#compressed air foam system

Text

USERCENT Portatile Compressore per Auto 12v,Pompa Pneumatica Intelligente da 2000mAH 150PSI,Mini Air Pump Gonfia Gomme per Auto,Moto,Palloni,Biciclette

Portatile Compressore per Auto 12v

Portatile Compressore per Auto 12v

Questo e compressore portatile dotato di batteria da 2000 mAh, nella confezione di vendita troviamo: compressore, cavo di ricarica USB C a USB A, cinque adattatori per, 2x palloni, 1xBici, 1 auto 1,moto. Non ho trovato un manuale all’interno ma il compressore e molto facile da utilizzare.

Il compressore e completamente in alluminio, sulla parte superiore…

View On WordPress

#Unboxing#air compressor#air compressor review#compressed air#compressed air duster#compressed air foam system#compressed air portable drying#compressed air tank#compressor#diy compressed air tank#how to make compressed air tank#make compressed air tank#portable#portable air compressor#portable air compressor for car#portable compressed air#portable compressed air atlas copco#portable compressed air tank#portable mini air compressor#silent air compressor#USERCENT

0 notes

Text

Make a mercy out of me

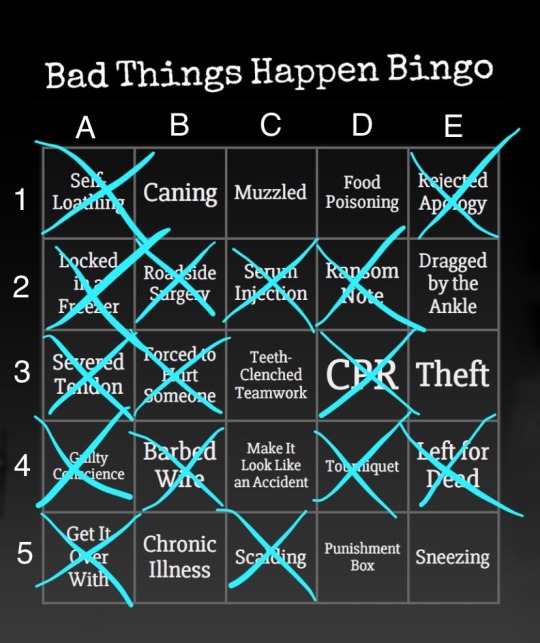

@febuwhump 2024: Day 25: ALT 5: cpr

@badthingshappenbingo: cpr (card at the end)

Rating: Teen And Up

Words: 200

Fandom: Hermitcraft

Warnings: Drowning, Burns, Crying

This is based on @amethystfairy1's Traveling Thieves AU, particularly the works centered around Tango and Zed. I highly recommend it!!

read on Ao3

Tango was sitting on the driver’s bench next to Zedaph, gripping the wood so hard his knuckles matched the foaming water below him. Below the wood planks barely wide enough to fit their wagon, rushing white peaks of frothing water screamed through the canyon.

Then a crack cut through the noise. Then he was falling. Cool air rushed around him as his hands scrambled for purchase on anything, his mind frozen. Then he plunged into the water.

His skin, his lungs, his entire body screamed as the water invaded his system, drowning it in slippery, burning ice. It was too slick to latch onto, but overwhelmed him nonetheless, replacing every spark of oxygen inside him, until he felt a hand grab his wrist.

Zedaph dragged Tango out of the water and laid him down on the shore, his heart aching at the deep purple burns covering Tango’s skin. He interlocked his hands and positioned them over Tango’s heart, then pushed, with a rhythm much steadier than his own heartbeat, apologizing all the time. With each compression, both of them grew more hurt, until finally, Tango started to cough. Zedaph almost collapsed into Tango, tears flowing freely. “I’m so sorry, Tango.”

#writing#creative writing#febuwhump#febuwhump 2024#febuwhump day 25#febuwhump alt 5#bad things happen bingo#prompt: cpr#hermitcraft#fandom: hermitcraft#tango tek#zedaph#chroma writing

1 note

·

View note

Text

Best Melbourne Fire Extinguisher Supplier

The best melbourne fire extinguisher supplier is one that is able to provide you with the right kind of fire extinguisher. If you are looking for a fire extinguisher manufacturer then it is important that you go through a lot of research before you make your choice. You should be able to find out whether or not they have the right experience in this field and whether or not they have all the necessary equipment. The best way to do this is by doing some online research so that you can get an idea about what kind of equipment they use, how much it costs and also how long it takes them to deliver their products.

There are many different types of fire extinguishers available on the market today but most people prefer using carbon dioxide extinguishers because they are highly effective at putting out fires. However, there are also other types available such as foam and halon but these tend to be more expensive than CO2 units and hence less popular among consumers who want their money's worth from their purchase.

If you want to buy a CO2 unit then it is important that you make sure that it has been tested for safety purposes so that there are no possible dangers associated with using it when needed in case of emergencies.

The fire extinguisher is one of the most essential tools in any home. It can save your life and the lives of others in case of fire or any other kind of emergency. You can use it to fight fires, prevent them from spreading and even revive smoke-inhaling victims.

If you are looking for the best fire extinguisher supplier, then you should look no further than Fire Extinguisher Supplier. They offer a wide range of fire protection equipment and have been serving customers for years now. They specialize in providing high quality products at affordable prices.

Fire Extinguisher Supplier offers a wide range of products including:

1) Fire Extinguishers

2) Fire Alarms

3) Smoke Detectors

4) Carbon Monoxide Detectors

5) Emergency Lighting Systems

The fire extinguisher is a portable device that can be used to put out fires when they occur. The most common types of fire extinguishers are those that use water or foam, but some also use chemicals or carbon dioxide. The primary purpose of a fire extinguisher is to reduce the amount of damage caused by a fire.

Fire extinguishers can be found in many different sizes and types. Some are designed to contain small fires, while others are designed for larger fires. Fire extinguishers can also be purchased individually or in bulk from companies that specialize in supplying them.

The first step in finding the best fire extinguisher supplier is deciding what type of extinguisher you need for your home or business. You may have experienced a house fire before, so you know what type of damage occurs when one occurs. If not, then you should read up on how these fires occur so that you know what type of extinguisher will work best for your needs.

After choosing an appropriate size and type of fire extinguisher, it's time to shop around for suppliers who offer competitive prices and good customer service along with quality products at reasonable prices.

If you need to extinguish a fire or prevent one from starting in a small area, then a fire extinguisher is the best solution. Fire extinguishers are an affordable way to protect yourself and others from injury or death. They can be used to put out many types of fires including electrical fires, grease fires and forest fires.

The types of fire extinguishers available include dry chemical powder (BCA), foam concentrate (CO2), halon 1301, carbon dioxide and halon 1211. Each type of fire extinguisher has its own advantages and disadvantages. For example, dry chemical powder has a longer shelf life than foam concentrate which means it can be used again more often without having to be replaced with new supplies. However, dry chemical powders require manual application whereas foam concentrates can be applied automatically by using compressed air or hoses powered by electricity or gas. Dry chemical powders are also more expensive than foam concentrates while they last longer before needing replacement compared to foam concentrates which can last only two years before needing replacement depending on how they are stored and handled during use.

