#conveyor loading system

Explore tagged Tumblr posts

Text

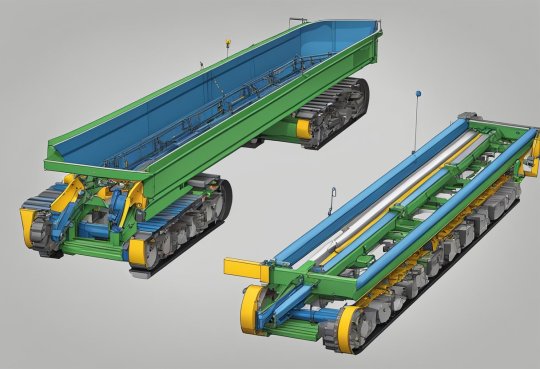

Choosing the Right Conveyor Loading System for Your Warehouse

Selecting the ideal conveyor loading system can transform your warehouse operations, enhancing productivity, safety, and efficiency. However, with so many types and configurations available, choosing the right system can be challenging. In this guide, we’ll explore the key considerations to keep in mind when selecting a conveyor loading system, from types and functionality to maintenance needs and adaptability. By understanding these factors, you can make an informed choice that aligns with your warehouse’s unique needs.

Why Invest in a Conveyor Loading System?

A conveyor loading system is more than just a mechanism for moving goods—it’s a strategic investment that can improve warehouse productivity and streamline operations. A well-chosen system can reduce labor costs, minimize handling times, and improve overall workflow efficiency. If your warehouse handles high volumes of products, investing in an efficient conveyor loading system can offer substantial returns over time.

Key Considerations When Choosing a Conveyor Loading System

To select the best conveyor loading system for your warehouse, you’ll need to evaluate several factors. Here are the primary considerations to guide your decision.

1. Type of Products and Material Handling Needs

The first step in choosing a conveyor loading system is to consider the type of products your warehouse handles. Different systems are optimized for specific types of materials and handling needs:

Heavy items: Roller conveyors or chain conveyors are best for heavy items, as they can handle significant weight without compromising speed.

Light or fragile items: Belt conveyors with soft surfaces or padded options can safely transport fragile goods.

Irregularly shaped items: Flexible or modular conveyors adapt well to items of varying shapes and sizes.

Understanding your product’s size, weight, and fragility will help determine which conveyor loading system will deliver the best results.

2. Warehouse Space and Layout

Warehouse space plays a crucial role in conveyor selection. A compact warehouse may benefit from an overhead or vertical conveyor loading system to save floor space, while larger warehouses can accommodate extensive horizontal conveyors for optimal efficiency.

Compact spaces: Consider vertical or ceiling-mounted conveyors to maximize floor space.

Larger layouts: Belt and roller conveyors can cover long distances, connecting multiple areas for efficient material flow.

Modular setups: For warehouses that frequently change layouts, a modular conveyor loading system offers flexibility and easy reconfiguration.

Tip: Assess your warehouse layout and plan conveyor paths in advance to optimize both space and efficiency.

3. Speed and Throughput Requirements

How quickly does your warehouse need to move goods from one area to another? Your conveyor loading system should match your throughput requirements to avoid bottlenecks.

High-speed conveyors: Ideal for facilities that require rapid movement of goods.

Variable-speed conveyors: Allow you to adjust speed based on specific needs, such as handling fragile items carefully or increasing speed during peak times.

Automated sorting options: Some conveyors include sorting mechanisms to further improve accuracy and speed.

Matching conveyor speed to your warehouse’s demand can help avoid delays and keep operations running smoothly.

4. Automation and Integration Capabilities

Automation is a growing trend in warehouses as companies strive to streamline operations and reduce reliance on manual labor. An automated conveyor loading system can further improve efficiency, especially when integrated with warehouse management software (WMS).

Automated loading and unloading: Reduces the need for manual intervention, accelerating processes.

Integrated scanning and sorting: Systems with built-in scanners and sorters can ensure items reach the correct destinations.

Compatibility with WMS: Integration with warehouse software allows real-time tracking, improving inventory accuracy.

Tip: Look for a conveyor loading system that supports future automation upgrades to keep pace with technological advances.

5. Maintenance Requirements

A conveyor loading system is an investment that requires regular maintenance to ensure it operates efficiently. When selecting a system, consider its maintenance needs and whether you have the resources for upkeep.

Durability: Opt for a conveyor made from high-quality materials to reduce wear and tear.

Ease of maintenance: Choose a system with easy-access components for quick repairs.

Maintenance schedule: Conveyor systems with long service intervals can reduce downtime and maintenance costs.

Tip: Create a maintenance plan that includes regular inspections, cleaning, and part replacements to extend the life of your conveyor loading system.

6. Budget and ROI

While initial costs may be a factor, the long-term benefits of a conveyor loading system can offer significant ROI. Calculate potential cost savings by estimating reductions in labor costs, time saved, and the potential for increased throughput.

Initial costs: Conveyor systems vary in price based on type, size, and features. Determine a budget that aligns with your warehouse needs.

Operational savings: A well-maintained conveyor loading system can reduce manual labor, leading to substantial savings over time.

Improved efficiency: With faster loading, unloading, and transportation of goods, conveyors enable your warehouse to process more orders, boosting profitability.

Types of Conveyor Loading Systems

To meet specific material handling needs, consider the types of conveyor loading systems available:

Belt Conveyors: Suitable for transporting a wide range of products, including light and fragile items.

