programmers work closely with you to deliver customized solutions, whether it’s for first-article inspections, gage repeatability and reproducibility (GR&R), or ongoing quality checks.

3. Cost-Effective Outsourcing: Outsourcing your CMM programming projects to DLA is a smart financial decision. You gain access to our pool of talented programmers without the added expense of hiring full-time employees. This allows you to focus on your core business while ensuring your CMM programming is handled by experts.

4. Commitment to Quality: Quality is at the core of DLA’s services. Our programmers adhere to stringent quality standards, ensuring that every project is executed with precision and attention to detail. This unwavering commitment to excellence has made us the preferred choice for businesses seeking reliable CMM programming services.

Elevate Your Business with DLA

Hiring the best CMM programmers from India is now within your reach. With DLA, you benefit from our expertise, experience, and cost-effectiveness, helping you achieve your project goals efficiently. Partner with us to take your manufacturing processes to the next level. Contact Diamond Lead Associates today to learn more about our CMM programming services and how we can help your business succeed.

#chennai#hrservices#hrconsultant#recruitment agency in chennai#payrolloutsourcing#tambaram#dlahr#cmm programming consultant

0 notes

Text

Digital Scan 3D LLC (DS3D) has the experienced staff to perform any 3D scanning, Reverse Engineering and Quality Assurance projects. Our technological expertise covers a variety of different technologies, including Blue Light, White Light, Blue Laser Line, and Vertical-Cavity Surface-emitting Laser (VCSEL).

Digital Scan 3D LLC

2828 S Kelly Avenue,

Portland, OR 97201

Phone: (503) 388.8888,

Phone: (206) 338.2112

Website: https://digitalscan3d.com/3d-services/

#Inspection and CMM services in Oregon#USA#Kreon 3D Scanner#Kreon 3D Scanner in USA#Polyworks inspector in Oregon

0 notes

Text

The Significance Of Calibration Services By FARE Labs.

Introduction:

In the realm of measurement and instrumentation, accuracy and precision are paramount. Calibration services are the cornerstone in ensuring the reliability and integrity of measurement instruments across various industries. FARE Labs, a renowned Calibration Lab, offers comprehensive calibration services to uphold these standards. This article delves into the importance of calibration and highlights how FARE Labs contributes to enhancing measurement accuracy and reliability.

Comprehensive Calibration Testing Services by FARE Labs:

FARE Labs stands as a beacon of precision in the field of calibration services, offering a diverse array of services tailored to meet the stringent requirements of industries ranging from healthcare to manufacturing. With accreditation as per ISO/IEC

17025:2017 by NABL and its recognition by esteemed regulatory bodies like the Food

Safety & Standards Authority of India (FSSAI), Agricultural & Processed Food Products Export Development Authority (APEDA), Export Inspection Council (EIC), Bureau of Indian Standards (BIS), and MOEF & CC attest to its credibility and adherence to stringent quality standards. FARE Labs employs advanced technologies to conduct thorough analyses, ensuring water meets the highest standards for safety and purity.

The major capabilities and competencies of FARE Labs are as follows:

Temperature Calibration:

Accurate temperature measurement is critical in numerous applications, including pharmaceuticals, food processing, and HVAC systems. FARE Labs provides temperature Calibration Services to ensure the accuracy of thermometers, thermocouples, and temperature sensors. This calibration helps industries maintain precise temperature control, ensuring product quality and safety.

Pressure Calibration:

Precision pressure measurement is essential in industries such as aerospace, automotive, and manufacturing. FARE Labs conducts pressure calibration to verify the accuracy of pressure gauges, transmitters, and sensors. This calibration ensures that pressure-sensitive processes operate within specified parameters, preventing costly errors and ensuring safety.

Electrical Calibration:

Electrical instruments and devices play a vital role in numerous industries, from electronics manufacturing to power generation. FARE Labs offers electrical calibration services to calibrate instruments such as multimeters, oscilloscopes, and power analyzers. This calibration ensures the accuracy of electrical measurements, facilitating reliable operation and troubleshooting.

Dimensional Calibration:

Accurate dimensional measurement is crucial in industries such as aerospace, automotive, and engineering. FARE Labs provides dimensional calibration services to calibrate instruments such as calipers, micrometers, and coordinate measuring machines (CMMs). This calibration service ensures precise measurement of length, width, and depth, supporting quality control and compliance with specifications.

Flow Calibration:

Accurate flow measurement is essential in industries such as oil and gas, chemical processing, and water treatment. FARE Labs offers flow calibration services to calibrate flow meters and sensors. This calibration ensures accurate measurement of flow rates, facilitating process optimization and resource conservation.

Conclusion:

FARE Labs, through its unwavering commitment to calibration testing, emerges as a trusted partner in ensuring measurement accuracy and reliability across industries. By conducting comprehensive analyses and adhering to stringent standards, the laboratory enables industries to operate with confidence, knowing that their measurement instruments are calibrated to the highest precision. As industries continue to rely on accurate measurements for quality assurance and compliance, FARE Labs stands ready to provide the analytical expertise and support needed to uphold these standards with precision and excellence.

SOURCE- https://farelabs.com/the-significance-of-calibration-services-by-fare-labs/

0 notes