#material handling systems

Explore tagged Tumblr posts

Text

Powering the Production Line: Messung’s NX-ERA PLCs in Automotive Material Handling

In automotive manufacturing, precision isn’t a luxury, it’s a necessity. From chassis and engine assembly lines to the press shop and paint line, seamless material handling is critical to keeping production on track. Whether it’s coordinating conveyors, pick-and-place systems, or synchronizing with robotic cells, the need for intelligent control is constant.

Messung’s NX-ERA PLCs deliver this control with unmatched flexibility. With native support for Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link, they enable high-speed communication across robots, HMIs, VFDs, servo amplifiers, and central SCADA systems. Plus, with remote I/O modules and protocols like CANopen, our PLCs handle large-scale, distributed inputs and outputs effortlessly. Simply put, NX-ERA makes advanced, synchronized automation easy, even in the most demanding environments.

What is Material Handling in the Automotive Industry?

Material handling in the automotive industry involves the movement, positioning, storage, safety, and tracking of components and assemblies throughout the production process—from the arrival of raw materials to the final stages of vehicle assembly. Efficiency here is critical; any delay or misstep can disrupt the entire manufacturing flow.

Key areas such as the chassis and engine assembly lines, along with the press shop and paint line, rely heavily on sophisticated material handling systems, including conveyors, pick-and-place machines, and robotics, to keep production moving seamlessly. These systems must operate in perfect sync, often across large, distributed areas with thousands of I/O points.

The Brain Behind the Brawn: NX-ERA PLCs

Our state-of-the-art NX-ERA PLCs including the NX-ERA Xpress and NX-ERA Jet, are compact PLCs designed for high-speed, reliable control. These programmable logic control systems are the heart of any automated material handling system. By offering real-time control, seamless connectivity, and robust communication protocols like Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link. They interface effortlessly with robots, HMIs, VFDs, servo amplifiers, and centralized SCADA systems, ensuring reliability and scalability.

Here are some of its most impactful features:

High-Speed Processing Power

The core point of NX-ERA PLCs is that they are capable of real-time processing. These robot systems run as fast as your machinery, and the synchronization is important for the overall efficiency of the system. This compact PLC will guarantee flawless optimization for every aspect of the bottling line, be it controlling the work of conveyors or robotic manipulation.

Modular Design for Flexibility

The greatest feature of the NX-ERA PLC is its modular design. Production plants in the automotive industry often aim for some form of adaptability, and, thus, this feature is very helpful. It allows the installation to expand while the business is developing. The implementation of modularity means that the system can be integrated with any new equipment, production units, or additional features to ensure that there will be no disruption to the system performance.

Integrated I/O Modules for Streamlined Setup

Our smart and compact PLC integration contains integrated I/O modules that reduce installation and wiring times, thus also focusing on the fast-paced phenomenon in the automotive industry. For simplification of the things, input/output capabilities are now directly included in the integrated PLC system, which substantially reduces the external wiring as a result of which the setting up is speedier and less prone to mistakes.

Advanced Web Server Capabilities

It is safe to say that we are far off the days when engineers would have to be on site for them to physically track and diagnose issues on the factory floor. The capability of the built-in web pages of our NX-ERA PLC allows easy remote access for getting the actual real-time state of the diagnostics and monitoring. This feature is incredibly important in an industry that operates around the clock, as it allows maintenance teams to resolve issues remotely, reducing downtime and keeping things running smoothly.

The Role of the NX-ERA PLCs in Material Handling

In the automotive industry, material handling is integral to the success of the production process. From raw materials to semi-finished goods, and finally to finished products, materials need to be handled with precision. Automation is key to achieving this, and Messung’s NX-ERA PLCs are designed to make this process as efficient and effective as possible.

Here is how it is done:

Conveyor Systems Optimization

Conveyor systems, which carry parts between the workstations and at the same time keep the production continuously running, are the most popular form of material handling in the automotive plants. NX-ERA PLCs make sure that the system, no matter what, functions without any breaks by adjusting the speed of the conveyors to fit the pace of production. The real-time processing feature ensures that the system in question becomes flexible almost immediately, providing the assembly line without any interruptions and preventing the end line packing in the last round.