Whether you need one for your home or business there are many factors involved in choosing the right type of fire extinguisher for your situation including size

2 notes

·

View notes

Text

Kerf Weather Stripping: The Unsung Hero of Home Comfort and Efficiency

In the quest for a comfortable, energy-efficient home, the focus often falls on high-profile upgrades like new windows, improved insulation, or advanced HVAC systems. Yet, there’s a less glamorous, often overlooked hero that plays a crucial role in maintaining a cozy, cost-effective living environment: kerf weather stripping. This unassuming strip of material works tirelessly behind the scenes, sealing gaps and keeping the elements at bay. Let’s delve into the world of kerf weather stripping and explore why it deserves a spotlight in your home improvement efforts.

Understanding Kerf Weather Stripping

Kerf weather stripping is a slender, flexible material designed to fit into a small groove, or kerf, cut into the edge of doors and windows. This groove, typically around 1/4 inch wide, allows the weather stripping to create a snug seal between the door or window and its frame. The primary purpose of this seal is to prevent air leaks, but the benefits extend far beyond just keeping drafts out.

The Importance of Kerf Weather Stripping

Energy Efficiency and Cost Savings

One of the most significant advantages of kerf weather stripping is its impact on energy efficiency. Gaps around doors and windows can be major culprits of heat loss in the winter and cool air escape in the summer. These leaks force your heating and cooling systems to work harder, driving up energy consumption and, consequently, your utility bills. According to the U.S. Department of Energy, sealing drafts can save up to 20% on heating and cooling costs. By installing kerf weather stripping, you create a more airtight home, reducing the strain on your HVAC system and lowering your energy expenses.

Enhanced Comfort

Beyond the financial benefits, kerf weather stripping significantly enhances home comfort. In the colder months, it keeps chilly drafts from creeping in, ensuring that your living spaces remain warm and cozy. During the summer, it prevents cool air from escaping, helping maintain a consistent indoor temperature. This improved insulation reduces the occurrence of cold or hot spots in your home, providing a more uniform and pleasant environment.

Noise Reduction

Kerf weather stripping also acts as a barrier against external noise. If you live in a busy neighborhood or near a noisy street, you know how intrusive outside sounds can be. The seal created by kerf weather stripping helps dampen these noises, contributing to a quieter, more serene living space. This is particularly beneficial for bedrooms and other areas where peace and quiet are essential.

Pest Prevention

In addition to its thermal and acoustic benefits, kerf weather stripping serves as a deterrent to pests. Small gaps around doors and windows are inviting entry points for insects and rodents. By sealing these gaps, kerf weather stripping helps keep unwanted critters out, protecting your home from potential infestations and the damage they can cause.

Types of Kerf Weather Stripping

Kerf weather stripping comes in various materials, each with its own set of characteristics and benefits:

Vinyl: Known for its affordability and durability, vinyl weather stripping is a popular choice for many homeowners. It provides a good balance of performance and cost-effectiveness.

Rubber: Rubber weather stripping tends to be more expensive but offers superior sealing capabilities. It’s highly flexible and resilient, making it an excellent option for areas with heavy use or extreme temperatures.

Foam: Foam weather stripping is another viable option, particularly for doors and windows that undergo frequent use. Its compressibility ensures a tight seal even after repeated opening and closing.

Choosing the Right Kerf Weather Stripping

Selecting the appropriate kerf weather stripping for your needs involves considering several factors:

Type of Door or Window: Exterior doors and windows require more robust weather stripping to withstand the elements, while interior doors may need less durable materials.

Climate: If you live in a region with harsh winters or scorching summers, opt for weather stripping that can handle extreme temperatures.

Frequency of Use: Doors and windows that are opened and closed frequently should have durable weather stripping that can withstand wear and tear.

Budget: While it’s important to invest in quality weather stripping, there are options available to suit different budget constraints.

Installing Kerf Weather Stripping

One of the great aspects of kerf weather stripping is its ease of installation. With a few basic tools and a bit of patience, you can tackle this project yourself:

Remove Old Weather Stripping: Use a putty knife or similar tool to carefully remove any existing weather stripping from the kerf.

Clean the Groove: Ensure the kerf is clean and free of debris to promote a secure fit for the new weather stripping.

Measure and Cut: Measure the length of the kerf and cut the new weather stripping to the appropriate size.

Install: Press the weather stripping into the kerf, making sure it fits snugly and evenly along the edge of the door or window.

#Homerenovation #Weatherstripping #KerfWeatherstripping #housewindowrepair #housedoorrepair #kerfDoorSeals

0 notes

Text

Enhance Comfort and Efficiency with American Insulation Removal Services

When it comes to maintaining a comfortable and energy-efficient home or building, insulation plays a crucial role. Over time, insulation can become outdated, ineffective, or damaged, leading to compromised energy efficiency, increased utility bills, and reduced comfort levels. This is where professional insulation removal services like those offered by Americaninsulationco.com come into play, providing comprehensive solutions to address insulation issues effectively.

American Insulation Removal Services specializes in removing old, worn-out insulation and replacing it with modern, energy-efficient options. Their skilled crew is equipped with the knowledge, experience, and tools necessary to handle insulation removal projects of any size or complexity, making the process hassle-free for property owners.

One of the primary reasons to consider insulation removal is to improve energy efficiency. Old insulation may have deteriorated over time, leading to gaps, compression, or damage that compromises its ability to provide adequate thermal protection. This can result in increased energy consumption as heating and cooling systems work harder to maintain desired indoor temperatures. By removing outdated insulation and installing newer, more effective materials, property owners can significantly reduce their energy costs while enhancing comfort levels.

Moreover, removing old insulation is essential for maintaining indoor air quality. Insulation materials such as fiberglass or cellulose can trap dust, allergens, and other pollutants over time, contributing to poor air quality and potential health issues. By replacing old insulation with cleaner, healthier options, such as spray foam or mineral wool, American Insulation Removal Services helps create a healthier indoor environment for occupants.

Additionally, insulation removal is often necessary when upgrading or renovating a property. Whether adding new rooms, upgrading HVAC systems, or addressing moisture issues, proper insulation removal and replacement are crucial steps to ensure optimal performance and longevity of the building.

What sets American Insulation Removal Services apart is their commitment to customer satisfaction and quality workmanship. Their crew conducts thorough inspections before beginning any removal work, identifying areas of concern and recommending the most suitable insulation solutions based on the property's needs and budget.

Furthermore, the team at Americaninsulationco.com prioritizes safety throughout the removal process, adhering to industry best practices and safety protocols to protect both their crew and the property itself.

In conclusion, American Insulation Removal Services offers a comprehensive and hassle-free solution for property owners looking to upgrade their insulation systems. By removing outdated, ineffective insulation and replacing it with modern, energy-efficient materials, they help improve comfort, energy efficiency, and indoor air quality. For anyone considering insulation removal or upgrade projects, Americaninsulationco.com is a trusted partner to rely on for exceptional service and results.

For more info:

American Insulation Removal Services

american insulation in south florida

0 notes

Text

The Invisible Powerhouse: Liquid CO2's Uses and Major Manufacturing Methods

Have you ever stopped to think about the magic behind a perfectly chilled beverage, the fire extinguisher hanging on the wall, or the delicate components in your smartphone? The answer might surprise you: it could all be thanks to liquid carbon dioxide.

This fascinating substance plays a surprisingly vast role in our everyday lives. From keeping food fresh to ensuring our safety in emergencies, liquid CO2 is a true hidden powerhouse. Let's dvelve deeper into the world of liquid CO2 and explore its diverse applications.