Roller Conveyors: Designed for heavy or bulky items, roller conveyors are durable and require minimal maintenance.

Chain Conveyors: These conveyors handle heavy loads and are ideal for transporting pallets.

Modular Conveyors: Flexible and easy to reconfigure, making them suitable for warehouses with changing layouts.

Vertical and Overhead Conveyors: Ideal for compact warehouses needing to maximize floor space.

Each conveyor type offers unique advantages, so it’s essential to align the system’s features with your warehouse’s specific requirements.

Best Practices for Implementing a Conveyor Loading System

After selecting the right conveyor loading system for your warehouse, effective implementation is crucial to maximizing its potential. Here are some best practices:

Plan the layout: Design a layout that optimizes material flow from loading docks to storage areas and shipping zones.

Train staff: Ensure employees are trained on system operation and safety protocols to maintain efficiency and minimize accidents.

Perform regular maintenance: Schedule inspections and repairs to prevent downtime and extend system longevity.

Following these best practices ensures a seamless transition to automated material handling, enhancing your warehouse’s overall productivity.

FAQs

1. How do I know which conveyor loading system is best for my warehouse?

Consider your product type, warehouse layout, speed needs, and budget. Consulting a conveyor specialist can help determine the best system for your unique requirements.

2. Are conveyor systems expensive to maintain?

Maintenance costs depend on the system type and usage. However, high-quality conveyors with regular upkeep often have minimal maintenance costs over time.

3. Can a conveyor loading system be expanded as my business grows?

Yes, many conveyors are modular, allowing you to add sections or adjust layouts as needed, making them ideal for growing warehouses.

4. Do conveyor systems improve worker safety?

Yes, by reducing the need for manual handling, conveyors can lower the risk of injuries and create a safer work environment.

5. How long does it take to install a conveyor loading system?

Installation time depends on the system’s complexity. Simple setups may take a few days, while larger, automated systems may require weeks.

Conclusion

Selecting the right conveyor loading system for your warehouse involves careful consideration of various factors, from product type and space constraints to budget and automation capabilities. With the right system in place, you can improve your warehouse's efficiency, accuracy, and safety, all while reducing labor costs. By assessing your warehouse’s needs and consulting with conveyor specialists, you can make an informed choice that supports your operational goals. A well-chosen conveyor loading system is a valuable asset that will streamline your warehouse operations and help you stay competitive in today’s fast-paced logistics industry.

0 notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

Truck Loading Conveyor Manufacturers in Faridabad: Leaders in Innovation

Looking for cutting-edge truck loading conveyor solutions? Discover why Faridabad is the heart of conveyor manufacturing in India. Home to industry-leading companies, Faridabad-based manufacturers are known for their technological innovation, customized designs, and cost-effective solutions for modern logistics and warehousing.

From telescopic conveyors to hydraulic truck loaders, these manufacturers are empowering India’s supply chains with faster, safer, and more efficient material handling systems. Whether you're in e-commerce, FMCG, agriculture, or manufacturing, these conveyors are engineered to deliver unmatched performance.

#truck loading conveyor#Faridabad manufacturers#conveyor systems India#telescopic conveyor#hydraulic loading conveyor#material handling India#warehouse automation#belt conveyor#loading solutions India

0 notes

Text

Truck Loading Conveyor Manufacturing in India | Vashnavi Conveyor Industry

Looking for efficient truck loading conveyor solutions in India? Vashnavi Conveyor Industry is a leading manufacturer of high-performance truck loading conveyors designed for fast, safe, and efficient material handling. Our systems are ideal for warehouses, logistics hubs, and industrial loading bays. Get customized solutions with durable design and easy operation.

#Truck loading conveyor#conveyor manufacturer India#Vashnavi Conveyor#loading conveyor#material handling systems#industrial conveyor#truck loading system#conveyor suppliers India

1 note

·

View note

Text

The Industrial Workstations are structured and ergonomic settings that enhance productivity, reduce breakdown times, and minimize hazards in workplaces. Investing in an industrial workstation reaps more benefits over a period compared with costs carried at a time, leading to significant savings over time.

#Wave Soldering Machine#Reflow Soldering Machine#Industrial Work Station#Roller Conveyor#Roller Conveyor System#Flat Belt Conveyor#Assembly Conveyor#Inclined Conveyor Belt#Cleated Belt Conveyor#Truck Loading Conveyor#Telescopic Belt Conveyor#PCB Assembly Machines#PCB Manufacturing Machine

0 notes

Text

The Ultimate Guide to Truck Loading Conveyors and Portable Conveyor Systems

In the fast-paced world of logistics, efficiency is key. One innovation that has revolutionized material handling and loading operations is the truck loading conveyor. These systems not only improve productivity but also enhance safety and streamline workflows. Whether it’s a permanent setup or a portable truck loading conveyor, these systems cater to diverse industries, making them indispensable in warehouses, shipping docks, and production facilities.

Let’s dive into the world of truck loading conveyors, explore their benefits, and understand why they are a must-have for modern businesses.

What Are Truck Loading Conveyor Systems?

Truck loading conveyor systems are mechanical devices designed to facilitate the smooth and efficient transfer of goods from warehouses, production lines, or storage areas directly into trucks or trailers. These conveyors can handle a variety of goods, ranging from lightweight packages to heavy, bulk materials.