Predictive Maintenance to Maximize Uptime

The predictive maintenance of the system is seen as the golden nugget to maximize uptime. For the maintenance of a plant, having machines down during their run time is quite expensive. In the automotive industry, where the production rates run on a very tight schedule, even a moment's disruption would mean substantial losses. Our PLC Systems use a predictive maintenance system to keep a continuous check on the condition of the equipment. The control system will be equipped with predictive maintenance, which can track the system performance, increasing the change in predicting when maintenance is needed before failure occurs. These stains would reduce chances of equipment going down and also increase whole equipment machines productivity performance.

Power Management for Material Handling Equipment

How NX-ERA PLCs Integrate with SCADA Systems

Industrial automation relies not just on PLCs but also on supervisory control and data acquisition (SCADA) systems to monitor and control large-scale operations. The integration of NX-ERA PLCs with SCADA applications enhances material handling capabilities by providing plant operators with real-time insights into the performance of material handling equipment.

Real-Time Visualization and Data Monitoring

Data gathered from the cluster of service line sensors are then monitored by SCADA systems through real-time visualization and data troubling. By means of the material handling systems' connecting to the SCADA applications, operators are able to visualize every operation stage on a single interface. Our NX-ERA PLC assists the SCADA system in a way that allows real-time data visualization. As for plant automation, this integration enables the operators to redesign the production line and fabricate the survey that they are in full command, including the conveyor speed, robotic movement, and electrical power consumption.

Alarming and Fault Diagnostics

Unexpected malfunctions are a part of any complex system, but SCADA and PLC integration ensures they are dealt with swiftly. The NX-ERA PLC can send alerts to SCADA systems when material handling equipment encounters an issue, whether it’s a malfunction in a conveyor belt, a sensor failure in a robotic arm, or an electrical fault. This proactive approach helps resolve issues before they lead to extended downtime.

Historical data analysis for continuous improvement

Other benefits of integrating the SCADA system with the NX-ERA PLC is to have an ability to analyse historical data. These past data performances can better help the plant managers to see trends, adjust production schedules, and improve the efficiency of the material-handling systems over the long period. In actuality, the PLC saves and disposes of necessary data. This information, then, is fed into the SCADA system and used for analysis and presentation purposes.

The Future of Material Handling with NX-ERA PLCs

As the automotive industry embraces Industry 4.0, NX-ERA PLCs are positioned at the forefront of the shift towards smarter, more connected manufacturing systems. This is brought about by switching to smarter, more connected production systems. Thanks to NX-ERA PLCs, which are able to integrate with SCADA applications, robots, and power supplies, you can now easily build a factory that can quickly adapt to changes in the current demand and the production process.

Benefits Include:

More automation and efficiency with the increasing factories

As factories become more automated, the role of PLCs like the NX-ERA will only grow. The future of material handling will rely on even more precise and automated systems, from fully autonomous robots to smart conveyors that adjust their speed and behavior based on real-time conditions. The NX-ERA PLC is ready to support this evolution with its high-speed processing and robust integration capabilities.

Energy Management and Sustainability

Green manufacturing is a critical concern for the industry today. Automotive manufacturers demand advanced NX-ERA PLCs in a bid to bring down the environmental impact of the production. An essential element that plays a pivotal role in power solutions, predictive maintenance, and derived data for operational efficiency is a way for these to reduce the consumption of energy.

Real-Time Data and IoT Connectivity

With the rise of the Internet of Things (IoT) in manufacturing, NX-ERA PLCs will continue to integrate with a broader network of connected devices. This real-time data flow will empower automotive plants to make more informed decisions and improve their material handling systems.

Conclusion: The Future of Material Handling in the Automotive Industry

In the race for efficiency and innovation, Messung’s NX-ERA PLCs are the pit crew that keeps material handling equipment running at peak performance. Their combination of advanced features, modular design, and seamless integration with SCADA systems positions them as the ideal solution for automotive manufacturers aiming to stay ahead of the competition.

As automotive plants move towards smarter, more automated manufacturing processes, the need for reliable, high-performing PLCs like the NX-ERA will only continue to grow. By embracing the capabilities of Messung’s NX-ERA PLCs, automotive manufacturers can ensure that their material handling systems operate efficiently, sustainably, and with minimal downtime, ultimately contributing to the ongoing success of the industry.