Introduction

Liquid carbon dioxide is a versatile player in many industries. In the food world, it keeps things cool, acting as a refrigerant for freezing and chilling everything from ice cream to meats. It's also the secret behind the fizz in your favorite drinks by adding carbonation. Even water treatment gets a boost from liquid CO2. Beyond food and beverages, this liquid form of carbon dioxide has industrial applications. It helps test the durability of airplane and electronic parts at very low temperatures. In oil and gas operations, it can stimulate wells for better production. It even plays a role in controlling chemical reactions in various processes.

Fire safety is another area where liquid CO2 shines. Its non-flammable nature makes it a popular choice for fire extinguishers, both portable and built-in systems, to quickly extinguish flames. So next time you enjoy a bubbly drink, think about the many ways liquid CO2 keeps things running smoothly, from your kitchen to industrial freezers and even firefighting!

Manufacturing Method

Carbon dioxide (CO2) is a major product of alcohol fermentation. In the fermentation process, carbon dioxide bubbles that traverse through the mash layer absorb alcohol vapors along with its volatile impurities. The fermentation gases comprise carbon dioxide, alcohol vapors, air, water vapor, alcohols, aldehydes, organic acids, and complex esters. Evaporation-induced losses of alcohol vary depending on its concentration and the fermentation temperature. At a temperature of 30°C, the typical alcohol losses average to 0.74% of the alcohol content present in the mash.

The fermentation gases are directed into alcohol catchers, where they are absorbed by water and reintroduced into the matured mash as a water-alcohol mixture, with concentrations ranging from 1.5% to 7% by volume. Once devoid of Ethyl Alcohol and its impurities, the fermentation gases are either routed to the Carbon Dioxide production facility or released into the atmosphere.

To generate liquefied carbon dioxide from fermentation byproducts, it is necessary to cleanse the gas of liquid droplets and organic impurities while preventing air ingress into the gas stream. The purified and dehydrated carbon dioxide is then conveyed to the cooling section of the facility for further liquefaction. However, the quality of the resultant carbon dioxide from this raw material may not consistently meet consumer standards.

Modern technology adopts a two-step purification process for carbon dioxide. Initially, it undergoes adsorption purification using activated charcoal columns following the initial compression stage. Subsequently, it undergoes further adsorption purification and dehydration, first in a silica gel adsorber and then in a zeolite adsorber for enhanced drying.

The fermentation gases are initially directed from the fermentation vessels to a foam catcher and then to an alcohol catcher, where they undergo washing with water to eliminate organic impurities and are subsequently cooled. This purified gas is then conveyed to a water ring compressor for further purification and cooling before undergoing compression to a pressure of 0.5 MPa in the initial stage of a three-stage compressor, followed by entry into a refrigeration unit. Oil separators are installed both before and after the refrigeration unit to purify and dry the carbon dioxide.

Subsequently, the gas undergoes purification using activated charcoal in two adsorbers, with one operational while the other undergoes regeneration using heated carbon dioxide produced during throttling. From the adsorbers, the carbon dioxide proceeds to the second stage of the compressor, where it is compressed to a pressure of 2.4…2.5 MPa before passing through the refrigeration unit and an oil separator, then entering the third compressor stage. Here, the gas, compressed to approximately 7 MPa, undergoes further purification and drying through a series of adsorbers containing silica gel and zeolite.

In the condenser, following the third compression stage, the gas condenses, releasing heat. The resulting liquefied carbon dioxide is transferred through a high-pressure receiver into steel cylinders placed on scales. Alternatively, overcooled liquefied carbon dioxide can be produced and stored without the use of cylinders. In this process, liquid carbon dioxide is throttled from 6.5 to 7.0 to 0.8 to 1.2 MPa, resulting in an emulsion state. The liquid and gaseous phases are separated in a vortex distributor, with the gaseous phase constituting about 47%.

The liquid carbon dioxide flows through circular channels of the vortex chamber to a separation vessel and then to a storage vessel, isothermal storage, or a transport isothermal reservoir. The gaseous phase is directed through central openings of the vortex chamber and then through corresponding communication channels to a mixer, where it combines with the gas supplied by the first stage of the compressor before proceeding to the second stage.

The level of liquid carbon dioxide entering the isothermal storage is monitored by a level indicator, and pressure is measured by a pressure gauge, with the maximum filling of the isothermal storage being 85…90% of the geometric volume. Parameters of the liquid carbon dioxide in the isothermal reservoir include a pressure of 0.8 to 1.2 MPa, a temperature ranging from -43.5 to -33.3 °C, a heat of vaporization of 326 to 309 kJ/kg, and a density of 1130.8 to 1087.8 kg/m³.

Cryocap XLL Process

The Cryocap XLL Process is an industrial technique devised to compress, cool, and refine raw CO₂ streams from initial units. This is a process owned by Air Liquide Engineering & Construction. It follows a sequential procedure, commencing with the compression of CO₂ feed gas via a feed/recycle compressor. Following this, the compressed gas undergoes drying at an intermediate pressure prior to a secondary compression phase. Then, the compressed gas is cooled and directed towards the cold process.

Within this cold process, the high-pressure, dry CO₂ is cooled and split into various streams. One stream undergoes distillation within the Stripping Column to yield liquid CO₂ product, which is subsequently dispatched to the unit's battery limits. The remaining streams are expanded to different extents and vaporized within the main heat exchanger, providing the required refrigeration load for CO₂ liquefaction. Post-vaporization, these streams are recycled at ambient temperature back to the feed/recycle compressor. This unique setup enables both feed gas compression and refrigeration to be handled by a single compressor, establishing a self-refrigerated cycle.

The Cryocap XLL process demonstrates environmental friendliness concerning health, safety, and the environment (HSE) as it eliminates the necessity for toxic or flammable external refrigerants such as ammonia or propane. Moreover, employing a single compressor for both feed and cycle operations leads to a compact and cost-effective solution in terms of capital expenditure.

Source: Air Liquide Engineering & Construction

Major Applications of Liquid Carbon Dioxide

Food & Beverages

Pressurized CO2 plays a crucial role in the food industry, serving as a versatile tool for refrigeration, preservation, storage, and softening processes. Liquid CO2 serves as a vital cryogenic cooling agent, maintaining a consistent temperature for food preservation and during the transportation of ice cream due to its high volumetric cooling capacity. Additionally, compressed CO2 gas is integral in the production of soft drinks, where it is utilized to carbonate beverages, replacing natural fermentation methods. Bottled drinks are preserved and softened using pressurized CO2, ensuring their quality and shelf life. Liquid CO2's versatility extends to its use as a solvent, facilitating the removal of caffeine from coffee. Overall, the significance of pressurized CO2 in the food industry cannot be overstated, impacting various aspects of food processing and beverage production.

Fire Extinguishers

Liquid carbon dioxide serves as an effective fire extinguisher due to its non-flammable properties. It operates by depriving flames of oxygen, the essential gas for combustion. Particularly suited for electrical fires, extinguishers containing liquid carbon dioxide eliminate oxygen to extinguish the fire while also cooling the burning surfaces, thereby preventing additional damage.

Oil & Gas

In the process of oil recovery, the liquid is injected into oil wells, where it blends seamlessly with the oil. This blending reduces the viscosity of the oil, making it less thick and allowing it to flow more readily towards the extraction point.