Typically, these systems include features like adjustable heights, flexible designs, and smooth rollers or belts to accommodate different types of cargo. They can be customized to suit specific industries and operations, making them a versatile solution for businesses of all sizes.

Types of Truck Loading Conveyors

Fixed Truck Loading Conveyors

Installed permanently at loading docks, these conveyors are ideal for high-volume operations.

Equipped with durable belts or rollers, they ensure consistent performance for repetitive tasks.

Portable Truck Loading Conveyors

Lightweight and mobile, these conveyors can be moved to different locations as needed.

Perfect for smaller facilities or operations requiring flexibility in loading and unloading processes.

Telescopic Conveyors

Designed to extend into trucks or trailers, these conveyors minimize manual handling and improve loading efficiency.

Their extendable sections make them suitable for loading vehicles of various sizes.

Inclined Belt Conveyors

Ideal for transferring goods at an upward or downward angle.

Commonly used in facilities with elevation differences between storage and loading areas.

Benefits of Truck Loading Conveyor Systems

Increased Efficiency

By automating the loading process, truck loading conveyor systems significantly reduce the time taken to load or unload goods.

They allow workers to focus on other critical tasks, improving overall productivity.

Enhanced Safety

Manual lifting and loading can lead to injuries, especially when handling heavy or awkward items. Conveyors eliminate much of this physical strain.

Features like anti-slip belts and secure handling systems minimize accidents during operations.

Cost Savings

Reduced labor requirements and faster operations translate to lower operational costs.

Long-term durability ensures a high return on investment.

Versatility

Whether you need a portable truck loading conveyor for occasional use or a permanent setup for daily operations, there’s a solution to fit your needs.

These systems can handle a wide range of materials, from fragile packages to bulk goods.

Why Portable Truck Loading Conveyors Are Gaining Popularity

The demand for portable truck loading conveyors has surged due to their flexibility and convenience. These mobile systems are designed to be easily transported, making them ideal for businesses with dynamic operational needs.

Key Features of Portable Truck Loading Conveyors:

Compact Design: Easy to store and move around, especially in smaller facilities.

Quick Setup: Can be deployed within minutes, ensuring minimal disruption to workflows.

Adjustable Configurations: Designed to handle various cargo sizes and loading heights.

Durable Build: Despite their portability, these conveyors are built to withstand heavy-duty use.

Industries like e-commerce, retail, and manufacturing often prefer portable conveyors to accommodate seasonal spikes in demand or to optimize operations across multiple locations.

Applications of Truck Loading Conveyor Systems

Truck loading conveyor systems are versatile and find applications across numerous industries, including:

Warehousing and Distribution

Ensuring efficient loading and unloading of packages for faster turnaround times.

Manufacturing

Moving finished products directly from production lines to shipping areas.

Agriculture

Transporting bulk goods like grains, fertilizers, and produce into transport vehicles.

E-commerce and Retail

Streamlining order fulfillment and last-mile delivery processes.

Construction

Loading construction materials such as cement bags or tiles into trucks.

Choosing the Right Truck Loading Conveyor

When selecting a truck loading conveyor system, consider the following factors:

Material Handling Requirements

Assess the type, size, and weight of goods to determine the right conveyor design and capacity.

Operational Flexibility

For businesses with variable loading needs, a portable truck loading conveyor is an excellent choice.

Space Constraints

Measure the available space to ensure the conveyor fits seamlessly into your facility.

Durability and Maintenance

Opt for high-quality materials and designs to minimize wear and tear.

Budget

While initial costs can vary, focus on long-term value and operational efficiency.

Future Trends in Truck Loading Conveyors

As technology advances, truck loading conveyor systems are becoming smarter and more efficient. Some emerging trends include:

Automation and IoT Integration

Sensors and IoT-enabled systems allow for real-time monitoring, predictive maintenance, and optimized performance.

Energy-Efficient Designs

Eco-friendly materials and energy-saving motors reduce operational costs and environmental impact.

Modular Systems

Customizable conveyors that can adapt to changing business needs without significant upgrades.

Final Thoughts

In today’s competitive landscape, businesses must embrace innovative solutions to stay ahead. Truck loading conveyors, particularly portable truck loading conveyors, offer the perfect blend of efficiency, safety, and versatility. By investing in these systems, companies can enhance their operations, reduce costs, and improve customer satisfaction.

Whether you’re a small-scale operation or a large enterprise, integrating the right truck loading conveyor system can transform your logistics and material handling processes. Explore your options, assess your needs, and make the shift to a more efficient future.

1 note

·

View note

Text

Lifting Plough Assembly: Calculations for Conveyor System Loads and Forces

Lifting plough assemblies are a crucial component of conveyor systems that aid in the efficient transfer of bulk materials. These assemblies are used to divert materials from the conveyor belt to various discharge points, ensuring that the materials are delivered to their intended location. The design and calculation of lifting plough assemblies require a thorough understanding of the forces…

View On WordPress

#acceleration load#belt conveyor#conveyor motor#conveyor speed#conveyors#dead load#flat belt conveyor system#friction load#impact load#lifting plough assembly#live load

0 notes

Text

feeder for president!