In this fast-paced industry where precision is the name of the game, Messung’s NX-ERA PLCs are the game changers that automotive manufacturers need to optimize their material handling systems and maintain a competitive edge in the global market.

#chassis and engine assembly lines#Modbus TCP/IP#Ethernet/IP#EtherCAT#OPC-UA#remote I/O modules#CANopen#compact PLCs#programmable logic control systems#SCADA systems#automotive industry#PLC system#material handling#PLC Systems#material handling systems#SCADA applications#PLC integration#Automotive manufacturers#Internet of Things (IoT)

0 notes

Text

Chain Conveyor Manufacturer in Faridabad | Vashnavi Conveyor Industry

Vashnavi Conveyor Industry is a leading chain conveyor manufacturer in Faridabad, offering rugged and reliable solutions for heavy-duty material handling across manufacturing and assembly lines. Our chain conveyors are built for strength, durability, and smooth operation, ideal for industrial automation and large-scale production setups.

#Chain conveyor Faridabad#conveyor manufacturer Faridabad#Vashnavi Conveyor#industrial chain conveyor#heavy-duty conveyor#material handling systems#automation conveyors

0 notes

Text

Reliable Material Handling Systems for Optimal Results

At AMC Conveyors, we specialize in delivering dependable material handling systems that simplify operations and drive efficiency. Our solutions are tailored to meet the demands of diverse industries, offering automation and durability. With a focus on quality, our systems improve workflow and reduce downtime, enabling you to achieve operational excellence. Whether you need conveyor systems or fully integrated solutions, AMC has you covered. Contact us today to learn how our material handling systems can benefit your business.

1 note

·

View note

Text

pressure vessel manufacturers

Pressure vessel manufacturers design and produce specialized containers capable of withstanding high-pressure environments. These Pressure vessel manufacturers are used across various industries, including chemical, oil and gas, power generation, to store or transport gases, liquids, or steam safely. Quality control, testing, and compliance with international standards are central to their operations, ensuring reliability and durability in critical applications.

Visit here: Timesautomation

Contact us:9416055180

1 note

·

View note

Text

Discover efficient and reliable solutions with our advanced material handling systems at Conesco. Our innovative material handling systems optimize warehouse operations, enhance productivity, and ensure smooth logistics. Explore how our systems can transform your business today.

0 notes

Text

Artificial Intelligence for Developers in pune | India

Artificial intelligence developers are concentrating on developing algorithms that allow robots to emulate human intelligence. These people create artificial intelligence systems that are capable of sorting through massive amounts of data, identifying patterns, projecting results, and resolving challenging problems.

#Artificial Intelligence for Developers Pune#AI-Based solutions#Energy Management Centre with Cutting-Edge Solutions#Global Engineering Services Outsourcing Pune#Services India#Panel Design Electrical Pune#Eplan Electrical#Material handling systems

0 notes

Text

Exploring the Power of Material Handling Equipment in Modern Industries

Material Handling Equipment is not just a means to an end but a strategic investment for businesses seeking to stay competitive in today’s dynamic market landscape. From enhancing safety and efficiency to driving productivity gains, MHE is the cornerstone of modern industrial operations.

For more information click here: https://bit.ly/3xGgLtr

#Material Handling Equipment Rental#Material Handling Systems#Material Handling Tools#Heavy Duty material Handling Equipment#Material Handling Solutions Provider#Material Handling Equipment Suppliers#Material Handling Solutions#Material Handling Equipment manufacturers

0 notes

Text

Katalyst Engineering: Pioneering Excellence in Engineering & Manufacturing

In the dynamic landscape of modern industry, Katalyst Engineering stands out as a beacon of innovation and excellence. Specializing in a comprehensive array of engineering disciplines, Katalyst has become synonymous with cutting-edge solutions in Engineering & Manufacturing, Contract Manufacturing, Mechanical Engineering, Electrical Engineering, and Civil Engineering.