Market Outlook

The food and beverage industry are a major driver for liquid carbon dioxide (CO2) due to its versatility. CO2 not only carbonates beverages but also acts as a natural preservative, extending the shelf life and freshness of food products during storage and transportation. Its inert properties and ability to suppress bacterial growth make it a critical component in food processing and packaging. As consumer demand for packaged and convenient food options continues to rise, the CO2 market within this sector is expected to see significant growth. Furthermore, CO2 plays a crucial role in enhanced oil recovery (EOR) techniques used in the oil and gas industry. By injecting CO2 into existing reservoirs, companies can increase pressure and extract more oil from the rock formations. This method effectively extends the lifespan of oil fields and boosts production rates, driving demand for CO2 in the energy sector.

Liquid Carbon Dioxide Major Global Players

Major players in the Global Liquid Carbon Dioxide market are Punjab Carbonic private Limited, SICGIL India Limited, India Glycols Limited, Prime Gases, Jubilant lifesciences limited, Indo Gulf Corporation, Hangzhou Oxygen Co. Ltd., Messer Group GmbH, Linde Plc, Bangkok Industrial Gas Company Limited (BIG), Messer - AlcoBioFuel Bio-Refinery - IJsfabriek Strombeek JV, Air Products (ACP Belgium), CropEnergies - Tyczka Energie JV, CF Fertilisers UK Ltd, Linde Gáz Magyarország Zrt, and Others.

Conclusion:

Beyond its role in fizzing drinks and keeping food fresh, liquid carbon dioxide (CO2) offers a surprising range of uses. In the oil and gas industry, it even helps extract more resources. Additionally, liquid carbon dioxide functions as a fire extinguisher and can be used to control chemical reactions for safer industrial processes. The liquid carbon dioxide market is poised for significant growth, driven by its expanding role in various industries. From its essential function in carbonating beverages and preserving food to its growing applications in enhanced oil recovery and medical procedures, CO2's versatility and unique properties guarantee its continued relevance. As consumer demand for convenience and efficient production methods rises, the CO2 market is expected to flourish, presenting exciting opportunities for stakeholders across the supply chain.

#liquidcarbondioxide#liquidcarbondioxideprices#liquidcarbondioxidemarket#liquidcarbondioxidepricetrend#liquidcarbondioxidepriceforecast#liquidcarbondioxidepricenews#liquidcarbondioxidemarketprice#liquidcarbondioxidedemand#liquidcarbondioxidesupply

1 note

·

View note

Text

Spray Paint and Car Care Products from FUNGOM

Shenzhen Jiaxun Industrial Co., Ltd. offers single-source solutions and for R & D, manufacturing, marketing, and value-added services. Our main automobile care products include: material refinish paint, eco-friendly household paint, car maintenance (car cleaning, polish, lubrication and protection), silicone sealant(for building material sealing) etc. All our wholesale car products adhere to EU ROHS regulations, cleared the ISO 14001 and ISO 9001 exams. Our quality control method is very stringent.

Types of FUNGOM Aerosol Spray Paint and Car Care Products

FUNGOM Spray Paint Wholesale

Spray Paint

Spray Paint is one of the most important products in our wholesale car care supplies. Our different kinds of spray paint are used for the surface of metal, wood, plastic, glass, high temperature primer, can Print on the door, wall, road, crafts, cloth, etc.

Spray Lubricant

Ant-rust lubricant product include silicone spray, grease spray, rust converter, chain lube, copper grease spray, and universal degreaser.

Car Cleaner Spray

Main use for professional car care, include carb & choke, engine, tire, brake part, chain, wheel, injector, air-conditioner, windshiled. Also for bug & tar, decal clean.

Car Paint Maintenance Products

Kinds of car wax for car maintenance, include ard wax, soft wax, liquid wax, polish wax.

Car Maintenance Products

Protect wholesale car products, car starting fluid, auto ice scraper, defrost spray, anti fog spray, also dashboard and leather wax, tire sealant & inflator.

Household Care Products

Home use product, including home air freshener, funiture polish spray, carpet cleaner spray, insect killer aerosol.

Silicone Sealant

Home use sealant product, including neutral silicone sealant, acetic silicone sealant, liquid nails, pu-foam insulation sealant, pu sealant (auto glass), and rtv silicone gasket maker.

FUNGOM-Leading Aerosol Spray Paint and Car Care Products Manufacturer in China

Strict Quality Control

The wholesale car care products and spray paint produced comply with the EU's ROHS standards, have obtained the EU REACH registered enterprise, passed ISO9001 and SO4001, have advanced inspection and testing equipment, and strict quality control.

Complete OEM Customization Services

It has R & D and design departments that can meet customers' customized needs. The automobile care products range is rich, including different kinds of spray paint, car maintenance, lubricant series, industrial maintenance, home care, etc. Meet the cleaning, maintenance and lubrication of all parts of the car.

Strong Production Capacity

With strong production experience and complete production equipment, we have introduced advanced automated production line PAMASOL and have strict monitoring and management of the production process for car care wholesale and system.

Hot Questions of Spray Paint and Car Care Products

What is spray paint?

Spray painting is a painting technique in which a device sprays coating material (paint, ink, varnish, etc.) through the air onto a surface. The most common types employ compressed gas—usually air—to atomize and direct the paint particles.Generally applied via canned self-spray paint and spray gun.

How do I prepare my car for spray painting?

1. Gathering the necessary tools and materials.

2. Cleaning and washing the car.

3. Remove old paint and rust.

4. Filling and sanding imperfections.

5. Masking and protecting areas.

6. Priming the surface.

7. Choosing the right Spray paint.

8. Applying Spray paint.

9. Drying and curing the paint.

10. Buffing and polishing.

11. Final touches and reassembly.

What are the differences between spray paint and regular paint?

1. Spray paint is applied using an aerosol can or spray gun, while regular paint is applied with brushes, rollers, or other traditional painting tools.

2. Spray paint provides a smooth, even finish and is ideal for covering irregular surfaces, while regular paint may require more skill and effort to achieve a consistent appearance.

3. Spray paint dries more quickly than regular paint, but it may be less durable and require additional protective coatings.

How does spray lubricant work?

The liquid product releasing, i.e. paint, lubricant, detergent etc., and the pressurised gas called a propellant (typically Butane, Propane or CO2). The gas helps to push the liquid into the air and turn it into an aerosol cloud, resulting in the fine mist we see when we press down on the nozzle of the aerosol can.

What car care products do I need for basic maintenance?

1. Multi-Purpose Foam Cleaner.

2. Windshield Cleaner.

3. Tire Sealant & Inflator.

1 note

·

View note

Text

Exploring Expanded Polystyrene: Applications, Manufacturing Techniques, and Major Market Players!

Welcome to the world of Expanded Polystyrene (EPS), a polymer with boundless versatility across industries. In construction, EPS reigns supreme for its remarkable insulation properties, resistance to pests and bacteria, and minimal water absorption. It serves as a key player in building elements, from insulated panels for facades to flotation material for marinas.

In food packaging, EPS proves its adaptability by being molded into trays for fruits and vegetables, ensuring freshness with its non-nutritive composition that deters microbial Join us as we explore the range of applications of EPS, from enhancing construction efficiency to preserving the freshness of our daily produce and safeguarding fragile goods along their journey. We will also throw light on the manufacturing process used for the production of EPS.

Introduction

Expanded Polystyrene (EPS) is a white foam plastic material, consisting of solid beads of Polystyrene, primarily used in packaging and construction. It is a closed-cell, rigid foam produced from styrene, which forms the cellular structure, and pentane, serving as a blowing agent. Comprising 98% air, EPS is highly recyclable and exceptionally lightweight. Its notable attributes include low thermal conductivity, minimal moisture absorption, and superior cushioning properties. With physical properties stable within a service temperature range of up to 167°F/75°C, EPS exhibits chemical resistance comparable to Polystyrene. EPS remains a versatile and widely utilized material across various industries, offering solutions for insulation, protection, and structural support. Also, Expanded Polystyrene, identified by plastic resin code 6, is entirely recyclable.