Lots of excitement was shared when Frank wheeler was elected as the new president of the United States. He seemed to have great ambitions and an incredible spirit. But just a few months after he was elected, he put a new law into place. Every single American over the age of 18 must consume at least 5000 calories per day or they will be executed. He implanted every single American with a chip in the back of their throat that counted their calories. If the requirement had not been met, it would start leaking a poisonous substance into your system immediately. Effectively killing the person. This wasn’t all though. All gyms and any form of exercise equipment became illegal. Sidewalks were replaced with conveyor belts to prevent people from burning calories. Every year, you are required to gain at least 25 pounds. For every pound over this goal, the government will send a $100 check to your home.

as expected, all hell broke loose. People began rioting and begged for the law to be reversed. The smart people didn’t hesitate to start stuffing their face. Fast food restaurants had their busiest days in years as people frantically raced to consume as many calories as possible. To bring in more customers, McDonald’s released the heart attack burger. It was three burger patties cooked in pure oil and fat, then there was 6 pieces of bacon, loaded fries, a mountain of cheese, and McDonald’s new secret sauce. The burger contained almost 2000 calories and people went nuts for it. Companies removed small drinks and fries and replaced them with xtra large and supersize. A supersized coke was two liters and contained almost 100 calories.

the new system quickly weeded out the protesters and the only people left were obedient, soon to be fatties. Fitness influencers became weight gain influencers. They would give tips and tricks on how to eat more and expand your stomach. New stores began to open where you would pay to be mindlessly fed by one of the employees. You could set a certain amount of calories or a certain amount of time to be stuffed. If you were really desperate, some places carried an item called a lard ball. It had exactly 5000 calories all in the size of a pill. You would take it and immediately feel like you had just stuffed yourself silly at a buffet. It was quite expensive, but for those who could afford it, it was a game changer.

after a couple years with the new law, there wasn’t a person in sight without at least a bit of a belly. Abs were a thing of the past and it was hard for new 18 year olds to let go of theirs. But they obeyed and ate till they passed out. Some people took the $100 a pound rule very seriously. With how easy it was to gain weight, some people could gain over 100 pounds and get tens of thousands of dollars. Desk jobs became popular as no one was fit enough to do much else. Jobs were now required to give multiple snack breaks to employees so they had time to stuff themselves. it was paradise. Bulging bellies in all directions, former abs were memories of the past, countless people racing to shove food down their throats to meet the limit. I think this law may stay in place forever!

#fat#fat belly#fatty#gaining fat#chubby#fat gut#fatty piggy#gaining#gaining weight#getting bigger#force fed#feedee belly#feeding kink#feed me#fatboy

200 notes

·

View notes

Text

Low Voltage Relays Explained: Types, Functions, and Applications

In the complex world of electrical systems, relays play a crucial role in ensuring safety, efficiency, and automation. Among these, low voltage relays stand out as versatile components that manage and protect circuits operating below 1000 volts. Whether in industrial automation, residential power distribution, or commercial infrastructure, these devices act as the nerve center of electrical control and protection.

In this comprehensive guide, we will break down what low voltage relays are, explore their types, explain their functions, and highlight their diverse applications across industries.

What Are Low Voltage Relays?

A low voltage relay is an electrically operated switch that uses a small control voltage (typically below 1000V AC or DC) to switch larger electrical loads on and off. These relays act as intermediaries between control circuits and power circuits, providing isolation, control, and protection.

Unlike manual switches, relays automate the process of circuit management, responding to electrical signals, fault conditions, or system commands without human intervention.

Types of Low Voltage Relays

Low voltage relays come in several forms, each tailored to specific tasks within an electrical system. Here are the main types:

1. Electromechanical Relays (EMRs)

· Use a coil and a movable armature to open or close contacts.

· Provide physical isolation between input and output.

· Common in traditional control panels and basic automation.

2. Solid-State Relays (SSRs)

· Use semiconductors (like thyristors or triacs) instead of mechanical contacts.

· Offer silent operation, faster switching, and longer lifespan.

· Ideal for high-speed applications and environments requiring low maintenance.

3. Overload Relays

· Specifically designed to protect motors and equipment from sustained overcurrent.

· Available as thermal overload relays (using bimetallic strips) or electronic overload relays (using sensors and processors).

4. Time Delay Relays

Provide a deliberate time lag between the relay receiving a signal and switching.

Used in motor control circuits, lighting systems, and sequential operations.

5. Overcurrent and Short-Circuit Relays

· Detect and react to current exceeding preset thresholds.

· Essential for system protection against faults and overloads.

6. Voltage Monitoring Relays

· Monitor voltage levels and trip when voltages fall below or rise above safe limits.

· Protect sensitive devices from under voltage and overvoltage conditions.

Functions of Low Voltage Relays

Low voltage relays serve multiple vital functions in electrical systems:

1. Switching and Control

Relays control the opening and closing of power circuits in response to low voltage signals from controllers, timers, or sensors. This enables remote and automated control of large electrical loads.

2. Protection

Relays detect abnormal conditions like overloads, overcurrent, under voltage, and phase failures. When such conditions arise, they disconnect the affected circuit to prevent equipment damage or fire hazards.

3. Isolation

They electrically isolate control circuits (usually low voltage, low current) from power circuits (high voltage, high current), ensuring safety and reducing interference.

4. Signal Amplification

A small control signal (from a PLC, sensor, or microcontroller) can trigger a relay to switch much larger loads, effectively amplifying the control power.

5. Automation and Sequencing

In complex systems, relays help sequence operations by ensuring that processes occur in the correct order and at the right time intervals.