1. Engineering & Manufacturing:

At the core of Katalyst's success is its unwavering commitment to engineering excellence and advanced manufacturing processes. The company seamlessly integrates engineering principles with state-of-the-art manufacturing technologies to deliver products that not only meet but exceed client expectations. Whether it's designing intricate components or optimizing production lines, Katalyst Engineering is a paragon of precision and efficiency.

2. Contract Manufacturing:

Katalyst's prowess extends to contract manufacturing, where the company's agile approach and adaptability shine. By offering end-to-end contract manufacturing solutions, Katalyst becomes a strategic partner for businesses looking to outsource their production needs. The company's commitment to quality control and timely delivery ensures that clients can focus on their core competencies while Katalyst handles the intricacies of manufacturing.

3. Mechanical Engineering:

In the realm of Mechanical Engineering, Katalyst is a trailblazer. From concept to realization, the company's mechanical engineering team tackles challenges with creativity and technical expertise. Whether it's designing robust machinery, optimizing existing systems, or developing innovative solutions, Katalyst's mechanical engineering division is the driving force behind many success stories.

4. Electrical Engineering:

The world is becoming increasingly electrified, and Katalyst Engineering stands at the forefront of this electrification revolution. The Electrical Engineering division leverages the latest advancements in technology to design and implement electrical systems that are not only efficient but also sustainable. Katalyst's electrical engineers are adept at navigating the complexities of power distribution, automation, and energy management. Visit here for more information: https://katalystengineering.com/

5. Civil Engineering:

Katalyst's influence extends to the foundations of our physical world through its Civil Engineering endeavors. From infrastructure projects to urban planning, the company's civil engineers bring a blend of creativity and technical acumen to the table. Katalyst's involvement in civil engineering projects spans the spectrum, ensuring that each endeavor contributes to the advancement of society.

In essence, Katalyst Engineering is not just a provider of engineering services; it is a catalyst for progress. The company's multidisciplinary approach, coupled with a relentless pursuit of excellence, has positioned Katalyst as a leader in the engineering and manufacturing landscape. As industries continue to evolve, Katalyst Engineering remains a reliable partner, driving innovation and shaping the future of engineering.

#engineering & manufacturing#agriculture equipment manufacturers#material handling systems#heavy machinery#Katalyst Engineering

0 notes

Text

wow my dudes, dealing with a parent with cancer has to be the absolute hardest thing I've been through in my life

#wondering what tags should i used to get actual advice#cancer#cancer support#this has triggered my anxiety to absolutely unparalleled levels and I'm about to start going down that deep black hole and somehow#seeking internet advice moves my mind away from things#my siblings are the absolute worst and here i am having to send a message because he's refusing to go get A BLOOD TRANSFUSION#the way I've been tested this year is insane#my other side of the family already talking about dead and legal issues?? instead of idk being my support system?#it's like a clock is ticking and the end is imminent and it feels so close and i just don't have the mental capacity to process anything#i think im going to look for psychological help now because i don't think i can handle this#everything came crashing down on me this year and i simply cannot handle it anymore#anyway fellas#this is like my biggest fear materializing in the worst way possible

5 notes

·

View notes

Text

At KEW ENGG. & MFG. PVT. LTD., we bring you a cutting-edge Material Handling System designed to streamline your winding and unwinding processes, reduce material wastage, and optimize production output—all with minimal manpower.

3 notes

·

View notes

Text

Roller Conveyor Manufacturer in Faridabad | Vashnavi Conveyor Industry

Vashnavi Conveyor Industry is a leading roller conveyor manufacturer in Faridabad, offering high-performance and durable roller conveyor systems for industrial automation and material handling needs. Our precision-engineered conveyors are ideal for manufacturing units, warehouses, and packaging industries. Get reliable and customizable solutions at competitive prices.