Here's a breakdown of the key features that make EPS so valuable in the world of polymers:

Energy Efficiency: Building on the high R-Value, EPS products translate to significant energy savings. By keeping your desired temperature (hot or cold) contained within a space, you can rely less on heating or cooling systems, leading to lower energy bills.

Constant Thermal Resistance: Unlike some insulation materials, EPS maintains its insulating properties consistently over time.

Strength: Don't be fooled by its lightweight nature! EPS is surprisingly strong and can withstand significant compression and impact. This makes it suitable for various applications where structural integrity is important.

Recyclability: EPS can be recycled multiple times throughout its life cycle, and its manufacturing process does not generate any leftover solid waste.

No Bacterial Growth or Decay: EPS is resistant to mold, mildew, and bacteria growth. This makes it ideal for applications where hygiene is a concern, especially in food packaging and construction materials.

Dimensional Stability: EPS maintains its shape and size over time, ensuring consistent performance and long-lasting functionality.

Chemical Inertness: EPS doesn't react with most chemicals, making it a safe and reliable material for use in various settings.

Low Cost: Compared to many other insulation materials, EPS offers excellent value for money. This affordability makes it an attractive option for a wide range of applications.

Manufacturing Process

Here's a breakdown of the key points involved in the manufacturing of EPS:

Expanded Polystyrene (EPS) foam is derived from expandable polystyrene (EPS) beads, a rigid cellular plastic containing an expansion agent sourced from oil. The EPS manufacturing process is closely linked to the process described previously, which traced the journey from oil extraction to the creation of expandable polystyrene. Now, let's delve into the transformation process leading to the production of EPS foam parts. The raw material, obtained through a chemical process, undergoes a series of physical transformations in three stages.

Firstly, in the pre-expansion stage, the raw material (beads) is heated in specialized machines known as pre-expanders using steam at temperatures around 215°F. This causes the material's density to decrease from approximately 40 lbs/cu ft to typically between 1 to 2 lbs/cu ft. During pre-expansion, the solid beads transform into cellular plastic beads with small closed cells that trap air inside.

In the second stage, intermediate maturing and stabilization, the recently expanded particles cool down, forming a vacuum within. This vacuum is compensated for by air diffusion, enhancing the beads' mechanical elasticity and expanding capacity. This stage occurs during the material's intermediate maturing in aerated silos or mesh bags, where the beads are simultaneously dried.

Finally, in the third stage, expansion and final molding, the stabilized pre-expanded beads are transported to molds where they are exposed to steam once again, causing them to fuse together. This process yields large blocks through "block molding" (later cut into desired shapes like boards, panels, cylinders, etc.) or directly produces products in their final finished form through "shape molding."

Here is the production process used by INEOS, one of the leading producers of EPS on a global scale. INEOS Technologies provides cutting-edge expandable polystyrene (EPS) technology, offering a combination of competitive variable costs, low investment expenses, and a diverse range of high-quality products widely accepted globally. The demonstrated operational reliability of the process presents a significant competitive edge over other expandable polystyrene producers for upcoming projects.

In the production phase, a reactor is employed to catalyze the polymerization of styrene by introducing a specific blend containing blowing agents, water, initiators, suspending agents, and various additives. This complex mixture undergoes controlled temperature-time conditions with continuous stirring to ensure the dispersion of the monomer and the formation of Polystyrene beads. The entire process is managed by a Distributed Control System (DCS) following an automated sequence.

After polymerization, the resulting Polystyrene beads and water are transferred to a slurry tank, where the subsequent steps become fully continuous. This involves centrifugation to remove a significant portion of the suspension water, followed by conveying the beads to a pneumatic flash dryer to eliminate surface moisture. The dried beads undergo screening, resulting in the extraction of two specific product cuts out of a potential four. The effectiveness of this separation is enhanced by the presence of mineral suspension.

The precise segmentation achieved through this process allows for tailored targeting of product cuts to meet market demands. Typically, finer to medium cuts serve the packaging market, while medium to larger cuts are directed towards insulation applications.

Source: INEOS Technologies

Main Applications of Expanded Polystyrene

Food Packaging

EPS can undergo extrusion using standard equipment to create a continuous sheet, which can then be shaped through vacuum forming and pressure forming processes to manufacture items like fruit trays. Devoid of any nutritional value, EPS effectively inhibits the growth of fungi, bacteria, and other microorganisms. Its thermal insulation properties play a pivotal role in preserving the freshness of food and preventing condensation across the distribution chain. Widely employed in food packaging, EPS serves as a protective medium for seafood, fruits, and vegetables. Furthermore, it is utilized in the production of food service containers such as drink cups, food trays, and clamshell containers, offering versatility and practicality in various culinary settings.

Construction:

EPS finds extensive application in various structural components of buildings, including walls, roofs, and floors, where its compressive strength can be customized to suit specific construction systems such as beam and block setups, underfloor heating installations, and beneath concrete floor slabs. Additionally, it is utilized for void filling purposes and, when densified, serves as a suitable base material for road or rail embankments, particularly in scenarios where traditional fill materials prove excessively heavy. Notably, in urban areas, EPS offers the advantage of alleviating congestion and traffic by facilitating the efficient delivery of large quantities of product compared to conventional hardcore materials.

Industrial Packaging

EPS ensures the comprehensive safeguarding of industrial products during transportation and handling, thanks to its remarkable shock absorption capabilities. This rigid yet lightweight foam can be molded into various shapes to effectively protect and insulate sensitive items, ranging from delicate medical equipment and electronic components to toys and horticultural products during storage and transit. Additionally, EPS finds utility in crafting disposable foam coolers and packing peanuts for shipping purposes. In packaging applications, the selection of appropriate cushioning levels depends on the packaging density to ensure optimal protection.

Market Outlook:

The Expanded Polystyrene (EPS) market is experiencing momentum from various factors, notably its diverse applications spanning construction, packaging, and insulation, leveraging its lightweight nature and excellent insulation capabilities. Particularly, the escalating demand for sustainable and energy-efficient construction materials propels EPS utilization in the building sector. In packaging, EPS's ability to provide protective cushioning proves advantageous, alongside its cost-effectiveness, recyclability, and ease of shaping, all contributing to its extensive acceptance. As environmental consciousness grows, the recyclability and sustainability aspects of EPS products emerge as pivotal drivers, resonating with worldwide initiatives toward eco-conscious solutions.

Expanded Polystyrene Main Players

Significant companies in the Global Expanded Polystyrene market are BASF SE, Atlas Roofing Corp., Alpek S.A.B. de C.V., Kaneka Corp., SIBUR Holding PJSC, BEWI, SUNPOR, Synthos, TotalEnergies, Flint Hills Resources, NOVA Chemicals Corporate, StyroChem, Ravago Manufacturing, UNIPOL, Versalis S.p.A., SABIC, Sundolitt Ltd, and Others.