Applications of Low Voltage Relays

Low voltage relays are the backbone of automation and protection in various industries. Here are some key application areas:

Industrial Automation

· Control of motors, pumps, conveyor belts, and production lines.

· Use in programmable logic controllers (PLCs) and distributed control systems (DCS).

Power Distribution Systems

· Protect electrical panels from overload and short circuits.

· Monitor voltage and current levels in distribution boards.

Building Automation

· Lighting control systems.

· HVAC (heating, ventilation, and air conditioning) systems.

· Elevator and escalator controls.

Renewable Energy Systems

· Manage and protect solar inverters, battery banks, and wind turbines.

· Automatically disconnect faulty sections to prevent system-wide failures.

Data Centers and IT Infrastructure

· Ensure stable power supply to servers and networking equipment.

· Protect sensitive electronics from voltage fluctuations.

Transportation

· Railways, metros, and automotive applications for control and safety circuits.

Home Appliances

· Found in washing machines, microwave ovens, and HVAC units to automate functions and provide protection.

Advantages of Using Low Voltage Relays

· Enhanced Safety: Isolate control and power circuits, reducing electrical shock risks.

· Automation Ready: Easily integrated into automated systems for smarter operation.

· Cost-Effective Protection: Safeguard expensive equipment from damage due to electrical faults.

· Versatile: Available in many forms to suit different voltage levels, currents, and response times.

· Reduced Maintenance: Especially with solid-state relays, which have no moving parts.

Future Trends: Smart Relays and IoT Integration

As industries move toward smart grids and Industry 4.0, low voltage relays are also evolving:

· Digital relays offer programmable settings, self-testing, and event recording.

· IoT-enabled relays can send status updates and alerts to centralized monitoring systems.

· Energy-efficient designs reduce power consumption while providing reliable protection.

Conclusion

Low voltage relays are indispensable in modern electrical engineering, seamlessly combining protection, control, and automation. From safeguarding your home appliances to managing the power in a sprawling industrial plant, these devices ensure that electrical systems run smoothly and safely.

Understanding the different types, functions, and applications of low voltage relays empowers system designers, engineers, and even DIY enthusiasts to build safer and more efficient electrical setups.

As technology advances, the role of these small but mighty devices will only grow, driving the future of safe, smart, and automated power systems.

9 notes

·

View notes

Text

The Role of Relays and Timers in Industrial Automation Systems

In the world of industrial automation, efficiency, safety, and precision are crucial. Among the many components that contribute to a well-functioning automated system, relays and timers play a foundational role. These devices act as control elements that manage the flow of electricity, signal processes, and coordinate timing sequences — ensuring that operations run smoothly and safely.

In this article, we’ll explore how relays and timers work, their types, applications in automation systems, and how high-quality products — like those offered by Enza Electric — can enhance performance and reliability in industrial settings.

What Are Relays?

A relay is an electromechanical or electronic switch used to control a circuit by a separate low-power signal or multiple signals. In industrial automation, relays act as a bridge between the control system and the equipment being operated — allowing machines to be turned on or off automatically.

Types of Relays Commonly Used in Automation:

Electromechanical Relays (EMRs): Use physical moving parts; reliable and easy to maintain.

Solid-State Relays (SSRs): No moving parts; faster switching, longer lifespan, and better for high-speed applications.

Thermal Overload Relays: Protect motors and equipment from overheating.

Control Relays: Designed for controlling multiple contacts simultaneously in automation systems.

What Are Timers?

Timers are devices used to delay or repeat electrical signals at predetermined intervals. They help synchronize tasks, automate sequences, and provide controlled outputs over time — critical for complex industrial processes.

Common Timer Functions:

On-delay and off-delay timing

Interval timing

Cyclic or repeat cycle operation

Flashing and sequencing operations

Types of Timers:

Analog Timers: Manual dial settings, simple and cost-effective.

Digital Timers: Offer precise programming, displays, and flexible timing ranges.

Programmable Timers: Ideal for complex automation routines requiring multiple sequences.

Key Roles in Industrial Automation Systems

1. Process Control and Sequencing

Relays and timers enable automated machines to follow a specific sequence — turning motors, lights, or pumps on and off in a logical order. For example, a conveyor system can use a relay-timer combination to control material flow with millisecond precision.

2. Safety and Protection

Relays protect systems by interrupting circuits in case of faults. Combined with timers, they can ensure delay before activating emergency stop functions, preventing false triggers and increasing worker safety.

3. Load Management

In high-demand industrial environments, relays help manage load distribution by selectively energizing or de-energizing machinery. Timers assist in staggered starts, reducing power surges.

4. Energy Efficiency

By automating start/stop functions and managing operation durations, timers help reduce unnecessary energy use. Relays ensure only the necessary loads are powered, minimizing wastage.

5. System Monitoring and Feedback

In smart automation, relays provide feedback signals to the control system. Timers assist with diagnostics by creating intervals for testing or data collection.

Benefits of Using High-Quality Relays and Timers

Choosing the right components significantly impacts system performance and longevity. Enza Electric’s relays and timers are engineered with:

High durability for tough industrial environments

Precision timing for reliable operation

Easy installation and compact designs

Compliance with international safety and quality standards

By integrating Enza’s low-voltage solutions, businesses in the GCC, MENA, and Africa regions benefit from cost-effective, scalable automation that supports both current needs and future expansion.