#Roller conveyor Faridabad#conveyor manufacturer Faridabad#Vashnavi Conveyor#gravity roller conveyor#powered roller conveyor#industrial conveyors#material handling systems

0 notes

Text

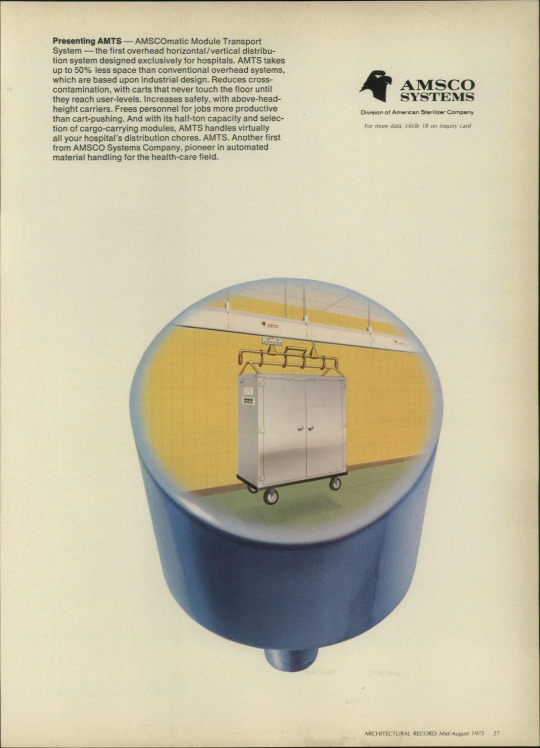

Amsco Systems AMTS advertisement, 1975.

15 notes

·

View notes

Text

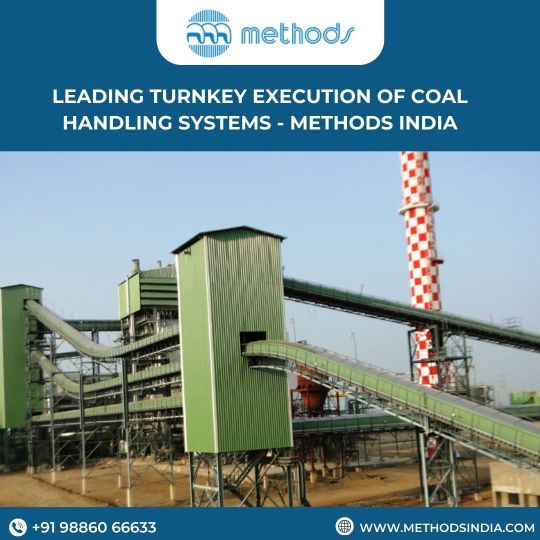

Leading Turnkey Execution of Coal Handling Systems - Methods India

In the realm of material handling, Methods India stands out as a leader in providing Turnkey execution of Coal Handling Systems. The products from Methods India are made with a focus on efficiency, safety, and simplicity. This allows for simple maintenance, which guarantees smooth operation. These turnkey solutions are designed to make moving and storing bulk materials easier.

The organization's dedication to quality has secured its standing as one of the top players in the bulk material handling sector. Find out how Methods India's innovative ideas can help you streamline your coal handling operations.

To contact us, Click on the link below- https://methodsindia.com/contact-information/

#Turnkey execution of Coal Handling Systems#Turnkey execution of Bulk Material Handling Systems#Independent Design House#Bagasse Handling Systems#Bulk material handling equipment manufacturers in Bangalore

2 notes

·

View notes

Text

"Boil water to turn fan" as if multistage steam turbine generators are not one of the sexiest kinds of machines every made

nuclear power is impressive until you get up to why. "we use the most precisely engineered machinery ever created to split atoms to release energy" oh yeah how come? "boil water to turn a fan" get the fuck out