Conclusion:

Expanded Polystyrene (EPS) is quietly revolutionizing the packaging industry with its impressive versatility. This lightweight champion is a favorite for its protective qualities, safeguarding products in sectors like industrial, food & beverage, and electronics with its exceptional shock-resistance. Not only does EPS shield products from bumps, but its chemical-resistant nature and ability to inhibit bacterial growth ensure items stay safe from harmful interactions and unwanted microbes. Furthermore, EPS goes beyond protection - its insulating properties make it a cost-effective choice for cold storage, refrigerators, and construction applications, promoting temperature control and long-lasting durability. The future of EPS seems particularly promising, with the rapid urbanization driving demand for efficient packaging solutions in construction and consumer goods. As sustainability remains a top concern, ongoing advancements in EPS recyclability promise an even brighter future for this versatile and adaptable material.

0 notes

Text

Several Categories of Plastic Molds

1. Injection mold

It is mainly used in the production of thermoplastic parts of a common molding mold, injection mold corresponding processing equipment is injection molding machine, plastic first in the bottom of the injection molding machine heating cylinder heat melt, and then in the injection molding machine screw or plunger push, through the injection molding machine nozzle and mold pouring system into the mold cavity, plastic cooling hardening molding, release products.

2. Extrusion mold

A kind of mold used to form and produce continuous shape plastic products, also called extrusion molding head, widely used in pipe, bar, monofilament, sheet, film, wire and cable coating, profile processing.

3. High foaming polystyrene molding mold

It is a kind of mold for molding foam packaging materials of various desired shapes with the application of flexible polystyrene (beaded material composed of polystyrene and blowing agent) raw materials. The principle is that the polystyrene can be steam formed in the mold, including two types of simple manual operation mold and hydraulic press straight-through foam mold, mainly used to produce industrial packaging products. The materials for making this mold are cast aluminum, stainless steel, bronze and so on.

4. Blister mold

A kind of mold for some relatively simple plastic products formed with plastic plates and sheets as raw materials, the principle is to use vacuum blooming method or compressed air forming method to make the plastic plates and sheets fixed on the concave die or punch, deformed and stuck on the mold cavity under heating and softening to get the required molding products. Blister mold mainly used in the production of some daily necessities, food and toy packaging products.

0 notes

Text

What are the different uses of PVC Foam Tape Single Sided?

Whether your aim is to bind materials, protect surfaces, or mitigate vibrations, selecting the appropriate adhesive tape is paramount. In the realm of adhesive solutions, PVC Foam Tape and Poron Foam Tape stand out as versatile options with diverse applications.

Picture a tape that effortlessly molds to uneven surfaces, endures extreme environmental conditions, and delivers exceptional cushioning and sealing capabilities. This is the essence of what PVC Foam Tape and Poron Foam Tape bring to the table. From everyday household fixes to demanding industrial settings, these tapes have consistently demonstrated their indispensability, establishing a track record for reliability and effectiveness.

What is single sided foam tape used for?

PVC Foam Tape Single Sided, featuring adhesive on one side and a foam carrier on the other, finds versatile applications owing to its distinct characteristics:

Sealing and Insulation: Employed to seal crevices and provide insulation against air, moisture, dust, and sound. Widely used around windows, doors, HVAC systems, and various openings to enhance energy efficiency and indoor comfort.

Mounting: Frequently utilized for affixing lightweight items like signs, posters, nameplates, and decorative trim. Its foam backing ensures adaptability to uneven surfaces, fostering a robust bond.

Cushioning and Shock Absorption: The foam's inherent properties offer cushioning and shock absorption, making it ideal for safeguarding delicate items during transit or handling. Additionally, it serves in electronics to mitigate vibrations and diminish noise levels.

What is Poron Foam Tape

Poron Foam Tape is a specialized foam tape renowned for its cushioning and sealing prowess. Crafted from microcellular urethane, it boasts exceptional resistance to compression set, along with remarkable durability and elasticity. Widely embraced across electronics, automotive, medical devices, and aerospace sectors, Poron foam tape stands as a versatile solution.

Its superior cushioning capabilities render it indispensable for tasks demanding shock absorption, shielding delicate components from vibrations and impacts. Moreover, its adept sealing properties establish a robust defense against dust, moisture, and contaminants, making it an invaluable asset for sealing applications aimed at thwarting the ingress of fluids.

1 note

·

View note

Text

Wall Insulation Installation Solution

Internal wall insulation reduces heating bills and boosts indoor consolation. The amount of insulation you want will rely upon the surface space of the wall and the thickness of the gap being filled. Our products are designed to bring consolation and safety to residential dwellings and industrial buildings through their acoustic absorption and fireplace-resilient properties. Internal insulation may be fitted when you’re planning to redecorate anyway or to suit a new kitchen or toilet. Plug holes within the high and bottom plates with expanding spray foam. These gaps create pathways for warm interior air to leak into the attic, losing energy and causing attic condensation or even ice dams in cold climates - insulation removal brisbane.

Most exterior insulation systems deal with this problem via the inclusion of a vapor barrier between the wall and the insulation, but it's value checking with your manufacturer/supplier. The resolution helps to create quiet, peaceful, and comfortable areas in residential and industrial environments. They can even forestall strain on the compression factors of the insulation and give it a constant thickness. It additionally supplies info on the best follow for inside wall insulation. If you’re putting in in-between wall studs, you need to choose a product that has a particular width - roof insulation removal.

Attics and basements usually remain accessible after a house is built, so it's not a problem to upgrade the insulation in these areas. The same can't be said for walls since the insulation spaces between studs are hidden behind drywall and exterior siding. However, insufficient wall insulation can have a huge impact on home comfort and efficiency.

Make your home warmer in winter and cooler in summer while saving money with proper insulation. We'll show you how to insulate several areas around the home with batt and roll insulation, including a crawlspace, a basement, walls or an attic. When installing home insulation, always follow the manufacturer's instructions. Here are some things you need to do before you begin. We can help you upgrade your home's insulation with a variety of wall insulation options. If you want to enjoy more comfortable rooms and reduce your heating and cooling bills, contact us today to get started. For more information, please visit our site https://roofsuckers.com.au/

0 notes

Text

The Significance Of Accurate Installation In Enhancing Phenolic Foam Insulation Performance

As the pursuit of energy-efficient building solutions continues, phenolic foam insulation has risen as a pioneering material. Boasting exceptional thermal conductivity properties and outstanding fire-resistant characteristics, it has become the preferred option for architects and builders dedicated to constructing sustainable and secure structures. However, amidst the accolades, a crucial factor often escapes the limelight, profoundly influencing the performance of phenolic foam insulation—its installation. In this article, we delve into the pivotal role of accurate installation in optimizing the efficiency and durability of phenolic foam insulation systems.

The Distinct Advantages of Phenolic Foam Insulation

Before delving into installation intricacies, it’s paramount to comprehend the inherent advantages of phenolic foam insulation. This advanced material possesses one of the lowest thermal conductivities among insulation materials, leading to outstanding heat resistance. Moreover, its non-combustible nature coupled with excellent fire performance ensures a secure environment for occupants.

The Nexus Between Installation and Performance

While the material’s properties are indeed impressive, the key to unlocking its full potential lies in meticulous installation. Phenolic foam insulation’s effectiveness hinges on its ability to create a seamless thermal barrier, preventing heat transfer and enhancing energy efficiency. An improper installation, on the other hand, can introduce gaps, voids, and compression, thereby compromising the insulation’s overall efficacy.

Factors Influencing Phenolic Foam Insulation Installation

Skilled Workmanship: A successful installation requires skilled professionals well-versed in the nuances of phenolic foam insulation. Trained installers understand the correct methods to ensure proper fitting and adhesion, eliminating the risk of air pockets that could hinder performance.