Common Applications in Industrial Sectors

Manufacturing Plants: Control of motors, robotic arms, and production lines.

HVAC Systems: Timed control of fans, compressors, and dampers.

Water Treatment Facilities: Sequenced operation of pumps and valves.

Packaging Machinery: Relay and timer-based coordination of packing, sealing, and labeling.

Food and Beverage Industry: Process automation with hygiene-compliant controls.

Final Thoughts

Relays and timers are the silent operators behind the success of industrial automation systems. From process optimization to enhanced safety and energy management, these components are indispensable.

When sourced from a trusted manufacturer like Enza Electric, businesses are not only investing in reliable hardware but also in the longevity, scalability, and safety of their entire operation.

Ready to Power Your Automation?

Explore Enza Electric’s wide range of relays, timers, and other low-voltage switchgear solutions designed to meet the evolving demands of modern industries. Visit www.enzaelectric.com to learn more or request a quote today.

9 notes

·

View notes

Text

A band of robbers targets a train in the remote desert of Arizona, sneaking on board, slashing an air hose and forcing the locomotive to come to a dead halt. Then they take the goods and flee.

No, it's not the 1800s. It's 2025.

In less than a year, at least 10 such train heists in California and Arizona have netted about $2 million worth of Nike shoes, USA TODAY has confirmed after the Los Angeles Times first reported the string of robberies. More than 60 people are being charged in federal court in connection with the 10 heists, as well as other thefts in 2023 and 2024.

The robberies work like a “human conveyor belt,” with the goods passed from the train to the ground, to a truck, according to Keith Lewis, vice president of operations at CargoNet, a private company that provides supply-chain theft intelligence to law enforcement.

“It’s done fast. It’s fast as lightning,” Lewis told the Arizona Republic, part of the USA TODAY Network, adding that the thieves like conducting the heists in isolated areas so they have time to flee. “A lot of those areas you can't get to other than with a helicopter ... You can't even get to some of those rail tracks with off-road vehicles.”

The majority of the thefts have targeted trains operated by BNSF. The company says it's working with local authorities to address the problem.

"We work hard to protect our customers' freight from pickup to delivery and have security measures in place to help ensure these goods arrive safely," BNSF said in a statement to USA TODAY on Tuesday. "We are working with federal, state, local, and tribal police departments to coordinate our approach to disrupting criminal activity and arresting offenders."

Train, ground, truck: a quick process

In multiple affidavits submitted in federal court filings and obtained by USA TODAY, Homeland Security Investigations special agent Brynna Cooke describes how the heists are done.

Robbers scout containers to identify those that could have valuable cargo like Nike shoes and electronics, Cooke says.

They usually board trains in staging areas before they begin rolling. Then while the train is moving, they move from container to container, opening them with saws and bolt-cutters.

When they find something worth stealing, they’ll often force the train to stop by cutting the braking system air hose, causing it to “go into an emergency stop.” According to Cooke, once the train comes to a halt, box trucks are sent in to unload the merchandise and flee.

Lewis has seen the process firsthand.

“I've watched them through binoculars,” he told the Republic. “I just couldn't get there in time.”

Jan 13: More than $400,000 in shoes are stolen in Arizona

One of the most recent train thefts happened on Jan. 13 in northern Arizona, when police arrested 11 people in connection with the robbery of Nike shoes from a BNSF train in a remote area outside of Williams, some 170 miles north of Phoenix, according to court records obtained by USA TODAY.

Robbers who were on board the train cut its air hose around 11 a.m., causing the train to automatically go into an emergency stop.

Shortly after the thieves cut the Arizona train's air hose on Jan. 13, a BNSF police officer who was in the area spotted several cases of Nike shoes beside the train and later saw several people loading Nike cases into a U-Haul truck and a Ford Econoline truck nearby.

There were trackers inside some of the boxes that authorities then used to conduct a traffic stop on the van, court records say. When authorities later searched both trucks, they found 1,985 pairs of unreleased Nike shoes worth over $440,000, according to court records.

The shoes targeted were a new Air Jordan 4 style, a striking red-orange collaboration with BMX athlete Nigel Sylvester, dubbed “Bike Air.” When they go on sale in the spring, they will retail for $225.

But not all train heists end in arrests. When thieves cut air hoses in remote areas, conductors and engineers are stranded along with the disabled train. Ill-equipped to stop a robbery, they can’t do much beyond call 911.

“I've had conductors telling me that they actually watched them unload it," Lewis told the Republic. "But by policy they can't confront them because they're not armed, and the bad guys could be armed."

Jan: 10, $18,000 in shoes are stolen

In Southern California, two suspects are accused of stealing about $18,000 worth of merchandise in a remote area known as the Wonder Valley. According to a news release from the San Bernardino Sheriff's Department, BNSF Police contacted authorities for help.

Police said they were notified that several suspects were robbing a train. On the way to the scene, police said they saw a box truck driving in the area.

“Deputies conducted a traffic enforcement stop on the vehicle and, through investigation, located approximately $18,000 in stolen items inside the truck,” police said.

Two men, 28-year-old Oscar Sosa of Apple Valley, California, and 45-year-old Jose Villalobos-Infante of Phoenix, were arrested in connection to the robbery. They've since been charged with second-degree burglary, grand theft and conspiracy, according to the Hi-Desert Star.

USA TODAY was not able to immediately find attorneys representing the men.