#its genuinely crazy the math and engineering that go into making these absolutely massive steam turbines#its an incredible balancing act to optimize between the interconnected variables of pressure velocity and temperature in order#to extract as much energy as possible from the steam as it moves through the system#especially like. those generators need to maintain a very precise rotational speed in order to prevent the coupled generator#from going out of phase with the power grid#(3000 RPM for 50 Hz grids and 3600 RPM for 60 Hz grids)#like the reactor part sounds like a lot of engineering work (and it is!) but like. the turbine is fucking incredibly impressive too#each one of those turbine stages needs to have very specifically shaped blades in order to control steam pressure drop and steam velocity#and the blades need to be able to physically handle being in a wet (at least for nuclear plants where the steam is pretty wet) high temp#environment and constantly being spun at high rotational speeds for decades at a time.#we had to develop specialized nickel titanium superalloys with tightly controlled crystalline structures in order to build turbines this big#stare into the depths of “wow we really just use steam to spin a big fan that sounds simple” and you encounter#the lifes work of thousands of mathematicians computer engineers material scientists and mechanical engineers#the first device we could call a steam turbine was made as a toy in tthe first century ancient greece and egypt#the first steam turbine with a practical use was described in 1551 in Ottoman Egypt. it was used to turn a spit of meat over a fire.#the first modern multistage impluse steam turbine was made in 1884 and revolutionized electricity generation and marine propulsion#in the 141 years since there have been more improvements than one could even list#from major design changes credited to great men to miniscule efficiencies and optimizations gained from tweaking the composition of an alloy#idk. i think its beautiful to think about the web of human knowledge woven collectively by thousands of hands across history#could you imagine what the ancient greek engineers who first put together the prototype for an aeolipile would think to see what we have#made now. could they even recognize our designs as belonging to the same category of object as their little toy#anyway#appreciate the humble steam turbine with the same eye you give to the reactor core#mine#just my thoughts

73K notes

·

View notes

Text

Time Automation Private Limited – Trusted Name in Liquid Handling Systems

Time Automation Private Limited is one of the fastest-growing names in the industrial automation segment. Among its various specialties, the company stands out for providing high-performance liquid handling systems that are both efficient and cost-effective. These systems are widely used in industries such as pharmaceuticals, food processing, chemicals, and water treatment. If you're looking for reliable and modern liquid handling systems, Time Automation offers well-engineered and durable options.

Let’s explore the features, benefits, and applications of their liquid handling systems in a simple way:

What Are Liquid Handling Systems?

Liquid handling systems are used for the precise movement, measurement, and distribution of liquids in a controlled and automated environment. Time Automation Private Limited delivers high-quality systems that offer accuracy, repeatability, and ease of use.

Why Choose Time Automation for Liquid Handling Systems?

✓ Precision & Accuracy

Their liquid handling systems are built for high accuracy and consistency, ensuring your liquid measurements are always on point.

✓ Custom Design Options

Time Automation Private Limited understands different industries have unique needs. They offer customizable liquid handling systems as per client specifications.

✓ Advanced Automation

With a focus on automation, their systems help reduce manual errors and increase speed in the liquid handling process.

✓ Durable Build Quality

Only top-grade materials are used in manufacturing these systems, making them long-lasting and reliable even in demanding conditions.

✓ Low Maintenance

Their liquid handling systems are designed to operate with minimal maintenance, saving both time and operational costs.

Applications of Liquid Handling Systems

✔ Pharmaceutical Industry

Used for mixing, transferring, and dosing liquids during drug manufacturing.

✔ Food & Beverage Sector

For controlled dispensing, mixing, and packaging processes.

✔ Chemical Industry

To handle and measure various chemical fluids safely and efficiently.

✔ Water Treatment Plants

To dose chemicals like chlorine or lime accurately.

✔ Laboratories

Ideal for research and diagnostic labs where precise liquid measurements are essential.

Benefits of Using Time Automation’s Liquid Handling Systems

● Improved Accuracy Automation ensures exact amounts of liquid are handled every time.

● Time Saving Processes become faster and more streamlined, leading to higher productivity.

● Consistency No human error means every batch is the same in quality and quantity.

● Enhanced Safety Automated handling reduces the risk of exposure to hazardous liquids.

● Cost-Efficient Lower labor needs and reduced wastage lead to better cost control.

Final Thoughts

Time Automation Private Limited continues to lead the way in providing dependable and efficient liquid handling systems to businesses across India. Whether you operate in a lab, a factory, or a large-scale industrial plant, their systems are built to optimize your workflow and improve precision. With strong customer support and a focus on innovation, they are the go-to brand for industries that rely on smart liquid automation.

For performance, reliability, and tailored liquid handling systems, choose Time Automation Private Limited — where technology meets efficiency.

0 notes

Text

Material Handling Equipment is the backbone of modern industries, revolutionizing how materials are handled, stored, and transported. From enhancing safety and efficiency to driving productivity gains, MHE plays a pivotal role in shaping the future of manufacturing, warehousing, and logistics.

0 notes