Adherence to Manufacturer Guidelines: Following the manufacturer’s installation guidelines is paramount. Deviations from these guidelines can lead to poor installation, impacting the material’s R-value and overall insulation performance.

Sealing and Moisture Management: Phenolic foam insulation’s moisture resistance capabilities are noteworthy, but improper sealing can compromise this attribute. Inadequate sealing allows moisture intrusion, leading to reduced insulation efficiency and potential structural damage.

Avoiding Compression: Phenolic foam’s structural integrity can be compromised if subjected to excessive pressure during installation. Preventing compression is essential to maintain the material’s insulating properties and ensure it functions as intended.

Long-Term Implications of Accurate Installation

Investing in the proper installation of phenolic foam insulation yields substantial long-term benefits:

Enhanced Energy Efficiency: A flawlessly installed insulation system prevents thermal bridging and air leakage, enabling the building to maintain a consistent internal temperature with minimal reliance on heating and cooling systems.

Lifecycle Savings: The reduction in energy consumption due to optimal insulation performance translates into significant cost savings over the building’s lifecycle.

Environmental Impact: Energy-efficient buildings contribute to lowered carbon emissions. Properly installed phenolic foam insulation aids in decreasing a structure’s carbon footprint, aligning with environmental sustainability goals.

Comfort and Wellbeing: A thermally insulated building provides a comfortable and healthy indoor environment for occupants, shielding them from extreme temperatures and potential moisture-related issues.

Conclusion

Phenolic foam insulation stands as a remarkable solution for modern construction challenges. Its exceptional properties can only be fully harnessed through accurate installation practices. Hiring skilled professionals, adhering to manufacturer guidelines, and focusing on sealing and moisture management are essential steps in ensuring the insulation performs at its peak. By appreciating the vital interplay between material and installation, we can create energy-efficient and sustainable buildings that stand the test of time, embodying the best of modern construction practices.

This blog was originally posted here - https://oceanstar-me.com/the-significance-of-accurate-installation-in-enhancing-phenolic-foam-insulation-performance/

0 notes

Text

During A Lot Of The 19th Century

Thirdly, the gun has a thirty-six ft taking pictures vary. Lastly, if its options do not excite you, then it will! The Orbi gun comes in a pair of two. What does this mean? Your child can go all Clint East Wood with two water guns. It's attractive for a four-12 months-outdated. It comes in pairs. Can shoot at ranges of thirty-six feet. The water gun is totally different from other water guns. The water gun is electric. Its system is motorized and can shoot forty photographs in lower than fifteen seconds. Secondly, it has no pumping, solely automatic shooting. Lastly, it has a shooting range of twenty-five ft. Apart from that, its design is that of an MP5 submachine gun. Thus, it provides you or your kid the experience of a sub-machine gun. Gives you a real gun experience. It is electric, thus no pumping. It is easy to use. Firstly, the gun is available in pairs of two or 4. Thus, the advantage of this is that it saves you money.

The water gun has a blaster and a ranger able to capturing thirty ft away, thus offering a number of capturing options. If you're on the lookout for the very best reservoir water gun, we recommend you select this one. It has a large tank reservoir that can final for two hours before reloading. It presents two taking pictures options. The gun can operate without its reservoir when related to a water source. The water gun has a one-liter reserve tank; therefore you won't have to fret about reloading incessantly. On high of that, the tank comes with adjustable shoulder straps. Thus, you is not going to have to fret about carrying the tank. Lastly, it is simple to reload compared to other water guns. It has a large tank reservoir. Comes with straps, thus simple to carry. It is simple to reload in comparison with other water guns. The water gun has very light pump-motion it is suitable for multiple player video games. Secondly, the water gun has a twenty-5 oz reservoir.

Foam guns are dynamic and safe fun for youngsters of all ages. The youthful ones will get pleasure from capturing at the targets, whereas the older ones will certainly combat one another. Most of most of these toys work by compressing air with a lever or tension, however Roller Rifles are gaining an increasing number of popularity. Inside, there are two or more rollers which, rotating rapidly, pull within the foam projectile, throwing it by the barrel. Roller Foam Dart Rifle is a robust piece of toy. Its design is very large so it may be held in lots of alternative ways. There is a handle below the barrel that permits you to seize the toy more firmly, whereas the rear part consists of a inventory that allows the rifle to relaxation on the shoulder. The good benefit of the rifle is a large magazine mounted at the underside, which may hold as much as 20 foam bullets. It is made of clear plastic, so you possibly can simply management the quantity of arrows remaining to fire. There is a spring in the magazine that pushes the bullets remaining inside upwards to the main chamber linked to the barrel. There is a button below the trigger that must be held while taking pictures - because of this, your youngster will keep away from uncontrolled shots. On the right side of the rifle, there's a sliding window, due to which you can look into the cartridge chamber so that in case of jamming it may be simply eliminated. At the underside of the handle of the weapon there may be an orange hook to which you can attach carabiners for a extra comfortable carrying of the weapon. The set features a Roller Rifle, 20 darts with a clean tip, 20 darts with a suction cup and a transparent magazine that holds 20 foam bullets. The toy needs 6 "AA" batteries to work - they aren't included within the set.

Our editors will overview what you’ve submitted and decide whether or not to revise the article. Our editors will assessment what you’ve submitted and decide whether to revise the article. 1,000 km (600 miles) or less in diameter, that orbit the Sun primarily between the orbits of Mars and Jupiter in a nearly flat ring known as the asteroid belt. It is due to their small dimension and enormous numbers relative to the major planets that asteroids are additionally known as minor planets. The 2 designations have been used interchangeably, although the term asteroid is extra widely recognized by most of the people. Among scientists, those who study individual objects with dynamically attention-grabbing orbits or groups of objects with similar orbital characteristics typically use the time period minor planet, whereas those who examine the bodily properties of such objects usually refer to them as asteroids. The distinction between asteroids and meteoroids having the identical origin is culturally imposed and is mainly one among size.

The introduction of images to the search for brand new asteroids in 1891, by which time 322 asteroids had been identified, accelerated the discovery charge. The asteroid designated (323) Brucia, detected in 1891, was the primary to be discovered by means of photography. By the end of the nineteenth century, 464 had been discovered, and that number grew to 108,066 by the top of the 20th century and more than 1,000,000 in the third decade of the twenty first century. In 1918 the Japanese astronomer Hirayama Kiyotsugu recognized clustering in three of the orbital parts (semimajor axis, eccentricity, and inclination) of varied asteroids. In the mid-20th century, astronomers began to contemplate the concept, in the course of the formation of the photo voltaic system, Jupiter was liable for interrupting the accretion of a planet from a swarm of planetesimals situated about 2.Eight astronomical items (AU) from the Sun; for elaboration of this idea, see beneath Origin and evolution of the asteroids.

1 note

·

View note

Text

How Do You Reinforce The Stopper In Your Water Gun?

Abstract:We present a brand new crater chronology for Jupiter's Trojan asteroids. This software can be used to interpret the collisional historical past of the our bodies noticed by NASA's Lucy mission. The Lucy mission will visit a complete of six Trojan asteroids: Eurybates, Polymele, Orus, Leucus, and the near equal mass binary Patroclus-Menoetius. In addition, Eurybates and Polymele each have a small satellite. Here we present a prediction of Trojan cratering primarily based on current models of how the Solar System and the objects themselves advanced. We give specific emphasis to the time lapsed since their implantation into stable areas near Jupiter's Lagrangian L4 and L4 factors. 10 Myr) after implantation, through which cometary impacts might have been important. For adopted crater scaling legal guidelines, we discover that the overall spatial density of craters on Trojans is significantly lower than that of Main Belt asteroids on surfaces with related formation ages. We additionally focus on specific predictions for similar-sized Eurybates and Orus, and the binary system Patroclus-Menoetius.