Jan: 15, $400,000 in shoes are stolen again

Only two days after the Arizona heist and five days after the robbery in San Bernardino County, robbers allegedly targeted a train in the same area of California.

According to a news release from police, BNSF Railroad police notified the San Bernardino County Sheriff's Department of a train robbery. Deputies again spotted a white van leaving the area.

"However, the vehicle failed to yield, and a pursuit ensued," a sheriff's department statement said. "The vehicle became disabled on a dirt berm, two occupants fled, and a foot pursuit ensued."

Two teenagers, whose names have not been released, were arrested in connection with the robbery. Police said they were able to recover 218 cases of Nike shoes valued at about $408,000.

Police have identified possible “ringleader”

According to federal court records, a man identified as Felipe Avalos-Mejia is alleged to be the ringleader of some of the train heists, operating out of Phoenix and Los Angeles.

Investigators say that Avalos Mejia had a network of scouts who helped him select trains to target. Investigators also said Avalos-Mejia provided cars and paid burglary crews to rob the trains.

Police raided 11 homes and 16 storage units connected to Avalos-Mejia in June, arresting 43 suspects and recovering $3 million in merchandise believed to have been stolen from BNSF trains.

Avalos-Mejia was arrested one day later on June 21. Court documents say police found $120,000 in cash, as well as a "detailed ledger that listed Nike and other merchandise that is typically burglarized from BNSF trains, as well as dollar amounts detailing what the merchandise is worth and for what it is sold."

Avaloz-Mejia's attorney declined USA TODAY's request for comment on Tuesday.

6 notes

·

View notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

About Poppy Playtime Chapter 4, Poppy Playtime Games & The Prototype

Hello everybody, this is Shadow264 aka, Shadow Wrath. It has been too lomg, hasn't it? My apologies. Thing have been very very busy at my end, with loads of issues and stuff. Hopefully they'll be sorted out soon.

SO ANYWAY, you guys heard that Poppy Playtime Chapter 4 is coming next year? Excited? You know I am, too.

Now, about the entire game of Poppy Playtime.... i really need to get this off my chest since its Chapter 2 Game and before Chapter 3 was released and way before Chapter 4 and Project Playtime came about.....

I, came the closest to solving Poppy Playtime in terms of the Prototype and the ENTIRE Facility.

Now, you all maybe wondering how I managed that, do you?

Now, you see the Factory, it is so gigantic. SO GIGANTIC that it can home many trains inside the facility to go anywhere around the factory. That includes the conveyor belts back in Chapter 1. Now, I must confess to you guys, too that I can picture things in my head. Which means possibilities are endless for me.

And after seeing the conveyor belts in Chapter 1 and the trains in Chapter 2 and Project Playtime, and the locations, as well in all game chapters, THEN things began to add up. The Factory is more than just a Factory. It is like... well, like the Hive from Resident Evil, but twisted, which means this Factory is not a Toy Factory. It is a Laboratory. The Toy Factory gig is simply a cover up to get people off their backs from the BIGGER and UTTER abominations that they're making out of the kids they took in. The Game Station is nothing more than tests to see which toy each child is compatible with.

..... which is when, the Prototype comes in.

Now, the Prototype. Believe it or not. I was the only one who came the closest to revealing him. And how did that come about? Well, that's simple. This eventually leads us to Chapter 3 and upcoming Chapter 4 and my ealier findings. Yes, the Prototype caused the Hour of Joy and he was the one who caused everything behind the scenes. But what if I were to tell you that he had subordinates? Those, were Huggy Wuggy, Mommy Long Legs and his disciple, Catnap. He didn't want to show himself yet because he was still incomplete. That is why he sent them out as his pawns, his foot soldiers so he can slowly prepare himself to fight you while he watches you, where ever he lies.

And YES, The Prototype has been watching us the whole time. There were a few occasions, really when we play the tapes about the Prototype at the near ends of the Chapters. You will notice that there was a laser pointer pointing on the TV. THAT was actually the sign that the Prototype.... was watching.... and he was.... behind you.

Shocking, isn't it?

Now, continuing on about the Factory as I'll be also bring in The Prototype, too. Moving on, yes the Factory is like a Hive, whereby there is a train system, conveyor belt system, a Playcare, the new edition from Chapter 4, a Prison or a Security Facility are stationed waaaaay waaaaaaaaaay underground of the Factory, which tells us this; On the outside, they are making toys for Joy, but on the inside, it is all experimentation and hell in there. Which brings to what I have thought about and pictured.

You see, before Chapter 3, Project Playtime and Chapter 4 came out, I always believed that Playtime Co. is much more bigger than this to make those huge toys that turn into monsters. So, I decided to picture, think and draw them out. An underground school, an experiment room, a facility to house the toys in, a testing chamber, the TOP SECRET Room, and many more which also involves the Prototype. When Chapter 3 and the upcoming Chapter 4 surfaced, that's when I realized (again, I say this), I came the closest to solving the Prototype. While discovering that, I also discover that the Factory is like a Hive, meaning if there is a way in, that means there has to be multiple ways out of the Factory, from both above, and below.

The Experiment Rooms are one thing, but when it comes to the Prototype, what I discover is quite simple and easy to read. The Prototype is not just like a living Frankenstein's Monster, or the Kindred itself, it is a sentient being with its own singularity. That's why it's so smart to make a laser pointer and escape. Now, you are wondering why the other toys didn't escape but the Prototype somehow did? Well that is simple. Its Experiment Room was located sonewhere else beyond the bigger bodies experiements' reach comsidering the Prototype's sentience. Which leaves me to suspect that the Prototype is being stationed.... way below the Chapter 4 levels of the Playtime Co. Factory.... why else would it be able to move freely? Cause' it already knows in and out of that Factory. That's why.