Some repeating firearms require manipulation of a bolt (as in bolt action), lever, or slide to eject the fired cartridge case, draw a fresh cartridge from the journal, and insert it into the firing chamber, and "cock" (draw to the rear and place under spring tension) the hammer or striker, so that pulling the trigger will fire the weapon. Others use both the firearm's recoil, or a small portion of the propellant gas drawn from the barrel, to function the firearm's mechanism and prepared it for the subsequent shot. Such firearms are typically referred to as "self-loading," however are more commonly known as semi-automated, if they hearth one shot for each pull of the trigger, or automated or "full-auto" in the event that they continue to hearth until the trigger is released and/or the magazine is empty. A revolver is a singular type of firearm in which a rotating cylinder holds plenty of cartridges; the cylinder "revolves" to align each "chamber" or "charge hole" with the rear of the barrel, hold the cartridge and include the pressure (as much as 65,000 pounds per sq. inch or 450 MPa) produced when the cartridge is fired.

We love the development of this mannequin. It has 5 integrated magazines that hold three foam balls each, and because the toy is about, its whole entrance cylinder is loaded. Also, it is nice that the Rival Roundhouse XX-1500 has a set off security lever. The entire entrance cylinder has to rotate every time you need to shoot, making this Nerf gun a bit arduous to set. Because of this, it is not the most effective possibility for small youngsters. Once the foam balls hit their goal, they are likely to roll and bounce into odd places, making them a bit challenging to keep observe of. Even so, the Rival Roundhouse XX-1500 is perfect for a ball-model toy blaster. The Nerf Longstrike Modulus has a really inventive design with an array of configurations. It can be utilized as a short barrel blaster, or you'll be able to attach an extended barrel, or then set it up as a bipod with extendable legs to the barrel. The Modulus scope could be hooked up in any configuration.

It also has an interesting history, wherein it was accidentally created by an inventor named Lonnie Johnson. Johnson was a nuclear engineer for the Air Force in the 1980s, and he was working on a heat pump that used compressed air to cool properties. He was testing his invention by capturing water out of a nozzle when he realized that he could flip his system into a toy. He assembled the tubing, grabbed the nozzle, and started shooting water. This accidental invention made him involved in making a simpler and more efficient model. He created a prototype water gun and let his daughter play with it. For days his daughter loved the water gun, and the toy turned well-known in the neighborhood. Due to this, Johnson started to create a more sensible model of the water gun. After creating the improved version of the water Orbi Gun, Johnson patented his work to ensure he’s credited for his invention. Once every thing was set, Johnson began to market his work.

As of Friday morning, the hashtag "orbeezchallenge" appeared to be disabled in TikTok’s search. However, the hashtag still exists with more than 182 million views. Several different hashtags with slight spelling differences even have garnered tens of millions of views. TikTok did not instantly respond to a request for touch upon Friday. Hours after the shooting, New York City police shared a warning about bead blasters guns Thursday evening, calling them an air rifle as they shoot gel water beads propelled by a spring-loaded air pump. "Air rifles are a violation in NYC & are unlawful to own," the department mentioned. Violators found with such toy guns will be issued criminal summons and the weapons will likely be confiscated, in accordance with police. Incidents involving toy guns firing gel or water beads have led to arrests across the nation. Last month, Ohio high school senior Ethan Liming was crushed to dying after he and his pals were in a automotive taking pictures a SplatRBall Water Bead Blaster gel gun "at objects and possibly unsuspecting individuals," police said. Akron police Chief Stephen Mylett was requested if Liming was taking part in the Orbeez problem, but he did circuitously tackle the trend. In Florida, a 17-yr-outdated high school pupil was hit with a felony cost in March after deputies mentioned he shot a faculty worker in the face from his automotive. The Volusia County Sheriff’s Office, which dealt with the investigation, shared a warning about the "Orbeez challenge" and reported at the very least five arrests associated to the development.

1 note

·

View note

Link

Check out this listing I just added to my Poshmark closet: Merrell Tideriser Luna Hiking Sandals Mens 15.

0 notes

Text

The Power of Insulation: How Wall Insulation Helps Cut Electricity Expenses

In an era of increasing electricity costs and growing environmental awareness, the significance of wall insulation cannot be understated.

As individuals and businesses alike strive to reduce energy consumption and minimise their carbon footprint, the impact of proper wall insulation Adelaide on cutting electricity expenses is a topic of great interest and importance.

Understanding the Importance of Wall Insulation

Wall insulation serves as a critical component in maintaining indoor thermal comfort by minimising heat transfer between the interior and exterior of buildings. By effectively reducing the influence of outdoor temperatures on indoor climate control, insulation helps to stabilise internal conditions, creating a more comfortable living and working environment.

In addition to thermal regulation, wall insulation also plays a vital role in soundproofing and improving acoustics within a space, contributing to overall occupant well-being.

The Financial Benefits of Wall Insulation

One of the most compelling arguments for investing in wall insulation is its substantial impact on reducing electricity expenses. Properly insulated walls help to maintain a consistent indoor temperature, minimising the need for excessive heating and cooling. As a result, property owners and occupants can experience significant reductions in energy consumption, leading to lower utility bills and long-term cost savings.

https://premierinsulation.com.au/wp-content/uploads/2022/08/imp.jpg

The initial investment in high-quality wall insulation Adelaide often translates into substantial financial returns over time, making it a sound financial decision for residential and commercial properties.

Environmental Impact and Sustainability

Beyond the financial advantages, wall insulation aligns with broader environmental goals by promoting energy efficiency and reducing carbon emissions. By curbing the demand for heating and cooling, insulation contributes to a decreased reliance on fossil fuels, thereby mitigating the environmental impact of energy production. This, in turn, supports sustainability initiatives and aids in the global effort to combat climate change, making wall insulation a tangible and effective contribution to environmental preservation.

Factors to Consider When Choosing Wall Insulation

Selecting the most suitable wall insulation involves careful consideration of various factors. These include the climate in which the building is situated, the building's structural characteristics, and the occupant's specific requirements. High-quality insulation materials, such as fibreglass, mineral wool, and foam, offer different levels of thermal resistance and performance, necessitating informed decision-making based on the unique needs of each property.

Additionally, fire resistance, moisture control, and environmental impact should be evaluated to ensure that the chosen insulation aligns with practical and sustainable considerations.

Professional Installation: Ensuring Optimal Performance

While choosing the right insulation is crucial, the importance of professional installation cannot be overstated. A properly installed insulation system maximises its effectiveness and longevity, ensuring that the desired thermal and financial benefits are realised. The professional installation addresses issues such as air gaps, compression, and inadequate coverage, providing a comprehensive and reliable solution for energy efficiency and cost savings. Moreover, engaging skilled installers offers peace of mind, knowing that the insulation will perform optimally and deliver the expected outcomes.

Final Thoughts

In conclusion, the impact of wall insulation on cutting electricity expenses extends far beyond simple thermal regulation. Its influence on financial savings, environmental responsibility, and overall occupant comfort underscores its indispensable role in modern building design and operation. When strategically selected and professionally installed, wall insulation Adelaide represents an investment with multifaceted benefits, ultimately contributing to a more sustainable and cost-effective built environment.

0 notes