I was coming close to solving the entire Factory's schematics and the Prototype's identity theoratically all on my own, but.... idk.... something stopped me from proceeding further due to the fact that something is telling me.... that 'I know too much'.

So, I stopped. But not out, yet. I'm just secretly theorizing still so i'll do my best to crack everything the best I can.

Yeah. That's what's going on and the thing I wanna get off my chest. Creepy right? Though i'm beatin the bush around and repeating but, you should get the idea on where i am coming from.

Welp, that should be all for me for the time being. If you like, I'll put some posts about Chapters 1 to 4, too on my own time. So for now, this is it for me, and it's good to be back.

9 notes

·

View notes

Text

Northtown Maintenance-of-Way, part 3

For the final part of this mini-series, I'll be focusing on a few miscellaneous, specialized machines used in the track maintenance process. Each one's role can be done by other, less specialized machines, but it would be a good deal harder.

This is a Mineral Products Inc. Multi-Purpose Machine. It's a mechanical jack of all trades, used for everything from trenching to blowing snow off of tracks. Its most common use is as a 'yard cleaner': the big broom mounted to the front picks up material between the rails and loads it onto a conveyor belt, which can dump it off to the side or into a towed railcar. Another popular job is snow removal: the broom is exchanged for an auger system, and the rear-most conveyor can be replaced with an impeller fan and chute. MPI's website says the machine can move 2000 pounds of snow per hour, and the blower can fling it up to 150 feet away from the tracks. Because it's not limited to just the rails, it can also be used on yard roads & parking lots. Other attachments include a trencher, air blower, rotary broom, and a hydraulic arm which can be fitted with its own range of attachments. I'm starting to sound like a shill here... but it is a pretty cool piece of kit.

The next piece of machinery is Herzog's ACT, or Automated Conveyor Train. It's a special set of cars which uses a conveyor system and swinging boom to "precisely" drop ballast where it's needed. The yellow thing seen above is the train's main power unit. I don't know if it uses hydraulic or electric motors, but this car powers them. Each train set has up to 30 cars, which are just high-side gondolas with conveyors in the bottom. Each car has its own conveyor, which dumps into the next car's conveyor through a small hopper.

A closer look at the connection between cars. I don't know if the water is from recent rains or the train's dust suppression system.

And here's the 'front' of the train, which is really the end. It features the operator's cabin and the most important bit, the unloading arm. It can move ballast 50 feet from the center of the tracks, according to Herzog's website. Conveyor trains like this one are mostly used for filling in washed-out track beds, but can also strategically place piles of ballast for future projects. As of writing this post, the control car is still less than a year old. It really is the cutting edge of ballast-dropping technology!

The last machine is another Herzog product: the creatively-named Rail Unloading Machine. It looks complicated, but is actually quite simple. A crane arm feeds sticks of continuously-welded rail (CWR) into a roller system, which feeds it forward (backwards, really) through two clamps and onto the ground.

A view of the other side. Same deal, but all folded up. Check out the flex on that arm!

6 notes

·

View notes

Text

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, playing a crucial role in everything from consumer electronics to industrial applications. Over the years, the manufacturing process of PCBs has evolved significantly, with advancements in technology leading to increased efficiency, precision, and scalability. Today, PCB manufacturing machines have transitioned from manual operations to fully automated systems, revolutionizing the industry. One company at the forefront of this transformation is Yontro Mechatronic Systech, a leader in cutting-edge PCB manufacturing solutions.

#Reflow Soldering Machine#Industrial Work Station#Roller Conveyor#Roller Conveyor System#Flat Belt Conveyor#Assembly Conveyor#Inclined Conveyor Belt#Cleated Belt Conveyor#Truck Loading Conveyor#Telescopic Belt Conveyor

0 notes

Text

Abrasion Resistance Plate

Abrasion resistance plates, often referred to as wear plates, are specialized steel components designed to withstand the severe wear and tear encountered in various industrial applications.

Abrasion resistance plates are engineered to withstand severe wear and tear from friction and impact, making them ideal for high-demand environments where durability is essential. These plates are commonly made from high-carbon steel alloys, which are heat-treated to enhance hardness and improve their resistance to abrasion. The most common grades include AR400, AR500, and AR600, each offering progressively higher levels of hardness and wear resistance. Overall, abrasion resistance plates are a critical component in industries that require robust solutions to withstand abrasive environments.

Top Industry Applications

In the construction industry, Abrasion-Proof Plate play a significant role in safeguarding machinery and infrastructure subjected to heavy loads and abrasive conditions. These plates are used in various applications, including the construction of crushers, aggregate screens, and wear liners for earth-moving equipment.

These plates are primarily used in industries such as mining, construction, and material handling, where the ability to withstand abrasive environments is crucial. For example, in mining operations, Heavy-Duty Abrasion Plate are employed in the linings of chutes, hoppers, and conveyor systems to protect the underlying steel structures from the continuous impact and friction of transported materials.

To read more about our product you can visit our website.

https://www.wearplates.co.in/abrasion-resistant-plates-sheets.html

7 notes

·

View notes